Screening of Chemical Composition, Antimicrobial and Antioxidant Activities of Essential Oil and Volatile Fraction from Olive Mill Wastewater

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling and Origin of Olive Mill Wastewater

2.2. Chemicals

2.3. Preparation of Crude Extract

2.4. Extraction of Volatile Fraction

2.5. Extraction of Essential Oil

2.6. Chromatographic Analyses of VF and EO

2.7. ATR-FTIR Spectroscopy Analyses of VF and EO

2.8. Antimicrobial Assay of VF and EO

2.8.1. Test Microorganisms

2.8.2. Determination of the Minimum Inhibitory Concentration of VF and EO

2.9. Antioxidant Activity of VF and EO

3. Results and Discussions

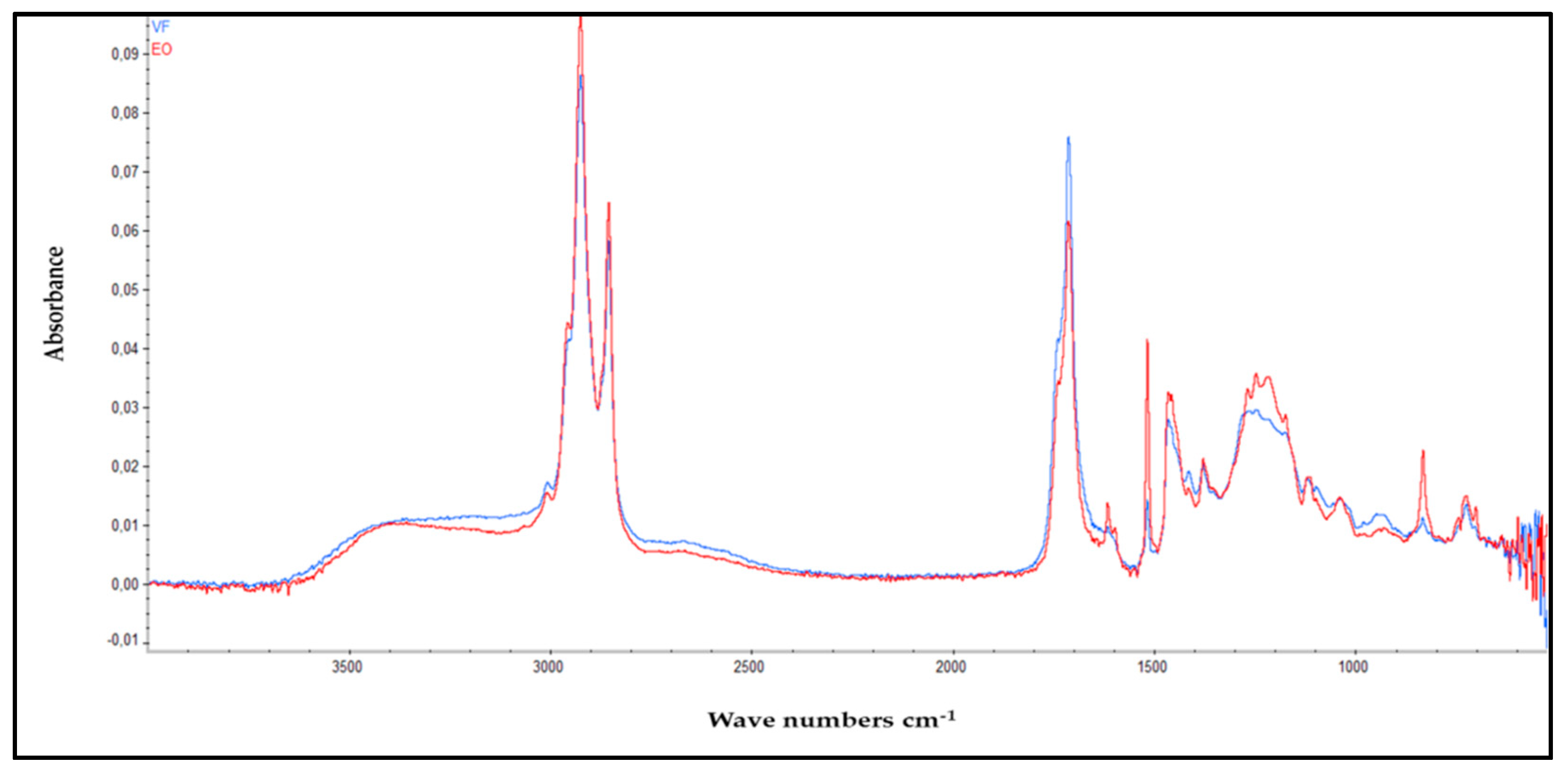

3.1. ATR-FTIR Analyses of VF and EO

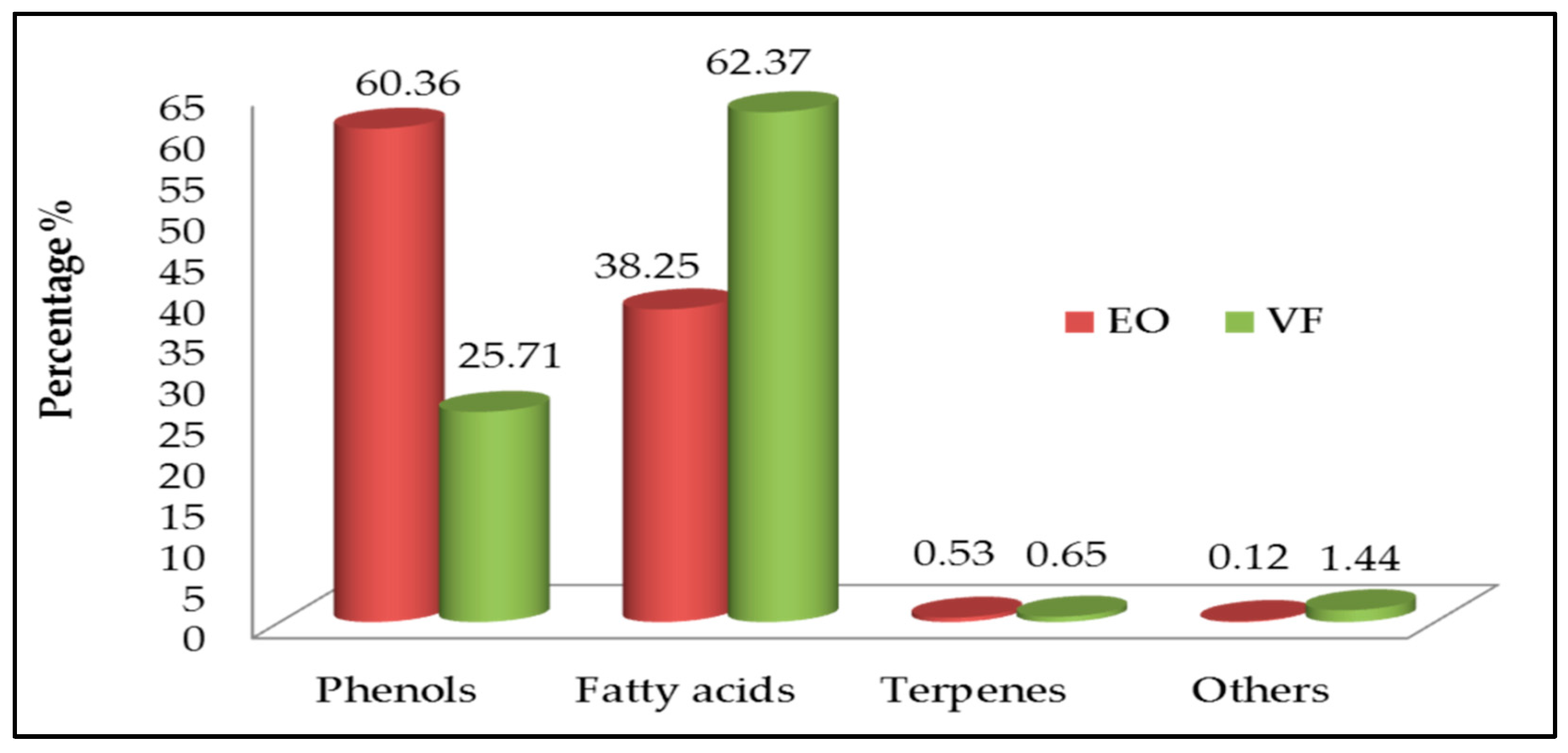

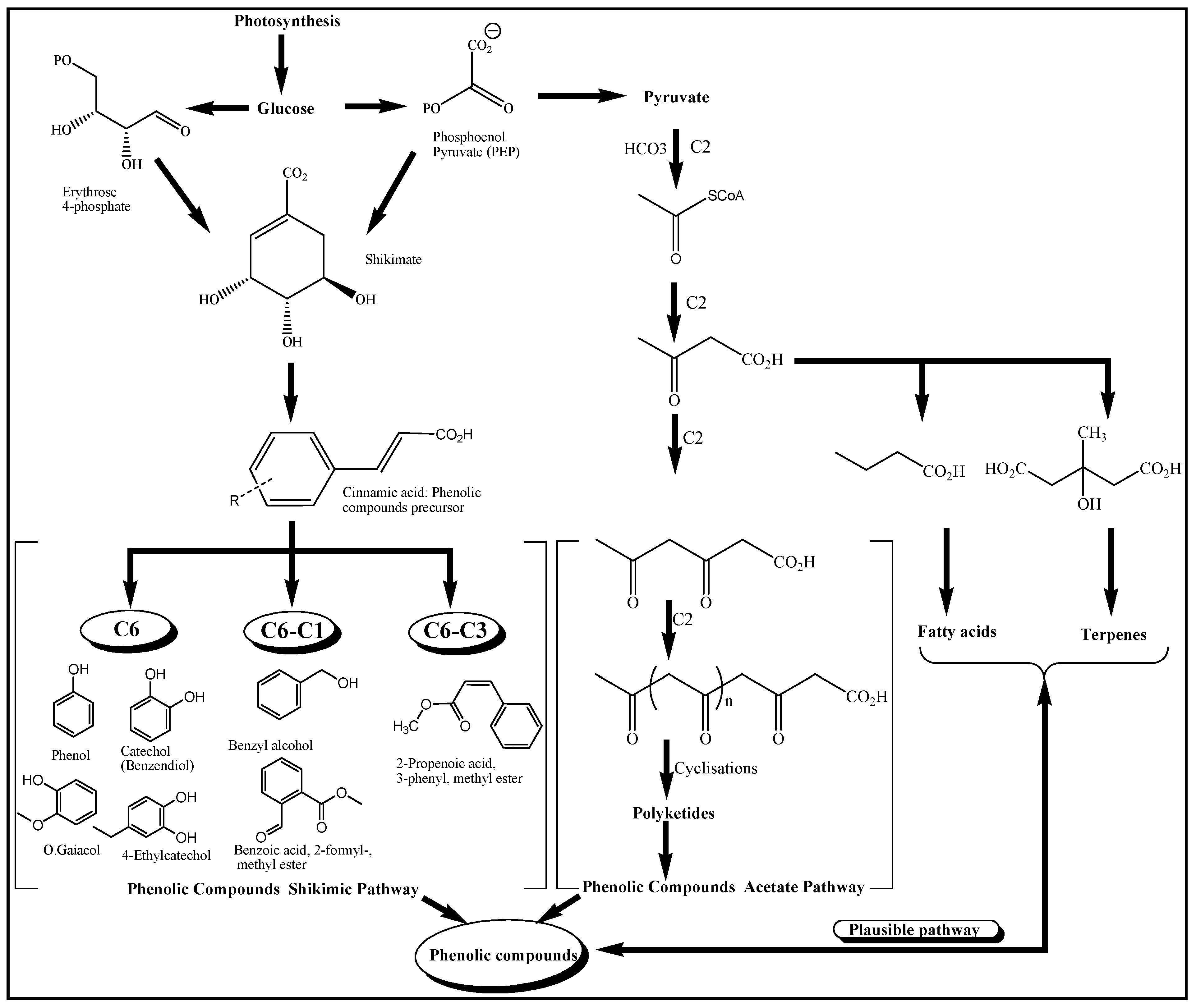

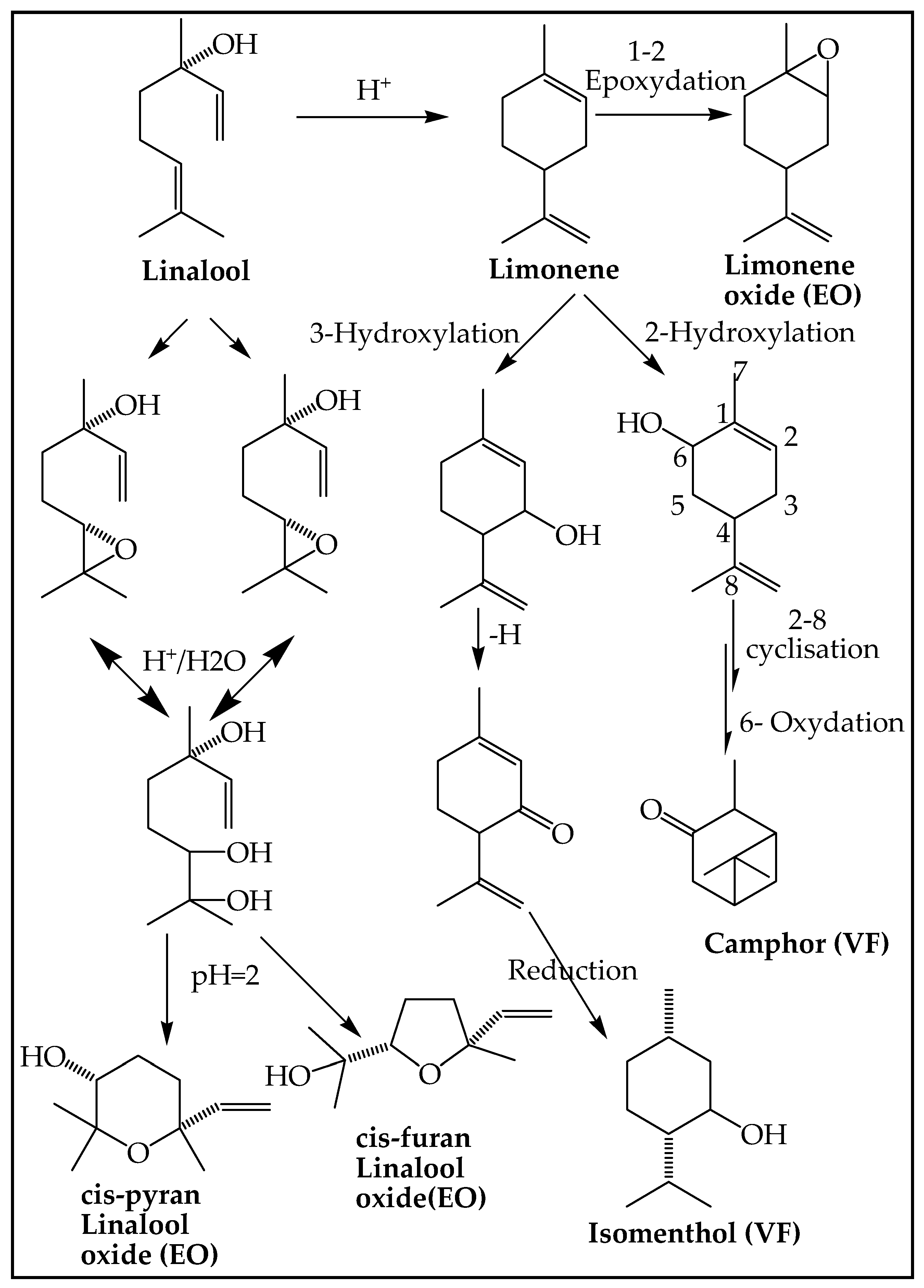

3.2. GC/MS and GC/FID Analyses of VF and EO

3.3. Antimicrobial Activity

3.4. Antioxidant Capacity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shabir, S.; Ilyas, N.; Saeed, M.; Bibi, F.; Sayyed, R.; Almalki, W.H. Treatment technologies for olive mill wastewater with impacts on plants. Environ. Res. 2022, 216, 114399. [Google Scholar] [CrossRef] [PubMed]

- Rocha, C.; Soria, M.A.; Madeira, L.M. Olive Mill Wastewater Valorization through Steam Reforming Using Multifunctional Reactors: Challenges of the Process Intensification. Energies 2022, 15, 920. [Google Scholar] [CrossRef]

- Mekersi, N.; Kadi, K.; Casini, S.; Addad, D.; Bazri, K.E.; Marref, S.E.; Lekmine, S.; Amari, A. Effects of single and combined olive mill wastewater and olive mill pomace on the growth, reproduction, and survival of two earthworm species (Aporrectodea trapezoides, Eisenia fetida). Appl. Soil Ecol. 2021, 168, 104123. [Google Scholar] [CrossRef]

- Halimi, C.W.; Laamari, M.; Goldarazena, A. A Preliminary Survey of Olive Grove in Biskra (Southeast Algeria) Reveals a High Diversity of Thrips and New Records. Insects 2022, 13, 397. [Google Scholar] [CrossRef]

- Ochando-Pulido, J.M.; Vellido-Pérez, J.A.; González-Hernández, R.; Martínez-Férez, A. Optimization and modeling of two-phase olive-oil washing wastewater integral treatment and phenolic compounds recovery by novel weak-base ion exchange resins. Sep. Purif. Technol. 2020, 249, 117084. [Google Scholar] [CrossRef]

- Azzam, M.O.; Al-Gharabli, S.I.; Alrawash, F.F. Air gap membrane distillation applied to olive mill wastewater. J. Environ. Chem. Eng. 2022, 10, 108465. [Google Scholar] [CrossRef]

- Hattab, A.; Bagané, M.; Ben Amor, H. Combined Treatment by Coagulation-Flocculation and Oxidation of Olive Mill Wastewater. J. Mater. Environ. Sci. 2020, 11, 522–530. [Google Scholar]

- De Leonardis, A.; Macciola, V.; Iorizzo, M.; Lombardi, S.J.; Lopez, F.; Marconi, E. Effective assay for olive vinegar production from olive oil mill wastewaters. Food Chem. 2018, 240, 437–440. [Google Scholar] [CrossRef] [PubMed]

- Miklavčič Višnjevec, A.; Baker, P.; Charlton, A.; Preskett, D.; Peeters, K.; Tavzes, Č.; Kramberger, K.; Schwarzkopf, M. Developing an olive biorefinery in slovenia: Analysis of phenolic compounds found in olive mill pomace and wastewater. Molecules 2020, 26, 7. [Google Scholar] [CrossRef]

- Solomakou, N.; Goula, A.M. Treatment of olive mill wastewater by adsorption of phenolic compounds. Rev. Environ. Sci. Biotechnol. 2021, 20, 839–863. [Google Scholar] [CrossRef]

- Rahmanian, N.; Jafari, S.M.; Galanakis, C.M. Recovery and removal of phenolic compounds from olive mill wastewater. J. Am. Oil Chem. Soc. 2014, 91, 1–18. [Google Scholar] [CrossRef]

- Gueboudji, Z.; Addad, D.; Kadi, K.; Nagaz, K.; Secrafi, M.; Yahya, L.B.; Lachehib, B.; Abdelmalek, A. Biological activities and phenolic compounds of olive oil mill wastewater from Abani, endemic Algerian variety. Sci. Rep. 2022, 12, 6042. [Google Scholar] [CrossRef] [PubMed]

- Lončarić, M.; Habuda-Stanić, M.; Molnar, M. Various techniques for phenolic removal from olive mill wastewater. Croat. J. Food Sci. Technol. 2021, 13, 268–276. [Google Scholar] [CrossRef]

- Bouknana, D.; Jodeh, S.; Sbaa, M.; Hammouti, B.; Arabi, M.; Darmous, A.; Slamini, M.; Haboubi, K. A phytotoxic impact of phenolic compounds in olive oil mill wastewater on fenugreek “Trigonella foenum-graecum”. Environ. Monit. Assess 2019, 191, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Babić, S.; Malev, O.; Pflieger, M.; Lebedev, A.T.; Mazur, D.M.; Kužić, A.; Čož-Rakovac, R.; Trebše, P. Toxicity evaluation of olive oil mill wastewater and its polar fraction using multiple whole-organism bioassays. Sci. Total Environ. 2019, 686, 903–914. [Google Scholar] [CrossRef] [PubMed]

- Morón, M.; Pozo-Morales, L.; Benito Mora, C.; Garvi, D.; Lebrato, J. OMW spillage control tool based on tracking p-Coumaric acid degradation by HPLC. Environ. Technol. 2019, 40, 2157–2172. [Google Scholar] [CrossRef] [PubMed]

- El Yamani, M.; Boussakouran, A.; Benali, T.; Rharrabti, Y. Antibacterial and antioxidant potentials of phenolic extracts from olive mill wastewater and their use to enhance the stability of olive oil. Riv. Ital. Delle Sostanze Grasse 2020, 97, 31–42. [Google Scholar]

- Laganà, P.; Anastasi, G.; Marano, F.; Piccione, S.; Singla, R.K.; Dubey, A.K.; Delia, S.; Coniglio, M.A.; Facciolà, A.; Di Pietro, A. Phenolic substances in foods: Health effects as anti-inflammatory and antimicrobial agents. J. AOAC Int. 2019, 102, 1378–1387. [Google Scholar] [CrossRef] [PubMed]

- Xing, L.; Zhang, H.; Qi, R.; Tsao, R.; Mine, Y. Recent advances in the understanding of the health benefits and molecular mechanisms associated with green tea polyphenols. J. Agric. Food Chem. 2019, 67, 1029–1043. [Google Scholar] [CrossRef]

- Kandeil, A.; Mostafa, A.; Kutkat, O.; Moatasim, Y.; Al-Karmalawy, A.A.; Rashad, A.A.; Kayed, A.E.; Kayed, A.E.; El-Shesheny, R.; Kayali, G. Bioactive polyphenolic compounds showing strong antiviral activities against severe acute respiratory syndrome coronavirus 2. Pathogens 2021, 10, 758. [Google Scholar] [CrossRef] [PubMed]

- Bonetti, A.; Venturini, S.; Ena, A.; Faraloni, C. Innovative method for recovery and valorization of hydroxytyrosol from olive mill wastewaters. Water Sci. Technol. 2016, 74, 73–86. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kreatsouli, K.; Fousteri, Z.; Zampakas, K.; Kerasioti, E.; Veskoukis, A.S.; Mantas, C.; Gkoutsidis, P.; Ladas, D.; Petrotos, K.; Kouretas, D. A polyphenolic extract from olive mill wastewaters encapsulated in whey protein and maltodextrin exerts antioxidant activity in endothelial cells. Antioxidants 2019, 8, 280. [Google Scholar] [CrossRef] [PubMed]

- Russo, E.; Spallarossa, A.; Comite, A.; Pagliero, M.; Guida, P.; Belotti, V.; Caviglia, D.; Schito, A.M. Valorization and Potential Antimicrobial Use of Olive Mill Wastewater (OMW) from Italian Olive Oil Production. Antioxidants 2022, 11, 903. [Google Scholar] [CrossRef] [PubMed]

- Kadi, K.; Mrah, R.; Hamli, S.; Lekmine, S.; Dib, D.; Addad, D.; Boukeria, S.; Gueboudji, Z.; Hafsaoui, I. Evaluation of the anticoagulant activity of margins from olives extraction in the Khenchela region. J. Fund. Appl. Sci. 2020, 12, 634–649. [Google Scholar]

- Silvan, J.M.; Pinto-Bustillos, M.A.; Vásquez-Ponce, P.; Prodanov, M.; Martinez-Rodriguez, A. Olive mill wastewater as a potential source of antibacterial and anti-inflammatory compounds against the food-borne pathogen Campylobacter. Innov. Food Sci. Emerg. Technol. 2019, 51, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Ben Mansour, A.; Chtourou, F.; Khbou, W.; Flamini, G.; Bouaziz, M. Phenolic and volatile compounds of Neb Jmel olive oil cultivar according to their geographical origin using chemometrics. Eur. Food Res. Technol. 2017, 243, 403–418. [Google Scholar] [CrossRef]

- Olmo-Cunillera, A.; Casadei, E.; Valli, E.; Lozano-Castellón, J.; Miliarakis, E.; Domínguez-López, I.; Ninot, A.; Romero-Aroca, A.; Lamuela-Raventós, R.M.; Pérez, M. Aromatic, Sensory, and Fatty Acid Profiles of Arbequina Extra Virgin Olive Oils Produced Using Different Malaxation Conditions. Foods 2022, 11, 3446. [Google Scholar] [CrossRef]

- Vidović, N.; Pasković, I.; Marcelić, Š.; Lukić, I.; Brkić Bubola, K.; Klisović, D.; Novoselić, A.; Palčić, I.; Polić Pasković, M.; Herak Ćustić, M. Effect of Combined Sulfur and Nitrogen Foliar Supply on Olive Oil Volatile Compounds and Sensory Attributes. Hortic 2022, 8, 912. [Google Scholar] [CrossRef]

- Zahi, M.R.; Zam, W.; El Hattab, M. State of knowledge on chemical, biological and nutritional properties of olive mill wastewater. Food Chem. 2022, 381, 132238. [Google Scholar] [CrossRef]

- Ladhari, A.; Zarrelli, A.; Ghannem, M.; Ben Mimoun, M. Olive wastes as a high-potential by-product: Variability of their phenolic profiles, antioxidant and phytotoxic properties. Waste Biomass Valorization 2021, 12, 3657–3669. [Google Scholar] [CrossRef]

- Riad, N.; Zahi, M.R.; Trovato, E.; Bouzidi, N.; Daghbouche, Y.; Utczás, M.; Mondello, L.; El Hattab, M. Chemical screening and antibacterial activity of essential oil and volatile fraction of Dictyopteris polypodioides. Microchem. J. 2020, 152, 104415. [Google Scholar] [CrossRef]

- Adams, R.P. Identification of Essential Oil Components by Gas Chromatography/Mass Spectrometry, 4th ed.; Allured Publishing: Carol Stream, IL, USA, 2007. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.-E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Hafidi, M.; Amir, S.; Revel, J.C. Structural characterization of olive mill waster-water after aerobic digestion using elemental analysis, FTIR and 13C NMR. Process Biochem. 2005, 40, 2615–2622. [Google Scholar] [CrossRef]

- Jimenez-Lopez, C.; Carpena, M.; Lourenço-Lopes, C.; Gallardo-Gomez, M.; Lorenzo, J.M.; Barba, F.J.; Prieto, M.A.; Simal-Gandara, J. Bioactive compounds and quality of extra virgin olive oil. Foods 2020, 9, 1014. [Google Scholar] [CrossRef]

- Zakia, G.; Kenza, K.; Kamel, N. Extraction and quantification of polyphenols of olive oil mill wastewater from the cold extraction of olive oil in the region of Khenchela-Algeria. Genet. Biodivers. J. 2021, 5, 116–122. [Google Scholar] [CrossRef]

- Suárez Montenegro, Z.J.; Álvarez-Rivera, G.; Sánchez-Martínez, J.D.; Gallego, R.; Valdés, A.; Bueno, M.; Cifuentes, A.; Ibáñez, E. Neuroprotective effect of terpenoids recovered from olive oil by-products. Foods 2021, 10, 1507. [Google Scholar] [CrossRef]

- Vichi, S.; Guadayol, J.M.; Caixach, J.; López-Tamames, E.; Buxaderas, S. Monoterpene and sesquiterpene hydrocarbons of virgin olive oil by headspace solid-phase microextraction coupled to gas chromatography/mass spectrometry. J. Chromatogr. A 2006, 1125, 117–123. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Baldermann, S.; Watanabe, N. Recent studies of the volatile compounds in tea. Food Res. Int. 2013, 53, 585–599. [Google Scholar] [CrossRef]

- Genovese, A.; Caporaso, N.; Leone, T.; Paduano, A.; Mena, C.; Perez-Jimenez, M.A.; Sacchi, R. Use of odorant series for extra virgin olive oil aroma characterisation. J. Sci. Food Agric. 2019, 99, 1215–1224. [Google Scholar] [CrossRef]

- Kesen, S.; Kelebek, H.; Selli, S. Characterization of the volatile, phenolic and antioxidant properties of monovarietal olive oil obtained from cv. Halhali. J. Am. Oil Chem. Soc. 2013, 90, 1685–1696. [Google Scholar] [CrossRef]

- Demyttenaere, J.C. Biotransformation of terpenoids by microorganisms. Stud. Nat. Prod. Chem. 2001, 25, 125–178. [Google Scholar] [CrossRef]

- Aissam, H.; Errachidi, F.; Penninckx, M.; Merzouki, M.; Benlemlih, M. Production of tannase by Aspergillus niger HA37 growing on tannic acid and olive mill waste waters. World J. Microbiol. Biotechnol. 2005, 21, 609–614. [Google Scholar] [CrossRef]

- Bose, S.K.; Yadav, R.K.; Mishra, S.; Sangwan, R.S.; Singh, A.; Mishra, B.; Srivastava, A.; Sangwan, N.S. Effect of gibberellic acid and calliterpenone on plant growth attributes, trichomes, essential oil biosynthesis and pathway gene expression in differential manner in Mentha arvensis L. Plant Physiol. Biochem. 2013, 66, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Flamini, G.; Cioni, P.L.; Morelli, I. Volatiles from leaves, fruits, and virgin oil from Olea europaea Cv. Olivastra Seggianese from Italy. J. Agric. Food Chem. 2003, 51, 1382–1386. [Google Scholar] [CrossRef] [PubMed]

- Termopoli, V.; Piergiovanni, M.; Cappiello, A.; Palma, P.; Famiglini, G. Tyrosol and Hydroxytyrosol Determination in Extra Virgin Olive Oil with Direct Liquid Electron Ionization–Tandem Mass Spectrometry. Separations 2021, 8, 173. [Google Scholar] [CrossRef]

- Zheng, C.J.; Yoo, J.-S.; Lee, T.-G.; Cho, H.-Y.; Kim, Y.-H.; Kim, W.-G. Fatty acid synthesis is a target for antibacterial activity of unsaturated fatty acids. FEBS Lett. 2005, 579, 5157–5162. [Google Scholar] [CrossRef] [Green Version]

- Thormar, H. Lipids and Essential Oils as Antimicrobial Agents; John Wiley & Sons, Ltd.: London, UK, 2010. [Google Scholar]

- McGaw, L.; Jäger, A.; Van Staden, J. Antibacterial effects of fatty acids and related compounds from plants. S. Afr. J. Bot. 2002, 68, 417–423. [Google Scholar] [CrossRef] [Green Version]

- Skalicka-Woźniak, K.; Los, R.; Głowniak, K.; Malm, A. Antimicrobial activity of fatty acids from fruits of Peucedanum cervaria and P. alsaticum. Chem. Biodivers. 2010, 7, 2748–2754. [Google Scholar] [CrossRef]

- Leouifoudi, I.; Harnafi, H.; Zyad, A. Olive mill waste extracts: Polyphenols content, antioxidant, and antimicrobial activities. Adv. Pharmacol. Sci. 2015, 2015, 714138. [Google Scholar] [CrossRef]

- Azaizeh, H.; Halahlih, F.; Najami, N.; Brunner, D.; Faulstich, M.; Tafesh, A. Antioxidant activity of phenolic fractions in olive mill wastewater. Food Chem. 2012, 134, 2226–2234. [Google Scholar] [CrossRef]

| N° | Compound | Database | Chem. Class | LRIlit | LRIcal | VF (%) | EO (%) |

|---|---|---|---|---|---|---|---|

| 1 | Ethanol, 2,2′-oxybis- | DB1, DB2 | O | 967 | 962 | 0.5 | t |

| 2 | Hexanoic Acid | DB1, DB2 | FA | 984 | 980 | 0.23 | 0.3 |

| 3 | Phenol | DB1, DB2 | PC | 986 | 982 | 0.4 | 0.5 |

| 4 | Benzyl alcohol | DB1, DB2 | PC | 1032 | 1033 | 2 | 4.9 |

| 5 | cis-furan Linalool oxide | DB1, DB2 | T | 1070 | 1072 | _ | 0.12 |

| 6 | p-Cresol | DB1, DB2 | PC | 1077 | 1077 | 0.32 | _ |

| 7 | o. Guaiacol | DB1, DB2 | PC | 1088 | 1088 | 0.11 | 0.5 |

| 8 | Nonanal | DB1, DB2 | O | 1104 | 1104 | 0.17 | _ |

| 9 | Benzene ethanol | DB1, DB2 | PC | 1116 | 1112 | 3.61 | 7 |

| 10 | Cyclohexanecarboxylic acid | DB1, DB2 | O | 1127 | 1120 | _ | 0.12 |

| 11 | cis-Limonene oxide | DB1, DB2 | T | 1134 | 1134 | _ | t |

| 12 | Camphor | DB1, DB2 | T | 1143 | 1141 | t | _ |

| 13 | 4-Ethylphenol | DB1, DB2 | PC | 1170 | 1170 | 11.7 | 28.5 |

| 14 | cis-pyran Linalool oxide | DB1, DB2 | T | 1173 | 1174 | _ | 0.41 |

| 15 | Octanoic acid | DB1, DB2 | FA | 1178 | 1175 | 0.8 | _ |

| 16 | Isomenthol | DB1, DB2 | T | 1182 | 1182 | 0.65 | _ |

| 17 | Catechol | DB1, DB2 | PC | 1197 | 1205 | 1.1 | 0.2 |

| 18 | 4-vinylphenol | DB1, DB2 | PC | 1226 | 1221 | 0.3 | 0.7 |

| 19 | cis-p-Propenylanisole | DB1, DB2 | PC | 1269 | 1265 | _ | 0.3 |

| 20 | Nonanoic acid | DB1, DB2 | FA | 1272 | 1272 | 0.8 | t |

| 21 | 4-Ethylguaiacol | DB1, DB2 | PC | 1282 | 1279 | 1.31 | 3.8 |

| 22 | Cinnamic acid, methyl ester | DB1, DB2 | PC | 1350 | 1352 | 0.20 | 1.4 |

| 23 | Neric acid | DB1, DB2 | FA | 1347 | 1358 | _ | 0.2 |

| 24 | o-Toluic acid, methyl ester | DB1, DB2 | FA | 1362 | 1365 | 0.2 | 0.4 |

| 25 | Eugenol | DB1, DB2 | PC | 1361 | 1368 | _ | 11 |

| 26 | Capric acid | DB1, DB2 | FA | 1380 | 1370 | _ | 0.17 |

| 27 | 4-Ethylcatechol | DB1, DB2 | PC | 1392 | 1388 | 2.11 | 0.8 |

| 28 | Tyrosol | DB1, DB2 | PC | 1427 | 1427 | 2 | 0.36 |

| 29 | 9-Oxononanoic acid | DB1, DB2 | FA | 1483 | 1480 | 0.26 | 0.12 |

| 30 | α-Farnesene | DB1, DB2 | T | 1508 | 1509 | _ | t |

| 31 | 2,4-di-tert-Butylphenol | DB1, DB2 | PC | 1519 | 1514 | 0.15 | _ |

| 32 | 5-tert-Butylpyrogallol | DB1, DB2 | PC | 1526 | 1527 | 0.2 | 0.7 |

| 33 | Tyrosol, acetate | DB1, DB2 | PC | 1567 | 1566 | 0.20 | _ |

| 34 | Tetradecanoic acid | DB1, DB2 | FA | 1768 | 1761 | 0.1 | 0.16 |

| 35 | Palmitoleic acid, methyl ester | DB1, DB2 | FA | 1890 | 1905 | _ | 0.2 |

| 36 | Palmitic acid, ethyl ester | DB1, DB2 | FA | 1926 | 1927 | 0.14 | 1.5 |

| 37 | Palmitoleic acid | DB1, DB2 | FA | 1944 | 1943 | 0.55 | 1.7 |

| 38 | Palmitic acid | DB1, DB2 | FA | 1969 | 1967 | 3.3 | 2.1 |

| 39 | Ethyl (E)-9-palmitoleate | DB1, DB2 | FA | 1978 | 1974 | 1.04 | 1.1 |

| 40 | Palmitic acid, ethyl ester | DB1, DB2 | FA | 1990 | 1995 | 4.4 | 7.4 |

| 41 | cis-Linoleic acid, methyl ester | DB1, DB2 | FA | 2096 | 2095 | 0.7 | 0.7 |

| 42 | Elaidic acid, methyl ester | DB1, DB2 | FA | 2110 | 2101 | 2.01 | 2 |

| 43 | Oleic Acid | DB1, DB2 | FA | 2146 | 2145 | 24.9 | 6 |

| 44 | Linoleic acid, ethyl ester | DB1, DB2 | FA | 2164 | 2164 | 5.7 | 3 |

| 45 | Elaidic acid, ethyl ester | DB1, DB2 | FA | 2174 | 2170 | 16.42 | 11 |

| 46 | Stearic acid, ethyl ester | DB1, DB2 | FA | 2199 | 2195 | 0.3 | 0.2 |

| 47 | Isopentyl palmitate | DB1, DB2 | FA | 2246 | 2246 | 0.21 | _ |

| 48 | Tributyl acetylcitrate | DB1, DB2 | O | 2254 | 2269 | 0.4 | _ |

| 49 | Tetracosne | DB1, DB2 | O | 2400 | 2400 | 0.2 | _ |

| 50 | 2-Octyldodecyl propionate | DB1, DB2 | O | 2411 | 2411 | 0.17 | _ |

| 51 | Oleic acid, pentyl ester | DB1, DB2 | FA | 2421 | 2421 | 0.31 | _ |

| Microorganisms | Gram | MIC (µg/mL) | |||

|---|---|---|---|---|---|

| EO | VF | Kanamycin | Chloramphenicol | ||

| B. subtilis | + | 3125.0 | 3125.0 | 62.50 | 3.90 |

| B. cereus | + | 1562.5 | 1562.5 | 7.81 | 1.95 |

| S. aureus | + | 781.25 | 781.25 | 15.62 | 15.62 |

| M. luteus | + | 1562.5 | 781.25 | 15.62 | 7.81 |

| L. monocytogenes | + | 1562.5 | 1562.5 | 15.62 | 7.81 |

| E. cloacae | - | 781.25 | 1562.5 | 7.81 | 3.90 |

| E. feacium | - | 1562.5 | 781.25 | 62.50 | 3.90 |

| A. tumefaciens | - | 1562.5 | 781.25 | 1.95 | 15.62 |

| E. coli | - | 390.625 | 195.30 | _ | 3.90 |

| P. aeruginosa | - | 1562.5 | 1562.5 | 1.95 | 3.90 |

| C. albicans | Yeast | 1562.5 | 781.25 | 3.90 | 3.90 |

| S. cerevisiae | Yeast | 781.25 | 390.625 | _ | 3.90 |

| Samples | DPPH Assay | |

|---|---|---|

| IP (%) | IC50 (µg/mL) | |

| VF | 73.9 | 244 |

| EO | 79.8 | 218 |

| BHA | 90.14 | 6.14 |

| BHT | 95.02 | 12.99 |

| α-Tocopherol | 89.52 | 13.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ait Si Said, C.; Riad, N.; Zahi, M.R.; Sabour, S.; Akkal, S.; Zam, W.; Touafek, O.; El Hattab, M. Screening of Chemical Composition, Antimicrobial and Antioxidant Activities of Essential Oil and Volatile Fraction from Olive Mill Wastewater. Chemosensors 2022, 10, 491. https://doi.org/10.3390/chemosensors10110491

Ait Si Said C, Riad N, Zahi MR, Sabour S, Akkal S, Zam W, Touafek O, El Hattab M. Screening of Chemical Composition, Antimicrobial and Antioxidant Activities of Essential Oil and Volatile Fraction from Olive Mill Wastewater. Chemosensors. 2022; 10(11):491. https://doi.org/10.3390/chemosensors10110491

Chicago/Turabian StyleAit Si Said, Chahinez, Nacera Riad, Mohamed Reda Zahi, Smain Sabour, Salah Akkal, Wissam Zam, Ouassila Touafek, and Mohamed El Hattab. 2022. "Screening of Chemical Composition, Antimicrobial and Antioxidant Activities of Essential Oil and Volatile Fraction from Olive Mill Wastewater" Chemosensors 10, no. 11: 491. https://doi.org/10.3390/chemosensors10110491

APA StyleAit Si Said, C., Riad, N., Zahi, M. R., Sabour, S., Akkal, S., Zam, W., Touafek, O., & El Hattab, M. (2022). Screening of Chemical Composition, Antimicrobial and Antioxidant Activities of Essential Oil and Volatile Fraction from Olive Mill Wastewater. Chemosensors, 10(11), 491. https://doi.org/10.3390/chemosensors10110491