Novel SAW Temperature Sensor with Pt/Ti/AlN/Mo/AlN/Si Structure for High Temperature Application

Abstract

1. Introduction

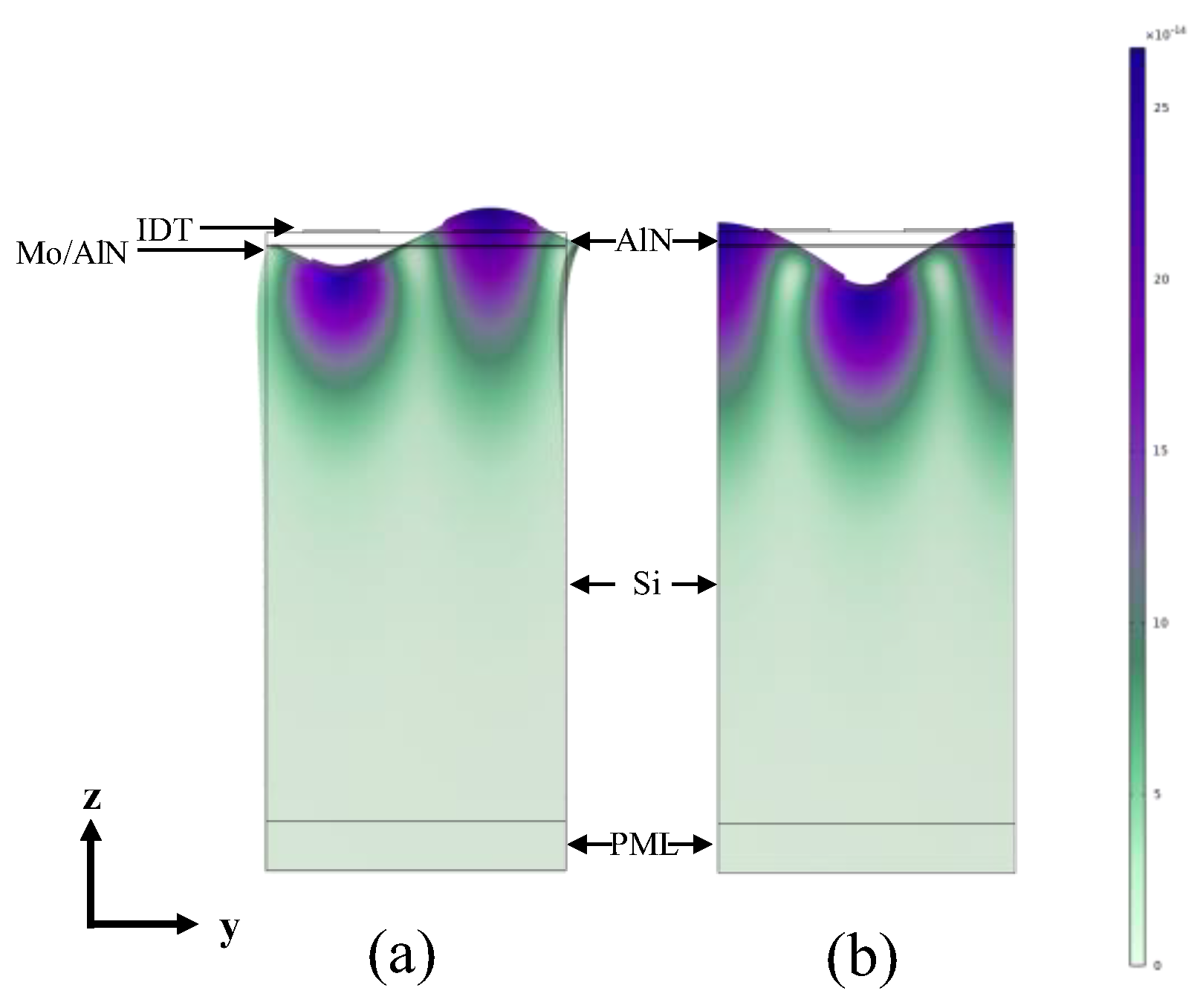

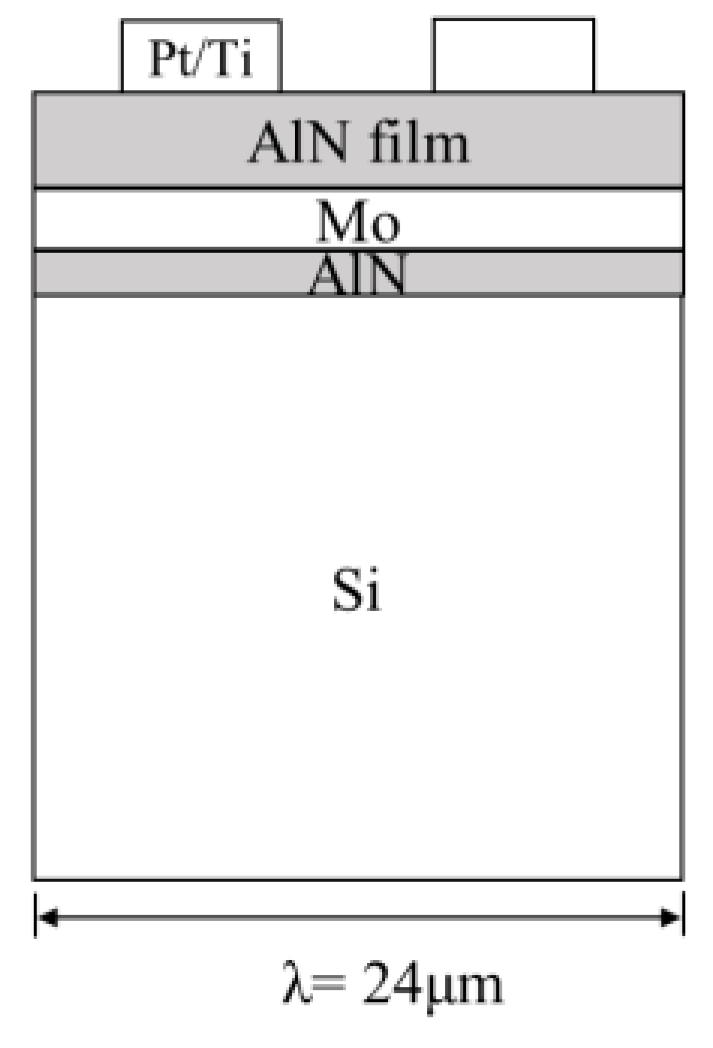

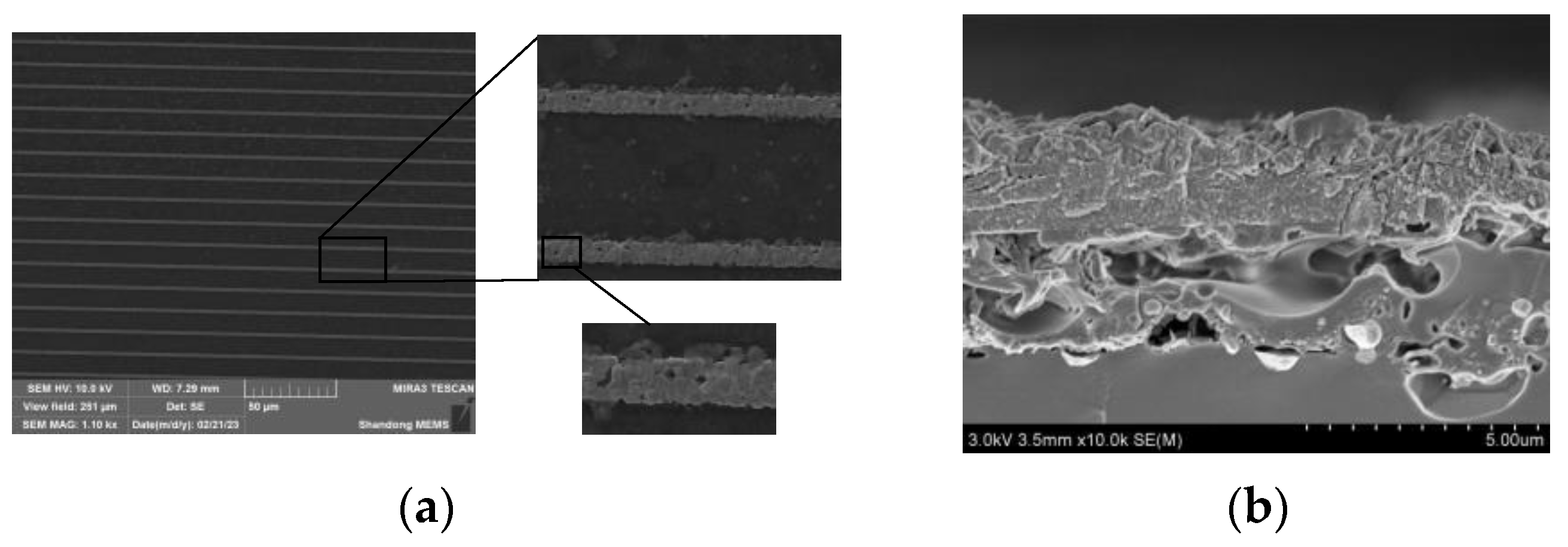

2. Design and Simulation

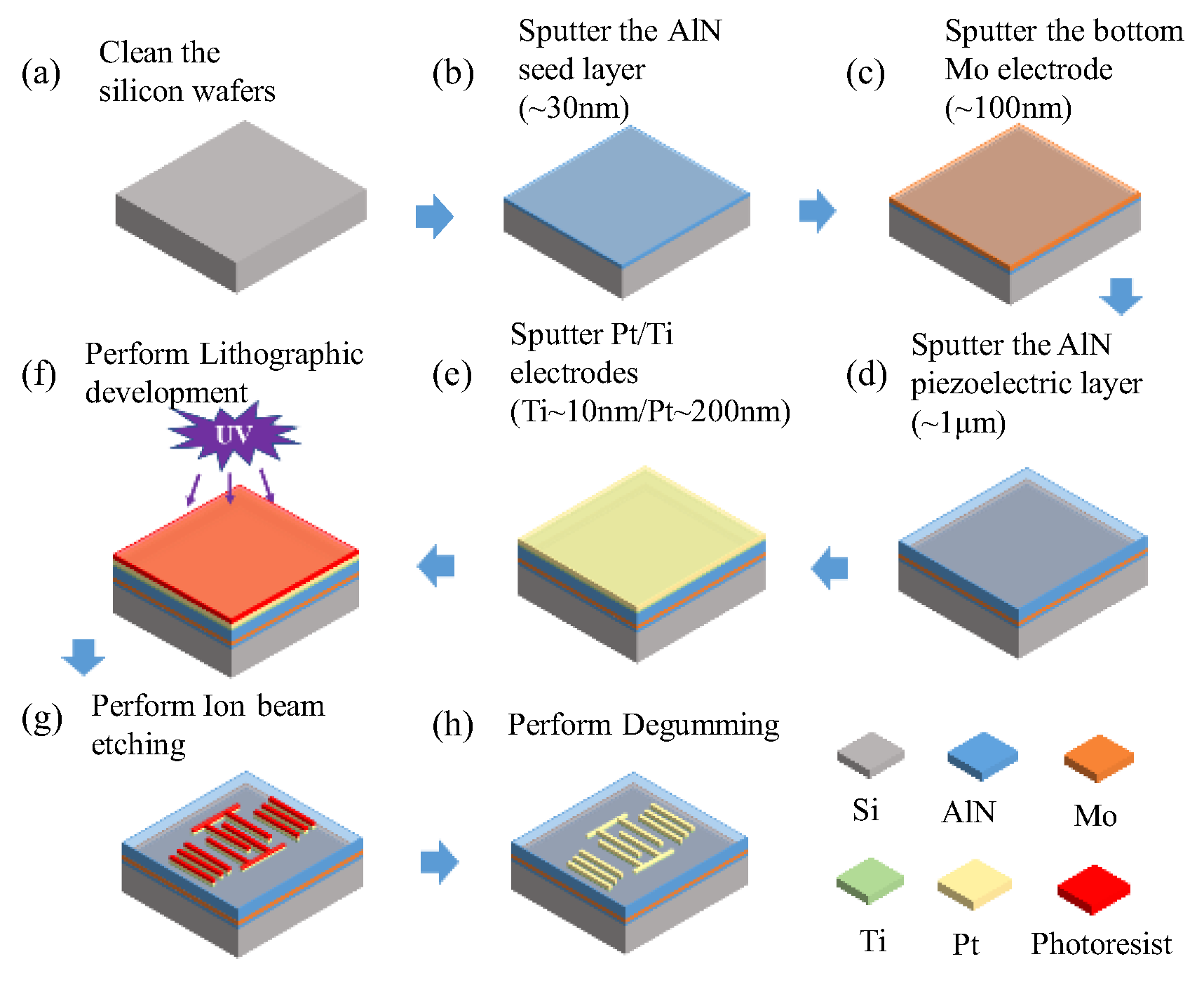

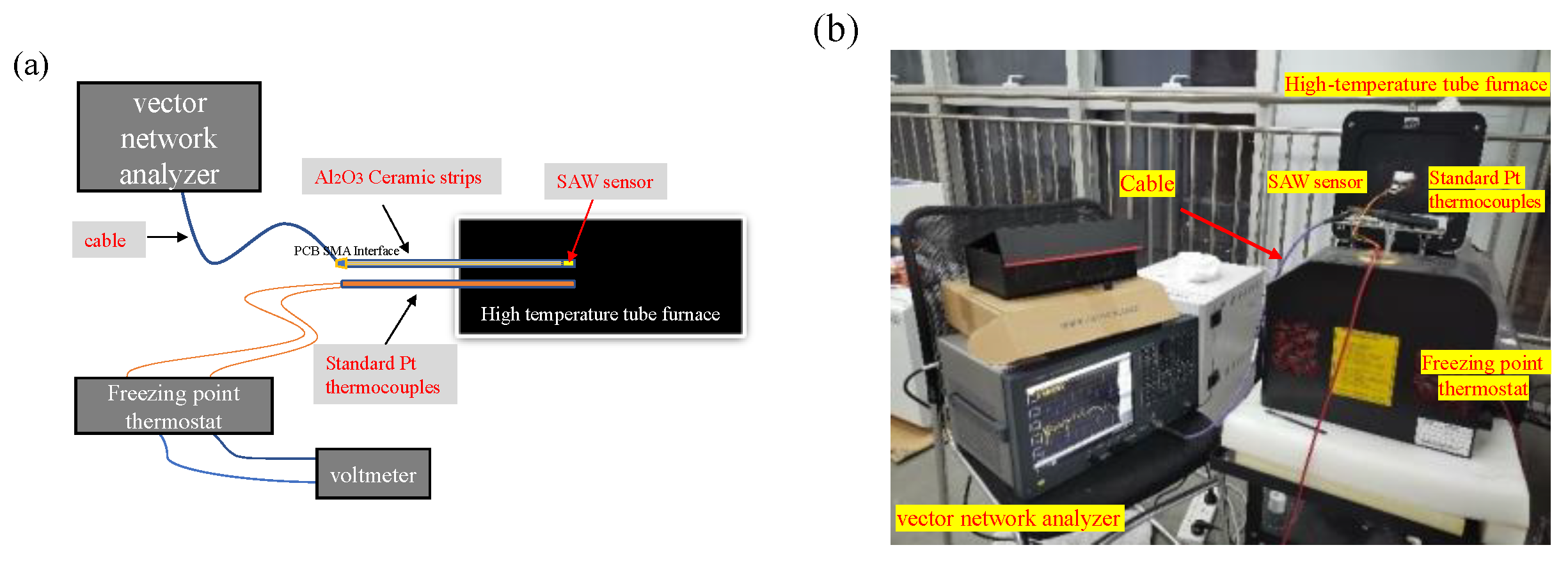

3. Materials and Methods

4. Results and Discussion

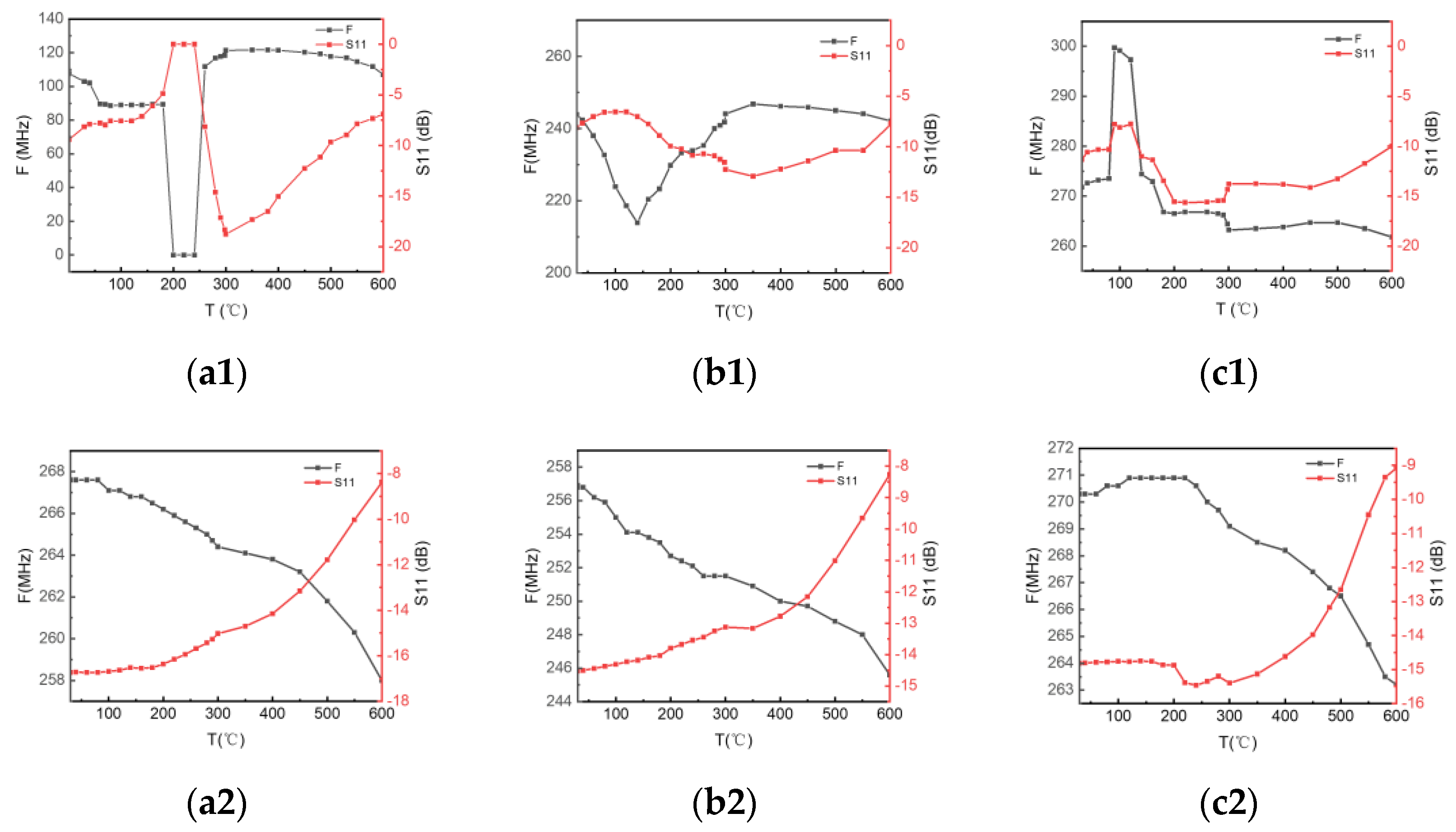

4.1. Analysis of the First Temperature Test

4.2. Analysis after Multiple Temperature Tests

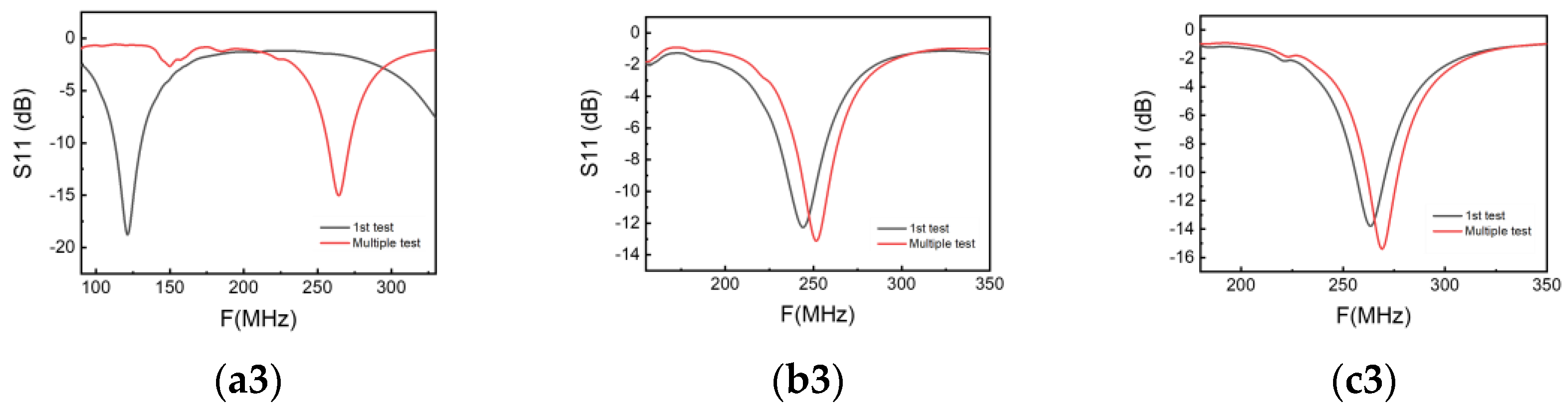

4.3. Comparison of the First Test and Multiple Tests

4.4. Comparison before and after Annealing

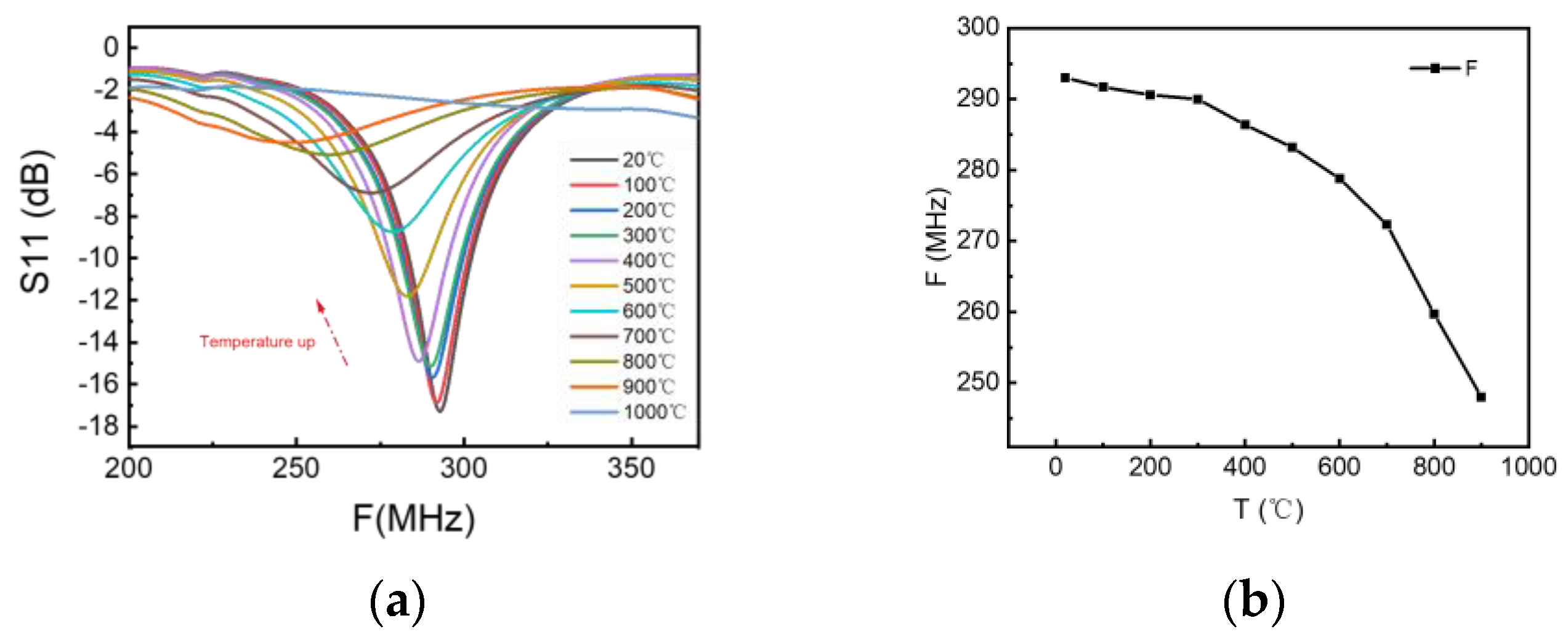

4.5. High-Temperature Test of Annealed Sensor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Korashy, A.; Attia, H.; Thomson, V.; Oskooei, S. Characterization of fretting wear of cobalt-based superalloys at high temperature for aero-engine combustor components. Wear 2015, 330–331, 327–337. [Google Scholar] [CrossRef]

- Jurgens, R.F. High-Temperature Electronics Applications in Space Exploration. IEEE Trans. Ind. Electron. 1982, IE-29, 107–111. [Google Scholar] [CrossRef]

- Schmitt, A.K.; Hulen, J.B. Buried rhyolites within the active, high-temperature Salton Sea geothermal system. J. Volcanol. Geotherm. Res. 2008, 178, 708–718. [Google Scholar] [CrossRef]

- Fonseca, M.A.; English, J.M.; Arx, M.v.; Allen, M.G. Wireless micromachined ceramic pressure sensor for high-temperature applications. J. Microelectromech. Syst. 2002, 11, 337–343. [Google Scholar] [CrossRef]

- Mrosk, J.W.; Berger, L.; Ettl, C.; Fecht, H.J.; Fischerauer, G.; Dommann, A. Materials issues of SAW sensors for high-temperature applications. IEEE Trans. Ind. Electron. 2001, 48, 258–264. [Google Scholar] [CrossRef]

- Kang, A.; Zhang, C.; Ji, X.; Han, T.; Li, R.; Li, X. SAW-RFID enabled temperature sensor. Sens. Actuators A Phys. 2013, 201, 105–113. [Google Scholar] [CrossRef]

- Fachberger, R.; Bruckner, G.; Knoll, G.; Hauser, R.; Biniasch, J.; Reindl, L. Applicability of LiNbO/sub3/, langasite and GaPO/sub4/ in high temperature SAW sensors operating at radio frequencies. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2004, 51, 1427–1431. [Google Scholar] [CrossRef]

- Shu, L.; Peng, B.; Yang, Z.; Wang, R.; Deng, S.; Liu, X. High-Temperature SAW Wireless Strain Sensor with Langasite. Sensors 2015, 15, 28531–28542. [Google Scholar] [CrossRef]

- Rodríguez-Madrid, J.G.; Iriarte, G.F.; Williams, O.A.; Calle, F. High precision pressure sensors based on SAW devices in the GHz range. Sens. Actuators A Phys. 2013, 189, 364–369. [Google Scholar] [CrossRef]

- Martin, L.C.; Wrbanek, J.D.; Fralick, G.C. Thin film sensors for surface measurements [in aerospace simulation facilities]. In Proceedings of the ICIASF 2001 Record, 19th International Congress on Instrumentation in Aerospace Simulation Facilities (Cat. No.01CH37215), Cleveland, OH, USA, 27–30 August 2001; pp. 196–203. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.; Dalmau, R.; Schlesser, R.; Preble, E.; Jiang, X. High-temperature electromechanical characterization of AlN single crystals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 1880–1887. [Google Scholar] [CrossRef]

- Turner, R.C.; Fuierer, P.A.; Newnham, R.E.; Shrout, T.R. Materials for high temperature acoustic and vibration sensors: A review. Appl. Acoust. 1994, 41, 299–324. [Google Scholar] [CrossRef]

- Lin, C.-M.; Chen, Y.-Y.; Felmetsger, V.V.; Lien, W.-C.; Riekkinen, T.; Senesky, D.G.; Pisano, A.P. Surface acoustic wave devices on AlN/3C–SiC/Si multilayer structures. J. Micromech. Microeng. 2013, 23, 025019. [Google Scholar] [CrossRef]

- Wu, S.; Ro, R.; Lin, Z.-X.; Lee, M.-S. Rayleigh surface acoustic wave modes of interdigital transducer/(100) AlN/(111) diamond. J. Appl. Phys. 2008, 104, 064919. [Google Scholar] [CrossRef]

- Naumenko, N.; Nicolay, P. AlN/Pt/LN structure for SAW sensors capable of operating at high temperature. Appl. Phys. Lett. 2017, 111, 073507. [Google Scholar] [CrossRef]

- Floer, C.; Elmazria, O.; Naumenko, N.; Bartoli, F.; Ghanbaja, J.; Aubert, T.; Hage-Ali, S. AlN/Pt/LN-Y128 Packageless Acoustic Wave Temperature Sensor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 2315–2318. [Google Scholar] [CrossRef] [PubMed]

- Iriarte, G.F.; Bjurstrom, J.; Westlinder, J.; Engelmark, F.; Katardjiev, I.V. Synthesis of c-axis-oriented AlN thin films on high-conducting layers: Al, Mo, Ti, TiN, and Ni. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 1170–1174. [Google Scholar] [CrossRef]

- Hoang, T.; Rey, P.; Vaudaine, M.H.; Robert, P.; Benech, P. Effect of Mo layer on performance of AlN/Si SAW filter. In Proceedings of the 2008 IEEE International Frequency Control Symposium, Honolulu, HI, USA, 19–21 May 2008; pp. 615–618. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.-Z.; Peng, B.; Shu, L.; Li, Y.-R. AlN-based surface acoustic wave resonators on platinum bottom electrodes for high-temperature sensing applications. Rare Met. 2016, 35, 408–411. [Google Scholar] [CrossRef]

- Sung, C.C.; Chiang, Y.F.; Ro, R.; Lee, R.; Wu, S. Effects of conducting layers on surface acoustic wave in AlN films on diamond. J. Appl. Phys. 2009, 106, 124905. [Google Scholar] [CrossRef]

- Burgess, J.W.; Hales, M.C. Temperature coefficients of frequency in LiNbO3 and LiTaO3 plate resonators. Proc. Inst. Elect. Eng. 1976, 123, 499–504. [Google Scholar] [CrossRef]

- Kan, M.-Q.; Du, J.-K.; He, L.-W. In Analysis on saw device of LiNbO3 film with multi-layered media. In Proceedings of the 2017 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), Chengdu, China, 27–30 October 2017; pp. 476–480. [Google Scholar] [CrossRef]

- Li, Q.; Qian, L.; Fu, S.; Song, C.; Zen, F.; Pan, F. Characteristics of one-port surface acoustic wave resonator fabricated on ZnO/6H-SiC layered structure. J. Phys. D Appl. Phys. 2018, 51, 145305. [Google Scholar] [CrossRef]

- Miyake, H.; Lin, C.-H.; Tokoro, K.; Hiramatsu, K. Preparation of high-quality AlN on sapphire by high-temperature face-to-face annealing. J. Cryst. Growth 2016, 456, 155–159. [Google Scholar] [CrossRef]

- Herth, E.; Fall, D.; Rauch, J.-Y.; Mourtalier, V.; Guisbiers, G. Thermal annealing of AlN films for piezoelectric applications. J. Mater. Sci. Mater. Electron. 2020, 31, 4473–4478. [Google Scholar] [CrossRef]

- Yoshizawa, R.; Miyake, H.; Hiramatsu, K. Effect of thermal annealing on AlN films grown on sputtered AlN templates by metalorganic vapor phase epitaxy. Jpn. J. Appl. Phys. 2018, 57, 01AD05. [Google Scholar] [CrossRef]

- Auberta, T.; Elmazria, O.; Assouar, B.; Bouvot, L.; Oudich, M. Surface acoustic wave devices based on AlN/sapphire structure for high temperature applications. Appl. Phys. Lett. 2010, 96, 203503. [Google Scholar] [CrossRef]

- Lee, J.W.; Radu, I.; Alexe, M. Oxidation behavior of AIN substrate at low temperature. J. Mater. Sci. Mater. Electron. 2002, 13, 131–137. [Google Scholar] [CrossRef]

| Material Constant | Temperature Coefficient | |||

|---|---|---|---|---|

| AlN | AlN | |||

| Density (kg/m3) | ρ | 3260 | (10−6/K) | −14.69 |

| Elasticity constant (GPa) | C11 | 345 | (10−4/K) | 0.8 |

| C12 | 125 | 1.8 | ||

| C13 | 120 | 1.6 | ||

| C14 | - | - | ||

| C33 | 395 | 1 | ||

| C44 | 118 | 0.5 | ||

| Piezoelectric constant (C/m2) | e15 | −0.48 | (10−4/K) | - |

| e31 | −0.58 | - | ||

| e33 | 1.55 | - | ||

| Dielectric constant (10−11 F/m) | ε11 | 8.2 | (10−4/K) | - |

| ε33 | 9.5 | - | ||

| Coefficient of thermal expansion (ppm/K) | α11 | 5.27 | ||

| α33 | 4.15 |

| Pt | Ti | Mo | Si | |

|---|---|---|---|---|

| Density (kg/m3) | 21,450 | 4506 | 10,200 | 2329 |

| Relative permittivity | 1 | 1 | 1 | 11.7 |

| Young’s modulus (Pa) | 168 × 109 | 115.7 × 109 | 312 × 109 | 170 × 109 |

| Poisson’s ratio | 0.38 | 0.321 | 0.31 | 0.28 |

| Sample | Resonant Frequency/MHz | Inverse Resonant Frequency/MHz |

|---|---|---|

| Pt/Ti/AlN/Mo/AlN/Si | 197.8 | 191.1 |

| Pt/Ti/AlN/Mo/Si | 197.8 | 191.2 |

| Index | Numeric Value |

|---|---|

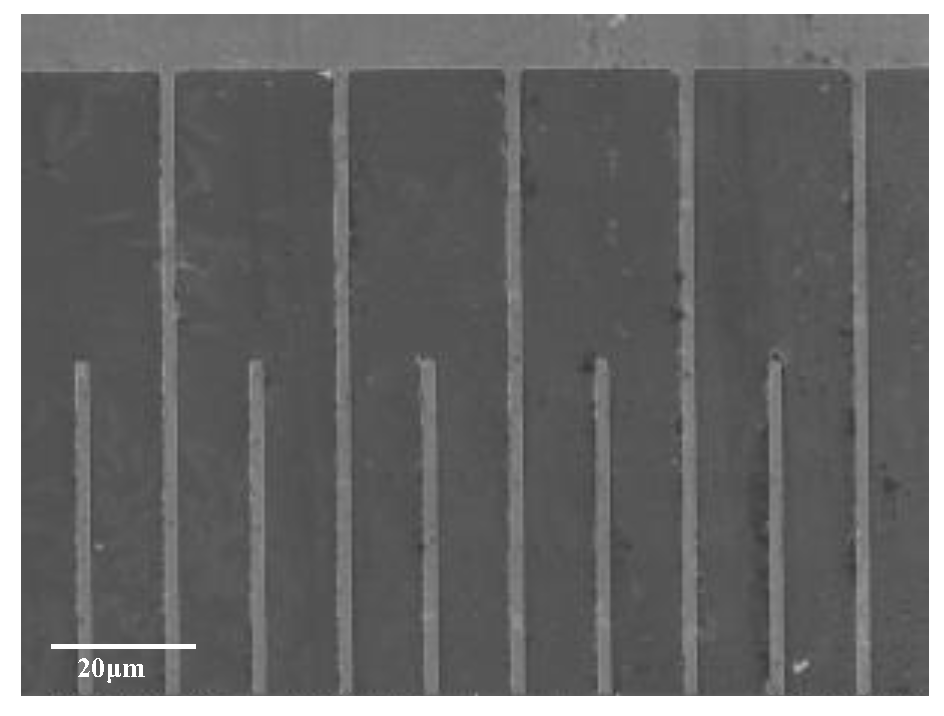

| wavelength λ | 24 μm |

| pore size W | 90 λ |

| interdigital spacing P | 12 μm |

| reflected gate pairs Nr | 100 pairs |

| interdigital electrode pairs Nt | 100 pairs |

| Sample | Metallization Rate | Sensitivity/KHz K−1 | Q |

|---|---|---|---|

| 1 | 25% | 14.77 | 34.8 |

| 2 | 50% | 17.27 | 19.8 |

| 3 | 67% | 12.34 | 25.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruan, Y.; Chen, Y.; Wu, Y.; Shi, M.; Du, Y.; Song, Z.; Chen, Y.; Dong, H.; Zhang, C.; Teng, J. Novel SAW Temperature Sensor with Pt/Ti/AlN/Mo/AlN/Si Structure for High Temperature Application. Chemosensors 2023, 11, 225. https://doi.org/10.3390/chemosensors11040225

Ruan Y, Chen Y, Wu Y, Shi M, Du Y, Song Z, Chen Y, Dong H, Zhang C, Teng J. Novel SAW Temperature Sensor with Pt/Ti/AlN/Mo/AlN/Si Structure for High Temperature Application. Chemosensors. 2023; 11(4):225. https://doi.org/10.3390/chemosensors11040225

Chicago/Turabian StyleRuan, Yong, Yang Chen, Yu Wu, Meng Shi, Yan Du, Zhiqiang Song, Yiyang Chen, Helei Dong, Congchun Zhang, and Jiao Teng. 2023. "Novel SAW Temperature Sensor with Pt/Ti/AlN/Mo/AlN/Si Structure for High Temperature Application" Chemosensors 11, no. 4: 225. https://doi.org/10.3390/chemosensors11040225

APA StyleRuan, Y., Chen, Y., Wu, Y., Shi, M., Du, Y., Song, Z., Chen, Y., Dong, H., Zhang, C., & Teng, J. (2023). Novel SAW Temperature Sensor with Pt/Ti/AlN/Mo/AlN/Si Structure for High Temperature Application. Chemosensors, 11(4), 225. https://doi.org/10.3390/chemosensors11040225