Novel Approach for the Immobilization of Cellobiose Dehydrogenase in PEDOT:PSS Conductive Layer on Planar Gold Electrodes

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Solutions

2.2. Preparation of Gold Sensors

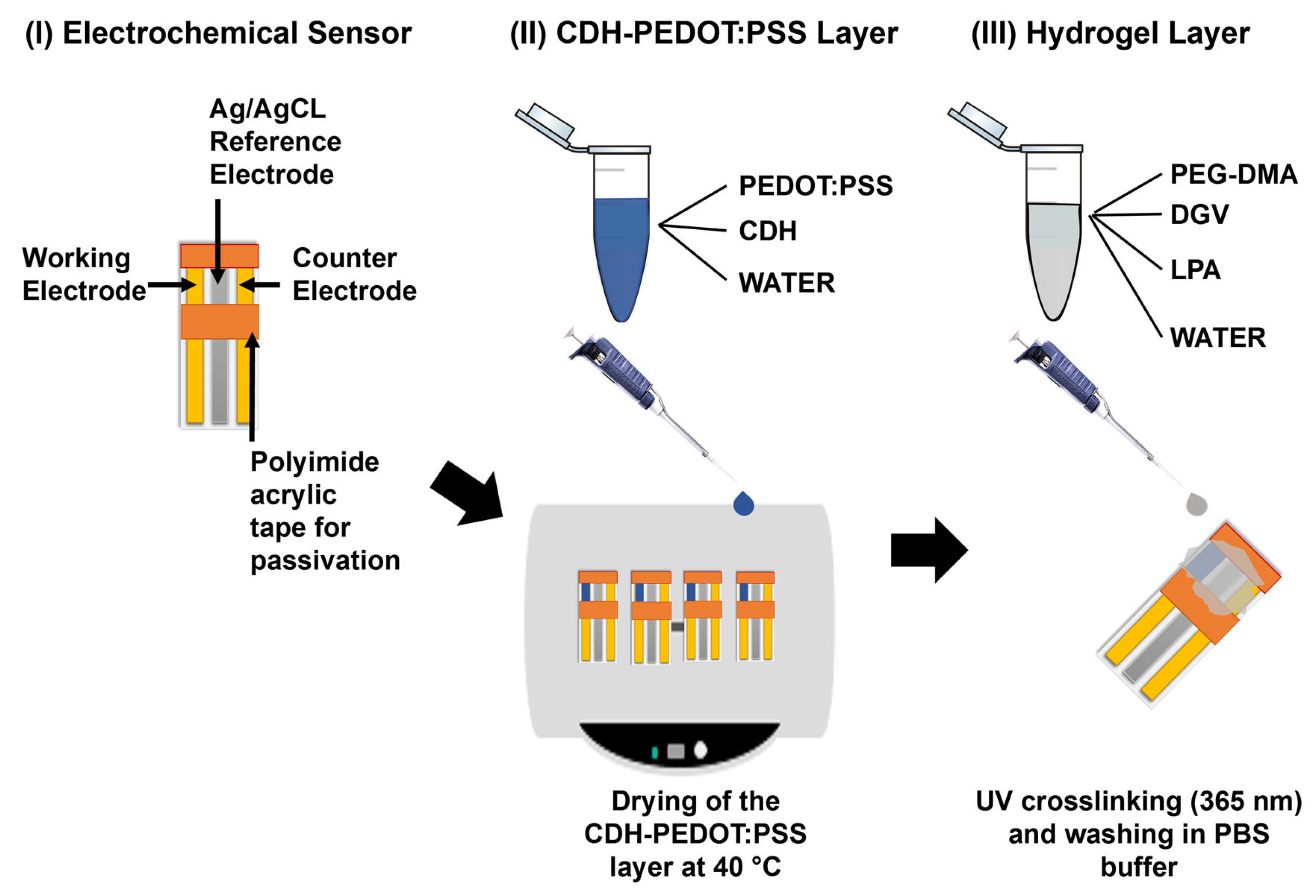

2.3. Electrode Modification

- PEDOT:PSS ink and CDH-PEDOT:PSS ink formulation: PEDOT:PSS ink was prepared by mixing 16% v/v PEDOT:PSS and 84% v/v ultrapure water. CDH-PEDOT:PSS ink was prepared by mixing 16% v/v PEDOT:PSS, 54% v/v ultrapure water, and 30% v/v (24 mg/mL in water) of CDH. The final concentration of CDH of 7.2 mg/mL in the ink was used in all the experiments, except in Section 3.4, “Investigation of the CDH concentration in the CDH-PEDOT:PSS ink”. An amount of 3 μL of these solutions in total was drop-casted on the working electrode of the sensors by applying six times 0.5 µL on the working electrode with drying at 40 °C for 1 min on a Präzitherm heating plate after each layer.

- Hydrogel precursor solutions: Acrylate-based hydrogel precursor solutions were prepared by mixing 30% v/v PEG-DMA (1 kDa, 700 mg/mL in water or 10 kDa, 175 mg/mL in water), 60% v/v DEGVE, 8% v/v water, and 2% v/v of LPA (10 mg/100 µL in 50% v/v ethanol, 50% v/v water mixture). LPA (10 mg) was dissolved by ultrasonication. LPA is the UV-induced free radical photoinitiator, PEG-DMA (1 or 10 kDa) is the crosslinking substance, and DEGVE is the water-soluble monomer for chain extension.

- An amount of 1.5 μL/mm2 of the hydrogel precursor solutions was drop-casted on the sensing area covering working, counter, and reference electrode (in total 3 µL).

- UV crosslinking: After modification with the hydrogel precursor solution, the sensors were transferred into a UV crosslinker (UVP CL-1000 ultraviolet crosslinker, from Analytik Jena US LLC (Formerly UVP LLC), Upland, CA, USA, purchased through VWR International, Vienna, Austria) and crosslinked at 365 nm with 1 J/cm2.

- Washing: The sensors were dipped in physiological PBS for 10 min and then 5 more min in fresh physiological PBS.

2.4. Electrochemical Measurements

2.5. Selectivity Test

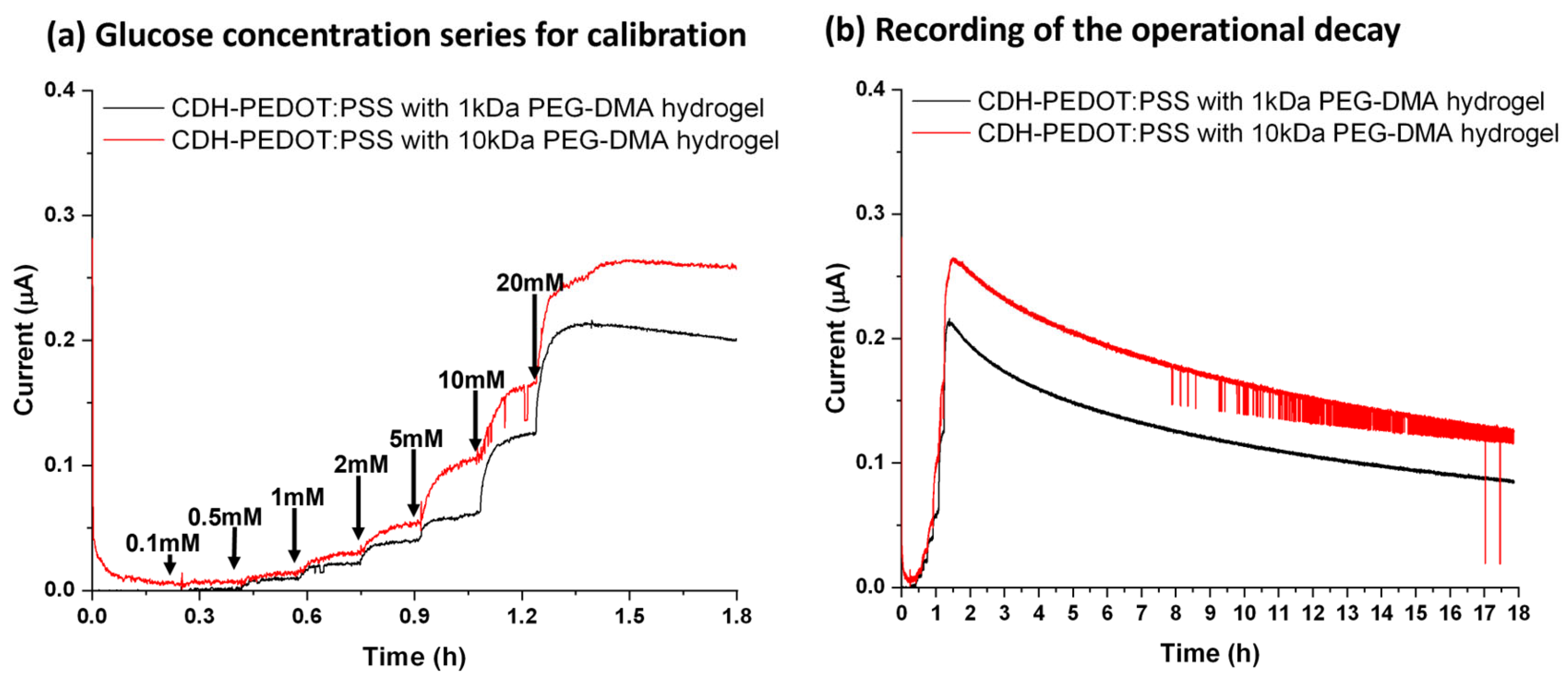

2.6. Operational Stability and PEG-DMA Crosslinkers with Different Molar Masses

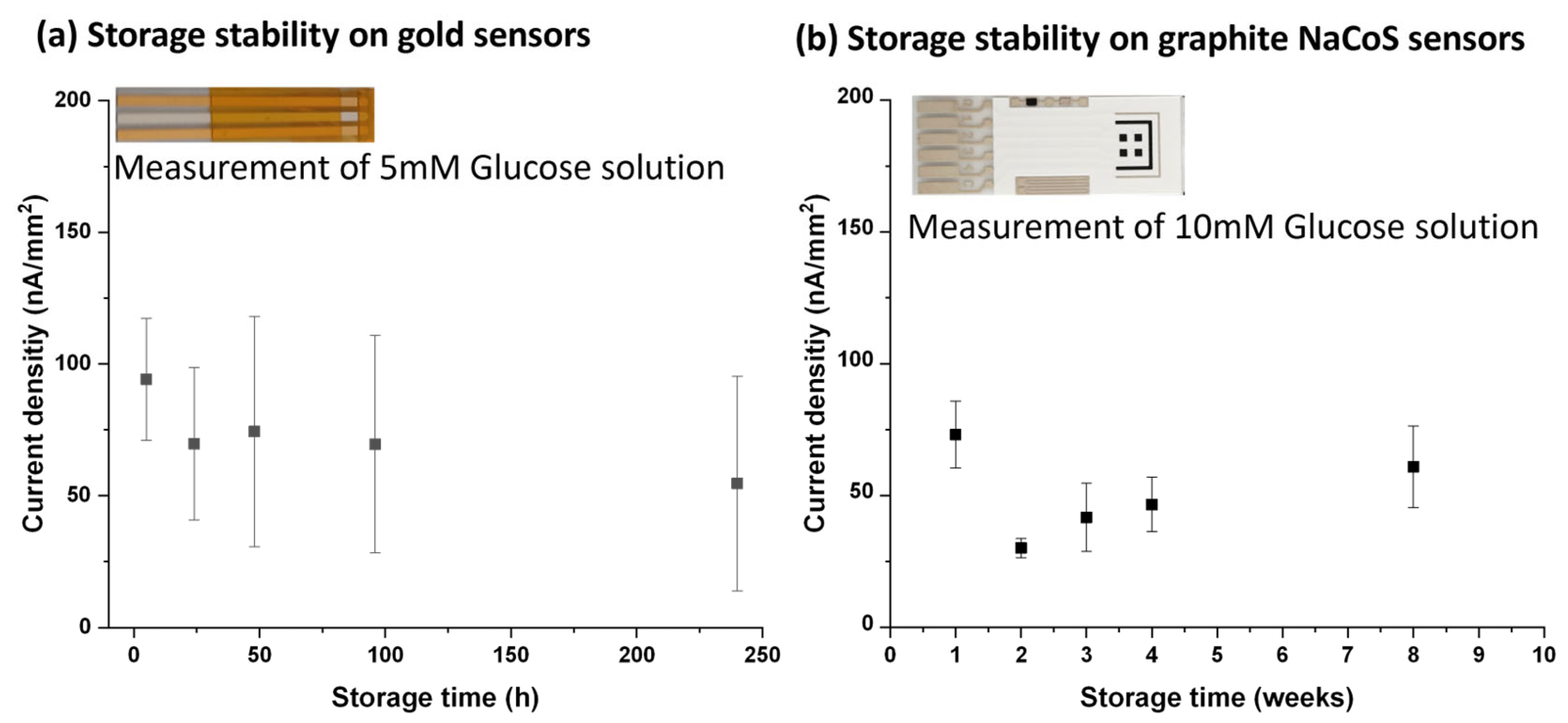

2.7. Storage Stability

3. Results

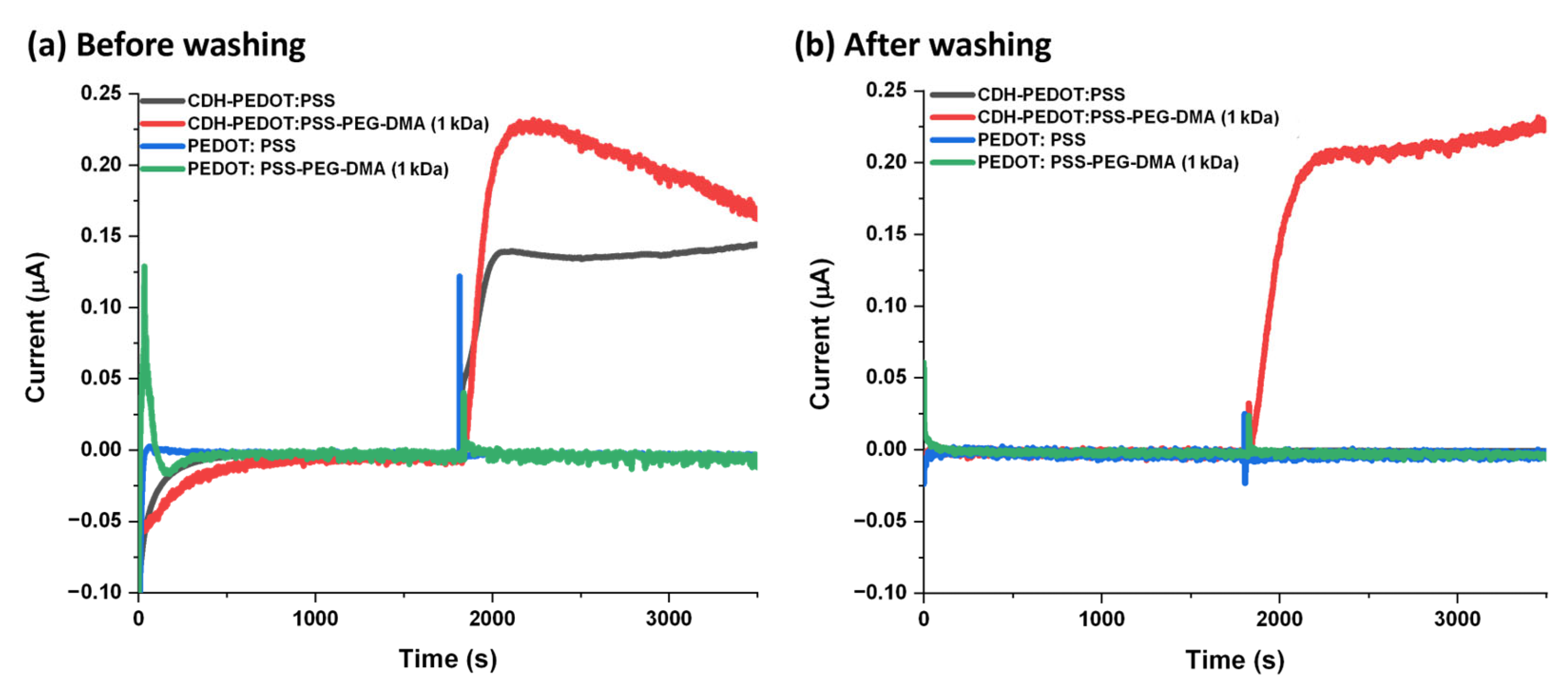

3.1. CDH-PEDOT:PSS Layer Stability

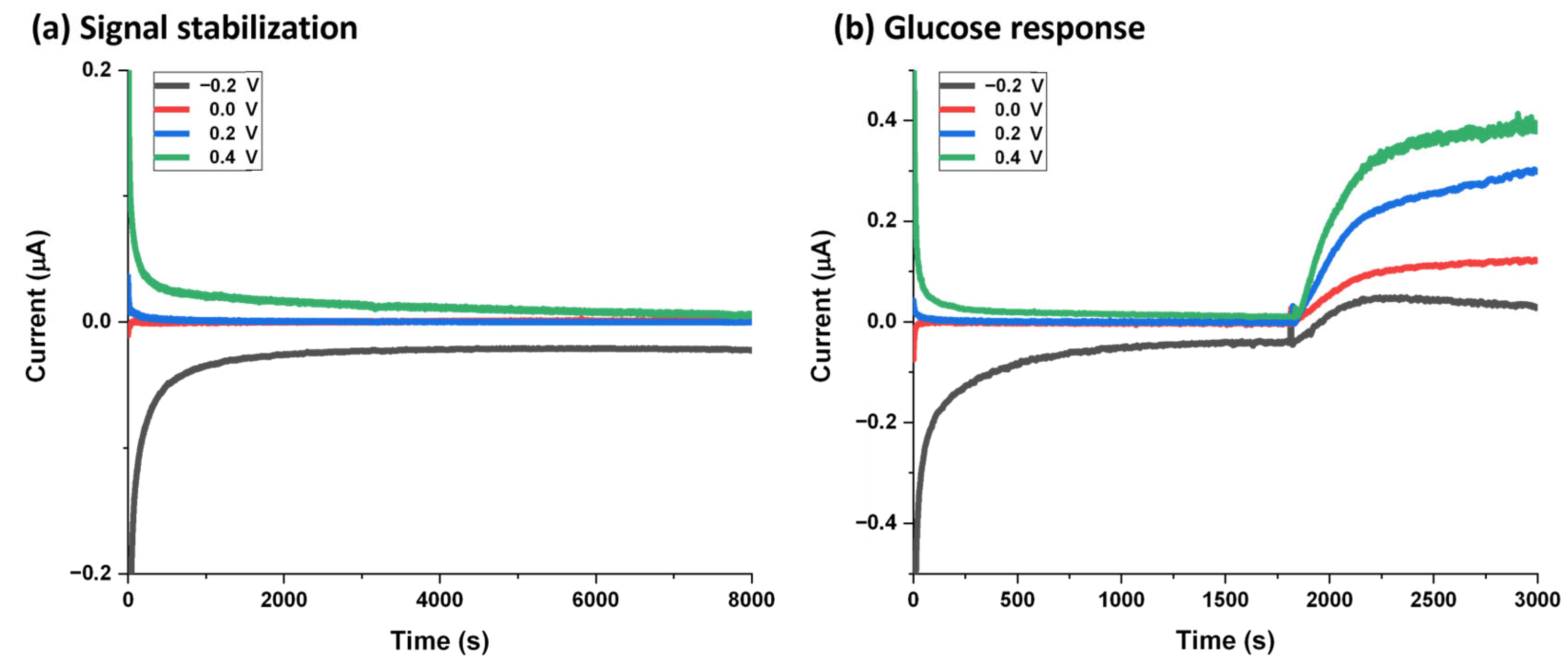

3.2. Potential Dependency of the Current Response

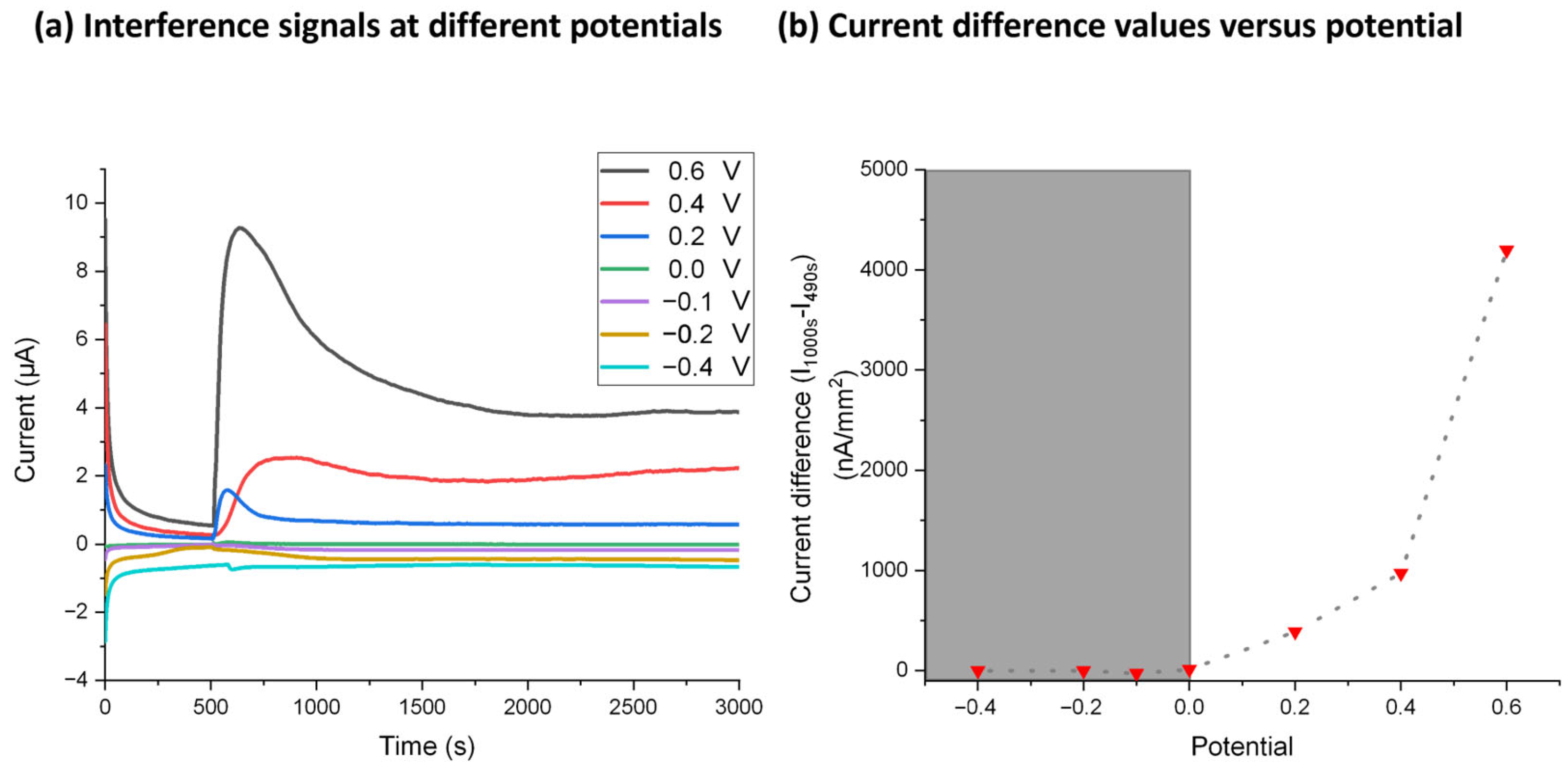

3.3. Selectivity Test

3.4. Investigation of CDH Concentration in CDH-PEDOT:PSS Ink on Sensor Responses to Glucose

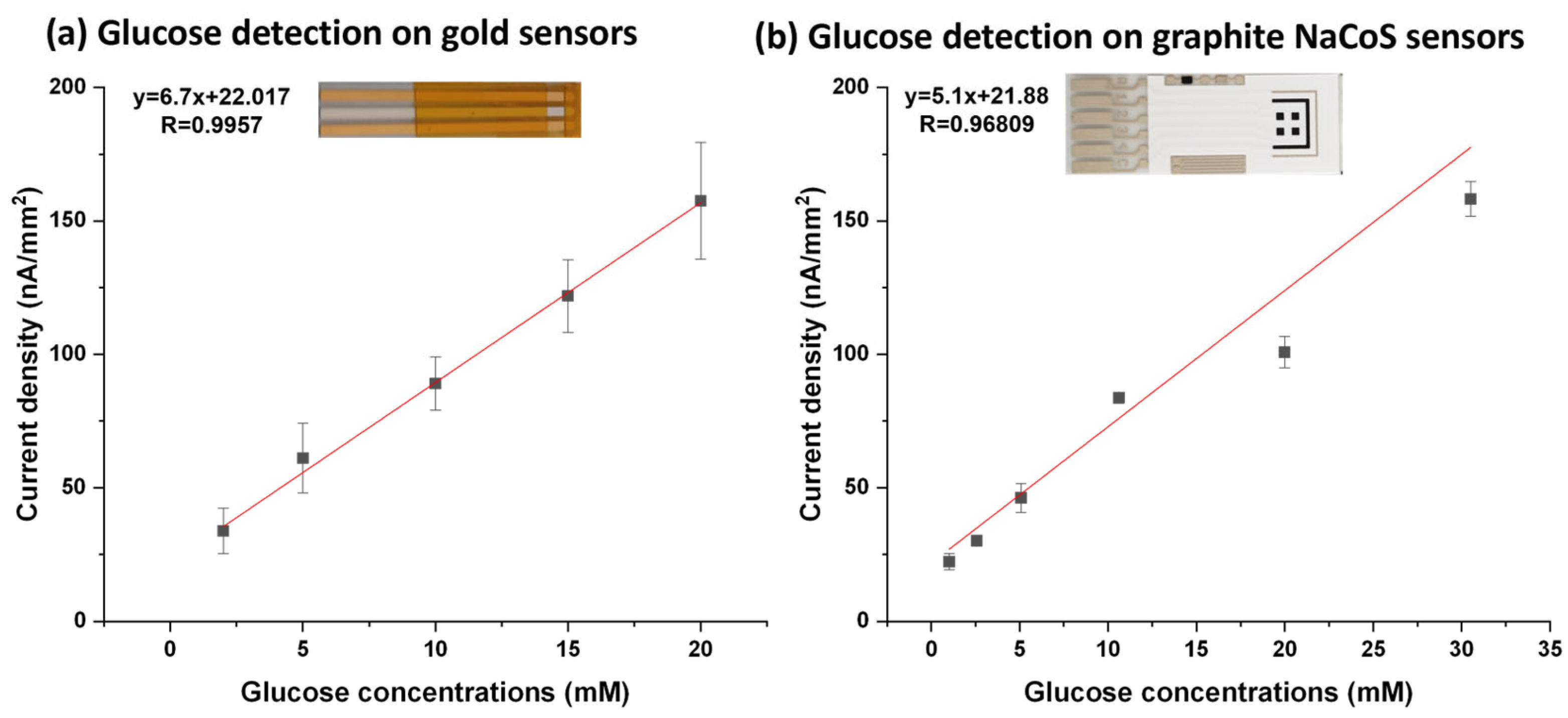

3.5. Enzyme Kinetics of Glucose Response

3.6. Glucose Detection in the Presence of PEG-DMA Crosslinkers with Different Molar Masses

3.7. Storage Stability

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Güemes, M.; Rahman, S.A.; Hussain, K. What is a normal blood glucose? Arch. Dis. Child. 2016, 101, 569–574. [Google Scholar] [CrossRef]

- Vashist, S.K. Point-of-Care Glucose Detection for Diabetic Monitoring and Management, 1st ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2017; ISBN 978-1-4987-8875-5. [Google Scholar]

- Wang, Y.-F.; Jia, W.-P.; Wu, M.-H.; Chien, M.-O.; Hsieh, M.-C.; Wang, C.-P.; Lee, M.-S. Accuracy Evaluation of 19 Blood Glucose Monitoring Systems Manufactured in the Asia-Pacific Region: A Multicenter Study. J. Diabetes Sci. Technol. 2017, 11, 953–965. [Google Scholar] [CrossRef]

- Soskolne, W.A.; Klinger, A. The relationship between periodontal diseases and diabetes: An overview. Ann. Periodontol. 2001, 6, 91–98. [Google Scholar] [CrossRef]

- Papatheodorou, K.; Banach, M.; Bekiari, E.; Rizzo, M.; Edmonds, M. Complications of Diabetes 2017. J. Diabetes Res. 2018, 2018, 3086167. [Google Scholar] [CrossRef]

- Al Hayek, A.A.; Robert, A.A.; Al Dawish, M.A. Evaluation of FreeStyle Libre Flash Glucose Monitoring System on Glycemic Control, Health-Related Quality of Life, and Fear of Hypoglycemia in Patients with Type 1 Diabetes. Clin. Med. Insights Endocrinol. Diabetes 2017, 10, 1179551417746957. [Google Scholar] [CrossRef]

- Tehrani, F.; Teymourian, H.; Wuerstle, B.; Kavner, J.; Patel, R.; Furmidge, A.; Aghavali, R.; Hosseini-Toudeshki, H.; Brown, C.; Zhang, F.; et al. An integrated wearable microneedle array for the continuous monitoring of multiple biomarkers in interstitial fluid. Nat. Biomed. Eng. 2022, 6, 1214–1224. [Google Scholar] [CrossRef]

- Ju, J.; Li, L.; Regmi, S.; Zhang, X.; Tang, S. Microneedle-Based Glucose Sensor Platform: From Vitro to Wearable Point-of-Care Testing Systems. Biosensors 2022, 12, 606. [Google Scholar] [CrossRef]

- Gallaway, J.W.; Calabrese Barton, S.A. Kinetics of redox polymer-mediated enzyme electrodes. J. Am. Chem. Soc. 2008, 130, 8527–8536. [Google Scholar] [CrossRef]

- Estrada-Osorio, D.V.; Escalona-Villalpando, R.A.; Gutiérrez, A.; Arriaga, L.G.; Ledesma-García, J. Poly-L-lysine-modified with ferrocene to obtain a redox polymer for mediated glucose biosensor application. Bioelectrochemistry 2022, 146, 108147. [Google Scholar] [CrossRef]

- Ramanavicius, A.; Rekertaitė, A.I.; Valiūnas, R.; Valiūnienė, A. Single-step procedure for the modification of graphite electrode by composite layer based on polypyrrole, Prussian blue and glucose oxidase. Sens. Actuator B Chem. 2017, 240, 220–223. [Google Scholar] [CrossRef]

- Jeon, W.-Y.; Kim, H.-S.; Jang, H.-W.; Lee, Y.-S.; Shin, U.S.; Kim, H.-H.; Choi, Y.-B. A stable glucose sensor with direct electron transfer, based on glucose dehydrogenase and chitosan hydro bonded multi-walled carbon nanotubes. Biochem. Eng. J. 2022, 187, 108595. [Google Scholar] [CrossRef]

- Cai, Y.; Tu, T.; Li, T.; Zhang, S.; Zhang, B.; Fang, L.; Ye, X.; Liang, B. Research on direct electron transfer of native glucose oxidase at PEDOT:PSS hydrogels modified electrode. J. Electroanal. Chem. 2022, 922, 116738. [Google Scholar] [CrossRef]

- Chen, J.; Zheng, X.; Li, Y.; Zheng, H.; Liu, Y.; Suye, S. A Glucose Biosensor Based on Direct Electron Transfer of Glucose Oxidase on PEDOT Modified Microelectrode. J. Electrochem. Soc. 2020, 167, 67502. [Google Scholar] [CrossRef]

- Bollella, P. Enzyme-based amperometric biosensors: 60 years later … Quo Vadis? Anal. Chim. Acta 2022, 1234, 340517. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Al-Lolage, F.A. There is no evidence to support literature claims of direct electron transfer (DET) for native glucose oxidase (GOx) at carbon nanotubes or graphene. J. Electroanal. Chem. 2018, 819, 26–37. [Google Scholar] [CrossRef]

- Wilson, G.S. Native glucose oxidase does not undergo direct electron transfer. Biosens. Bioelectron. 2016, 82, 7–8. [Google Scholar] [CrossRef]

- Jayakumar, K.; Reichhart, T.M.B.; Schulz, C.; Ludwig, R.; Felice, A.K.G.; Leech, D. An Oxygen Insensitive Amperometric Glucose Biosensor Based on An Engineered Cellobiose Dehydrogenase: Direct versus Mediated Electron Transfer Responses. ChemElectroChem 2022, 9, e202200418. [Google Scholar] [CrossRef]

- Larsson, T.; Lindgren, A.; Ruzgas, T.; Lindquist, S.E.; Gorton, L. Bioelectrochemical characterisation of cellobiose dehydrogenase modified graphite electrodes: Ionic strength and pH dependences. J. Electroanal. Chem. 2000, 482, 1–10. [Google Scholar] [CrossRef]

- Lindgren, A.; Gorton, L.; Ruzgas, T.; Baminger, U.; Haltrich, D.; Schülein, M. Direct electron transfer of cellobiose dehydrogenase from various biological origins at gold and graphite electrodes. J. Electroanal. Chem. 2001, 496, 76–81. [Google Scholar] [CrossRef]

- Bollella, P.; Mazzei, F.; Favero, G.; Fusco, G.; Ludwig, R.; Gorton, L.; Antiochia, R. Improved DET communication between cellobiose dehydrogenase and a gold electrode modified with a rigid self-assembled monolayer and green metal nanoparticles: The role of an ordered nanostructuration. Biosens. Bioelectron. 2017, 88, 196–203. [Google Scholar] [CrossRef]

- Kielb, P.; Sezer, M.; Katz, S.; Lopez, F.; Schulz, C.; Gorton, L.; Ludwig, R.; Wollenberger, U.; Zebger, I.; Weidinger, I.M. Spectroscopic Observation of Calcium-Induced Reorientation of Cellobiose Dehydrogenase Immobilized on Electrodes and its Effect on Electrocatalytic Activity. ChemPhysChem 2015, 16, 1960–1968. [Google Scholar] [CrossRef]

- Bollella, P.; Ludwig, R.; Gorton, L. Cellobiose dehydrogenase: Insights on the nanostructuration of electrodes for improved development of biosensors and biofuel cells. Appl. Mater. Today 2017, 9, 319–332. [Google Scholar] [CrossRef]

- Feifel, S.C.; Ludwig, R.; Gorton, L.; Lisdat, F. Catalytically active silica nanoparticle-based supramolecular archi-tectures of two proteins--cellobiose dehydrogenase and cytochrome C on electrodes. Langmuir 2012, 28, 9189–9194. [Google Scholar] [CrossRef]

- Ma, S.; Ludwig, R. Direct Electron Transfer of Enzymes Facilitated by Cytochromes. ChemElectroChem 2019, 6, 958–975. [Google Scholar] [CrossRef]

- Gerwig, R.; Fuchsberger, K.; Schroeppel, B.; Link, G.S.; Heusel, G.; Kraushaar, U.; Schuhmann, W.; Stett, A.; Stelzle, M. PEDOT–CNT Composite Microelectrodes for Recording and Electrostimulation Applications: Fabrication, Morphology, and Electrical Properties. Front. Neuroeng. 2012, 5, 1–11. [Google Scholar] [CrossRef]

- Pranti, A.S.; Schander, A.; Bödecker, A.; Lang, W. PEDOT: PSS coating on gold microelectrodes with excellent stability and high charge injection capacity for chronic neural interfaces. Sens. Actuators B Chem. 2018, 275, 382–393. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, J.; Yao, Y.; Zhang, L.; Wen, Y.; Song, H.; Zhu, D. Facile preparation of highly water-stable and flexible PEDOT:PSS organic/inorganic composite materials and their application in electrochemical sensors. Sens. Actuators B Chem. 2014, 196, 357–369. [Google Scholar] [CrossRef]

- Fan, X.; Nie, W.; Tsai, H.; Wang, N.; Huang, H.; Cheng, Y.; Wen, R.; Ma, L.; Yan, F.; Xia, Y. PEDOT:PSS for Flexible and Stretchable Electronics: Modifications, Strategies, and Applications. Adv. Sci. 2019, 6, 1900813–1900853. [Google Scholar] [CrossRef]

- Riegel, A.-L.; Borzenkova, N.; Haas, V.; Scharfer, P.; Schabel, W. Activity determination of FAD-dependent glucose dehydrogenase immobilized in PEDOT: PSS-PVA composite films for biosensor applications. Eng. Life Sci. 2016, 16, 577–585. [Google Scholar] [CrossRef]

- Lin-Gibson, S.; Bencherif, S.; Cooper, J.A.; Wetzel, S.J.; Antonucci, J.M.; Vogel, B.M.; Horkay, F.; Washburn, N.R. Synthesis and characterization of PEG dimethacrylates and their hydrogels. Biomacromolecules 2004, 5, 1280–1287. [Google Scholar] [CrossRef]

- Yin, R.; Wang, K.; Han, J.; Nie, J. Photo-crosslinked glucose-sensitive hydrogels based on methacrylate modified dextran–concanavalin A and PEG dimethacrylate. Carbohydr. Polym. 2010, 82, 412–418. [Google Scholar] [CrossRef]

- Ludwig, R.; Sygmund, C.; Harreither, W.; Kittl, R.; Felice, A.K.G. Mutated Cellobiose Dehydrogenase with Increased Substrate Specificity. Granted Patent US 2015083611 A1; USA, 26 March 2015. [Google Scholar]

- Felice, A.K.G.; Sygmund, C.; Harreither, W.; Kittl, R.; Gorton, L.; Ludwig, R. Substrate specificity and interferences of a direct-electron-transfer-based glucose biosensor. J. Diabetes Sci. Technol. 2013, 7, 669–677. [Google Scholar] [CrossRef]

- Jarmoskaite, I.; AlSadhan, I.; Vaidyanathan, P.P.; Herschlag, D. How to measure and evaluate binding affinities. eLife 2020, 9, e57264. [Google Scholar] [CrossRef]

- Bollella, P.; Gorton, L.; Ludwig, R.; Antiochia, R. A Third Generation Glucose Biosensor Based on Cellobiose Dehydrogenase Immobilized on a Glassy Carbon Electrode Decorated with Electrodeposited Gold Nanoparticles: Characterization and Application in Human Saliva. Sensors 2017, 17, 1912. [Google Scholar] [CrossRef]

- Ito, K.; Okuda-Shimazaki, J.; Mori, K.; Kojima, K.; Tsugawa, W.; Ikebukuro, K.; Lin, C.-E.; La Belle, J.; Yoshida, H.; Sode, K. Designer fungus FAD glucose dehydrogenase capable of direct electron transfer. Biosens. Bioelectron. 2019, 123, 114–123. [Google Scholar] [CrossRef]

- Ito, K.; Okuda-Shimazaki, J.; Kojima, K.; Mori, K.; Tsugawa, W.; Asano, R.; Ikebukuro, K.; Sode, K. Strategic design and improvement of the internal electron transfer of heme b domain-fused glucose dehydrogenase for use in direct electron transfer-type glucose sensors. Biosens. Bioelectron. 2021, 176, 112911–112917. [Google Scholar] [CrossRef]

- Cass, A.E.G.; Sharma, S. Microneedle Enzyme Sensor Arrays for Continuous In Vivo Monitoring. Methods Enzymol. 2017, 589, 413–427. [Google Scholar] [CrossRef]

- Kai, H.; Kumatani, A. A porous microneedle electrochemical glucose sensor fabricated on a scaffold of a polymer monolith. J. Phys. Energy 2021, 3, 024006–024014. [Google Scholar] [CrossRef]

- Bollella, P.; Sharma, S.; Cass, A.E.G.; Tasca, F.; Antiochia, R. Minimally Invasive Glucose Monitoring Using a Highly Porous Gold Microneedles-Based Biosensor: Characterization and Application in Artificial Interstitial Fluid. Catalysts 2019, 7, 580. [Google Scholar] [CrossRef]

- H2020 ELSAH Project. Available online: www.elsah.researchproject.at (accessed on 25 January 2024).

- Brinkmann, C.; Bloch, W.; Mutinati, G.C. ELSAH (Electronic smart patch system for wireless monitoring of molecular biomarkers for healthcare and well-being): Definition of possible use cases. Front. Bioeng. Biotechnol. 2023, 11, 1–6. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cihan, E.; Melnik, E.; Kurzhals, S.; Plata, P.; Mutinati, G.C.; Hainberger, R.; Felice, A.K.G.; Schulz, C.; Lieberzeit, P. Novel Approach for the Immobilization of Cellobiose Dehydrogenase in PEDOT:PSS Conductive Layer on Planar Gold Electrodes. Chemosensors 2024, 12, 36. https://doi.org/10.3390/chemosensors12030036

Cihan E, Melnik E, Kurzhals S, Plata P, Mutinati GC, Hainberger R, Felice AKG, Schulz C, Lieberzeit P. Novel Approach for the Immobilization of Cellobiose Dehydrogenase in PEDOT:PSS Conductive Layer on Planar Gold Electrodes. Chemosensors. 2024; 12(3):36. https://doi.org/10.3390/chemosensors12030036

Chicago/Turabian StyleCihan, Esra, Eva Melnik, Steffen Kurzhals, Paulina Plata, Giorgio C. Mutinati, Rainer Hainberger, Alfons K.G. Felice, Christopher Schulz, and Peter Lieberzeit. 2024. "Novel Approach for the Immobilization of Cellobiose Dehydrogenase in PEDOT:PSS Conductive Layer on Planar Gold Electrodes" Chemosensors 12, no. 3: 36. https://doi.org/10.3390/chemosensors12030036

APA StyleCihan, E., Melnik, E., Kurzhals, S., Plata, P., Mutinati, G. C., Hainberger, R., Felice, A. K. G., Schulz, C., & Lieberzeit, P. (2024). Novel Approach for the Immobilization of Cellobiose Dehydrogenase in PEDOT:PSS Conductive Layer on Planar Gold Electrodes. Chemosensors, 12(3), 36. https://doi.org/10.3390/chemosensors12030036