A New Implantation Method for Orthodontic Anchor Screws: Basic Research for Clinical Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Animal Selection and Handling

2.2. Implantation of Orthodontic Anchor Screws: Histological Examination to Confirm the Distance between the Bone Surface and the Mini-Screw

2.3. Histometric Analysis

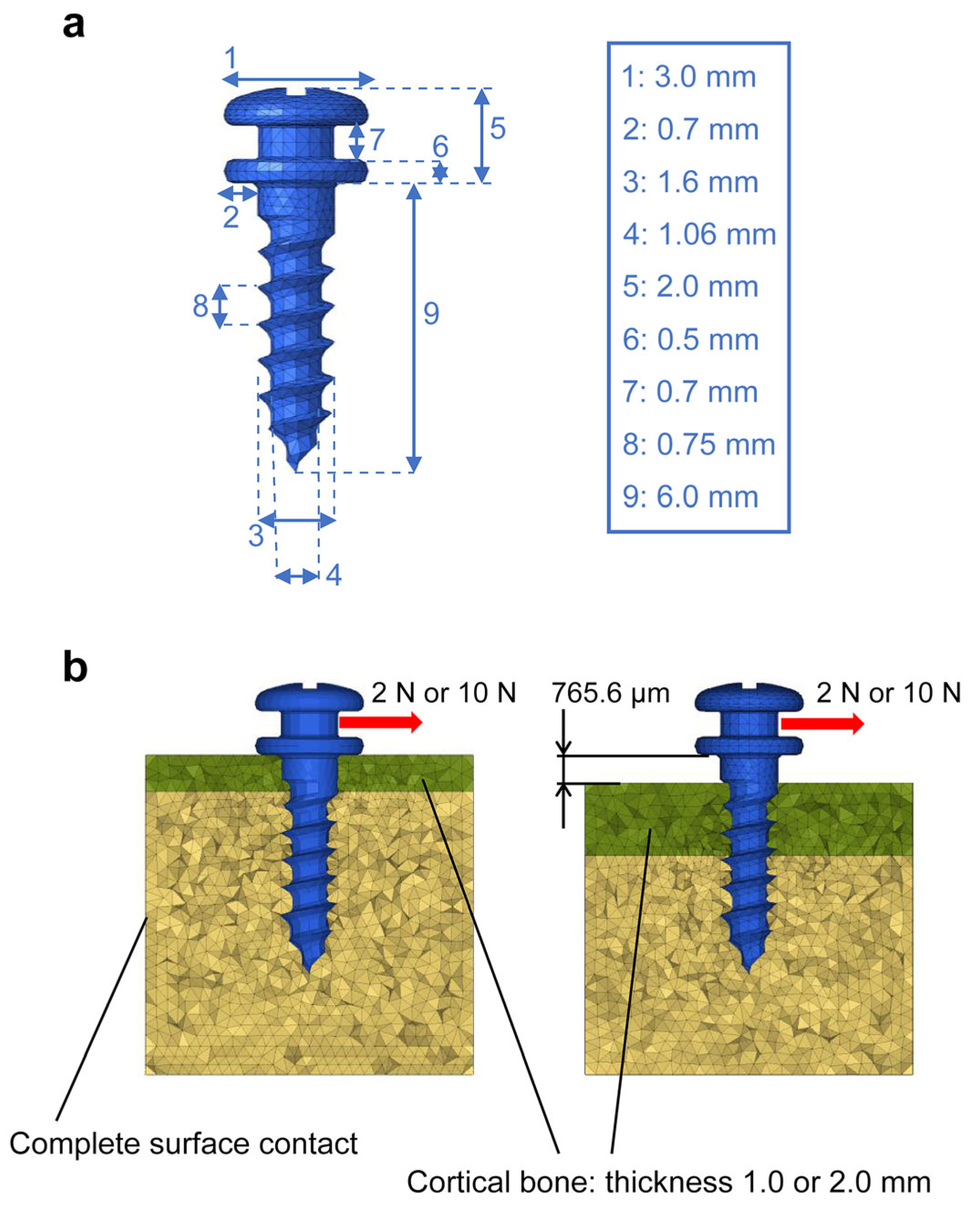

2.4. FEM Analysis Modeling

2.5. Statistical Analysis

3. Results

3.1. Distance between the Underside of the Screw Head and the Bone Surface Obtained from Histological Examination in Animal Experiments

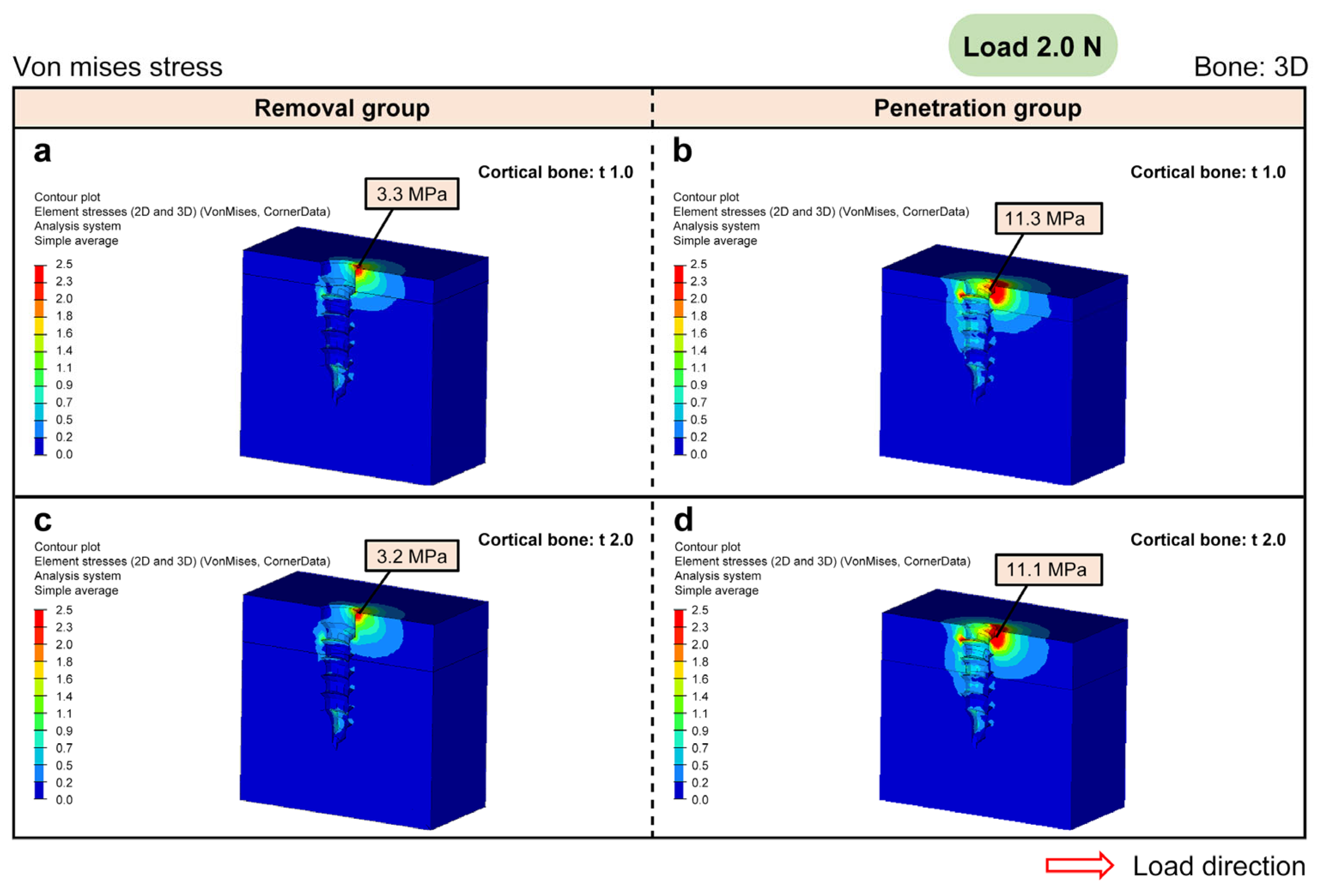

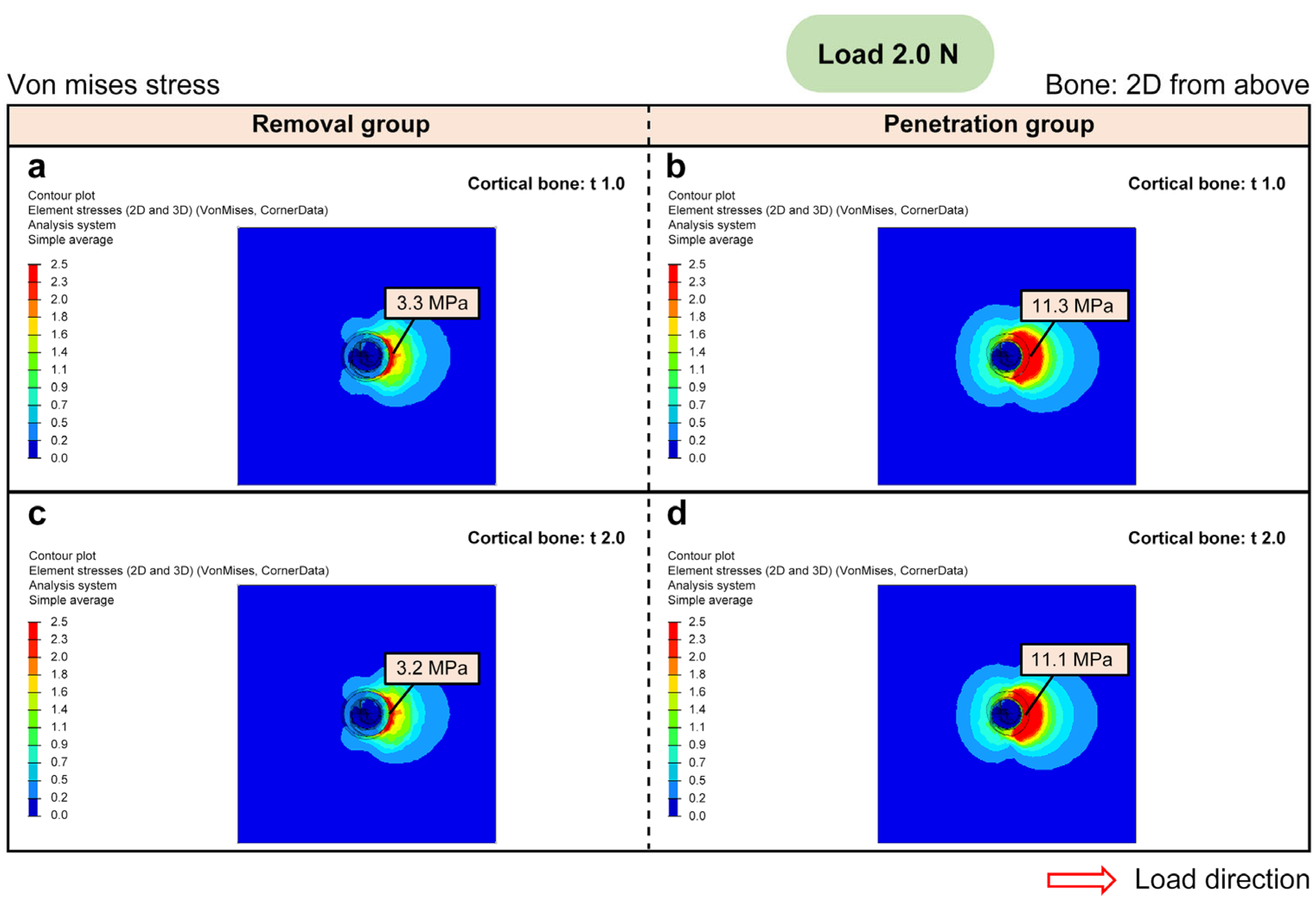

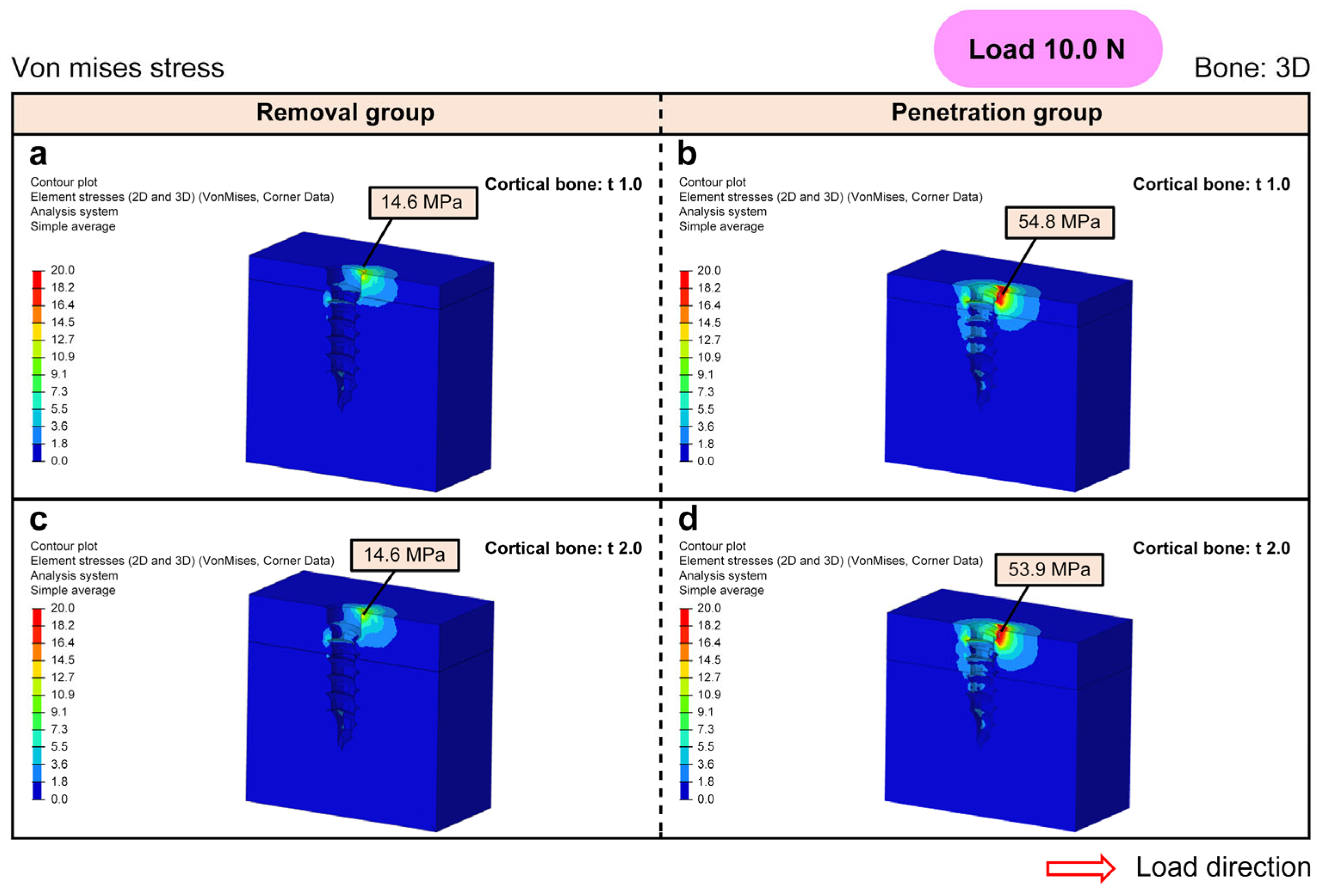

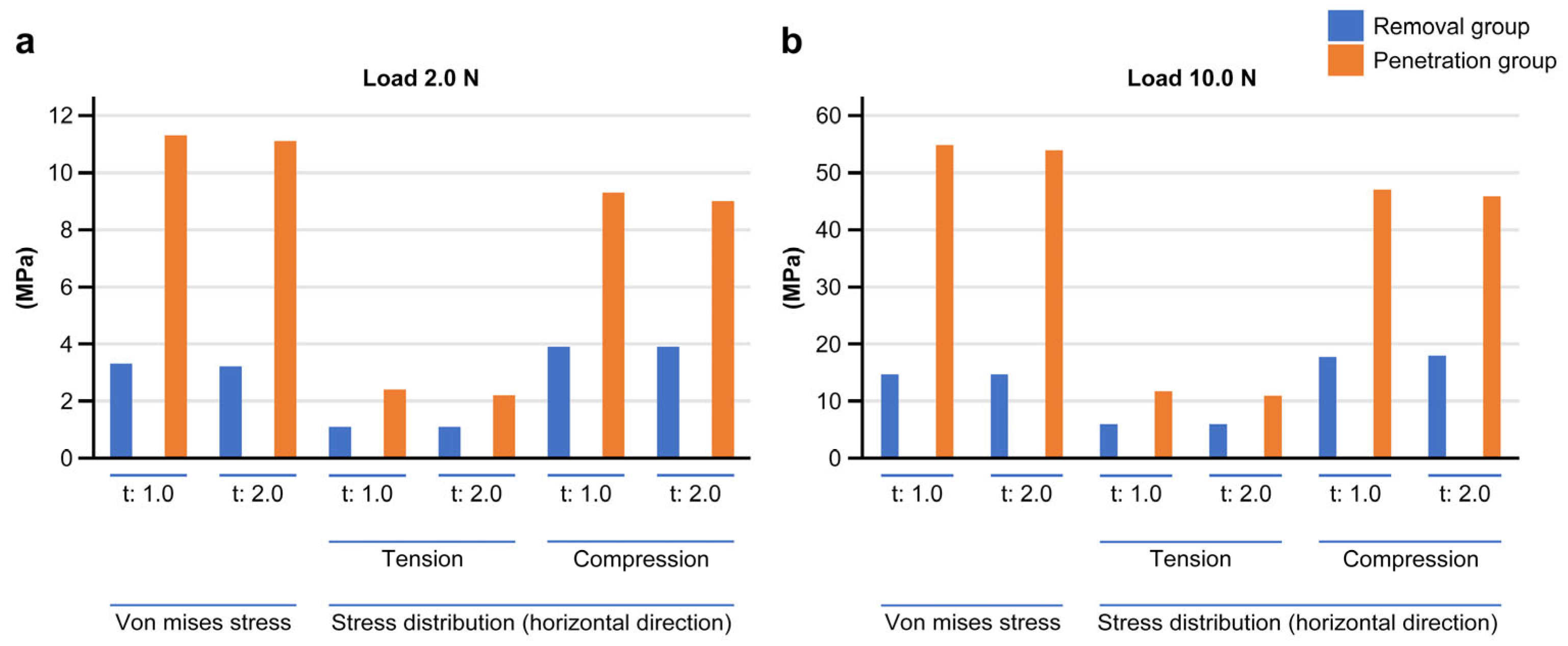

3.2. FEM Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kanomi, R. Mini-Implant for Orthodontic Anchorage. J. Clin. Orthod. 1997, 31, 763–767. [Google Scholar] [PubMed]

- Costa, A.; Raffainl, M.; Melsen, B. Miniscrews as Orthodontic Anchorage: A Preliminary Report. Int. J. Adult Orthod. Orthognath. Surg. 1998, 13, 201–209. [Google Scholar]

- Giancotti, A.; Arcuri, C.; Barlattani, A. Treatment of Ectopic Mandibular Second Molar with Titanium Miniscrews. Am. J. Orthod. Dentofac. Orthop. 2004, 126, 113–117. [Google Scholar] [CrossRef] [PubMed]

- Park, H.S.; Kwon, O.W.; Sung, J.H. Micro-implant Anchorage for Forced Eruption of Impacted Canines. J. Clin. Orthod. 2004, 38, 297–302. [Google Scholar] [PubMed]

- Wilmes, B.; Ottenstreuer, S.; Su, Y.Y.; Drescher, D. Impact of Implant Design on Primary Stability of Orthodontic Mini-Implants. J. Orofac. Orthop. 2008, 69, 42–50. [Google Scholar] [CrossRef]

- Ye, Y.; Yi, W.; Fan, S.; Zhao, L.; Yu, Y.; Lu, Y.; Yao, Q.; Wang, W.; Chang, S. Effect of Thread Depth and Thread Pitch on the Primary Stability of Miniscrews Receiving a Torque Load: A Finite Element Analysis. J. Orofac. Orthop. 2021. online ahead of print. [Google Scholar] [CrossRef]

- Ye, Y.S.; Yi, W.M.; Zhuang, P.L.; Liu, M.; Yu, Y.S.; Lu, Y.J.; Yao, Q.H.; Wang, W.; Chang, S.H. Thread Shape Affects the Stress Distribution of Torque Force on Miniscrews: A Finite Element Analysis. Comput. Methods Biomech. Biomed. Eng. 2020, 23, 1034–1040. [Google Scholar] [CrossRef]

- Gracco, A.; Cirignaco, A.; Cozzani, M.; Boccaccio, A.; Pappalettere, C.; Vitale, G. Numerical/Experimental Analysis of the Stress Field around Miniscrews for Orthodontic Anchorage. Eur. J. Orthod. 2009, 31, 12–20. [Google Scholar] [CrossRef]

- Lombardo, L.; Gracco, A.; Zampini, F.; Stefanoni, F.; Mollica, F. Optimal Palatal Configuration for Miniscrew Applications. Angle Orthod. 2010, 80, 145–152. [Google Scholar] [CrossRef]

- Melsen, B.; Verna, C. Miniscrew Implants: The Aarhus Anchorage System. Semin. Orthod. 2005, 11, 24–31. [Google Scholar] [CrossRef]

- Motoyoshi, M.; Inaba, M.; Ono, A.; Ueno, S.; Shimizu, N. The Effect of Cortical Bone Thickness on the Stability of Orthodontic Mini-Implants and on the Stress Distribution in Surrounding Bone. Int. J. Oral Maxillofac. Surg. 2009, 38, 13–18. [Google Scholar] [CrossRef]

- Motoyoshi, M.; Yoshida, T.; Ono, A.; Shimizu, N. Effect of Cortical Bone Thickness and Implant Placement Torque on Stability of Orthodontic Mini-Implants. Int. J. Oral Maxillofac. Implants 2007, 22, 779–784. [Google Scholar]

- Wang, Z.; Zhao, Z.; Xue, J.; Song, J.; Deng, F.; Yang, P. Pullout Strength of Miniscrews Placed in Anterior Mandibles of Adult and Adolescent Dogs: A Microcomputed Tomographic Analysis. Am. J. Orthod. Dentofac. Orthop. 2010, 137, 100–107. [Google Scholar] [CrossRef]

- Kim, J.W.; Ahn, S.J.; Chang, Y.I. Histomorphometric and Mechanical Analyses of the Drill-Free Screw as Orthodontic Anchorage. Am. J. Orthod. Dentofac. Orthop. 2005, 128, 190–194. [Google Scholar] [CrossRef]

- Wilmes, B.; Su, Y.Y.; Drescher, D. Insertion Angle Impact on Primary Stability of Orthodontic Mini-Implants. Angle Orthod. 2008, 78, 1065–1070. [Google Scholar] [CrossRef]

- Motoyoshi, M.; Hirabayashi, M.; Uemura, M.; Shimizu, N. Recommended Placement Torque When Tightening an Orthodontic Mini-Implant. Clin. Oral Implants Res. 2006, 17, 109–114. [Google Scholar] [CrossRef]

- Stahl, E.; Keilig, L.; Abdelgader, I.; Jäger, A.; Bourauel, C. Numerical Analyses of Biomechanical Behavior of Various Orthodontic Anchorage Implants. J. Orofac. Orthop. 2009, 70, 115–127. [Google Scholar] [CrossRef]

- Liu, T.C.; Chang, C.H.; Wong, T.Y.; Liu, J.K. Finite Element Analysis of Miniscrew Implants Used for Orthodontic Anchorage. Am. J. Orthod. Dentofac. Orthop. 2012, 141, 468–476. [Google Scholar] [CrossRef]

- Miyawaki, S.; Koyama, I.; Inoue, M.; Mishima, K.; Sugahara, T.; Takano-Yamamoto, T. Factors Associated with the Stability of Titanium Screws Placed in the Posterior Region for Orthodontic Anchorage. Am. J. Orthod. Dentofac. Orthop. 2003, 124, 373–378. [Google Scholar] [CrossRef]

- Cheng, S.J.; Tseng, I.Y.; Lee, J.J.; Kok, S.H. A Prospective Study of the Risk Factors Associated with Failure of Mini-Implants Used for Orthodontic Anchorage. Int. J. Oral Maxillofac. Implants 2004, 19, 100–106. [Google Scholar]

- Papadopoulos, M.A.; Tarawneh, F. The Use of Miniscrew Implants for Temporary Skeletal Anchorage in Orthodontics: A Comprehensive Review. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2007, 103, e6–e15. [Google Scholar] [CrossRef]

- Justens, E.; De Bruyn, H. Clinical Outcome of Mini-Screws Used as Orthodontic Anchorage. Clin. Implant Dent. Relat. Res. 2008, 10, 174–180. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.J.; Chang, H.H.; Huang, C.Y.; Hung, H.C.; Lai, E.H.; Yao, C.C. A Retrospective Analysis of the Failure Rate of Three Different Orthodontic Skeletal Anchorage Systems. Clin. Oral Implants Res. 2007, 18, 768–775. [Google Scholar] [CrossRef] [PubMed]

- Crismani, A.G.; Bertl, M.H.; Celar, A.G.; Bantleon, H.P.; Burstone, C.J. Miniscrews in Orthodontic Treatment: Review and Analysis of Published Clinical Trials. Am. J. Orthod. Dentofac. Orthop. 2010, 137, 108–113. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, F.; Almuzian, M.; Bearn, D. Miniscrews Failure Rate in Orthodontics: Systematic Review and Meta-Analysis. Eur. J. Orthod. 2018, 40, 519–530. [Google Scholar] [CrossRef] [PubMed]

- Deguchi, T.; Takano-Yamamoto, T.; Kanomi, R.; Hartsfield, J.K., Jr.; Roberts, W.E.; Garetto, L.P. The Use of Small Titanium Screws for Orthodontic Anchorage. J. Dent. Res. 2003, 82, 377–381. [Google Scholar] [CrossRef]

- Park, H.S.; Kwon, T.G. Sliding Mechanics with Microscrew Implant Anchorage. Angle Orthod. 2004, 74, 703–710. [Google Scholar] [CrossRef]

- Cope, J.B. Temporary Anchorage Devices in Orthodontics: A Paradigm Shift. Semin. Orthod. 2005, 11, 3–9. [Google Scholar] [CrossRef]

- Motoyoshi, M.; Ueno, S.; Okazaki, K.; Shimizu, N. Bone Stress for a Mini-Implant Close to the Roots of Adjacent Teeth—3D Finite Element Analysis. Int. J. Oral Maxillofac. Surg. 2009, 38, 363–368. [Google Scholar] [CrossRef]

- Park, H.S.; Lee, S.K.; Kwon, O.W. Group Distal Movement of Teeth Using Microscrew Implant Anchorage. Angle Orthod. 2005, 75, 602–609. [Google Scholar] [CrossRef]

- Parmar, R.; Reddy, V.; Reddy, S.K.; Reddy, D. Determination of Soft Tissue Thickness at Orthodontic Miniscrew Placement Sites Using Ultrasonography for Customizing Screw Selection. Am. J. Orthod. Dentofac. Orthop. 2016, 150, 651–658. [Google Scholar] [CrossRef]

- Luzi, C.; Verna, C.; Melsen, B. Guidelines for Success in Placement of Orthodontic Mini-Implants. J. Clin. Orthod. 2009, 43, 39–44. [Google Scholar]

- Hong, S.B.; Kusnoto, B.; Kim, E.J.; BeGole, E.A.; Hwang, H.S.; Lim, H.J. Prognostic Factors Associated with the Success Rates of Posterior Orthodontic Miniscrew Implants: A Subgroup Meta-Analysis. Korean J. Orthod. 2016, 46, 111–126. [Google Scholar] [CrossRef]

| Component | Material | Young’s Modulus [MPa] | Poisson’s Ratio | Density [ton/mm3] |

|---|---|---|---|---|

| Mini-screw | Titanium alloy | 110,000 | 0.33 | 4.5 × 10−9 |

| Cortical bone | — | 18,000 | 0.3 | 0.9 × 10−9 |

| Cancellous bone | — | 13,700 | 0.3 | 0.9 × 10−9 |

| Case | Load [N] | Cortical Bone Thickness [mm] | Screw-Bone Distance [μm] | Element | Count | |

|---|---|---|---|---|---|---|

| Screw | Cortical Bone | Cancellous Bone | ||||

| 1–1 | 2.0 | 1.0 | 0.0 | 6601 | 17,957 | 124,262 |

| 1–2 | 2.0 | 1.0 | 765.6 | 6601 | 19,365 | 111,551 |

| 1–3 | 2.0 | 2.0 | 0.0 | 6601 | 38,807 | 88,182 |

| 1–4 | 2.0 | 2.0 | 765.6 | 6601 | 32,821 | 98,220 |

| 2–1 | 10.0 | 1.0 | 0.0 | 6601 | 17,957 | 124,262 |

| 2–2 | 10.0 | 1.0 | 765.6 | 6601 | 19,365 | 111,551 |

| 2–3 | 10.0 | 2.0 | 0.0 | 6601 | 38,807 | 88,182 |

| 2–4 | 10.0 | 2.0 | 765.6 | 6601 | 32,821 | 98,220 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tokuyama-Toda, R.; Umeki, H.; Ide, S.; Kobayashi, F.; Tooyama, S.; Umehara, M.; Tadokoro, S.; Tomonari, H.; Satomura, K. A New Implantation Method for Orthodontic Anchor Screws: Basic Research for Clinical Applications. Biomedicines 2023, 11, 665. https://doi.org/10.3390/biomedicines11030665

Tokuyama-Toda R, Umeki H, Ide S, Kobayashi F, Tooyama S, Umehara M, Tadokoro S, Tomonari H, Satomura K. A New Implantation Method for Orthodontic Anchor Screws: Basic Research for Clinical Applications. Biomedicines. 2023; 11(3):665. https://doi.org/10.3390/biomedicines11030665

Chicago/Turabian StyleTokuyama-Toda, Reiko, Hirochika Umeki, Shinji Ide, Fumitaka Kobayashi, Shunnosuke Tooyama, Mai Umehara, Susumu Tadokoro, Hiroshi Tomonari, and Kazuhito Satomura. 2023. "A New Implantation Method for Orthodontic Anchor Screws: Basic Research for Clinical Applications" Biomedicines 11, no. 3: 665. https://doi.org/10.3390/biomedicines11030665

APA StyleTokuyama-Toda, R., Umeki, H., Ide, S., Kobayashi, F., Tooyama, S., Umehara, M., Tadokoro, S., Tomonari, H., & Satomura, K. (2023). A New Implantation Method for Orthodontic Anchor Screws: Basic Research for Clinical Applications. Biomedicines, 11(3), 665. https://doi.org/10.3390/biomedicines11030665