Life Cycle Assessment of Industrial Building Construction and Recovery Potential. Case Studies in Seville

Abstract

:1. Introduction

1.1. Industrial Building Assessment

1.2. Life Cycle Assessment of Architectural Projects and Construction Materials

1.3. The Proposal

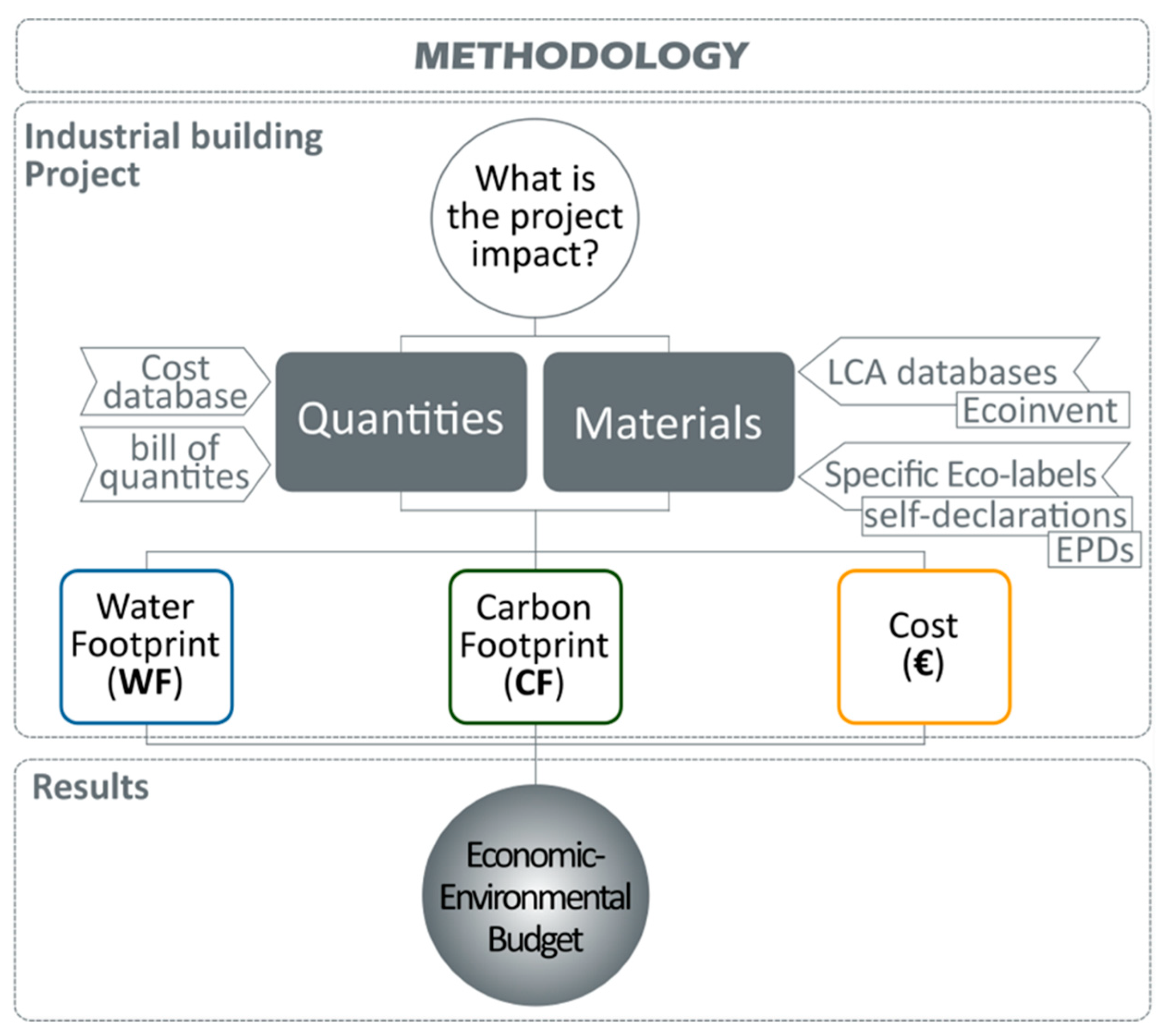

2. Materials and Methods

2.1. Work Units Classification

2.2. Environmental Analysis

3. Case Studies

3.1. RecoverIND Project

3.2. Actual Projects

- Classification of industrial buildings based on specific construction criteria of the buildings. This included the following as the most important aspects: (industrial) use, number of floors, foundation, structure, roof, roof support, envelope, height and wall-to-wall width.

- Performing the survey. The surveys were carried out to obtain the characteristics and quantities (Q) of work. Each survey was divided into two parts: the first was aimed at identifying the project according to the typology and the period in which it was carried out; the second collected the values of each of the different concepts into which each system is divided. This was organized according to a new classification model based on the ACCD [41], which can be found in Table A1 in Appendix A. Based on the economic budget, the survey gathered data on the amount of each construction element (in its corresponding unit) per m2 of floor area (see Table 3).

- Analysis of the construction typologies of industrial buildings. The survey study was carried out in three municipalities of Los Alcores. A total of 87 industrial buildings were studied, 28 in Alcalá, 29 in Carmona and 30 in Mairena del Alcor.

- Obtaining average statistical values of each construction element per m2 of floor area for the identified as most representative building typologies. These average values are obtained from the interquartile range of 75%, to eliminate discordant extreme values.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Code | Unit | Description |

| 02 | EARTH WORK | |

| 02EX | m3 | Open excavation |

| 02RR | m3 | Refilling and compacting |

| 02TX | m3 | Transport |

| 03 | FOUNDATION | |

| 03AX | kg | Rebars |

| 03CP | m | Piles |

| 03EX | m2 | Formwork |

| 03HA | m3 | Reinforced concrete |

| 03HM | m3 | Bulk concrete |

| 04 | SEWAGE | |

| 04EA | u | Manholes and pits |

| 04EC | m | Underground pipeline |

| 04VB | m | Vertical pipelines |

| 05 | STRUCTURE | |

| 05AC | kg | Hot rolled steel |

| 05AF | Kg | Cold rolled steel |

| 05FX | m2 | Concrete slab |

| 05HA | kg | Steel rebar |

| 05HE | m2 | Formwork |

| 05HH | m3 | Reinforced concrete |

| 05MX | m3 | Structure wood |

| 06 | BRICK WORK | |

| 06BZ | m2 | Wall made of concrete blocks |

| 06DX | m2 | Chamber wall made with bricks |

| 06DY | m2 | Partitions made with bricks |

| 06LX | m2 | Brick exterior wall |

| 06LY | m2 | Brick interior wall |

| 06LZ | m2 | Masonry walls |

| 06PA | m2 | Metal precast |

| 06PH | m2 | Precast concrete |

| 07 | ROOF | |

| 07HX | m2 | Horizontal roof |

| 07IX | m2 | Sloping roof |

| 08 | INSTALLATIONS | |

| 08CA | u | Air conditioning and hot water |

| 08CC | m | Air conditioning ducts |

| 08EC | m | Electric circuits |

| 08ED | m | Electric bypass |

| 08EL | u | Lights |

| 08ET | u | Electric socket |

| 08EP | m | Grounding conductor |

| 08FF | m | Water pipes |

| 08FS | u | Bathroom sanitary ware |

| 09 | INSULATION | |

| 09AX | m2 | Acoustic |

| 09TX | m2 | Thermal |

| 10 | FINISHES | |

| 10AA | m2 | Tiles |

| 10AC | m2 | Front plates |

| 10CE | m2 | Continuous |

| 10CG | m2 | Continuous light weight |

| 10SC | m2 | Ceramic floor |

| 10SN | m2 | Natural stone floor |

| 10SX | m2 | Light weight floor |

| 10SY | m2 | Medium weight floor |

| 10SZ | m2 | High weight floor |

| 10TX | m2 | Ceiling |

| 10RX | m | Windowsill |

| 11 | CARPENTRY AND SAFETY | |

| 11AX | m2 | Steel |

| 11LX | m2 | Aluminum |

| 11MX | m2 | Wood |

| 12 | GLASS AND POLYESTER | |

| 12XX | m2 | Glass |

| 13 | PAINT | |

| 13EX | m2 | Exterior |

| 13IX | m2 | Interior |

References

- United Nations UN General Assembly Resolution on The Future we Want (Adopted on 27 July 2012); UN General Assembly: Rio de Janeiro, Brazil, 2012; pp. 1–53.

- Renukappa, S.; Akintoye, A.; Egbu, C.; Suresh, S. Sustainable procurement strategies for competitive advantage: An empirical study. Proc. Inst. Civ. Eng.-Manag. Procure. Law 2016, 169, 17–25. [Google Scholar] [CrossRef] [Green Version]

- San-José Lombera, J.T.; Garrucho Aprea, I. A system approach to the environmental analysis of industrial buildings. Build. Environ. 2010, 45, 673–683. [Google Scholar] [CrossRef]

- San-José Lombera, J.T.; Cuadrado Rojo, J. Industrial building design stage based on a system approach to their environmental sustainability. Constr. Build. Mater. 2010, 24, 438–447. [Google Scholar] [CrossRef]

- Bonamente, E.; Cotana, F. Carbon and energy footprints of prefabricated industrial buildings: A systematic life cycle assessment analysis. Energies 2015, 8, 12685–12701. [Google Scholar] [CrossRef] [Green Version]

- Tulevech, S.M.; Hage, D.J.; Jorgensen, S.K.; Guensler, C.L.; Himmler, R.; Gheewala, S.H. Life cycle assessment: A multi-scenario case study of a low-energy industrial building in Thailand. Energy Build. 2018, 168, 191–200. [Google Scholar] [CrossRef]

- Opher, T.; Duhamel, M.; Posen, I.D.; Panesar, D.K.; Brugmann, R.; Roy, A.; Zizzo, R.; Sequeira, L.; Anvari, A.; MacLean, H.L. Life cycle GHG assessment of a building restoration: Case study of a heritage industrial building in Toronto, Canada. J. Clean. Prod. 2021, 279, 123819. [Google Scholar] [CrossRef]

- Shubbar, A.; Nasr, M.; Falah, M.; Al-Khafaji, Z. Towards net zero carbon economy: Improving the sustainability of existing industrial infrastructures in the uk. Energies 2021, 14, 5896. [Google Scholar] [CrossRef]

- Heravi, G.; Fathi, M.; Faeghi, S. Evaluation of sustainability indicators of industrial buildings focused on petrochemical projects. J. Clean. Prod. 2015, 109, 92–107. [Google Scholar] [CrossRef]

- Židoniene, S.; Kruopiene, J. Life Cycle Assessment in environmental impact assessments of industrial projects: Towards the improvement. J. Clean. Prod. 2015, 106, 533–540. [Google Scholar] [CrossRef]

- Kovacic, I.; Waltenbereger, L.; Gourlis, G. Tool for life cycle analysis of facade-systems for industrial buildings. J. Clean. Prod. 2016, 130, 260–272. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M.; Pošiváková, T. Analysis of selected building constructions used in industrial construction in terms of sustainability benefits. Sustainability 2018, 10, 4394. [Google Scholar] [CrossRef] [Green Version]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Begum, R.A.; Satari, S.K.; Pereira, J.J. Waste Generation and Recycling: Comparison of Conventional and Industrialized Building Systems. Am. J. Environ. Sci. 2010, 6, 383–388. [Google Scholar] [CrossRef] [Green Version]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the impact of prefabrication on construction waste reduction: An empirical study in China. Resour. Conserv. Recycl. 2014, 91, 27–39. [Google Scholar] [CrossRef] [Green Version]

- Lu, W.; Lee, W.M.W.; Xue, F.; Xu, J. Revisiting the effects of prefabrication on construction waste minimization: A quantitative study using bigger data. Resour. Conserv. Recycl. 2021, 170, 105579. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Environmental impacts of construction and demolition waste management alternatives. Chem. Eng. Trans. 2018, 63, 343–348. [Google Scholar] [CrossRef]

- Lützkendorf, T. Sustainability in Building Construction-A Multilevel Approach. Junio 2019. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Prague, Czech Republic, 2–4 July 2019; Volume 290. [Google Scholar]

- International Organization for Standardization. ISO 14040; Environmental Management, Life Cycle Assessment, Principles and Framework. ISO: Geneva, Switzerland, 2006.

- International Organization for Standardization. ISO 14044; Environmental Management, Life Cycle Assessment, Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- LPSC_9/2017 Law 9/2017 of 8 November, on Public Sector Contracts, which Transposes into Spanish Law the Directives of the European Parliament and Council 2014/23/EU and 2014/24/EU, of 26 February 2014; Government of Spain: Madrid, Spain, 2017.

- Orden, P.C.I. 86/2019, de 31 de Enero, por la que se Publica el Acuerdo del Consejo de Ministros de 7 de diciembre de 2018, por el que se Aprueba el Plan de Contratación Pública Ecológica de la Administración General del Estado, sus Organismos Autónomos; 2019; pp. 9572–9597. Available online: https://www.boe.es/diario_boe/txt.php?id=BOE-A-2019-1394 (accessed on 24 November 2021). (In Spanish)

- BREEAM BREEAM International New Construction 2016, Technical Manual, Version: SD233 2.0. Available online: https://tools.breeam.com/filelibrary/Technical Manuals/BREEAM_International_NC_2016_Technical_Manual_2.0.pdf (accessed on 15 December 2021).

- SpainGBC LEED en España 2015. Available online: http://www.spaingbc.org/web/detalle-noticia.php?id=91 (accessed on 15 December 2021).

- Ecómetro Association Ecómetro. Association for the Measurement and Diffusion of Ecology in Architecture. Available online: http://ecometro.org/ (accessed on 15 December 2021).

- ITeC Construction Cost Database (BEDEC). Available online: https://itec.es/servicios/bedec/?gclid=EAIaIQobChMI57HB4MTm9AIVlfhRCh1wdwThEAAYASAAEgI8OPD_BwE (accessed on 30 November 2021).

- SOFIA Situated learning Opportunities Fostered by ICT Applications in Alternative Agro-Food Networks (SOFIA). Available online: https://cordis.europa.eu/project/id/702884 (accessed on 30 November 2021).

- e2CO2cero Software to calculate the Embodied Energy and Carbon Footprint of buildings in a simple way. Available online: http://online.e2co2cero.com/ (accessed on 15 December 2021).

- Ruiz-Pérez, M.R.; Alba-Rodríguez, M.D.; Rivero-Camacho, C.; Solís-Guzmán, J.; Marrero, M. The budget as a basis for ecological management of urbanization projects. Case study in Seville, Spain. Sustainability 2021, 13, 4078. [Google Scholar] [CrossRef]

- INE Encuesta Industrial de Empresas. Serie 2008–2014. CNAE-2009. Número de Empresas por Sectores de Actividad. Available online: https://www.ine.es/jaxiT3/Datos.htm?t=2539 (accessed on 24 November 2021).

- Freire-Guerrero, A.; Alba-Rodríguez, M.D.; Marrero, M. A budget for the ecological footprint of buildings is possible: A case study using the dwelling construction cost database of Andalusia. Sustain. Cities Soc. 2019, 51, 101737. [Google Scholar] [CrossRef]

- Marrero, M.; Wojtasiewicz, M.; Martínez-Rocamora, A.; Solís-Guzmán, J.; Alba-Rodríguez, M.D. BIM-LCA integration for the environmental impact assessment of the urbanization process. Sustainability 2020, 12, 4196. [Google Scholar] [CrossRef]

- Marrero, M.; Rivero-Camacho, C.; Alba-Rodríguez, M.D. What are we discarding during the life cycle of a building? Case studies of social housing in Andalusia, Spain. Waste Manag. 2020, 102, 391–403. [Google Scholar] [CrossRef]

- Construction Specifications Institute/Construction Specifications Canada (CSI/CSC). Masterformat Manual of Practice (MP2-1); Construction Specifications Institute: Alexandria, VA, USA; Construction Specifications Canada: Toronto, ON, Canada, 1983. [Google Scholar]

- Jones, A.R. CI/SfB Construction Indexing Manual; RIBA Publishing: London, UK, 1987. [Google Scholar]

- Telford, T. Civil Engineering Standard Method of Measurement, 3rd ed.; The Institution of Civil Engineers and The Federation of Civil Engineering Contractors: London, UK, 1991; pp. 4–39. [Google Scholar]

- UniFormat™ A Uniform Classification of Construction Systems and Assemblies; The Construction Specifications Institute: Alexandria, VA, USA, 1998.

- Omniclass. Omniclass™: A Strategy for Classifying the Built Environment—Table 13: Spaces by Function; The Construction Specifications Institute: Alexandria, VA, USA, 2012. [Google Scholar]

- Marrero, M.; Ramirez-de-Arellano, A. The building cost system in Andalusia: Application to construction and demolition waste management. Constr. Manag. Econ. 2010, 28, 495–507. [Google Scholar] [CrossRef]

- Ministry of Development and Housing Andalusian Construction Cost Database (ACCD). Available online: https://www.juntadeandalucia.es/organismos/fomentoinfraestructurasyordenaciondelterritorio/areas/vivienda-rehabilitacion/planes-instrumentos/paginas/bcca-sept-2017.html (accessed on 30 November 2021).

- Alba-Rodríguez, M.D.; Machete, R.; Glória Gomes, M.; Paula Falcão, A.; Marrero, M. Holistic model for the assessment of restoration projects of heritage housing. Case studies in Lisbon. Sustain. Cities Soc. 2021, 67, 102742. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Freire Guerrero, A.; Marrero Meléndez, M.; Muñoz Martín, J. Incorporación de huella de carbono y huella ecológica en las bases de costes de construcción. Estudio de caso de un proyecto de urbanización en Écija, España. Hábitat Sustentable 2016, 6, 6–17. (In Spanish) [Google Scholar] [CrossRef] [Green Version]

- Solís-Guzmán, J.; Martínez-Rocamora, A.; Marrero, M. Methodology for Determining the Carbon Footprint of the Construction of Residential Buildings; Springer: Singapore, 2014; pp. 49–83. [Google Scholar]

- Solís-Guzmán, J.; Rivero-Camacho, C.; Alba-Rodríguez, D.; Martínez-Rocamora, A. Carbon Footprint Estimation Tool for Residential Buildings for Non-Specialized Users: OERCO2 Project. Sustainability 2018, 10, 1359. [Google Scholar] [CrossRef] [Green Version]

- Chastas, P.; Theodosiou, T.; Kontoleon, K.J.; Bikas, D. Normalising and assessing carbon emissions in the building sector: A review on the embodied CO 2 emissions of residential buildings. Build. Environ. 2018, 130, 212–226. [Google Scholar] [CrossRef]

- Ruiz-Pérez, M.R.; Alba Rodríguez, M.D.; Marrero, M. Systems of Water Supply and Sanitation for Domestic Use. In Proceedings of the Water Footprint and Carbon Footprint Evaluation: First Results; IV International Congress on Construction and Building Research—Santa Cruz de Tenerife, Tenerife, Spain, 14–15 December 2017. [Google Scholar]

- Ruiz-Pérez, M.R.; Alba-Rodríguez, M.D.; Marrero, M. The water footprint of city naturalisation. Evaluation of the water balance of city gardens. In Proceedings of the 22nd biennial conference of The International Society for Ecological Modelling (ISEM), Salzburg, Austria, 30 September–4 October 2019. [Google Scholar]

- WFN Water Footprint Network. Available online: https://waterfootprint.org/en/ (accessed on 15 December 2021).

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. Water Footprint Manual: State of the Art 2009; Faculty of Engineering Technology, University of Twente: Enschede, The Netherlands, 2009. [Google Scholar]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual; Routledge: Abingdon-on-Thames, UK, 2011; ISBN 9781849712798. [Google Scholar]

- Martínez-Rocamora, A.; Solís-Guzmán, J.; Marrero, M. LCA databases focused on construction materials: A review. Renew. Sustain. Energy Rev. 2016, 58, 565–573. [Google Scholar] [CrossRef]

- ISO 15804:2012+A1:2013 Sustainability of Construction Works. Environmental Product Declarations. Core Rules for the Product Category of Construction Products; ISO: Geneva, Switzerland, 2012.

- IDAE Factores de emisión de CO2/CO2 Emission Factors. Available online: http://www.idae.es/uploads/documentos/documentos_Factores_Conversion_Energia_y_CO2_2011_0a9cb734.pdf (accessed on 4 August 2015).

- REE Informe del Sistema Eléctrico Español 2020/Report on the Spanish Electricity System 2020. Available online: https://www.ree.es/es/datos/publicaciones/informe-anual-sistema/informe-del-sistema-electrico-espanol-2020 (accessed on 15 December 2021).

- IDAE Factores de emisión de CO2 y coeficientes de paso a energía primaria de diferentes fuentes de energía final consumidas en el sector de edificios de España/CO2 emission factors and transformation coefficients of different final energy sources consumed by. Available online: https://energia.gob.es/desarrollo/EficienciaEnergetica/RITE/Reconocidos/Reconocidos/Otros documentos/Factores_emision_CO2.pdf (accessed on 15 December 2021). (In Spanish).

- IETcc. Catálogo de Elementos Constructivos del CTE; Instituto Eduardo Torroja de Ciencias de la Construcción (IETcc): Madrid, Spain, 2010. (In Spanish) [Google Scholar]

- Spanish Ministry of Housing. Royal Decree 314/2006 of 17 March 2006, Approving the Technical Building Code; Spanish Ministry of Housing: Madrid, Spain, 2006; ISBN 843401632X. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G. The ecoinvent database: Overview and methodological framework (7 pp). Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- Ecoinvent Association Ecoinvent Database v3. Available online: http://www.ecoinvent.org/database/database.html (accessed on 28 March 2018).

- REE. El Sistema Eléctrico Español/The Spanish Electric System; REE: Madrid, Spain, 2014. [Google Scholar]

- Hoekstra, A.Y. Virtual water trade between nations: A global mechanism affecting regional water systems. IGBP Glob. Chang. News Lett. 2003, 54, 2–4. [Google Scholar]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef]

- Marrero, M.; Puerto, M.; Rivero-Camacho, C.; Freire-Guerrero, A.; Solís-Guzmán, J. Assessing the economic impact and ecological footprint of construction and demolition waste during the urbanization of rural land. Resour. Conserv. Recycl. 2017, 117, 160–174. [Google Scholar] [CrossRef]

- UniTBv; US; RoGBC; CTM; Datacomp; FPiP; Poznan, P. Erasmus+ Project RecoverIND Website. Available online: www.recoverind.eu (accessed on 24 November 2021).

- González-Vallejo, P.; Muntean, R.; Solís-Guzmán, J.; Marrero, M. Carbon footprint of dwelling construction in Romania and Spain. A comparative analysis with the OERCO2 tool. Sustainability 2020, 12, 6745. [Google Scholar] [CrossRef]

- Scheuer, C.; Keoleian, G.A.; Reppe, P. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Life cycle energy assessment of a typical office building in Thailand. Energy Build. 2009, 41, 1076–1083. [Google Scholar] [CrossRef]

- EHE. Real Decreto 1247/2008, de 18 de Julio, por el que se Aprueba la Instrucción de Hormigón Estructural (EHE-08). Royal Decree 1247/2008, of July 18, which Approves the Structural Concrete Instruction (EHE-08); 2008; Available online: https://www.boe.es/buscar/doc.php?id=BOE-A-2008-14167 (accessed on 24 November 2021). (In Spanish)

- National Statistics Institute. Estadísticas Sobre la Recogida y Tratamiento de Residuos 2019; National Statistics Institute: Madrid, Spain, 2019. (In Spanish) [Google Scholar]

- Redcicla Construcción/Construction. Available online: http://www.redcicla.com/construccion.html (accessed on 15 December 2021).

| ACCDC ode | Cost (€) | Unit | Description | Volume (m3) | Density (kg/m3) | Weight (kg) | Source | ||

|---|---|---|---|---|---|---|---|---|---|

| X | Y | Z | |||||||

| AG00100 | 10.86 | m3 | Gravel | 1.00 | 1.00 | 1.00 | 1784.00 | 1784.000 | [58] |

| CA80030 | 3.78 | kg | Steel triangular section mesh | 1.00 | 1.00 | 1.00 | 1.00 | 1.000 | [58] |

| CH80200 | 157.08 | m3 | Light concrete-25 N/mm2 | 1.00 | 1.00 | 1.00 | 2 549.25 | 2549.250 | [59] |

| FB80200 | 2.14 | u | Concrete block 50 × 20 × 25 cm | 0.50 | 0.20 | 0.25 | 900.00 | 22.500 | [58] |

| IE02600 | 4.43 | m | Copper wire 1 × 16 mm2 H07V-K(AS) | 1.00 | 16.00 | 10−6 | 880.00 | 0.0141 | [58] |

| PA00500 | 1.71 | Kg | Acrylic paint | 1.00 | 1.00 | 1.00 | 1.00 | 1.000 | [58] |

| QP00800 | 3.99 | m | Sheet flashing for sandwich panel. Polyester | 1.00 | 0.50 | 0.005 | 1140.00 | 2.085 | [59] |

| QP02000 | 22.70 | m2 | Sandwich panel 30 mm polyester | 1.00 | 1.00 | 0.03 | 1223.64 | 36.709 | [59] |

| RA00300 | 0.17 | u | Soft solid color tile 15 × 15 cm | 0.15 | 0.15 | 0.01 | 2300.00 | 0.518 | [58] |

| WW00300 | 0.55 | u | Special small material | 0.10 | 0.005 | 0.005 | 8004.65 | 0.020 | [59] |

| Constructive Element | Waste Origin | Waste Generated | CR | CC | CT |

|---|---|---|---|---|---|

| Sandwich panel for cover | Sandwich panel | Losses | 0.01 | 0.367 | 1.00 |

| Wooden | Packaging | 0.05 | 9.380 | 1.00 | |

| Plastic | Packaging | 1.00 | 0.006 | 1.00 | |

| Steel (kg) | Steel | Losses | 0.01 | 0.001 | 1.00 |

| Paint (kg) | Container | Packaging | 1.00 | 0.035 | 1.00 |

| Wooden | Packaging | 0.05 | 0.00025 | 1.00 | |

| Plastic | Packaging | 1.00 | 1.28 × 10−5 | 1.00 | |

| Lighting circuit (m) | Copper | Losses | 0.05 | 0.829 | 1.00 |

| Wood | Packaging | 0.05 | 0.001 | 1.00 | |

| Earth excavation (m3) | Soil | Excavation | 1.00 | 1.000 | 1.25 |

| Join cover of roof | Plastic | Losses | 0.01 | 2.000 | 1.00 |

| High-density polyethylene water pipe | HDPE | Losses | 0.05 | 0.00213 | 1.00 |

| Sand | Losses | 0.01 | 0.065 | 1.00 | |

| Reinforced concrete | Concrete | Losses | 0.05 | 1.000 | 1.00 |

| Project N1 | Project N2 | Project N3 | |

|---|---|---|---|

| LOCALIZATION | |||

| Municipality | Carmona | Alcalá de Guadaira | Mairena del Alcor |

| Plastic | Seville | Seville | Seville |

| Community | Los Alcores | Los Alcores | Los Alcores |

| DIMENSIONS | |||

| Floor area (m2) | 673.88 | 464.45 | 787.90 |

| Number of floors | 1 | 1 | 1 |

| Total height of building (m) | 7.90 | 8.84 | 7.50 |

| Total width of building (m) | 20.00 | 10.00 | 30.10 |

| CONSTRUCTIVE FEATURES | Heavy slab, continuous trench, metal structure, heavy enclosure executed on site with concrete blocks and sloping sheet metal in roof. | Heavy slab, insulated footing, concrete structure, precast enclosure, and sloping roof with sandwich panel. | Semi-heavy slab, piles, metal structure, precast enclosure, and sloping roof with precast panels. |

| IMAGES | |||

| Exterior |  |  |  |

| Interior |  |  |  |

| Code | Unit | Description | N1 | N2 | N3 |

|---|---|---|---|---|---|

| 02 | EARTH WORK | ||||

| 02EX | m3 | Open excavation | 0.09 | 1.17 | 0.10 |

| 02RR | m3 | Refilling and compacting | 0.00 | ||

| 02TX | m3 | Transport | 0.11 | 0.22 | 0.13 |

| 03 | FOUNDATION | ||||

| 03AX | kg | Rebars | 15.70 | 0.65 | 3.99 |

| 03EX | m2 | Formwork | 0.36 | ||

| 03HA | m3 | Reinforced concrete | 0.07 | 0.11 | 0.09 |

| 03HM | m3 | Bulk concrete | 0.01 | 0.17 | 0.01 |

| 04 | SEWAGE | ||||

| 04EA | u | Manholes and pits | 0.01 | 0.03 | 0.01 |

| 04EC | m | Underground pipeline | 0.12 | 0.16 | 0.04 |

| 04VB | m | Vertical pipelines | 0.08 | 0.08 | 0.02 |

| 05 | STRUCTURE | ||||

| 05AC | kg | Hot rolled steel | 4.11 | 19.55 | |

| 05AF | Kg | Cold rolled steel | 5.66 | ||

| 05FX | m2 | Concrete slab | 1.03 | ||

| 05HA | kg | Steel rebar | 0.69 | ||

| 06 | BRICK WORK | ||||

| 06BZ | m2 | Wall made of concrete blocks | 0.61 | ||

| 06PH | m2 | Precast concrete | 1.28 | 2.19 | |

| 07 | ROOF | ||||

| 07IX | m2 | Sloping roof | 0.79 | 0.93 | 0.93 |

| 08 | INSTALLATIONS | ||||

| 08EC | m | Electric circuits | 0.09 | 0.35 | |

| 08ED | m | Electric bypass | 0.06 | 0.01 | |

| 08EL | u | Lights | 0.01 | 0.07 | |

| 08ET | u | Electric socket | 0.02 | 0.05 | |

| 08EP | m | Grounding conductor | 0.00 | 0.38 | |

| 08FF | m | Water pipes | 0.01 | 0.10 | |

| 08FS | u | Bathroom sanitary ware | 0.00 | 0.01 | |

| 10 | FINISHES | ||||

| 10AA | m2 | Tiles | 0.02 | ||

| 10SC | m2 | Ceramic floor | 0.00 | ||

| 10SY | m2 | Medium weight floor | 0.99 | ||

| 10SZ | m2 | High weight floor | 1.00 | 0.20 | |

| 10RX | m | Windowsill | 0.02 | ||

| 11 | CARPENTRY AND SAFETY | ||||

| 11AX | m2 | Steel | 0.00 | 0.07 | 0.03 |

| 11LX | m2 | Aluminium | 0.07 | 0.07 | |

| 12 | GLASS AND POLYESTER | ||||

| 12XX | m2 | Glass | 0.03 | ||

| 13 | PAINT | ||||

| 13EX | m2 | Exterior | 0.02 | ||

| 13IX | m2 | Interior | 0.15 |

| Material Family | N1 (kg) | N1 (kg/m2) | N2 (kg) | N2 (kg/m2) | N3 (kg) | N3 (kg/m2) |

|---|---|---|---|---|---|---|

| Concrete and cement | 927,550 | 1177.2 | 739,335 | 1591.8 | 952,434 | 1413.3 |

| Ceramic and bricks | 9776 | 12.4 | 5763 | 12.4 | 8361 | 12.4 |

| Wood | 3990 | 5.0 | 3342 | 7.1 | 2533 | 3.7 |

| Metals and alloys | 41,755 | 52.9 | 16,865 | 36.3 | 32,788 | 48.6 |

| Plastics | 2649 | 3.3 | 4079 | 8.7 | 3166 | 4.6 |

| Water | 6007 | 7.6 | 5885 | 12.6 | 3137 | 4.6 |

| Aggregates and stones | 271,077 | 344.0 | 181,726 | 391.2 | 209,129 | 310.3 |

| Others | 36,223 | 45.9 | 25546 | 55.0 | 36,808 | 54.6 |

| TOTAL | 1,299,031 | 1648.7 | 982,543 | 2115.5 | 1,248,359 | 1.852.5 |

| Project | N1 | N2 | N3 (Concrete Block) | N3 (Precast Concrete) |

|---|---|---|---|---|

| Budget (€) | 181,623 | 137,964 | 208,182 | 190,879 |

| Cost per floor area (€/m2) | 230.52 | 297.05 | 308.93 | 283.25 |

| Carbon footprint (tCO2eq) | 271.36 | 204.043 | 234.949 | 232,442 |

| Carbon footprint (tCO2eq/m2) | 0.34 | 0.44 | 0.349 | 0.35 |

| Water footprint (m3) | 8423 | 6778 | 7407 | 7,62 |

| Water footprint (m3/m2) | 10.69 | 14.60 | 10.992 | 11.30 |

| CDW (t total) | 39,399 | 29,79 | 37,870 | 34,39 |

| CDW (t total/m2) | 50.01 | 64.15 | 56.198 | 50.97 |

| % Recyclability of raw materials | 64.15 | 64.12 | 34.89 | 64,31 |

| % Recyclability of CDW | 49.88 | 49.19 | 49.58 | 49,37 |

| Total working hours | 3618 | 2972 | 3336 | 3095 |

| Total machine working hours | 354.72 | 383.35 | 148.74 | 208.35 |

| Material Family | N1 (kg) | N1 (kg/m2) | N2 (kg) | N2 (kg/m2) | N3 (kg) | N3 (kg/m2) |

|---|---|---|---|---|---|---|

| Concrete and cement | 27,826.514 | 35.317 | 22,180.058 | 47.756 | 28,573.022 | 42.401 |

| Ceramic and bricks | 586.596 | 0.745 | 345.785 | 0.745 | 501.707 | 0.745 |

| Wood | 199.542 | 0.253 | 167.103 | 0.360 | 126.687 | 0.188 |

| Metals and alloys | 1252.661 | 1.590 | 505.958 | 1.089 | 983.653 | 1.460 |

| Plastics | 132.464 | 0.168 | 203.986 | 0.439 | 158.304 | 0.235 |

| Water | 147.337 | 0.187 | 173.704 | 0.374 | 148.927 | 0.221 |

| Aggregates and stones | 8132.319 | 10.322 | 5451.782 | 11.738 | 6273.879 | 9.310 |

| Others | 1086.720 | 1.379 | 766.389 | 1.650 | 9.310 | 1.639 |

| TOTAL | 39,364.153 | 49.961 | 29,794.765 | 64.151 | 36,775.490 | 56.198 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marrero, M.; Rivero-Camacho, C.; Martínez-Rocamora, A.; Alba-Rodríguez, M.D.; Solís-Guzmán, J. Life Cycle Assessment of Industrial Building Construction and Recovery Potential. Case Studies in Seville. Processes 2022, 10, 76. https://doi.org/10.3390/pr10010076

Marrero M, Rivero-Camacho C, Martínez-Rocamora A, Alba-Rodríguez MD, Solís-Guzmán J. Life Cycle Assessment of Industrial Building Construction and Recovery Potential. Case Studies in Seville. Processes. 2022; 10(1):76. https://doi.org/10.3390/pr10010076

Chicago/Turabian StyleMarrero, Madelyn, Cristina Rivero-Camacho, Alejandro Martínez-Rocamora, María Desirée Alba-Rodríguez, and Jaime Solís-Guzmán. 2022. "Life Cycle Assessment of Industrial Building Construction and Recovery Potential. Case Studies in Seville" Processes 10, no. 1: 76. https://doi.org/10.3390/pr10010076

APA StyleMarrero, M., Rivero-Camacho, C., Martínez-Rocamora, A., Alba-Rodríguez, M. D., & Solís-Guzmán, J. (2022). Life Cycle Assessment of Industrial Building Construction and Recovery Potential. Case Studies in Seville. Processes, 10(1), 76. https://doi.org/10.3390/pr10010076