Forest Fuel Drying, Pyrolysis and Ignition Processes during Forest Fire: A Review

Abstract

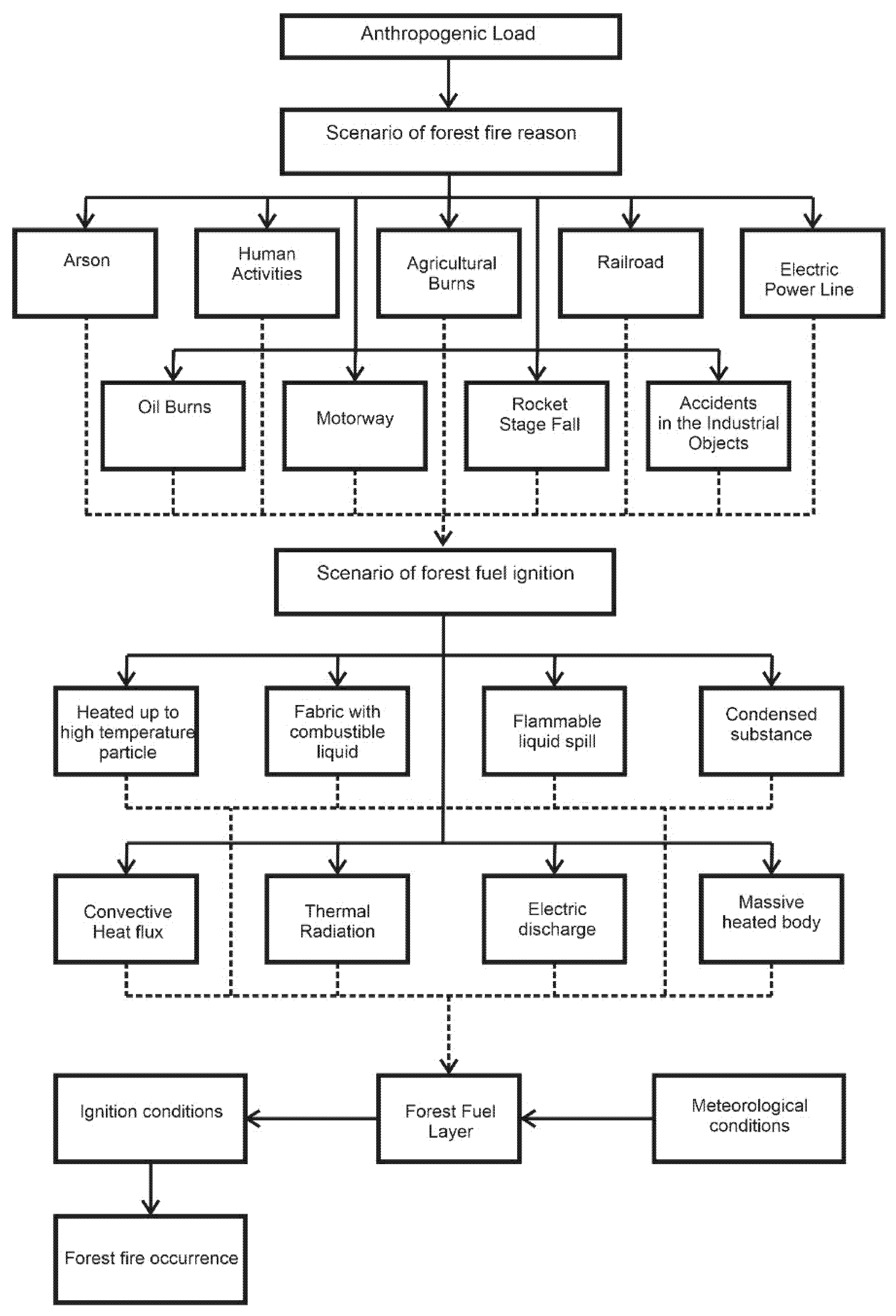

1. Introduction

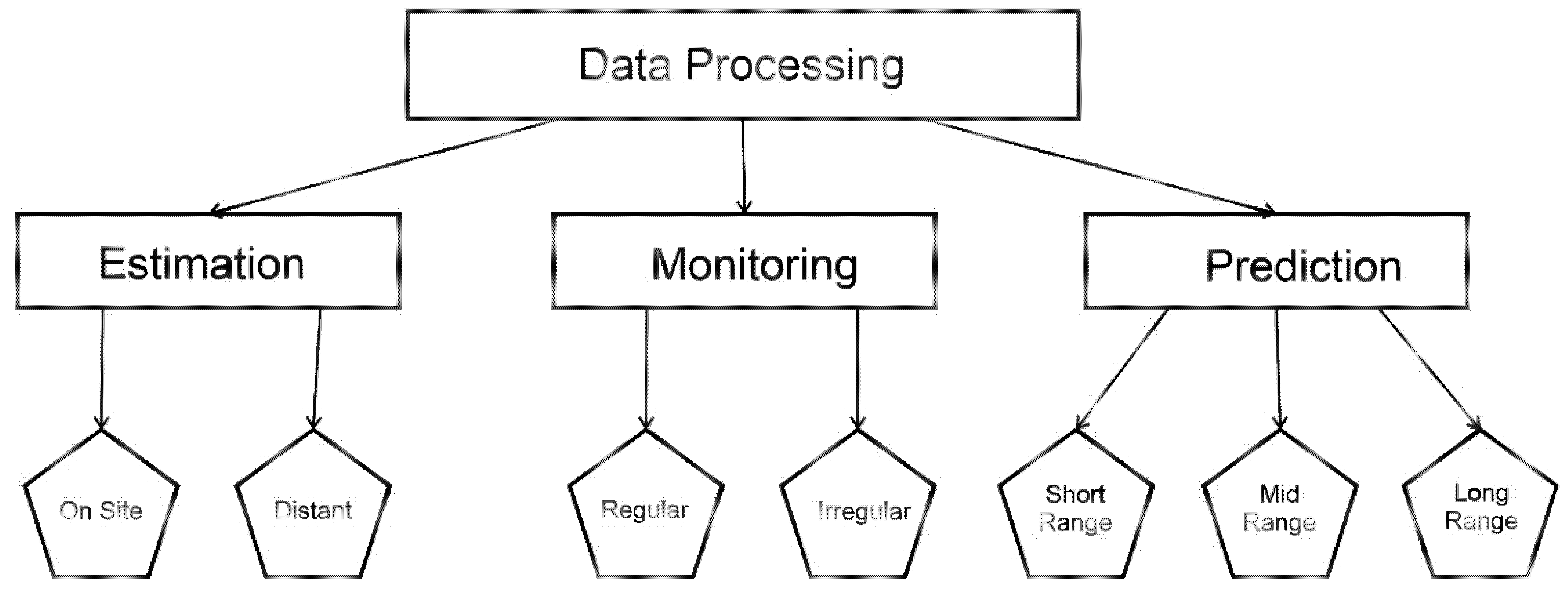

2. Summary

- Assessment of the current level of the forest fire hazard (allows for obtaining up-to-date information on the forest fuel characteristics and forest fire danger factors, as well as conducting qualitative and quantitative analysis to estimate the forest fire danger level using special scales).

- Monitoring the forest areas state in the context of forest fire danger (designed to track daily changes in assessing the forest fuel properties, factors, and indicators of forest fire danger in order to identify temporal and spatial trends in the change in the forest fire danger level).

- Prediction of forest fire danger (the most important type of information processing, which is intended for predictive modeling of forest fire conditions based on estimated and monitoring information on the factors and indicators of forest fire danger).

- Short-range prediction assumes the calculations of the parameters for the next day period using estimated and monitoring information.

- Medium-range prediction proposes to calculate the required parameters and the level of the forest fire danger for a 5–7 days period. In this case, predicted information for the days of the previous period can be used in addition to estimated and monitoring information.

- Long-range prediction enables using retrospective data for previous fire seasons. However, the reliability of such type predictions is the lowest. This is especially important to understand in the context of global climate change.

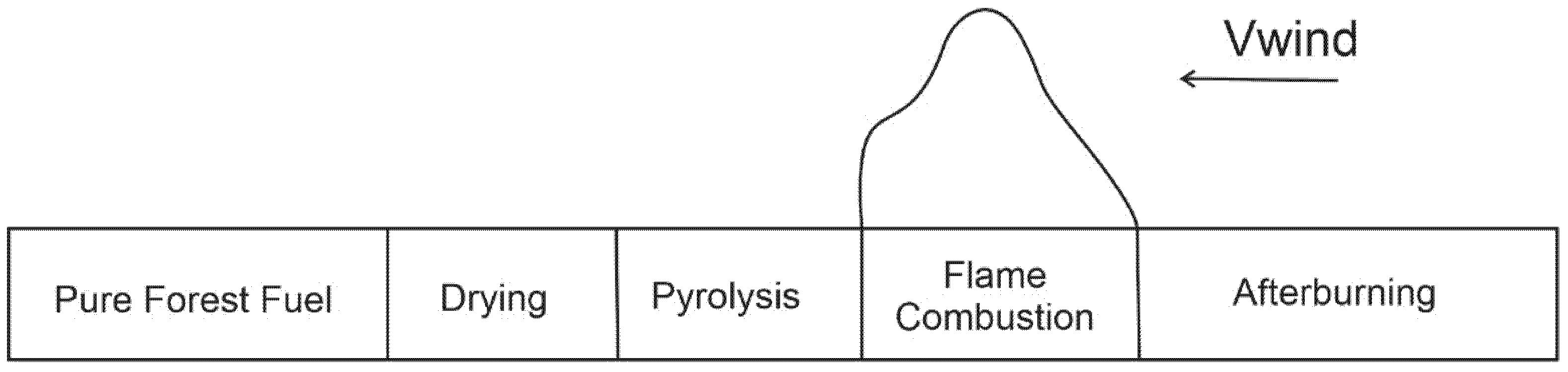

3. Forest Fuel Drying

- Mechanical bond is the weakest one, which requires 100 Joules of energy to break. Mechanical moisture includes moisture from micro and macro capillaries. The macrocapillaries only fill when they come into contact with the material, and the microcapillaries can also absorb moisture from the environment.

- Physicomechanical bond takes 3000 Joules of energy to remove moisture. This type of bond includes adsorptive (firmly adhered to the surface) and osmotically (inside cells) bound moisture.

- Chemical bond is the strongest, which requires 5000 Joules of energy to break. In this case, a chemical reaction or heating to high temperatures is required to remove moisture. This moisture is not removed during normal drying.

- The Newton model

- The Page model

- The modified Page model

- The Henderson and Pabis model

- The Logarithmic model

- Class (moisture content is approximately equal to the environment moisture content. This class includes dead herbaceous plants that form the forest floor, as well as round wood fuel with a diameter of up to 6 mm).

- Class (moisture content ranges from 1 to 60%. This group includes round wood fuel with a diameter in the range from 6 to 25 mm or a layer of forest floor up to 20 mm thick).

- Class (moisture content ranges from 1 to 50%. These include round wood fuel with a diameter of 25 to 75 mm, as well as forest floor with a thickness of 20–100 mm).

- Class (moisture content ranges from 1 to 40%. These include wood fuel with a diameter of 75 to 203 mm, as well as forest floor with a thickness of more than 100 mm).

4. Forest Fuel Pyrolysis

5. Forest Fuel Ignition

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eugenio, F.C.; dos Santos, A.R.; Pedra, B.D.; Macedo Pezzopane, J.E.; Mafia, R.G.; Loureiro, E.B.; Martins, L.D.; Saito, N.S. Causal, Temporal and Spatial Statistics of Wildfires in Areas of Planted Forests in Brazil. Agric. For. Meteorol. 2019, 266, 157–172. [Google Scholar] [CrossRef]

- Molina-Terrén, D.M.; Xanthopoulos, G.; Diakakis, M.; Ribeiro, L.; Caballero, D.; Delogu, G.M.; Viegas, D.X.; Silva, C.A.; Cardil, A.; Molina-Terrén, D.M.; et al. Analysis of Forest Fire Fatalities in Southern Europe: Spain, Portugal, Greece and Sardinia (Italy). Int. J. Wildland Fire 2019, 28, 85–98. [Google Scholar] [CrossRef]

- Read, S.; Howell, C. National ‘State of the Forests’ Reporting in Australia. Aust. For. 2019, 82, 53–55. [Google Scholar] [CrossRef]

- Barhoumi, C.; Peyron, O.; Joannin, S.; Subetto, D.; Kryshen, A.; Drobyshev, I.; Girardin, M.P.; Brossier, B.; Paradis, L.; Pastor, T.; et al. Gradually Increasing Forest Fire Activity during the Holocene in the Northern Ural Region (Komi Republic, Russia). Holocene 2019, 29, 1906–1920. [Google Scholar] [CrossRef]

- Gongalsky, K.B.; Zaitsev, A.S.; Korobushkin, D.I.; Saifutdinov, R.A.; Butenko, K.O.; de Vries, F.T.; Ekschmitt, K.; Degtyarev, M.I.; Gorbunova, A.Y.; Kostina, N.V.; et al. Forest Fire Induces Short-Term Shifts in Soil Food Webs with Consequences for Carbon Cycling. Ecol. Lett. 2021, 24, 438–450. [Google Scholar] [CrossRef]

- Zaini, J.; Susanto, A.D.; Samoedro, E.; Bionika, V.C.; Antariksa, B. Health Consequences of Thick Forest Fire Smoke to Healthy Residents in Riau, Indonesia: A Cross-Sectional Study. Med. J. Indones. 2020, 29, 58–63. [Google Scholar] [CrossRef]

- Kirdyanov, A.V.; Saurer, M.; Siegwolf, R.; Knorre, A.A.; Prokushkin, A.S.; Churakova, O.V.S.; Fonti, M.V.; Büntgen, U. Long-Term Ecological Consequences of Forest Fires in the Continuous Permafrost Zone of Siberia. Environ. Res. Lett. 2020, 15, 034061. [Google Scholar] [CrossRef]

- de la Asunción, M.; Castillo, L.; Fdez-Olivares, J.; García-Pérez, O.; González, A.; Palao, F. SIADEX: An Interactive Knowledge-Based Planner for Decision Support in Forest Fire Fighting. AI Commun. 2005, 18, 257–268. [Google Scholar]

- Laschi, A.; Foderi, C.; Fabiano, F.; Neri, F.; Cambi, M.; Mariotti, B.; Marchi, E. Forest Road Planning, Construction and Maintenance to Improve Forest Fire Fighting: A Review. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2019, 40, 207–219. [Google Scholar]

- Bordado, J.C.M.; Gomes, J.F.P. New Technologies for Effective Forest Fire Fighting. Int. J. Environ. Stud. 2007, 64, 243–251. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, Z.; Zhang, Y. Aerial Images-Based Forest Fire Detection for Firefighting Using Optical Remote Sensing Techniques and Unmanned Aerial Vehicles. J. Intell. Robot Syst. 2017, 88, 635–654. [Google Scholar] [CrossRef]

- Shchetinsky, E.A. Sputnik of the Head of Extinguishing Forest Fires; VNIILM: Moscow, Russia, 2003; 96p. (In Russian) [Google Scholar]

- Baranovskiy, N.V. Predictive Modeling of Forest Fire Danger. Ph.D. Thesis, Tomsk Polytechnic University, Tomsk, Russia, 2012. (In Russian). [Google Scholar]

- Baranovsky, N.V. The development of application to software origin pro for informational analysis and forecast of forest fire danger caused by thunderstorm activity. J. Autom. Inf. Sci. 2019, 51, 12–23. [Google Scholar] [CrossRef]

- Grishin, A.M.; Filkov, A.I. A deterministic-probabilistic system for predicting forest fire danger. Fire Saf. J. 2011, 46, 56–62. [Google Scholar] [CrossRef]

- Nesterov, V.G. Combustibility of the Forest and Methods of Its Determination; Goslesbumizdat: Moscow, Russia, 1949; 76p. (In Russian) [Google Scholar]

- Nieto, H.; Aguado, I.; Garcia, M.; Chuvieco, E. Lightning-caused fires in Central Spain: Development of a probability model of occurrence for two Spanish regions. Agric. For. Meteorol. 2012, 162, 35–43. [Google Scholar] [CrossRef]

- Titaev, P.S. Simulation model of the probability of forest fires taking into account lightning activity and anthropogenic factor. Fire Explos. Saf. 2015, 24, 44–53. (In Russian) [Google Scholar]

- Baranovskiy, N.V.; Kuznetsov, G.V.; Nemova, T.N. Mathematical computing of coniferous tree ignition by the cloud-to-ground lightning discharge using Joule-Lenz’s law. Int. J. Electr. Comput. Eng. 2017, 7, 1337–1346. [Google Scholar] [CrossRef][Green Version]

- Pourghasemi, H.R.; Kariminejad, N.; Amiri, M.; Edalat, M.; Zarafshar, M.; Blaschke, T.; Cerda, A. Assessing and mapping multi-danger risk susceptibility using a machine learning technique. Sci. Rep. 2020, 10, 3203. [Google Scholar] [CrossRef]

- Baranovskiy, N.V. (Ed.) Forest Fire Danger Prediction Using Deterministic-Probabilistic Approach; IGI Global: Hershey, PA, USA, 2021. [Google Scholar]

- Baranovskiy, N.; Kirienko, V. Mathematical simulation of forest fuel pyrolysis in one-dimensional statement taking into account soot formation. Processes 2021, 9, 1616. [Google Scholar] [CrossRef]

- Baranovskii, N.V.; Kirienko, V.A. Ignition of Forest Combustible Materials in a High-Temperature Medium. J. Eng. Phys. Thermophys. 2020, 93, 1266–1271. [Google Scholar] [CrossRef]

- Grishin, A.M.; Baranovskij, N.V. Comparative analysis of simple models of drying of the layer of forest combustibles, including the data of experiments and natural observations. Inzhenerno-Fizicheskii Zhurnal 2003, 76, 166–169. [Google Scholar] [CrossRef]

- Strumillo, C.; Kudra, T. Drying: Principles, Applications, and Design; CRC Press: Boca Raton, FL, USA, 1986; p. 448. [Google Scholar]

- Kasatkin, A.G. Basic Processes and Apparatuses of Chemical Technology; Chemistry: Moscow, Russia, 1973. (In Russian) [Google Scholar]

- Yan, Y.; Qi, B.; Zhang, W.; Wang, X.; Mo, Q. Investigations into the Drying Kinetics of Biomass in a Fluidized Bed Dryer Using Electrostatic Sensing and Digital Imaging Techniques. Fuel 2022, 308, 122000. [Google Scholar] [CrossRef]

- Pereira, J.; Chuvieco, E.; Beaudoin, A.; Desbois, N. Remote Sensing of Burned Areas: A Review. A Review of Remote Sensing Methods for the Study of Large Wildland Fires; University of Alcala: Alcala, Spain, 1997; p. 184. [Google Scholar]

- Camuffo, D. (Ed.) Chapter 19—Measuring Time of Wetness and Moisture in Materials. In Microclimate for Cultural Heritage, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 459–482. ISBN 9780444641069. [Google Scholar]

- Wildland Fuel Fundamentals and Applications. SpringerLink. Available online: https://link.springer.com/book/10.1007/978-3-319-09015-3 (accessed on 3 November 2021).

- Aguado, I.; Chuvieco, E.; Borén, R.; Nieto, H. Estimation of Dead Fuel Moisture Content from Meteorological Data in Mediterranean Areas. Applications in Fire Danger Assessment. Int. J. Wildland Fire 2007, 16, 390–397. [Google Scholar] [CrossRef]

- Simard, A.J. The Moisture Content of Forest Fuels—A Review of the Basic Concepts. FF-X-14; Forest Fire Research Institute: Ottawa, ON, Canada, 1968. [Google Scholar]

- Viney, N.R. A Review of Fine Fuel Moisture Modelling. Int. J. Wildland Fire 1991, 1, 215–234. [Google Scholar] [CrossRef]

- Chuvieco, E.; Riaño, D.; Aguado, I.; Cocero, D. Estimation of Fuel Moisture Content from Multitemporal Analysis of Landsat Thematic Mapper Reflectance Data: Applications in Fire Danger Assessment. Int. J. Remote Sens. 2002, 23, 2145–2162. [Google Scholar] [CrossRef]

- Veraverbeke, S.; Dennison, P.; Gitas, I.; Hulley, G.; Kalashnikova, O.; Katagis, T.; Kuai, L.; Meng, R.; Roberts, D.; Stavros, N. Hyperspectral Remote Sensing of Fire: State-of-the-Art and Future Perspectives. Remote Sens. Environ. 2018, 216, 105–121. [Google Scholar] [CrossRef]

- Julien, Y.; Sobrino, J.; Verhoef, W.; Julien, Y.; Sobrino, J.A.; Verhoef, W. Changes in Land Surface Temperatures and NDVI Values over Europe between 1982 and 1999. Remote Sens. Environ. 2006, 103, 43–55. [Google Scholar] [CrossRef]

- Guha, S.; Govil, H. An Assessment on the Relationship between Land Surface Temperature and Normalized Difference Vegetation Index. Environ. Dev. Sustain. 2021, 23, 1944–1963. [Google Scholar] [CrossRef]

- Wang, L.; Hunt, E.R.; Qu, J.J.; Hao, X.; Daughtry, C.S.T. Remote Sensing of Fuel Moisture Content from Ratios of Narrow-Band Vegetation Water and Dry-Matter Indices. Remote Sens. Environ. 2013, 129, 103–110. [Google Scholar] [CrossRef]

- Quan, X.; He, B.; Yebra, M.; Yin, C.; Liao, Z.; Li, X. Retrieval of Forest Fuel Moisture Content Using a Coupled Radiative Transfer Model. Environ. Model. Softw. 2017, 95, 290–302. [Google Scholar] [CrossRef]

- Viskanta, R. Overview of Some Radiative Transfer Issues in Simulation of Unwanted Fires. Int. J. Therm. Sci. 2008, 47, 1563–1570. [Google Scholar] [CrossRef]

- Yebra, M.; Chuvieco, E. Linking Ecological Information and Radiative Transfer Models to Estimate Fuel Moisture Content in the Mediterranean Region of Spain: Solving the Ill-Posed Inverse Problem. Remote Sens. Environ. 2009, 113, 2403–2411. [Google Scholar] [CrossRef]

- Regional Estimation of Woodland Moisture Content by Inverting Radiative Transfer Models. Remote Sens. Environ. 2013, 132, 59–70. [CrossRef]

- Zhu, X.; Skidmore, A.K.; Darvishzadeh, R.; Wang, T. Estimation of Forest Leaf Water Content through Inversion of a Radiative Transfer Model from LiDAR and Hyperspectral Data. Int. J. Appl. Earth Obs. Geoinf. 2019, 74, 120–129. [Google Scholar] [CrossRef]

- Luo, K.; Quan, X.; He, B.; Yebra, M. Effects of Live Fuel Moisture Content on Wildfire Occurrence in Fire-Prone Regions over Southwest China. Forests 2019, 10, 887. [Google Scholar] [CrossRef]

- Luo, K.; He, B.; Quan, X.; Liu, X.; Wen, C. Preliminarily Analysis of the Relation Between Satellite Derived Fuel Moisture Content and Wildfire Activity in Southwestern China. In Proceedings of the 2019 IEEE International Geoscience and Remote Sensing Symposium (IGARSS 2019), Yokohama, Japan, 28 July–2 August 2019; pp. 9906–9909. [Google Scholar]

- Riano, D.; Vaughan, P.; Chuvieco, E.; Zarco-Tejada, P.J.; Ustin, S.L. Estimation of Fuel Moisture Content by Inversion of Radiative Transfer Models to Simulate Equivalent Water Thickness and Dry Matter Content: Analysis at Leaf and Canopy Level. IEEE Trans. Geosci. Remote Sens. 2005, 43, 819–826. [Google Scholar] [CrossRef]

- Jin, S.; Chen, P.; Jin, S.; Chen, P. Modelling Drying Processes of Fuelbeds of Scots Pine Needles with Initial Moisture Content above the Fibre Saturation Point by Two-Phase Models. Int. J. Wildland Fire 2012, 21, 418–427. [Google Scholar] [CrossRef]

- González, A.D.R.; Hidalgo, J.A.V.; González, J.G.Á.; González, A.D.R.; Hidalgo, J.A.V.; González, J.G.Á. Construction of Empirical Models for Predicting Pinus Sp. Dead Fine Fuel Moisture in NW Spain. I: Response to Changes in Temperature and Relative Humidity. Int. J. Wildland Fire 2009, 18, 71–83. [Google Scholar] [CrossRef]

- Bilgili, E.; Coskuner, K.A.; Usta, Y.; Goltas, M. Modeling Surface Fuels Moisture Content in Pinus Brutia Stands. J. For. Res. 2019, 30, 577–587. [Google Scholar] [CrossRef]

- Matthews, S.; Matthews, S. A Process-Based Model of Fine Fuel Moisture. Int. J. Wildland Fire 2006, 15, 155–168. [Google Scholar] [CrossRef]

- Fan, C.; He, B. A Physics-Guided Deep Learning Model for 10-h Dead Fuel Moisture Content Estimation. Forests 2021, 12, 933. [Google Scholar] [CrossRef]

- Banerjee, T. Impacts of Forest Thinning on Wildland Fire Behavior. Forests 2020, 11, 918. [Google Scholar] [CrossRef]

- Matthews, S.; McCaw, W.L.; Neal, J.E.; Smith, R.H. Testing a Process-Based Fine Fuel Moisture Model in Two Forest Types. Can. J. For. Res. 2007, 37, 23–35. [Google Scholar] [CrossRef]

- Matthews, S.; Matthews, S. Dead Fuel Moisture Research: 1991–2012. Int. J. Wildland Fire 2013, 23, 78–92. [Google Scholar] [CrossRef]

- Chuvieco, E.; Cocero, D.; Riaño, D.; Martin, P.; Martínez-Vega, J.; de la Riva, J.; Pérez, F. Combining NDVI and Surface Temperature for the Estimation of Live Fuel Moisture Content in Forest Fire Danger Rating. Remote Sens. Environ. 2004, 92, 322–331. [Google Scholar] [CrossRef]

- Yebra, M.; Dennison, P.E.; Chuvieco, E.; Riaño, D.; Zylstra, P.; Hunt, E.R.; Danson, F.M.; Qi, Y.; Jurdao, S. A Global Review of Remote Sensing of Live Fuel Moisture Content for Fire Danger Assessment: Moving towards Operational Products. Remote Sens. Environ. 2013, 136, 455–468. [Google Scholar] [CrossRef]

- Bowyer, P.; Danson, F.M. Sensitivity of Spectral Reflectance to Variation in Live Fuel Moisture Content at Leaf and Canopy Level. Remote Sens. Environ. 2004, 92, 297–308. [Google Scholar] [CrossRef]

- García, M.; Riaño, D.; Yebra, M.; Salas, J.; Cardil, A.; Monedero, S.; Ramirez, J.; Martín, M.P.; Vilar, L.; Gajardo, J.; et al. A Live Fuel Moisture Content Product from Landsat TM Satellite Time Series for Implementation in Fire Behavior Models. Remote Sens. 2020, 12, 1714. [Google Scholar] [CrossRef]

- Bradshaw, L.S.; Deeming, J.E.; Burgan, R.E.; Cohen, J.D. The 1978 National Fire-Danger Rating System: Technical Documentation; General Technical Report INT-169; U.S. Department of Agriculture, Forest Service, Intermountain Forest and Range Experiment Station: Ogden, UT, USA, 1984.

- Marsden-Smedley, J.B.; Catchpole, W.R. Fire Modelling in Tasmanian Buttongrass Moorlands. III. Dead Fuel Moisture. Int. J. Wildland Fire 2001, 10, 241–253. [Google Scholar] [CrossRef]

- Matthews, S.; Gould, J.; McCaw, L.; Matthews, S.; Gould, J.; McCaw, L. Simple Models for Predicting Dead Fuel Moisture in Eucalyptus Forests. Int. J. Wildland Fire 2010, 19, 459–467. [Google Scholar] [CrossRef]

- Slijepcevic, A.; Anderson, W.R.; Matthews, S.; Anderson, D.H. Evaluating models to predict daily fine fuel moisture content in eucalypt forest. For. Ecol. Manag. 2015, 335, 261–269. [Google Scholar] [CrossRef]

- Rossa, C.G. The effect of fuel moisture content on the spread rate of forest fires in the absence of wind or slope. Int. J. Wildland Fire 2017, 26, 24–31. [Google Scholar] [CrossRef]

- Van Wagner, C.E. Structure of the Canadian Fire Weather Index; Publication, No. 1333; Petawawa Forest Experiment Station, Department of the Environment Canadian Forestry Service: Ottawa, CA, USA, 1974.

- Anderson, H.E. Predicting Equilibrium Moisture Content of Some Foliar Forest Litter in the Northern Rocky Mountains; U.S. Department of Agriculture, Forest Service, Intermountain Research Station: Ogden, UT, USA, 1990.

- Nelson, R.M., Jr. A Method for Describing Equilibrium Moisture Content of Forest Fuels. Can. J. For. Res. 1984, 14, 597–600. [Google Scholar] [CrossRef]

- Britton, C.M.; Countryman, C.M.; Wright, H.A.; Walvekar, A.G. The Effect of Humidity, Air Temperature, and Wind Speed on Fine Fuel Moisture Content. Fire Technol. 1973, 9, 46–55. [Google Scholar] [CrossRef]

- Matthews, S. Effect of Drying Temperature on Fuel Moisture Content Measurements. Int. J. Wildland Fire 2010, 19, 800–802. [Google Scholar] [CrossRef]

- Gorbunov, N.B. Assessment of the moisture content of forest combustible materials at the beginning of the fire hazardous season. In Vavilovskie Readings—2014: Collection of Articles International Scientific-Practical Conference, Dedicated to the 127th Anniversary of the Birth of Academician; N.I. Vavilov: Saratov, Russia, 2014; 380p. (In Russian) [Google Scholar]

- Grishin, A.M.; Sinitsyn, S.P.; Akimova, I.V. Comparative analysis of thermokinetic constants of drying and pyrolysis of forest combustible materials. Phys. Combust. Explos. 1991, 6, 17–241. (In Russian) [Google Scholar]

- Ostapenko, A.; Morkovin, V.; Manmareva, V.; Manmarev, D. Risk Analysis in the Management of Forest Fire in Russia. IOP Conf. Ser. Earth Environ. Sci. 2019, 392, 012074. [Google Scholar] [CrossRef]

- Hamadeh, N.; Karouni, A.; Daya, B.; Chauvet, P. Chauvet Using correlative data analysis to develop weather index that estimates the risk of forest fires in Lebanon: Assessment versus prevalent meteorological indices. Int. J. Phys. Sci. Res. 2017, 1, 14–38. [Google Scholar]

- Pagnon Eriksson, C.; Johansson, N. Review of Wildfire Indices: Indices Applicable for a Swedish Context; TVBB; Division of Fire Safety Engineering: Lund, Sweden, 2020. [Google Scholar]

- Zhdanko, V.A. Scientific basis of development of regional scales and their importance for forest fire management. In Contemporary Problems of Forest Protection from Fire and Firefighting; Melekhov, I.S., Ed.; Lesnaya Promyshlennost’ Publ.: Moscow, Russia, 1965; pp. 53–86. [Google Scholar]

- Zong, X.; Tian, X.; Yin, Y. Impacts of Climate Change on Wildfires in Central Asia. Forests 2020, 11, 802. [Google Scholar] [CrossRef]

- Hadisuwito, A.S.; Hassan, F.H. A Comparative Study of Drought Factors in the Mcarthur Forest Fire Danger Index in Indonesian Forest. Ecol. Environ. Conserv. Pap. 2021, 5, 202–206. [Google Scholar]

- Gannon, C.S.; Steinberg, N.C. A Global Assessment of Wildfire Potential under Climate Change Utilizing Keetch-Byram Drought Index and Land Cover Classifications. Environ. Res. Commun. 2021, 3, 035002. [Google Scholar] [CrossRef]

- de Jong, M.C.; Wooster, M.J.; Kitchen, K.; Manley, C.; Gazzard, R.; McCall, F.F. Calibration and evaluation of the Canadian Forest Fire Weather Index (FWI) System for improved wildland fire danger rating in the United Kingdom. Nat. Hazards Earth Syst. Sci. 2016, 16, 1217–1237. [Google Scholar] [CrossRef]

- Hamadeh, N.; Daya, B.; Hilal, A.; Chauvet, P. An Analytical Review on the Most Widely Used Meteorological Models in Forest Fire Prediction. In Proceedings of the 2015 Third International Conference on Technological Advances in Electrical, Electronics and Computer Engineering (TAEECE), Beirut, Lebanon, 29 April–1 May 2015; pp. 239–244. [Google Scholar]

- Gomar, D.A.; Brebbia, C.A. Ecosystems and Sustainable Development XI; WIT Press: Ashurst, UK, 2017; ISBN 9781784661816. [Google Scholar]

- Eriksson, C.P.; Johansson, N. Review of Wildfire Indices. Available online: https://lucris.lub.lu.se/ws/portalfiles/portal/87339976/Review_of_wildfire_indices_Indices_applicable_for_a_Swedish_context.pdf (accessed on 29 December 2021).

- Plucinski, M.P.; Sullivan, A.L.; McCaw, W.L.; Plucinski, M.P.; Sullivan, A.L.; McCaw, W.L. Comparing the Performance of Daily Forest Fire Danger Summary Metrics for Estimating Fire Activity in Southern Australian Forests. Int. J. Wildland Fire 2020, 29, 926–938. [Google Scholar] [CrossRef]

- Vega-Nieva, D.J.; Briseño-Reyes, J.; Nava-Miranda, M.G.; Calleros-Flores, E.; López-Serrano, P.M.; Corral-Rivas, J.J.; Montiel-Antuna, E.; Cruz-López, M.I.; Cuahutle, M.; Ressl, R.; et al. Developing Models to Predict the Number of Fire Hotspots from an Accumulated Fuel Dryness Index by Vegetation Type and Region in Mexico. Forests 2018, 9, 190. [Google Scholar] [CrossRef]

- Hadisuwito, A.; Hassan, F.H. A Comparative Study of the Forest Fire Danger Index Calculation Methods Using Backpropagation. J. Phys. Conf. Ser. 2020, 1529, 052051. [Google Scholar] [CrossRef]

- Garcia-Perez, M.; Chaala, A.; Pakdel, H.; Kretschmer, D.; Roy, C. Characterization of Bio-Oils in Chemical Families. Biomass Bioenergy 2007, 31, 222–242. [Google Scholar] [CrossRef]

- Sharma, A.; Pareek, V.; Zhang, D. Biomass Pyrolysis—A Review of Modelling, Process Parameters and Catalytic Studies. Renew. Sustain. Energy Rev. 2015, 50, 1081–1096. [Google Scholar] [CrossRef]

- Banyasz, J.L.; Li, S.; Lyons-Hart, J.; Shafer, K.H. Gas Evolution and the Mechanism of Cellulose Pyrolysis. Fuel 2001, 80, 1757–1763. [Google Scholar] [CrossRef]

- Hameed, S.; Sharma, A.; Pareek, V.; Wu, H.; Yu, Y. A Review on Biomass Pyrolysis Models: Kinetic, Network and Mechanistic Models. Biomass Bioenergy 2019, 123, 104–122. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, X.; Dong, C.; Zhang, Z.; Zhang, X.; Zhu, X. Influence of Pyrolysis Temperature and Time on the Cellulose Fast Pyrolysis Products: Analytical Py-GC/MS Study. J. Anal. Appl. Pyrolysis 2011, 92, 430–438. [Google Scholar] [CrossRef]

- Collard, F.-X.; Blin, J. A Review on Pyrolysis of Biomass Constituents: Mechanisms and Composition of the Products Obtained from the Conversion of Cellulose, Hemicelluloses and Lignin. Renew. Sustain. Energy Rev. 2014, 38, 594–608. [Google Scholar] [CrossRef]

- Demirbaş, A. Mechanisms of Liquefaction and Pyrolysis Reactions of Biomass. Energy Convers. Manag. 2000, 41, 633–646. [Google Scholar] [CrossRef]

- Papari, S.; Hawboldt, K. A Review on the Pyrolysis of Woody Biomass to Bio-Oil: Focus on Kinetic Models. Renew. Sustain. Energy Rev. 2015, 52, 1580–1595. [Google Scholar] [CrossRef]

- Ravikrishnan, V.; Broadbelt, L.J. Mechanistic modeling of fast pyrolysis of cellulose to predict bio-oil composition. In Proceedings of the 11AIChE—2011 AIChE Annual Meeting, Minneapolis, MN, USA, 16–21 October 2011; 1p. [Google Scholar]

- Zhang, M.; Geng, Z.; Yu, Y. Density Functional Theory (DFT) Study on the Dehydration of Cellulose. Energy Fuels 2011, 25, 2664–2670. [Google Scholar] [CrossRef]

- Zhang, M.; Geng, Z.; Yu, Y. Density Functional Theory (DFT) Study on the Pyrolysis of Cellulose: The Pyran Ring Breaking Mechanism. Comput. Theor. Chem. 2015, 1067, 13–23. [Google Scholar] [CrossRef]

- Lu, Q.; Hu, B.; Zhang, Z.; Wu, Y.; Cui, M.; Liu, D.; Dong, C.; Yang, Y. Mechanism of Cellulose Fast Pyrolysis: The Role of Characteristic Chain Ends and Dehydrated Units. Combust. Flame 2018, 198, 267–277. [Google Scholar] [CrossRef]

- Solomon, P.R.; Hamblen, D.G.; Carangelo, R.M.; Serio, M.A.; Deshpande, G.V. General Model of Coal Devolatilization. Energy Fuels 1988, 2, 405–422. [Google Scholar] [CrossRef]

- Niksa, S. Predicting the Rapid Devolatilization of Diverse Forms of Biomass with Bio-Flashchain. Proc. Combust. Inst. 2000, 28, 2727–2733. [Google Scholar] [CrossRef]

- Vizzini, G.; Bardi, A.; Biagini, E.; Falcitelli, M.; Tognotti, L. Prediction of Rapid Biomass Devolatilization Yields with An Upgraded Version of The Bio-CPD Model; Proceedings of the Combustion Institute, Italian Section: Turin, Italy, 2008. [Google Scholar]

- Prakash, N.; Karunanithi, T. Kinetic modeling in biomass pyrolysis—A review. Appl. Sci. Res. 2008, 4, 1627–1636. [Google Scholar]

- Amini, E.; Safdari, M.-S.; Johnson, N.; Weise, D.R.; Fletcher, T.H. Pyrolysis Kinetics of Wildland Vegetation Using Model-Fitting Methods. J. Anal. Appl. Pyrolysis 2021, 157, 105167. [Google Scholar] [CrossRef]

- Kansa, E.J.; Perlee, H.E.; Chaiken, R.F. Mathematical Model of Wood Pyrolysis Including Internal Forced Convection. Combust. Flame 1977, 29, 311–324. [Google Scholar] [CrossRef]

- Várhegyi, G.; Szabó, P.; Antal, M.J. Kinetics of the Thermal Decomposition of Cellulose under the Experimental Conditions of Thermal Analysis. Theoretical Extrapolations to High Heating Rates. Biomass Bioenergy 1994, 7, 69–74. [Google Scholar] [CrossRef]

- Xia, C.; Cai, L.; Zhang, H.; Zuo, L.; Shi, S.Q.; Lam, S.S. A review on the modeling and validation of biomass pyrolysis with a focus on product yield and composition. Biofuel Res. J. 2021, 8, 1296–1315. [Google Scholar] [CrossRef]

- Radmanesh, R.; Courbariaux, Y.; Chaouki, J.; Guy, C. A Unified Lumped Approach in Kinetic Modeling of Biomass Pyrolysis. Fuel 2006, 85, 1211–1220. [Google Scholar] [CrossRef]

- Barneto, A.G.; Carmona, J.A.; Alfonso, J.E.M.; Serrano, R.S. Simulation of the Thermogravimetry Analysis of Three Non-Wood Pulps. Bioresour. Technol. 2010, 101, 3220–3229. [Google Scholar] [CrossRef]

- Manyà, J.J.; Velo, E.; Puigjaner, L. Kinetics of Biomass Pyrolysis: A Reformulated Three-Parallel-Reactions Model. Ind. Eng. Chem. Res. 2003, 42, 434–441. [Google Scholar] [CrossRef]

- Orfão, J.J.M.; Antunes, F.J.A.; Figueiredo, J.L. Pyrolysis Kinetics of Lignocellulosic Materials—Three Independent Reactions Model. Fuel 1999, 78, 349–358. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, J.; Wu, J. Kinetic and Energy Production Analysis of Pyrolysis of Lignocellulosic Biomass Using a Three-Parallel Gaussian Reaction Model. Bioresour. Technol. 2016, 211, 502–508. [Google Scholar] [CrossRef]

- Conesa, J.A.; Domene, A. Biomasses Pyrolysis and Combustion Kinetics through N-Th Order Parallel Reactions. Thermochim. Acta 2011, 523, 176–181. [Google Scholar] [CrossRef][Green Version]

- Thurner, F.; Mann, U. Kinetic Investigation of Wood Pyrolysis. Ind. Eng. Chem. Process Des. Dev. 1981, 20, 482–488. [Google Scholar] [CrossRef]

- Chan, W.-C.R.; Kelbon, M.; Krieger, B.B. Modelling and Experimental Verification of Physical and Chemical Processes during Pyrolysis of a Large Biomass Particle. Fuel 1985, 64, 1505–1513. [Google Scholar] [CrossRef]

- Di Blasi, C.; Branca, C. Kinetics of Primary Product Formation from Wood Pyrolysis. Ind. Eng. Chem. Res. 2001, 40, 5547–5556. [Google Scholar] [CrossRef]

- Wagenaar, B.M.; Prins, W.; van Swaaij, W.P.M. Flash Pyrolysis Kinetics of Pine Wood. Fuel Process. Technol. 1993, 36, 291–298. [Google Scholar] [CrossRef]

- Gonzalez-Quiroga, A.; Van Geem, K.M.; Marin, G.B. Towards first-principles based kinetic modeling of biomass fast pyrolysis. Biomass Convers. Biorefinery 2017, 7, 305–317. [Google Scholar] [CrossRef][Green Version]

- Ranzi, E.; Cuoci, A.; Faravelli, T.; Frassoldati, A.; Migliavacca, G.; Pierucci, S.; Sommariva, S. Chemical Kinetics of Biomass Pyrolysis. Energy Fuels 2008, 22, 4292–4300. [Google Scholar] [CrossRef]

- Ranzi, E.; Corbetta, M.; Manenti, F.; Pierucci, S. Kinetic Modeling of the Thermal Degradation and Combustion of Biomass. Chem. Eng. Sci. 2014, 110, 2–12. [Google Scholar] [CrossRef]

- Vinu, R.; Broadbelt, L.J. A Mechanistic Model of Fast Pyrolysis of Glucose-Based Carbohydrates to Predict Bio-Oil Composition. Energy Environ. Sci. 2012, 5, 9808–9826. [Google Scholar] [CrossRef]

- Cai, J.; Wu, W.; Liu, R. An Overview of Distributed Activation Energy Model and Its Application in the Pyrolysis of Lignocellulosic Biomass. Renew. Sustain. Energy Rev. 2014, 36, 236–246. [Google Scholar] [CrossRef]

- Dhaundiyal, A.; Singh, S.B. Parametric Study of N TH Order Distributed Activation Energy Model for Isothermal Pyrolysis of Forest Waste Using Gaussian Distribution. Acta Technol. Agric. 2017, 20, 23–28. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic Biomass Pyrolysis Mechanism: A State-of-the-Art Review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Dhaundiyal, A.; Singh, S.B. Distributed Activation Energy Modelling for Pyrolysis of Forest Waste Using Gaussian Distribution. Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci. 2016, 70, 64–70. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mohanty, K. Pyrolysis Kinetics and Thermal Behavior of Waste Sawdust Biomass Using Thermogravimetric Analysis. Bioresour. Technol. 2018, 251, 63–74. [Google Scholar] [CrossRef] [PubMed]

- Bach, Q.-V.; Tran, K.-Q.; Skreiberg, Ø. Combustion Kinetics of Wet-Torrefied Forest Residues Using the Distributed Activation Energy Model (DAEM). Appl. Energy 2017, 185, 1059–1066. [Google Scholar] [CrossRef]

- Tian, Y.; Perré, P. Multiple-Distribution DAEM Modelling of Spruce Pyrolysis: An Investigation of the Best Trade-off Regarding the Number and Shape of Distributions. Energy Convers. Manag. 2021, 229, 113756. [Google Scholar] [CrossRef]

- Sfakiotakis, S.; Vamvuka, D. Development of a Modified Independent Parallel Reactions Kinetic Model and Comparison with the Distributed Activation Energy Model for the Pyrolysis of a Wide Variety of Biomass Fuels. Bioresour. Technol. 2015, 197, 434–442. [Google Scholar] [CrossRef]

- Wadhwani, R.; Sutherland, D.; Moinuddin, K. Suitable Pyrolysis Model for Physics-Based Bushfire Simulation. In Proceedings of the 11th Asia-Pacific Conference of Combustion, Sydney, NSW, Australia, 10–14 December 2017. [Google Scholar]

- Hostikka, S.; Matala, A. Pyrolysis Model for Predicting the Heat Release Rate of Birch Wood. Combust. Sci. Technol. 2017, 189, 1373–1393. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Strizhak, P.A. Heat and Mass Transfer in Quenching the Reaction of Thermal Decomposition of a Forest Combustible Material with a Group of Water Drops. J. Eng. Phys. 2014, 87, 608–617. [Google Scholar] [CrossRef]

- Zhdanova, A.O.; Kuznetsov, G.V.; Strizhak, P.A. Numerical Investigation of Physicochemical Processes Occurring During Water Evaporation in the Surface Layer Pores of a Forest Combustible Material. J. Eng. Phys. 2014, 87, 773–781. [Google Scholar] [CrossRef]

- Zhdanova, A.O.; Kuznetsov, G.V.; Legros, J.C.; Strizhak, P.A. Thermal Conditions for Stopping Pyrolysis of Forest Combustible Material and Applications to Firefighting. Therm. Sci. 2017, 21, 2565–2577. [Google Scholar] [CrossRef]

- Korsakov, V.G.; Sychev, M.M.; Myakin, S.V. Physical Chemistry of Condensed Systems and Highly Organized Substances; SPbGTI (TU): Saint Peterburg, Russia, 2013; 177p. (In Russian) [Google Scholar]

- Vilyunov, V.N. Theory of Ignition of Condensed Substances; Nauka: Novosibirsk, Russia, 1984; 191p. (In Russian) [Google Scholar]

- Reszka, P.; Borowiec, P.; Steinhaus, T.; Torero, J.L. A Methodology for the Estimation of Ignition Delay Times in Forest Fire Modelling. Combust. Flame 2012, 159, 3652–3657. [Google Scholar] [CrossRef]

- Liodakis, S.; Bakirtzis, D.; Dimitrakopoulos, A. Ignition Characteristics of Forest Species in Relation to Thermal Analysis Data. Thermochim. Acta 2002, 390, 83–91. [Google Scholar] [CrossRef]

- Reszka, P.; Cruz, J.J.; Valdivia, J.; González, F.; Rivera, J.; Carvajal, C.; Fuentes, A. Ignition Delay Times of Live and Dead Pinus Radiata Needles. Fire Saf. J. 2020, 112, 102948. [Google Scholar] [CrossRef]

- Hernández, N.; Fuentes, A.; Consalvi, J.L.; Elicer-Cortés, J.C. Spontaneous Ignition of Wildland Fuel by Idealized Firebrands. Exp. Therm. Fluid Sci. 2018, 95, 88–95. [Google Scholar] [CrossRef]

- Zhang, H.; Qiao, Y.; Chen, H.; Liu, N.; Zhang, L.; Xie, X. Experimental Study on Flaming Ignition of Pine Needles by Simulated Lightning Discharge. Fire Saf. J. 2021, 120, 103029. [Google Scholar] [CrossRef]

- Grishin, A.M.; Zima, V.P.; Kuznetsov, V.T.; Skorik, A.I. Ignition of Combustible Forest Materials by a Radiant Energy Flux. Combust. Explos. Shock Waves 2002, 38, 24–29. [Google Scholar] [CrossRef]

- Fernandez-Pello, A.C.; Lautenberger, C.; Rich, D.; Zak, C.; Urban, J.; Hadden, R.; Scott, S.; Fereres, S. Spot Fire Ignition of Natural Fuel Beds by Hot Metal Particles, Embers, and Sparks. Combust. Sci. Technol. 2015, 187, 269–295. [Google Scholar] [CrossRef]

- Urban, J.L.; Zak, C.D.; Fernandez-Pello, C. Spot Fire Ignition of Natural Fuels by Hot Aluminum Particles. Fire Technol. 2018, 54, 797–808. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; Chen, H.; Liu, N.; Wang, S.; Huang, X.; Chen, H.; Liu, N. Interaction between Flaming and Smouldering in Hot-Particle Ignition of Forest Fuels and Effects of Moisture and Wind. Int. J. Wildland Fire 2016, 26, 71–81. [Google Scholar] [CrossRef]

- Urban, J.L. Spot Ignition of Natural Fuels by Hot Metal Particles. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2017. [Google Scholar]

- Ramljak, I.; Majstrovic, M.; Sutlovic, E. Statistical Analysis of Particles of Conductor Clashing. In Proceedings of the 2014 IEEE International Energy Conference (ENERGYCON), 13–16 May 2014, Dubrovnik, Croatia; IEEE: Cavtat, Croatia, 2014; pp. 638–643. [Google Scholar]

- Baranovskiy, N.V.; Zakharevich, A.V.; Osotova, D.S. Experimental study of pine forest fuel layer ignition by the steel heated particle. EPJ Web of Conferences 2015, 82, 01020. [Google Scholar] [CrossRef]

- Fernandez-Pello, A.C. Wildland Fire Spot Ignition by Sparks and Firebrands. Fire Saf. J. 2017, 91, 2–10. [Google Scholar] [CrossRef]

- Baranovskiy, N.V.; Zakharevich, A.V. Experimental investigation of processes of typical forest fuel ignition by a high-temperature steel particle. Heat Transf. Res. 2016, 47, 681–689. [Google Scholar] [CrossRef]

- Rivera, J.; Hernández, N.; Consalvi, J.L.; Reszka, P.; Contreras, J.; Fuentes, A. Ignition of Wildland Fuels by Idealized Firebrands. Fire Saf. J. 2021, 120, 103036. [Google Scholar] [CrossRef]

- Bartoli, P.; Simeoni, A.; Biteau, H.; Torero, J.L.; Santoni, P.A. Determination of the Main Parameters Influencing Forest Fuel Combustion Dynamics. Fire Saf. J. 2011, 46, 27–33. [Google Scholar] [CrossRef]

- Tihay, V.; Morandini, F.; Santoni, P.-A.; Perez-Ramirez, Y.; Barboni, T. Combustion of Forest Litters under Slope Conditions: Burning Rate, Heat Release Rate, Convective and Radiant Fractions for Different Loads. Combust. Flame 2014, 161, 3237–3248. [Google Scholar] [CrossRef]

- Barboni, T.; Leonelli, L.; Santoni, P.-A.; Tihay-Felicelli, V. Influence of Particle Size on the Heat Release Rate and Smoke Opacity during the Burning of Dead Cistus Leaves and Twigs. J. Fire Sci. 2017, 35, 259–283. [Google Scholar] [CrossRef]

- Hadden, R.M.; Scott, S.; Lautenberger, C.; Fernandez-Pello, A.C. Ignition of Combustible Fuel Beds by Hot Particles: An Experimental and Theoretical Study. Fire Technol. 2011, 47, 341–355. [Google Scholar] [CrossRef]

- Altamirova, E.; Perminov, V.A. Mathematical Modeling of Forest Canopy Ignition by Thermal Radiation from a Hydrocarbon Explosion. Combust. Explos. Shock Waves 2019, 55, 574–579. [Google Scholar] [CrossRef]

- Urban, J.L.; Zak, C.D.; Song, J.; Fernandez-Pello, C. Smoldering Spot Ignition of Natural Fuels by a Hot Metal Particle. Proc. Combust. Inst. 2017, 36, 3211–3218. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Salomatov, V.V.; Syrodoy, S.V. Ignition of Particles of Wet Woody Biomass under Convective Diffusion of Water Vapor in the Near-Wall Region. Combust. Explos. Shock Waves 2018, 54, 325–336. [Google Scholar] [CrossRef]

- Hollis, J.J.; McCaw, W.L.; Cruz, M.G.; Hollis, J.J.; McCaw, W.L.; Cruz, M.G. The Effect of Woody Fuel Characteristics on Fuel Ignition and Consumption: A Case Study from a Eucalypt Forest in South-West Western Australia. Int. J. Wildland Fire 2018, 27, 363–375. [Google Scholar] [CrossRef]

- Baranovskiy, N.V.; Naumkin, A.S. Mathematical Simulation of Heat Transfer in Heterogenous Forest Fuel Layer Influenced by Heated Up to High Temperatures Steel Particle. MATEC Web Conf. 2014, 19, 01036. [Google Scholar] [CrossRef]

- Matvienko, O.V.; Kasymov, D.P.; Filkov, A.I.; Daneyko, O.I.; Gorbatov, D.A. Simulation of Fuel Bed Ignition by Wildland Firebrands. Int. J. Wildland Fire 2018, 27, 550–561. [Google Scholar] [CrossRef]

- Grishin, A.M.; Dolgov, A.A.; Zima, V.P.; Kryuchkov, D.A.; Reino, V.V.; Subbotin, A.N.; Tsvyk, R.S. Ignition of a Layer of Combustible Forest Materials. Combust. Explos. Shock Waves 1998, 34, 613–620. [Google Scholar] [CrossRef]

- Shotorban, B.; Yashwanth, B.L.; Mahalingam, S.; Haring, D.J. An Investigation of Pyrolysis and Ignition of Moist Leaf-like Fuel Subject to Convective Heating. Combust. Flame 2018, 190, 25–35. [Google Scholar] [CrossRef]

- Yashwanth, B.L.; Shotorban, B.; Mahalingam, S.; Lautenberger, C.W.; Weise, D.R. A Numerical Investigation of the Influence of Radiation and Moisture Content on Pyrolysis and Ignition of a Leaf-like Fuel Element. Combust. Flame 2016, 163, 301–316. [Google Scholar] [CrossRef]

- Baranovskiy, N.; Demikhova, A. Mathematical Modeling of Heat Transfer in an Element of Combustible Plant Material When Exposed to Radiation from a Forest Fire. Safety 2019, 5, 56. [Google Scholar] [CrossRef]

- Engstrom, J.D.; Butler, J.K.; Smith, S.G.; Baxter, L.L.; Fletcher, T.H.; WEISE, D.R. Ignition Behavior of Live California Chaparral Leaves. Combust. Sci. Technol. 2004, 176, 1577–1591. [Google Scholar] [CrossRef]

- Pickett, B.M.; Isackson, C.; Wunder, R.; Fletcher, T.H.; Butler, B.W.; Weise, D.R.; Pickett, B.M.; Isackson, C.; Wunder, R.; Fletcher, T.H.; et al. Experimental Measurements during Combustion of Moist Individual Foliage Samples. Int. J. Wildland Fire 2010, 19, 153–162. [Google Scholar] [CrossRef]

- Borujerdi, P.R.; Shotorban, B.; Mahalingam, S. A Computational Study of Burning of Vertically Oriented Leaves with Various Fuel Moisture Contents by Upward Convective Heating. Fuel 2020, 276, 118030. [Google Scholar] [CrossRef]

- Nesterov, V.G. General Forestry; Goslesbumizdat: Moscow, Russia, 1954; 656p. (In Russian) [Google Scholar]

- GOST R 22.1.09-99; Monitoring and Forecasting Forest Fires. General Requirements. Gosstandart RF: Moscow, Russia, 1999; 10p. (In Russian)

- Baranovskiy, N.V.; Kuznetsov, G.V. Forest Fire Occurrences and Ecological Impact Prediction: Monograph; Publishing House of the Siberian Branch of the Russian Academy of Science: Novosibirsk, Russia, 2017. [Google Scholar]

- Kuznetsov, G.V.; Sheremet, M.A. Conjugate natural convection with radiation in an enclosure. Int. J. Heat Mass Transfer. 2009, 52, 2215–2223. [Google Scholar] [CrossRef]

- Camia, A.; Barbosa, P.; Amatulli, G.; San-Miguel-Ayanz, J. Fire danger rating in the European Forest Fire Information System (EFFIS): Current developments. For. Ecol. Manag. 2006, 234 (Suppl. 1), S20. [Google Scholar] [CrossRef]

- Viegas, D.X.; Bovio, G.; Ferreira, A.; Nosenzo, A.; Sol, B. Comparative Study of Various Methods of Fire Danger Evaluation in Southern Europe. Int. J. Wildland Fire 2000, 9, 235–246. [Google Scholar] [CrossRef]

- Pankratov, B.M.; Polezhaev, Y.V.; Rudko, A.K. Interaction of Materials with Gas Streams; Zuev, V.S., Ed.; Mechanical Engineering: Moscow, Russia, 1975; 224p. (In Russian) [Google Scholar]

- Grishin, A.M.; Golovanov, A.N.; Rusakov, S.V. Evaporation of free water and water bound with forest combustibles under isothermal conditions. Inzhenerno-Fizicheskii Zhurnal 2003, 76, 175–180. [Google Scholar] [CrossRef]

- Grishin, A.M.; Golovanov, A.N.; Kataeva, L.Y.; Loboda, E.L. Problem of drying of a layer of combustible forest materials. Inzhenerno-Fizcheskii Zhurnal 2001, 74, 58–64. [Google Scholar]

- Grishin, A.M.; Golovanov, A.N.; Kataeva, L.Y.; Loboda, E.L. Formulation and solution of the problem of drying of a combustible forest materials layer. Fizika Goreniya i Vzryva 2001, 37, 65–76. [Google Scholar]

- Grishin, A.M.; Kuzin, A.Y.; Alekseenko, E.M. Determination of kinetic characteristics of the process of drying of forest combustibles. Inzhenerno-Fizcheskii Zhurnal 2003, 76, 170–174. [Google Scholar] [CrossRef]

- Baranovskiy, N. Deterministic-Probabilistic Approach to Predict Lightning-Caused Forest Fires in Mounting Areas. Forecasting 2021, 3, 43. [Google Scholar] [CrossRef]

- Baranovskiy, N.V. Forest fire danger assessment using SPMD-model of computation for massive parallel system. Int. Rev. Model. Simul. 2017, 10, 193–201. [Google Scholar] [CrossRef]

- Baranovskiy, N.V.; Kirienko, V.A. Mathematical simulation of heat and mass transfer during forest fuel pyrolysis caused by high temperature from crown forest fire. Int. Rev. Model. Simul. 2020, 13, 223–233. [Google Scholar] [CrossRef]

- Grishin, A.M. Mathematical Modeling of Forest Fires and New Ways to Fighting Them; Science: Novosibirsk, Russia, 1992; 401p. (In Russian) [Google Scholar]

- Baranovskiy, N.V. Algorithms for parallelizing a mathematical model of forest fires on supercomputers and theoretical estimates for the efficiency of parallel programs. Cybern. Syst. Anal. 2015, 51, 471–480. [Google Scholar] [CrossRef]

- Baranovskiy, N.V. Prediction of Forest Fire Danger Caused by Lightning Activity; Publishing House of the Siberian Branch of the Russian Academy of Sciences: Novosibirsk, Russia, 2019. (In Russian) [Google Scholar]

- Kuznetsov, G.V.; Strizhak, P.A. Ignition of Condensed Substances with Local Heating; Publishing house of the SB RAS: Novosibirsk, Russia, 2010. (In Russian) [Google Scholar]

- Baranovskiy, N.V.; Zakharevich, A.V. Mechanical, thermophysical and aerothermochemical processes at forest fuel ignition caused by the heated to high temperatures single metal particle. Int. Rev. Mech. Eng. 2018, 12, 522–532. [Google Scholar] [CrossRef]

- Sandberg, D.V.; Ottmar, R.D.; Cushon, G.H. Characterizing fuels in the 21st century. Int. J. Wildland Fire 2001, 10, 381–387. [Google Scholar] [CrossRef]

| Number | Type | Reference | Input Data | Index |

|---|---|---|---|---|

| 1 | Empirical (Fieldworks, calibrated sticks) | [28,31,32,63,64,65,66] | Forest fuel samples from the forest area under study | FMC (living and dead), EMC |

| 2 | Remote sensing | [31,36,37,38] | Satellite data, forest fuel reflectance in the near-infrared, shortwave infrared, and red bands | NDVI, NDII, LWCI |

| 3 | Radiative transfer models | [39,42,43,44,45,46] | Satellite data, forest fuel spectral characteristics and properties | FMC |

| 4 | Meteorological index | [71,72,73,74,75,76,77,78,79,80] | Daily synoptic data (temperature, humidity, daily precipitation) | Nesterov Index, Modified Nesterov index, Keetch-Byram drought index, Angstrom index |

| Number | Type | Reference | Dry Organic Matter | Stages |

|---|---|---|---|---|

| 1 | Mechanistic models | [93,94,95,96] | considered as a multicomponent substance (cellulose, hemicellulose, and lignin). The components pyrolysis can be considered separately | All the reaction paths and the formed components are considered. |

| 2 | Network models | [93,97,98,99] | considered as a multicomponent substance (cellulose, hemicellulose, and lignin). Components have different macromolecular structure | Sequence of stages (depolymerization, repolymerization, external transport, internal transport) |

| 3 | Kinetic models | [100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127] | considered as a single substance | Lumped and distributed, global and detailed, one-stage, tree independent reactions and competing reactions |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baranovskiy, N.V.; Kirienko, V.A. Forest Fuel Drying, Pyrolysis and Ignition Processes during Forest Fire: A Review. Processes 2022, 10, 89. https://doi.org/10.3390/pr10010089

Baranovskiy NV, Kirienko VA. Forest Fuel Drying, Pyrolysis and Ignition Processes during Forest Fire: A Review. Processes. 2022; 10(1):89. https://doi.org/10.3390/pr10010089

Chicago/Turabian StyleBaranovskiy, Nikolay Viktorovich, and Viktoriya Andreevna Kirienko. 2022. "Forest Fuel Drying, Pyrolysis and Ignition Processes during Forest Fire: A Review" Processes 10, no. 1: 89. https://doi.org/10.3390/pr10010089

APA StyleBaranovskiy, N. V., & Kirienko, V. A. (2022). Forest Fuel Drying, Pyrolysis and Ignition Processes during Forest Fire: A Review. Processes, 10(1), 89. https://doi.org/10.3390/pr10010089