Modeling and Analysis of Industry 4.0 Adoption Challenges in the Manufacturing Industry

Abstract

:1. Introduction

1.1. Literature Review on I4.0 Adoption Challenges

1.2. Research Gaps

- RQ1. What are the possible challenges in the I4.0 technologies adoption with regards to the manufacturing sector?

- RQ2. How can these challenges be analysed to develop a structural model between them?

- RQ3. What can be the potential solutions to mitigate critical challenges?

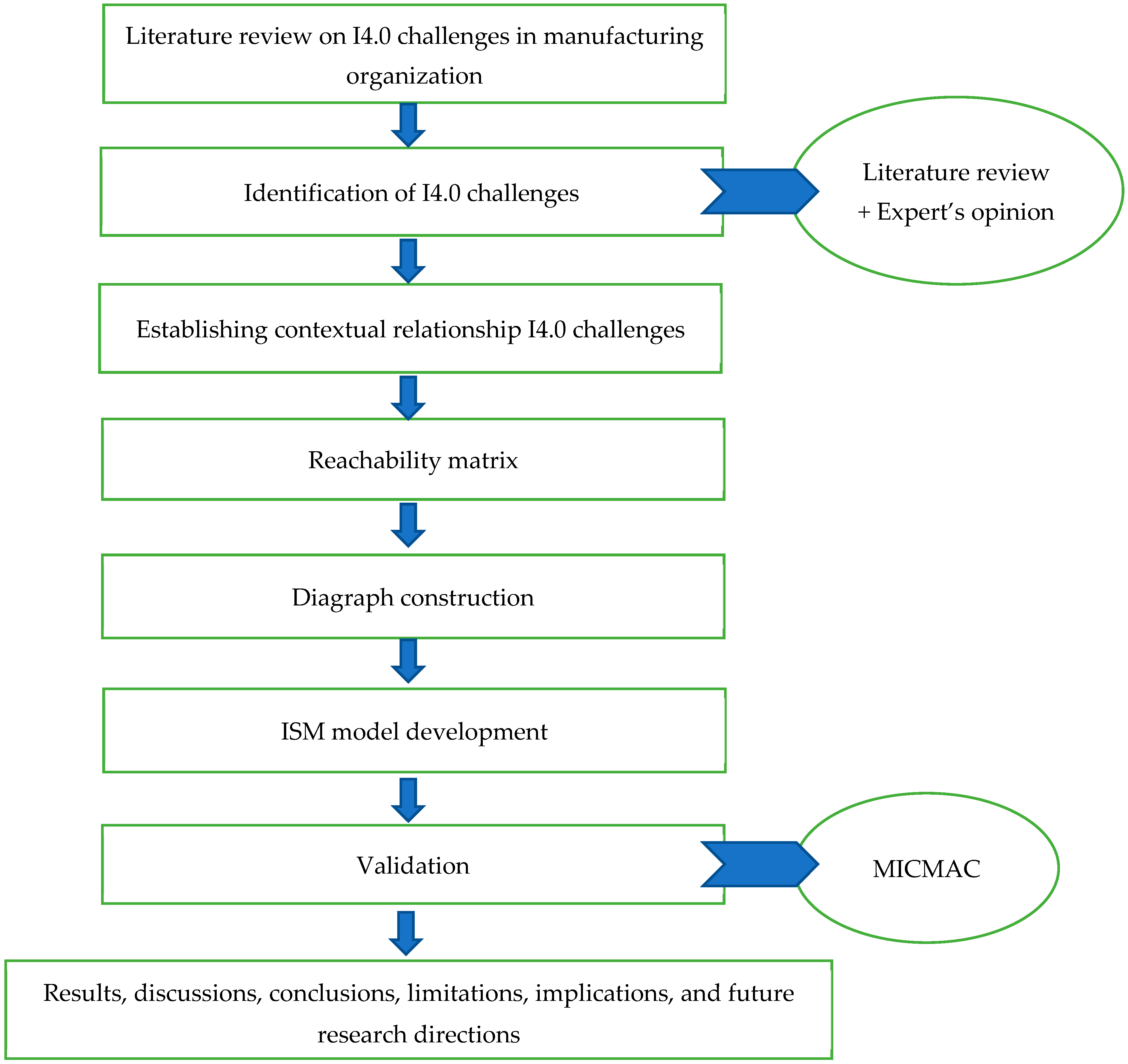

2. Materials and Methods

2.1. Case Study

2.1.1. Building the SSIM

- Challenge j helping to obtain challenge k = ‘V’.

- Challenge k obtained with the help of challenge j = ‘A’.

- Challenge j and k helped each other for accomplishment = ‘X’’.

- No relationship = ‘O’.

2.1.2. Initial Reachability Matrix

2.1.3. Final Reachability Matrix

2.1.4. Level Partitions

3. Results

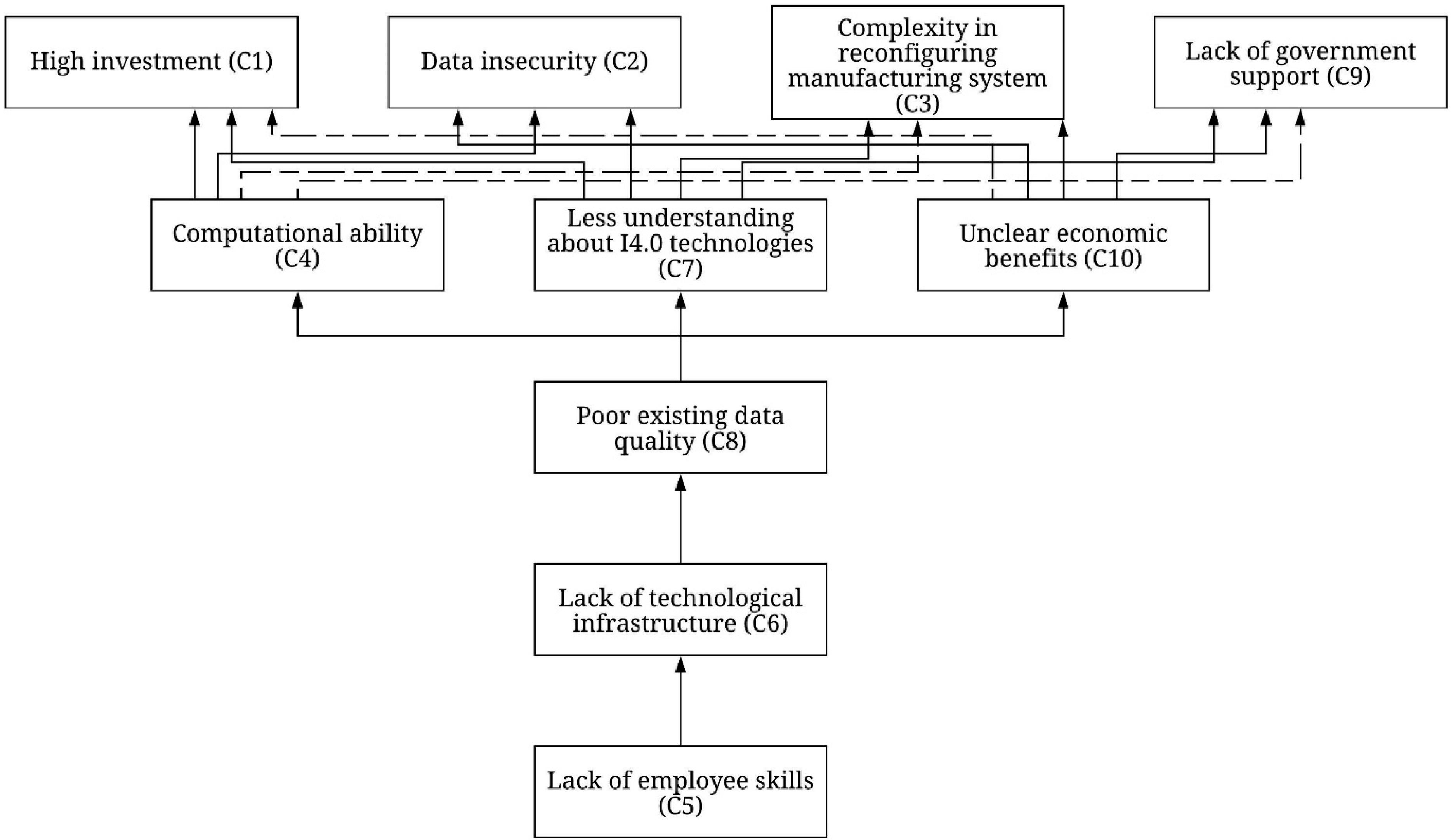

3.1. Establishment of ISM Model

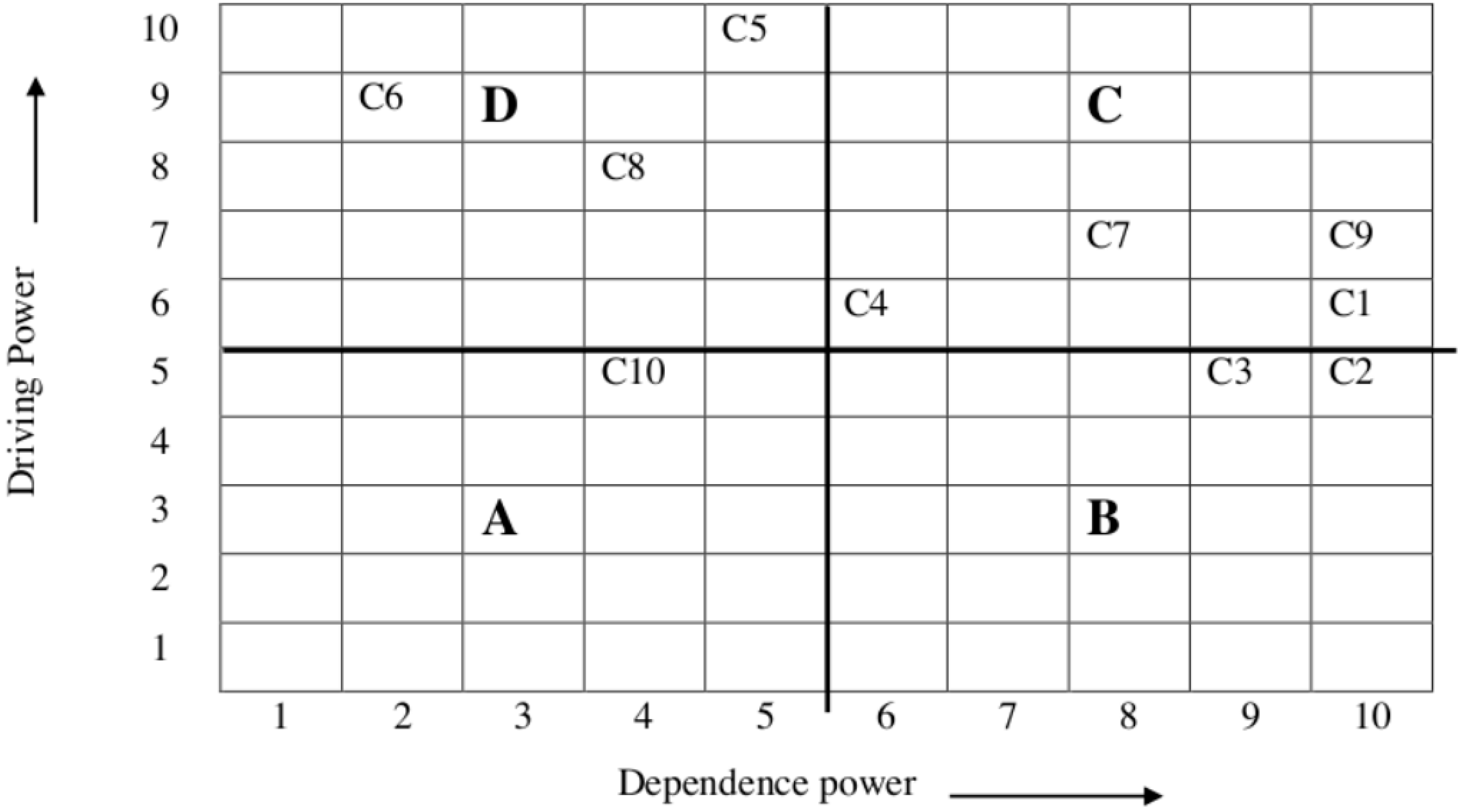

3.2. MICMAC Analysis

4. Discussions

Practical and Managerial Implications

5. Conclusions

Limitations, and Future Research Directions

Funding

Conflicts of Interest

References

- Manufacturing-Saudi Arabia. Available online: https://www.statista.com/outlook/io/manufacturing/saudi-arabia (accessed on 8 October 2022).

- de Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Vinodh, S.; Antony, J.; Agrawal, R.; Douglas, J.A. Integration of continuous improvement strategies with Industry 4.0: A systematic review and agenda for further research. TQM J. 2021, 33, 441–472. [Google Scholar] [CrossRef]

- Etemadi, N.; Van Gelder, P.; Strozzi, F. An ism modeling of barriers for blockchain/distributed ledger technology adoption in supply chains towards cybersecurity. Sustainability 2021, 13, 4672. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef] [Green Version]

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Luthra, S.; Huisingh, D. Progress and trends in integrating Industry 4.0 within Circular Economy: A comprehensive literature review and future research propositions. Bus. Strategy Environ. 2021, 31, 559–579. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ingaldi, M.; Ulewicz, R. Problems with the implementation of industry 4.0 in enterprises from the SME sector. Sustainability 2020, 12, 217. [Google Scholar] [CrossRef] [Green Version]

- Majumdar, A.; Garg, H.; Jain, R. Managing the barriers of Industry 4.0 adoption and implementation in textile and clothing industry: Interpretive structural model and triple helix framework. Comput. Ind. 2021, 125, 103372. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A supply chain innovation perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Grendel, H.; Larek, R.; Riedel, F.; Wagner, J.C. Enabling manual assembly and integration of aerospace structures for Industry 4.0-Methods. Procedia Manuf. 2017, 14, 30–37. [Google Scholar] [CrossRef]

- Pace, P.; Aloi, G.; Gravina, R.; Caliciuri, G.; Fortino, G.; Liotta, A. An Edge-Based Architecture to Support Efficient Applications for Healthcare Industry 4.0. IEEE Trans. Ind. Informatics. 2019, 15, 481–489. [Google Scholar] [CrossRef] [Green Version]

- Bianco, D.; Filho, M.G.; Osiro, L.; Ganga, G.M.D. Unlocking the Relationship Between Lean Leadership Competencies and Industry 4.0 Leadership Competencies: An ISM/Fuzzy MICMAC Approach. IEEE Trans. Eng. Manag. 2022, 1–25. [Google Scholar] [CrossRef]

- Khan, A.; Turowski, K. A survey of current challenges in manufacturing industry and preparation for industry 4.0. In Proceedings of the First International Scientific Conference “Intelligent Information Technologies for Industry; Springer: Cham, Switzerland, 2016; pp. 15–26. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery, FSKD, Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar] [CrossRef]

- Kergroach, S. Industry 4.0: New challenges and opportunities for the labour market. Foresight STI Gov. 2017, 11, 6–8. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and managerial challenges in the path toward Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]

- Sevinç, A.; Gür, S.; Eren, T. Analysis of the difficulties of SMEs in industry 4.0 applications by analytical hierarchy process and analytical network process. Processes 2018, 6, 264. [Google Scholar] [CrossRef] [Green Version]

- Moktadir, M.A.; Ali, S.M.; Kusi-Sarpong, S.; Shaikh, M.A.A. Assessing challenges for implementing Industry 4.0: Implications for process safety and environmental protection. Process Saf. Environ. Prot. 2018, 117, 730–741. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Turkyilmaz, A.; Dikhanbayeva, D.; Suleiman, Z.; Shaikholla, S.; Shehab, E. Industry 4.0: Challenges and opportunities for Kazakhstan SMEs. Procedia CIRP 2021, 96, 213–218. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tran, T.P.T.; Ha, H.M.; Bui, T.-D.; Lim, M.K. Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: A data driven analysis. J. Ind. Prod. Eng. 2021, 38, 581–598. [Google Scholar] [CrossRef]

- Aoun, A.; Ilinca, A.; Ghandour, M.; Ibrahim, H. A review of Industry 4.0 characteristics and challenges, with potential improvements using blockchain technology. Comput. Ind. Eng. 2021, 162, 107746. [Google Scholar] [CrossRef]

- Lelli, F. Interoperability of the Time of Industry 4.0 and the Internet of Things. Future Internet 2019, 11, 36. [Google Scholar] [CrossRef] [Green Version]

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in Smart Manufacturing: Research Challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef] [Green Version]

- Calderón Godoy, A.J.; González Pérez, I. Integration of Sensor and Actuator Networks and the SCADA System to Promote the Migration of the Legacy Flexible Manufacturing System towards the Industry 4.0 Concept. J. Sens. Actuator Netw. 2018, 7, 23. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Zheng, X.; Villalba-Díez, J.; Ordieres-Meré, J. Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors 2020, 20, 3046. [Google Scholar] [CrossRef]

- Sajjad, A.; Ahmad, W.; Hussain, S.; Mehmood, R.M. Development of Innovative Operational Flexibility Measurement Model for Smart Systems in Industry 4.0 Paradigm. IEEE Access 2021, 10, 6760–6774. [Google Scholar] [CrossRef]

- Karadayi-Usta, S. An Interpretive Structural Analysis for Industry 4.0 Adoption Challenges. IEEE Trans. Eng. Manag. 2020, 67, 973–978. [Google Scholar] [CrossRef]

- Naz, F.; Agrawal, R.; Kumar, A.; Gunasekaran, A.; Majumdar, A.; Luthra, S. Reviewing the applications of artificial intelligence in sustainable supply chains: Exploring research propositions for future directions. Bus. Strategy Environ. 2022, 31, 2400–2423. [Google Scholar] [CrossRef]

- Agrawal, R.; Majumdar, A.; Majumdar, K.; Raut, R.D.; Narkhede, B.E. Attaining sustainable development goals (SDGs) through supply chain practices and business strategies: A systematic review with bibliometric and network analyses. Bus. Strategy Environ. 2022, 1–19. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.C.; Suryadevara, N.K. Internet of Things: Challenges and Opportunities. Internet Things 2014, 1–17. [Google Scholar] [CrossRef]

- Ozkan-Ozen, Y.D.; Kazancoglu, Y.; Kumar Mangla, S. Synchronized Barriers for Circular Supply Chains In Industry 3.5/Industry 4.0 Transition For Sustainable Resource Management. Resour. Conserv. Recycl. 2020, 161, 104986. [Google Scholar] [CrossRef]

- Alladi, T.; Chamola, V.; Parizi, R.M.; Choo, K.-K.R. Blockchain Applications for Industry 4.0 and Industrial IoT: A Review. IEEE Access 2019, 7, 176935–176951. [Google Scholar] [CrossRef]

- Kumar, S.; Suhaib, M.; Asjad, M. Analyzing the barriers to industry 4.0 through best-worst method. Int. J. Perform. Eng. 2020, 16, 27–36. [Google Scholar] [CrossRef]

- Wankhede, V.A.; Vinodh, S. Analysis of Industry 4.0 challenges using best worst method: A case study. Comput. Ind. Eng. 2021, 159, 10748. [Google Scholar] [CrossRef]

- Kumar, A. Methods and Materials for Smart Manufacturing: Additive Manufacturing, Internet of Things, Flexible Sensors and Soft Robotics. Manuf. Lett. 2018, 15, 122–125. [Google Scholar] [CrossRef]

- Peralta, M.E.; Soltero, V.M. Analysis of fractal manufacturing systems framework towards industry 4.0. J. Manuf. Syst. 2020, 57, 46–60. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Sommer, L. Industrial revolution-industry 4.0: Are German manufacturing SMEs the first victims of this revolution? J. Ind. Eng. Manag. 2015, 8, 1512–1532. [Google Scholar] [CrossRef] [Green Version]

- Machado, C.G.; Winroth, M.; Carlsson, D.; Almström, P.; Centerholt, V.; Hallin, M. Industry 4.0 readiness in manufacturing companies: Challenges and enablers towards increased digitalization. Procedia CIRP 2019, 81, 1113–1118. [Google Scholar] [CrossRef]

- Saniuk, S.; Caganova, D.; Saniuk, A. Knowledge and Skills of Industrial Employees and Managerial Staff for the Industry 4.0 Implementation. Mob. Networks Appl. 2021, 1–11. [Google Scholar] [CrossRef]

- Wankhede, V.A.; Vinodh, S. Analysis of barriers of cyber-physical system adoption in small and medium enterprises using interpretive ranking process. Int. J. Qual. Reliab. Manag. 2021. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; Lopes de Sousa Jabbour, A.B.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Kumar, P.; Bhamu, J.; Sangwan, K.S. Analysis of Barriers to Industry 4.0 adoption in Manufacturing Organizations: An ISM Approach. Procedia CIRP 2021, 98, 85–90. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Jepsen, S.C.; Mørk, T.I.; Hviid, J.; Worm, T. A Pilot Study of Industry 4.0 Asset Interoperability Challenges in an Industry 4.0 Laboratory. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 14–17 December 2020; pp. 571–575. [Google Scholar] [CrossRef]

- Santos, M.Y.; e Sá, J.O.; Costa, C.; Galvão, J.; Andrade, C.; Martinho, B.; Lima, F.V.; Costa, E. A Big Data Analytics Architecture for Industry 4.0. In World Conference on Information Systems and Technologies; Springer: Cham, Switzerland, 2017; pp. 175–184. [Google Scholar] [CrossRef]

- Kumar, A.; Agrawal, R.; Wankhede, V.A.; Sharma, M.; Mulat-weldemeskel, E. A framework for assessing social acceptability of industry 4.0 technologies for the development of digital manufacturing. Technol. Forecast. Soc. Chang. 2022, 174, 121217. [Google Scholar] [CrossRef]

- Marques, M.; Agostinho, C.; Zacharewicz, G.; Jardim-Gonçalves, R. Decentralized decision support for intelligent manufacturing in Industry 4.0. J. Ambient Intell. Smart Environ. 2017, 9, 299–313. [Google Scholar] [CrossRef]

- Abdul-Hamid, A.Q.; Ali, M.H.; Tseng, M.L.; Lan, S.; Kumar, M. Impeding challenges on industry 4.0 in circular economy: Palm oil industry in Malaysia. Comput. Oper. Res. 2020, 123, 105052. [Google Scholar] [CrossRef]

- Watson, R.H. Interpretive structural modeling—A useful tool for technology assessment? Technol. Forecast. Soc. Chang. 1978, 11, 165–185. [Google Scholar] [CrossRef]

- Song, L.; Li, Q.; List, G.F.; Deng, Y.; Lu, P. Using an AHP-ISM based method to study the vulnerability factors of urban rail transit system. Sustainability 2017, 9, 1065. [Google Scholar] [CrossRef] [Green Version]

- Gholami, H.; Bachok, M.F.; Saman, M.Z.M.; Streimikiene, D.; Sharif, S.; Zakuan, N. An ISM approach for the barrier analysis in implementing green campus operations: Towards higher education sustainability. Sustainability 2020, 12, 363. [Google Scholar] [CrossRef] [Green Version]

- Agrawal, R.; Wankhede, V.A.; Nair, R.S. Analysis of Drivers of Digital Learning in COVID-19 and Post-COVID-19 Scenario Using an ISM Approach. J. Inst. Eng. India Ser. B 2021, 102, 1143–1155. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput. Ind. 2018, 101, 107–119. [Google Scholar] [CrossRef]

| Challenges | Description | References |

|---|---|---|

| High investment (C1) | High investment refers to the capital expenditure for establishing I4.0 infrastructure in the manufacturing industry. Several organizations face difficulty due to a lack of funding. | [32,33,34] |

| Data insecurity (C2) | Data insecurity due to losing existing security system. | [35,36] |

| Complexity in reconfiguring manufacturing systems (C3) | Lack of capabilities in reconfiguring of fabrication pattern for effortless execution of I4.0 in the manufacturing organization. Traditional manufacturing firms are not flexible enough to adopt I4.0 technologies. Different sensors and actuators may not be fitted into traditional manufacturing system. So, manufacturing firms must reconfigure their systems to adopt I4.0 technologies | [19,37,38] |

| Computational ability (C4) | High computational ability results in agile decision making. | [36,39,40] |

| Lack of employee skills (C5) | Employee skills refer to the higher level of skill sets of employees in I4.0. | [41,42,43] |

| Lack of technological infrastructure (C6) | Deployment of advanced technologies smoothens the I4.0 execution in an organization. Traditional manufacturing firms may not have good data information system. So, collecting information is quite difficult with traditional systems. Moreover, exchange of information among different departments is difficult with traditional systems. So, there must be sound technological infrastructure to support I4.0 technologies. | [44,45,46] |

| Less understanding about I4.0 technologies (C7) | Less knowledge on I4.0 technologies may result in resistance to the change with respect to I4.0 implementation. | [46,47,48] |

| Poor existing data quality (C8) | Good data quality improves the overall productivity of an organization. | [45,49] |

| Lack of government support (C9) | Government support is essential in the smooth adoption of I4.0 technologies. | [46,50] |

| Unclear economic benefits (C10) | Unclear economic benefits refer to the poor understanding of the advantages of I4.0 implementation. | [51,52] |

| High Investment | Data Insecurity | Complexity in Reconfiguring Manufacturing System | Computational Ability | Lack of Employee Skills | Lack of Technological Infrastructure | Less Understanding about I4.0 Technologies | Poor Existing Data Quality | Lack of Government Support | Unclear Economic Benefits | |

|---|---|---|---|---|---|---|---|---|---|---|

| High investment | - | V | A | A | O | A | X | O | A | O |

| Data insecurity | - | - | X | A | A | A | A | A | X | O |

| Complexity in reconfiguring manufacturing system | - | - | - | O | A | A | A | A | O | O |

| Computational ability | - | - | - | - | A | A | A | A | O | O |

| Lack of employee skills | - | - | - | - | - | V | V | V | X | O |

| Lack of technological infrastructure | - | - | - | - | - | - | O | V | O | V |

| Less understanding about I4.0 technologies | - | - | - | - | - | - | - | A | V | O |

| Poor existing data quality | - | - | - | - | - | - | - | - | O | V |

| Lack of government support | - | - | - | - | - | - | - | - | - | A |

| Unclear economic benefits | - | - | - | - | - | - | - | - | - | - |

| Condition | Relationship | Entry in SSIM | Binary Value |

|---|---|---|---|

| 1 | j → k | V | 1 |

| k → j | 0 | ||

| 2 | j → k | A | 0 |

| k → j | 1 | ||

| 3 | j → k | X | 1 |

| k → j | 1 | ||

| 4 | j → k | O | 0 |

| k → j | 0 |

| High Investment | Data Insecurity | Complexity in Reconfiguring Manufacturing System | Computational Ability | Lack of Employee Skills | Lack of Technological Infra-Structure | Less Under-Stand-Ing about I4.0 Technologies | Poor Existing Data Quality | Lack of Government Support | Unclear Economic Benefits | |

|---|---|---|---|---|---|---|---|---|---|---|

| High investment | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| Data insecurity | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| Complexity in reconfiguring manufacturing system | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Computational ability | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| Lack of employee skills | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| Lack of technological infrastructure | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| Less understanding about I4.0 technologies | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 |

| Poor existing data quality | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 1 |

| Lack of government support | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 |

| Unclear economic benefits | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| High Investment | Data Insecurity | Complexity in Reconfiguring Manufacturing System | Computational Ability | Lack of Employee Skills | Lack of Technological Infrastructure | Less Understanding about I4.0 Technologies | Poor Existing Data Quality | Lack of Government Support | Unclear Economic Benefits | |

|---|---|---|---|---|---|---|---|---|---|---|

| High investment | 1 | 1 | 1 * | 1 * | 0 | 0 | 1 | 0 | 1 * | 0 |

| Data insecurity | 1 * | 1 | 1 | 0 | 1 * | 0 | 0 | 0 | 1 | 0 |

| Complexity in reconfiguring manufacturing system | 1 | 1 | 1 | 0 | 0 | 0 | 1 * | 0 | 1 * | 0 |

| Computational ability | 1 | 1 | 1 * | 1 | 0 | 0 | 1 * | 0 | 1 * | 0 |

| Lack of employee skills | 1 * | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 * |

| Lack of technological infrastructure | 1 | 1 | 1 | 1 | 0 | 1 | 1 * | 1 | 1 * | 1 |

| Less understanding about I4.0 technologies | 1 | 1 | 1 | 1 | 1 * | 0 | 1 | 0 | 1 | 0 |

| Poor existing data quality | 1 * | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 * | 1 |

| Lack of government support | 1 | 1 | 1 * | 0 | 1 | 0 | 1 * | 1 * | 1 | 0 |

| Unclear economic benefits | 1 * | 1 | 0 | 0 | 1 * | 0 | 0 | 0 | 1 | 1 |

| Challenges | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| Iteration 1 | ||||

| C1 | (1,2,3,4,7,9) | (1,2,3,4,5,6,7,8,9,10) | (1,2,3,4,7,9) | I |

| C2 | (1,2,3,5,9) | (1,2,3,4,5,6,7,8,9,10) | (1,2,3,5,9) | I |

| C3 | (1,2,3,7,9) | (1,2,3,4,5,6,7,8,9) | (1,2,3,7,9) | I |

| C4 | (1,2,3,4,7,9) | (1,4,5,6,7,8) | (1,2,4,7) | |

| C5 | (1,2,3,4,5,6,7,8,9,10) | (2,5,7,9,10) | (2,5,7,9,10) | |

| C6 | (1,2,3,4,6,7,8,9,10) | (5,6) | (6) | |

| C7 | (1,2,3,4,5,7,9) | (1,3,4,5,6,7,8,9) | (1,3,4,5,7,9) | |

| C8 | (1,2,3,4,7,8,9,10) | (5,6,8,9) | (8,9) | |

| C9 | (1,2,3,5,7,8,9) | (1,2,3,4,5,6,7,8,9,10) | (1,2,3,5,7,8,9) | I |

| C10 | (1,2,5,9,10) | (5,6,8,10) | (5,10) | |

| Iteration 2 | ||||

| C4 | (4,7) | (4,5,6,7,8) | (4,7) | II |

| C5 | (4,5,6,7,8,10) | (5,7,10) | (5,7,10) | |

| C6 | (4,6,7,8,10) | (5,6) | (6) | |

| C7 | (4,5,7) | (4,5,6,7,8) | (4,5,7) | II |

| C8 | (4,7,8,10) | (5,6,8) | (8) | |

| C10 | (5,10) | (5,6,8,10) | (5,10) | II |

| Iteration 3 | ||||

| C5 | (5,6,8) | (5) | (5) | |

| C6 | (6,8) | (5,6) | (6) | |

| C8 | (8) | (5,6,8) | (8) | III |

| Iteration 4 | ||||

| C5 | (5,6) | (5) | (5) | |

| C6 | (6) | (5,6) | (6) | IV |

| Iteration 5 | ||||

| C5 | (5) | (5) | (5) | V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsaadi, N. Modeling and Analysis of Industry 4.0 Adoption Challenges in the Manufacturing Industry. Processes 2022, 10, 2150. https://doi.org/10.3390/pr10102150

Alsaadi N. Modeling and Analysis of Industry 4.0 Adoption Challenges in the Manufacturing Industry. Processes. 2022; 10(10):2150. https://doi.org/10.3390/pr10102150

Chicago/Turabian StyleAlsaadi, Naif. 2022. "Modeling and Analysis of Industry 4.0 Adoption Challenges in the Manufacturing Industry" Processes 10, no. 10: 2150. https://doi.org/10.3390/pr10102150

APA StyleAlsaadi, N. (2022). Modeling and Analysis of Industry 4.0 Adoption Challenges in the Manufacturing Industry. Processes, 10(10), 2150. https://doi.org/10.3390/pr10102150