Abstract

Industry 4.0 is the latest technological age, in which recent technological developments are being integrated within industrial systems. Consequently, maintenance management of current industrial manufacturing systems is affected by the emergence of the technologies and features of Industry 4.0. This study aimed to conduct a comprehensive literature review to understand how Industry 4.0 technologies and features affect the various functions of maintenance management systems. The reviewing process was initiated by examining the most recent related literature in three different databases. In total, 54 articles were classified into three research categories. Then, the integration of the main functions and components of the adopted maintenance management model and the Industry 4.0 features and technologies were aligned, focusing on the driving force of predictive maintenance. The analysis focused mainly on the technical aspects of the integration process, including integration concepts and integration-assisting tools, identifying the main applications and highlighting the challenges identified in the analysed literature. The key findings were that the main functions of maintenance management systems are significantly influenced by different Industry 4.0 technologies, mainly artificial intelligence–machine learning, CPS, IoT, big data, augmented reality, and cloud computing, in terms of successful integration. Consequently, the overall system implied tangible improvements through the involvement of different Industry 4.0 features which promote real-time condition monitoring, enable data management and curation, increase coordination between various maintenance tasks, facilitate supervision through remote maintenance applications, and, overall, improve operations and productivity, reduce unplanned shutdowns and, as a result, reduce the associated costs. To provide research directions, examples, and methodologies for integrating the various maintenance management system functions with the cutting-edge Industry 4.0 technologies and features based on real and practical cases present in the reviewed literature, the review’s findings are comprehensively categorised and summarised.

1. Introduction

The changes occurring now in every aspect of our daily lives result from technological advancement. This advancement has resulted in the emergence of new concepts, such as the Internet of Things (IoT), cloud computing, big data, artificial intelligence (AI), and cyber–physical systems (CPSs). These new technologies have paved the way for new innovative opportunities and more significant development in socioeconomic life [1]. This new stage of technological development is often referred to as “Industry 4.0” [2].

Industry 4.0 was first introduced by the German government to maintain mass production effectiveness and efficiency [3]. Industry 4.0 was proposed to respond to an increasing market demand around the globe, which implies more challenges, including intensified competition with leading industrial economies, such as the United States, and other developing economies, such as China and India. In addition to this, Industry 4.0 has come into being since many European countries are struggling to maintain their leading economic positions while facing various challenges, such as ageing communities, resource limitations, demographic and social changes, and the dynamic nature of world markets [4,5]. Industrial development has gone through four major advancement stages. The first industrial revolution was initiated in the 18th century and was characterised by mechanisation enabled by the power generated by steam and water. The second started at the beginning of the 20th century and was characterised by the utilisation of conveyor-based mass production supported by the emergence of electricity. The third revolution began in the 1960s and continued afterwards, witnessing the deployment of the programable logic controller (PLC) and the integration of computerised systems in machines to elevate automation and mass production [3,6,7]. The fourth development stage, namely, “Industry 4.0”, or the fourth industrial revolution, occurring now, is characterised by the utilisation of new technologies [8], which are resulting in new intelligent manufacturing systems [4]. Parallel with the development of industry, maintenance management has continuously developed to cope with the new requirements of industrial revolutions [8,9]. The origin of maintenance goes back to the first industrial revolution. During this period, maintenance meant using a machine until it failed and then repairing it. During the second industrial revolution, more complex machines were born, which needed more care and more complex maintenance activities. This age was characterised by frequency-based maintenance [10]. After the Second World War, in the 1950s, manufacturing sectors rapidly grew and were characterised by high competitiveness. Japanese engineers started to work on more proactive maintenance strategies to keep machines working and reduce downtimes; that is, a preventive maintenance strategy was applied. All technicians were encouraged to schedule general maintenance activities and report any other noted observations of machines. This method succeeded in reducing downtimes but resulted in high costs. Later, in the 1960s, more proactive maintenance strategies were developed, such as reliability-centred maintenance, risk-based maintenance, and total productive maintenance, due to the development of new manufacturing technologies. In the 21st century, the complexity of manufacturing systems is increasing, and maintenance has become a crucial and integrated part of the overall production system, which demands more concentration on the reduction of the associated costs, as well as increases in productivity, quality, and profits. More complex knowledge is needed to achieve these goals. Thus, the predictive maintenance strategy is being improved by better decision-support systems, which lead to fewer machine failures and fewer downtimes. Furthermore, another strategy that needs very complex knowledge is prescriptive maintenance, which is aligned with software support, AI, complex sensory systems for instant condition-based monitoring, IoT, big data, augmented reality (AR), and other integration-assisting tools in the total integration of maintenance management with Industry 4.0.

This paper reviews the most recent research works on integrating maintenance management systems’ functions and Industry 4.0 technologies and features to answer the research questions posed in the research objectives.

2. Background

This section aims at providing an overview of the maintenance management system model adopted in this study, as well as maintenance strategies and Industry4.0 technologies and features.

2.1. Maintenance Management

According to the European Committee of Standardization [11], maintenance management “includes all activities that determine the maintenance objectives, strategies, and responsibilities, and implementation by such means as maintenance planning, maintenance control, and the improvement of maintenance activities and economics”.

Maintenance was considered a nightmare in past decades due to the application of corrective maintenance only [12]. In this process, maintenance mainly involved repairing and replacing things when needed, without planning, scheduling, or optimisation, combined with a lack of awareness of machine downtimes and behaviour. After that, maintenance activities became an independent function in most factories instead of being a production sub-function [13]. Nowadays, with the inherent development of technological and industrial sectors, maintenance management has become a more complex function, including all technical and managerial skills and the flexibility to deal with dynamic business environments.

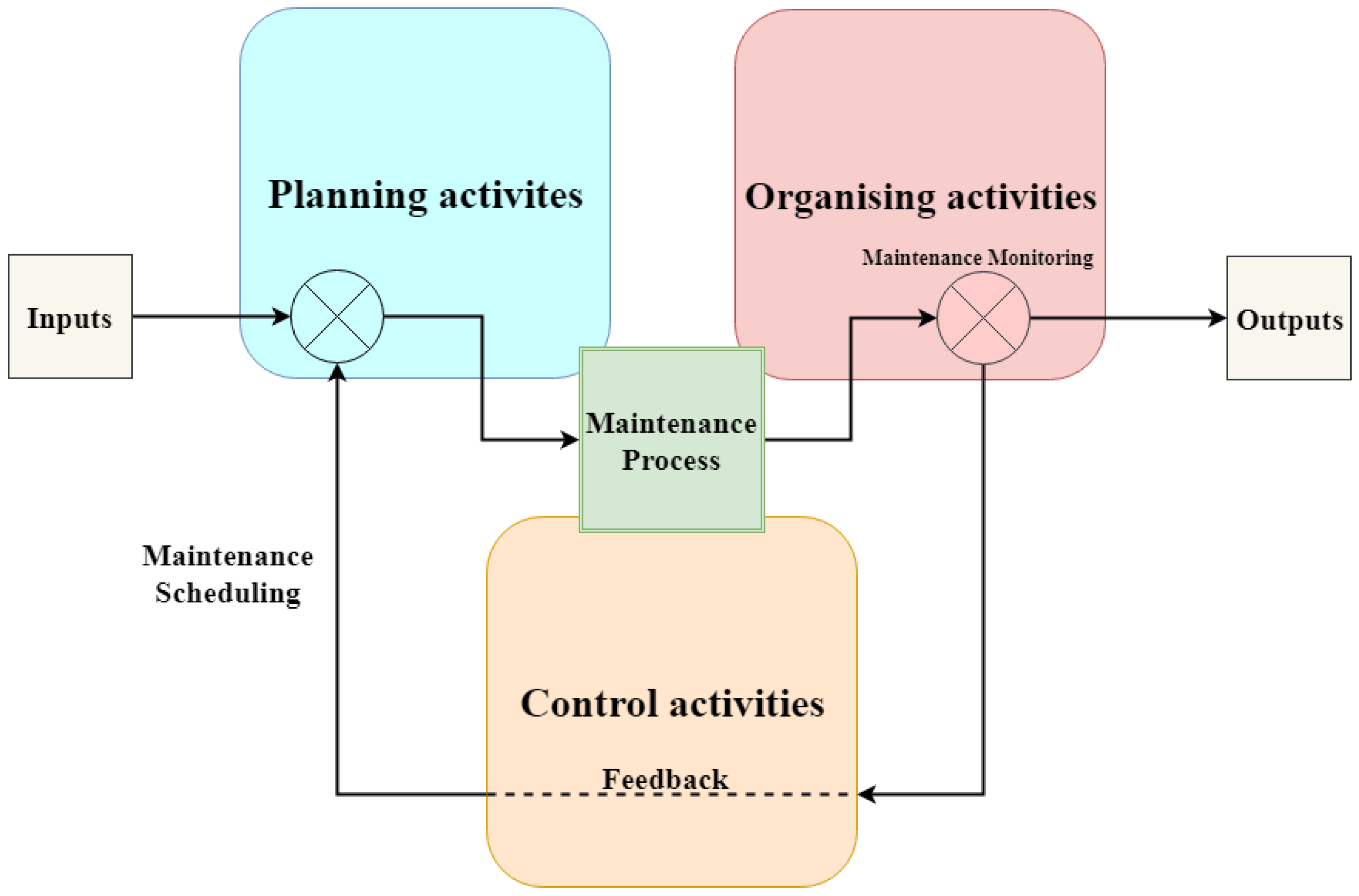

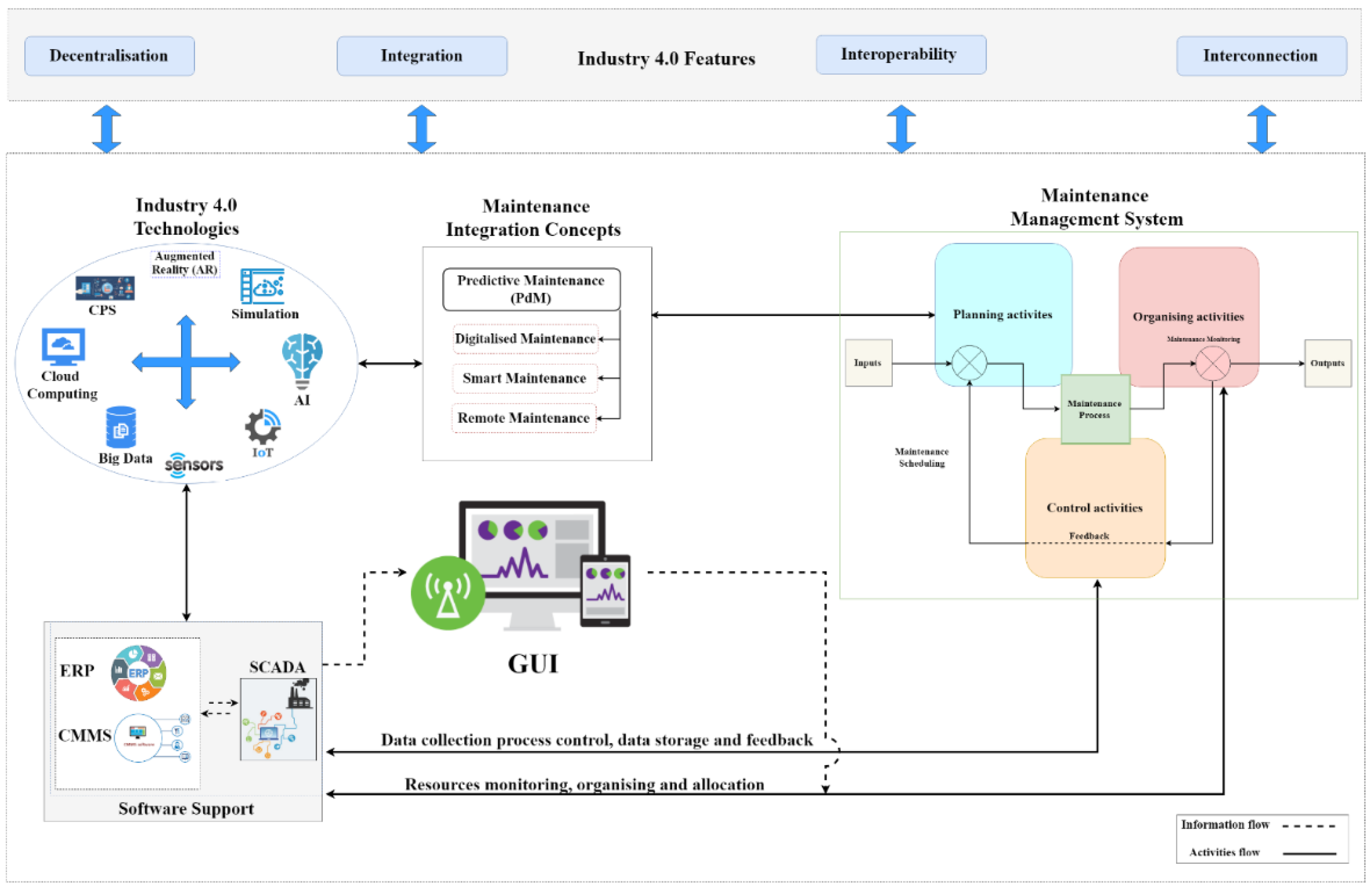

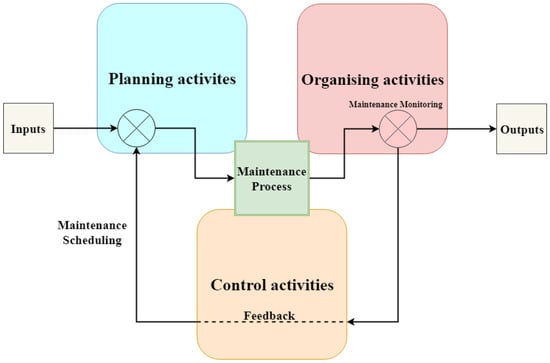

According to Duffuaa and Raouf [14], maintenance management systems consist of three major functions: planning, organisation and control. As depicted in Figure 1, planning activities include strategic maintenance alliances, in which the maintenance department should have its strategic maintenance plans comply with the strategic objectives of the company, such as outsourcing, organisation, and support. Moreover, planning includes maintenance load forecasting; its outputs are used as inputs for maintenance scheduling, maintenance control, and maintenance capacity planning, in which the needed resources for maintenance activities are determined, including manpower, material, spare parts, tools, and equipment. Furthermore, maintenance organisation planning is about the planning of factors that affect the maintenance process, such as plant size, maintenance load, type of organisation, and craftsmen skills. The last activity of maintenance planning is maintenance scheduling, in which resources, including manpower, are assigned to specific tasks within a timeframe.

Figure 1.

Maintenance Management System. Source: adopted from [14].

Similarly, organising activities include designing jobs and tasks, standards, and project management for better control. Feedback and control represent essential parts of management to control work, materials, and inventories, including spare parts, costs, quality, and the overall performance of manufacturing systems.

Maintenance is not just about retaining and restoring a unit, but includes another important aspect, namely, optimising the overall cost. The goal is to find the general optimum for any process based on predetermined requirements and targets. For this purpose, maintenance strategies need to be addressed and selected. Accordingly, the main maintenance strategies in any modern manufacturing system include but are not limited to the following:

Corrective maintenance (CM): Also known as run-to-failure maintenance or breakdown maintenance. This concept is based on fixing things after a failure occurrence [13]. It can be carried out promptly after the failure occurrence or postponed for further repair or replacement actions.

Preventive maintenance (PM): Ensures that equipment does not break unexpectedly. To achieve this, maintenance must be performed regularly to maintain the stability of machines [15].

Risk-based maintenance (RBM): In which the available resources for maintenance tasks are prioritised toward the machines or other assets the failure of which poses the most significant threats to the whole system [16]. Based on the associated risk analysis of the potentially failed asset, maintenance plans and schedules are updated, then they are monitored through other maintenance strategies, such as condition-based maintenance [17,18].

Condition-based maintenance (CBM): A maintenance action and decision-making program which recommends suitable actions according to condition monitoring information by utilising prognostic methods for more reliable and cost-effective maintenance [19].

Reliability-centred maintenance (RCM): An approach that was originally developed for the aircraft industry and used to generate a cost-effective maintenance schedule by utilising estimated parameters for the reliability of the system [20]. For applications that have safety issues, the minimisation of costs and downtime as the main goals are usually achieved by eliminating the chance of failure occurrence by striking a balance between safety and availability, along with cost-effective maintenance. RCM has two categories: the first involves the analysis and categorisation of failure modes according to their effects on systems; the second involves the assessment of maintenance scheduled impacts on system reliability. The results are formalised in the methodology of failure mode and effects analysis (FMEA).

Predictive maintenance (PdM): Represents an optimised trade-off between maintenance and performance costs. In addition, it measures efficiency and productivity and predicts remaining useful life before failure happens; it includes health condition monitoring and prognostics for future system behaviour and helps in decision-making processes [21,22]. It has been found that predictive maintenance is an effective strategy that can reduce the downtime of machines by 30–50% and extend their lifetime by 20–40% compared to traditional strategies [23,24].

Prescriptive maintenance: An advanced version of predictive maintenance supported by further decision-making mechanisms. Prescriptive maintenance goes one step further than PdM; it inspects not only the equipment to be maintained but also its environment and the correlation between them [25].

Opportunistic maintenance (OM): According to [26,27], OM is a systematic method of collecting, investigating, and preplanning activities for the generation of maintenance tasks to be implemented given opportunity [28]. A typical example is when a complex machine is disassembled to replace a broken component and it might be worth replacing other components that are close to end of life.

2.2. Industry 4.0

Industry 4.0 has been intensively discussed since the time it was first proposed by the German government in 2011 [4,29]. However, a brief definition of Industry 4.0, including its features and technologies, is vital to justify the topic being discussed in this paper.

Industry 4.0 indicates the current technological advancement and the integration of information and communication technology (ICT) applications in production systems [30]. This integration has resulted in new production and management system paradigms that depend mainly on higher communication and collaboration along value chains [7]. Furthermore, the availability and affordability of sensors, networking, and control devices, in addition to supercomputing power and cloud computing, have paved the way for what are called cyber–physical systems (CPSs), where whole systems, including information, objects, and humans, are interconnected [31,32]. Industry 4.0 is also known for integrating IoT on the manufacturing shopfloor and in the management supporting activities, such as logistics and planning. Such integration has resulted in a global network for the whole system, including machining, warehousing, and customers, where each party can control and exchange information with the others [5].

Industry 4.0 significantly impacts several aspects of production systems, i.e., optimising resource allocation and reducing human resources and logistical costs [33]. Moreover, Industry 4.0 has enhanced the flexibility of business processes by combining different business inputs, such as time, cost, quality, labour, and logistics [5]. Overall, Industry 4.0 is the synergistic combination of several technologies, resulting in several features that can be utilised in modern production systems and whole value chains.

2.2.1. Industry 4.0 Technologies

This section presents the most commonly studied Industry 4.0 technologies.

The Internet of Things (IoT) represents the system in which elements in the material world, such as machines, equipment, and devices, communicate with each other and with cyber elements, such as software and data [1,34]. The main characteristic of IoT is the strongly decentralised and heterogeneous digital information exchange between devices connected in a network. IoT offers the possibility of providing an instant response to any request from surrounding objects or environments [35]. IoT has enhanced production systems by optimising resources based on the collection of data from different locations in a value chain. Such information includes production monitoring, quality inspection, consumption information, and product performance under different operational conditions [32,36,37].

Cloud computing comprises online resources, such as servers, applications, and networks, to offer regular services that require more investment and resources to operate locally. Cloud computing is commonly used nowadays for its efficiency, cost-effectiveness, stability, and high-power availability, if needed [38]. Moreover, cloud computing is one of the main infrastructures for big data.

Big data is related to the development of the Internet and connectivity, which have generated production-related data in large volumes, with high velocity, variety, and veracity. Such data require more sophisticated systems that can handle, analyse, and transform them into useful knowledge. Data obtained with IoT devices are analysed, only meaningful information is extracted, and knowledge is transferred efficiently to support business activities [1].

Simulation has become an important tool in Industry 4.0 contexts. It is a powerful computational tool for designing, analysing, and understanding the behaviour of complex systems; it plays a key role in the successful implementation of digital manufacturing [39,40]. Moreover, complex systems can be modelled with simulation, and virtual experiments can be conducted to validate or configure processes or products to support decision making [34,41]. Deep insights into such complex systems can be obtained through different simulation techniques, while digital twin creation helps analyse real-time data to predict failures and breakdowns and improve maintenance planning and scheduling activities [42].

Artificial intelligence (AI) is considered one of the primary keys to transforming manufacturing systems in the era of Industry 4.0. Through the integration of IoT, big data, and AI tools, manufacturing systems are able to make factual decisions by real monitoring and analysis of their processes through real communication modules to coordinate and monitor all activities between machines, people, sensors, and other parts of the manufacturing system [43]. Meanwhile, machine-learning (ML) techniques are used in real-life scenarios to predict the future behaviour of systems [44]. The most suitable algorithm can be chosen based on the given computational power, memory resources, and the number and quality of the data to be analysed [45]. Artificial neural networks (ANNs) [46], neuro-fuzzy systems [47,48], hidden Markov models in Bayesian methods [49,50], Kalman filters, particle filters, and variants [51], and logistic regression [52] algorithms, along with many other tools, are used to develop effective machine-learning models to achieve high levels of operational maintenance and business excellence.

Cyber–physical systems (CPSs) comprise environments in which the physical world, including machines, warehousing, and whole manufacturing systems, are transformed into the cyber world through network devices [3], where both the cyber and the physical parts interact. Exhaustive connectivity, supported by supercomputing power, has enabled such systems to gather and process real-time data and control production processes instantly. In an Industry 4.0-enabled facility, every process is simulated and verified virtually, and once an optimum plan is ready, it is directly transformed into the physical world [53]. Such technology has automatically enabled production systems to adapt to instant production changes [6]. The vision of future factories (smart factories) can be achieved through Industry 4.0, in which CPSs monitor physical processes and visualise the real world by making virtual copies of these processes to implement and make decentralised decisions and actions [54]. A new type of smart production system known as a cyber–physical production system (CPPS) has emerged due to the development of new Industry 4.0 applications in smart factories [55]. Moreover, as stated by Monostori [56], CPPSs are more specific applications of CPSs in manufacturing [57,58]. The term refers to the integration of computer sciences, information and communication technologies, and manufacturing science and technologies.

2.2.2. Industry 4.0 Features

Ibarra et al. [31] highlighted the major features of Industry 4.0 as the following:

Interconnection refers to the interconnection between different elements in a value chain. An example is interconnection between machines that handle similar work to coordinate the flow of products and avoid downtime or production delays. The product can inform the machine about the kind of operation to perform. Such interconnection elevates intelligent production. Similarly, products are smart and connected; once a product is produced in a machine, the next machine is well-informed jointly with the conveyor or the logistics robot responsible for transporting the product to the location of the next production process [53]. Moreover, the connection between products, machines, and processes through data-exchange points results in more flexibility and autonomy. Such a process is realised by integrating the elements of cyber–physical systems and results in an intelligent value chain that can adapt, diagnose, and repair itself remotely [59].

Interoperability is a crucial feature in Industry 4.0; it is the ability of two different systems to communicate with each other and make mutual use of their functionalities according to basic and common technological standards [6]. Therefore, machines, products, suppliers, and customers are integrated through a common language. Interoperability is vital for the effective operation of IoT, as every machine should have an interoperability standard that makes communication with other machines possible [34].

Integration is the process of combining all elements of the production system, including machines, products, and control systems, using sensors and actuators, and connecting these elements with other key players, such as customers, suppliers, logistics, transportation, maintenance, and production management [33]. Henning et al. [5] highlighted three types of integration: horizontal, vertical, and end-to-end. Vertical integration refers to the integration of different units within an intelligent factory, while horizontal integration refers to the integration of the factories in the whole manufacturing value chain. End-to-end integration means the inherent integration in the entire value chain supporting the processes of the different stages in a product’s lifecycle, such as product design, production planning, maintenance, and recycling [4,60].

Decentralisation is the capability of a smart product or CPS to identify and successfully connect itself to another physically decentralised system and provide information about its state or conditions; thus, decentralisation could be either physical or logical [61].

3. Research Methodology

3.1. Research Objectives

This study aimed to examine, through a literature review, the current state of the integration of maintenance management systems within an Industry 4.0 environment. Moreover, it aimed to understand how the functions of maintenance management systems are impacted not only by Industry 4.0 technologies but also by Industry 4.0 features that appear to have a significant impact on the integration process, with a focus on key integration enablers, such as integration concepts and integration-assisting tools. This study attempted to answer the following research questions:

- How can Industry 4.0 influence maintenance management system functions?

- What assisting tools are used in the integration process within an Industry 4.0 environment?

- What are the impacts of Industry 4.0 features on the different components of a maintenance management system?

Moreover, potential applications, future trends, and challenges are also addressed.

3.2. Research Method

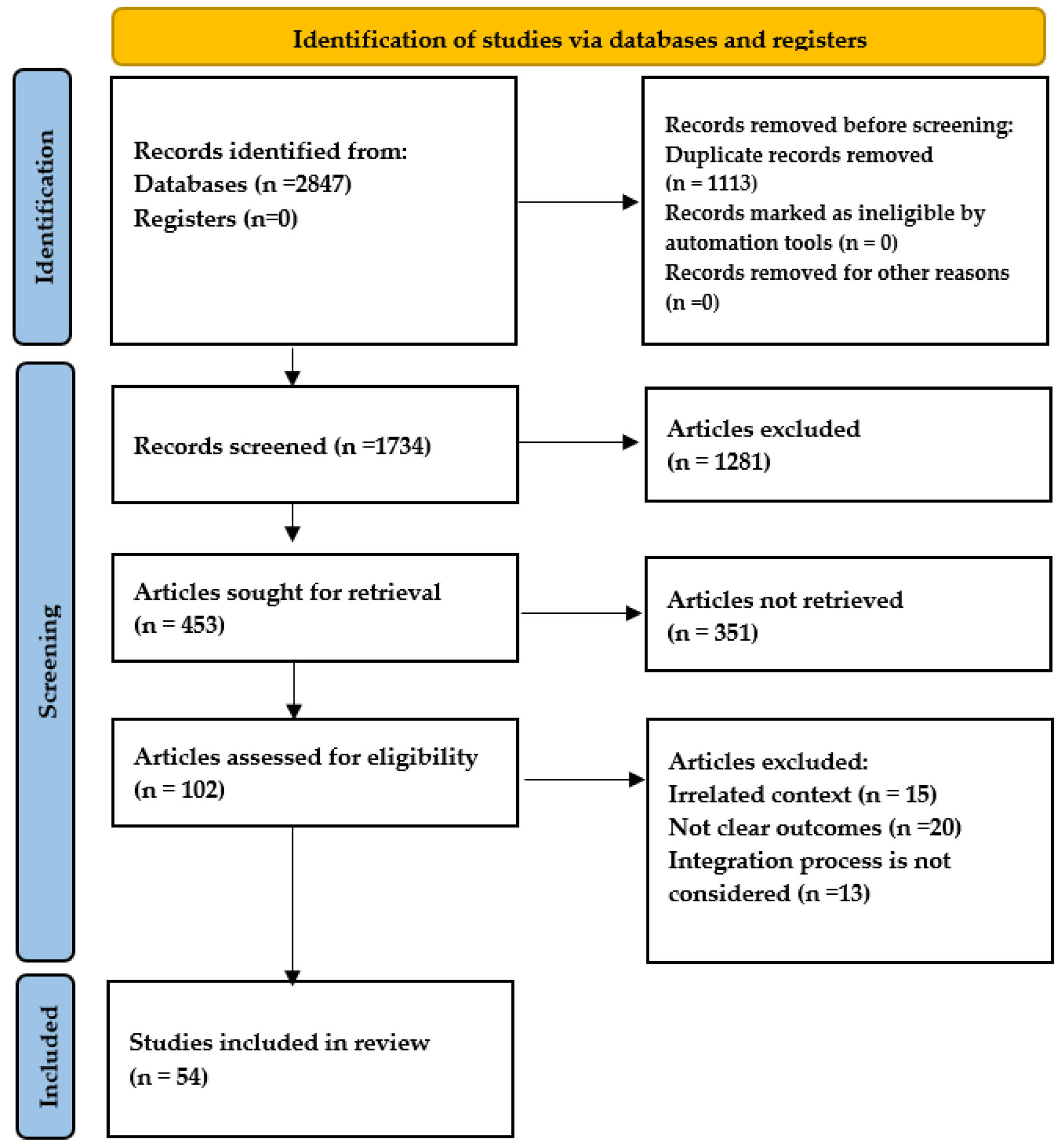

To initialise a comprehensive literature review process based on [62], three keywords were selected to search for papers published from 2017 to July 2022 available from different scientific resources (Web of Science, Scopus, and Google Scholar). The keywords used in the search were “Industry 4.0 & Maintenance”, “Industry 4.0 & Maintenance Management”, and “Industry 4.0 & Maintenance Planning”.

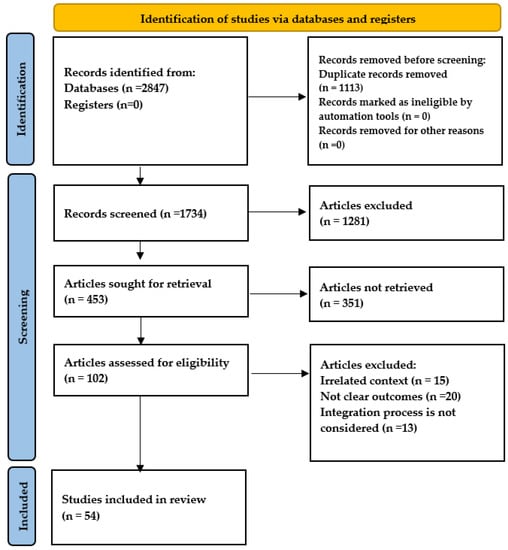

The search resulted in 102 papers related to maintenance and Industry 4.0 with both parts of each keyword pair in their titles.

In the next step, each paper was reviewed carefully, and irrelevant papers were excluded. The final number of papers included in this study was 54. Note that the duplicate papers found in more than one scientific resource were eliminated; only one instance was considered.

The inclusion and exclusion criteria are presented in detail using the PRISMA flow diagram in Figure 2.

Figure 2.

PRISMA 2020 flow diagram—Inclusion and exclusion criteria. Source: Authors’ elaboration.

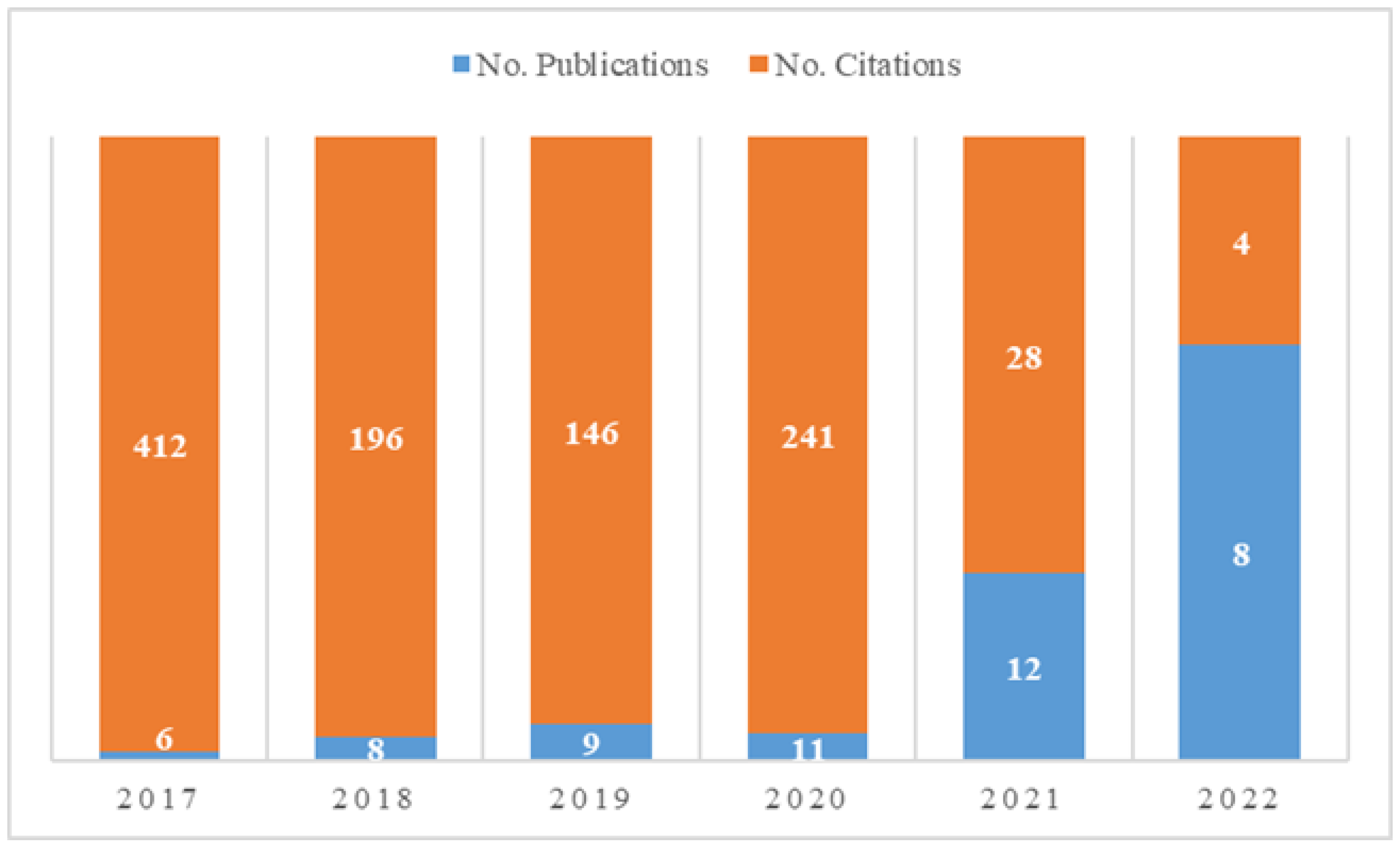

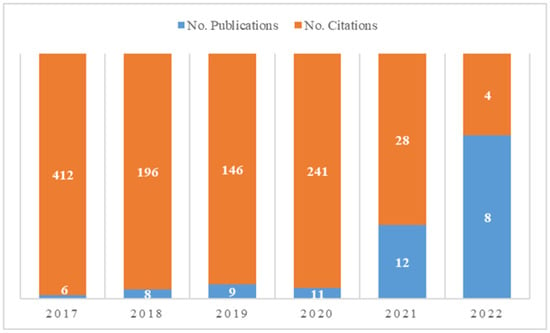

The publication years and numbers of citations of the selected 54 papers are detailed in Figure 3. The average number of papers published annually from 2017 to July 2022 was about nine, while the average number of citations was 171, with a peak in 2017. The number of published papers increased yearly, indicating that researchers have become more and more interested in this research area.

Figure 3.

Numbers of publications studied and their citations. Studied period: 2017–July 2022. Total number of publications: 54; Total number of citations: 1027. Source: Authors’ elaboration.

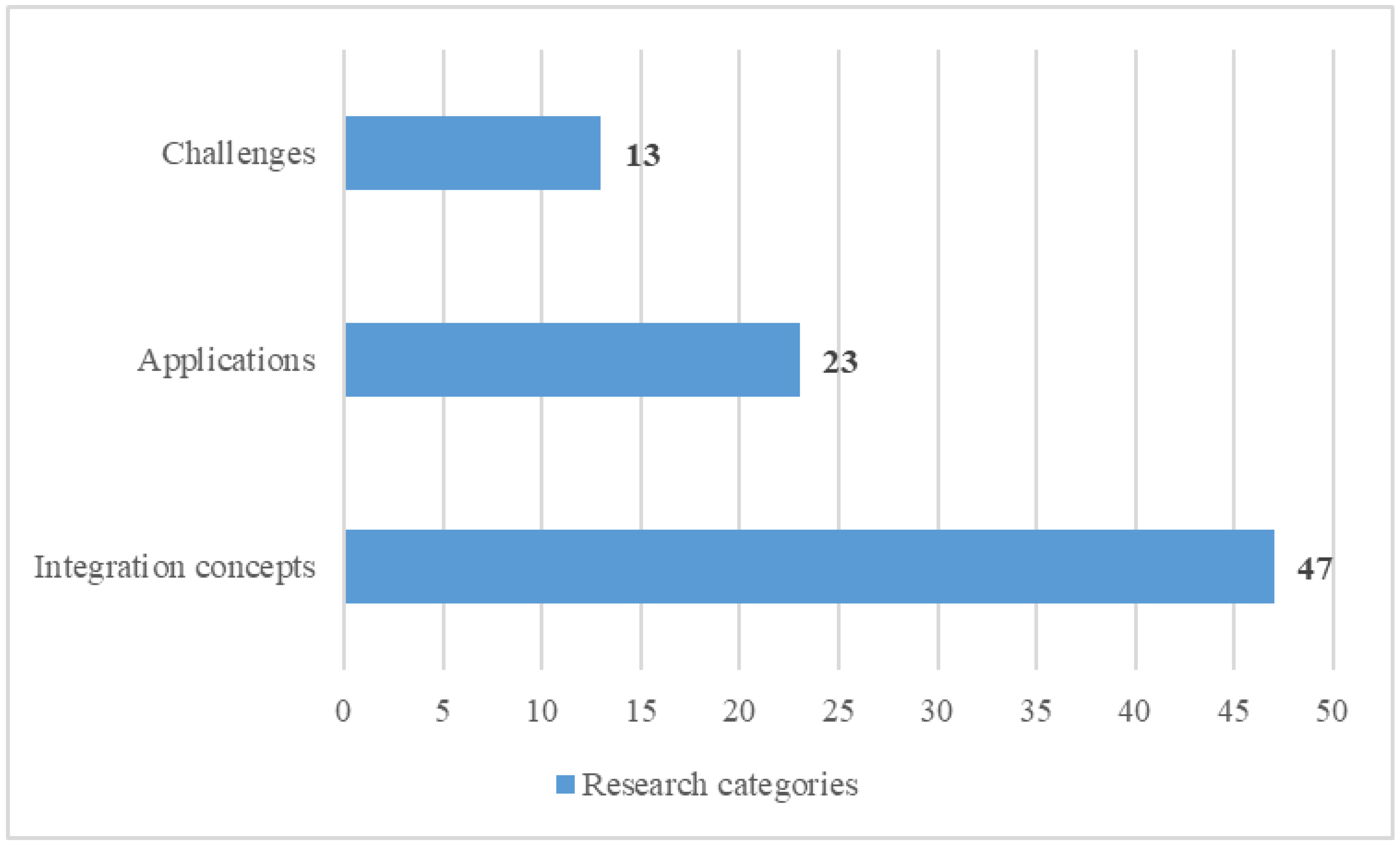

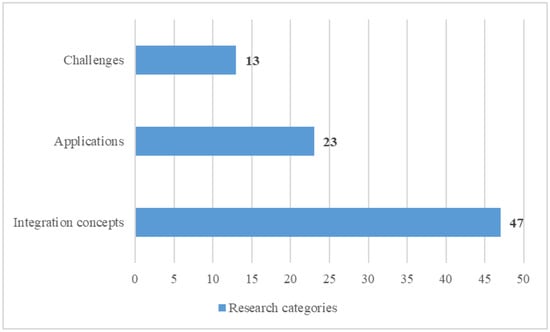

Finally, the selected articles were categorised into three research categories: integration concepts, applications, and challenges, as shown in Figure 4.

Figure 4.

Number of publications per research category. Source: Authors’ elaboration.

The analysed articles employed different scientific approaches in their studies, such as frameworks, case studies, experimental designs, simulations, prototypes, surveys, and conceptual approaches. It is worth mentioning that some of the researchers used more than one approach in their studies, for example, using case studies or simulations to test and validate the developed framework. Table 1 summarises the categories of the analysed research articles along with the scientific approach used.

Table 1.

Categorisation of the analysed articles. Source: Authors’ elaboration.

It is also noticeable that most of the researchers developed frameworks or models in addition to other types of scientific approaches. Almost all the researchers used trendy or new integration concepts in their studies; on the other hand, they gave more attention to the challenges of such modes of integration or even proposed solutions to handle them.

4. Maintenance Management in the Context of Industry 4.0

Various technologies are being used in manufacturing systems, but new concepts of integration can transform production and other related systems, such as maintenance. The full integration of such technologies can transform manufacturing cells and other supporting systems, such as maintenance engineering, to operate as fully integrated and automated systems with higher performance and greater efficiency. Extensive research has been conducted to investigate the interaction of Industry 4.0 and maintenance management systems. In this section, the 54 research articles filtered are summarised and classified using the previously mentioned research categories based on the major Industry 4.0 technologies, and their implications for relevant maintenance management system functions are considered.

4.1. Aligning Maintenance Management and Industry 4.0 Technologies—Trending Concepts and Integration-Assisting Tools

As explained earlier, Industry 4.0 is an umbrella term for several newly developed technologies, such as IoT, cloud computing, big data, simulation, AI, and CPSs. The adaptation of Industry 4.0 is vital at many managerial levels in manufacturing systems. To facilitate this, an implementation strategy is needed to digitalise manufacturing systems and their support systems, such as maintenance planning and scheduling. This can be achieved by the successful integration of new ICT technologies and big data capabilities through CPSs, which can enable significant improvements in maintenance throughout manufacturing systems.

The transformation from current maintenance systems to digital maintenance complying with Industry 4.0 requirements needs recommendations and instructions to be generated, as in Fusko et al. [64]. Moving forward to digital or smart factories, the following Industry 4.0 factors present the main triggers of such transformation: real-time data collection through sensory or condition-monitoring systems, data-processing methods to ensure the accuracy and quality of collected data, and, finally, prediction models to prevent failures and update information. Smart and predictive maintenance are the main concepts used in smart factories [108], where many production and maintenance tasks need to be managed simultaneously, such as data collection and evaluation, resource availability, production, maintenance, and quality control.

To increase the effectiveness of production processes in terms of maintenance, reduce the workforces required, and increase the effectiveness of management and planning processes, total productive maintenance (TPM) practices were digitalised by Tortorella et al. [65], who derived five case-based research propositions. It is likely that an innovative approach to managing the maintenance process for complex equipment in a production hall with preventive maintenance and TPM concepts was developed by Hardt et al. [90]. This approach focuses on gathering and analysing operational data for different equipment components working under different users and operational conditions.

4.1.1. Predictive Maintenance (PdM)

Based on Industry 4.0 features and technologies and the intensive literature review conducted in this paper, the latest maintenance trends and terms have been investigated. These new trends are based on the key role of predictive maintenance (PdM) as the main integration enabler.

The predictive maintenance approach is the focal point of recent AI applications in the context of Industry 4.0. ML algorithms help detect and predict failures before their occurrence to avoid unplanned shutdowns and predict the remaining useful life (RUL) of equipment. Machine-learning methods also support the scheduling of maintenance activities through combined IoT technology to reduce downtime and maintenance costs and increase machine availability [63,109,114,117]. PdM can also be implemented using digital twins [115].

For instance, Kiangala and Wang [72] designed an experimental method to detect conveyor motor faults and generate a predictive maintenance schedule accordingly. Real-time vibration data are collected from SCADA systems connected to a graphical user interface (GUI) to display the predictive maintenance schedule. This leads to an easy reconfiguration of the maintenance rules when needed. Additionally, historical records and the number of previous breakdowns can be obtained from the CMMS for future planning and to evaluate the applied reconfigurations [73].

To connect the predictive maintenance concept with Industry 4.0 technologies, Li et al. [75] introduced a framework for predictive maintenance to analyse and predict faults in a machining centre. The framework included data acquisition, data pre-processing, fault diagnosis, and prognosis based on ANN, performance analysis, and maintenance schedule optimisation. Similarly, Tran Anh et al. [82] presented a PdM strategy applied in an automotive manufacturing company to cope with Industry 4.0 requirements, focusing on its impact on maintenance optimisation, in addition to the financial situation.

ML algorithms and data-driven modelling are widely used for failure prediction [116]. A PdM model using the ML technique (Bayesian Filter) was developed by Ruiz-Sarmiento et al. [79] to predict the gradual degradation of machinery in a rolling process and then apply maintenance actions. Similarly, Paolanti et al. [80] used a random forest approach for PdM. The required data were collected from the sensory system and the machine’s PLC, while the communication protocols were set using Microsoft Azure. The results showed that the developed PdM predicted machine statuses efficiently and with high accuracy. Kiangala and Wang [83] suggested an experimental design for a PdM framework to detect the deterioration in conveyor motors in small manufacturing firms. To classify abnormalities into those that are production-threatening and those that are not, an ML classification model was built using time-series imaging and a convolutional neural network (CNN) to increase the accuracy of classification combined with parameterised rectifier linear units to improve the performance of the model. Moreover, principal component analysis (PCA) was applied to the multivariate time series to reduce the dimensions to two channels. The experimental results showed that this PdM framework was better in terms of performance and accuracy than the traditional approaches.

In the same way, a prediction model to predict anomalies in the bearings of an assembly conveyor carrier using Industrial Internet of Things (IIoT) devices, a neural network (NN), and sound analysis were developed by Tanuska et al. [95]. This model is based on an online condition-monitoring system consisting of data collection and processing, data storage, and anomaly detection to provide early warnings. These processes aim at detecting the wheel bearing failure that leads to bearings getting stuck, stopping the movement of the carrier, and shutting down the whole conveyor. Moreover, the detection process aims to minimise unscheduled shutdowns of the conveyor and prepare proper schedules for maintenance. Fernandes et al. [96] implemented a mixed CBM/PdM approach in an automotive case study by introducing the business process management (BPM) and the business process model and notation (BPMN) methods to decrease maintenance costs and improve productivity. The implemented methods resulted in better prediction of the breakdown of machines, better scheduling for maintenance and component replacement, minimisation of the periodic inspection of the machines, and, finally, minimisation of the numbers of unplanned shutdowns and emergency stops.

Moreover, data-driven models can be used to develop architectures for PdM. Thus, Calabrese et al. [81] used such a model combined with machine-learning algorithms in an industrial woodworking machine to predict failure probabilities and the RUL of the machine. The proposed method was tested and showed high effectiveness in reducing machine downtime. Lastly, it was deployed in a big data framework to monitor multiple connected machines. It is worth mentioning that the prediction is a valuable source of information that can be used in maintenance management systems.

Yan et al. [84] proposed a processing scheme for industrial big data to provide new solutions for PdM implementation. The scheme is based on structuring heterogeneous multisource information, characterising it, modelling invisible factors, and, finally, implementing PdM using machine-learning techniques, such as ANN. The scheme was verified by an actual case study to predict the RUL of a key machine tool component. In terms of the effective use of PdM, Sahal et al. [85] filled the technological integration gaps between Industry 4.0 applications and existing open-source big data and streaming analytic technologies in railway transportation and wind energy industries by showing the requirements for implementing PdM, along with the available big data technologies that could serve these requirements, as one of Industry 4.0’s main technologies. This study resulted in guidelines and technology combinations of open-source tools that could help implement PdM and support decision makers.

PdM is considered the central concept of integration; in fact, different concepts connected with it were found in the literature. Ferreira et al. [66] utilised a CPS in sheet-metal-working machinery to achieve a full proactive maintenance system; three approaches were employed: (1) component failure detection using various detection means and models; (2) component failure prediction, depending on data collected from the sensory system, and then prediction of the RULs of the machine and its components, as well as potential failures before their occurrence; and (3) component failure diagnosis to identify the root causes of problems. These approaches utilise empirical models to help technicians diagnose problems. Pilot implementation of the framework was realised, and the result was a CPS integrated with the maintenance system (combined predictive and proactive maintenance).

Similarly, smart or intelligent maintenance strategies based on the concept of PdM are other sub-concepts used by some researchers. Einabadi et al. [67] suggested an Industry 4.0-based predictive maintenance system for the automotive industry which enabled dynamic and real-time prediction of the RULs of machine components using an ANN method based on data gathered from a sensory system. At the plant level, Chiu et al. [70] proposed a predictive maintenance system based on Industry 4.0 technologies to overcome the problem resulting from the fact that PdM is usually designed for single items of equipment in contexts where resource allocation might be complicated, when there are tens or hundreds of pieces of equipment at the factory level. The proposed PdM system is based on modified Industry 4.0 tools, namely, “cyber-physical agent and advanced manufacturing cloud of things”. Moreira et al. [87] upgraded an injection moulding machine in an Industry 4.0 environment with real-time monitoring sensors to reduce the number of unnecessary shutdowns and failures, decrease maintenance costs, and maximise the performance of the tool. Moreover, the collected data enable the implementation of smart predictive maintenance, solving the main challenge of Industry 4.0.

In the same way, Nordal and El-Thalji [88] proposed an intelligent maintenance management system in compliance with Industry 4.0 requirements. The developed intelligent system included (1) analysis, evaluation, and needs identification of the existing maintenance system; (2) extraction of the requirements of the future system, including the business model and the related stakeholders and Industry 4.0 requirements; and, finally, (3) modelling of the desired future system. Communication at all maintenance management levels was clarified, including asset-to-asset, asset-to-enterprise, and enterprise-to-enterprise communication, supported by advanced technologies for computation, such as predictive maintenance, machine learning, and maintenance optimisation. Maintenance operations were managed using an appropriate integrated ERP and computerised maintenance management system (CMMS).

In terms of asset management, as a central part of a maintenance management system, Toeh et al. [89] presented an integrated predictive-maintenance-based machine-learning model in fog computing to manage assets (physical, virtual, and human resources), using a genetic algorithm (GA). Fog Workflowsim was used to simulate time and costs and to evaluate the performance of the GA, along with other methods, such as MinMin and MaxMin. Logistic regression as a supervised machine-learning algorithm was used to build the predictive maintenance model that reached 95.1% training and prediction accuracy.

Bourezza and Mousrij [97] presented an approach to implementing an intelligent maintenance strategy based on the concept of PdM and aligned with Industry 4.0 technologies. The approach consisted of several modules: condition data acquisition, analysis, failure detection, and prediction of device RULs. The main aim of such an approach is to support engineers and technicians in their decision making in planning, scheduling, and implementing maintenance tasks by providing them with real-time monitoring of machines and equipment.

Remote maintenance is another concept of integration based on augmented reality (AR) and off-the-shelf smartphones, which was examined by Masoni et al. [69]. This application allows an unskilled maintenance operator acting in the maintenance location to be connected to the control room and be remotely guided by a skilled operator, equipment, and machines. Similarly, Contreras et al. [107] defined a model of integrating additive manufacturing technology in an Industry 4.0 environment to improve maintenance management systems and allow the use of trendy techniques, such as self-maintenance and remote maintenance.

To facilitate integration within an Industry 4.0 environment and compliance with the evolution of the technical documentation of Industry 4.0, Scurati et al. [93] proposed a controlled and comprehensive visual manual that includes a vocabulary of graphical symbols related to all maintenance instructions by exploiting AR technology. Thus, all available maintenance actions were converted into graphical symbols. The resulting manual integrated all these symbols in a real application of AR technology to assist in applying remote maintenance.

To support low-skilled technicians in performing maintenance tasks and procedures by utilising AR and computer vision (CV) techniques, Konstantinidis et al. [94] described a model called the Augmented Reality Maintenance Assistant (MARMA) that is able to generate maintenance instructions and support technicians. Additionally, integrating Industry 4.0 technologies and maintenance practices in the aeronautical industry is widely discussed to address how Industry 4.0 impacts maintenance. Ceruti et al. [92] suggested a method of such integration using AR and additive manufacturing (AM) technologies, where the main role of AR is to provide the technician with enhanced ways to perform maintenance tasks, such as maintenance user manuals with virtual models of machines and their components. On the other hand, AM assists in reducing large warehouses by manufacturing some types of maintenance spare parts when needed. Overall, AM and AR can work together to reduce maintenance costs and time by identifying failed components, scanning them with reverse-engineering techniques, and printing replacements instantly using AM techniques.

To support the decision-making process in a successful integration, different factors must be identified [103]. These factors can be summarised as the classification and identification of production, maintenance tasks, and supporting Industry 4.0 technologies, description of the capabilities of the available technologies, and, finally, the analysis and interpretation of the obtained results. For example, failure prediction can be supported by decision-making algorithms, whereas more responsive information systems can support the decision-making process by increasing the availability of sensory systems and big data technologies [106]. Therefore, to select the appropriate maintenance strategy in an Industry 4.0 environment, Caterino et al. [101] presented a new maintenance framework to automate the decision-making process and choose the optimum maintenance strategy for preventive or opportunistic maintenance. This framework was enhanced by Industry 4.0 technologies, such as CPS and IoT. The framework was tested, and it was able to select the optimum maintenance strategy to reduce the maintenance costs associated with the selected strategy.

In a related context, Li et al. [86] presented a framework for so-called cognitive maintenance, which integrates CPSs and advanced AI techniques (deep learning) to support the decision-making processes of maintenance systems and provide technical solutions and real-time monitoring of maintenance tasks. CPSs, IoT, data mining using deep-learning techniques, and the Internet of Services are the main modules in cognitive maintenance.

To synchronise production and maintenance planning and scheduling problems, hybrid approaches have been proposed. Alves and Ravetti used two concepts to develop such a hybrid approach, namely, robustness and semi-heuristics, considering three types of maintenance strategies (predictive, preventive, and corrective maintenance) in a production line composed of parallel machines within an Industry 4.0 environment [91]. In the same way, a predictive maintenance approach was suggested by Spendla et al. [68] to increase the quality of production processes in accordance with Industry 4.0 by increasing the operability of manufacturing systems through predicting faults in production processes using ANNs. Big data and IoT can be used along with predictive maintenance to deal with the large numbers of data collected in manufacturing processes. The results of this study were used not only to determine the maintenance intervals (scheduling) and predict failures but also to enhance the quality of the whole manufacturing process and the final products.

“PdM4.0” is a new concept defined by researchers using different approaches to implement PdM in Industry 4.0 environments. Sahba et al. [76] proposed a novel framework for PdM based on the advanced Reference Architecture Model Industry 4.0 (RAMI 4.0) that aims at reducing the maintenance and operation-associated costs in broadcasting chains. RAMI 4.0 is a model demonstrating features of technical assets and the concepts of Industry 4.0. The proposed framework, called PdM4.0, succeeded in increasing the stability of the broadcasting system and decreasing maintenance costs. Similarly, RAMI 4.0 architecture was used by Sang et al. [78] to support the PdM strategy in an Industry 4.0 environment using a unique framework called FIWARE for data exchange between various organisations and considering security requirements. This integrated PdM model provided an effective method for optimising the processes and monitoring equipment conditions using different machine-learning models and big data technologies.

Finally, in terms of reducing associated maintenance costs, various studies have focused on developing low-cost PdM models. Sezer et al. [71] developed an Industry 4.0 (CPS) architecture for low-cost predictive maintenance for small and medium manufacturing enterprises. In the developed CPS architecture, the temperature and vibration variables of a CNC machining process were measured. Accordingly, a regression tree model was used to predict the quality of the machined parts and then to reject or accept them based on the quality threshold and the correlations between temperature, vibration, and roughness. Furthermore, Alarcón et al. [74] presented a low-cost integration model for energy management systems (EMSs) and maintenance management systems (MMSs) in a manufacturing firm. Several technologies and tools that support work in an Industry 4.0 environment were used in the model, such as ERP, distributed control systems (DCSs), and manufacturing execution systems (MESs), to collect and analyse data on, control, detect failure in, and monitor the conditions of machinery, including the electrical energy consumed. The results showed a significant reduction in energy consumption, the number of required maintenance events, and the time taken for component replacements. Similarly, for small and medium manufacturing enterprises, Adu-Amankwa et al. [77] proposed a cost-effective PdM architecture for a CNC machine which could reduce maintenance costs.

4.1.2. Maintenance 4.0

Recent studies have investigated “Maintenance 4.0”, which term is used to describe the latest trends in maintenance management to meet the integration requirements of Industry 4.0 and the sustainable development aspects [98]. It was found that Maintenance 4.0 involves the use of advanced analytic methods not only to predict failure (predictive maintenance) but also to avoid such failures and optimise maintenance schedules and resources (prescriptive maintenance). In other words, Kumar and Galar [99] stated that Maintenance 4.0 uses advanced technologies to perform predictive analytics and generate solutions through the integration of maintenance practices that deal with data collection, processing, analysis, visualisation, decision making, and Industry 4.0 technologies and features. On the other hand, Maintenance 4.0 enables the effective use of ICT platforms, such as ERP and CMMS, to manage the whole maintenance management system at all levels [118]. Smart and sustainable maintenance is the key element in maintenance 4.0, where the integration of digital technologies enables instant access to the real-time detailed information required and manages asset life cycles [119]. Similarly, Giacotto et al. [100] discussed two related terms in the context of the integration process of Industry 4.0. They defined “Maintenance 4.0” as a smart or intelligent maintenance framework along with its technological enablers, while “ecosystem 4.0”, also associated with Maintenance 4.0, refers to a situation where the applied maintenance technologies for different machines are supported by and in harmony with a production system; meanwhile, ecosystem 4.0 facilitates the integration process between machines and their operators in an Industry 4.0 environment. In a case study of an aircraft assembly line, Giacotto et al. [100] designed and tested a framework-based ecosystem 4.0 and maintenance activities integration using the smart prescriptive maintenance framework (SPMF) as a key reference. The SPMF was built at different levels, including the system’s reliability, availability, maintainability, and safety (RAMS) factors, the operational environment, and the available maintenance resources.

4.2. Applications

The integration process of Industry 4.0 technologies and maintenance systems can be found in many application areas in the automotive, aerospace, and machining industries. In addition, chemical industries, including oil and gas, services such as broadcasting chains, and transportation and wind energy industries are also involved in such integration. The main applications of such integration in the 23 papers reviewed are summarised in Table 2. Tools, technologies, and other integration tools of such applications were discussed thoroughly in Section 4.1.

Table 2.

Classification results of the “Applications” category. Source: Authors’ elaboration.

4.3. Challenges

Maintenance management and engineering play key roles in modern manufacturing systems, where the main objective is to plan, organise, and control all materials, processes, and information [102]. In order to integrate these objectives within an Industry 4.0 environment, all maintenance management levels must be connected with the other related production management levels to ensure overall harmony in an intelligent way [110]. The main challenge in changing existing maintenance management systems into intelligent ones is upgrading them to use the three main technologies: IoT, big data, and cloud computing [88].

Table 3 summarises the investigated papers which address the main challenge regarding Industry 4.0: maintenance management system integration.

Table 3.

Classification results of “Challenges” category. Source: Authors’ elaboration.

The use of such tools is feasible wherever it is technically possible and economically advantageous. Pavlu et al. [102] concluded that maintenance management of manufacturing systems has many challenges and is not ready yet to integrate Industry 4.0 tools into existing systems, especially when we talk about designing embedded smart systems to monitor and predict the conditions of machines, except for the automotive sector, which moves in quick steps toward Industry 4.0 integration. Further development at all levels is required in the future, in which the selection of proper Industry 4.0 technologies is essential; otherwise, negative effects might result from the integration process [112].

On the other hand, Compare et al. [104] indicated that new Industry 4.0 technologies, including IoT, are great enablers of PdM, which needs considerable investment in the required software and hardware to track and monitor the health of machinery and equipment. Thus, cost–benefit models that clarify the impact of implementing PdM in the entire production management system must be built and integrated into the system. Hence, a trade-off between the opportunities for implementing PdM and the required expenditures is needed. Lack of available data, especially for new systems, is another challenge that may dissuade companies from investing in PdM [84,104]. However, the vast numbers of generated data are another big challenge for engineers and data scientists in finding the proper ways to understand, analyse, use, and store them [73,111]. Moreover, to reach “maintenance 4.0”, not only are there technological challenges related to integration with Industry 4.0 that must be overcome, there are other challenges that must also be taken into consideration, such as sustainability, including social, economic, and environmental challenges, to ensure sustainable production, which is strognly affected by maintenance [98]. Kumar and Galar [98] addressed five main challenges in designing a maintenance system that complies with Industry 4.0 requirements at the maintenance management system level. The first is an organisational challenge, which refers to enterprise resource management, such as resource planning (i.e., spare parts and materials), as well as information and knowledge management. Another challenge deals with the issues resulting from the developed architecture of the required smart or intelligent maintenance solutions; these include the development of frameworks and models for data processing and analysis, business models, and the development of prognostic tools and models, such as PdM. Providing a proper infrastructure to meet the integration requirement, such as tools and technologies, raises another challenge. These could be related to service management and interaction and management configuration to enable integration capabilities through complex platforms and technologies. Dalzochio et al. [105] indicated that the main challenges involving PdM in Industry 4.0 through applying different ML techniques are the digitalisation and automation of factories using CPSs or digital twins to provide early failure detection. The lack of failure-related data from the CMMS is another challenge that data scientists face. Another problem that needs to be resolved by decision makers is the identification of the required goals of prediction models, which may be the reduction of maintenance costs or the improvement of the efficiency of production systems [116]. Another challenge in implementing PdM is the fact that most studies deal with PdM as a preventive maintenance action, and actual use of PdM in real time applications is rare [113].

Lastly, cyber security is considered an essential factor that manufacturers should consider if more and more devices and machines are to be integrated and included in the IoT [103]. Security considerations represent another challenge that could burden the integration process.

5. Discussion

In the examined articles, all of the authors concluded that Industry 4.0 features and technologies support the modern maintenance concepts, resulting in “digitalised maintenance”, “smart maintenance”, “self-maintenance”, and “remote maintenance”, even “Maintenance 4.0”, based on the driving force of predictive maintenance strategies and other types of maintenance strategies, such as corrective, preventive, and prescriptive maintenance. The optimum maintenance strategy is affected by different factors in an Industry 4.0 environment, mainly the complexity of the technologies used, which can be evaluated and selected according to specific objectives and constraints (e.g., maximisation of availability, maximisation of reliability, minimisation of life cycle costs), using an appropriate multi-objective optimisation method.

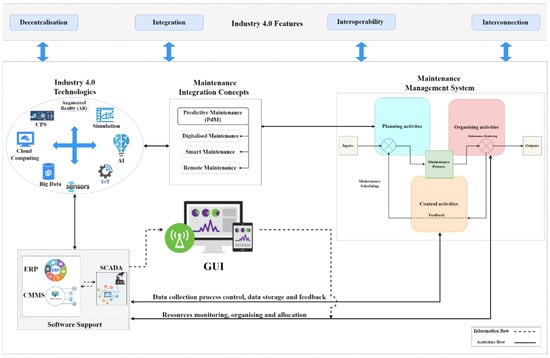

Figure 5 summarises the connections between Industry 4.0 technologies and features and maintenance integration concepts found in the examined literature and the maintenance management system model adopted in this study. The overall integration concept is discussed thoroughly below.

Figure 5.

Summary of Integration of Industry 4.0 features and technologies and the adopted maintenance management system. Source: Authors’ elaboration.

Simulation, a key technology in Industry 4.0 [120], can provide optimised short- and long-term decision support for maintenance planning and scheduling tasks. Additionally, simulation can help in risk evaluation, cost reduction, and performance improvement and provide a roadmap for better integration. Using simulation, advanced sensory systems and IoT can immensely support the formulation of digital twins, with which more accurate predictions can be made in cyber–physical systems. Optimal maintenance scenarios, including maintenance strategies, schedules, and load forecasting, are suggested based on the analysis of data gathered by sensory systems and transferred from shopfloor level to big data systems. Such data could include machine health conditions and other information on the surrounding environment. Data are analysed using AI algorithms, and degradation processes, failures and the remaining useful life of equipment are predicted. Prediction results are then sent away for further planning and organisation of maintenance tasks, such as updating maintenance plans and schedules and allocating maintenance technicians and spare parts; credit goes to the IIoT for making it possible to improve quality and performance based on prediction results. Opportunistic maintenance implementation based on advanced prediction, simulation tools, and/or digital twins and multi-objective optimisation, along with IIoT, can also be an ideal approach for better integration, with highly mitigated integration risks and costs, and, on the other hand, highly increased performance, productivity, resource utilisation, and planning and scheduling. Table 4 identifies the aligned relationships between the examined Industry 4.0 technologies and the main functions of the adopted maintenance management model.

Table 4.

Relationships between Industry 4.0 technologies and maintenance management system functions. Source: Authors’ elaboration.

Maintenance organisation requires high levels of coordination and resource allocation. Accordingly, maintenance organisation is aided by monitoring tools, such as supervisory control and data acquisition (SCADA) systems, ERP systems, and computerised maintenance management systems (CMMSs), which are considered some of the most important integration-assisting tools in Industry 4.0 due to their substantial influence on operations and maintenance processes and their associated costs [118]. Resources and spare parts allocation are managed effectively in the cloud by the ERP system.

Maintenance control is handled using computerised systems and knowledge dashboards. Maintenance effectiveness can be monitored and enhanced at different levels, starting at the machine level and ending with the overall plant. Many applications of Industry 4.0 technologies can enhance maintenance control through data modelling, optimisation, and behaviour-pattern detection. AI techniques, such as machine learning, can detect unseen factors affecting machine performance, product quality, and productivity.

Feedback is carried out through software support systems, passing through maintenance control and resulting in maintenance planning and rescheduling activities. Overall system performance is evaluated and governed based on the traditional evaluation metrics of maintenance management systems. Using an integrated sensory system and SCADA provides industrial organisations with a new method for information collection for monitoring and control of the performance of manufacturing systems. AI-based predictive maintenance modules process the data. Graphical user interfaces (GUIs) show the real-time measurements and information communicated between the CMMSs, ERPs, integration-assisting tools, and SCADA systems.

Interoperability enables seamless maintenance management by providing common means of communication between machines and operators, production departments, and different maintenance systems at the other locations of companies’ plants. Conditions and operational performance data are transmitted and pipelined in a standard format, and therefore provide the various maintenance management systems with software support, such as ERP, CMMS, and SCADA, with further compatibility. Such compatibility results in smooth report generation and data exchange.

For more details, refer to Table A1 in Appendix A, which classifies the investigated articles according to the integration concepts, Industry 4.0 technologies, and integration-assisting tools.

Integrating all elements in a value chain supports maintenance by integrating maintenance activities with other key contributors. For example, spare part orders can be automatically sent to spare part suppliers or warehouses once a failure is predicted and can be carried out optimally considering multiple objective functions. Moreover, the replacement process can be effectively planned considering production capacity, stability, customer orders, and market demand.

Smart machines (called augmented operators) can recommend instructions to operators to avoid downtime. Additionally, maintenance monitoring can be available and visualised at single-component, machine, or production-system levels.

Effective integration of Industry 4.0 features and technologies with maintenance management systems can improve whole systems through decentralisation, integration, interoperability, and interconnection. Table 5 summarises the possible impacts of Industry 4.0 features on maintenance management systems. For instance, the Industry 4.0 feature “Interconnection” promotes real-time measurements and data flow along a value chain and between stakeholders. Interconnection enhances responsiveness and the coordination of all contributors in maintenance tasks. Moreover, equipment and machine manufacturers can monitor the performance of their machines under different operational conditions; therefore, they can enhance future generations of machines or improve the performance of current machines remotely. Smart machines can communicate with their original manufacturers periodically, receive software updates, and improve machine performance.

Table 5.

Impact of Industry 4.0 features on maintenance management systems. Source: Authors’ elaboration.

Despite the significant benefits of the previously discussed integration on the whole production system, various challenges and disadvantages of such integration must be taken into consideration and could have unintended negative consequences. The primary integration problems concern how to finance the transformation process and afford the necessary infrastructure, which needs huge investment. Numerous studies have also addressed organisational and technical challenges regarding the ability to afford the necessary resources, the lack of vast numbers of required data, the increased complexity of the prediction algorithms used, the proper selection of Industry 4.0 technologies, and cyber-security issues. Other sustainability challenges have started to be raised in some recent studies.

6. Conclusions, Limitations, and Future Work

In this paper, an intensive literature review has been conducted concerning maintenance management and Industry 4.0, and their synergistic integration has been discussed. Fifty-four articles published between 2017 and July 2022 were examined. Information from each examined article was analysed, categorised, and summarised. An adopted maintenance management system model was used to facilitate the alignment of the integration concepts of Industry 4.0 features and technologies and the main functions of the model, focusing on predictive maintenance and integration-assisting tools. In conclusion, digitalisation is the first step in the integration process. However, the synergistic integration of the maintenance management system’s functions and Industry 4.0 features and technologies can result in more efficient production systems. To achieve the full technical efficiency of a maintenance system in an Industry 4.0 environment, attention must be paid not only to how to apply PdM, as the central concept of integration and the main enabler of Industry 4.0, but also to look at all levels and components of the maintenance management system. The mainly used integration concepts, such as PdM, PdM 4.0, Maintenance 4.0, and remote and smart maintenance, have been investigated and discussed, indicating that successful integration needs to involve other tools, i.e., “integration-assisting tools”, such as ERP, SCADA, CMMS, sensors, and real-time condition-monitoring systems, supported by the necessary software and GUIs to facilitate monitoring and assist technicians in speeding up decision-making processes. Some data-driven maintenance strategies, such as PdM, might face difficulties in their full implementation due to the complex equipment required for the integration, such as sensors, which cannot be installed in all locations.

Based on the findings of this research, it can also be concluded that the integration of maintenance management systems with Industry 4.0 technologies and features needs further research to investigate more theoretical and practical areas. The inclusion and exclusion criteria, as well as the search keywords, could be expanded to include more concepts and maintenance strategies. For instance, reliability-centred maintenance and risk-based maintenance integration could be investigated in future work.

While this research has focused on the technological aspects of integration, other important issues, such as the human factors in the new industrial paradigms and their roles in the integration process, could also be considered in further reviews.

Moreover, regarding future opportunities, extending the existing research focuses to develop new PdM frameworks to include more components and levels of maintenance management systems could increase the efficiency of the integration process, and the definition of the concept of “Maintenance 4.0” could be refined. Additionally, including more areas and applications not only in the manufacturing industry but also in the services sector by utilising more tools and technologies, such as big data, AI, and IoT, in the main domain of CPSs is another research opportunity to be investigated. Therefore, further studies are needed to address the challenges of integration in both sectors. Finally, more attention should be paid to Industry 4.0 features and their importance in the integration process.

Author Contributions

Conceptualisation, B.W.S. and I.N.; methodology, B.W.S.; resources, B.W.S.; data curation, B.W.S. formal analysis, B.W.S. and I.N.; investigation, B.W.S.; writing—original draft preparation, B.W.S.; writing—review and editing, B.W.S. and I.N.; visualization, B.W.S.; supervision, I.N.; project administration, I.N.; funding acquisition, I.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the APC were funded by the National Research Development and Innovation Office under the auspices of the Ministry for Innovation and Technology—Hungary, and by the European Commission through the H2020 project EPIC under grant No. 739592.

Data Availability Statement

All data are available in the manuscript.

Acknowledgments

The research reported in this paper and carried out at the Budapest University of Technology and Economics has been supported by the National Laboratory of Artificial Intelligence, the National Research Development and Innovation Office under the auspices of the Ministry for Innovation and Technology and the European Commission through the H2020 project EPIC.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Classification results for “integration concept” categories. Source: Authors’ elaboration.

Table A1.

Classification results for “integration concept” categories. Source: Authors’ elaboration.

| Article | Integration Concept | Industry 4.0 Technologies | Integration-Assisting Tools |

|---|---|---|---|

| [63] | PdM | AI-ML | Sensory—CM system |

| [64] | Digital maintenance | AI-ML | Sensory—CM system |

| [65] | Industry 4.0—TPM | - | CMMS/ERP/SCADA |

| [66] | Combined PdM | CPS and AI-ML | Sensory—CM system |

| [67] | Intelligent PdM | AI-ML | Sensory—Real-time CM system |

| [68] | Synchronous production—PdM | AI-ML, big data, and IoT | Real-time CM system |

| [69] | Remote maintenance | Augmented reality | Software support |

| [70] | Intelligent PdM | CPS, AI-ML, cloud computing, and IoT | Sensory—Real-time CM system |

| [71] | Low-cost PdM | AI-ML and CPS | Sensory—Real-time CM system |

| [72] | PdM | AI-ML | SCADA and GUI |

| [73] | PdM | AI-ML | SCADA and CMMS |

| [74] | Low-cost PdM | AI-ML | ERP, DCS, and MES |

| [75] | PdM | AI-ML | Sensory—CM system |

| [76] | PdM 4.0 | AI-ML and CPS | Sensory—CM system |

| [77] | Low-cost PdM | AI-ML | Sensory—CM system |

| [78] | PdM 4.0 | AI-ML, big data, and CPS | Sensory—CM system |

| [79] | PdM | AI-ML | Real-time CM system |

| [80] | PdM | AI-ML | Sensory system and Microsoft Azure |

| [81] | PdM | AI-ML and big data | Sensory—CM system |

| [82] | PdM | AI-ML | Sensory—CM system |

| [83] | PdM | AI-ML | Sensory—CM system |

| [84] | PdM | Big data and AI-ML | Sensory—CM system |

| [85] | PdM | Big data and AI-ML | CM system |

| [86] | Cognitive maintenance | CPS, big data, and AI-ML | Real-time CM system |

| [87] | Smart PdM | AI-ML | Real-time CM system |

| [88] | Intelligent maintenance | AI-ML, IoT, and big data | Real-time CM system, CMMS, and ERP |

| [89] | Intelligent PdM | AI-ML, simulation, and cloud computing | Sensory—CM system |

| [90] | Industry 4.0—TPM | - | CMMS/ERP/SCADA |

| [91] | Synchronous production—PdM | AI-ML | Real-time CM system |

| [92] | Labour support maintenance | Augmented reality and additive manufacturing | Software support |

| [93] | Labour support maintenance | Augmented reality | Software support |

| [94] | Labour support maintenance | Augmented reality and additive manufacturing | Software support |

| [96] | PdM | AI-ML, big data, and IIoT | Real-time CM system |

| [96] | PdM | AI-ML | Real-time CM system |

| [97] | Intelligent maintenance | AI-ML | Real-time CM system |

| [98] | Maintenance 4.0 | - | ERP and CMMS |

| [99] | Maintenance 4.0 | - | ERP and CMMS |

| [100] | Maintenance 4.0 | Simulation | ERP and CMMS |

| [101] | Maintenance decision-making support | CPS and IoT | ERP and CMMS |

| [102] | - | AI-ML | GUI, ERP and CMMS |

| [103] | Maintenance decision-making support | - | ERP and CMMS |

| [104] | - | IoT | CMMS |

| [105] | - | AI-ML and CPS | CMMS |

| [106] | Maintenance decision-making support | AI-ML and big data | Sensory system |

| [107] | Self-maintenance/remote maintenance | Big data, AI-ML, and additive manufacturing | CMMS and software support |

| [108] | Smart maintenance | Sensory—CM system | |

| [109] | PdM | CPS | Real-time CM system |

| [110] | - | - | - |

| [111] | - | AI-ML and big data | - |

| [112] | - | - | - |

| [113] | PdM | - | - |

| [114] | PdM | IoT | Real-time CM system |

| [115] | PdM | AI-ML and digital twin | Real-time CM system |

| [116] | PdM | AI-ML | Sensory—CM system |

References

- Witkowski, K. Internet of Things, Big Data, Industry 4.0—Innovative Solutions in Logistics and Supply Chains Management. Procedia Eng. 2017, 182, 763–769. [Google Scholar] [CrossRef]

- Fraunhofer IPT. Industry 4.0—Connected, Adaptive Production; Fraunhofer IPT: Aachen, Germany, 2016. [Google Scholar]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery, FSKD, Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar] [CrossRef]

- Henning, K.; Wolfgang, W.; Johannes, H. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. In Proceedings of the 15th International Scientific Conference on Production Engineering—CIM, Vodice, Croatia, 10–13 June 2013. [Google Scholar] [CrossRef]

- Keller, M.; Rosenberg, M.; Brettel, M.; Friederichsen, N. How Virtualization, Decentralization and Network Building Change the Manufacturing Landscape: An Industry 4.0 Perspective. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2014, 8, 37–44. [Google Scholar]

- Gilchrist, A. Industry 4.0: The Industrial Internet of Things; Apress: Berkeley, CA, USA, 2016. [Google Scholar]

- The Past and the Future of Industrial Maintenance Management. Available online: https://automation.isa.org/past-and-future-industrial-maintenance-management/ (accessed on 2 February 2021).

- Silvestri, L.; Forcina, A.; Introna, V.; Santolamazza, A.; Cesarotti, V. Maintenance transformation through Industry 4.0 technologies: A systematic literature review. Comput. Ind. 2020, 123, 103335. [Google Scholar] [CrossRef]

- Sherwin, D. A review of overall models for maintenance management. J. Qual. Maint. Eng. 2000, 6, 138–164. [Google Scholar] [CrossRef]

- EN 13306; Maintenance—Maintenance Terminology. European Committee for Standardization: Brussels, Belgium, 2010.

- Birkedal, L.; Møgelberg, R. On the Definition of Maintenance Management. In The Maintenance Management Framework; Springer: London, UK, 2004; pp. 3–10. [Google Scholar]

- Mostafa, S.; Dumrak, J.; Soltan, H. Lean Maintenance Roadmap. Procedia Manuf. 2015, 2, 434–444. [Google Scholar] [CrossRef]

- Duffuaa, S.O.; Raouf, A. Planning and Control of Maintenance Systems; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Tucker, M. Maintenance management. Hydrocarb. Eng. 2006, 11, 35. [Google Scholar] [CrossRef]

- Khan, F.I.; Haddara, M.M. Risk-based maintenance (RBM): A quantitative approach for maintenance/inspection scheduling and planning. J. Loss Prev. Process Ind. 2003, 16, 561–573. [Google Scholar] [CrossRef]

- Arunraj, N.S.; Maiti, J. Risk-based maintenance-Techniques and applications. J. Hazard. Mater. 2007, 142, 653–661. [Google Scholar] [CrossRef]

- Li, G.; Shi, D. Risk-based maintenance schedule of transmission line using multi-objective evolutionary algorithm. In Proceedings of the 2011 IEEE Power Engineering and Automation Conference (PEAM), Wuhan, China, 8–9 September 2011. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. Mechanical Systems and Signal Processing A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Duffuaa, S.O.; Knezevic, J.; Ait-Kadi, D.; Raouf, A. Handbook of Maintenance Management and Engineering; Springer: London, UK, 2009. [Google Scholar]

- Sakib, N.; Wuest, T. Challenges and Opportunities of Condition-based Predictive Maintenance: A Review. Procedia CIRP 2018, 78, 267–272. [Google Scholar] [CrossRef]

- Peng, Y.; Dong, M.; Zuo, M.J. Current status of machine prognostics in condition-based maintenance: A review. Int. J. Adv. Manuf. Technol. 2010, 50, 297–313. [Google Scholar] [CrossRef]

- Thomas, E.; Levrat, E.; Iung, B.; Cocheteux, P. Opportune maintenance and predictive maintenance decision support. In Proceedings of the 13th IFAC Symposium on Information Control Problems in Manufacturing (INCOM 2009), Moscow, Russia, 3–5 June 2009. [Google Scholar]

- Lorenz, M.; Rüßmann, M.; Strack, R.; Lueth, K.L.; Bolle, M. Man and Machine in Industry 4.0; Boston Consulting Group: Boston, MA, USA, 2015; p. 18. [Google Scholar]

- Ansari, F.; Glawar, R.; Nemeth, T. PriMa: A prescriptive maintenance model for cyber-physical production systems. Int. J. Comput. Integr. Manuf. 2019, 32, 482–503. [Google Scholar] [CrossRef]

- di Dio, M.; Iannone, R.; Miranda, S.; Riemma, S. A framework for the choice of the opportunistic maintenance policy in industrial contexts. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor Darul Ehsan, Malaysia, 9–12 December 2014; pp. 1716–1720. [Google Scholar] [CrossRef]

- Day, J.A.; George, L.L. Opportunistic Replacement of Fusion Power System Parts. 1982. Available online: https://www.osti.gov/servlets/purl/5559083 (accessed on 18 October 2022).

- Goyal, D.; Pabla, B.S. Condition based maintenance of machine tools—A review. CIRP J. Manuf. Sci. Technol. 2015, 10, 24–35. [Google Scholar] [CrossRef]

- Zezulka, F.; Marcon, P.; Vesely, I.; Sajdl, O. Industry 4.0—An Introduction in the phenomenon. IFAC-PapersOnLine 2016, 49, 8–12. [Google Scholar] [CrossRef]

- MacDougall, W. Industrie 4.0: Smart Manufacturing for the Future. 2013. Available online: https://www.pac.gr/bcm/uploads/industrie4-0-smart-manufacturing-for-the-future-en.pdf (accessed on 24 August 2022).

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Wang, L.; He, J.; Xu, S. The Application of Industry 4.0 in Customized Furniture Manufacturing Industry. In Proceedings of the MATEC Web of Conferences, Zhengzhou, China, 28–30 November 2016. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Trappey, C.V.; Govindarajan, U.H.; Chuang, A.C.; Sun, J.J. A review of essential standards and patent landscapes for the Internet of Things: A key enabler for Industry 4.0. Adv. Eng. Inform. 2016, 33, 208–229. [Google Scholar] [CrossRef]

- Melo, P.F.S.; Godoy, E.P.; Ferrari, P.; Sisinni, E. Open source control device for industry 4.0 based on RAMI 4.0. Electronics 2021, 10, 869. [Google Scholar] [CrossRef]

- Hankel, M.; Rexroth, B. The reference architectural model industrie 4.0 (rami 4.0). ZVEI 2015, 2, 4–9. [Google Scholar]

- Ge, M.; Bangui, H.; Buhnova, B. Big Data for Internet of Things: A Survey. Future Gener. Comput. Syst. 2018, 87, 601–614. [Google Scholar] [CrossRef]

- Armbrust, M.; Stoica, I.; Zaharia, M.; Fox, A.; Griffith, R.; Joseph, A.D.; Katz, R.; Konwinski, A.; Lee, G.; Patterson, D.; et al. A view of cloud computing. Commun. ACM 2010, 53, 50. [Google Scholar] [CrossRef]