Abstract

Innovative adhesive formulations have been developed in the laboratory based on urea-formaldehyde resin by adding medicinal plants to an industrial adhesive formulation containing raw materials: urea-formaldehyde resin, urea, ammonium sulphate and starch. Specifically, Thymus species (Thymus bleicherianus, Thymus capitates, Thymus satureioides, Thymus vulgaris and Thymus zygis) replaced part of the starch and were considered as the second filler in the formulations. The physico-chemical properties of the resulting adhesive formulations, such as: pH, viscosity, gel time, solids content, density, concentration of free formaldehyde and color were measured, and characterized using Scanning Electron Microscope (SEM), X-ray Diffraction (XRD), Differential Thermal Analysis (DTA), Thermogravimetric Analysis (TGA) and Fourier Transform Infrared spectroscopy (FTIR). In order to evaluate the mechanical performances of adhesive formulations based on plants, plywood panels were produced and their mechanical properties were studied. These mechanical properties included the shear strength, bending strength and the modulus of elasticity. The performance of these panels is comparable to that of plywood panels made using the standard adhesive formulation. From the results obtained, and following the statistical studies, the new adhesive formulations based on plants have the same physico-chemical properties, the same morphologies, and the same mechanical properties. Moreover, the novel adhesives are more viscous, and they have less free formaldehyde content than the commercial formulation.

1. Introduction

Wood is the most extensively utilized renewable resource in the world; however, its dimensions are somewhat constrained by the nature of its raw materials [1,2]. Wood pieces require connections in order to produce clearly defined forms. Both mechanical and laminar by adhesive connections are employed for this purpose [3,4,5,6].

In industrial applications, multiple adhesives have been created using various chemical formulations and different procedures [7]. The thermosetting adhesives based on urea-formaldehyde (UF) resins, which are widely employed in the production of plywood panels, are by far the most well-liked [8]. Under ideal operational circumstances, condensation of urea and formaldehyde produces these adhesives in recognized methods [9]. These adhesives’ principal drawback is that they produce significant amounts of free formaldehyde emissions [10]. Free formaldehyde emissions have been controlled using a variety of techniques, such as by adding fillers that fix the substance [11,12].

Fillers are solid and relatively inviscid substances. They are primarily divided into two groups, inorganic fillers, and organic fillers, based on their chemical compositions [13]. Along with formaldehyde fixing, fillers may enhance the capacity, weight, toughness, thermal conductivity, water resistance, curing, resistance to aging, heat resistance, and other properties of wood adhesives [14]. The main natural fillers used are wheat flour, sawdust and ash, as well as other derived substances, including starch, lignin, tannin extracts, etc. [15,16]. However, flour is the primary filler used in the commercial manufacture of plywood [17]. A lot of flour is used as a filler in wood glues, wasting grain resources. As a result, the pursuit of the right filler to take the place of flour has become more and more popular.

The main objective of the study was to investigate the effect of some thymus plant species as alternatives to starch filler in an adhesive formulation based on UF resin. Physical, chemical, morphological and mechanical properties of the obtained new adhesive formulations were compared with a commercial UF formulation used in the wood industry for bonding plywood.

2. Materials and Methods

2.1. Materials Required

The medicinal plants used in this work (Thymus bleicherianus, Thymus capitates, Thymus satureioides, Thymus vulgaris and Thymus zygis) were purchased from the local market in Khenifra (Morocco). The aerial parts of all plants were washed repeatedly with water to remove dust and soluble impurities on the surface and dried overnight at room temperature in the shade. The sample was then dried at 40 °C for 3 days in an air oven. The dried sample was ground to pass through a 30 mesh screen. The fine powder of the plants was stored in plastic bags for use as a filler in adhesive formulations.

Apart from the aforementioned sample, all chemicals used in this work were of analytical grade and obtained from Merck (Darmstadt, Germany) and ACROS (Geel, Belgium).

2.2. Preparation of Material

2.2.1. Preparation of Adhesive Formulations

The preparation of the adhesive formulations based on plants (AFBP) was carried out according to the following procedure.

The UF resin in the form of a 50% aqueous solution was placed in a reactor equipped with an agitator, with a percentage of water as indicated in Table 1. Then, a powder based on starch and the plant was added to the mixture. Next, 2% urea and 3% ammonium sulphate were poured over the previous mixture. Stirring was continued until a viscous and homogeneous liquid was obtained [7].

Table 1.

The constituents in percentage (%) of the AFs.

The AFBP prepared are:

- AF1: Using the plant Thymus bleicherianus.

- AF2: Using the plant Thymus capitates.

- AF3: Using the plant Thymus satureioides.

- AF4: Using the plant Thymus vulgaris.

- AF5: Using the plant Thymus zygis.

To properly study the physico-chemical characteristics and the mechanical properties of the new adhesive formulations (AFs), another adhesive formulation utilized in the local wood market was used as a reference (SAF).

2.2.2. Preparation of Plywood Panels

The plywood was composed of veneer sheets from different species, of the following dimensions: 2100 × 1000 × 4 mm3. The face and back of the plywood were made from the wood of the kapok tree species, while the core was made with the wood of the okoumé species. The folds are placed symmetrically on either side of a central ply (core), which gives an odd number of folds (3 plies) and a balanced structure.

Gluing: The veneers were glued using a roller gluer, with a grammage of 373 g/m2 of the Afs, which were distributed on both sides of the core veneer.

Pressing: The pressing was carried out using the following parameters: Cold pre-pressing (under a pressure of 15 bars and at room temperature) and hot pressing (under a pressure of 10 bars and at a temperature of 98 °C for 4 min).

One panel was fabricated per each AF and conditioned at 25 °C and 65% relative humidity in a climate room for a week before testing.

2.3. AFs and Plywood Characterization Techniques

2.3.1. Determination of the AFs Properties

Color, pH, viscosity, gel time and solid content were determined at the end of each synthesis. The AFs’ pH were determined with a pH-meter. The viscosity of the AFs was measured by a Ford cup (MeterTo, N°4, 25 °C). The non-volatile solids content was determined by measuring approximately 7 g of AF in a disposable aluminum dish and taking an accurate weight before and after drying in a convective oven for 3 h at 105 °C. The AF reactivity was determined by measuring the gel time of a resin sample at 100 °C after addition of the 10% NH4Cl (20% aqueous solution) as a cure catalyst [18]. The density values of the liquid AF were obtained by density hydrometer (VWR, range 1.000–1.250 g/cm3). The overall content of formaldehyde in the aqueous solution was determined by titration with the Na2SO3 method [19].

2.3.2. Analytical Instruments

The analysis of the AFs prepared was carried out by a set of techniques commonly used for this type of material, such as:

Scanning Electron Microscope (SEM, JEOL JSM-6700F) (Japan), which was employed to determine the sample surface morphology;

X-ray Diffraction (XRD, Bruker D8 Advance diffractometer with Cu Kα radiation: 1.54 Å), which was used for the investigation of the phase crystalline structure of the samples, this system worked at a current of 80 mA and a voltage of 60 kV with Cu Kα-radiation;

Differential Thermal Analysis and Thermogravimetric Analysis (DTA/TGA, Shimadzu DTG-60H system) were carried out at the atmosphere of Ar and with a heating rate of 10 °C min−1. These thermal techniques were used to determine the major transformations and to identify the temperature regimes of the main weight losses of all AF samples.

Fourier Transform Infrared spectroscopy (FTIR, Bruker Vertex 70), from where infrared spectra were recorded in the frequency range of 400–4000 cm−1 at a resolution of 4 cm−1 with Fourier spectroscopy.

2.3.3. Determination of Plywood Properties

A shear strength test of the plywood panels was performed to evaluate the bonding strength according to the EN 314-1 [20]. Samples prepared for shear strength were tested after being soaked in water at 20 °C for 24 h. Bending strength and the modulus of elasticity values of plywood panels were evaluated according to the EN 310 standard [21]. Three specimens were cut for each mechanical test from the middle area of a panel sample.

2.4. Statistical Analysis

Experimental values were obtained in triplicate for each test. The statistical analysis of all numerical data was carried out by Type A evaluation of standard uncertainty with the Student test (t < 0.05).

An analysis of variance (ANOVA) with Tukey’s test was used to initially determine any significant data differences between the groups of samples.

3. Results

3.1. Physical-Chemical Properties of AFs

Physical and chemical characteristics, such as: pH, viscosity, gel duration, solid content, density, free formaldehyde concentration, and color are crucial indicators of the AFs’ quality. All of the values obtained during these determinations are shown in Table 2. The examination of ANOVA of the experimental values obtained for all the examined parameters, including pH, gel duration, solid content and density shows no significant difference. On the other hand, there are significant differences in the viscosity and the free formaldehyde concentration.

Table 2.

Physico-chemical properties of the AFs with a comparison of means using the ANOVA test.

The new AFBPs have better viscosity. This can be attributed to the organic molecules found in the fillers of the plants utilized, which combine with the AF’s composition to create bonds that raise the suspension’s viscosity, as detailed in earlier research by Rui Ding et al. (2013) [22] on the use of wheat gluten in adhesives.

The increase in formulation quality is demonstrated by the lower free formaldehyde content in AFBP compared to SAF. The presence of polyphenols in the additional fillers of the plants employed can be used to explain these outcomes. It has been noticed that the Thymus genus has a variety of plants that are high in polyphenols, notably tannins, the latter of which is particularly interesting for lowering formaldehyde emissions [23].

Finally, the white color of the SAF was changed to a brown color for the AFBP, this change is due to the colors of the added plant filler in place of the starch filler, which has a white color.

3.2. Characterization of AFs

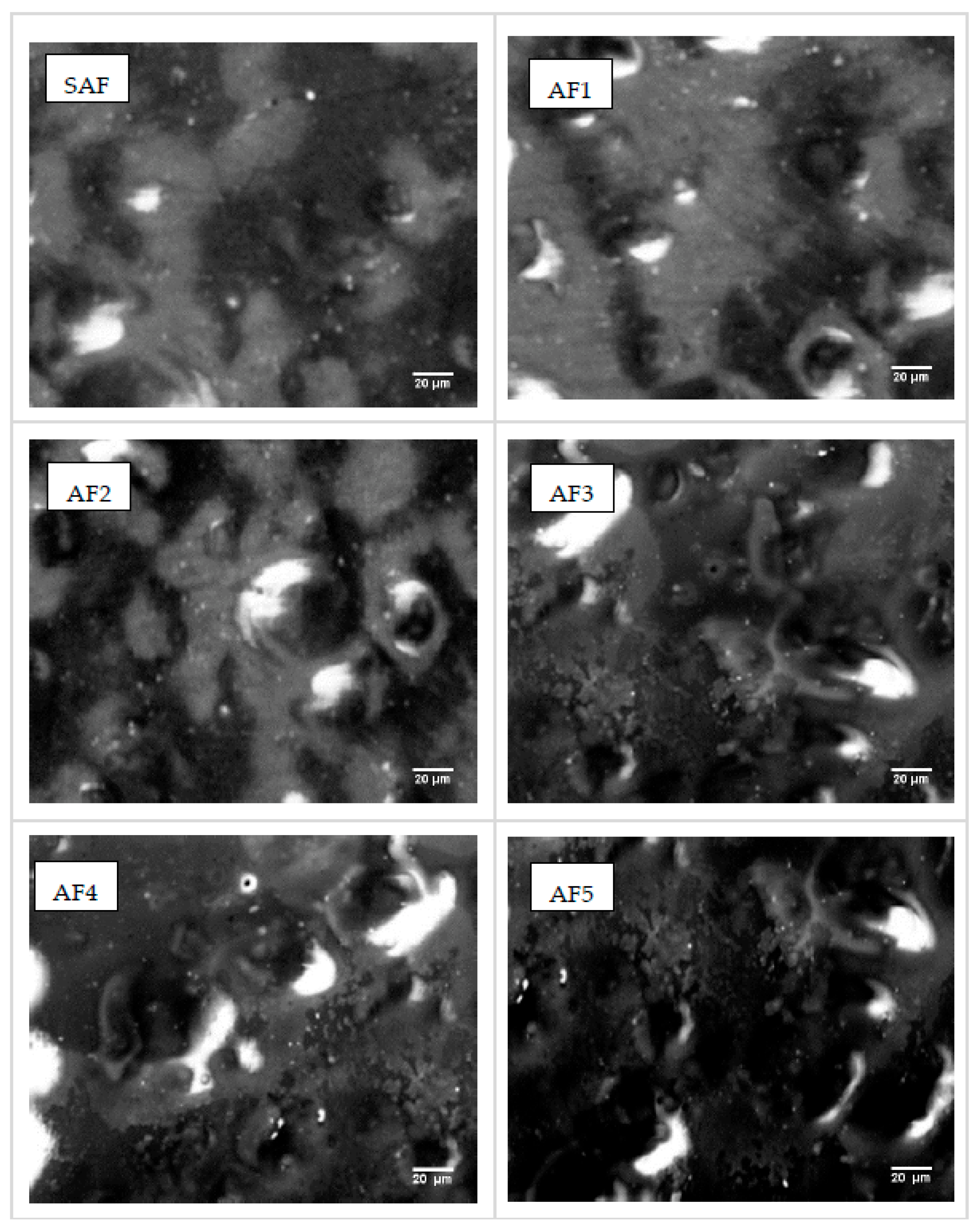

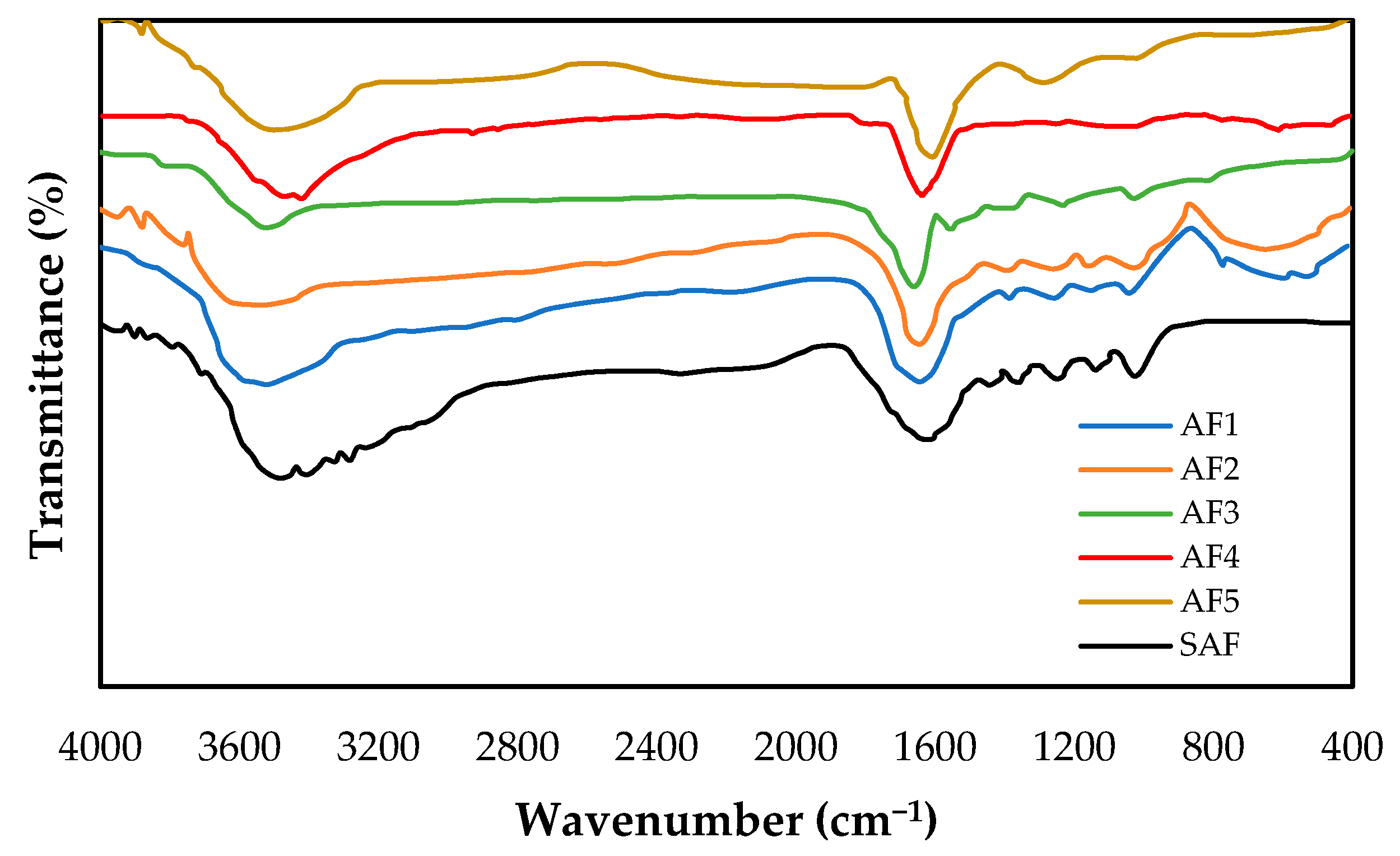

3.2.1. Scanning Electron Microscopy (SEM)

Results from SEM of the generated AFs are shown in Figure 1 at a resolution of 20 μm. These images used to infer that the formulations are homogenous, non-porous and that they also exhibit the same colloidal textures with aggregates that range in size from 3 μm to 30 μm. Some articles claim that the colloidal form of liquid UF resins is one of their shared properties [24,25]. Aging causes colloidal particles to combine to create bigger, more intricate aggregates. Particles with nodular, globular, and spherical forms have all been used to characterize the architecture of cured UF resins. Moreover, the powder of the plants has disappeared in the prepared AFs, which shows that this material has been totally dissolved in the UF system.

Figure 1.

SEM images of AFs. (SAF: standard adhesive formulation; AF1: Thymus bleicherianus; AF2: Thymus capitates; AF3: Thymus satureioides; AF4: Thymus vulgaris; AF5: Thymus zygis).

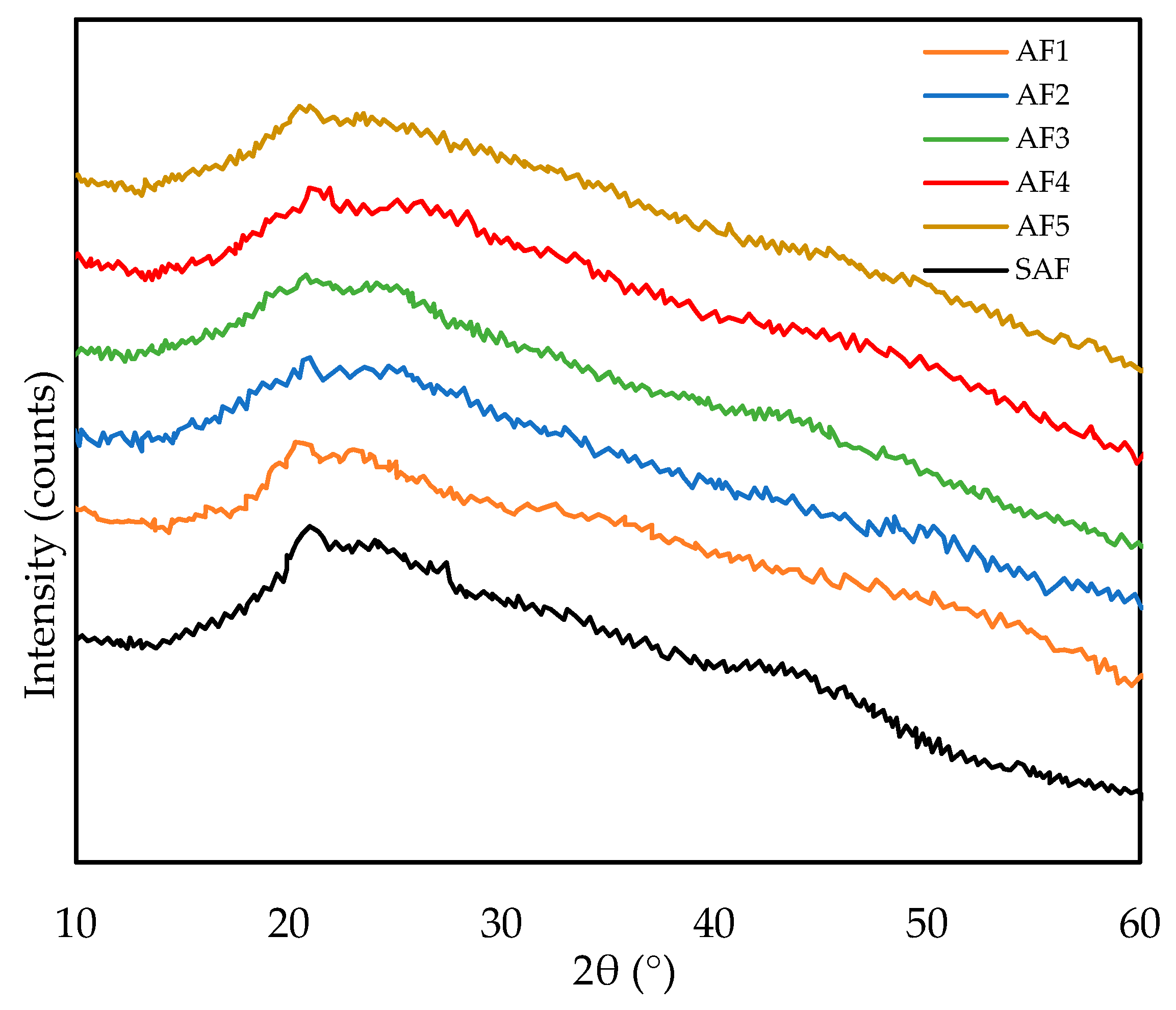

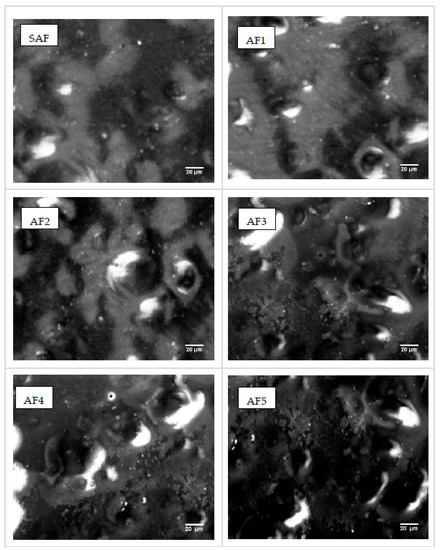

3.2.2. X-ray Diffraction (XRD)

Figure 2 shows the XRDs of all AFs prepared. With the exception of a few peaks at low intensities that are positioned between 22° and 24°, the diffractograms of the formulations exhibit amorphous structures. These peaks correspond to the descriptions of pure UF resin that are found in several works in the literature [26,27,28]. The crystallization of UF adhesive structures depends on the F/U molar ratio. If the UF formulation has a lower F/U molar ratio of 1.1 to 0.5 then the adhesive has a crystalline structure, whereas if the UF formulation has a higher F/U molar ratio then the adhesive is an amorphous polymer, the latter is well shown by the diffractograms in our study (F/U~2).

Figure 2.

Diffractograms of AFs. (SAF: standard adhesive formulation; AF1: Thymus bleicherianus; AF2: Thymus capitates; AF3: Thymus satureioides; AF4: Thymus vulgaris; AF5: Thymus zygis).

3.2.3. Thermal Analysis

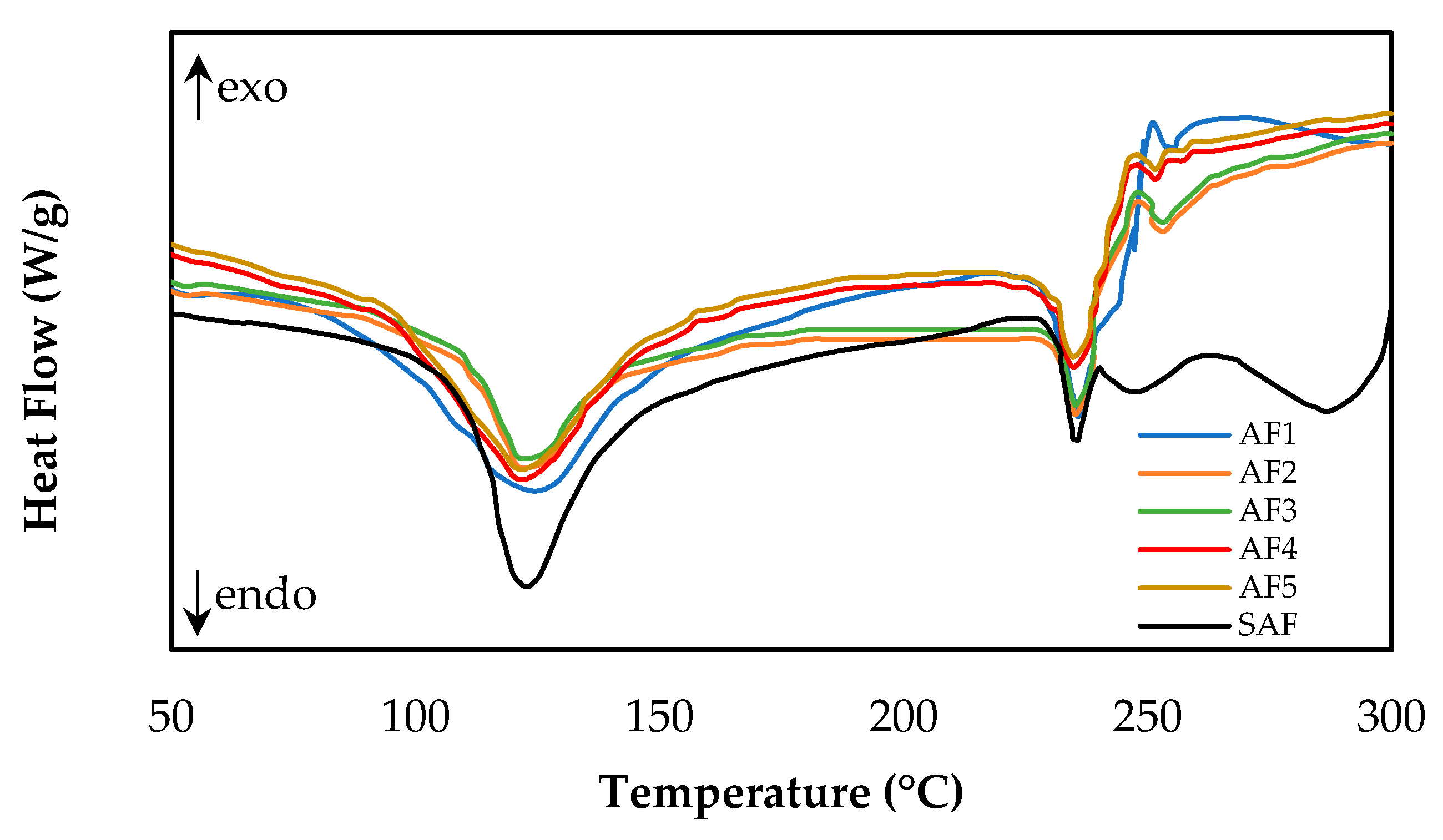

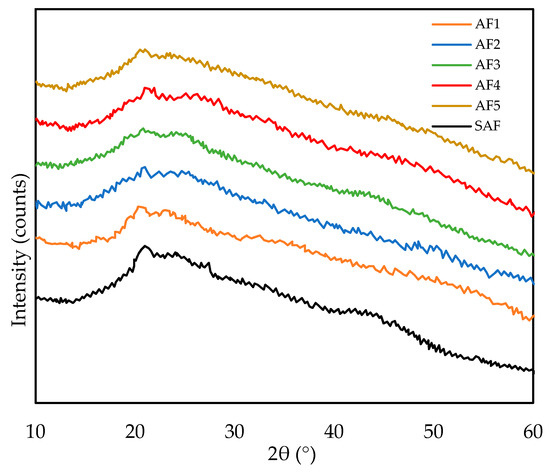

Figure 3.

Differential Thermal Analysis of AFs. (SAF: standard adhesive formulation; AF1: Thymus bleicherianus; AF2: Thymus capitates; AF3: Thymus satureioides; AF4: Thymus vulgaris; AF5: Thymus zygis).

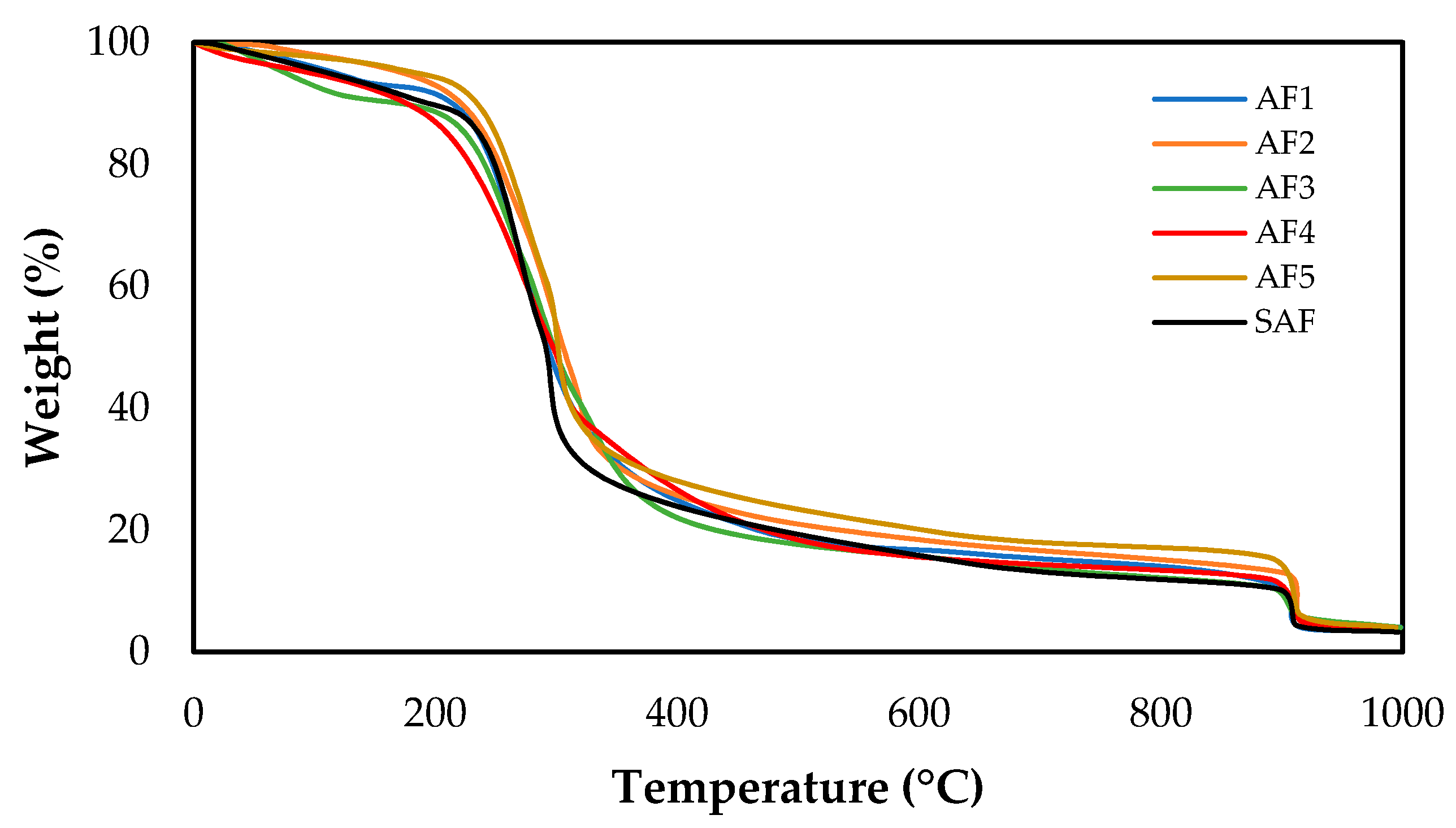

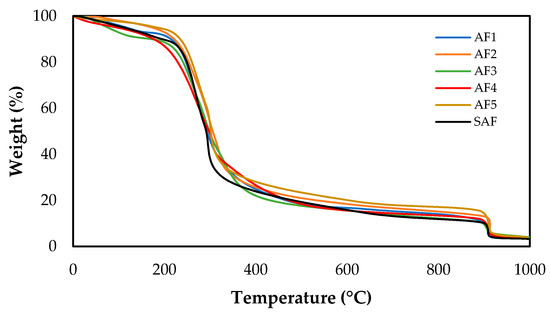

Figure 4.

Thermogravimetric Analysis of AFs. (SAF: standard adhesive formulation; AF1: Thymus bleicherianus; AF2: Thymus capitates; AF3: Thymus satureioides; AF4: Thymus vulgaris; AF5: Thymus zygis).

The DTA analyses revealed the existence of three endothermic peaks, with 123 °C signifying urea melting and 235 °C and 255 °C signifying resin deterioration. Importantly, there was no high quantity of free formaldehyde present in all samples, which was also consistent with the expected polymerization pathway, since formaldehyde has a very strong reactivity with urea. More precisely, the mechanism of the degradation process is initiated when chain scissions begin, and the radicals formed induce the formation of cyclic structures in the polymer chain. This phase results in the extensive polymer fragmentation. Degradation of cured resins begins with the release of formaldehyde from dimethylene ether groups and the maximum degradation rate happens when the stable methylene ether linkages deconstruct [29,30].

Two fundamental losses are provided for all AFs by the TGA analyses. Between 100 °C and 150 °C, there was an initial mass loss of roughly 10%. The second mass loss that is considered important (around 80%) occurred above 200 °C.

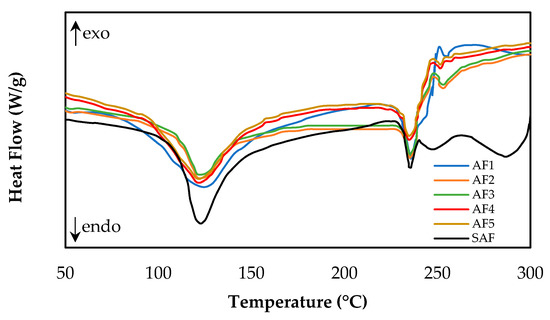

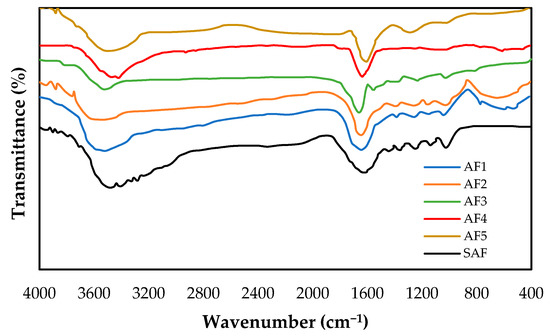

3.2.4. Fourier Transform Infrared Spectroscopy

Figure 5 displays the FTIR spectra of the AFs. As can be observed, there is a wide band between 3400 cm−1 and 3500 cm−1, which corresponds to the intramolecular OH group lengthening resulting from the reaction between the polyphenolic compounds of fillers (plants) and the formaldehyde present in the resin. Another band located around 1642 cm−1 confirms the presence of C=C aromatic ethylenic bonds in the phenolic ring [31,32].

Figure 5.

FTIR spectra of AFs. (SAF: standard adhesive formulation; AF1: Thymus bleicherianus; AF2: Thymus capitates; AF3: Thymus satureioides; AF4: Thymus vulgaris; AF5: Thymus zygis).

3.3. Mechanical Properties of Plywood

Shear strength, bending strength and modulus of elasticity are recommended properties for testing the quality of plywood panels. Table 3 presents all the results obtained during the mechanical tests carried out. The values obtained from several mechanical tests are nearly the same. These results are confirmed by the statistical analysis of ANOVA, from which the data from all the formulations show no significant difference at 5%. In conclusion, obtaining the same mechanical properties of plywood bonded by the AFs developed, compared to the SAF, proves the effectiveness of the other formulations for gluing plywood panels in a more ecofriendly way.

Table 3.

Mechanical characteristics of the plywoods manufactured using the elaborated AFs.

4. Discussion

Wood industries are large users of UF resins, because they are involved in the major composition of AFs, in particular for the manufacture of plywood panels [33,34,35]. These substances might come with some risks, notably those connected to the emissions of free formaldehyde [36].

Several studies aimed to limit the emission of this product during the use and manufacture of panels by optimizing variables relating to technological viability, human and organizational concerns, health, economy, and environment [37,38,39]. The use of other fillers to minimize formaldehyde emissions in various ways has been suggested in a number of earlier papers; for examples: tannin [40], urea [41], sodium metabisulphite [42], different waste [43,44,45,46] and nanomaterials [47,48]. For all the above reasons, the goal of our study was to develop novel AFs using medicinal plants as an alternative filler; as such, five plants of the Thymus genus were included in the composition of a commercial adhesive formulation along with other substances; hence, the chemical composition of the elaborated AFs are: urea-formaldehyde resin (50%), water (15%), urea (2%), ammonium sulfate (3%), starch (15%) and plants (15%).

The analysis of the physico-chemical properties reveals that the addition of plants decreased the free formaldehyde content while simultaneously increasing viscosity. Additionally, the other characteristics, such as: pH, gel duration, solid content, density, and color, did not mention significant differences. Furthermore, all of the novel AFs as well as the standard formulation have undergone physical and morphological characterizations using the SEM, XRD, DTA, TGA, and FTIR analytical techniques, which have proven the stability and homogeneity of their structures. Additionally, the mechanical properties of the AFs under investigation have not revealed any significant differences when compared to the SAF, this supports earlier findings about the stability of the formulations’ structures [7].

Ruziak et al. (2017) [49] investigated the influence of beech bark (Fagus grandifolia) concentrations as a filler in urea-formaldehyde (UF) adhesives, from which prepared AFs demonstrated a decrease in formaldehyde emissions. In addition, the works carried out by Khammour et al. (2018a, 2018b) [7,8] on the development of urea-formaldehyde adhesive formulations based on waste from the mint medicinal plant (Mentha spicata) have shown high physico-chemical and mechanical performance with the use of this biomass in wood industries according to required international standards and recommendations, particularly the reduction in formaldehyde emissions.

In light of these results, powdered medicinal plants might be employed as an organic filler with UF resins for the production of plywood panels. In addition, plants, which are inexpensive and easy to obtain, showed a similar positive effect on reducing free formaldehyde emissions.

5. Conclusions

Our studies have made it feasible to develop medicinal plants-modified UF adhesives suitable for plywood production. Specifically, 15% medicinal plants from the genus Thymus are added as an alternative filler, in addition to 15% starch, to the adhesive formulation of a urea-formaldehyde resin along with other constituents. According to all the information acquired from the physico-chemical and statistical investigations, the biomass was used to minimize formaldehyde and increase viscosity while retaining other attributes, particularly mechanical properties. Due to safety and environmental concerns, our studies have made it feasible to develop suitable urea-formaldehyde type adhesives based on medicinal plants.

Author Contributions

Conceptualization, F.M.A.-L. and T.A.; methodology, Z.E.M. and A.A.; software, A.M. and J.M.; validation, F.M.A.-L., A.A. and T.A.; formal analysis, S.G. and E.H.S.; investigation, F.M.A.-L.; resources, F.M.A.-L. data curation, T.A.; writing—original draft preparation, T.A. and Z.E.M.; writing—review and editing, F.M.A.-L.; visualization, A.A.; supervision, F.M.A.-L.; project administration, F.M.A.-L. funding acquisition, F.M.A.-L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors received no external funding for this article.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kamperidou, V.; Terzopoulou, P.; Barboutis, I. Marginal lands providing treeinal biomass as feedstock for solid biofuels. Biofuels Bioprod. Biorefining 2021, 15, 1395–1405. [Google Scholar] [CrossRef]

- Khammour, F.; Kenz, A.; Ainane, A.; El Kouali, M.; Talbi, M.; Ainane, T. Determination of the content and release of formaldehyde from a particle board sample. J. Anal. Sci. Appl. Biotechnol. 2019, 1, 19–21. [Google Scholar]

- Otero-Chans, D.; Estévez-Cimadevila, J.; Suárez-Riestra, F.; Martín-Gutiérrez, E. Experimental analysis of glued-in steel plates used as shear connectors in Timber-Concrete-Composites. Eng. Struct. 2018, 170, 1–10. [Google Scholar] [CrossRef]

- Li, J.; Zhou, A. Mechanical behavior of laminated bamboo lumber dowel-type connection. Adv. Struct. Eng. 2020, 23, 65–73. [Google Scholar] [CrossRef]

- Aladejana, J.T.; Wu, Z.; Yves, K.G.; Hou, X.; Xie, Y. Application of functionalized carboxymethyl cellulose in development of hierarchical lamellar aluminophosphate for the industrial fabrication of wood based panels. Int. J. Adhes. Adhes. 2022, 113, 103051. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Mo, H.; Xie, E.; Fang, J.; Gan, W. Current utilization of waste biomass as filler for wood adhesives: A review. J. Ind. Eng. Chem. 2022, 115, 48–61. [Google Scholar] [CrossRef]

- Khammour, F.; Ainane, A.; Elmatar, M.; Kenz, A.; Elkouali, M.H.; Talbi, M.; Ainane, T. Effect of waste mint in urea formaldehyde adhesive on the thermal degradation of plywood. Orient. J. Chem. 2018, 34, 1375. [Google Scholar] [CrossRef]

- Khammour, F.; Ainane, A.; Kenz, A.; Talbi, M.; Elkouali, M.H.; Ainane, T.; Elmatar, M. Mechanical properties of particleboards based on mint waste manufactured from different content of urea formaldehyde adhesive. Int. J. Mech. Eng. Technol. 2018, 9, 756–762. [Google Scholar]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Hejna, A. Recent progress in ultra-low formaldehyde emitting adhesive systems and formaldehyde scavengers in wood-based panels: A review. Wood Mater. Sci. Eng. 2022, 1–20. [Google Scholar] [CrossRef]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W. Technological performance of formaldehyde-free adhesive alternatives for particleboard industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- Sanghvi, M.R.; Tambare, O.H.; More, A.P. Performance of various fillers in adhesives applications: A review. Polym. Bull. 2022, 1–63. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Savov, V. Properties of eco-friendly particleboards bonded with lignosulfonate-urea-formaldehyde adhesives and PMDI as a crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Mo, H.; Xie, E.; Fang, J.; Hou, Z.; Gan, W. Utilization of carbon black from Mao bamboo as reinforcing agent for melamine urea formaldehyde resin wood adhesive. Ind. Crops Prod. 2022, 187, 115373. [Google Scholar] [CrossRef]

- Ebewele, R.O.; River, B.H.; Koutsky, J.A. Relationship between phenolic adhesive chemistry and adhesive joint performance: Effect of filler type on fraction energy. J. Appl. Polym. Sci. 1986, 31, 2275–2302. [Google Scholar] [CrossRef]

- Réh, R.; Krišťák, Ľ.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Savov, V. Utilization of birch bark as an eco-friendly filler in urea-formaldehyde adhesives for plywood manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef] [PubMed]

- Bumanis, G.; Vitola, L.; Pundiene, I.; Sinka, M.; Bajare, D. Gypsum, Geopolymers, and starch—Alternative binders for bio-based building materials: A review and life-cycle assessment. Sustainability 2020, 12, 5666. [Google Scholar] [CrossRef]

- Aydin, I.; Demirkir, C.; Colak, S.; Colakoglu, G. Utilization of bark flours as additive in plywood manufacturing. Eur. J. Wood Wood Prod. 2017, 75, 63–69. [Google Scholar] [CrossRef]

- Böhm, M.; Salem, M.Z.; Srba, J. Formaldehyde emission monitoring from a variety of solid wood, plywood, blockboard and flooring products manufactured for building and furnishing materials. J. Hazard. Mater. 2012, 221, 68–79. [Google Scholar] [CrossRef] [PubMed]

- Dorieh, A.; Mahmoodi, N.O.; Mamaghani, M.; Pizzi, A.; Zeydi, M.M. New insight into the use of latent catalysts for the synthesis of urea formaldehyde adhesives and the mechanical properties of medium density fiberboards bonded with them. Eur. Polym. J. 2019, 112, 195–205. [Google Scholar] [CrossRef]

- EN 314-1:2004; Plywood—Bonding Quality—Part 1: Test Methods. European Committee for Standardization: Brussels, Belgium, 2004.

- EN 310: 1993; Wood-Based Panels: Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- Ding, R.; Su, C.; Yang, Y.; Li, C.; Liu, J. Effect of wheat flour on the viscosity of urea-formaldehyde adhesive. Int. J. Adhes. Adhes. 2013, 41, 1–5. [Google Scholar] [CrossRef]

- Marsal, A.; Cuadros, S.; Manich, A.M.; Izquierdo, F.; Font, J. Reduction of the formaldehyde content in leathers treated with formaldehyde resins by means of plant polyphenols. J. Clean. Prod. 2017, 148, 518–526. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y. Morphology and crystallinity of urea-formaldehyde resin adhesives with different molar ratios. Polymers 2021, 13, 673. [Google Scholar] [CrossRef] [PubMed]

- Despres, A.; Pizzi, A. Colloidal aggregation of aminoplastic polycondensation resins: Urea–formaldehyde versus melamine–formaldehyde and melamine–urea–formaldehyde resins. J. Appl. Polym. Sci. 2006, 100, 1406–1412. [Google Scholar] [CrossRef]

- Wibowo, E.S.; Park, B.D. Crystalline Lamellar Structure of Thermosetting Urea–Formaldehyde Resins at a Low Molar Ratio. Macromolecules 2021, 54, 2366–2375. [Google Scholar] [CrossRef]

- Wibowo, E.S.; Park, B.D.; Causin, V. Hydrogen-bond-induced crystallization in low-molar-ratio urea–formaldehyde resins during synthesis. Ind. Eng. Chem. Res. 2020, 59, 13095–13104. [Google Scholar] [CrossRef]

- Wibowo, E.S.; Lubis, M.A.R.; Park, B.D.; Kim, J.S.; Causin, V. Converting crystalline thermosetting urea–formaldehyde resins to amorphous polymer using modified nanoclay. J. Ind. Eng. Chem. 2020, 87, 78–89. [Google Scholar] [CrossRef]

- Samaržija-Jovanović, S.; Jovanović, V.; Konstantinović, S.; Marković, G.; Marinović-Cincović, M. Thermal behavior of modified urea–formaldehyde resins. J. Therm. Anal. Calorim. 2011, 104, 1159–1166. [Google Scholar] [CrossRef]

- Siimer, K.; Kaljuvee, T.; Christjanson, P. Thermal behaviour of urea-formaldehyde resins during curing. J. Therm. Anal. Calorim. 2003, 72, 607–617. [Google Scholar] [CrossRef]

- Faris, A.H.; Ibrahim, M.N.M.; Rahim, A.A. Preparation and characterization of green adhesives using modified tannin and hyperbranched poly (amine-ester). Int. J. Adhes. Adhes. 2016, 71, 39–47. [Google Scholar] [CrossRef]

- Poljanšek, I.; Šebenik, U.; Krajnc, M. Characterization of phenol–urea–formaldehyde resin by inline FTIR spectroscopy. J. Appl. Polym. Sci. 2006, 99, 2016–2028. [Google Scholar] [CrossRef]

- Demirkir, C.; Özsahin, Ş.; Aydin, I.; Colakoglu, G. Optimization of some panel manufacturing parameters for the best bonding strength of plywood. Int. J. Adhes. Adhes. 2013, 46, 14–20. [Google Scholar] [CrossRef]

- Bekhta, P.; Hiziroglu, S.; Shepelyuk, O. Properties of plywood manufactured from compressed veneer as building material. Mater. Des. 2009, 30, 947–953. [Google Scholar] [CrossRef]

- Abdullah, Z.A.; Park, B.D. Influence of acrylamide copolymerization of urea–formaldehyde resin adhesives to their chemical structure and performance. J. Appl. Polym. Sci. 2010, 117, 3181–3186. [Google Scholar] [CrossRef]

- Tohmura, S.I.; Hse, C.Y.; Higuchi, M. Formaldehyde emission and high-temperature stability of cured urea-formaldehyde resins. J. Wood Sci. 2000, 46, 303–309. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Hosseini, S.B.; Ghahri, S.; Ghofrani, M.; Papadopoulos, A.N. Formaldehyde emission in micron-sized wollastonite-treated plywood bonded with soy flour and urea-formaldehyde resin. Appl. Sci. 2020, 10, 6709. [Google Scholar] [CrossRef]

- Park, B.D.; Causin, V. Crystallinity and domain size of cured urea–formaldehyde resin adhesives with different formaldehyde/urea mole ratios. Eur. Polym. J. 2013, 49, 532–537. [Google Scholar] [CrossRef]

- Boran, S.; Usta, M.; Gümüşkaya, E. Decreasing formaldehyde emission from medium density fiberboard panels produced by adding different amine compounds to urea formaldehyde resin. Int. J. Adhes. Adhes. 2011, 31, 674–678. [Google Scholar] [CrossRef]

- Moubarik, A.; Pizzi, A.; Allal, A.; Charrier, F.; Khoukh, A.; Charrier, B. Cornstarch–mimosa tannin–urea formaldehyde resins as adhesives in the particleboard production. Starch-Stärke 2010, 62, 131–138. [Google Scholar] [CrossRef]

- Park, B.D.; Chang Kang, E.; Yong Park, J. Effects of formaldehyde to urea mole ratio on thermal curing behavior of urea–formaldehyde resin and properties of particleboard. J. Appl. Polym. Sci. 2006, 101, 1787–1792. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Park, B.D.; Lee, S.M. Modification of urea-formaldehyde resin adhesives with blocked isocyanates using sodium bisulfite. Int. J. Adhes. Adhes. 2017, 73, 118–124. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J.; Kačík, F.; Noshchenko, G.; Kleinová, A. Lignocellulosic waste fibers and their application as a component of urea-formaldehyde adhesive composition in the manufacture of plywood. Eur. J. Wood Wood Prod. 2019, 77, 495–508. [Google Scholar] [CrossRef]

- Ong, H.R.; Khan, M.R.; Yousuf, A.; Jeyaratnam, N.; Prasad, D.R. Effect of waste rubber powder as filler for plywood application. Pol. J. Chem. Technol. 2015, 17, 41–47. [Google Scholar] [CrossRef]

- Nazeryan, M.; Dalirzadeh, A.; Farokhpayam, S.R. The effect of old corrugated container (OCC) powder and as urea formaldehyde adhesive filler on properties of medium density fiberboard made from bagasse and waste MDF. Iran. J. Wood Pap. Sci. Res. 2014, 29, 452–463. [Google Scholar]

- Alma, M.H.; Basturk, M.A. Liquefaction of grapevine cane (Vitis vinisera L.) waste and its application to phenol–formaldehyde type adhesive. Ind. Crops Prod. 2006, 24, 171–176. [Google Scholar] [CrossRef]

- Yadav, S.M.; Lubis, M.A.R.; Wibowo, E.S.; Park, B.D. Effects of nanoclay modification with transition metal ion on the performance of urea–formaldehyde resin adhesives. Polym. Bull. 2021, 78, 2375–2388. [Google Scholar] [CrossRef]

- De Cademartori, P.H.G.; Artner, M.A.; de Freitas, R.A.; Magalhães, W.L.E. Alumina nanoparticles as formaldehyde scavenger for urea-formaldehyde resin: Rheological and in-situ cure performance. Compos. Part B Eng. 2019, 176, 107281. [Google Scholar] [CrossRef]

- Ružiak, I.; Igaz, R.; Krišťák, L.; Réh, R.; Mitterpach, J.; Očkajová, A.; Kučerka, M. Influence of urea-formaldehyde adhesive modification with beech bark on chosen properties of plywood. BioResources 2017, 12, 3250–3264. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).