Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires

Abstract

:1. Introduction

2. Materials and Methods

3. Results

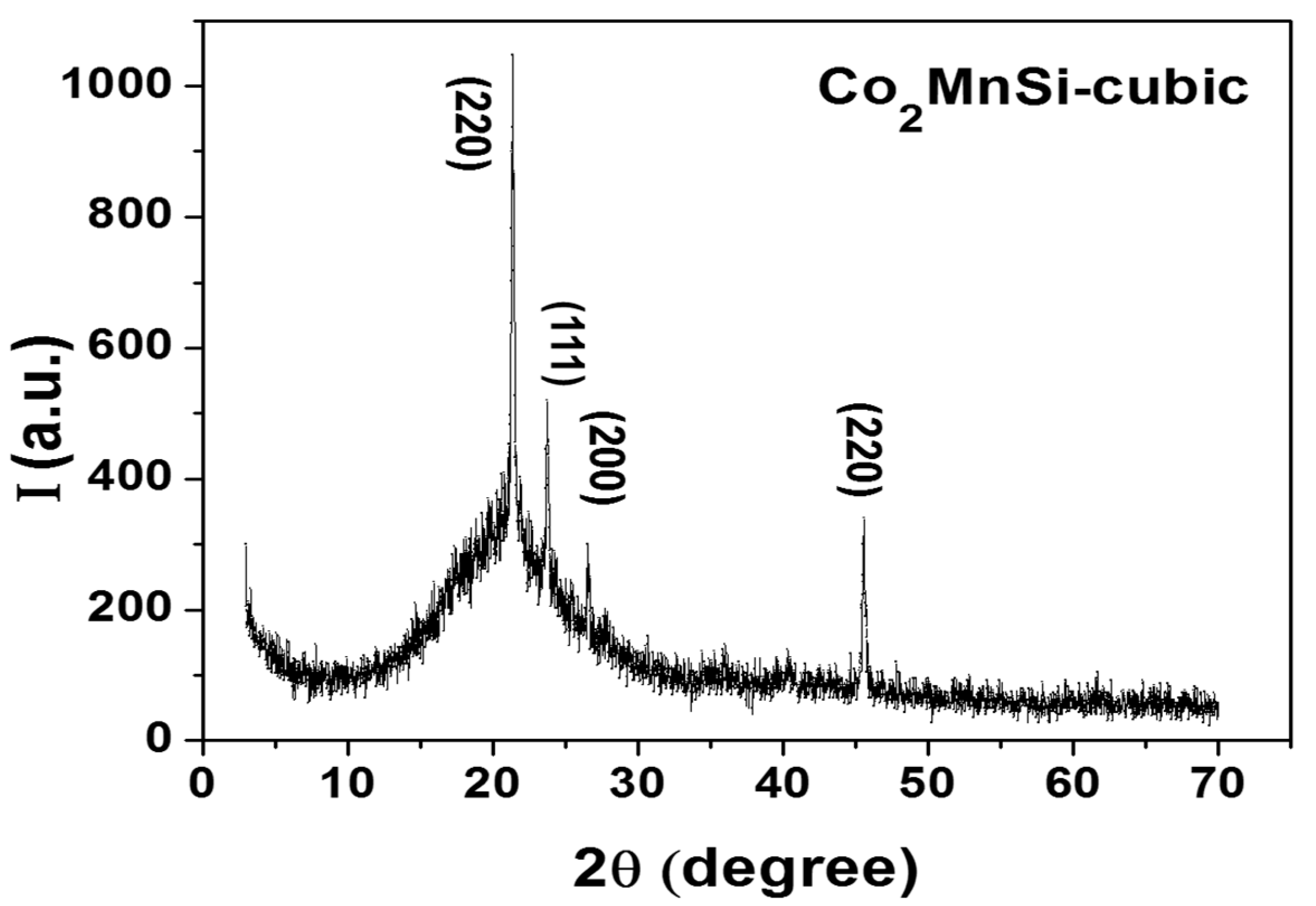

3.1. Morphological and Structure Properties

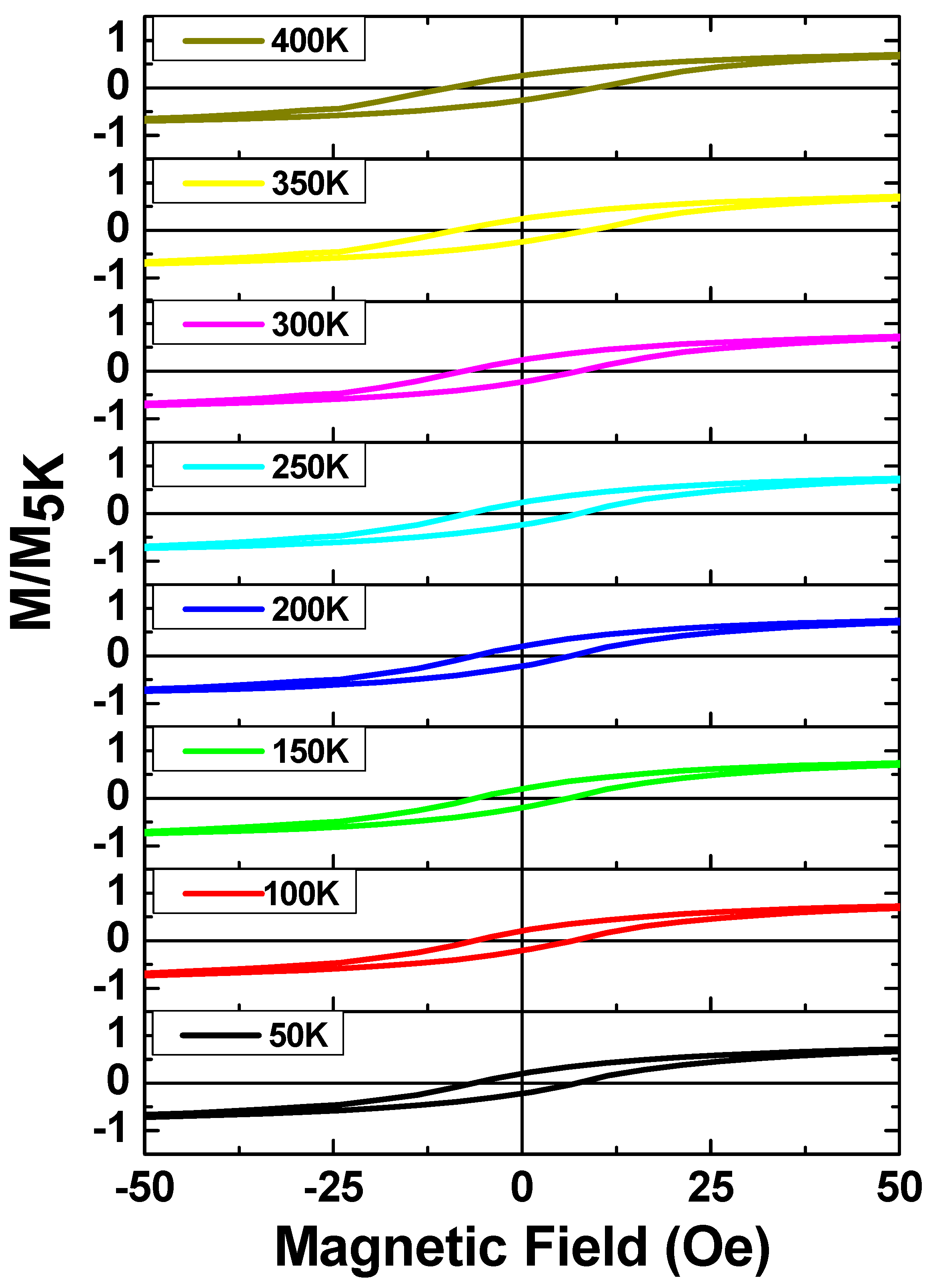

3.2. Magnetic Properties

3.2.1. Room Temperature Magnetic Properties

3.2.2. Temperature Dependence of Magnetic Behavior

4. Discussion

- (i)

- Presence of flexible glass coating can improve the mechanical properties of glass-coated microwires [42]

- (ii)

- Proposed method allows preparation of thin Heusler alloy microwires by single step preparation method, directly in the form of a microwire.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Inomata, K.; Ikeda, N.; Tezuka, N.; Goto, R.; Sugimoto, S.; Wojcik, M.; Jedryka, E. Highly Spin-Polarized Materials and Devices for Spintronics. Adv. Mater. 2008, 9, 14101. [Google Scholar] [CrossRef] [PubMed]

- Chumak, O.M.; Pacewicz, A.; Lynnyk, A.; Salski, B.; Yamamoto, T.; Seki, T.; Domagala, J.Z.; Głowiński, H.; Takanashi, K.; Baczewski, L.T.; et al. Magnetoelastic Interactions and Magnetic Damping in Co2Fe0.4Mn0.6Si and Co2FeGa0.5Ge0.5 Heusler Alloys Thin Films for Spintronic Applications. Sci. Rep. 2021, 11, 7608. [Google Scholar] [CrossRef] [PubMed]

- De Groot, R.A.; Mueller, F.M.; Engen, P.G.V.; Buschow, K.H.J. New Class of Materials: Half-Metallic Ferromagnets. Phys. Rev. Lett. 1983, 50, 2024. [Google Scholar] [CrossRef] [Green Version]

- Elphick, K.; Frost, W.; Samiepour, M.; Kubota, T.; Takanashi, K.; Sukegawa, H.; Mitani, S.; Hirohata, A. Heusler Alloys for Spintronic Devices: Review on Recent Development and Future Perspectives. Sci. Technol. Adv. Mater. 2021, 22, 235–271. [Google Scholar] [CrossRef]

- Bai, Z.; Shen, L.E.I.; Han, G.; Feng, Y.P. Data Storage: Review of Heusler Compounds. Spin 2012, 2, 1230006. [Google Scholar] [CrossRef] [Green Version]

- Galanakis, I.; Dederichs, P.H.; Papanikolaou, N. Slater-Pauling Behavior and Origin of the Half-Metallicity of the Full-Heusler Alloys. Phys. Rev. B 2002, 66, 174429. [Google Scholar] [CrossRef] [Green Version]

- Hazra, B.K.; Kaul, S.N.; Srinath, S.; Raja, M.M. Uniaxial Anisotropy, Intrinsic and Extrinsic Damping in Co2FeSi Heusler Alloy Thin Films. J. Phys. D Appl. Phys. 2019, 52, 325002. [Google Scholar] [CrossRef] [Green Version]

- Wurmehl, S.; Fecher, G.H.; Kandpal, H.C.; Ksenofontov, V.; Felser, C.; Lin, H.J.; Morais, J. Geometric, Electronic, and Magnetic Structure of Co2FeSi: Curie Temperature and Magnetic Moment Measurements and Calculations. Phys. Rev. B Condens. Matter. Mater. Phys. 2005, 72, 184434. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Koo, J.; Ning, W.; Li, J.; Miao, L.; Min, L.; Zhu, Y.; Wang, Y.; Alem, N.; Liu, C.X.; et al. Giant Room Temperature Anomalous Hall Effect and Tunable Topology in a Ferromagnetic Topological Semimetal Co2MnAl. Nat. Commun. 2020, 11, 3476. [Google Scholar] [CrossRef]

- Belopolski, I.; Manna, K.; Sanchez, D.S.; Chang, G.; Ernst, B.; Yin, J.; Zhang, S.S.; Cochran, T.; Shumiya, N.; Zheng, H.; et al. Discovery of Topological Weyl Fermion Lines and Drumhead Surface States in a Room Temperature Magnet. Science 2019, 365, 1278–1281. [Google Scholar] [CrossRef]

- Ahmed, S.J.; Boyer, C.; Niewczas, M. Magnetic and Structural Properties of Co2MnSi Based Heusler Compound. J. Alloy. Compd. 2019, 781, 216–225. [Google Scholar] [CrossRef] [Green Version]

- Guillemard, C.; Petit-Watelot, S.; Pasquier, L.; Pierre, D.; Ghanbaja, J.; Rojas-Sánchez, J.C.; Bataille, A.; Rault, J.; le Fèvre, P.; Bertran, F.; et al. Ultralow Magnetic Damping in Co2Mn-Based Heusler Compounds: Promising Materials for Spintronics. Phys. Rev. Appl. 2019, 11, 064009. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.X.; Honda, Y.; Taira, T.; Matsuda, K.I.; Arita, M.; Uemura, T.; Yamamoto, M. Giant Tunneling Magnetoresistance in Epitaxial Co2MnSi/MgO/Co2MnSi Magnetic Tunnel Junctions by Half-Metallicity of Co2MnSi and Coherent Tunneling. Appl. Phys. Lett. 2012, 101, 132418. [Google Scholar] [CrossRef] [Green Version]

- Stuelke, L.; Kharel, P.; Shand, P.M.; Lukashev, P.V. First Principles Study of Perpendicular Magnetic Anisotropy in Thin-Film Co2MnSi. Phys. Scr. 2021, 96, 125818. [Google Scholar] [CrossRef]

- Ishida, S.; Fujii, S.; Kashiwagi, S.; Asano, S. Search for Half-Metallic Compounds in Co2MnZ (Z = IIIb, IVb, Vb Element). J. Phys. Soc. Jpn. 1995, 64, 2152–2157. [Google Scholar] [CrossRef]

- Pradines, B.; Arras, R.; Abdallah, I.; Biziere, N.; Calmels, L. First-Principles Calculation of the Effects of Partial Alloy Disorder on the Static and Dynamic Magnetic Properties of Co2MnSi. Phys. Rev. B 2017, 95, 094425. [Google Scholar] [CrossRef]

- Cheng, S.F.; Nadgorny, B.; Bussmann, K.; Carpenter, E.E.; Das, B.N.; Trotter, G.; Raphael, M.P.; Harris, V.G. Growth and Magnetic Properties of Single Crystal Co2MnX (X = Si, Ge) Heusler Alloys. IEEE Trans. Magn. 2001, 37, 2176–2178. [Google Scholar] [CrossRef]

- Jourdan, M.; Minár, J.; Braun, J.; Kronenberg, A.; Chadov, S.; Balke, B.; Gloskovskii, A.; Kolbe, M.; Elmers, H.J.; Schönhense, G.; et al. Direct Observation of Half-Metallicity in the Heusler Compound Co2MnSi. Nat. Commun. 2014, 5, 3974. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Liu, Y. Exchange Bias and Inverse Magnetocaloric Effect in Co and Mn Co-Doped Ni2MnGa Shape Memory Alloy. Metals 2013, 3, 69–76. [Google Scholar] [CrossRef] [Green Version]

- Dunand, D.C.; Müllner, P. Size Effects on Magnetic Actuation in Ni-Mn-Ga Shape-Memory Alloys. Adv. Mater. 2011, 23, 216–232. [Google Scholar] [CrossRef]

- Felser, C.; Hirohata, A. (Eds.) Heusler Alloys Properties, Growth, Applications; Springer Series in Materials Science; Springer International Publishing: Cham, Switzerland, 2016; Volume 222, ISBN 978-3-319-21448-1. [Google Scholar]

- Alam, J.; Bran, C.; Chiriac, H.; Lupu, N.; Óvári, T.A.; Panina, L.V.; Rodionova, V.; Varga, R.; Vazquez, M.; Zhukov, A. Cylindrical Micro and Nanowires: Fabrication, Properties and Applications. J. Magn. Magn. Mater. 2020, 513, 167074. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Abu-Dief, A.M.; Martínez-Goyeneche, L.; Alzahrani, S.O.; Alkhatib, F.; Álvarez-Alonso, P.; Blanco, J.Á. Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film. Materials 2020, 13, 5788. [Google Scholar] [CrossRef] [PubMed]

- Zhukov, A.; Rodionova, V.; Ilyn, M.; Aliev, A.M.; Varga, R.; Michalik, S.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Ipatov, M.; et al. Magnetic Properties and Magnetocaloric Effect in Heusler-Type Glass-Coated NiMnGa Microwires. J. Alloy. Compd. 2013, 575, 73–79. [Google Scholar] [CrossRef]

- Mallick, S.; Mondal, S.; Seki, T.; Sahoo, S.; Forrest, T.; Maccherozzi, F.; Wen, Z.; Barman, S.; Barman, A.; Takanashi, K.; et al. Tunability of Domain Structure and Magnonic Spectra in Antidot Arrays of Heusler Alloy. Phys. Rev. Appl. 2019, 12, 014043. [Google Scholar] [CrossRef] [Green Version]

- Zhukov, A.; Corte-Leon, P.; Gonzalez-Legarreta, L.; Ipatov, M.; Blanco, J.M.; Gonzalez, A.; Zhukova, V. Advanced Functional Magnetic Microwires for Technological Applications. J. Phys. D Appl. Phys. 2022, 55, 253003. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Blanco, J.M.; Zhukov, A. Fabrication and Magneto-Structural Properties of Co2-Based Heusler Alloy Glass-Coated Microwires with High Curie Temperature. Chemosensors 2022, 10, 225. [Google Scholar] [CrossRef]

- Zhukov, A.; Garcia, C.; Ilyn, M.; Varga, R.; del Val, J.J.; Granovsky, A.; Rodionova, V.; Ipatov, M.; Zhukova, V. Magnetic and transport properties of granular and Heusler-type glass-coated microwires. J. Magn. Magn. Mater. 2012, 324, 3558–3562. [Google Scholar] [CrossRef]

- Shevyrtalov, S.; Rodionova, V.; Lyatun, I.; Zhukova, V.; Zhukov, A. Post-Annealing Influence on Magnetic Properties of Rapidly Quenched Ni-Mn-Ga Glass-Coated Microwires. IEEE Trans. Magn. 2021, 57, 2000706. [Google Scholar] [CrossRef]

- Garcia, C.; Zhukova, V.; Shevyrtalov, S.; Ipatov, M.; Corte-Leon, P.; Zhukov, A. Tuning of Magnetic Properties in Ni-Mn-Ga Heusler-Type Glass-Coated Microwires by Annealing. J. Alloy. Compd. 2020, 838, 155481. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Corte-Leon, P.; Ipatov, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Anomalous Magnetic Behavior in Half-Metallic Heusler Co2FeSi Alloy Glass-Coated Microwires with High Curie Temperature. J. Alloy. Compd. 2022, 923, 166379. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Corte-León, P.; Gonzalez, A.; Ipatov, M.; Zhukova, V.; Gonzalez, J.M.; López Antón, R.; Zhukov, A. Manipulation of Magnetic and Structure Properties of Ni2fesi Glass-Coated Microwires by Annealing. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia, A.; Corte-Leon, P.; Ipatov, M.; Zhukova, V.; Zhukov, A. Unveiling the Effect of Annealing on Magnetic Properties of Nanocrystalline Half-Metallic Heusler Co2FeSi Alloy Glass-Coated Microwires. J. Mater. Res. Technol. 2022, 20, 4161–4172. [Google Scholar] [CrossRef]

- Mitxelena-Iribarren, O.; Campisi, J.; de Apellániz, I.M.; Lizarbe-Sancha, S.; Arana, S.; Zhukova, V.; Mujika, M.; Zhukov, A. Glass-Coated Ferromagnetic Microwire-Induced Magnetic Hyperthermia for in Vitro Cancer Cell Treatment. Mater. Sci. Eng. C 2020, 106, 110261. [Google Scholar] [CrossRef] [PubMed]

- Talaat, A.; Alonso, J.; Zhukova, V.; Garaio, E.; García, J.A.; Srikanth, H.; Phan, M.H.; Zhukov, A. Ferromagnetic Glass-Coated Microwires with Good Heating Properties for Magnetic Hyperthermia. Sci. Rep. 2016, 6, 39300. [Google Scholar] [CrossRef] [Green Version]

- Kozejova, D.; Fecova, L.; Klein, P.; Sabol, R.; Hudak, R.; Sulla, I.; Mudronova, D.; Galik, J.; Varga, R. Biomedical Applications of Glass-Coated Microwires. J. Magn. Magn. Mater. 2019, 470, 2–5. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Corte-Leon, P.; Blanco, J.M.; Zhukova, V. Advanced Functional Magnetic Microwires for Magnetic Sensors Suitable for Biomedical Applications. In Magnetic Materials and Technologies for Medical Applications; Tishin, A.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 527–579. [Google Scholar] [CrossRef]

- Aronin, A.S.; Abrosimova, G.E.; Kiselev, A.P.; Zhukova, V.; Varga, R.; Zhukov, A. The effect of mechanical stress on Ni63.8Mn11.1Ga25.1 microwire crystalline structure and properties. Intermetallics 2013, 43, 60–64. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeño, A.F.; Zhukov, A.; de Arellano Lopez, A.R.; López-Pombero, S.; Blanco, J.M.; Larin, V.; Gonzalez, J. Correlation between magnetic and mechanical properties of devitrified glass-coated Fe71.8Cu1Nb3.1Si15B9.1 microwires. J. Magn. Magn. Mater. 2002, 249, 79–84. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Zhukova, V.; Chernenko, V.A. Magnetic and Structural Properties of Glass-Coated Heusler-Type Microwires Exhibiting Martensitic Transformation. Sci. Rep. 2018, 8, 621. [Google Scholar] [CrossRef] [Green Version]

- Zhukova, V.; Corte-Leon, P.; Blanco, J.M.; Ipatov, M.; Gonzalez-Legarreta, L.; Gonzalez, A.; Zhukov, A. Development of Magnetically Soft Amorphous Microwires for Technological Applications. Chemosensors 2022, 10, 26. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Hernando, B.; Gonzalez-Legarreta, L.; Suñol, J.J.; Zhukova, V. Correlation of Crystalline Structure with Magnetic and Transport Properties of Glass-Coated Microwires. Crystals 2017, 7, 41. [Google Scholar] [CrossRef]

- Guo, X.B.; Zuo, Y.L.; Cui, B.S.; Li, D.; Yun, J.J.; Wu, K.; Wang, T.; Xi, L. Post Annealing Induced Magnetic Anisotropy in CoFeSi Thin Films on MgO (001). J. Phys. D Appl. Phys. 2017, 50, 085006. [Google Scholar] [CrossRef]

- Velázquez, J.; Vázquez, M.; Hernando, A.; Savage, H.T.; Wun-Fogle, M. Magnetoelastic anisotropy in amorphous wires due to quenching. J. Appl. Phys. 1991, 70, 6525–6527. [Google Scholar] [CrossRef]

- Gunnarsson, K.; Svedlindh, P.; Andersson, J.O.; Nordblad, P.; Lundgren, L.; Aruga Katori, H.; Ito, A. Magnetic Behavior of a Reentrant Ising Spin Glass. Phys. Rev. B 1992, 46, 8227–8231. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Li, W.; Li, J.; Chen, H.; Liu, D.; Chen, X.; Yang, C. The Microstructure and Magnetic Properties of Co2MnSi Thin Films Deposited on Si Substrate. J. Alloy. Compd. 2017, 723, 188–191. [Google Scholar] [CrossRef]

- Zhukova, V.; Chernenko, V.; Ipatov, M.; Zhukov, A. Magnetic Properties of Heusler-Type NiMnGa Glass-Coated Microwires. IEEE Trans. Magn. 2015, 51, 501604. [Google Scholar] [CrossRef]

- Chiriac, H.; Vári, T.A.; Pop, G. Internal Stress Distribution in Glass-Covered Amorphous Magnetic Wires. Phys. Rev. B 1995, 52, 10104. [Google Scholar] [CrossRef]

- Torcunov, A.V.; Baranov, S.A.; Larin, V.S. The Internal Stresses Dependence of the Magnetic Properties of Cast Amorphous Microwires Covered with Glass Insulation. J. Magn. Magn. Mater. 1999, 196–197, 835–836. [Google Scholar] [CrossRef]

- Chiriac, H.; Lupu, N.; Stoian, G.; Ababei, G.; Corodeanu, S.; Óvári, T.A. Ultrathin Nanocrystalline Magnetic Wires. Crystals 2017, 7, 48. [Google Scholar] [CrossRef]

| Peak Position 2θ (°) | FWHM Bsize (°) | Dg (nm) |

|---|---|---|

| 45.6 | 0.17 | 53.9 |

| 21.4 | 0.21 | 40.3 |

| 23.7 | 0.20 | 44.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salaheldeen, M.; Talaat, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires. Processes 2022, 10, 2248. https://doi.org/10.3390/pr10112248

Salaheldeen M, Talaat A, Ipatov M, Zhukova V, Zhukov A. Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires. Processes. 2022; 10(11):2248. https://doi.org/10.3390/pr10112248

Chicago/Turabian StyleSalaheldeen, Mohamed, Ahmed Talaat, Mihail Ipatov, Valentina Zhukova, and Arcady Zhukov. 2022. "Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires" Processes 10, no. 11: 2248. https://doi.org/10.3390/pr10112248

APA StyleSalaheldeen, M., Talaat, A., Ipatov, M., Zhukova, V., & Zhukov, A. (2022). Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires. Processes, 10(11), 2248. https://doi.org/10.3390/pr10112248