Research on Fault Diagnosis of Steel Surface Based on Improved YOLOV5

Abstract

:1. Introduction

2. Methodology

2.1. YOLOV5

2.2. Coordinate Attention Mechanism

2.3. ShuffleNetV2 Architecture

2.4. Cosine Annealing with Warm Restarts Algorithm

3. Improved YOLOV5

3.1. CA-C3 Module

3.2. Improved YOLOV5

3.2.1. Improvement Based on the CA-C3 Module, New Connection and ShuffleNetV2

3.2.2. Optimization Based on Cosine Annealing with Warm Restarts Algorithm

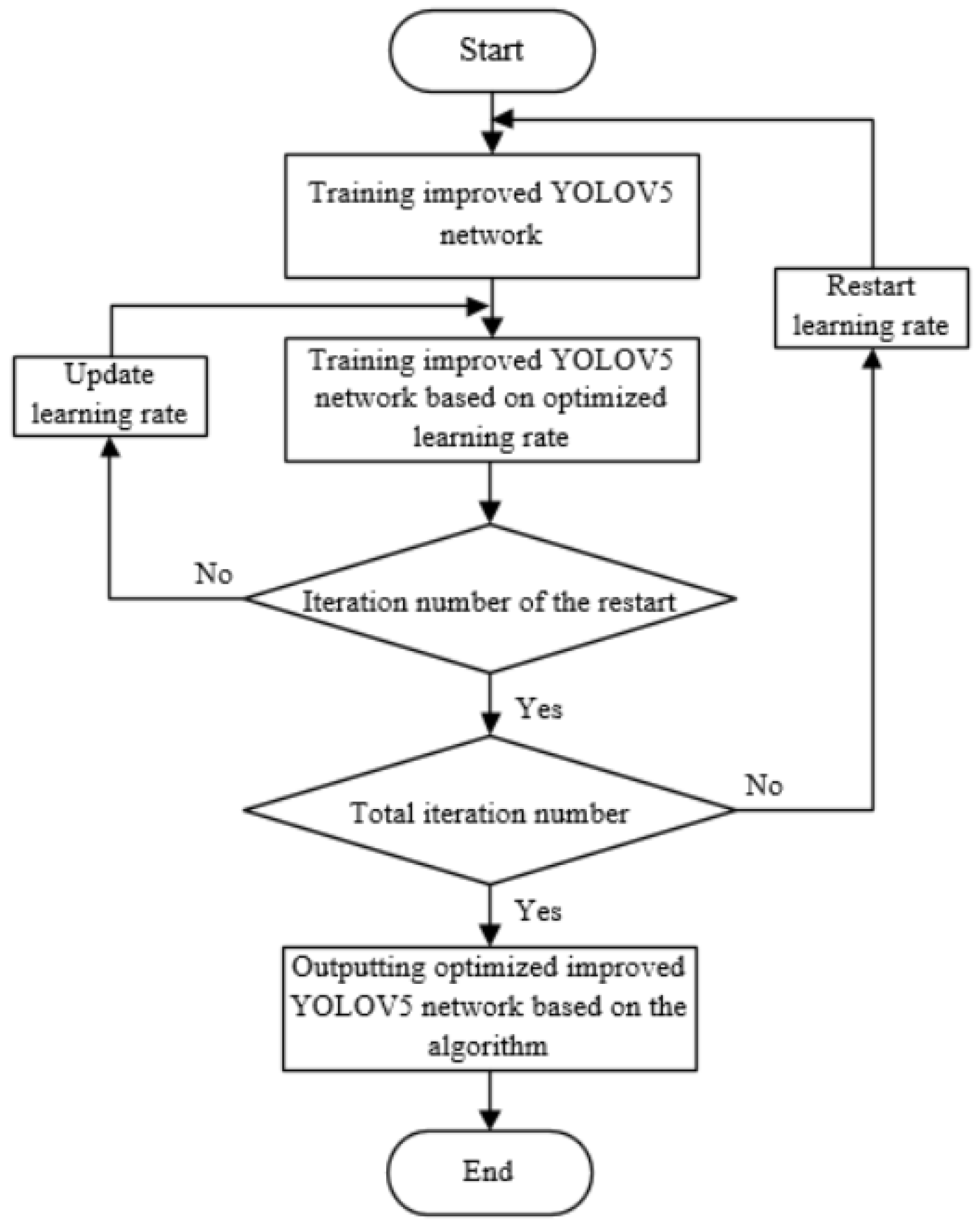

4. The Flowchart of Improved YOLOV5

5. The Dataset of NEU-DET

6. Case Study

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Y.; Li, G.; Tang, S.; Wang, R.; Su, H.; Wang, C. Acoustic signal-based fault detection of hydraulic piston pump using a particle swarm optimization enhancement CNN. Appl. Acoust. 2022, 192, 108718. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, Y.; Yuan, S. Intelligent Fault Identification of Hydraulic Pump Using Deep Adaptive Normalized CNN and Synchrosqueezed Wavelet Transform. Reliab. Eng. Syst. Saf. 2022, 224, 108560. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, Y.; Yuan, S. A Novel Adaptive Convolutional Neural Network for Fault Diagnosis of Hydraulic Piston Pump with Acoustic Images. Adv. Eng. Inform. 2022, 52, 101554. [Google Scholar] [CrossRef]

- Iravani, M.; Toghraie, D. Design a high-pressure test system to investigate the performance characteristics of ball valves in a compressible choked flow. Measurement 2020, 151, 107200. [Google Scholar] [CrossRef]

- Darvishyadegari, M.; Hassanzadeh, R. Heat and fluid flow around two co-rotating cylinders in tandem arrangement. Int. J. Therm. Sci. 2019, 135, 206–220. [Google Scholar] [CrossRef]

- Cao, L.; Tu, C.; Hu, P.; Liu, S. Influence of solid particle erosion (SPE) on safety and economy of steam turbines. Appl. Therm. Eng. 2019, 150, 552–563. [Google Scholar] [CrossRef]

- Li, Z.; Tian, X.; Liu, X.; Liu, Y.; Shi, X. A two-stage industrial defect detection framework based on improved-YOLOV5 and optimized-inception-ResnetV2 models. Appl. Sci. 2022, 12, 834. [Google Scholar] [CrossRef]

- Song, G.; Song, K.; Yan, Y. EDRNet: Encoder–decoder residual network for salient object detection of strip steel surface defects. IEEE Trans. Instrum. Meas. 2020, 69, 9709–9719. [Google Scholar] [CrossRef]

- Tian, R.; Jia, M. DCC-CenterNet: A rapid detection method for steel surface defects. Measurement 2022, 187, 110211. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, J.; Yang, C.; Zhou, Y. Cas-VSwin transformer: A variant swin transformer for surface-defect detection. Comput. Ind. 2022, 140, 103689. [Google Scholar] [CrossRef]

- Yin, J.; Guo, L.; Jiang, W.; Hong, S.; Yang, J. ShuffleNet-inspired lightweight neural network design for automatic modulation classification methods in ubiquitous IoT cyber–physical systems. Comput. Commun. 2021, 176, 249–257. [Google Scholar] [CrossRef]

- Ran, H.; Wen, S.; Wang, S.; Cao, Y.; Zhou, P.; Huang, T. Memristor-based edge computing of ShuffleNetV2 for image classification. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 2021, 40, 1701–1710. [Google Scholar] [CrossRef]

- Kulkarni, U.; Meena, S.M.; Gurlahosur, S.V.; Bhogar, G. Quantization friendly MobileNet (Qf-MobileNet) architecture for vision based applications on embedded platforms. Neural Netw. 2021, 136, 28–39. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, L. A new lightweight network based on MobileNetV3. KSII Trans. Internet Inf. Syst. (TIIS) 2022, 16, 1–15. [Google Scholar]

- Panigrahi, S.; Raju, U.S.N. MS-ML-SNYOLOV3: A robust lightweight modification of SqueezeNet based YOLOV3 for pedestrian detection. Optik 2022, 260, 169061. [Google Scholar] [CrossRef]

- Guan, S.; Chang, J.; Shi, H.; Xiao, X.; Li, Z.; Wang, X.; Wang, X. Strip steel defect classification using the improved GAN and EfficientNet. Appl. Artif. Intell. 2021, 35, 1887–1904. [Google Scholar] [CrossRef]

- Nagy, A.M.; Czúni, L. Classification and fast few-shot learning of steel surface defects with randomized network. Appl. Sci. 2022, 12, 3967. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, J.; Su, Z.; Zhou, Z.; Liu, L. Binary neural network for automated visual surface defect detection. Sensors 2021, 21, 6868. [Google Scholar] [CrossRef]

- Lin, Z.; Ye, H.; Zhan, B.; Huang, X. An efficient network for surface defect detection. Appl. Sci. 2020, 10, 6085. [Google Scholar] [CrossRef]

- Fu, G.; Sun, P.; Zhu, W.; Yang, J.; Cao, Y.; Yang, M.Y.; Cao, Y. A deep-learning-based approach for fast and robust steel surface defects classification. Opt. Laser Eng. 2019, 121, 397–405. [Google Scholar] [CrossRef]

- Li, Y.; Huang, H.; Xie, Q.; Yao, L.; Chen, Q. Research on a surface defect detection algorithm based on MobileNet-SSD. Appl. Sci. 2018, 8, 1678. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhong, H.; Karpowicz, N.; Chen, Y.; Zhang, X.C. Terahertz spectroscopy and imaging for defense and security applications. Proc. IEEE 2007, 95, 1514–1527. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, J.; Li, Y.; Gao, H.; Wang, X. BANet: A balanced atrous net improved from SSD for autonomous driving in smart transportation. IEEE Sens. J. 2020, 21, 25018–25026. [Google Scholar] [CrossRef]

- Yan, J.; Wang, Z. YOLOV3 + VGG16-based automatic operations monitoring and analysis in a manufacturing workshop under Industry 4.0. J. Manuf. Syst. 2022, 63, 134–142. [Google Scholar] [CrossRef]

- Xing, J.; Jia, M. A convolutional neural network-based method for workpiece surface defect detection. Measurement 2021, 176, 109185. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Wan, Z. Surface defect detection of steel strips based on improved YOLOv4. Comput. Electr. Eng. 2022, 102, 108208. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, S.; Zeng, Z.; Yu, D. Automatic visual defects inspection of wind turbine blades via YOLO-based small object detection approach. J. Electron. Imaging 2019, 28, 043023. [Google Scholar] [CrossRef]

- Wu, W.; Liu, H.; Li, L.; Long, Y.; Wang, X.; Wang, Z.; Chang, Y. Application of local fully convolutional neural network combined with YOLOV5 algorithm in small target detection of remote sensing image. PLoS ONE 2021, 16, e259283. [Google Scholar] [CrossRef]

- Zhang, R.; Wen, C. SOD-YOLO: A small target defect detection algorithm for wind turbine blades based on improved YOLOV5. Adv. Theory Simul. 2022, 5, 2100631. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, C.; Yang, G.; Huang, Z.; Li, G. MSFT-YOLO: Improved YOLOV5 based on transformer for detecting defects of steel surface. Sensors 2022, 22, 3467. [Google Scholar] [CrossRef]

- Kim, M.; Jeong, J.; Kim, S. ECAP-YOLO: Efficient channel attention pyramid YOLO for small object detection in aerial image. Remote Sens. 2021, 13, 4851. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Polosukhin, I. Attention is all you need. Adv. Neural Inf. Process. Syst. (NIPS) 2017, 30, 5998–6008. [Google Scholar]

- Dong, X.; Yan, S.; Duan, C. A lightweight vehicles detection network model based on YOLOV5. Eng. Appl. Artif. Intell. 2022, 113, 104914. [Google Scholar] [CrossRef]

- Zhang, Z.D.; Tan, M.L.; Lan, Z.C.; Liu, H.C.; Pei, L.; Yu, W.X. CDNet: A real-time and robust crosswalk detection network on Jetson nano based on YOLOv5. Neural Comput. Appl. 2022, 34, 10719–10730. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiao, Y.; Guo, Y.; He, D. Deep learning based automatic grape downy mildew detection. Front. Plant Sci. 2022, 13, 872107. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, X.; Zhou, Y.; Sun, Q.; Ge, Z.; Liu, D. Real-time detection of particleboard surface defects based on improved YOLOV5 target detection. Sci. Rep. 2021, 11, 21777. [Google Scholar] [CrossRef]

- Ying, Z.; Lin, Z.; Wu, Z.; Liang, K.; Hu, X. A modified-YOLOV5s model for detection of wire braided hose defects. Measurement 2022, 190, 110683. [Google Scholar] [CrossRef]

- Zaidi, S.S.A.; Ansari, M.S.; Aslam, A.; Kanwal, N.; Asghar, M.; Lee, B. A survey of modern deep learning based object detection models. Digit. Signal Process. 2022, 126, 103514. [Google Scholar] [CrossRef]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [Green Version]

- Diwan, T.; Anirudh, G.; Tembhurne, J.V. Object detection using YOLO: Challenges, architectural successors, datasets and applications. Multimed. Tools Appl. 2022, 1–33. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You only look once: Unified, real-time object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 779–788. [Google Scholar]

- Hou, Q.; Zhou, D.; Feng, J. Coordinate attention for Efficient mobile network design. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Nashville, TN, USA, 20–25 June 2021; pp. 13713–13722. [Google Scholar]

- Ma, N.; Zhang, X.; Zheng, H.T.; Sun, J. ShuffleNetV2: Practical guidelines for Efficient CNN architecture design. In Proceedings of the European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; pp. 116–131. [Google Scholar]

- Song, K.; Yan, Y. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl. Surf. Sci. 2013, 285, 858–864. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, F.; Huang, H.; Li, D.; Cheng, W. A new steel defect detection algorithm based on deep learning. Comput. Intell. Neurosci. 2021, 2021, 5592878. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Kang, X.; Ni, H.; Ren, F. Surface defect detection of steel strips based on classification priority YOLOV3-dense network. Ironmak. Steelmak. 2021, 48, 547–558. [Google Scholar] [CrossRef]

| Layer | Size | Stride | Channel | Output Feature Size | Note | |

|---|---|---|---|---|---|---|

| Input layer | \ | \ | \ | 224 × 224 × 3 | ||

| 0 | Convolution layer | 1 × 1 | 1 | 32 | 224 × 224 × 32 | |

| 1 | ShuffleNetV2 | \ | \ | 64 | 112 × 112 × 64 | |

| 2 | CA-C3 × 3 | \ | \ | 64 | 112 × 112 × 64 | |

| 3 | ShuffleNetV2 | \ | \ | 128 | 56 × 56 × 128 | |

| 4 | CA-C3 × 6 | \ | \ | 128 | 56 × 56 × 128 | |

| 5 | ShuffleNetV2 | \ | \ | 256 | 28 × 28 × 256 | |

| 6 | CA-C3 × 9 | \ | \ | 256 | 28 × 28 × 256 | |

| 7 | ShuffleNetV2 | \ | \ | 512 | 14 × 14 × 512 | |

| 8 | CA-C3 × 3 | \ | \ | 512 | 14 × 14 × 512 | |

| 9 | SPPF | \ | \ | \ | 14 × 14 × 512 | |

| 10 | Convolution layer | 1 × 1 | 1 | 256 | 14 × 14 × 256 | |

| 11 | Upsample | \ | \ | \ | 28 × 28 × 256 | |

| 12 | Concat | \ | \ | \ | \ | Layer 6 |

| 13 | CA-C3 | \ | \ | 256 | 28 × 28 × 256 | |

| 14 | Convolution layer | 1 × 1 | 1 | 128 | 28 × 28 × 128 | |

| 15 | Upsample | \ | \ | \ | 56 × 56 × 128 | |

| 16 | Concat | \ | \ | \ | \ | Layer 4 |

| 17 | CA-C3 | \ | \ | 128 | 56 × 56 × 128 | Output1 |

| 18 | Convolution layer | 3 × 3 | 2 | 128 | 28 × 28 × 128 | |

| 19 | Concat | \ | \ | \ | \ | Layer 14, 6 |

| 20 | CA-C3 | \ | \ | 256 | 28 × 28 × 256 | Output2 |

| 21 | Convolution layer | 3 × 3 | 2 | 256 | 14 × 14 × 256 | |

| 22 | Concat | \ | \ | \ | \ | Layer10, 8 |

| 23 | CA-C3 | \ | \ | 512 | 14 × 14 × 512 | Output3 |

| Parameters | Value | Note |

|---|---|---|

| Size of input images | 224 224 | NEU-DET |

| Batch size | 8 | |

| Weight | yolov5s.pt | |

| Learning rate | 10−3 | |

| The iterations number | 300 |

| Methods | Cosine Annealing with Warm Restarts Algorithm | CA-C3 Module | Connections of Line I and Line II | ShuffleNetV2 | Precision | Recall | mAP |

|---|---|---|---|---|---|---|---|

| YOLOV5 | × | × | × | × | 0.626 | 0.818 | 0.758 |

| Case 1 | √ | × | × | × | 0.723 | 0.796 | 0.791 |

| Case 2 | √ | √ | × | × | 0.730 | 0.799 | 0.806 |

| Case 3 | √ | √ | √ | × | 0.787 | 0.819 | 0.840 |

| Improved YOLOV5 | √ | √ | √ | √ | 0.822 | 0.817 | 0.859 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Xiao, Y.; Zheng, A.; Zheng, Z.; Liu, X.; Zhang, Z.; Li, C. Research on Fault Diagnosis of Steel Surface Based on Improved YOLOV5. Processes 2022, 10, 2274. https://doi.org/10.3390/pr10112274

Liu W, Xiao Y, Zheng A, Zheng Z, Liu X, Zhang Z, Li C. Research on Fault Diagnosis of Steel Surface Based on Improved YOLOV5. Processes. 2022; 10(11):2274. https://doi.org/10.3390/pr10112274

Chicago/Turabian StyleLiu, Weimin, Yao Xiao, Aiyun Zheng, Zhi Zheng, Xiaojie Liu, Zhen Zhang, and Chen Li. 2022. "Research on Fault Diagnosis of Steel Surface Based on Improved YOLOV5" Processes 10, no. 11: 2274. https://doi.org/10.3390/pr10112274