Pilot Scale Roller Milling of Chickpeas into a De-Hulled Coarse Meal and Fine Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pilot Scale Milling

2.2.1. Cleaning House

2.2.2. Storage and Tempering

2.2.3. Roller Milling

2.2.4. Packaging and Sealing

2.3. Proximate Analysis

2.4. Particle Size

2.5. Flow Properties

2.6. Statistical Analyses

3. Results and Discussion

3.1. Milling Yields

3.2. Proximate Analysis

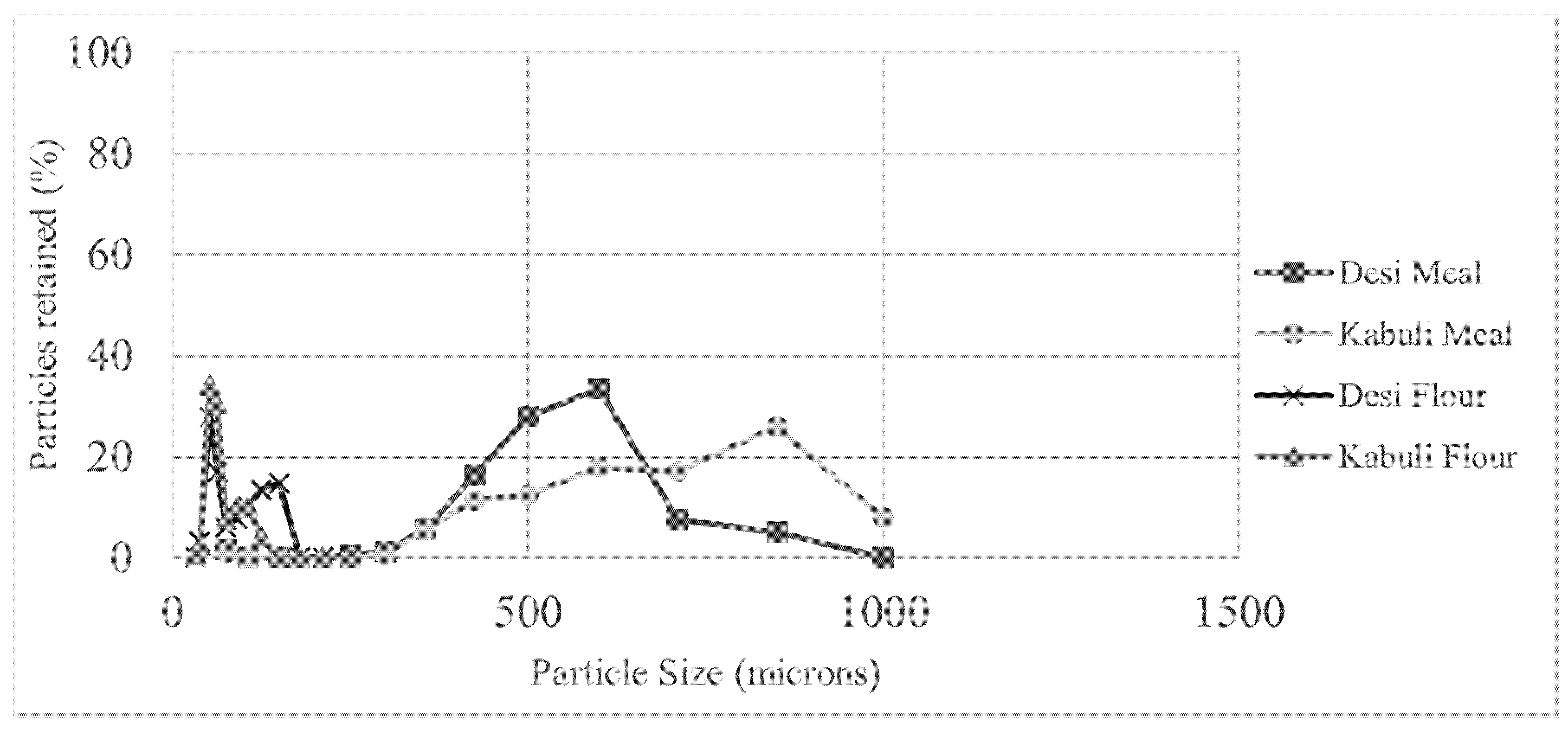

3.3. Particle Size

3.4. Flow Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gil, J.; Nadal, S.; Luna, D.; Moreno, M.T.; Haro, A.D. Variability of Some Physicochemical Characters in Desi and Kabuli Chickpea Types. J. Sci. Food Agric. 1996, 71, 179–184. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. Value of Water Research Report. Series No. 48. In Value of Water; UNESCO-IHE Institute for Water Education: Delft, The Netherlands, 2010. [Google Scholar]

- Van der Weele, C.; Feindt, P.; van der Goot, A.J.; van Mierlo, B.; van Boekel, M. Meat alternatives: An integrative comparison. Trends Food Sci. Technol. 2019, 88, 505–512. [Google Scholar] [CrossRef]

- Heiras-Palazuelos, M.J.; Ochoa-Lugo, M.I.; Gutiérrez-Dorado, R.; López-Valenzuela, J.A.; Mora-Rochín, S.; Milán-Carrillo, J.; Garzón-Tiznado, J.A.; Reyes-Moreno, C. Technological properties, antioxidant activity and total phenolic and flavonoid content of pigmented chickpea (Cicer arietinum L.) cultivars. Int. J. Food Sci. Nutr. 2013, 64, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Singh, U. Antinutritional factors of chickpea and pigeonpea and their removal by processing. Plant Foods Hum. Nutr. 1988, 38, 251–261. [Google Scholar] [CrossRef] [PubMed]

- Adamidou, S.; Nengas, I.; Grigorakis, K.; Nikolopoulou, D.; Jauncey, K. Chemical Composition and Antinutritional Factors of Field Peas (Pisum sativum), Chickpeas (Cicer arietinum), and Faba Beans (Vicia faba) as Affected by Extrusion Preconditioning and Drying Temperatures. Cereal Chem. J. 2011, 88, 80–86. [Google Scholar] [CrossRef]

- Ravi, R.; Harte, J.B. Milling and physicochemical properties of chickpea (Cicer arietinum L.) varieties. J. Sci. Food Agric. 2009, 89, 258–266. [Google Scholar] [CrossRef]

- Wood, J.A.; Knights, E.J.; Harden, S. Milling performance in desi-type chickpea (Cicer arietinum L.): Effects of genotype, environment and seed size. J. Sci. Food Agric. 2008, 88, 108–115. [Google Scholar] [CrossRef]

- Pulivarthi, M.K.; Nkurikiye, E.; Watt, J.; Li, Y.; Siliveru, K. Comprehensive understanding of roller milling on the physico chemical properties of red lentil and yellow pea flours. Processes 2021, 9, 1836. [Google Scholar] [CrossRef]

- Akinoso, R.; Lawal, I.A.; Aremu, A.K. Energy requirements of size reduction of some selected cereals using attrition mill. Int. Food Res. J. 2013, 20, 1205–1209. [Google Scholar]

- Sanchez, G.C.; Monteagudo Yanes, J.P.; Perez, M.M.; Cabrera Sanchez, J.L.; Padron, A.P.; Haeseldonckx, D. Efficiency in electromechanical drive motors and energy performance indicators for implementing a management system in balanced animal feed manufacturing. Energy 2020, 194, 116818. [Google Scholar] [CrossRef]

- Eras, J.J.C.; Gutierrez, A.S.; Ulloa, M.J.C. The temperature gradient of cereals as an optimization parameter of the milling process in hammermills. J. Clean. Prod. 2021, 297, 126685. [Google Scholar] [CrossRef]

- Sannik, U.; Pappel, T.K. Complete milling technologies of different valuable materials. In Proceedings of the 4th International DAAAM Conference “Industrial Engineering–Innovation as Competitive Edge for SME”, Tallinn, Estonia, 29–30 April 2004; pp. 146–148. [Google Scholar]

- Koch, K.B. Feed Mill Efficiency. Engormix. 2012. Available online: https://en.engormix.com/feed-machinery/articles/feed-mill-efficiency-t35290.htm (accessed on 11 September 2022).

- Smejtkova, A.; Vaculik, P. Comparison of power consumption of a two-roll mill and a disc mill. Agron. Res. 2018, 16 (Suppl. S2), 1486–1492. [Google Scholar]

- Ziggers, B.D. Hammering or rolling the grain. Feed. Technol. 2001, 5, 9–17. [Google Scholar]

- Official Methods of Analysis, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2006.

- S3194.4; Method of Determining and Expressing Fineness of Feed Materials by Sieving. ASABE Standards: St. Joseph, MI, USA, 2008.

- Wood, J.A.; Knights, E.J.; Chocty, M. Morphology of chickpea seeds (Cicer arietinum L.): Comparison of desi and kabuli types. Int. J. Plant Sci. 2011, 172, 632–643. [Google Scholar] [CrossRef]

- Soni, B.; Sarita, S. Comparative evaluation of milling bi-products: Finger millet seed coat (FMSC), chick pea husk (CPH) and wheat bran (WB) for their nutritional, nutraceutical potential. Int. J. Basic Appl. Agric. Res. 2014, 12, 104–110. [Google Scholar]

- Xu, Y.; Thomas, M.; Bhardwaj, H.L. Chemical composition, functional properties and microstructural characteristics of three kabuli chickpea (Cicer arietinum L.) as affected by different cooking methods. Int. J. Food Sci. Technol. 2014, 49, 1215–1223. [Google Scholar] [CrossRef]

- Hoseney, R.C. Principles of cereal science and technology. A general reference on cereal foods. In Principles of Cereal Science and Technology. A General Reference on Cereal Foods; American Association of Cereal Chemists, Inc.: St. Paul, MN, USA, 1986. [Google Scholar]

- Martin, R.C. Physico-Chemical Properties of Chickpea Flour Obtained Using Roller Milling and Extrusion Pre-Cooking. Master’s Thesis, Kansas State University, Manhattan, KS, USA, 2000. [Google Scholar]

- Riley, R.E.; Hausner, H.H. Effect of particle size distribution on the friction in a powder mass. Int. J. Powder Met. 1970, 6, 17–22. [Google Scholar]

| Parameter | Number |

|---|---|

| Grain type | 2 |

| Number of Break rolls | 4 |

| Number of Grinding rolls | 1 |

| Number of Middling rolls | 2 |

| Number of Purifiers | 4 |

| Flow Characteristic | HR | CI (%) | Angle of Repose |

|---|---|---|---|

| Excellent | 1.00–1.11 | <10 | 25–30 |

| Good | 1.12–1.18 | 11–15 | 31–35 |

| Fair | 1.19–1.25 | 16–20 | 36–40 |

| Passable | 1.26–1.34 | 21–25 | 41–45 |

| Poor | 1.35–1.45 | 26–31 | 46–55 |

| Very Poor | 1.46–1.59 | 32–37 | 56–65 |

| Very, Very Poor | >1.6 | >38 | >66 |

| Starting Material (kg) | Meal (%) | Flour (%) | Overs of 4th BK Hull (%) | Overs of 2M Shorts (%) | Process Loss (%) | |

|---|---|---|---|---|---|---|

| Kabuli | 3641.44 | 63.8 | 23.9 | 6.0 | 1.9 | 4.37 |

| Desi | 2147.31 | 54.07 | 16.03 | 17.37 | 0.7 | 11.8 |

| % Dry Basis | Sample | Crude Protein | Crude Fiber | Fat | Ash | Total Starch |

|---|---|---|---|---|---|---|

| Raw Materials | Whole Kabuli Seeds | 23.99 cd | 3.84 b | 5.54 c | 2.53 f | 39.90 d |

| Split Desi Seeds | 24.36 cd | 1.44 f | 6.47 b | 2.45 fg | 42.25 c | |

| Process 1: Whole Kabuli Seeds | Meal | 24.63 b | 2.72 c | 4.71 d | 2.74 d | 33.25 g |

| Flour | 22.41 e | 1.44 g | 6.45 b | 2.41 gh | 49.70 b | |

| Hull | 14.65 f | 20.90 a | 3.42 f | 4.52 a | 14.9 i | |

| Shorts | 29.09 a | 2.66 c | 6.77 b | 3.29 b | 31.75 h | |

| Process 2: Split Desi Seeds | Meal | 24.64 c | 2.09 e | 4.53 de | 2.59 fg | 37.15 f |

| Flour | 22.86 e | 0.94 g | 5.91 c | 2.34 h | 51.95 a | |

| Overs of 4th Break | 23.87 c | 2.43 d | 4.27 e | 2.64 e | 38.95 e | |

| Shorts | 27.50 b | 2.01 e | 7.40 a | 2.89 c | 37.55 f |

| Sample | Bulk Density (g/mL) | Tap Density (g/mL) | Hausner Ratio | Compressibility Index (%) | Angle of Repose (Degrees) | |

|---|---|---|---|---|---|---|

| Process 1 | Kabuli Meal | 0.719 b | 0.689 b | 0.958 c | −4.337 c | 28.9 b |

| Kabuli Flour | 0.508 c | 0.556 c | 1.095 b | 8.703 b | 42.1 a | |

| Process 2 | Desi Meal | 0.775 a | 0.719 a | 0.927 c | −7.826 d | 29.0 b |

| Desi Flour | 0.448 d | 0.520 d | 1.161 a | 13.896 a | 45.2 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martin, R.; Siliveru, K.; Watt, J.; Blodgett, P.; Alavi, S. Pilot Scale Roller Milling of Chickpeas into a De-Hulled Coarse Meal and Fine Flour. Processes 2022, 10, 2328. https://doi.org/10.3390/pr10112328

Martin R, Siliveru K, Watt J, Blodgett P, Alavi S. Pilot Scale Roller Milling of Chickpeas into a De-Hulled Coarse Meal and Fine Flour. Processes. 2022; 10(11):2328. https://doi.org/10.3390/pr10112328

Chicago/Turabian StyleMartin, Randall, Kaliramesh Siliveru, Jason Watt, Paul Blodgett, and Sajid Alavi. 2022. "Pilot Scale Roller Milling of Chickpeas into a De-Hulled Coarse Meal and Fine Flour" Processes 10, no. 11: 2328. https://doi.org/10.3390/pr10112328

APA StyleMartin, R., Siliveru, K., Watt, J., Blodgett, P., & Alavi, S. (2022). Pilot Scale Roller Milling of Chickpeas into a De-Hulled Coarse Meal and Fine Flour. Processes, 10(11), 2328. https://doi.org/10.3390/pr10112328