Abstract

The concern of sustainable supplier selection has been raised recently in organizations’ decision making to enhance their competitiveness. Many tools have been developed to support supplier evaluation, yet the factors of Industry 4.0 (I4.0) have been ignored despite their impact on sustainable performance. Hence, this paper aims to include the technology of I4.0 as the criteria to evaluate the competence of suppliers in sustainability. Multiple-criteria decision making (MCDM) has been used to build decision-making systems; thus, this study employed two advanced methods of MCDM, the ordinal priority approach (OPA) and measurement of alternatives and ranking according to compromise solution (MARCOS) in a fuzzy environment. To test the feasibility of the proposal, five manufacturers of Vietnam’s leather and footwear industry were hypothetically assigned. Firstly, the evaluation criteria were weighted by OPA. Then, the ranking of alternatives was determined by fuzzy MARCOS. The results show that “green image”, “green product innovation”, “cloud computing”, “service level”, and “blockchain” are the topmost significant criteria in evaluating sustainable practices in the supply chain from the I4.0 perspective. Furthermore, sensitivity and comparison analyses were carried out to verify the robustness of the methodology. The outcomes of this paper contribute a new model of decision making with respect to the involvement of sustainability and I4.0.

1. Introduction

Sustainable supply chain management (SSCM) is the term referring to supply chain management that is mostly driven by economic, environmental, and social interests, or the three pillars of sustainability [1]. The logistics industry is experiencing a number of difficulties due to the COVID-19 pandemic, leading to large-scale supply chain disruptions. Experts stated that the industry has passed the worst period, and businesses are planning to enter a new era with new technologies, methods, and standards to transform. As the complexity of modern transportation and logistics increases, it is important to understand where the short- and long-term focus is and what to invest in. Moreover, the 4.0 revolution and the popularity of the IoT system also require logistics enterprises to capture and make optimal use of the huge data source coming from all links in the supply chain.

To achieve SSCM, organizations have been pushed to be more agile, efficient, and smart. In this direction, Industry 4.0 (I4.0) has been widely adopted to efficiently manage the increasing complexity of systems. The benefits of I4.0 technologies are also mentioned in [2] as the enabler of sustainable manufacturing, and thus SSCM, by reducing industrial wastes and contaminants. Many advanced technologies have emerged to meet the demands of the market, as summarized in (Table 1). The impacts of those applications on the supply chain were also concluded in [3], including more accurate demand forecasts, the minimization of manufacturing wastes, more sustainable and robust processes, and effective inventory management and collaboration, reducing errors in material flow information and optimizing logistics systems.

Table 1.

The summary of technologies.

Technology plays a crucial part in firms’ strategies to reach their goal of competitiveness and sustainability. To obtain sustainable development, clean technology, which is any kind of technical method that can serve the purpose of saving the economy and environment with respect to resources, has been the optimal option for organizations to acquire [4]. However, the adoption of technological changes in businesses has remained insignificant. Khatri et al. [4] claimed that the problem is not technology availability or innovation but rather the risks to business stability. To implement new technology, technological, economic, and social parameters are considered with the organization’s resource limitations. Adopting changes makes firms exposed to many strategic decisions, and therefore, they are applied at a low rate. As a matter of fact, technology selection is one of the important decisions made by a company. Technology selection, in fact, is a process that starts with the recognition of technological changes, followed by evaluation and ending with absorption [4]. As mentioned in [5], there are some considerations during technology selection, such as manufacturing constraints and customer requirements. Since sustainability has become a great concern, ecological aspects have appeared to be an additional, but not minor, criterion to evaluate the right technology. To support the assessment, some decision-making tools have been used, for instance, Life Cycle Assessment, Life Cycle Costing, or multi-criteria decision making (MCDM) [5]. In the paper by Rinaldi et al. [5], the authors indicated several issues in the technology selection process, which are the lack of either a qualitative solution or quantitative analysis in the model, the combination of qualitative and quantitative approaches but the exclusion of normalization, and unavailable practical computational procedures to estimate indicators. The technological supplier selection problem, on the other hand, pays less attention to the performance of outbound suppliers, thus leading to low sustainable levels of companies [6]. MCDM, as discussed in [6], has been employed to measure the competence of technological suppliers, yet the I4.0 point of view is not being taken into consideration in criteria, expert ideas, and other linguistic variables. Considering the current concerns, this research intended to present a decision-support system comprising the ordinal priority approach (OPA) and measurement of alternatives and ranking according to compromise solution (MARCOS) in a fuzzy environment, two advanced variants of MCDM. OPA was utilized to calculate the weights of criteria, expertise, and alternatives, while fuzzy MARCOS was implemented to rank the alternatives. To test the feasibility of the system, a case study of five sustainable supplier selections in Vietnam’s leather and footwear industry with a focus on the technology drive was performed. The results of this research are expected to contribute a new model to decision-making tools, especially for sustainable supplier selection. Furthermore, a reference point of technological criteria was created to evaluate supplier competence.

This paper is constructed as follows. The next part provides a review of the relevant literature regarding approaches to sustainable or green supplier selection. After that, the details of materials and methods are described in Section 3, including the research process, the applied methods, OPA, and fuzzy MARCOS. The results analysis is presented in Section 4 with a description of the case study, criteria weighting, and alternative ranking. Finally, the conclusions include the main findings, research limitations, and further suggestion for reproducible works.

2. Literature Review

Over the years, many scholars have dedicated their works to building decision-support systems for sustainable supplier selection or green supplier selection, which focus primarily on environmental performance [6]. As can be seen in Table 2, from 2017 to 2020, while there was a variety of approaches, most of them were hybrid methods to compensate for the weaknesses of each other [7]. For instance, Data Envelopment Analysis was combined with the Differential Solution algorithm (DEA-DE) [8], Decision-Making Trial and Evaluation Laboratory (DEMATEL) was utilized with pairwise comparison [9] or Taguchi loss functions [10], and various uses of fuzzy inference systems are reported in [11,12,13,14]. In contrast, a few researchers employed traditional methods, such as Critical Success Factors (CSFs) [15], qualitative research [16], a supply chain model [17], gray relational analysis [18], and a programming model and tractable approximation for optimization [19]. It is noticeable that MCDM was the popular choice as a decision-making tool since the rest of the solutions are a mix of MCDM variations and other types of measures (Table 2). For instance, Hoseini et al. proposed a hybrid method of the best–worst method (BWM) and an inference system model to select sustainable suppliers in the construction industry [20]. Alternatively, Kuo et al. integrated the Kano model into the Fuzzy Analytical Hierarchy Process (FAHP) and the Decision Matrix Method to evaluate sustainable suppliers in palm oil companies [21]. Among MCDM methods, TOPSIS (technique for order of preference by similarity to ideal solution) was mostly applied. In recent years, some advanced methods of MCDM have been proposed to overcome the disadvantages of MCDM. For example, Ecer et al. developed an approach using the Full Consistency Method (FUCOM) and the Mixed Aggregation by Comprehensive Normalization Technique (MACONT) with a fuzzy set under the concept of stratification for sustainable circular supplier selection [22]. As described in [22], the weights of criteria can be obtained more consistently but with fewer pairwise comparisons with FUCOM, while MACONT appears to be a robust ranking method due to its three-step normalization. Also addressing MCDM’s drawbacks, Ataei et al. [23] introduced OPA to address MADM’s (Multiple-Attribute Decision Making) problems by handling the weight calculation of experts, criteria, and alternatives, dealing with incomplete data and group decision making simultaneously. Therefore, the application of OPA can be useful for evaluating sustainable suppliers, as suggested by Mahmoudi et al. [7], in which the combination of gray system theory and OPA was observed in their megaprojects. Another algorithm, the well-known MARCOS, was developed by Stankovi’c et al. [24] to offer a robust sorting of alternatives in the fuzzy environment despite the large scale. Ecer et al. applied MARCOS simultaneously with Evaluation Based on Distance from Average Solution (EDAS) and Multi-Attributive Ideal Real Comparative Analysis (MAIRCA) for weighting and ranking cryptocurrency [25]. Campilho et al. [26] employed MARCOS to find the optimal design of a passive compliance mechanism in a robot manipulator as the result of the Non-dominated Sorting Whale Optimization Algorithm (NSWOA), an optimization algorithm. Since the technique works best in an uncertain environment where most cases of sustainable supplier selection have been solved [7,24], the implementation of MARCOS has been applied in the field. It was evidenced in the research of Stević et al. [27] when they measured the sustainable candidates in the healthcare supply chain with MARCOS. The authors also claimed that the robustness and stability of MARCOS outperformed TOPSIS in assessing the decision-making units [27].

Table 2.

The summary of relevant literature on sustainable supplier selection [6,7].

From the review, the OPA technique considerably decreases decision-making time and processing costs by avoiding the usage of pairwise comparison matrices, decision-making matrices, and normalization procedures that are typical in many existing traditional MCDM systems. However, OPA cannot account for uncertainties, which are a key issue for decision makers in this study, which is connected to determining the optimal choices. To address these shortcomings, fuzzy MARCOS for sustainable supplier selection with technology 4.0 evaluation is proposed. Fuzzy MARCOS revitalizes the MCDM domain by utilizing an algorithm to investigate the links between options and reference points.

From the literature reviewed, the following points are recognized: (1) the optimal decision-making system is a hybrid method that can satisfy both qualitative and quantitative aspects; (2) MCDM has proved to be a suitable tool to support decision makers in sustainable supplier selection; (3) MCDM has evolved with more innovative methods. Nonetheless, work that can cover all of the above points has not been conducted sufficiently. Hence, this paper aims to make the following contributions:

- An exploration of a hybrid method between OPA and fuzzy MARCOS with a case study of sustainable supplier selection in the Vietnamese garment industry. The weights of criteria focused on technology elements, three experts, and five alternatives were calculated by OPA before the candidates were ranked by fuzzy MARCOS for the final decision.

- A new decision-support system based on advanced MCDM is proposed not only for sustainable supplier selection but also for multi-purpose assessment.

- A set of criteria, including I4.0 and sustainable factors, was built for further evaluation of supplier performance.

3. Methodology

3.1. Ordinal Priority Approach (OPA)

The ordinal priority approach (OPA) is a unique breakthrough in multi-criteria decision making (MCDM). It offers numerous advantages over other MCDM approaches, such as not requiring a pairwise comparison, a normalization procedure, averaging methods for integrating expert assessments, and data completeness [7]. The OPA technique is based on the linear programming model, and the sets, indexes, and decision variables are as follows. The parameters of the OPA model should be supplied by experts.

The OPA calculations for criteria weighting consist of (1) identifying and ranking experts based on their years of experience or academic degrees, (2) determining and ranking the criteria based on experts’ opinions, and (3) solving the OPA model below to determine the weights of criteria [23].

| Sets | |

| I | Set of experts |

| J | Set of criteria |

| Indexes | |

| Decision variables | |

| Z | Objective function |

| Weight (importance) of th criteria by th expert at th rank | |

The linear mathematical model is presented as follows.

where Z is unrestricted in sign.

After solving Model (1), in order to calculate the weights of criteria, Equation (2) should be utilized.

The weights of criteria calculated by the OPA model will be used to rank alternatives with fuzzy MARCOS in the next phase.

3.2. Fuzzy MARCOS

The fuzzy triangular numbers (TFNs) can be described as , indicating the least likely , most promising , and largest conceivable values of TFNs. TFNs can be defined as in Equations (3) and (4) below [60].

where and denote the left and right sides, respectively, of a fuzzy number.

The following Equations (5)–(9) illustrate fundamental computations involving two positive TFNs [61], and

Addition:

Subtraction:

Multiplication:

Division:

Reciprocal:

Fuzzy measurement of alternatives and ranking according to compromise solution (fuzzy MARCOS) is suitable for solving MCDM problems with more criteria and alternatives under uncertainty. This method has three starting points, namely, reference points, the relationship between alternatives, and the utility degree of alternatives, which help decision makers improve the robustness of MCDM in a fuzzy environment [27]. The process of fuzzy MARCOS is as follows [24].

Step 1: Define an initial fuzzy decision-making matrix including a set of n criteria (i.e., criteria) and m alternatives.

Step 2: Define an extended initial fuzzy decision-making matrix by introducing the fuzzy ideal and anti-ideal solutions.

The fuzzy is an alternative with the best performance, while the fuzzy is the worst alternative. Depending on the type of criteria, and are defined by applying Equations (11) and (12):

where B and C are the sets of benefit and cost criteria, respectively.

Step 3: Determine the normalization of the extended initial fuzzy decision-making matrix, which is , using Equations (13) and (14):

where elements , , and , , represent the elements of matrix .

Step 4: Determine the weighted fuzzy matrix , which is calculated by multiplying matrix with the fuzzy weight coefficients of criterion as follows.

where represents the elements of the fuzzy weights of the criteria.

Step 5: Calculate fuzzy matrix using Equation (16) below.

where is the sum of the elements of weighted fuzzy matrix .

Step 6: Calculate the utility degree of alternative using Equations (17) and (18):

Step 7: Calculate fuzzy matrix using Equation (19):

Then, a new fuzzy number, , is determined by Equation (20):

Following that, it is necessary to defuzzify the number using the expression , obtaining the number .

Step 8: Determine the utility function in relation to the ideal and anti-ideal solutions using Equations (21) and (22):

Finally, calculate the defuzzification of , , , and values using the same defuzzification formula.

Step 9: Determine the utility function of alternatives using Equation (23):

Step 10: Rank the alternatives based on the final values of the utility degree function. The alternative with a higher utility function value is more preferred.

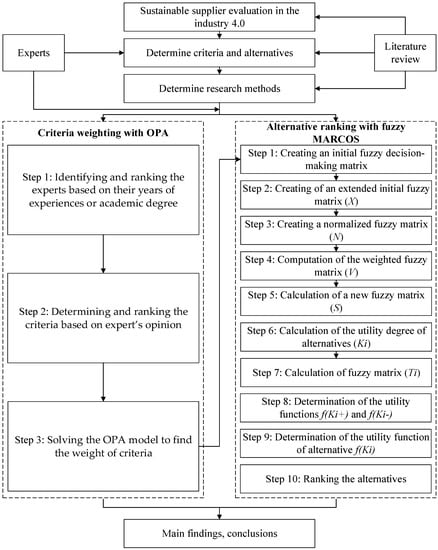

A new linguistic scale for evaluating alternatives was established in addition to the fuzzy MARCOS method, as indicated in Table 3. There are nine linguistic words specified, each with its own triangular fuzzy number. The process of this research is presented in Figure 1.

Table 3.

Linguistic scale for evaluating potential alternatives [24].

Figure 1.

Flowchart of the research.

4. Results Analysis

4.1. A Case Study in Vietnam’s Leather and Footwear Industry

Vietnam’s leather and footwear industry has a high position in the world market, ranking third in the world in terms of production and second in terms of exports [62]. In 2019, the leather and footwear industry exported USD 22 billion, accounting for 8.5% of the country’s merchandise export turnover, creating jobs for about 1.5 million workers. Footwear production is one of the industries most challenged by I4.0 due to its high use of labor. Connected automation in the Internet of Things, cloud computing, 3D printing, additive manufacturing technology, big data analysis, and artificial intelligence will gradually replace workers in production lines in factories and throughout the footwear supply chain. Leather and footwear businesses all realize the need to strongly innovate production technology through the application of digitization and automation technology of Industrial Revolution 4.0. This is the most effective solution to increase labor productivity, reduce production costs, and avoid being left behind in the context of increasing domestic labor costs and import prices of raw materials.

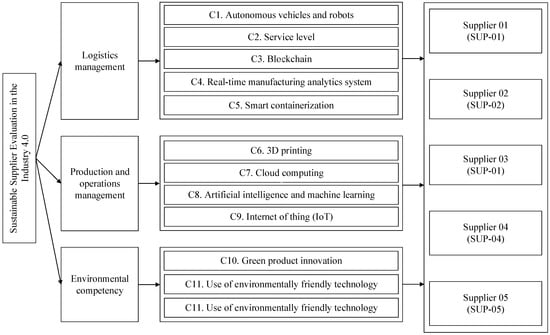

In this study, the proposed two-stage MCDM model was validated with a case study of company ABC located in Vietnam in choosing the best suppliers that provide leather and footwear products. It has been decided that five leather and footwear manufacturers in Vietnam, denoted by {SUP-01, SUP-02, SUP-03, SUP-04, SUP-05}, are potential partners. The profiles of three experts are shown in Table 4. Along with a search of the literature for determinants, the most important evaluation criteria were validated through relevant experts’ opinions from the I4.0 perspective. As a result, the selection of determinants in the evaluation process was limited to three criteria groups and 12 criteria based on the opinions of the decision makers and the literature review, as shown in Table 5. The hierarchical tree of the decision-making process is presented in Figure 2.

Table 4.

Details of the three experts.

Table 5.

Criteria explanation.

Figure 2.

The decision tree.

4.2. Criteria Weighting with OPA

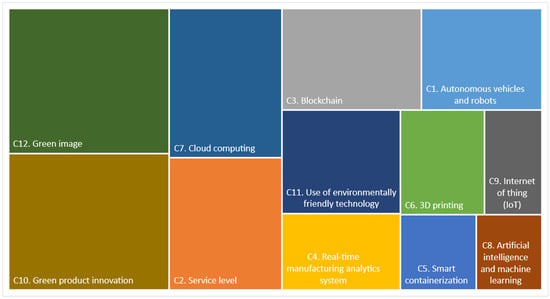

The OPA method is used to obtain the weights of criteria. There are three main criteria, namely, logistics management (five sub-criteria), production and operations management (four sub-criteria), and environmental competency (three sub-criteria). Experts are graded to enhance the accuracy of judgments based on their years of experience and academic degrees [7,23]. The weights of criteria from the OPA result are shown in Table 6, and their impact is visualized in Figure 3. From the result, in terms of criteria impact, green image (C12) is the most important criterion among the group of criteria (), while artificial intelligence and machine learning is the least important among the group of criteria (). In Figure 3, the results show that the top five impact criteria are “Green image”, “Green product innovation”, “Cloud computing”, “Service level”, and “Blockchain”; hence, those criteria need more attention in considering sustainable supplier selection and evaluation in the context of Industry 4.0 in Vietnam.

Table 6.

The weights of criteria from the OPA result.

Figure 3.

The impact weights of criteria from the OPA result.

4.3. Alternative Ranking with Fuzzy MARCOS

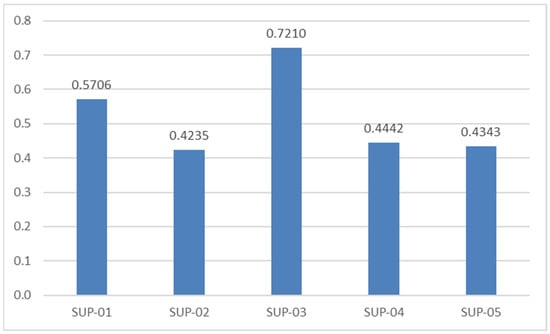

The proposed two-stage MCDM model (OPA and fuzzy MARCOS) was tested with a case study of a garment company in choosing the best suppliers that provide leather and footwear products. It has been decided that five leather and footwear manufacturers in Vietnam, denoted by {SUP-01, SUP-02, SUP-03, SUP-04, SUP-05}, are potential suppliers. Based on the fuzzy MARCOS process, the fuzzy ideal and anti-ideal solutions according to each criterion are defined. is the highest value of each criterion, while the lowest value is . Following that, the linguistic matrix of experts’ judgments and the integrated matrix for the fuzzy MARCOS method are calculated, as can be seen in Table 7. Table 8 shows the utility degree and fuzzy matrix of . Finally, the final utility function of suppliers is calculated. Using these values, the final ranking of suppliers is determined. The utility function and final ranking of the suppliers are presented in Table 9. The results show that the top three suppliers are {SUP-03, SUP-01, SUP-04}, ranking in the first, second, and third positions with utility function scores of 0.7210, 0.5706, and 0.4442, respectively. Figure 4 displays the final supplier ranking from the OPA–fuzzy MARCOS model.

Table 7.

The integrated matrix for fuzzy MARCOS.

Table 8.

Utility degree and fuzzy matrix of .

Table 9.

Utility functions and final ranking of suppliers.

Figure 4.

The final supplier ranking.

5. Results Validation

5.1. Sensitivity Analysis of Criteria Weights

In MCDM, sensitivity analysis can successfully aid in making sound judgments [67,68,69]. In this work, we applied a sensitivity analysis of all criteria to explore the influence of criteria on the decision-making result for the suppliers, namely, {SUP-01, SUP-02, SUP-03, SUP-04, SUP-05}, which can prove the practicality and robustness of the proposed OPA–fuzzy MARCOS model.

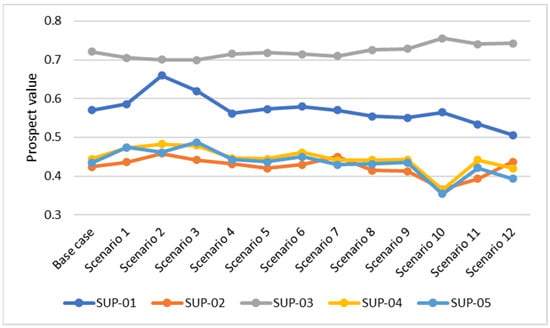

To that end, the elimination of criteria one by one and their influence on the final supplier rating was carried out [70]. As a result, the sensitivity analysis of criteria weight included 12 scenarios. Table 10 shows the weights of criteria in all scenarios. Table 11 displays the potential values of options in all scenarios, and Figure 5 depicts their ranking. While the prospect values of the alternatives fluctuate, the final supplier’s rating remains steady, with {SUP-03} being the ideal supplier across all scenarios. The sensitivity phase findings indicate that, in this case study, the supplier’s ranking is consistent regardless of the criteria weight change. As a result, the suggested OPA–fuzzy MARCOS model has a high level of reliability and applicability.

Table 10.

The weights of criteria for all scenarios.

Table 11.

The prospect values of suppliers for all scenarios.

Figure 5.

The ranking of suppliers for all scenarios.

5.2. Comparative Analysis of MCDM Methods

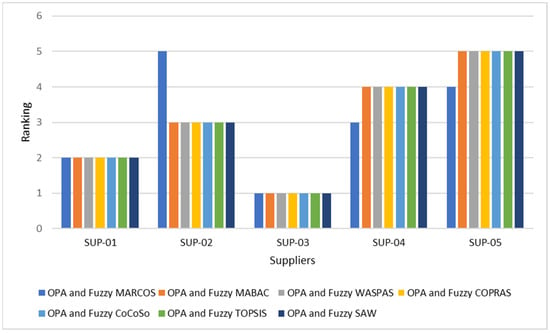

In addition to the sensitivity analysis of criteria, the applicability and reasonableness of the employed MCDM method must be validated by comparing it with certain mature and stable commonly used MCDM methods in relevant research. In this step, six different combined fuzzy MCDM methods were considered to validate the results obtained by the proposed OPA–fuzzy MARCOS model; these are the fuzzy multi-attributive border approximation area comparison (fuzzy MABAC) [71], the fuzzy weighted aggregated sum product assessment (fuzzy WASPAS) [72], the fuzzy complex proportional assessment of alternatives (fuzzy COPRAS) [73], the fuzzy combined compromise solution (fuzzy CoCoSo) [74], the fuzzy technique for order of preference by similarity to ideal solution (fuzzy TOPSIS) [75], and fuzzy simple additive weighting (fuzzy SAW) [76].

During the comparative analysis of MCDM approaches, the same weights of criteria were employed, and the results are provided in Table 12. Figure 6 depicts a comparison of OPA–fuzzy MARCOS with different MCDM approaches. The findings of the various MCDM approaches demonstrate that there is no significant difference in the ranking of the ideal provider. {SUP-03} was consistently regarded as the best supplier. All of the MCDM approaches used had similar findings, confirming the suggested OPA–fuzzy MARCOS model’s findings.

Table 12.

Results of the comparative analysis of MCDM methods.

Figure 6.

Comparison of OPA–fuzzy MARCOS with other MCDM methods.

6. Discussions

This study presents a two-stage MCDM model to choose the best provider of leather and footwear products in Vietnam in terms of sustainable performance. With a focus on I4.0 factors, three main criteria, namely, logistics management (five sub-criteria), production and operations management (four sub-criteria), and environmental competency (three sub-criteria), were introduced to OPA to find the weights of criteria. Then, the ranking of five candidates in the Vietnamese textile industry was obtained by MARCOS. The results of OPA revealed that the top five crucial criteria are “Green product innovation”, “Cloud computing”, “Service level”, “Blockchain”, and particularly “Green image”, the most significant criteria (). Based on the acquired criteria, the top three suppliers, denoted as {SUP-03, SUP-01, SUP-04}, were found with utility function scores of 0.7210, 0.5706, and 0.4442. The results of the sensitivity analysis of criteria and comparative analysis of methods show that the priorities of the experts are reliable and practical.

This paper’s findings confirm the results of Çalık et al. [6] that “Service level” is one of the most important factors in selecting sustainable suppliers in I4.0. Nevertheless, “Cloud computing” and “Green image” were not more significant than “IoT” in the study by Çalık et al. [6], which is in contrast to our outcomes. To achieve global net zero by mid-century, as defined in COP26 in Glasgow [77], the green concept is in demand for supplier performance, and thus, “Green image” and “Green product innovation” have become great concerns in sustainable supplier selection. The growth of the global trade network and the impact of COVID-19 have driven the increased requirement for “Cloud Computing” to maintain supply chain information collaboration despite the distance of stakeholders [78]. Though sharing information is the core of supply chain information collaboration, the authenticity of products can be exposed to information leakage. Hence, “Block Chain” has emerged as a technological breakthrough to secure the competitiveness and cybersecurity of enterprises [79]. Regarding the Vietnamese industry, technology has been defined as one of the key drivers of the national strategy for sustainable development until 2030; thus, around 1.2–1.5% of GDP is promised to be invested by 2025 [80]. “Cloud Computing” and “Block Chain” are the focus of information technology applications in Vietnam, as claimed in [81]. The textile industry, therefore, has adopted key technologies in I4.0, such as “Cloud Computing” and “Block Chain”, to promote innovation and environmentally friendly strategies, such as “Green image” and “Green product innovation”, to achieve sustainability [82,83].

This paper demonstrates the key criteria to evaluate supplier performance in the context of both sustainability and I4.0. As a result, this set of criteria can guide suppliers and partners to focus on what value they should obtain to meet customer demands and gain competence. In addition to the contribution of this research, by combining OPA and fuzzy MARCOS, a new approach to assessing sustainable suppliers for adapting to I4.0 was developed.

7. Conclusions

This paper presents a new model of decision making to support decision makers in the selection of sustainable suppliers by applying a hybrid method of OPA and fuzzy MARCOS, two variants of MCDM. The weights of criteria were calculated by OPA before ranking the suppliers by fuzzy MARCOS. Technological factors regarding sustainable performance were taken into account to build the criteria. A case study of five suppliers in Vietnam’s leather and footwear industry was illustrated to prove the feasibility of the model. The results show that “green image”, “green product innovation”, “cloud computing”, “service level”, and “blockchain” are the topmost significant criteria in evaluating sustainable practices in the supply chain from the I4.0 perspective. This work introduces not only a new tool for decision making but also the discovery of a combination of OPA and fuzzy MARCOS. In addition to its contribution, this study can be a reference for research on sustainable supplier selection with attention to I4.0 elements. The scope of research, on the other hand, was the limitation of this study in terms of alternatives, number of factors, and geography. For research in the future, it is suggested that the area of investigation be expanded to the global scale. In addition, more technological concepts should be included to obtain a wider range of criteria.

Author Contributions

Conceptualization, T.-T.D.; data curation, N.-A.-T.N.; formal analysis, T.T.T.N.; funding acquisition, C.-N.W.; investigation, N.-A.-T.N.; methodology, T.-T.D.; project administration, C.-N.W.; software, T.-T.D.; validation, T.T.T.N.; writing—original draft, T.T.T.N.; writing—review and editing, T.-T.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors appreciate the support from the National Kaohsiung University of Science and Technology, Taiwan; and Hong Bang International University, Vietnam.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Joshi, S. A Review on Sustainable Supply Chain Network Design: Dimensions, Paradigms, Concepts, Framework and Future Directions. Sustain. Oper. Comput. 2022, 3, 136–148. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; De, M.; Pieroni, P.; Kravchenko, M.; Awan, U.; Sroufe, R.; Bozan, K. Designing Value Chains for Industry 4.0 and a Circular Economy: A Review of the Literature. Sustainability 2022, 14, 7084. [Google Scholar] [CrossRef]

- Simonetto, M.; Sgarbossa, F.; Battini, D.; Govindan, K. Closed Loop Supply Chains 4.0: From Risks to Benefits through Advanced Technologies. A Literature Review and Research Agenda. Int. J. Prod. Econ. 2022, 253, 108582. [Google Scholar] [CrossRef]

- Khatri, J.; Srivastava, M. Technology Selection for Sustainable Supply Chains. Int. J. Technol. Manag. Sustain. Dev. 2016, 15, 275–289. [Google Scholar] [CrossRef]

- Rinaldi, M.; Caterino, M.; Fera, M.; Manco, P.; Macchiaroli, R. Technology Selection in Green Supply Chains–The Effects of Additive and Traditional Manufacturing. J. Clean. Prod. 2021, 282, 124554. [Google Scholar] [CrossRef]

- Çalık, A. A Novel Pythagorean Fuzzy AHP and Fuzzy TOPSIS Methodology for Green Supplier Selection in the Industry 4.0 Era. Soft Comput. 2021, 25, 2253–2265. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Deng, X.; Javed, S.A.; Zhang, N. Sustainable Supplier Selection in Megaprojects: Grey Ordinal Priority Approach. Bus. Strategy Environ. 2021, 30, 318–339. [Google Scholar] [CrossRef]

- Jauhar, S.K.; Pant, M. Integrating DEA with DE and MODE for Sustainable Supplier Selection. J. Comput. Sci. 2017, 21, 299–306. [Google Scholar] [CrossRef]

- Song, W.; Xu, Z.; Liu, H.C. Developing Sustainable Supplier Selection Criteria for Solar Air-Conditioner Manufacturer: An Integrated Approach. Renew. Sustain. Energy Rev. 2017, 79, 1461–1471. [Google Scholar] [CrossRef]

- Gören, H.G. A Decision Framework for Sustainable Supplier Selection and Order Allocation with Lost Sales. J. Clean. Prod. 2018, 183, 1156–1169. [Google Scholar] [CrossRef]

- Ghadimi, P.; Toosi, F.G.; Heavey, C. A Multi-Agent Systems Approach for Sustainable Supplier Selection and Order Allocation in a Partnership Supply Chain. Eur. J. Oper. Res. 2018, 269, 286–301. [Google Scholar] [CrossRef]

- Amindoust, A. A Resilient-Sustainable Based Supplier Selection Model Using a Hybrid Intelligent Method. Comput. Ind. Eng. 2018, 126, 122–135. [Google Scholar] [CrossRef]

- Khan, S.A.; Kusi-Sarpong, S.; Arhin, F.K.; Kusi-Sarpong, H. Supplier Sustainability Performance Evaluation and Selection: A Framework and Methodology. J. Clean. Prod. 2018, 205, 964–979. [Google Scholar] [CrossRef]

- Jain, N.; Singh, A.R. Sustainable Supplier Selection under Must-Be Criteria through Fuzzy Inference System. J. Clean. Prod. 2020, 248, 119275. [Google Scholar] [CrossRef]

- Kannan, D. Role of Multiple Stakeholders and the Critical Success Factor Theory for the Sustainable Supplier Selection Process. Int. J. Prod. Econ. 2018, 195, 391–418. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 Technologies to Enable Circular Economy Practices in a Manufacturing Context: A Business Model Proposal. J. Manuf. Technol. Manag. 2018, 30, 607–627. [Google Scholar] [CrossRef]

- Liu, B.; De Giovanni, P. Green Process Innovation through Industry 4.0 Technologies and Supply Chain Coordination. Ann. Oper. Res. 2019, 1–36. [Google Scholar] [CrossRef]

- Diba, S.; Xie, N. Sustainable Supplier Selection for Satrec Vitalait Milk Company in Senegal Using the Novel Grey Relational Analysis Method. In Grey Systems: Theory and Application; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Jia, R.; Liu, Y.; Bai, X. Sustainable Supplier Selection and Order Allocation: Distributionally Robust Goal Programming Model and Tractable Approximation. Comput. Ind. Eng. 2020, 140, 106267. [Google Scholar] [CrossRef]

- Hoseini, S.A.; Fallahpour, A.; Wong, K.Y.; Mahdiyar, A.; Saberi, M.; Durdyev, S. Sustainable Supplier Selection in Construction Industry through Hybrid Fuzzy-Based Approaches. Sustainability 2021, 13, 1413. [Google Scholar] [CrossRef]

- Kuo, T.-C.; Muniroh, M.; Fau, K.H. An Integrated Kano Model, Fuzzy Analytical Hierarchy Process, and Decision Matrix for Sustainable Supplier Selection in Palm Oil Industries Indonesia, a Case Study. Processes 2021, 9, 1078. [Google Scholar] [CrossRef]

- Ecer, F.; Torkayesh, A.E. A Stratified Fuzzy Decision-Making Approach for Sustainable Circular Supplier Selection; A Stratified Fuzzy Decision-Making Approach for Sustainable Circular Supplier Selection. IEEE Trans. Eng. Manag. 2022, 1–15. [Google Scholar] [CrossRef]

- Ataei, Y.; Mahmoudi, A.; Feylizadeh, M.R.; Li, D.F. Ordinal Priority Approach (OPA) in Multiple Attribute Decision-Making. Appl. Soft Comput. J. 2020, 86, 105893. [Google Scholar] [CrossRef]

- Stankovi’c, M.S.; Stevi’cstevi’c, Ž.; Das, D.K.; Suboti’c, M.S.; Pamučar, D. A New Fuzzy MARCOS Method for Road Traffic Risk Analysis. Mathematics 2020, 8, 457. [Google Scholar] [CrossRef]

- Ecer, F.; Böyükaslan, A.; Zolfani, S.H. Article Evaluation of Cryptocurrencies for Investment Decisions in the Era of Industry 4.0: A Borda Count-Based Intuitionistic Fuzzy Set Extensions EDAS-MAIRCA-MARCOS Multi-Criteria Methodology. Axioms 2022, 11, 404. [Google Scholar] [CrossRef]

- Campilho, D.S.G.; Shanmugasundar, G.; Fegade, V.; Mahdal, M.; Kalita, K. Optimization of Variable Stiffness Joint in Robot Manipulator Using a Novel NSWOA-MARCOS Approach. Processes 2022, 10, 1074. [Google Scholar] [CrossRef]

- Stević, Ž.; Pamučar, D.; Puška, A.; Chatterjee, P. Sustainable Supplier Selection in Healthcare Industries Using a New MCDM Method: Measurement of Alternatives and Ranking According to COmpromise Solution (MARCOS). Comput. Ind. Eng. 2020, 140, 106231. [Google Scholar] [CrossRef]

- Govindan, K.; Kadziński, M.; Sivakumar, R. Application of a Novel PROMETHEE-Based Method for Construction of a Group Compromise Ranking to Prioritization of Green Suppliers in Food Supply Chain. Omega 2017, 71, 129–145. [Google Scholar] [CrossRef]

- Qin, J.; Liu, X.; Pedrycz, W. An Extended TODIM Multi-Criteria Group Decision Making Method for Green Supplier Selection in Interval Type-2 Fuzzy Environment. Eur. J. Oper. Res. 2017, 258, 626–638. [Google Scholar] [CrossRef]

- Mousakhani, S.; Nazari-Shirkouhi, S.; Bozorgi-Amiri, A. A Novel Interval Type-2 Fuzzy Evaluation Model Based Group Decision Analysis for Green Supplier Selection Problems: A Case Study of Battery Industry. J. Clean. Prod. 2017, 168, 205–218. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Hashemkhani Zolfani, S. Integrated QFD-MCDM Framework for Green Supplier Selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An Integrated Framework for Sustainable Supplier Selection and Evaluation in Supply Chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Banaeian, N.; Mobli, H.; Fahimnia, B.; Nielsen, I.E.; Omid, M. Green Supplier Selection Using Fuzzy Group Decision Making Methods: A Case Study from the Agri-Food Industry. Comput. Oper. Res. 2018, 89, 337–347. [Google Scholar] [CrossRef]

- Erdogan, M.; Ozkan, B.; Karasan, A.; Kaya, I. Selecting the Best Strategy for Industry 4.0 Applications with a Case Study. In Industrial Engineering in the Industry 4.0 Era; Springer: Berlin/Heidelberg, Germany, 2018; pp. 109–119. [Google Scholar]

- Cheraghalipour, A.; Farsad, S. A Bi-Objective Sustainable Supplier Selection and Order Allocation Considering Quantity Discounts under Disruption Risks: A Case Study in Plastic Industry. Comput. Ind. Eng. 2018, 118, 237–250. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-Tier Sustainable Global Supplier Selection Using a Fuzzy AHP-VIKOR Based Approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Mondragon, A.E.C.; Mastrocinque, E.; Tsai, J.-F.; Hogg, P.J. An AHP and Fuzzy AHP Multifactor Decision Making Approach for Technology and Supplier Selection in the High-Functionality Textile Industry. IEEE Trans. Eng. Manag. 2019, 68, 1112–1125. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, L.; Chen, Y.; Chen, H. An Integrated Approach to Green Supplier Selection Based on the Interval Type-2 Fuzzy Best-Worst and Extended VIKOR Methods. Inf. Sci. 2019, 502, 394–417. [Google Scholar] [CrossRef]

- Gupta, S.; Soni, U.; Kumar, G. Green Supplier Selection Using Multi-Criterion Decision Making under Fuzzy Environment: A Case Study in Automotive Industry. Comput. Ind. Eng. 2019, 136, 663–680. [Google Scholar] [CrossRef]

- Liang, R.; Chong, H.-Y. A Hybrid Group Decision Model for Green Supplier Selection: A Case Study of Megaprojects. Eng. Constr. Archit. Manag. 2019, 26, 1712–1734. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Pardasani, K.R.; Mardani, A. A Novel Hesitant Fuzzy WASPAS Method for Assessment of Green Supplier Problem Based on Exponential Information Measures. J. Clean. Prod. 2019, 238, 117901. [Google Scholar] [CrossRef]

- Ulutag, A.; Topal, A.; Bakhat, R. An Application of Fuzzy Integrated Model in Green Supplier Selection. Math. Probl. Eng. 2019, 2019, 4256359. [Google Scholar] [CrossRef]

- Yucesan, M.; Mete, S.; Serin, F.; Celik, E.; Gul, M. Mathematics An Integrated Best-Worst and Interval Type-2 Fuzzy TOPSIS Methodology for Green Supplier Selection. Mathematics 2019, 7, 182. [Google Scholar] [CrossRef]

- Liou, J.J.H.; Chuang, Y.C.; Zavadskas, E.K.; Tzeng, G.H. Data-Driven Hybrid Multiple Attribute Decision-Making Model for Green Supplier Evaluation and Performance Improvement. J. Clean. Prod. 2019, 241, 118321. [Google Scholar] [CrossRef]

- Demircan Keskin, F.; Kabasakal, İ.; Kaymaz, Y.; Soyuer, H. An Assessment Model for Organizational Adoption of Industry 4.0 Based on Multi-Criteria Decision Techniques. In Proceedings of the The International Symposium for Production Research, Vienna, Austria, 28–31 August 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 85–100. [Google Scholar]

- Sachdeva, N.; Shrivastava, A.K.; Chauhan, A. Modeling Supplier Selection in the Era of Industry 4.0. Benchmarking Int. J. 2021, 28, 1809–1836. [Google Scholar] [CrossRef]

- Rashidi, K.; Cullinane, K. A Comparison of Fuzzy DEA and Fuzzy TOPSIS in Sustainable Supplier Selection: Implications for Sourcing Strategy. Expert Syst. Appl. 2019, 121, 266–281. [Google Scholar] [CrossRef]

- Liu, H.C.; Quan, M.Y.; Li, Z.W.; Wang, Z.L. A New Integrated MCDM Model for Sustainable Supplier Selection under Interval-Valued Intuitionistic Uncertain Linguistic Environment. Inf. Sci. 2019, 486, 254–270. [Google Scholar] [CrossRef]

- Yadavalli, V.S.S.; Darbari, J.D.; Bhayana, N.; Jha, P.C.; Agarwal, V. An Integrated Optimization Model for Selection of Sustainable Suppliers Based on Customers’ Expectations. Oper. Res. Perspect. 2019, 6, 100113. [Google Scholar] [CrossRef]

- Yu, C.; Shao, Y.; Wang, K.; Zhang, L. A Group Decision Making Sustainable Supplier Selection Approach Using Extended TOPSIS under Interval-Valued Pythagorean Fuzzy Environment. Expert Syst. Appl. 2019, 121, 1–17. [Google Scholar] [CrossRef]

- Xu, Z.; Qin, J.; Liu, J.; Martínez, L. Sustainable Supplier Selection Based on AHPSort II in Interval Type-2 Fuzzy Environment. Inf. Sci. 2019, 483, 273–293. [Google Scholar] [CrossRef]

- Abdel-Baset, M.; Chang, V.; Gamal, A.; Smarandache, F. An Integrated Neutrosophic ANP and VIKOR Method for Achieving Sustainable Supplier Selection: A Case Study in Importing Field. Comput. Ind. 2019, 106, 94–110. [Google Scholar] [CrossRef]

- Memari, A.; Dargi, A.; Jokar, M.R.A.; Ahmad, R.; Rahim, A.R.A. Sustainable Supplier Selection: A Multi-Criteria Intuitionistic Fuzzy TOPSIS Method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Li, J.; Fang, H.; Song, W. Sustainable Supplier Selection Based on SSCM Practices: A Rough Cloud TOPSIS Approach. J. Clean. Prod. 2019, 222, 606–621. [Google Scholar] [CrossRef]

- Rouyendegh, B.D.; Yildizbasi, A.; Üstünyer, P. Intuitionistic Fuzzy TOPSIS Method for Green Supplier Selection Problem. Soft Comput. 2020, 24, 2215–2228. [Google Scholar] [CrossRef]

- Hasan, M.M.; Jiang, D.; Ullah, A.M.M.S.; Noor-E-Alam, M. Resilient Supplier Selection in Logistics 4.0 with Heterogeneous Information. Expert. Syst. Appl. 2020, 139, 112799. [Google Scholar] [CrossRef]

- Chen, Z.; Ming, X.; Zhou, T.; Chang, Y. Sustainable Supplier Selection for Smart Supply Chain Considering Internal and External Uncertainty: An Integrated Rough-Fuzzy Approach. Appl. Soft Comput. 2020, 87, 106004. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Mardani, A.; Dashtian, Z.; Soltani, M.; Weber, G.-W. A Novel Hybrid Method Using Fuzzy Decision Making and Multi-Objective Programming for Sustainable-Reliable Supplier Selection in Two-Echelon Supply Chain Design. J. Clean. Prod. 2020, 250, 119517. [Google Scholar] [CrossRef]

- Hendiani, S.; Mahmoudi, A.; Liao, H. A Multi-Stage Multi-Criteria Hierarchical Decision-Making Approach for Sustainable Supplier Selection. Appl. Soft Comput. 2020, 94, 106456. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets as a Basis for a Theory of Possibility. Fuzzy Sets Syst. 1978, 1, 3–28. [Google Scholar] [CrossRef]

- Zadeh, L.A. The Concept of a Linguistic Variable and Its Application to Approximate Reasoning—I. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Applying 4.0 Technology in the Leather and Footwear Industry: It Is Necessary to Fully Assess the Impacts on Production and Society. Available online: https://congthuong.vn/ung-dung-cong-nghe-40-trong-nganh-da-giay-can-danh-gia-day-du-cac-tac-dong-doi-voi-san-xuat-va-xa-hoi-138348.html (accessed on 24 September 2022).

- Nofer, M.; Gomber, P.; Hinz, O.; Schiereck, D. Blockchain. Bus. Inf. Syst. Eng. 2017, 59, 183–187. [Google Scholar] [CrossRef]

- KENTON, W. Green Tech. Available online: https://www.investopedia.com/terms/g/green_tech.asp#:~:text=Greentech–orgreentechnology,%2Cmaterialscience%2Candhydrology (accessed on 11 September 2022).

- Global Infrastructure Hub Smart Containers. Available online: https://www.gihub.org/infrastructure-technology-use-cases/case-studies/smart-containers/#:~:text=SUMMARY,GPStrackingandsolarpanels (accessed on 11 September 2022).

- Mittal, R.; Arora, S.; Kuchhal, P.; Bhatia, M.P.S. An Insight into Tool and Software Used in AI, Machine Learning and Data Analytics. In AI and Machine Learning Paradigms for Health Monitoring System; Malik, H., Fatema, N., Alzubi, J.A., Eds.; Springer: Singapore, 2021; pp. 45–64. ISBN 978-981-33-4412-9. [Google Scholar]

- Dantas, J.; Matos, R.; Araujo, J.; Oliveira, D.; Oliveira, A.; Maciel, P. Hierarchical Model and Sensitivity Analysis for a Cloud-Based VoD Streaming Service. In Proceedings of the 2016 46th Annual IEEE/IFIP International Conference on Dependable Systems and Networks Workshop (DSN-W), Toulouse, France, 28 June–1 July 2016; pp. 10–16. [Google Scholar]

- Ouadah, A.; Hadjali, A.; Nader, F.; Benouaret, K. SEFAP: An Efficient Approach for Ranking Skyline Web Services. J. Ambient Intell. Humaniz. Comput. 2019, 10, 709–725. [Google Scholar] [CrossRef]

- Li, L.; Liu, M.; Shen, W.; Cheng, G. Recommending Mobile Services with Trustworthy QoS and Dynamic User Preferences via FAHP and Ordinal Utility Function. IEEE Trans. Mob. Comput. 2020, 19, 419–431. [Google Scholar] [CrossRef]

- Alinezhad, A.; Amini, A. Sensitivity Analysis of TOPSIS Technique: The Results of Change in the Weight of One Attribute on the Final Ranking of Alternatives. J. Optim. Ind. Eng. 2011, 7, 23–28. [Google Scholar]

- Božanić, D.; Tešić, D.; Kočić, J. Multi-Criteria FUCOM—Fuzzy MABAC Model for the Selection of Location for Construction of Single-Span Bailey Bridge. Decis. Mak. Appl. Manag. Eng. 2019, 2, 132–146. [Google Scholar] [CrossRef]

- Agarwal, S.; Kant, R.; Shankar, R. Evaluating Solutions to Overcome Humanitarian Supply Chain Management Barriers: A Hybrid Fuzzy SWARA—Fuzzy WASPAS Approach. Int. J. Disaster Risk Reduct. 2020, 51, 101838. [Google Scholar] [CrossRef]

- Yazdani, M.; Alidoosti, A.; Zavadskas, E.K. Risk Analysis of Critical Infrastructures Using Fuzzy Copras. Econ. Res. 2011, 24, 27–40. [Google Scholar] [CrossRef]

- Ecer, F.; Pamucar, D. Sustainable Supplier Selection: A Novel Integrated Fuzzy Best Worst Method (F-BWM) and Fuzzy CoCoSo with Bonferroni (CoCoSo’B) Multi-Criteria Model. J. Clean. Prod. 2020, 266, 121981. [Google Scholar] [CrossRef]

- Sun, C.-C. A Performance Evaluation Model by Integrating Fuzzy AHP and Fuzzy TOPSIS Methods. Expert Syst. Appl. 2010, 37, 7745–7754. [Google Scholar] [CrossRef]

- Roszkowska, E.; Kacprzak, D. The Fuzzy Saw and Fuzzy TOPSIS Procedures Based on Ordered Fuzzy Numbers. Inf. Sci. 2016, 369, 564–584. [Google Scholar] [CrossRef]

- UKCOP26 What do We Need to Achieve at COP26? Available online: https://ukcop26.org/cop26-goals/ (accessed on 17 October 2022).

- Chen, J.; Ma, Y.W. The Research of Supply Chain Information Collaboration Based on Cloud Computing. Procedia. Environ. Sci. 2011, 10, 875–880. [Google Scholar] [CrossRef]

- Li, Q.; Ji, H.; Huang, Y. The Information Leakage Strategies of the Supply Chain under the Block Chain Technology Introduction. Omega 2022, 110, 102616. [Google Scholar] [CrossRef]

- Part 1: Strategy for Science, Technology and Innovation Development until 2030 Approved|Sci-Tech|Vietnam + (VietnamPlus). Available online: https://en.vietnamplus.vn/part-1-strategy-for-science-technology-and-innovation-development-until-2030-approved/240042.vnp (accessed on 17 October 2022).

- Part 3: Strategy for Science, Technology and Innovation Development until 2030 Approved|Sci-Tech|Vietnam + (VietnamPlus). Available online: https://en.vietnamplus.vn/part-3-strategy-for-science-technology-and-innovation-development-until-2030-approved/240046.vnp (accessed on 17 October 2022).

- Ứng Dụng Công Nghệ, Định Hình Sản Phẩm Mới Của Ngành Dệt May Việt Nam Giai Đoạn 2022–2025. Available online: https://moit.gov.vn/khoa-hoc-va-cong-nghe/ung-dung-cong-nghe-dinh-hinh-san-pham-moi-cua-nganh-det-may-viet-nam-giai-doan-2022-2025.html (accessed on 17 October 2022).

- Xu Hướng Phát Triển Của Ngành Dệt May Việt Nam. Available online: http://vsi.gov.vn/vn/tin-cong-nghiep-ho-tro/xu-huong-phat-trien-cua-nganh-det-may-viet-nam-c1id1872.html (accessed on 17 October 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).