Mechanics Principle and Implementation Technology of Surrounding Rock Pressure Release in Gob-Side Entry Retaining by Roof Cutting

Abstract

:1. Introduction

2. Research Methods

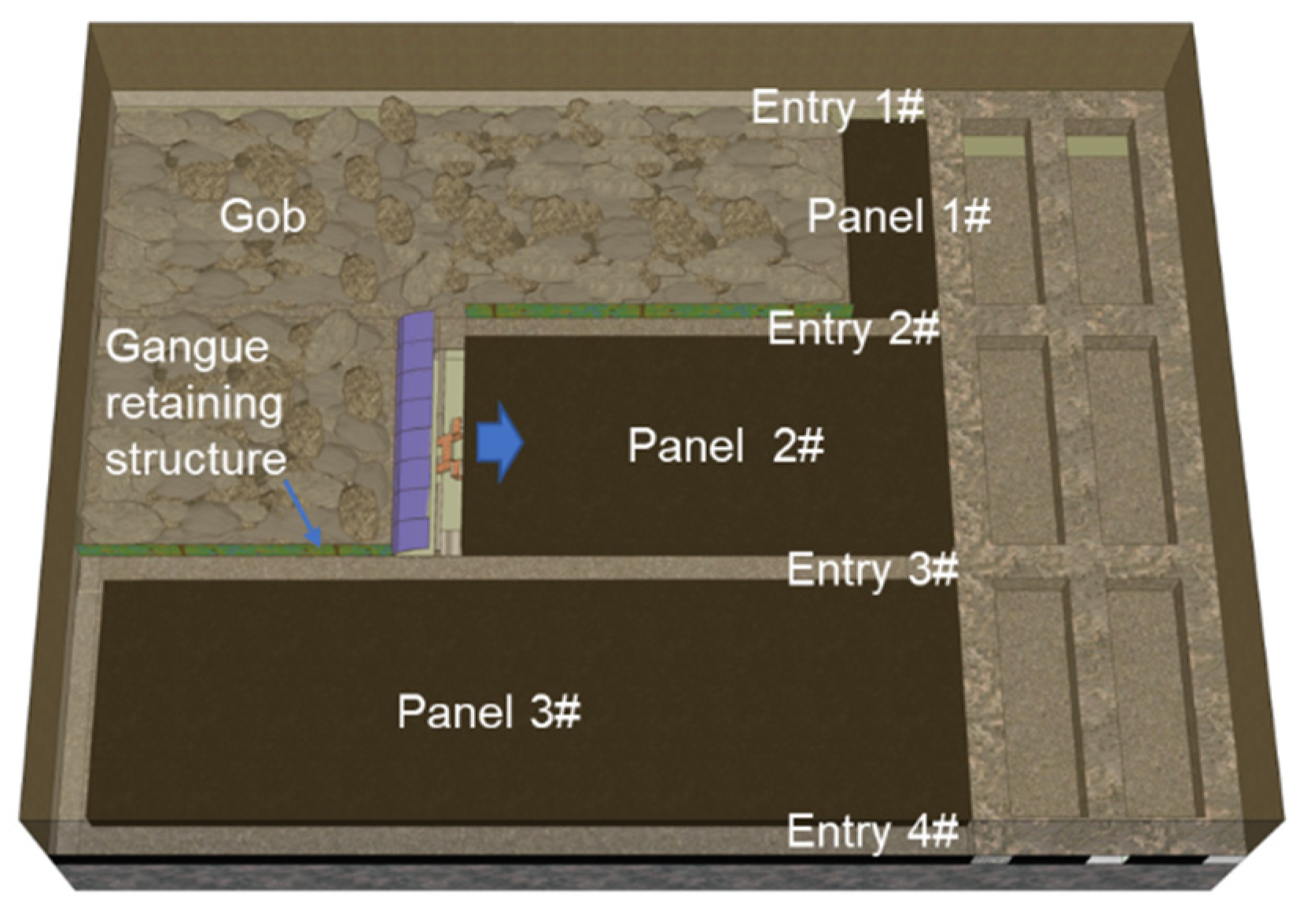

2.1. Brief Description of the GERRC

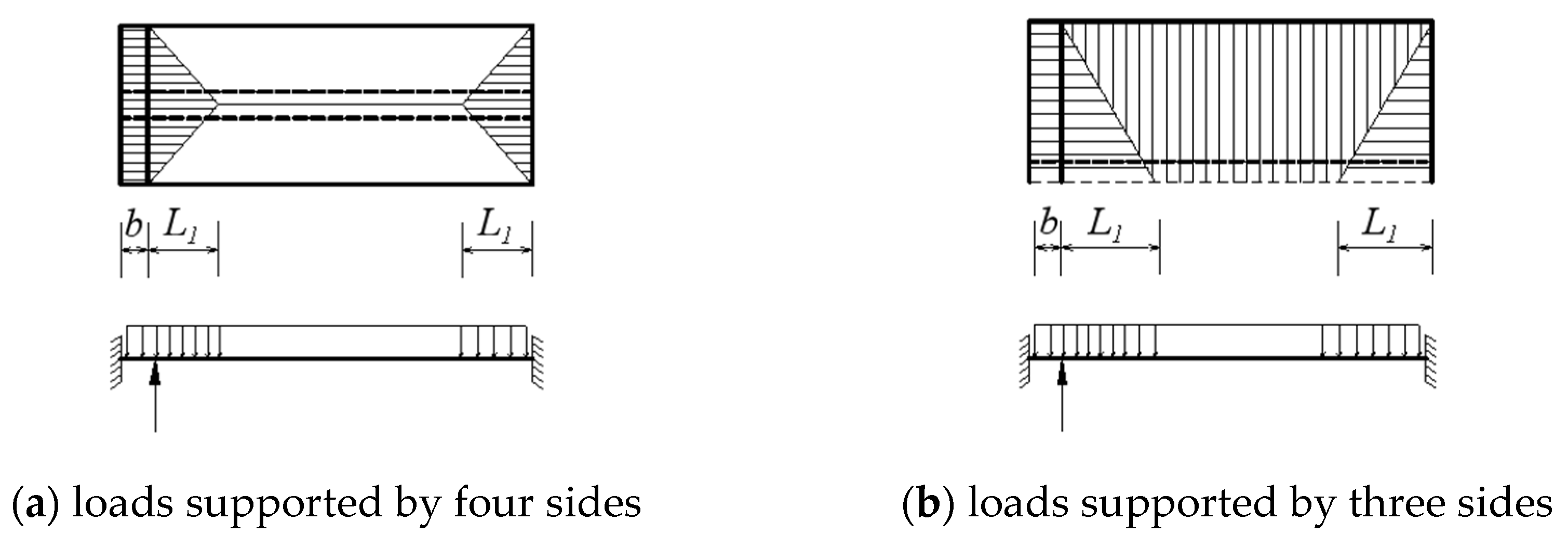

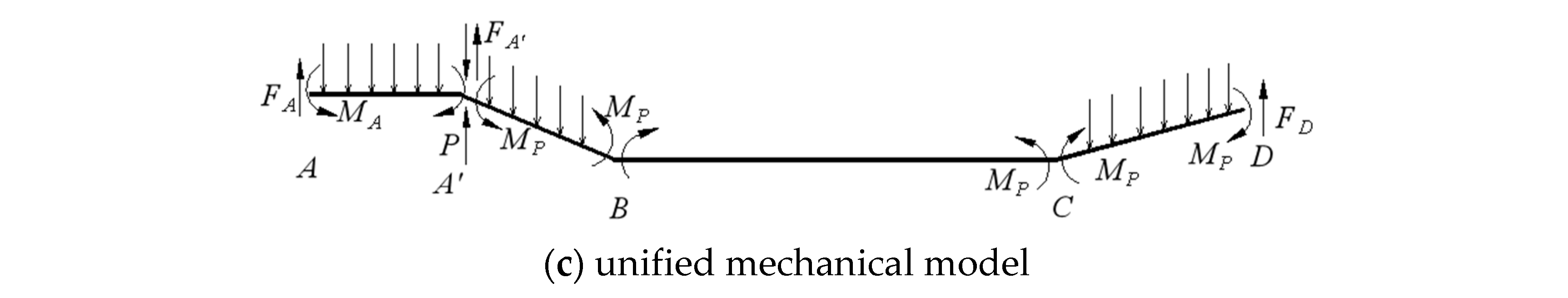

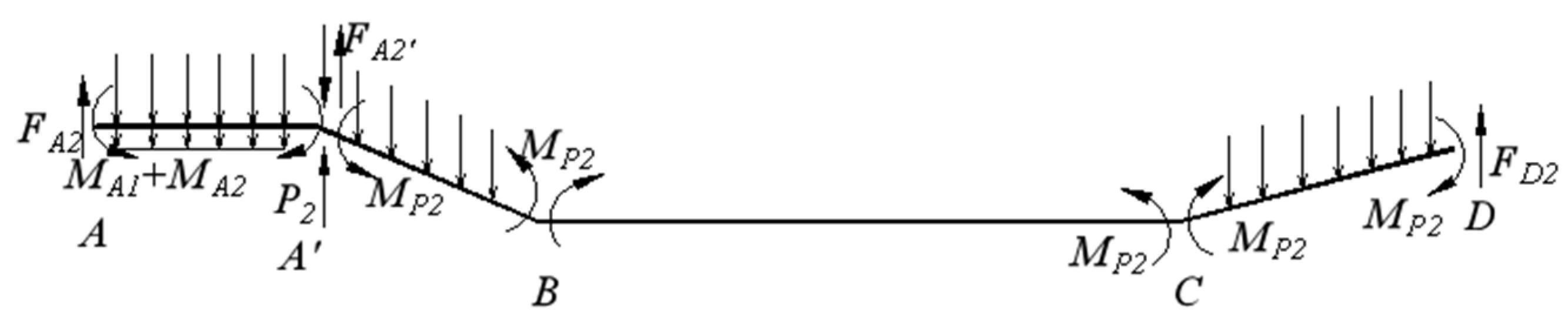

2.2. Loads Division Method

3. Results

3.1. Mechanical Equilibrium Equation

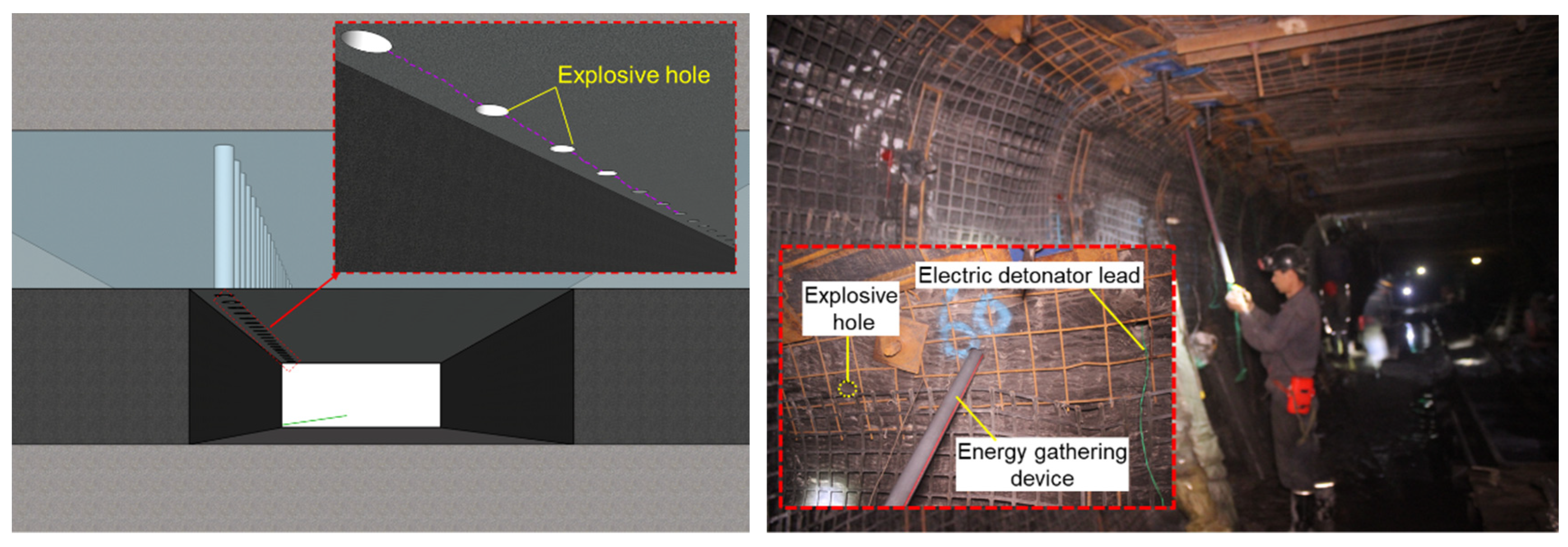

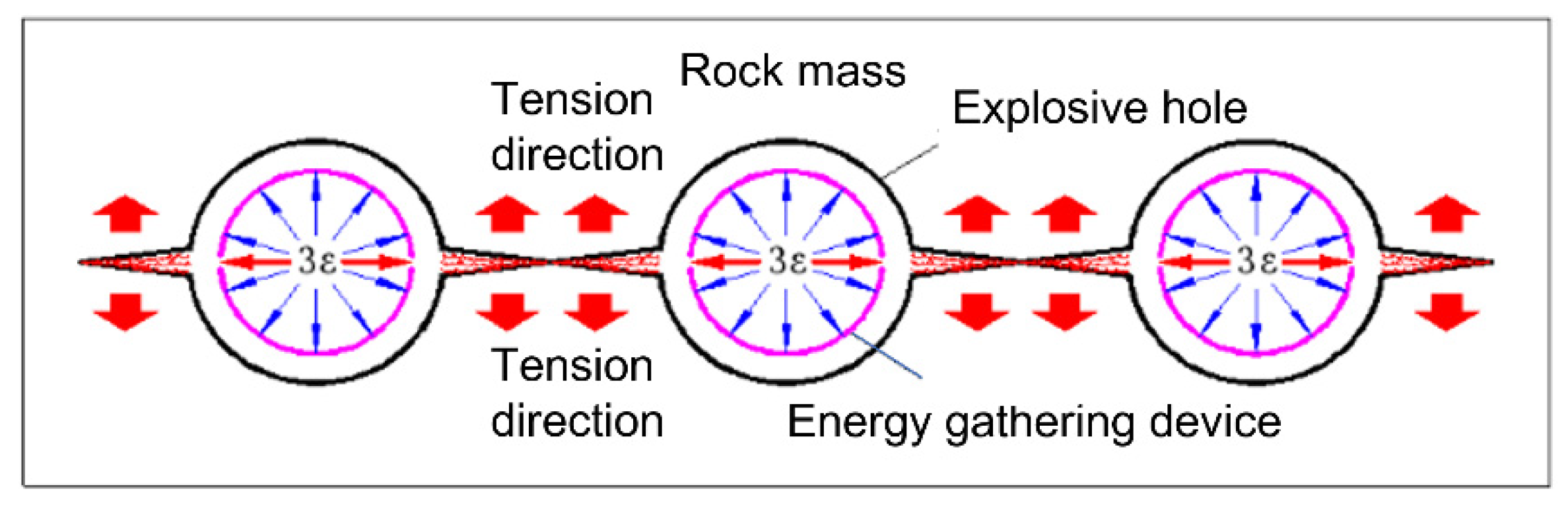

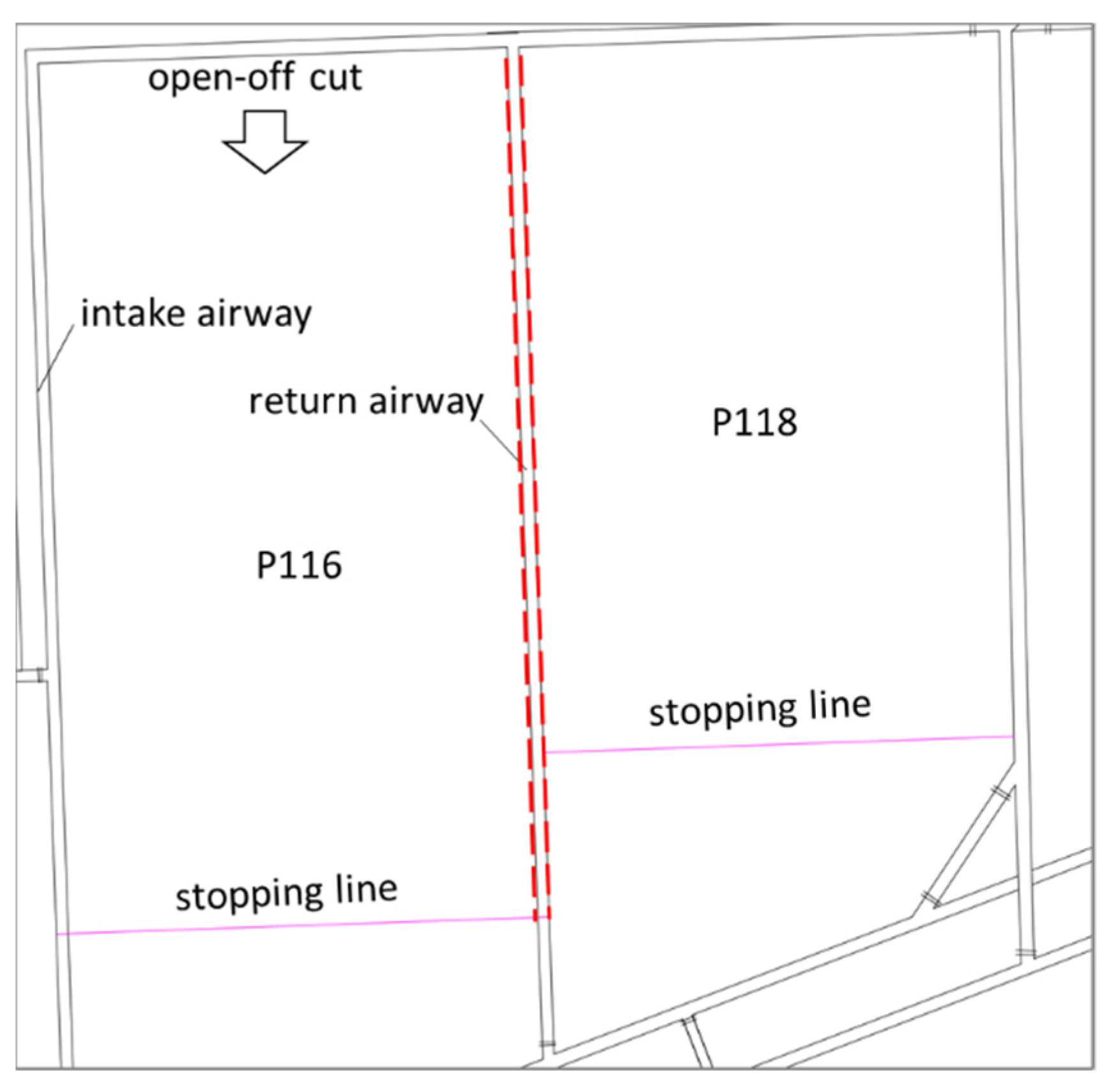

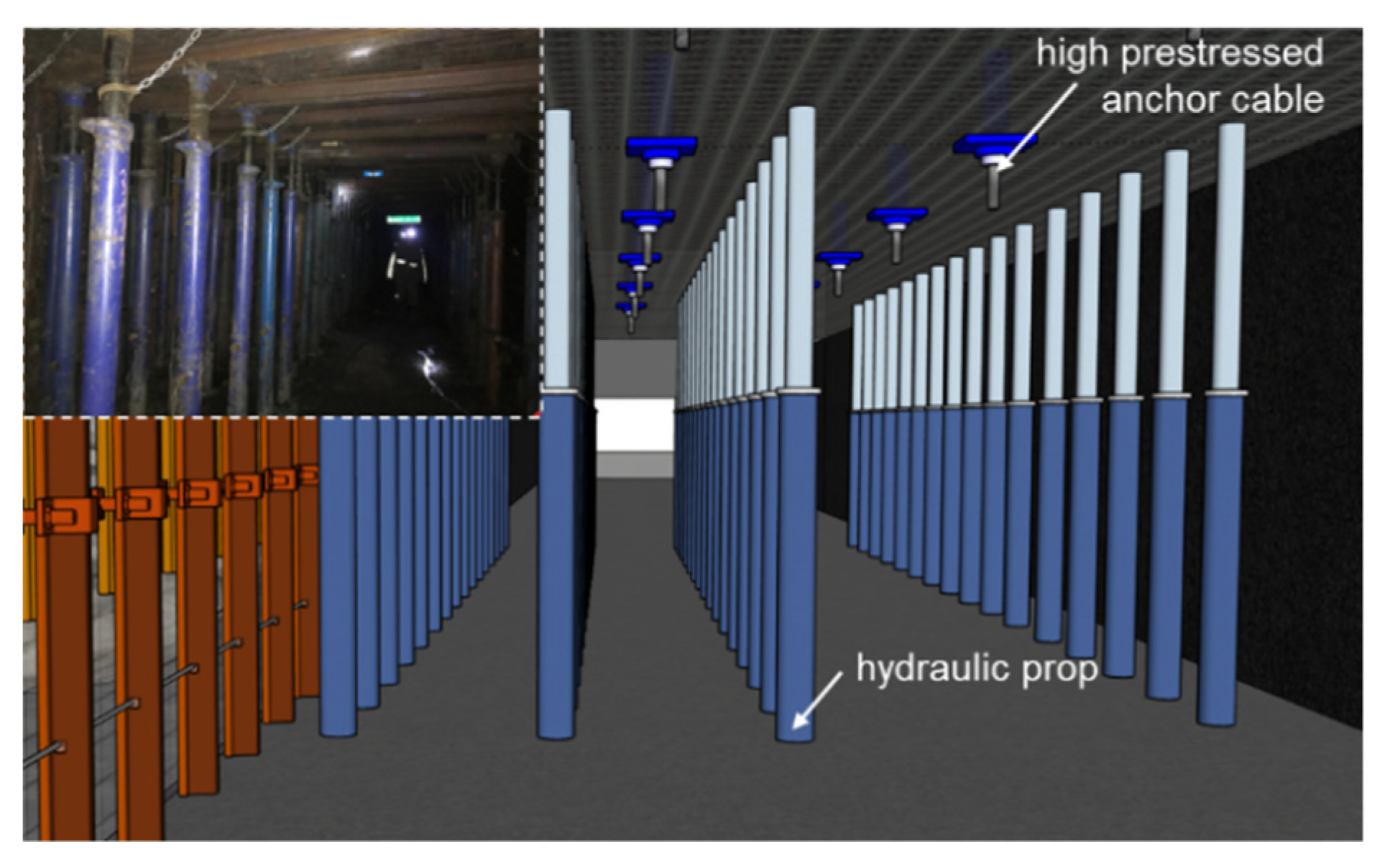

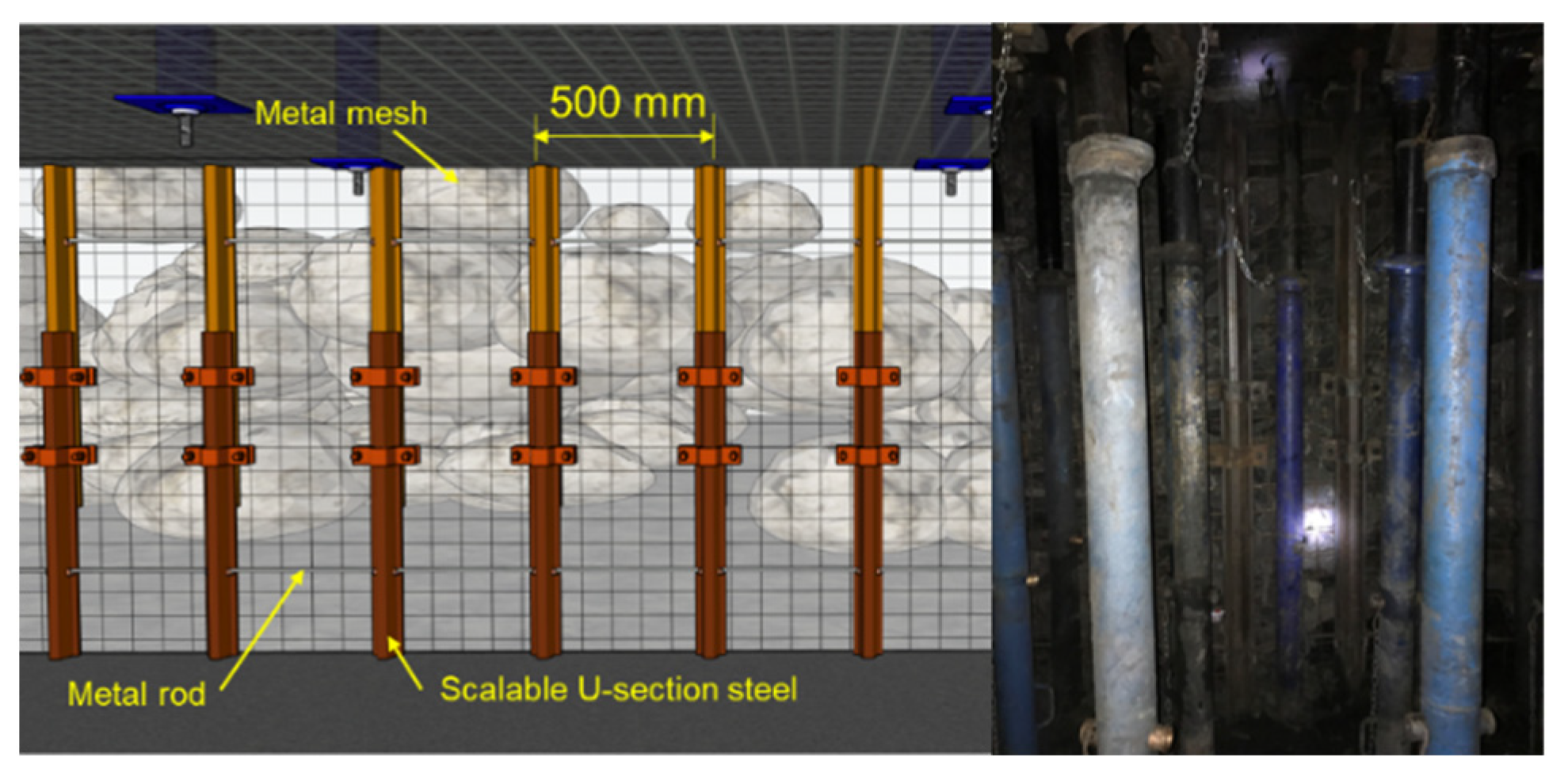

3.2. Implementation Technology fo Pressure Release

3.3. Engineering Verification

4. Conclusions

- (1)

- The derived mechanical balance equation shows that the surrounding rock of the gob-side entry and the external support structure are coupled. When the surrounding rock has good integrity and high strength, the external support resistance can be appropriately reduced. On the contrary, because the bearing capacity of the surrounding rock is limited, the external support resistance must be increased to keep the surrounding rock in a stable state. At the same time, the equilibrium equation also explains the mechanical principle of surrounding rock pressure release.

- (2)

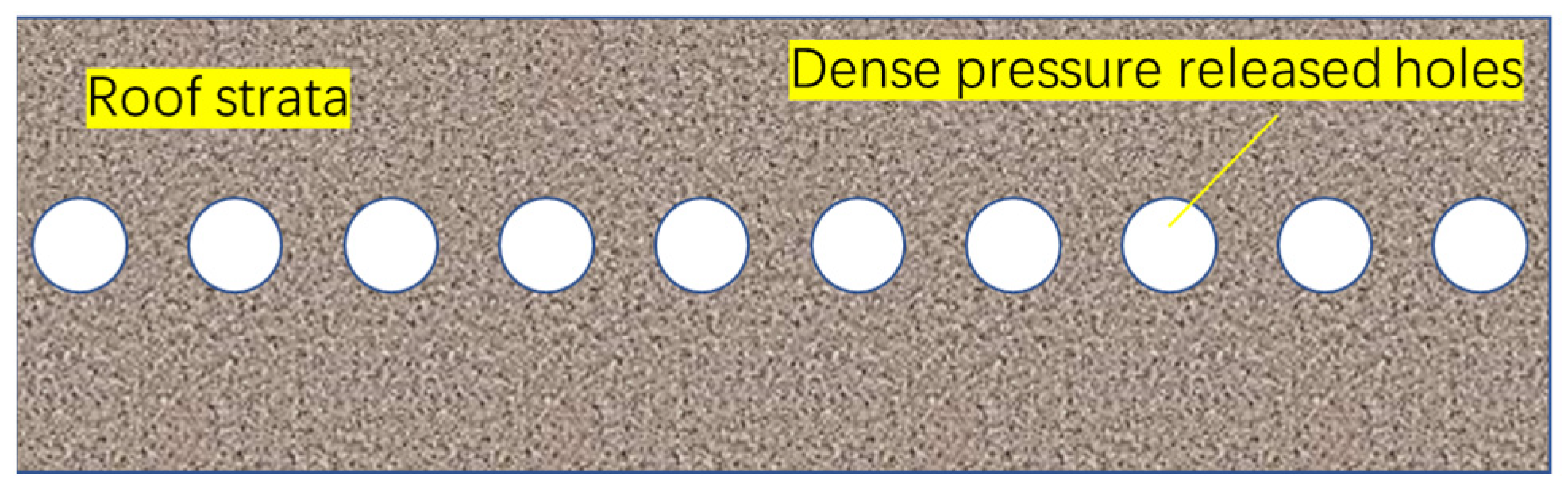

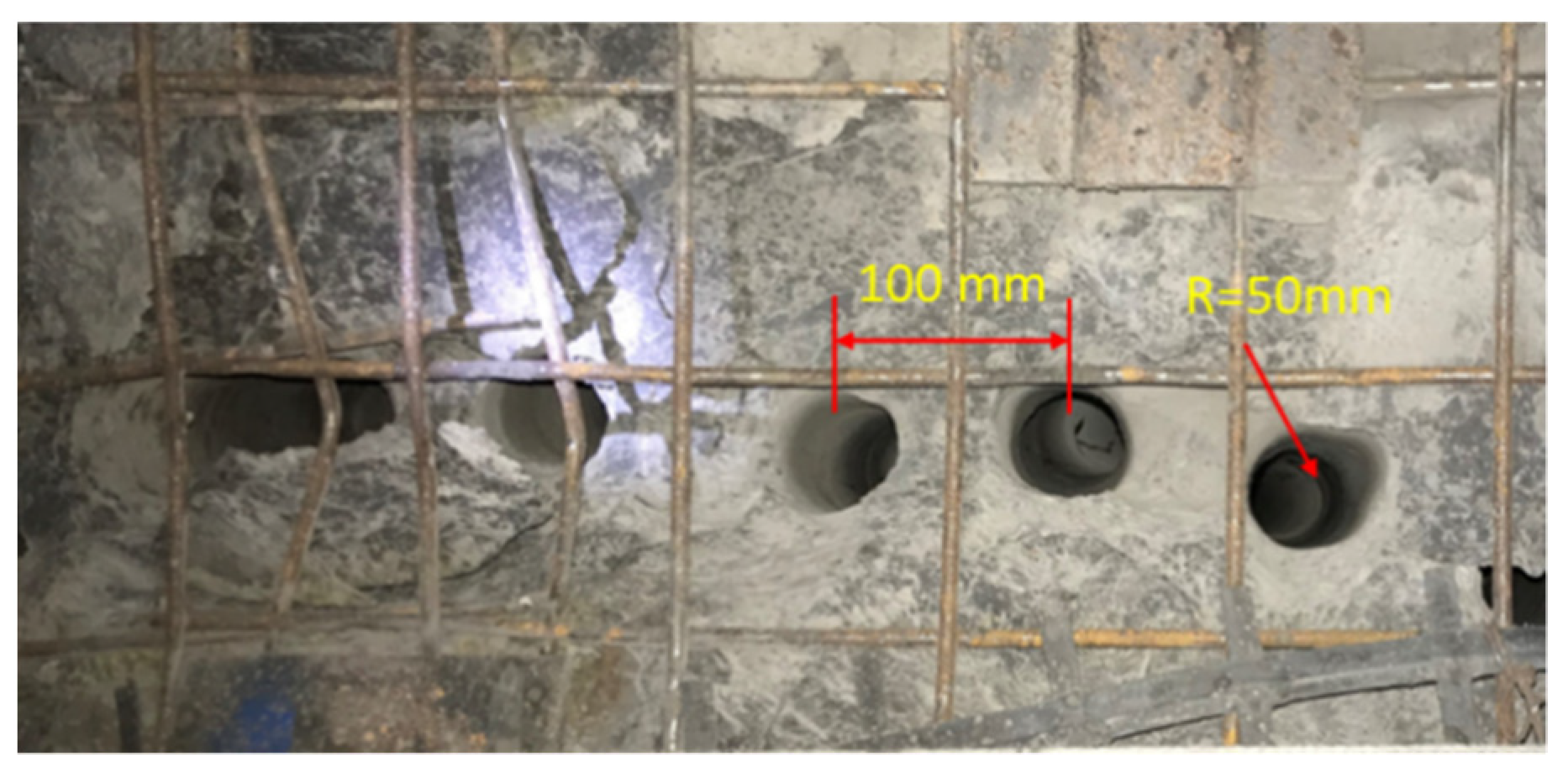

- In fact, according to the balance equation, there are many methods to achieve the purpose of surrounding rock pressure release, such as blasting, mechanical cutting, drilling, etc., but practice shows that dense drilling may be one of the safest, most reliable, and most feasible methods because it has the advantages of a simple process and safe operation, and does not need very complex and expensive mechanical equipment.

- (3)

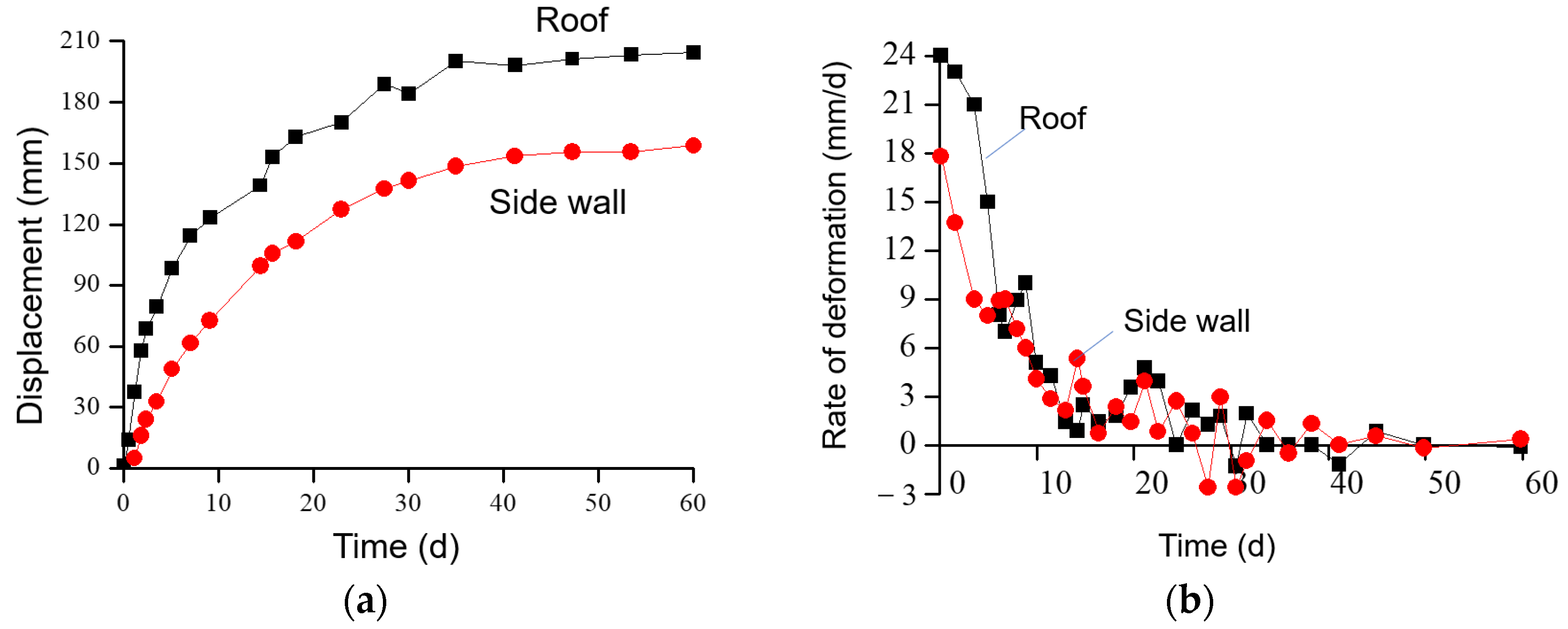

- The engineering test results in Ruineng Coal Mine show that the GERRC technology can be fully realized through intensive drilling technology. The measurement results show that the deformation of the roadway is very small, the maximum deformation of the roof is only about 200 mm, and the maximum deformation of the side wall is only about 150 mm, which ensures the safety of the roadway.

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, L.; Wang, J.; Feng, Y. Life cycle assessment of opencast coal mine production: A case study in Yimin mining area in China. Environ. Sci. Pollut. Res. 2018, 25, 8475–8486. [Google Scholar] [CrossRef]

- Zhu, Z.; He, M.; Wang, X.; Yuan, H. Mechanical Model and Control Technology of Roadside Gangues in Gob-Side Entry Retaining by Roof Cutting. Geotech. Geol. Eng. 2019, 38, 849–860. [Google Scholar] [CrossRef]

- Ju, J.; Xu, J.; Zhu, W. Longwall chock sudden closure incident below coal pillar of adjacent upper mined coal seam under shallow cover in the Shendong coalfield. Int. J. Rock Mech. Min. Sci. 2015, 77, 192–201. [Google Scholar] [CrossRef]

- Lolon, S.A.; Brune, J.F.; Bogin, G.E.; Grubb, J.W.; Saki, S.A.; Juganda, A. Computational fluid dynamics simulation on the longwall gob breathing. Int. J. Min. Sci. Technol. 2017, 27, 185–189. [Google Scholar] [CrossRef]

- Hua, X.Z. Development status and improved proposals on gob-side entry retaining support technology in China. Coal Sci. Technol. 2006, 34, 78–81. [Google Scholar]

- Luan, H.; Jiang, Y.; Lin, H.; Li, G. Development of a New Gob-Side Entry-Retaining Approach and Its Application. Sustainability 2018, 10, 470. [Google Scholar] [CrossRef] [Green Version]

- Kan, J.G.; Wu, J.K.; Zhang, N.; Liang, D.X. Structure stability analysis and control technology of surrounding rock of the secondary gob-side entry retaining. J. Min. Saf. Eng. 2018, 35, 877–884. [Google Scholar] [CrossRef]

- Cheng, Z.H.; Qi, Q.X.; Kong, W.Y.; Zhang, L.; Ji, W.B.; Liu, X.G. Study on the reasonable layout of gob-side remained gateway of lower coal seam close to coal seam group. J. Min. Saf. Eng. 2015, 32, 454–458. [Google Scholar] [CrossRef]

- Podkopaiev, S.; Gogo, V.; Yefremov, I.; Kipko, O.; Iordanov, I.; Simonova, Y. Phenomena of stability of the coal seam roof with a yielding support. Min. Miner. Deposits 2019, 13, 28–41. [Google Scholar] [CrossRef]

- Iordanov, I.; Novikova, Y.; Simonova, Y.; Yefremov, O.; Podkopayev, Y.; Korol, A. Experimental characteristics for deformation properties of backfill mass. Min. Miner. Deposits 2020, 14, 119–127. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Malashkevych, D.; Sai, K.; Bulat, I.; Popovych, V. Granulometric composition research of mine rocks as a material for backfilling the mined-out area in coal mines. Min. Miner. Deposits 2021, 15, 122–129. [Google Scholar] [CrossRef]

- Tang, J.X.; Hu, H.; Tu, X.D.; Deng, Y.H. Experimental on roadside packing gob-side entry retaining for ordinary concrete. J. China Coal Soc. 2010, 35, 1425–1429. [Google Scholar] [CrossRef]

- Li, T.; Chen, G.B.; Qin, Z.C.; Li, Q.H.; Cao, B.; Liu, Y.L. The gob-side entry retaining with the high-water filling material in Xin’an Coal Mine. Geomech. Eng. 2020, 22, 541–552. [Google Scholar] [CrossRef]

- Du, Z.; Chen, S.; Ma, J.; Guo, Z.; Yin, D. Gob-Side Entry Retaining Involving Bag Filling Material for Support Wall Construction. Sustainability 2020, 12, 6353. [Google Scholar] [CrossRef]

- Khairutdinov, A.; Ubysz, A.; Adigamov, A. The concept of geotechnology with a backfill is the path of integrated development of the subsoil. IOP Conf. Ser. Earth Environ. Sci. 2021, 684, 012007. [Google Scholar] [CrossRef]

- Rybak, J.; Kongar-Syuryun, C.; Tyulyaeva, Y.; Khayrutdinov, A.M. Creation of Backfill Materials Based on Industrial Waste. Minerals 2021, 11, 739. [Google Scholar] [CrossRef]

- Huang, W.P.; Gao, Y.F.; Wen, Z.Z.; Gao, L. Technology of gob-side entry retaining using concrete-filled steel tubular column as roadside supporting. J. China Univ. Min. Technol. 2015, 44, 604–611. [Google Scholar]

- Hua, X.Z.; Ma, J.F.; Xu, T.J. Study on controlling mechanism of surrounding rocks of gob-side entry with combination of roadside reinforced cable supporting and roadway bolt supporting, and its application. Chin. J. Rock Mech. Eng. 2005, 24, 2107–2112. [Google Scholar]

- Batugin, A.; Wang, Z.; Su, Z.; Sidikovna, S.S. Combined support mechanism of rock bolts and anchor cables for adjacent roadways in the external staggered split-level panel layout. Int. J. Coal Sci. Technol. 2021, 8, 659–673. [Google Scholar] [CrossRef]

- Han, C.L.; Zhang, N.; Li, B.Y.; Si, G.Y.; Zheng, X.G. Pressure relief and structure stability mechanism of hard roof for gob-side entry retaining. J. Cent. South Univ. 2015, 22, 4445–4455. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.X.; Huang, Y.L.; Yin, W. Failure mechanism and deformation characteristics of gob-side entry retaining in solid backfill mining: A case study. Nat. Resour. Res. 2019, 29, 2513–2527. [Google Scholar] [CrossRef]

- Eremenko, V.A.; Galchenko, Y.P.; Lipnitskiy, N.A.; Umarov, A.R. Frame mine structure for underground mining of thick ore bodies. Gornyi Zhurnal. 2021, 9, 11–18. [Google Scholar] [CrossRef]

- Cao, S.G.; Chen, X.Z.; Yang, H.Y.; Wang, S.; Zou, D.J. Analysis on roadway control technology of gob-side entry retaining and applicable conditions. Coal Sci. Technol. 2016, 44, 27–33. [Google Scholar] [CrossRef]

- He, M.C.; Zhu, G.L.; Guo, Z.B. Longwall mining “cutting cantilever beam theory” and 110 mining method in China: The third mining science innovation. J. Rock Mech. Geotech. Eng. 2015, 7, 483–492. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; He, M.; Guo, S.; Li, J.; Zhou, P.; Zhu, Z. Study on characteristics of pressure relief by roof cutting under nonpillar-mining approach. Bull. Eng. Geol. Environ. 2022, 81, 441. [Google Scholar] [CrossRef]

- Liu, J.; He, M.; Ming, C.; Zhang, J.; Yang, G.; Guo, L.; Guo, S.; Rodriguez-Dono, A.; Zhu, Z. Study on the bearing characteristics of random lumpiness gangue from a gob roof. Bull. Eng. Geol. Environ. 2022, 81, 406. [Google Scholar] [CrossRef]

| Name | Lithology | Thickness (m) |

|---|---|---|

| Main roof | Fine-grained sandstone with mudstone | 13.87~18.19 |

| Immediate roof | Mudstone | 1.65~2.3 |

| Immediate floor | Mudstone | 0.72~2.68 |

| Spacing of Holes/mm | Diameter of Holes/mm | Depth of Holes (m) |

|---|---|---|

| 50 | 100 | 10.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Du, M.; Xi, C.; Yuan, H.; He, W. Mechanics Principle and Implementation Technology of Surrounding Rock Pressure Release in Gob-Side Entry Retaining by Roof Cutting. Processes 2022, 10, 2629. https://doi.org/10.3390/pr10122629

Zhu Z, Du M, Xi C, Yuan H, He W. Mechanics Principle and Implementation Technology of Surrounding Rock Pressure Release in Gob-Side Entry Retaining by Roof Cutting. Processes. 2022; 10(12):2629. https://doi.org/10.3390/pr10122629

Chicago/Turabian StyleZhu, Zhen, Mingqing Du, Chuanhao Xi, Hongping Yuan, and Wenshuai He. 2022. "Mechanics Principle and Implementation Technology of Surrounding Rock Pressure Release in Gob-Side Entry Retaining by Roof Cutting" Processes 10, no. 12: 2629. https://doi.org/10.3390/pr10122629

APA StyleZhu, Z., Du, M., Xi, C., Yuan, H., & He, W. (2022). Mechanics Principle and Implementation Technology of Surrounding Rock Pressure Release in Gob-Side Entry Retaining by Roof Cutting. Processes, 10(12), 2629. https://doi.org/10.3390/pr10122629