Advancements in the Conversion of Lipid-Rich Biowastes and Lignocellulosic Residues into High-Quality Road and Jet Biofuels Using Nanomaterials as Catalysts

Abstract

:1. Introduction

2. Oleochemical and Lignocellulosic Feedstocks

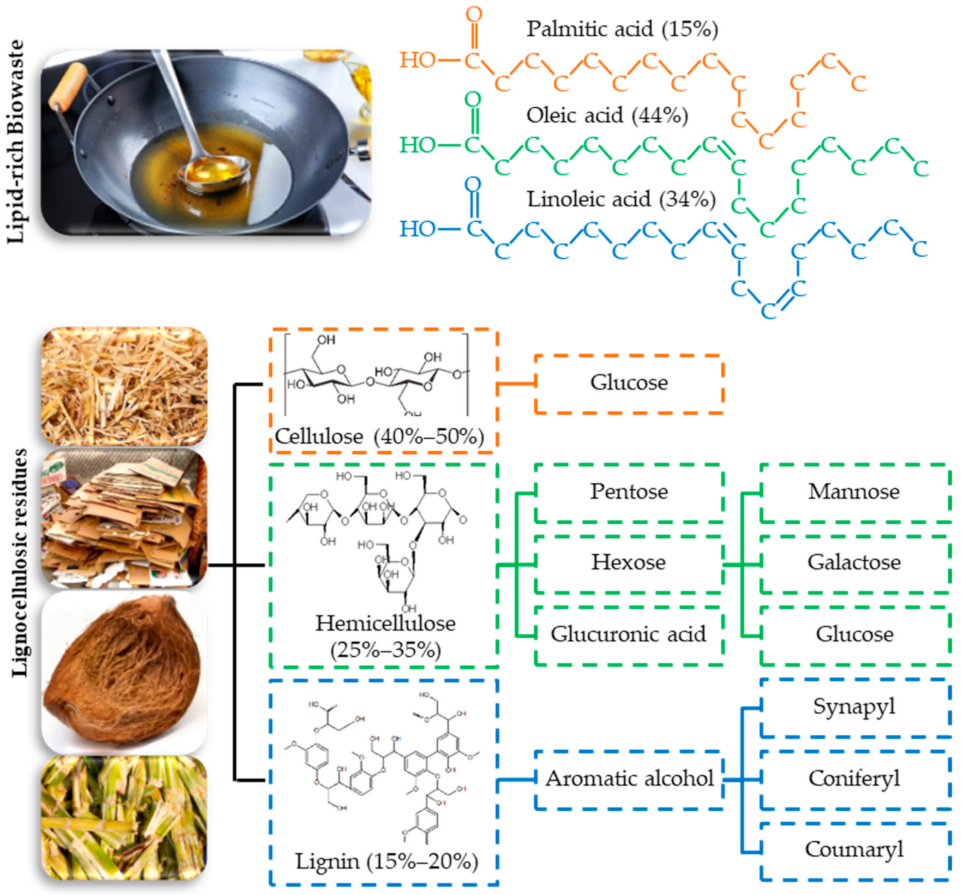

2.1. Vegetable Oils and Lipid-Rich Biowastes

2.2. Lignocellulosic Residues

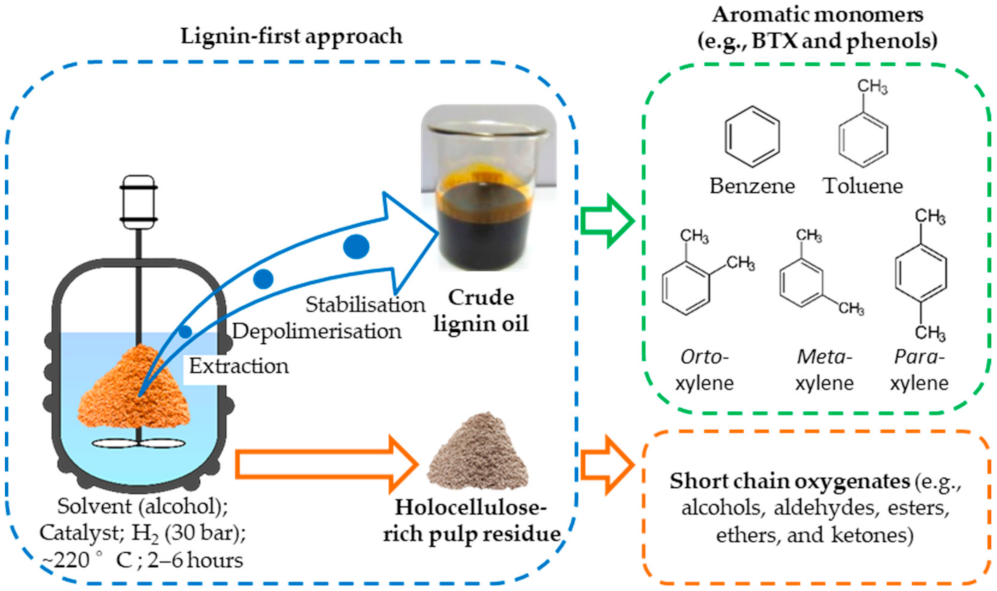

3. Characteristics of Diesel and Jet Biofuels

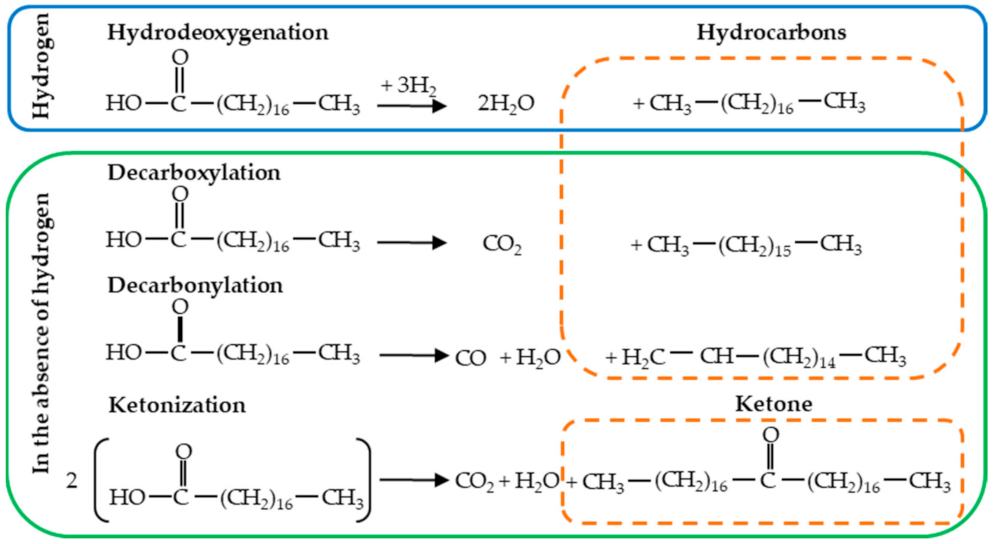

4. Deoxygenation of Oleochemical Feedstocks in a Free-Hydrogen Environment

5. Deoxygenation of Oleochemical Feedstocks Using Nanomaterials as Catalysts

6. Transformation of Lignocellulosic Feedstocks into Value-Added Products

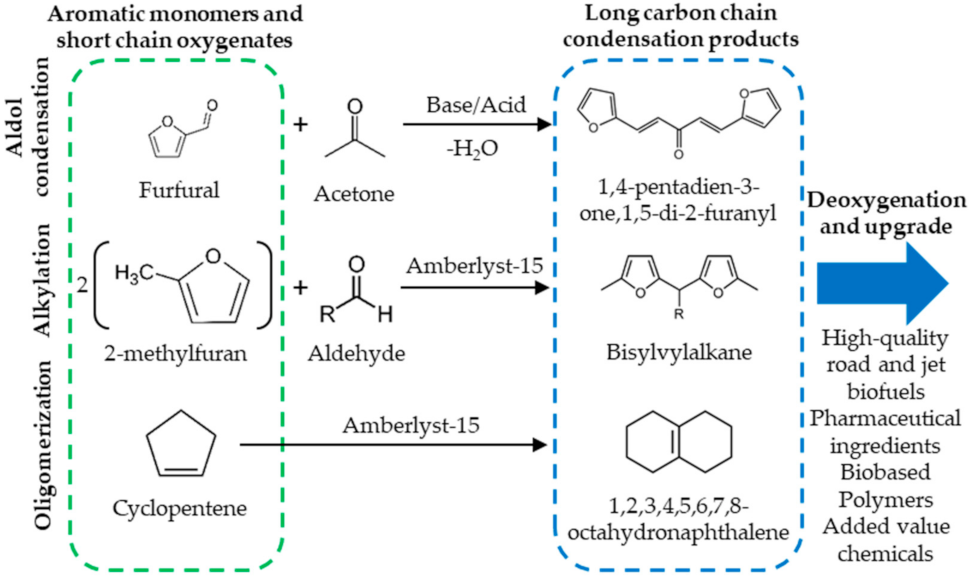

7. Deoxygenation and Upgrade of Lignin Oil and Holocellulose Derivatives into Road and Jet Biofuels

8. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Energy Technology Perspectives 2017, Executive Summary. Available online: https://www.iea.org/reports/energy-technology-perspectives-2017 (accessed on 3 February 2019).

- Olusola, J.O.; Adediran, M.M.; Oluseyi, A.K.; Ajao, U.L. Processing of triglycerides to diesel range hydrocarbon fuels: Easily practicable small-scale approach. Energy Environ. 2009, 20, 1325–1341. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.; Prasad, R. Triglycerides-based diesel fuels. Renew. Sustain. Energy Rev. 2000, 4, 111–113. [Google Scholar] [CrossRef]

- IRENA. Reaching Zero with Renewables: Biojet Fuels, International Renewable Energy Agency; IRENA: Abu Dhabi, United Arab Emirates, 2021; ISBN 978-92-9260-350-2. [Google Scholar]

- Hsu, K.; Wang, W.; Liu, Y. Experimental studies and techno-economic analysis of hydro-processed renewable diesel production in Taiwan. Energy 2018, 164, 99–111. [Google Scholar] [CrossRef]

- Li, H.; Riisager, A.; Saravanamurugan, S.; Pandey, A.; Sangwan, R.; Yang, S.; Luque, R. Carbon-Increasing Catalytic Strategies for Upgrading Biomass into Energy-Intensive Fuels and Chemicals. ACS Catal. 2018, 8, 148–187. [Google Scholar] [CrossRef]

- Wu, L.; Moteki, T.; Gokhale, A.; Flaherty, D.; Toste, F. Production of Fuels and Chemicals from Biomass: Condensation Reactions and Beyond. Chem 2016, 1, 32–58. [Google Scholar] [CrossRef] [Green Version]

- De, S.; Saha, B.; Luque, R. Hydrodeoxygenation processes: Advances on catalytic transformations of biomass-derived platform chemicals into hydrocarbon fuels. Bioresour. Technol. 2015, 178, 108–118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lup, A.; Abnisa, F.; Daud, W.; Aroua, M. A review on reaction mechanisms of metal-catalyzed deoxygenation process in bio-oil model compounds. Appl. Catal. A-Gen. 2017, 541, 87–106. [Google Scholar] [CrossRef]

- Hussein, A. Applications of nanotechnology in renewable energies—A comprehensive overview and understanding. Renew. Sustain. Energy Rev. 2015, 42, 460–476. [Google Scholar] [CrossRef]

- Sekoaia, P.; Moro, N.; Petrus du Preez, S.; Modisha, P.; Engelbrecht, N.; Bessarabov, D.; Ghimire, A. Application of nanoparticles in biofuels: An overview. Fuel 2019, 237, 380–397. [Google Scholar] [CrossRef]

- Shuttleworth, P.; De Bruyn, M.; Parker, H.; Hunt, A.; Budarin, V.; Matharub, A.; Clark, J. Applications of nanoparticles in biomass conversion to chemicals and fuels. Green Chem. 2014, 16, 573–584. [Google Scholar] [CrossRef]

- Buller, S.; Strunk, J. Nanostructure in energy conversion. J. Energy Chem. 2016, 25, 171–190. [Google Scholar] [CrossRef]

- Wang, Y.; De, S.; Yan, N. Rational control of nano-scale metal-catalysts for biomass conversion. Chem. Commun. 2016, 52, 6210–6224. [Google Scholar] [CrossRef] [PubMed]

- Carlsson, A.S. Plant oils as feedstock alternatives to petroleum—A short survey of potential oil crop platforms. Biochimie 2009, 91, 665–670. [Google Scholar] [CrossRef] [PubMed]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Norhasyima, R.S. Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renew. Sustain. Energy Rev. 2011, 15, 3501–3515. [Google Scholar] [CrossRef]

- Sawangkeawa, R.; Ngamprasertsith, S. A review of lipid-based biomasses as feedstocks for biofuels production. Renew. Sustain. Energy Rev. 2013, 25, 97–108. [Google Scholar] [CrossRef]

- No, S.Y. Inedible vegetable oils and their derivatives for alternative diesel fuels in CI engines: A review. Renew. Sustain. Energy Rev. 2011, 15, 131–149. [Google Scholar] [CrossRef]

- Sidibe, S.S.; Blin, J.; Vaitilingom, G.; Azoumah, Y. Use of crude filtered vegetable oil as a fuel in diesel engines state of the art: Literature review. Renew. Sustain. Energy Rev. 2010, 14, 2748–2759. [Google Scholar] [CrossRef]

- Naji, S.Z.; Tye, C.T.; Abd, A.A. State of the art of vegetable oil transformation into biofuels using catalytic cracking technology: Recent trends and future perspectives. Process Biochem. 2021, 109, 148–168. [Google Scholar] [CrossRef]

- Balat, M. Potential alternatives to edible oils for biodiesel production—A review of current work. Energy Convers. Manag. 2011, 52, 1479–1492. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, S. Potential non-edible oil resources as biodiesel feedstock: An Indian perspective. Renew. Sustain. Energy Rev. 2011, 15, 1791–1800. [Google Scholar] [CrossRef]

- Gui, M.M.; Lee, K.T.; Bhatia, S. Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 2008, 33, 1646–1653. [Google Scholar] [CrossRef]

- Pandey, V.C.; Sigh, K.; Sigh, J.S.; Kumar, A.; Singh, B.; Singh, R.P. Jatropha Curcas: A potential biofuel plant for sustainable environmental development. Renew. Sustain. Energy Rev. 2012, 16, 2870–2883. [Google Scholar] [CrossRef]

- Misra, R.D.; Murthy, M.S. Jatropha—The future fuel of India. Renew. Sustain. Energy Rev. 2011, 15, 1350–1359. [Google Scholar] [CrossRef]

- Akbar, E.; Yaakob, Z.; Kamarudin, S.K.; Ismail, M.; Salimon, J. Characteristic and composition of Jatropha Cucars oil seed from Malasya and its potential as biodiesel feedstock. Eur. J. Sci. Res. 2009, 29, 396–403. [Google Scholar]

- Dragone, G.; Fenandez, B.; Vicente, A.; Teixeira, J. Third generation biofuels from microalgae. In Current Research, Technology and Education Topics in Applied Microbiology and Microbial Biotechnology, 1st ed.; Mendez-Vilas, A., Ed.; World Scientific Publishing Company: Singapore, 2009; pp. 1355–1366. [Google Scholar]

- Zainana, N.H.; Srivatsa, S.C.; Lia, F.; Bhattacharya, S. Quality of bio-oil from catalytic pyrolysis of microalgae Chlorella vulgaris. Fuel 2018, 223, 12–19. [Google Scholar] [CrossRef]

- Biodegradable Waste. Available online: https://ec.europa.eu/environment/waste/compost/index.htm (accessed on 5 May 2019).

- Rossini, G.; Toscano, G.; Duca, D.; Corinaldesi, F.; Pedretti, E.F.; Riva, G. Analysis of the characteristics of the tomato manufacturing residues finalized to the energy recovery. Biomass Bioenergy 2013, 51, 177–182. [Google Scholar] [CrossRef]

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-biomethane or biowaste-to-energy? An LCA study on anaerobic digestion of organic waste. J. Clean. Prod. 2018, 174, 462–476. [Google Scholar] [CrossRef]

- Festel, G.; Würmsenher, M.; Rammer, C.; Boles, E.; Bellof, M. Modelling production cost scenarios for biofuels and fossil fuels in Europe. J. Clean. Prod. 2014, 66, 242–253. [Google Scholar] [CrossRef] [Green Version]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef]

- Karkal, S.S.; Kudre, T.G. Valorization of fish discards for the sustainable production of renewable fuels. J. Clean. Prod. 2020, 275, 122985. [Google Scholar] [CrossRef]

- Adeoti, I.A.; Hawboldt, K. A review of lipid extraction from fish processing by-product for use as a biofuel. Biomass Bioenergy 2014, 63, 330–340. [Google Scholar] [CrossRef]

- Thomas, A.; Pedram, F. Tall oil production from black liquor: Challenges and opportunities. Sep. Purif. Technol. 2017, 175, 469–480. [Google Scholar]

- Karmakar, A.; Karmakar, S.; Mukherjee, S. Properties of various plants and animals feedstocks for biodiesel production. Bioresour. Technol. 2010, 101, 7201–7210. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.H.K.; Gan, Y.Y.; Ong, H.C.; Lau, B.F.; Chen, W.H.; Chong, C.T.; Ling, T.C.; Klemes, J.J. Utilization of microalgae for bio-jet fuel production in the aviation sector: Challenges and perspective. Renew. Sustain. Energy Rev. 2021, 149, 111396. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Buffi, M.; Rizzo, A.M.; Lotti, G.; Prussi, M. Bio-hydrocarbons through catalytic pyrolysis of used cooking oils and fatty acids for sustainable jet and road fuel production. Biomass Bioenergy 2016, 95, 424–435. [Google Scholar] [CrossRef]

- Hassen-Trabelsi, A.B.; Kraiem, T.; Naoui, S.; Belayouni, H. Pyrolysis of waste animal fats in fixed-bed reactor: Production and characterization of bio-oil and bio-char. J. Waste Manag. 2014, 34, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Altiparmak, D.; Keskin, A.; Koca, A.; Gürü, M. Alternative fuel properties of tall oil fatty acid methyl ester–diesel fuel blends. Bioresour. Technol. 2007, 98, 241–246. [Google Scholar] [CrossRef] [PubMed]

- Qi, Z.; Jie, C.; Tiejun, W.; Ying, X. Review of biomass pyrolysis oil properties and upgrading research. Energy Convers. Manag. 2007, 48, 87–92. [Google Scholar]

- Varuvel, E.G.; Mrad, N.; Tazerout, M.; Aloui, F. Assessment of liquid fuel (bio-oil) production from waste fish fat and utilization in diesel engine. Appl. Energy 2012, 100, 249–257. [Google Scholar] [CrossRef]

- Malico, I.; Pereira, R.N.; Gonçalves, A.C.; Sousa, A.M.O. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- Anwar, Z.; Gulfraz, M.; Irshad, M. Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: A brief review. J. Radiat. Res. Appl. Sci. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Pari, L.; Toscano, G.; Suardi, A.; Bergonzol, S. Maize cob and cereal chaff: Feedstocks for energy production. In Proceedings of the 26th European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–17 May 2018. [Google Scholar]

- Pizzi, A.; Foppa Pedretti, E.; Duca, D.; Rossini, G.; Mengarelli, C.; Ilari, A.; Mancini, M.; Toscano, G. Emissions of heating appliances fuelled with agropellet produced from vine pruning residues and environmental aspects. Renew. Energy 2018, 121, 513–520. [Google Scholar] [CrossRef]

- Toscano, G.; Riva, G.; Duca, D.; Foppa Pedretti, E.; Corinaldesi, F.; Rossini, G. Analysis of the characteristics of the residues of the wine production chain finalized to their industrial and energy recovery. Biomass Bioenergy 2013, 55, 260–267. [Google Scholar] [CrossRef]

- Alonso, D.M.; Bond, J.Q.; Dumesic, J.A. Catalytic conversion of biomass to biofuels. Green Chem. 2010, 12, 1493–1513. [Google Scholar] [CrossRef]

- Saldarriaga-Hernández, S.; Velasco-Ayala, C.; Leal-Isla Flores, P.; Rostro-Alanis, M.J.; Parra-Saldivar, R.; Iqbal, H.M.N.; Carrillo-Nieves, D. Biotransformation of lignocellulosic biomass into industrially relevant products with the aid of fungi-derived lignocellulolytic enzymes. Int. J. Biol. Macromol. 2020, 161, 1099–1116. [Google Scholar] [CrossRef] [PubMed]

- Poveda-Giraldo, J.A.; Solarte-Toro, J.C.; Cardona-Alzate, C.A. The potential use of lignin as a platform product in biorefineries: A review. Renew. Sustain. Energy Rev. 2021, 138, 110688. [Google Scholar] [CrossRef]

- Bilal, M.; Wang, Z.; Cui, J.; Romanholo Ferreira, L.F.; Bharagava, R.N.; Iqbal, H.M.N. Environmental impact of lignocellulosic wastes and their effective exploitation as smart carriers—A drive towards greener and eco-friendlier biocatalytic systems. Sci. Total Environ. 2022, 722, 137903. [Google Scholar] [CrossRef]

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, S.S.; Zhang, S.; Ok, Y.S.; Matsagar, B.M.; Wu, K.C.W.; Tsang, D.C.W. Advances in lignin valorization towards bio-based chemicals and fuels: Lignin biorefinery. Bioresour. Technol. 2019, 291, 121878. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kothari, R.; Tyagi, V.V. Thermochemical conversion of biomass–eco friendly energy routes. Renew. Sustain. Energy Rev. 2012, 16, 1801–1816. [Google Scholar] [CrossRef]

- Hossain, A.K.; Davies, P.A. Pyrolysis liquids and gases as alternative fuels in internal combustion engines—A review. Renew. Sustain. Energy Rev. 2013, 21, 165–189. [Google Scholar] [CrossRef]

- Van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Bridgwater, A. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Dai, L.; Zhou, N.; Li, H.; Deng, W.; Cheng, Y.; Wang, Y.; Liu, Y.; Cobb, K.; Lei, H.; Chen, P.; et al. Recent advances in improving lignocellulosic biomass-based bio-oil production. J. Anal. Appl. Pyrol. 2020, 149, 104845. [Google Scholar] [CrossRef]

- Wildschut, J.; Arentz, J.; Rasrendra, C.B.; Venderbosch, R.H.; Heeres, H.J. Catalytic hydrotreatment of fast pyrolysis oil: Model studies on reaction pathways for the carbohydrate fraction. Environ. Prog. Sustain. Energy 2009, 28, 450–460. [Google Scholar] [CrossRef] [Green Version]

- Demirbas, M.F.; Balat, M.; Balat, H. Biowastes-to-biofuels. Energy Convers. Manag. 2011, 52, 1815–1828. [Google Scholar] [CrossRef]

- Hernando, H.; Jiménez-Sánchez, S.; Fermoso, J.; Pizarro, P.; Coronado, J.M.; Serrano, D.P. Assessing biomass catalytic pyrolysis in terms of deoxygenation pathways and energy yields for the efficient production of advanced biofuels. Catal. Sci. Technol. 2016, 6, 2829–2843. [Google Scholar] [CrossRef]

- Carmichael, E.; Ghassemieh, E.; Lyons, G. Biorefining of lignocellulosic feedstock and waste materials using ionic liquid. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2020, 262, 114741. [Google Scholar] [CrossRef]

- Ramamoorthy, N.K.; Sambavi, T.R.; Renganathan, S. A study on cellulase production from a mixture of lignocellulosic wastes. Process Biochem. 2019, 83, 148–158. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Jeevanantham, S.; Karishma, S.; Vo, D.V.N. Recent advances and sustainable development of biofuels production from lignocellulosic biomass. Bioresour. Technol. 2022, 344, 126203. [Google Scholar] [CrossRef]

- Kumari, D.; Singh, R. Pretreatment of lignocellulosic wastes for biofuel production: A critical review. Renew. Sustain. Energy Rev. 2018, 90, 877–891. [Google Scholar] [CrossRef]

- Gad, S.C. Diesel Fuel. In Encyclopedia of Toxicology, 2nd ed.; Wexler, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 19–22. [Google Scholar]

- Huth, M.; Heilos, A. Fuel flexibility in gas turbine systems: Impact on burner design and performance. In Modern Gas Turbine Systems; Jansohn, P., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 635–684. [Google Scholar]

- Neste Renewable Diesel Handbook. Available online: https://www.neste.com/sites/neste.com/files/attachments/neste_renewable_diesel_handbook.pdf (accessed on 5 February 2019).

- Knothe, G. Biodiesel and renewable diesel: A comparison. Prog. Energy Combust. Sci. 2010, 36, 364–373. [Google Scholar] [CrossRef]

- Wei, H.; Liu, W.; Chen, X.; Yang, Q.; Li, J.; Chen, H. Renewable bio-jet fuel production for aviation: A review. Fuel 2019, 254, 115599. [Google Scholar] [CrossRef]

- Gutiérrez-Antonio, C.; Gómez-Castro, F.I.; De Lira-Floresa, J.A.; Hernández, S. A review on the production processes of renewable jet fuel. Renew. Sustain. Energy Rev. 2017, 79, 709–729. [Google Scholar] [CrossRef]

- Duong, L.H.; Fujita, O.; Reksowardoj, I.K.; Soerawidjaja, T.H.; Neonufa, G.F. Experimental investigation of the effects of cycloparaffins and aromatics on the sooting tendency and the freezing point of soap-derived biokerosene and normal paraffins. Fuel 2016, 185, 855–862. [Google Scholar] [CrossRef]

- Blakey, S.; Rye, L.; Wilson, C.W. Aviation gas turbine alternative fuels: A review. Proc. Combust. Inst. 2011, 33, 2863–2885. [Google Scholar] [CrossRef]

- Al-Nuaimi, I.A.; Bohra, M.; Selam, M.; Choudhury, H.A.; El-Halwagi, M.M.; Elbashir, N.O. Optimization of the Aromatic/Paraffinic Composition of Synthetic Jet Fuels. Chem. Eng. Technol. 2016, 39, 2217–2228. [Google Scholar] [CrossRef]

- Khan, S.; Lup, A.N.K.; Qureshi, K.M.; Abnisa, F.; Daud, W.M.A.W.; Patah, M.F.A. A review on deoxygenation of triglycerides for jet fuel range hydrocarbons. J. Anal. Appl. Pyrolysis 2019, 140, 1–24. [Google Scholar] [CrossRef]

- Why, E.S.K.; Ong, H.C.; Lee, H.V.; Gan, Y.Y.; Chen, W.H.; Chong, C.T. Renewable aviation fuel by advanced hydroprocessing of biomass: Challenges and perspective. Energy Convers. Manag. 2019, 199, 112015. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Chong, C.T.; Ge, Y.; Ong, H.C.; Ng, J.H.; Tian, B.; Ashokkumar, V.; Lim, S.; Seljak, T.; J’ozsa, V. Progress in utilisation of waste cooking oil for sustainable biodiesel and biojet fuel production. Energy Convers. Manag. 2020, 223, 113296. [Google Scholar] [CrossRef]

- Lokesh, K.; Sethi, V.; Nikolaidis, T.; Goodger, E.; Nalianda, D. Life cycle greenhouse gas analysis of biojet fuels with a technical investigation into their impact on jet engine performance. Biomass Bioenergy 2015, 77, 26–44. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.K.; Han, J.H.; Lee, H.; Yum, T.; Kim, Y.; Kim, J. Production of renewable diesel via catalytic deoxygenation of natural triglycerides: Comprehensive understanding of reaction intermediates and hydrocarbons. Appl. Energy 2014, 116, 199–205. [Google Scholar] [CrossRef]

- Gosselink, R.W.; Hollak, S.A.W.; Chang, S.; Haveren, J.; Jong, K.P.; Bitter, J.H.; Es, D.S. Reaction Pathways for the Deoxygenation of Vegetable Oils and Related Model Compounds. ChemSusChem 2013, 6, 1576–1594. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Tomas, B.; Renz, M.; Corma, A. Ketone Formation from Carboxylic Acids by Ketonic Decarboxylation: The Exceptional Case of the Tertiary Carboxylic Acids. Chem. Eur. J. 2017, 23, 12900–12908. [Google Scholar] [CrossRef] [PubMed]

- Romero, M.; Pizzi, A.; Toscano, G.; Casazza, A.; Busca, G.; Bosio, B.; Arato, E. Deoxygenation of Non-Edible Vegetable Oil to Produce Hydrocarbons Over Mg-Al Mixed Oxides. Chem. Eng. Trans. 2018, 64, 121–126. [Google Scholar]

- Pattanaik, B.P.; Misra, R.D. Experimental studies on production of deoxygenated vegetable oils and their performance evaluation in a compression ignition engine. Biomass Convers. Biorefin. 2018, 8, 899–908. [Google Scholar] [CrossRef]

- Lup, A.N.K.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. A review on reactivity and stability of heterogeneous metal catalysts for deoxygenation of bio-oil model compounds. J. Ind. Eng. Chem. 2017, 56, 1–34. [Google Scholar] [CrossRef]

- Ooi, X.Y.; Gao, W.; Ong, H.C.; Lee, H.V.; Juan, J.C.; Chen, W.H.; Lee, K.T. Overview on catalytic deoxygenation for biofuel synthesis using metal oxide supported catalysts. Renew. Sustain. Energy Rev. 2019, 112, 834–852. [Google Scholar] [CrossRef]

- Santillan-Jimenez, E.; Crocker, M. Catalytic deoxygenation of fatty acids and their derivatives to hydrocarbon fuels via decarboxylation/decarbonylation. J. Chem. Technol. Biotechnol. 2012, 87, 1041–1050. [Google Scholar] [CrossRef]

- Romero, M.; Pizzi, A.; Toscano, G.; Bosio, B.; Arato, E. Study of an innovative process for the production of biofuels using non-edible vegetable oils. Chem. Eng. Trans. 2014, 37, 883–888. [Google Scholar]

- Romero, M.; Pizzi, A.; Toscano, G.; Casazza, A.; Busca, G.; Bosio, B.; Arato, E. Preliminary experimental study on biofuel production by deoxygenation of Jatropha oil. Fuel Process. Technol. 2015, 137, 31–37. [Google Scholar] [CrossRef]

- Romero, M.; Pizzi, A.; Toscano, G.; Busca, G.; Bosio, B.; Arato, E. Deoxygenation of waste cooking oil and non-edible oil for the production of liquid hydrocarbon biofuels. J. Waste Manag. 2016, 47, 62–68. [Google Scholar] [CrossRef] [PubMed]

- Abidin, S.N.Z.; Lee, H.V.; Asikin-Mijan, N.; Juan, J.C.; Rahman, N.A.; Mastuli, M.S.; Taufiq-Yap, Y.H.; Kong, P.S. Ni, Zn and Fe hydrotalcite-like catalysts for catalytic biomass compound into green biofuel. Pure Appl. Chem. 2019, 92, 587–600. [Google Scholar] [CrossRef]

- Morgan, T.; Santillan-Jimenez, E.; Harman-Ware, A.E.; Ji, Y.; Grubb, D.; Crocker, M. Catalytic deoxygenation of triglycerides to hydrocarbons over supported nickel catalysts. Chem. Eng. J. 2012, 189, 346–355. [Google Scholar] [CrossRef]

- Asikin-Mijana, N.; Lee, H.V.; Marliza, T.S.; Taufiq-Yap, Y.H. Pyrolytic-deoxygenation of triglycerides model compound and non-edible oil to hydrocarbons over SiO2-Al2O3 supported NiO-CaO catalysts. J. Anal. Appl. Pyrol. 2018, 129, 221–230. [Google Scholar] [CrossRef]

- Asikin-Mijana, N.; Lee, H.V.; Juana, J.C.; Noorsaadah, A.R.; Ong, H.C.; Razali, S.M.; Taufiq-Yap, Y.H. Promoting deoxygenation of triglycerides via Co-Ca loaded SiO2-Al2O3 Catalyst. Appl. Catal. A-Gen. 2018, 552, 38–48. [Google Scholar] [CrossRef]

- Gamala, M.S.; Asikin-Mijana, N.; Arumugama, M.; Rashidc, U.; Taufiq-Yap, Y.H. Solvent-free catalytic deoxygenation of palm fatty acid distillate over cobalt and manganese supported on activated carbon originating from waste coconut shell. J. Anal. Appl. Pyrol. 2019, 144, 104690. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Ooi, J.M.; AbdulKareem-Alsultan, G.; Lee, H.V.; Mastuli, M.S.; Mansir, N.; Alharthi, F.A.; Alghamdi, A.A.; Taufiq-Yap, Y.H. Free-H2 deoxygenation of Jatropha curcas oil into cleaner diesel-grade biofuel over coconut residue-derived activated carbon catalyst. J. Clean. Prod. 2020, 249, 119381. [Google Scholar] [CrossRef]

- Choi, I.; Lee, J.; Kim, C.; Kim, T.; Lee, K.; Hwang, K. Production of bio-jet fuel range alkanes from catalytic deoxygenation of Jatropha fatty acids on a WOx/Pt/TiO2 catalyst. Fuel 2018, 215, 675–685. [Google Scholar] [CrossRef]

- Abdulkareem-Alsultan, G.; Asikin-Mijan, N.; Lee, H.V.; Rashid, U.; Islam, A.; Taufiq-Yap, Y.H. A review on thermal conversion of plant oil (edible and inedible) into green fuel using carbon-based nanocatalyst. Catalysts 2019, 9, 350. [Google Scholar] [CrossRef] [Green Version]

- Lopez-Ruiz, J.A.; Davis, R.J. Decarbonylation of heptanoic acid over carbon-supported platinum nanoparticles. Curr. Green Chem. 2014, 16, 683–694. [Google Scholar] [CrossRef]

- Lopez-Ruiz, J.A.; Pham, H.N.; Datye, A.K.; Davis, R.J. Reactivity and stability of supported Pd nanoparticles during the liquid-phase and gas-phase decarbonylation of heptanoic acid. Appl. Catal. A-Gen. 2015, 504, 295–307. [Google Scholar] [CrossRef]

- Ahmad, M.; Farhana, R.; Raman, A.A.A.; Bhargava, S.K. Synthesis and activity evaluation of heterometallic nano oxides integrated ZSM-5 catalysts for palm oil cracking to produce biogasoline. Energy Convers. Manag. 2016, 119, 352–360. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Lee, H.; Taufiq-Yap, Y.; Juan, J.; Rahman, N.A. Pyrolytic–deoxygenation of triglyceride via natural waste shell derived Ca(OH)2 nanocatalyst. J. Anal. Appl. Pyrol. 2016, 117, 46–55. [Google Scholar] [CrossRef]

- Alsultan, A.; Asikin-Mijan, N.; Lee, H.; Albazzaz, A.; Taufiq-Yap, Y. Deoxygenation of waste cooking to renewable diesel over walnut shell derived nanorode activated carbon supported CaO-La2O3 catalyst. Energy Convers. Manag. 2017, 151, 311–323. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Lee, H.; Abdulkareem-Alsultan, G.; Afandi, A.; Taufiq-Yap, Y.H. Production of green diesel via cleaner catalytic deoxygenation of Jatropha curcas oil. J. Clean. Prod. 2017, 167, 1048–1059. [Google Scholar] [CrossRef]

- Asikin-Mijana, N.; Rosman, N.A.; Abdulkareem-Alsultan, G.; Mastulid, M.S.; Lee, H.V.; Nabihah-Fauzi, N.; Lokmand, I.M.; Alharthi, F.A.; Alghamdig, A.A.; Aisyahig, A.A.; et al. Production of renewable diesel from Jatropha curcas oil via pyrolytic-deoxygenation over various multi-wall carbon nanotube-based catalysts. Process Saf. Environ. Prot. 2020, 142, 336–349. [Google Scholar] [CrossRef]

- Abdulkareem-Alsultan, G.; Asikin-Mijana, N.; Mansira, N.; Lee, H.; Zainal, Z.; Islam, A.; Taufiq-Yap, Y.H. Pyro-lytic de-oxygenation of waste cooking oil for green diesel production over Ag2O3-La2O3/AC nano-catalyst. J. Anal. Appl. Pyrol. 2019, 137, 171–184. [Google Scholar] [CrossRef]

- Ouyang, X.; Huang, X.; Hendriks, B.; Boot, M.; Hensen, E. Coupling organosolv fractionation and reductive depolymerization of woody biomass in a two-step catalytic process. Green Chem. 2018, 20, 2308. [Google Scholar] [CrossRef] [Green Version]

- Renders, T.; Van den Bosch, S.; Koelewijn, S.; Schutyser, W.; Sels, B. Lignin-first biomass fractionation: The advent of active stabilisation strategies. Energy Environ. Sci. 2017, 10, 1551–1557. [Google Scholar] [CrossRef]

- Renders, T.; Den Bossche, G.V.; Vangeel, T.; Van Aelst, K.; Sels, B. Reductive catalytic fractionation: State of the art of the lignin-first biorefinery. Curr. Opin. Biotechnol. 2019, 56, 193–201. [Google Scholar] [CrossRef]

- Paone, E.; Tabanelli, T.; Mauriello, F. The rise of lignin biorefinery. Curr. Opin. Green Sustain. Chem. 2020, 24, 1–6. [Google Scholar] [CrossRef]

- Parsell, T.; Yohe, S.; Degenstein, J.; Jarrell, T.; Klein, I.; Gencer, E.; Hewetson, B.; Hurt, M.; Kim, J.; Choudhari, H.; et al. A synergistic biorefinery based on catalytic conversion of lignin prior to cellulose starting from lignocellulosic biomass. Green Chem. 2015, 17, 1492. [Google Scholar] [CrossRef]

- Carrozza, C.F.; Leonardi, G.; Vasso, M.; Gelfi, C.; Serafini, A.; Gambarotti, C.; Citterio, A.; Sebastiano, R. Novel in-situ preparation of nano sized Ni (0) catalyst for depolymerization of lignin-rich waste from industrial biorefinery. Bioresour. Technol. Rep. 2020, 10, 100355. [Google Scholar] [CrossRef]

- Kouris, P.; Oevering, H.; Boot, M.D.; Hensen, E.J.M. An integrated lignin biorefinery: Scaling-up lignin depolymerization technology for biofuels and chemicals. In Proceedings of the NOVACAM Winter School, Padua, Italy, 22–23 February 2017. [Google Scholar]

- Busca, G. Production of Gasolines and Monocyclic Aromatic Hydrocarbons: From Fossil Raw Materials to Green Processes. Energies 2021, 14, 4061. [Google Scholar] [CrossRef]

- Wang, H.; Pu, Y.; Ragauskas, A.; Yang, B. From lignin to valuable products–strategies, challenges, and prospects. Bioresour. Technol. 2019, 271, 449–461. [Google Scholar] [CrossRef] [PubMed]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From Fundamentals to Advanced Applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef] [PubMed]

- Barbash, V.A.; Yaschenko, O.V.; Shniruk, O.M. Preparation and Properties of Nanocellulose from Organosolv Straw Pulp. Nanoscale Res. Lett. 2017, 12, 241. [Google Scholar] [CrossRef] [Green Version]

- Poyraz, B.; Tozluoğlu, A.; Candan, Z.; Demir, A.; Yavuz, M.; Büyuksarı, Ü.; Ünal, H.İ.; Fidan, H.; Saka, R.C. TEMPO-treated CNF Composites: Pulp and Matrix Effect. Fibers Polym. 2018, 19, 195–204. [Google Scholar] [CrossRef]

- Poyraz, B.; Tozluoğlu, A.; Candan, Z.; Demir, A. Matrix impact on the mechanical, thermal and electrical properties of microfluidized nanofibrillated cellulose composites. J. Polym. Eng. 2017, 37, 921–931. [Google Scholar] [CrossRef]

- Reshmy, R.; Philip, E.; Madhavan, A.; Tarfdar, A.; Sindhu, R.; Binod, P.; Sirohi, R.; Awasthi, M.K.; Pandey, A. Biorefinery aspects for cost-effective production of nanocellulose and high value-added biocomposites. Fuel 2021, 122575. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, J.; Korányi, T.; Boot, M.; Hensen, E. Effective Release of Lignin Fragments from Lignocellulose by Lewis Acid Metal Triflates in the Lignin-First Approach. ChemSusChem 2016, 9, 3262–3267. [Google Scholar] [CrossRef]

- Huang, X.; Ouyang, X.; Hendriks, B.M.S.; Morales Gonzalez, O.M.; Zhu, J.; Korányi, T.I.; Boot, M.D.; Hensen, E.J.M. Selective production of mono-aromatics from lignocellulose over Pd/C catalyst: The influence of acid co-catalysts. Faraday Discuss. 2017, 202, 141. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Morales Gonzalez, O.M.; Zhu, J.; Korányi, X.T.I.; Boot, M.D.; Hensen, E.J.M. Reductive fractionation of woody biomass into lignin monomers and cellulose by tandem metal triflate and Pd/C catalysis. Green Chem. 2017, 19, 175. [Google Scholar] [CrossRef]

- Ouyang, X.; Huang, X.; Zhu, J.; Boot, M.; Hensen, E.J.M. Catalytic Conversion of Lignin in Woody Biomass into Phenolic Monomers in Methanol/Water Mixtures without External Hydrogen. ACS Sustain. Chem. Eng. 2019, 7, 13764–13773. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Atay, C.; Zhu, J.; Palstra, S.; Korányi, T.; Boot, M.; Hensen, E.J.M. Catalytic Depolymerization of Lignin and Woody Biomass in Supercritical Ethanol: Influence of Reaction Temperature and Feedstock. ACS Sustain. Chem. Eng. 2017, 5, 10864–10874. [Google Scholar] [CrossRef] [PubMed]

- Kouris, P.; Boot, M.; Hensen, E. Setting up the base for the first lignin biorefinery: From lignin to biofuels and chemicals. In Proceedings of the XVIIIth Netherlands Catalysis and Chemistry Conference (NCCC XVIII), Noordwijkerhout, The Netherlands, 6–8 March 2017. [Google Scholar]

- Kouris, P.; Huang, X.; Boo, M.; Hensen, E. Scaling-Up Catalytic Depolymerisation of Lignin: Performance Criteria for Industrial Operation. Top. Catal. 2018, 61, 1901–1911. [Google Scholar] [CrossRef] [Green Version]

- Sudarsanam, P.; Zhong, R.; Van den Bosch, S.; Coman, S.; Parvulescu, V.; Sels, B. Functionalised heterogeneous catalysts for sustainable biomass valorisation. Chem. Soc. Rev. 2018, 47, 8349–8402. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Wang, H.; Liu, F.; Wang, L.; He, H. Magnetic core–shell Fe3O4@C-SO3H nanoparticle catalyst for hydrolysis of cellulose. Cellulose 2013, 20, 127–134. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Z.; Liu, B. Catalytic Conversion of Fructose and 5-Hydroxymethylfurfural into 2,5-Furandicarboxylic Acid over a Recyclable Fe3O4−CoOx Magnetite Nanocatalyst. ACS Sustain. Chem. Eng. 2015, 3, 406–412. [Google Scholar] [CrossRef]

- Ferrini, P.; Rinaldi, R. Catalytic Biorefining of Plant Biomass to Non-Pyrolytic Lignin Bio-Oil and Carbohydrates through Hydrogen Transfer Reactions. Angew. Chem. 2014, 53, 8634–8639. [Google Scholar] [CrossRef]

- Dantas, J.; Leal, E.; Cornejo, D.; Kiminami, R.; Costa, A. Biodiesel production evaluating the use and reuse of magnetic nanocatalysts Ni0.5Zn0.5Fe2O4 synthesized in pilot-scale. Arab. J. Chem. 2020, 13, 3026–3042. [Google Scholar] [CrossRef]

- Corma, A.; Renz, M.; Schaverien, C. Coupling fatty acids by ketonic decarboxylation using solid catalysts for the direct production of diesel, lubricants, and chemicals. ChemSusChem 2008, 1, 739–741. [Google Scholar] [CrossRef] [PubMed]

- Simakova, I.; Murzin, D.Y. Transformation of bio-derived acids into fuel-like alkanes via ketonic decarboxylation and hydrodeoxygenation: Design of multifunctional catalyst, kinetic and mechanistic aspects. J. Energy Chem. 2016, 25, 208–224. [Google Scholar] [CrossRef]

- Mäki-Arvela, P.; Rozmysłowicz, B.; Lestari, S.; Simakova, O.; Eränen, K.; Salmi, T.; Murzin, D.Y. Catalytic deoxygenation of tall oil fatty acid over palladium supported on mesoporous carbon. Energy Fuels 2011, 25, 2815–2825. [Google Scholar] [CrossRef]

- Lu, Y.; Ma, B.; Zhao, C. Integrated Production of Bio-Jet Fuel Containing Lignin-derived Arenes via Lipid Deoxygenation. Chem. Commun. 2018, 54, 9829–9832. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Li, N.; Wang, X.; Sheng, X.; Li, S.; Wang, A.; Cong, Y.; Wang, X.; Zhang, T. Synthesis of Diesel or Jet Fuel Range Cycloalkanes with 2-Methylfuran and Cyclopentanone from Lignocellulose. Energy Fuels 2014, 28, 5112–5118. [Google Scholar] [CrossRef]

- Nie, G.; Zhang, X.; Pan, L.; Han, P.; Xie, J.; Li, Z.; Xie, J.; Zou, J. Hydrogenated intramolecular cyclization of diphenylmethane derivatives for synthesizing high-density biofuel. Chem. Eng. Sci. 2017, 173, 91–97. [Google Scholar] [CrossRef]

- Li, Z.; Pan, L.; Nie, G.; Xie, J.; Xie, J.; Zhang, X.; Wang, L.; Zou, J. Synthesis of high-performance jet fuel blends from biomass-derived 4-ethylphenol and phenylmethanol. Chem. Eng. Sci. 2018, 191, 343–349. [Google Scholar] [CrossRef]

- Chen, F.; Li, N.; Yang, X.; Li, L.; Li, G.; Li, S.; Wang, W.; Hu, Y.; Wang, A.; Cong, Y.; et al. Synthesis of High-Density Aviation Fuel with Cyclopentanol. ACS Sustain. Chem. Eng. 2016, 4, 6160–6166. [Google Scholar] [CrossRef]

- Pan, L.; Xie, J.; Nie, G.; Li, Z.; Zhang, X.; Zou, J. Zeolite catalytic synthesis of high-performance jet-fuel-range spiro-fuel by one-pot Mannich–Diels–Alder reaction. AIChE J. 2020, 66, e16789. [Google Scholar] [CrossRef]

- Yu, B.Y.; Tsai, C.C. Rigorous simulation and techno-economic analysis of a bio-jet-fuel intermediate production process with various integration strategies. Chem. Eng. Res. Des. 2020, 159, 47–65. [Google Scholar] [CrossRef]

- Bond, J.Q.; Upadhye, A.A.; Olcay, H.; Tompsett, G.A.; Jae, J.; Xing, R.; Alonso, D.M.; Wang, D.; Zhang, T.; Kumar, R.; et al. Production of renewable jet fuel range alkanes and commodity chemicals from integrated catalytic processing of biomass. Energy Environ. Sci. 2014, 7, 1500–1523. [Google Scholar] [CrossRef]

- Olcay, H.; Malina, R.; Upadhye, A.A.; Hileman, J.I.; Huber, G.W.; Barrett, S.R.H. Techno-economic and environmental evaluation of producing chemicals and drop-in aviation biofuels via aqueous phase processing. Energy Environ. Sci. 2018, 11, 2085–2101. [Google Scholar] [CrossRef] [Green Version]

- Corma, A.; De la Torre, O.; Renz, M.; Villandier, N. Production of High-Quality Diesel from Biomass Waste Products. Angew. Chem. Int. 2011, 50, 2375–2378. [Google Scholar] [CrossRef] [PubMed]

| Properties and Composition | Jatropha curcas Oil [37] | Microalgae Chlorella sp. [38] | WCO [39] | Swine Fatty Wastes [40] | Crude Tall Oil [41] | Wood Bio-Oil [42] | Waste Fish Oil [43] |

|---|---|---|---|---|---|---|---|

| Density (g/cm3) | 0.94 | - | 0.91 | - | - | - | 0.89 |

| Viscosity | 33.90 cSt at 40 °C | - | 38.15 cSt at 40 °C | - | 55.00 cSt at 70 °C | 40–100 cP at 50 °C | 27.00 cSt |

| HHV (MJ/kg) | 38.65 | 19.44 | 38.91 | - | 39.75 | 16–19 | 39.00 |

| Moisture content (wt.%) | - | 4.13 | 0.08 | - | 5.20 | 15–30 | <0.05 |

| Acid value (mg KOH g−1) | - | - | 263.00 | - | 157.70 | - | - |

| Fatty acid (%) | |||||||

| Myristic acid (C14:0) | 0.50–1.40 | 1.62 | 0.40 | - | - | - | 1.05 |

| Palmitic acid (C16:0) | 12.00–17.00 | 16.46 | 15.11 | 16.00 | - | - | 16.00 |

| Palmitoleic acid (C16:1) | - | - | - | - | - | - | 5.00 |

| Stearic acid (C18:0) | 5.00–9.50 | 3.27 | 3.96 | 11.00 | 2.10 | - | 10.50 |

| Oleic acid (C18:1) | 37.00–63.00 | 14.64 | 43.43 | 18.00 | 52.70 | - | 45.60 |

| Linoleic acid (C18:2) | 19.00–41.00 | 20.61 | 33.93 | - | 38.30 | - | 20.60 |

| Linolenic acid (C18:3) | - | 15.35 | 0.34 | - | 6.90 | - | - |

| Behenic acid (C22:0) | - | - | - | 10.00 | - | - | - |

| Others | - | 7.41 | 3.24 | 45.00 | - | - | - |

| Element (wt.%) | |||||||

| C | - | 44.93 | 76.30 | 65.38 | - | 54.00–58.00 | - |

| H | - | 6.42 | 11.70 | 11.32 | - | 5.50–7.00 | - |

| O | - | 40.67 | 11.98 | 21.99 | - | 35.00–40.00 | - |

| N | - | 6.41 | 0.02 | 0.58 | - | 0.00–0.20 | - |

| Lignocellulosic Residue | Cellulose (wt.%) | Hemicellulose (wt.%) | Lignin (wt.%) |

|---|---|---|---|

| Wheat straw [62] | 37.80 | 27.50 | 34.70 |

| Grass [63] | 32.50 | 19.93 | 3.10 |

| Willow [63] | 45.34 | 12.78 | 16.77 |

| Waste cardboard [64] | 12.50 | 45.00 | 35.00 |

| Rice straw [65] | 28.00 | 32.15 | 19.64 |

| Sorghum bagasse [65] | 31.28 | 34.80 | 24.77 |

| Coconut husk [65] | 17.33 | 21.26 | 46.36 |

| Olive tree pruning [65] | 25.70 | 41.00 | 21.80 |

| Groundnut shell [65] | 27.62 | 38.31 | 21.10 |

| Hardwood [65] | 40.00–46.00 | 24.50–36.00 | 20.00–26.00 |

| Softwood [65] | 39.5–42.00 | 23.00–30.60 | 24.00–27.50 |

| Corn cobs [66] | 33.60 | 37.20 | 19.30 |

| Newspaper [66] | 40.00–55.00 | 25.00–40.00 | 18.00–30.00 |

| Sugarcane bagasse [66] | 45.00 | 20.00 | 30.00 |

| Properties | Diesel Fuel (EN 590) [69] | Renewable Diesel [69] | Jet A (ASTM D1655) [76,78] | Bio-SPK (ASTM D7566) [76,78] | Bio-SPK from Jatropha c. [79] |

|---|---|---|---|---|---|

| Acidity (mg KOH/g) | - | - | <0.100 | <0.015 | - |

| Final BP (°C) | - | - | 300.00 | 25.00 | 254.90 |

| Flash point (°C) | >55.00 | >70.00 | >38.00 | >38.00 | 46.50 |

| Density at 15 °C (Kg/m3) | 820.00–845.00 | 780.00 | 775.00–840.00 | 730.00–772.00 | 749.00 |

| Freezing point (°C) | ≤10.00–≤ 34.00 | Severe winter grades available | <−40.00 | <−40.00 | <−54.50 |

| Viscosity (mm2/s) | 1.20–4.50 | 3.00 (at 40 °C) | <8.00 (at−20 to −35.5 °C) | <8.00 | 3.66 (at−20 °C) |

| Net heat of combustion (MJ/kg) | ~43.00 | ~44.00 | 43.28 | 42.80 | 44.30 |

| Smoke point (mm) | - | - | Min 25.00 | - | 53.00 |

| Distillation (°C), initial boiling point | - | 200.00 | - | - | 164.50 |

| FAME content | ≤7.00% (V/V) | 0.00% (V/V) | - | Max 5.00 (ppm) | - |

| Lubricity (mm) | ≤46.00 | ~65.00 | Max 0.85 | Max 0.85 | 0.76 |

| Sulphur | ≤10.00 | <5.00 (mg/kg) | Max 0.30 (total mass %) | - | 0.00 |

| Cetane number | >51.00 | >70.00 | - | - | - |

| Antioxidants (mg/L) | - | - | Max 24 (not including weight of solvent) | 17.00 to 24.00 | - |

| Aromatics | from 15% to 30% but not regulated by EN 590 | Below detection limit | 18.53 (wt. %) | 26.50 (vol%) | - |

| n-Paraffins (wt.%) | - | - | 19.98 | - | - |

| Cycloparaffins (wt.%) | - | - | 31.80 | - | - |

| iso-Paraffins (wt.%) | - | - | 29.69 | - | - |

| Material | Consumption | Unit Cost (USD Per Unit) |

|---|---|---|

| Feedstock | 25,000.00 kg/hr | 0.80/kg |

| Natural gas | 35,527.00 MJ/h | 0.39/m3 |

| Cooling water | 345,700.00 kg/hr | 0.41/m3 |

| Electricity | 2496.76 kWh | 0.07/kWh |

| Hydrogen | 676.84 kg/hr | 3.51/kg |

| Hydroprocessing catalyst | 25,000.00 kg/year | 3266.10/kg |

| Hydrocracking catalyst | 5991.34 kg/year | 5935.39/kg |

| Wastewater treatment chemicals | 21.75 kg/hr | 6.81/kg |

| Propane | 1771.55 kg/hr (production) | 1.00/kg |

| Heavy oil | 809.10 kg/hr (production) | 0.60/kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero, M.J.A.; Duca, D.; Toscano, G. Advancements in the Conversion of Lipid-Rich Biowastes and Lignocellulosic Residues into High-Quality Road and Jet Biofuels Using Nanomaterials as Catalysts. Processes 2022, 10, 187. https://doi.org/10.3390/pr10020187

Romero MJA, Duca D, Toscano G. Advancements in the Conversion of Lipid-Rich Biowastes and Lignocellulosic Residues into High-Quality Road and Jet Biofuels Using Nanomaterials as Catalysts. Processes. 2022; 10(2):187. https://doi.org/10.3390/pr10020187

Chicago/Turabian StyleRomero, Max J. A., Daniele Duca, and Giuseppe Toscano. 2022. "Advancements in the Conversion of Lipid-Rich Biowastes and Lignocellulosic Residues into High-Quality Road and Jet Biofuels Using Nanomaterials as Catalysts" Processes 10, no. 2: 187. https://doi.org/10.3390/pr10020187

APA StyleRomero, M. J. A., Duca, D., & Toscano, G. (2022). Advancements in the Conversion of Lipid-Rich Biowastes and Lignocellulosic Residues into High-Quality Road and Jet Biofuels Using Nanomaterials as Catalysts. Processes, 10(2), 187. https://doi.org/10.3390/pr10020187