Catalytic Transformation of Biomass-Derived Glucose by One-Pot Method into Levulinic Acid over Na-BEA Zeolite

Abstract

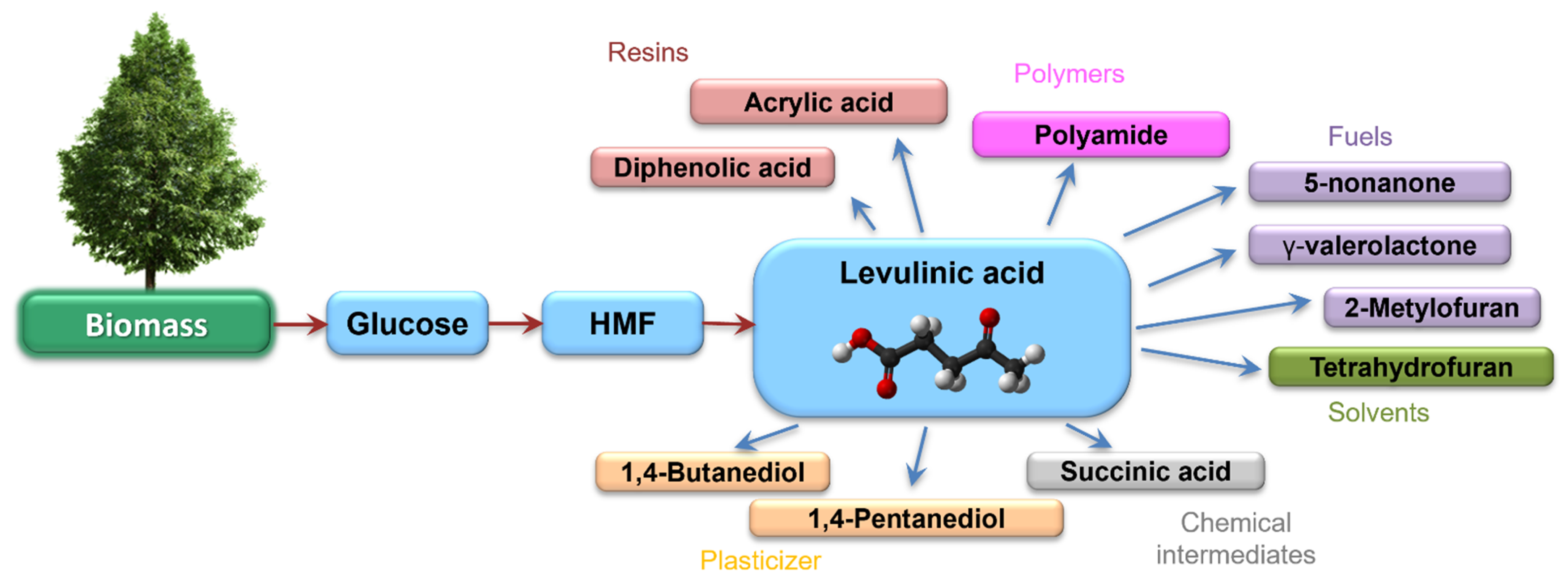

:1. Introduction

2. Materials and Methods

2.1. Catalytic Material

2.2. Characterization Methods

2.3. Catalytic Tests

3. Results

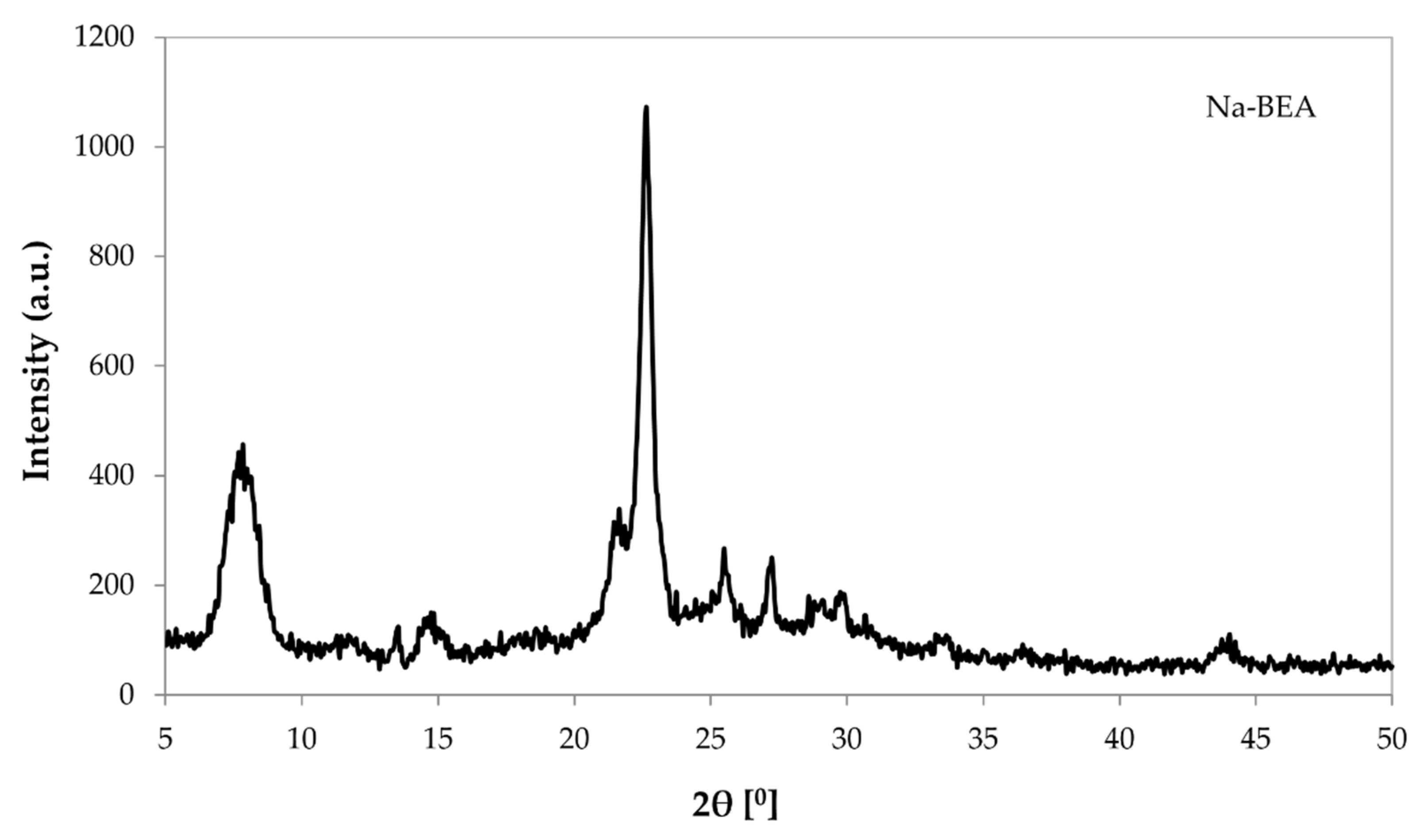

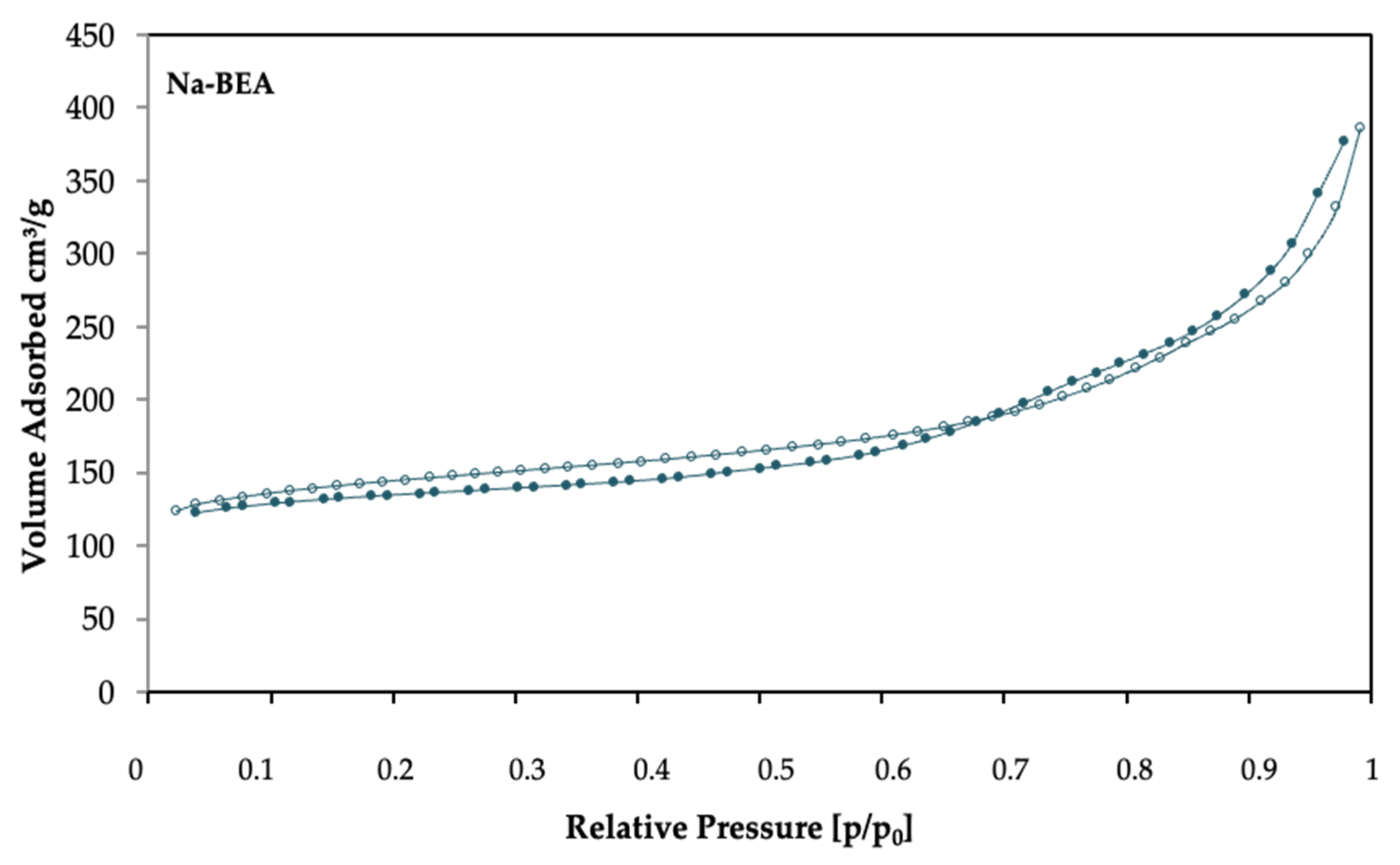

3.1. Na-BEA Characterization

3.2. Catalytic Tests

4. Discussion

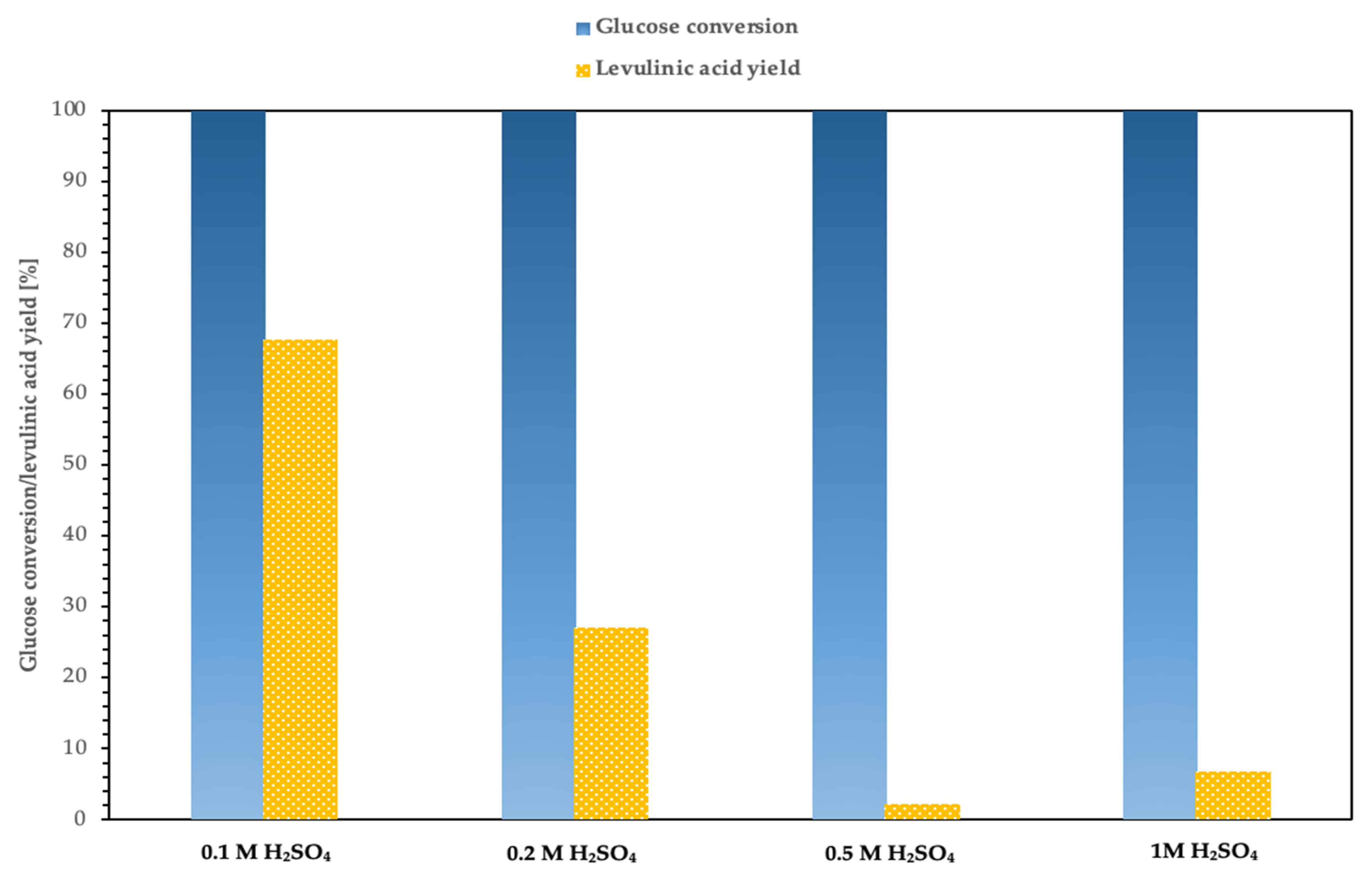

4.1. Homogeneous Process

4.2. Heterogeneous Process

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Czekaj, I.; Sobuś, N. Nano-Design of Zeolite-Based Catalysts for Selective Conversion of Biomass into Chemicals; Wydawnictwo PK: Kraków, Poland, 2018; ISBN 978-83-7242-785-4. [Google Scholar]

- Kumar, A.; Shende, D.Z.; Wasewar, K.L. Production of levulinic acid: A promising building block material for pharmaceutical and food industry. Mater. Today Proc. 2020, 29, 790–793. [Google Scholar] [CrossRef]

- Wang, S.; Dorcet, V.; Roisnel, T.; Bruneau, C.; Fischmeister, C. Ruthenium and Iridium Dipyridylamine Catalysts for the Efficient Synthesis of γ-Valerolactone by Transfer Hydrogenation of Levulinic Acid. Organometallics 2017, 36, 708–713. [Google Scholar] [CrossRef]

- Rackemann, D.W.; Doherty, W.O.S. The conversion of lignocellulosics to levulinic acid. Biofuels Bioprod. Bioref. 2011, 5, 198–214. [Google Scholar] [CrossRef] [Green Version]

- Hayes, D.J.; Fitzpatrick, S.; Hayes, M.H.B.; Ross, J.R.H. The Biofine process- production of levulinic acid, furfural and formic acid from lignocellulosic feedstocks. Bioref. Ind. Proc. Prod. 2006, 1, 139–164. [Google Scholar]

- Fugalli, S.; Raspolli Galletti, A.M.; Troiano, A. Production of levulinic acid and levulinate esters from renewable raw materials and waste products of plant origin. Italy Patent IT 2008CE0002 (to Le Calorie S.p.A., Italy), 2008. [Google Scholar]

- Besson, M.; Gallezot, P.; Pinel, C. Conversion of Biomass into Chemicals over Metal Catalysts. Chem. Rev. 2014, 114, 1827–1870. [Google Scholar] [CrossRef]

- Corma, A.; Iborra, S.; Velty, A. Chemical routes for the transformation of biomass into chemicals. Chem. Rev. 2007, 107, 2411–2502. [Google Scholar] [CrossRef]

- Girisuta, B.; Janssen, L.P.B.M.; Heeres, H.J. A Kinetic Study on the Conversion of Glucose to Levulinic Acid. Chem. Eng. Res. Des. 2006, 84, 339–349. [Google Scholar] [CrossRef]

- Hong, J.H.; Lee, M.J.; Kim, H.R.; Hwang, Y.K.; Chang, J.S.; Halligudi, S.B.; Han, Y.H. Efficient and selective conversion of methyl lactate to acrylic acid using Ca3(PO4)2–Ca2(P2O7) composite catalysts. Appl. Catal. A Gen. 2011, 396, 194–200. [Google Scholar] [CrossRef]

- Grzywa, E.; Molenda, J. Technologia Podstawowych Syntez Organicznych, 3th ed.; Tom 2; WNT: Warszawa, Polska, 2000. [Google Scholar]

- Kijeński, J.; Migdał, A.; Rejewski, P.; Kędziora, A. Przemysłowa synteza kwasu akrylowego i akrylanów—Droga do eliminacji białych plam w obszarze wytwórczym polskiego przemysłu chemicznego. Polimery 2016, 61, 702–709. [Google Scholar]

- Zhang, J.; Lin, J.; Peilin, C. Catalytic Dehydration of Lactic Acid to Acrylic Acid Over Sulfate Catalysts. Can. J. Chem Eng. 2008, 86, 1047–1053. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Y.; Pan, M.; Feng, X.; Ji, W.; Au, C.-T. Efficient acrylic acid production through bio lactic acid dehydration over NaY zeolite modified by alkali phosphates. ACS Catal. 2011, 1, 32–41. [Google Scholar] [CrossRef]

- Suo, X.; Zhang, H.; Ye, Q.; Dai, X.; Yu, H.; Li, R. Design and control of an improved acrylic acid process. Chem. Eng. Res. Des. 2015, 104, 346–356. [Google Scholar] [CrossRef]

- Galletti, R.; Antonetti, A.M.; De Luise, C.; Licursi, V.; Di Nasso, N. Levulinic acid production from waste biomass. BioResources 2012, 7, 1824–1835. [Google Scholar]

- Fjermestad, T.; Svelle, S.; Swang, O. Mechanistic Comparison of the Dealumination in SSZ-13 and the Desilication in SAPO-34. J. Phys. Chem. C 2013, 117, 13442–13451. [Google Scholar] [CrossRef]

- Da Costa Sousa, L.; Chundawat, S.P.S.; Balan, V.; Dale, B.E. Cradle-to-grave’ assessment of existing lignocellulose pretreatment technologies. Curr. Opin. Biotechnol. 2009, 20, 339–347. [Google Scholar] [CrossRef]

- Malola, S.; Svelle, S.; Bleken, F.L.; Swang, O. Detailed Reaction Paths for Zeolite Dealumination and Desilication from Density Functional Calculations. Angew. Chem. Int. Ed. 2012, 51, 652–655. [Google Scholar] [CrossRef]

- Fatouros, D.G.; Douroumis, D.; Nikolakis, V.; Ntais, S.; Moschovi, A.M.; Trivedi, V.; Khima, B.; Roldo, M.; Nazar, H.; Cox, P.A. In Vitro and in silico investigations of drug delivery via zeolite BEA. J. Mater. Chem. 2011, 21, 7789. [Google Scholar] [CrossRef]

- Sakai, M.; Yasuda, N.; Tsuzuki, Y.; Matsukata, M. Organic Structure-directing Agent-free Synthesis for *BEA-type Zeolite Membrane. J. Vis. Exp. 2020, 156, e60500. [Google Scholar] [CrossRef]

- Gabrienko, A.A.; Lashchinskaya, Z.N.; Arzumanov, S.S.; Toktarev, A.V.; Freude, D.; Haase, J.; Stepanov, A.G. Isobutene Transformation to Aromatics on Zn-Modified Zeolite: Particular Effects of Zn2+ and ZnO Species on the Reaction Occurrence Revealed with Solid-State NMR and FTIR Spectroscopy. J. Phys. Chem. C 2021, 125, 15343–15353. [Google Scholar] [CrossRef]

- Zholobenko, V.; Freitas, C.; Jendrlin, M.; Bazin, P.; Travert, A.; Thibault-Starzyk, F. Probing the acid sites of zeolites with pyridine: Quantitative AGIR measurements of the molar absorption coefficients. J. Catal. 2020, 385, 52–60. [Google Scholar] [CrossRef] [Green Version]

- Courtney, T.D.; Chang, C.-C.; Gorte, R.J.; Lobo, R.F.; Fan, W.; Nikolakis, V. Effect of water treatment on Sn-BEA zeolite: Origin of 960 cm−1 FTIR peak. Microporous Mesoporous Mater. 2015, 210, 69–76. [Google Scholar] [CrossRef] [Green Version]

- Król, M.; Minkiewicz, J.; Mozgawa, W. IR spectroscopy studies of zeolites in geopolymeric materials derived from kaolinite. J. Mol. Struct. 2016, 1126, 200–206. [Google Scholar] [CrossRef]

- Hajjar, R.; Millot, Y.; Man, P.P.; Che, M.; Dzwigaj, S. Two Kinds of Framework Al Sites Studied in BEA Zeolite by X-ray Diffraction, Fourier Transform Infrared Spectroscopy, NMR Techniques, and V Probe. J. Phys. Chem. C 2008, 112, 20167–20175. [Google Scholar] [CrossRef]

- Ma, Y.-K.; Rigolet, S.; Michelin, L.; Paillaud, J.-L.; Mintova, S.; Khoerunnisa, F.; Daou, T.J.; Eng-Poh, N.G. Facile and fast determination of Si/Al ratio of zeolites using FTIR spectroscopy technique. Microporous Mesoporous Mater. 2020, 311, 110683. [Google Scholar] [CrossRef]

- Tabor, E.; Lemishka, M.; Sobalik, Z.; Mlekodaj, K.; Andrikopoulos, P.C.; Dedecek, J.; Sklenak, S. Low-temperature selective oxidation of methane over distant binuclear cationic centers in zeolites. Commun. Chem. 2019, 2, 71. [Google Scholar] [CrossRef]

- Kalhor, P.; Ghandi, K. Deep Eutectic Solvents as Catalysts for Upgrading Biomass. Catalysts 2021, 11, 178. [Google Scholar] [CrossRef]

| Parameters | Unit | |

|---|---|---|

| Crystal structure | IUPAC | BEA |

| BET area | m2/g | 544 |

| Na | ppm | 40 |

| C | ppm | 30 |

| Silicon module | 24.7 |

| Sample | SBET [m2/g] | Vp total [cm3/g] | Vp micro [cm3/g] |

|---|---|---|---|

| Na-BEA | 547 | 0.60 | 0.14 |

| Catalyst Concentration [M] | GLU Conversion [%] | Volume of 10% NaOH for Neutralization [mL] | Selectivity [%] | Yield to LA [%] | |

|---|---|---|---|---|---|

| LA | Others | ||||

| 0.1 | 100 | 0.37 | 67.7 | 38.3 | 67.7 |

| 0.2 | 100 | 0.75 | 27.1 | 72.9 | 27.1 |

| 0.5 | 100 | 1.88 | 2.2 | 97.8 | 2.2 |

| 1 | 100 | 3.76 | 6.8 | 93.2 | 6.8 |

| Catalyst Weight [g] | Process Temp. [°C] | Process Time [h] | GLU Conversion [%] | Selectivity [%] | Yield to LA [%] | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LAC | FA | DHA | FUR | Others | |||||

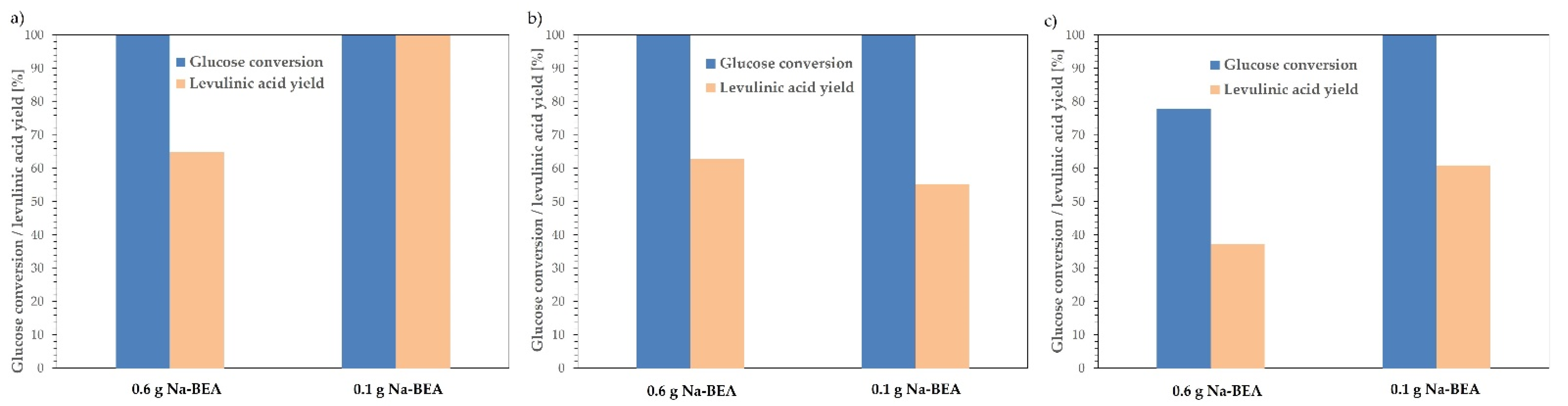

| 0.6 | 200 | 5 | 100 | 54.8 | 19.4 | - | - | 15.8 | - | 64.8 |

| 0.1 | 200 | 5 | 100 | 100 | - | - | - | - | - | 100 |

| 0.6 | 220 | 2 | 100 | 62.8 | 16.2 | - | 4.4 | 16.7 | - | 62.8 |

| 0.1 | 220 | 2 | 100 | 55.3 | 27.1 | - | 4.2 | 13.4 | - | 55.3 |

| 0.6 | 250 | 1 | 77.9 | 61.4 | 22.5 | 16.1 | - | - | - | 37.2 |

| 0.1 | 250 | 1 | 100 | 60.8 | 19.7 | 8.3 | 11.3 | - | 60.8 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobuś, N.; Czekaj, I. Catalytic Transformation of Biomass-Derived Glucose by One-Pot Method into Levulinic Acid over Na-BEA Zeolite. Processes 2022, 10, 223. https://doi.org/10.3390/pr10020223

Sobuś N, Czekaj I. Catalytic Transformation of Biomass-Derived Glucose by One-Pot Method into Levulinic Acid over Na-BEA Zeolite. Processes. 2022; 10(2):223. https://doi.org/10.3390/pr10020223

Chicago/Turabian StyleSobuś, Natalia, and Izabela Czekaj. 2022. "Catalytic Transformation of Biomass-Derived Glucose by One-Pot Method into Levulinic Acid over Na-BEA Zeolite" Processes 10, no. 2: 223. https://doi.org/10.3390/pr10020223

APA StyleSobuś, N., & Czekaj, I. (2022). Catalytic Transformation of Biomass-Derived Glucose by One-Pot Method into Levulinic Acid over Na-BEA Zeolite. Processes, 10(2), 223. https://doi.org/10.3390/pr10020223