Influence of Yield Pillar Width on Coal Mine Roadway Stability in Western China: A Case Study

Abstract

:1. Introduction

2. Case Study

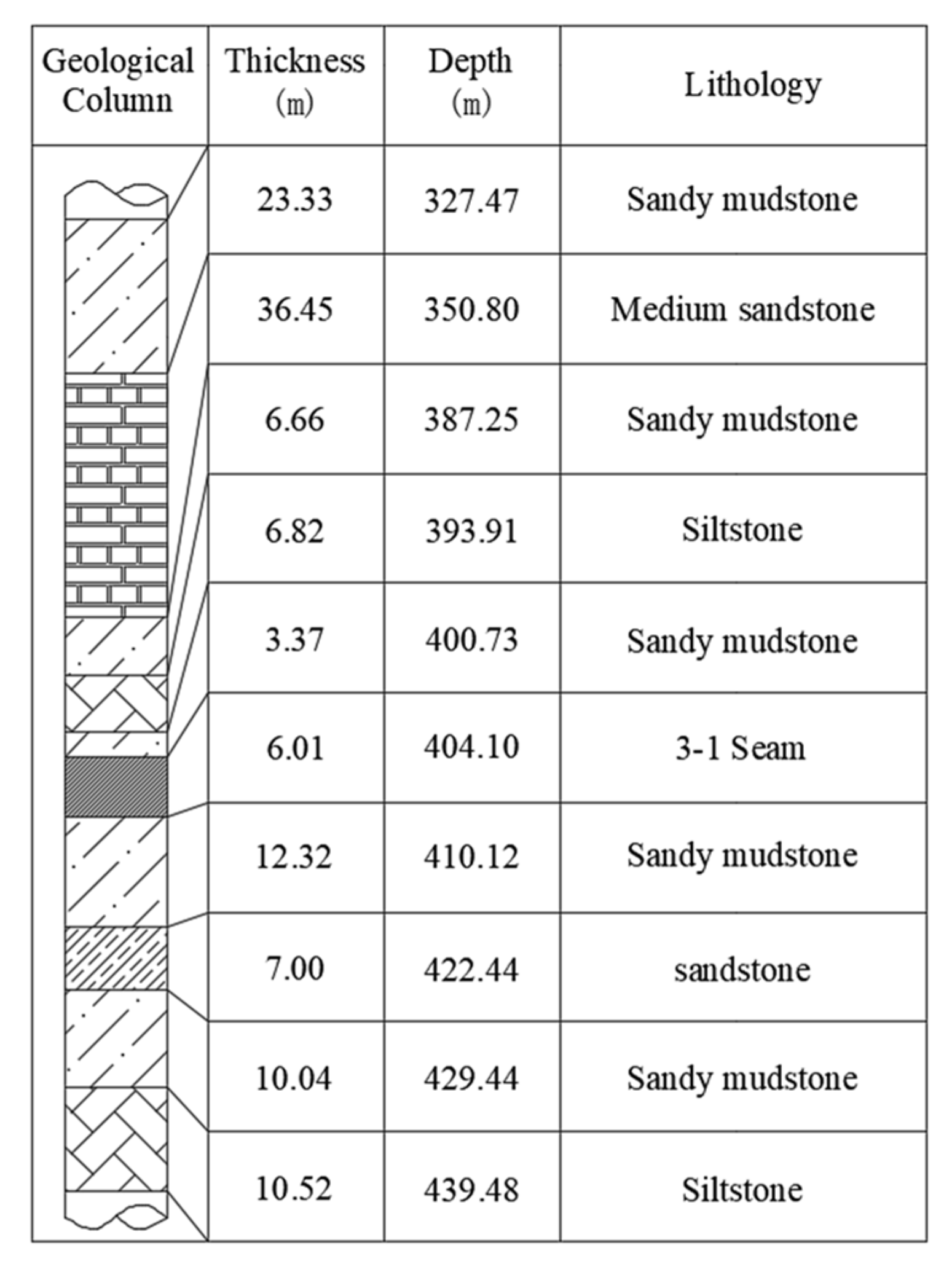

2.1. Geological and Geotechnical Overview of the Mataihao Mine

2.2. Theoretical Demonstration and Analysis of Yield Pillar Width in Goaf-Side Entry

3. Numerical Analysis of Ground Stability of Goaf-Side Entry

3.1. Establishment of Numerical Simulation Model for Goaf-Side Entry

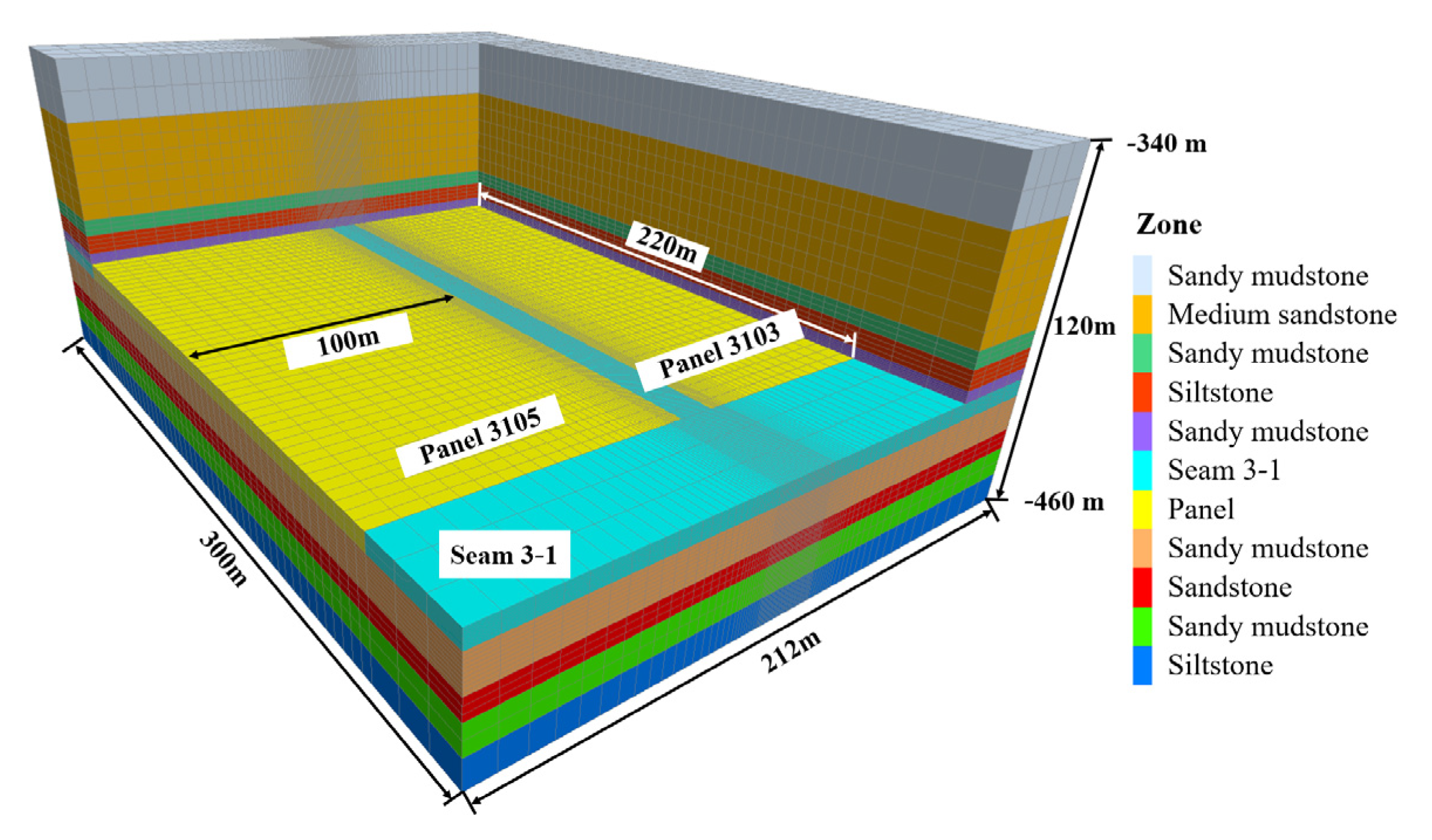

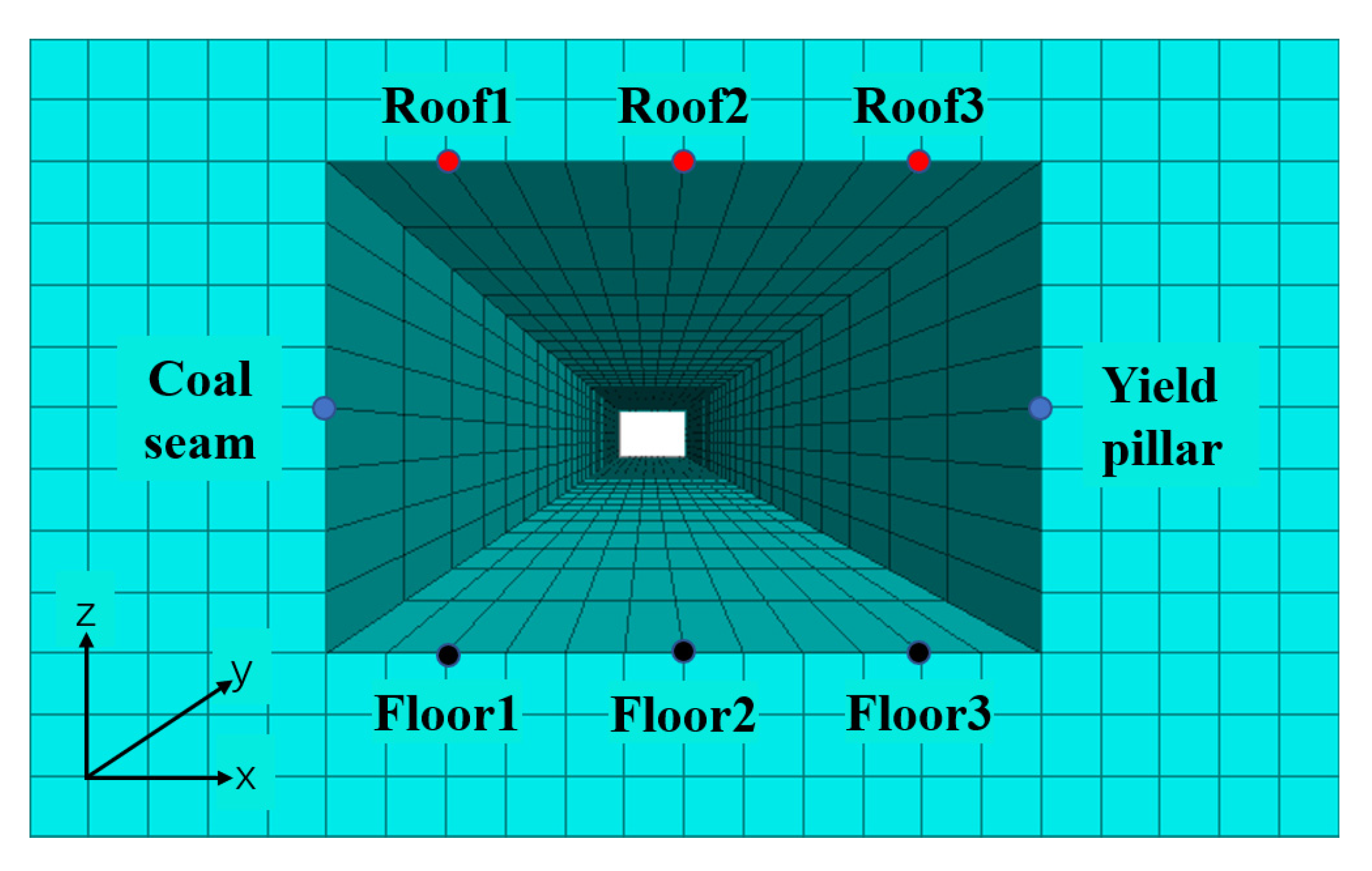

3.1.1. Three-Dimensional Numerical Model

3.1.2. Sensitivity Analyses

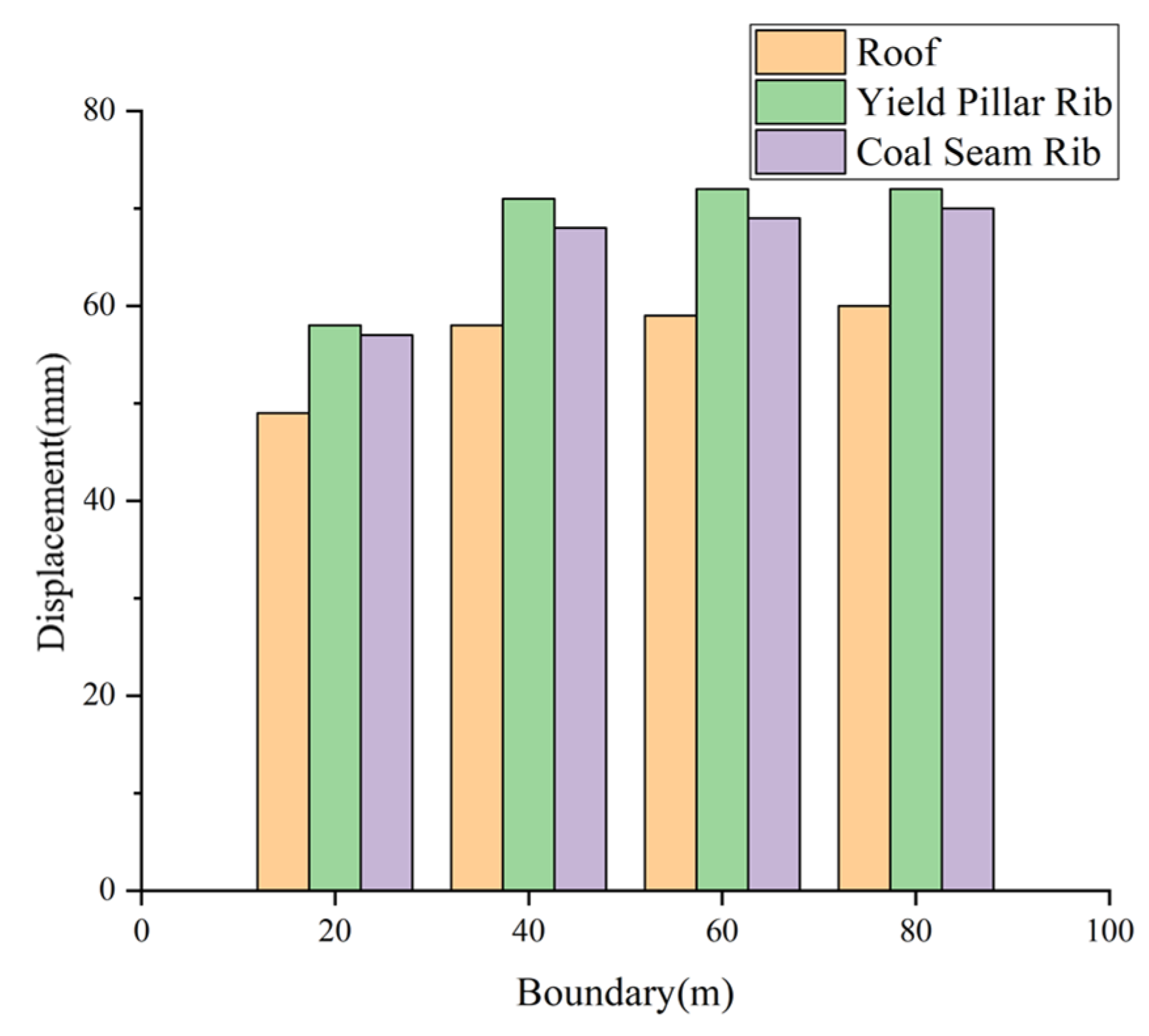

- Base boundary

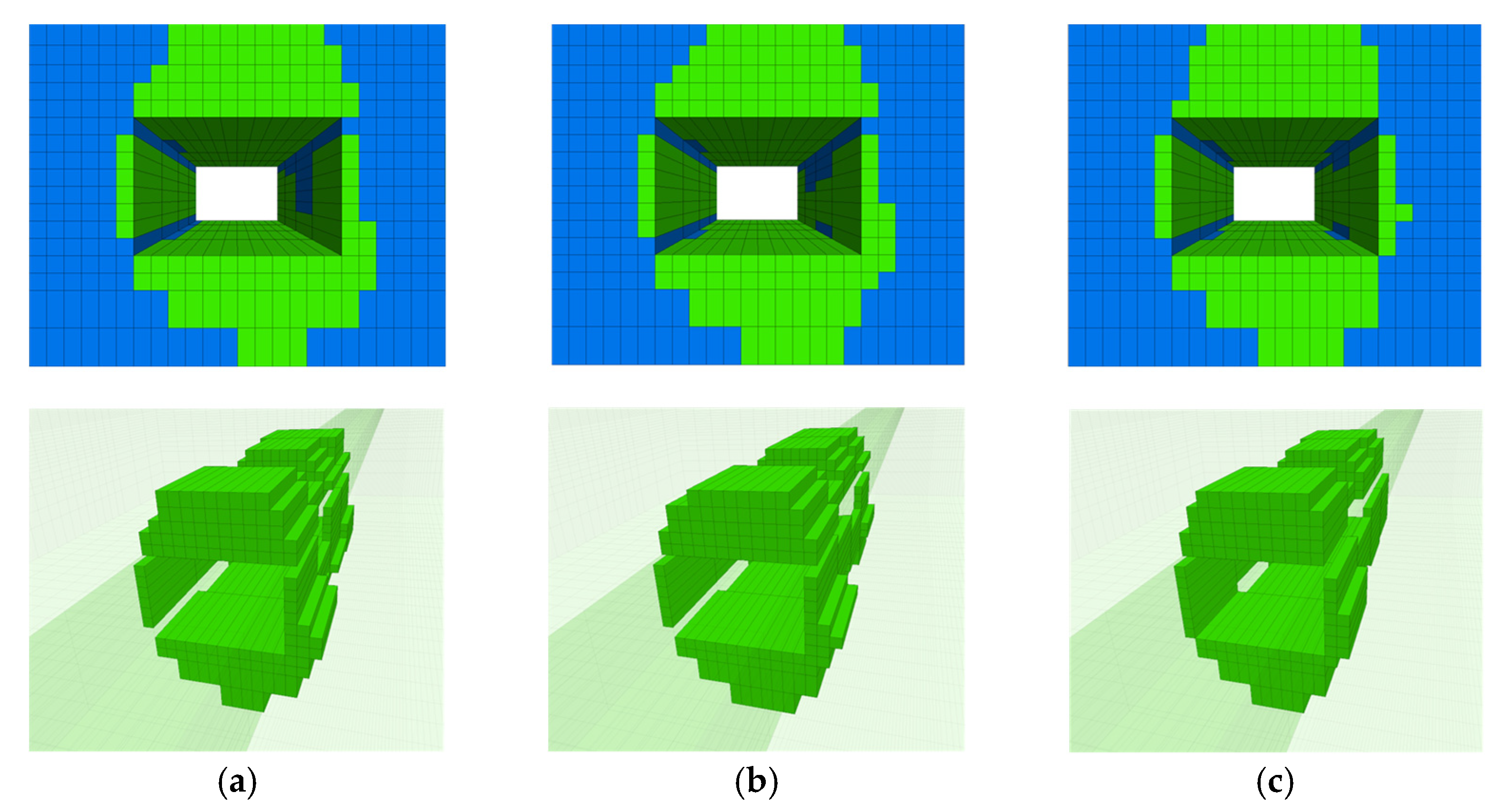

- Mesh dependency

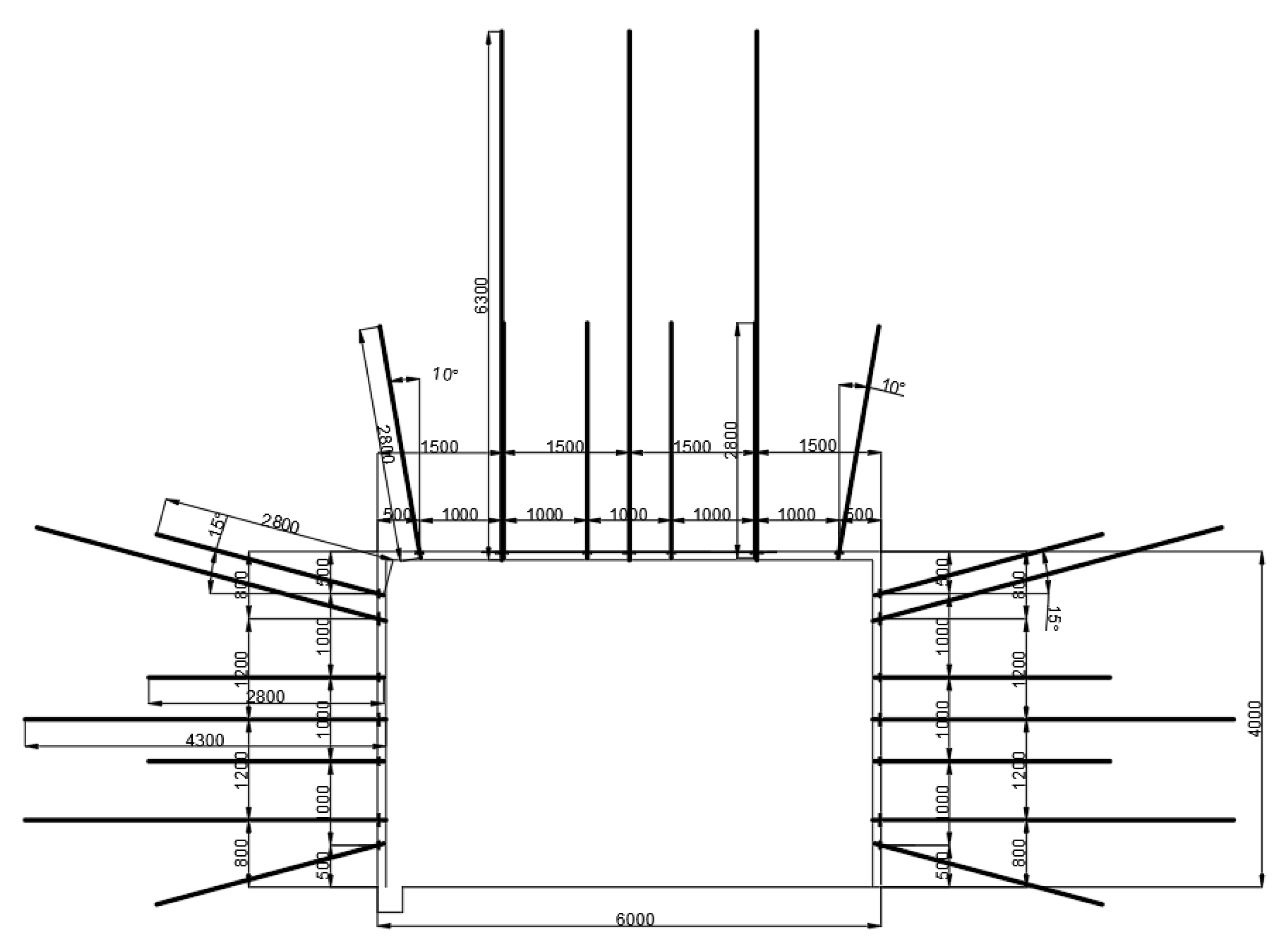

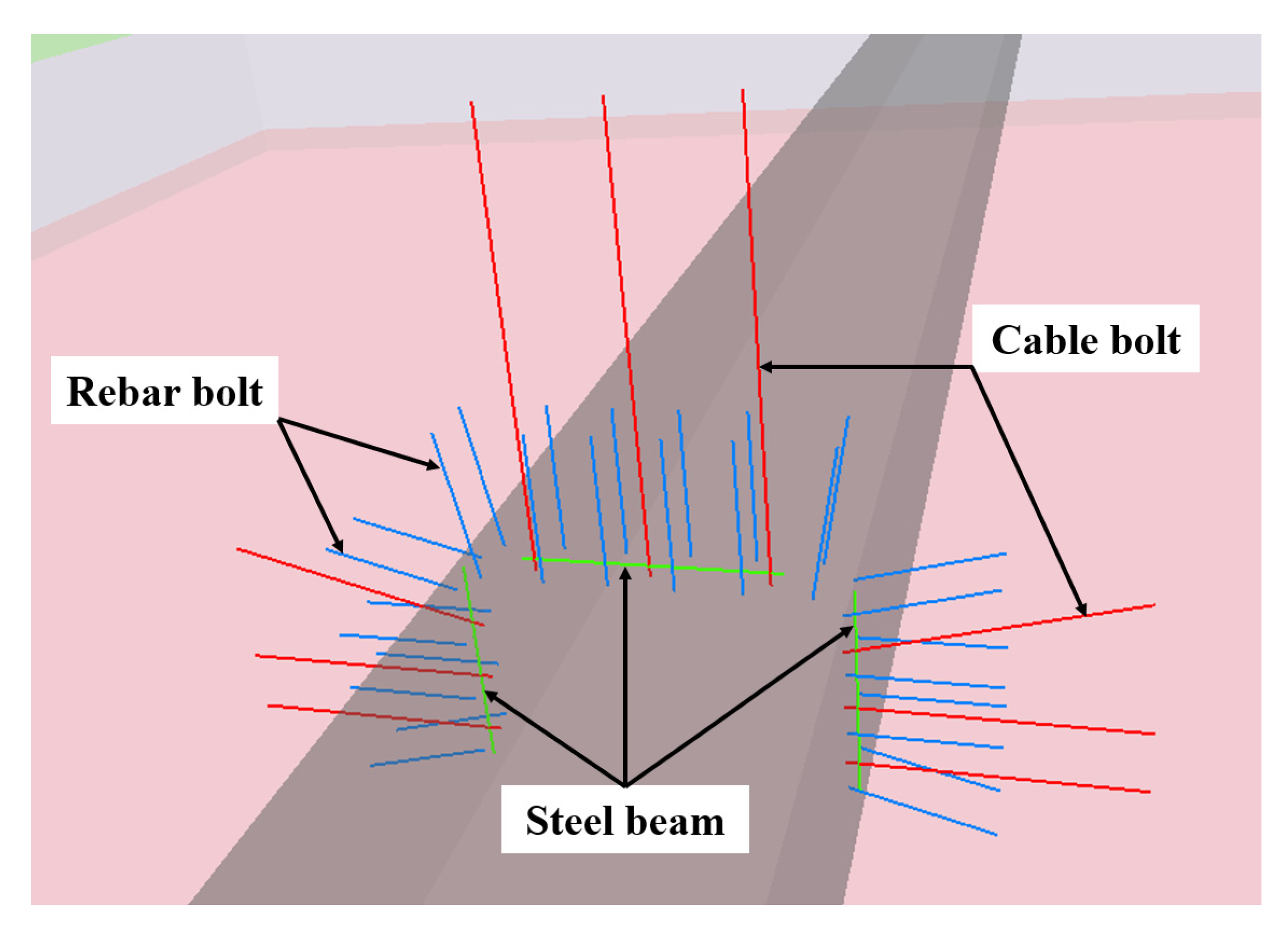

3.1.3. Simulation Scheme and Roadway Support

3.2. Stress State and Mechanical Characteristics of Rock Surrounding the Roadway Goaf-Side Entry with Different Yield Pillar Widths

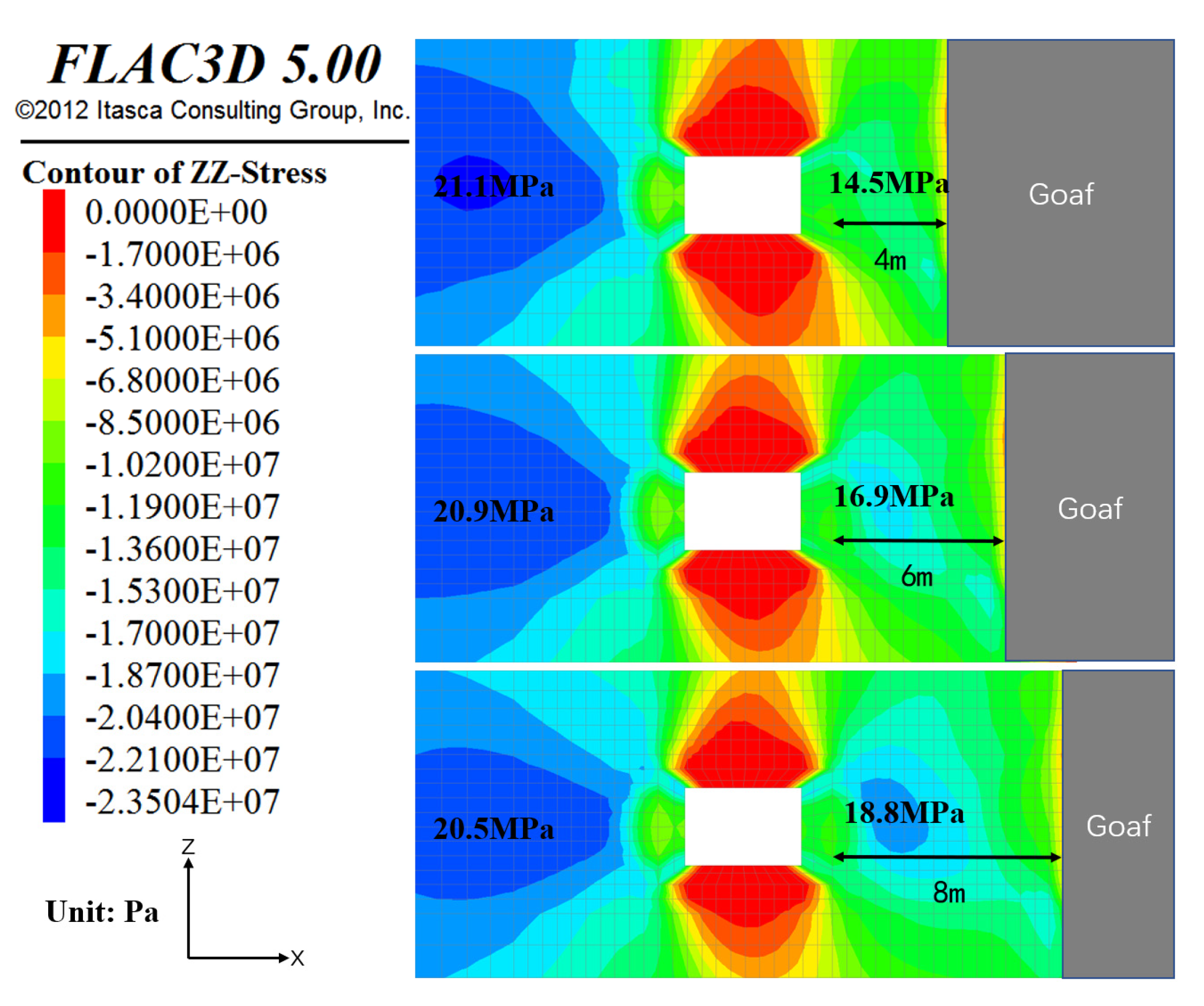

3.2.1. Boundary Stress Distribution Coal Seam Goaf before Goaf-Side Entry

3.2.2. Stress State of Surrounding Rock of Roadway Driving along Goaf under Different Yield Pillar Widths

3.2.3. Development Characteristics of Tensile Failure of Surrounding Rock of Goaf-Side Entry

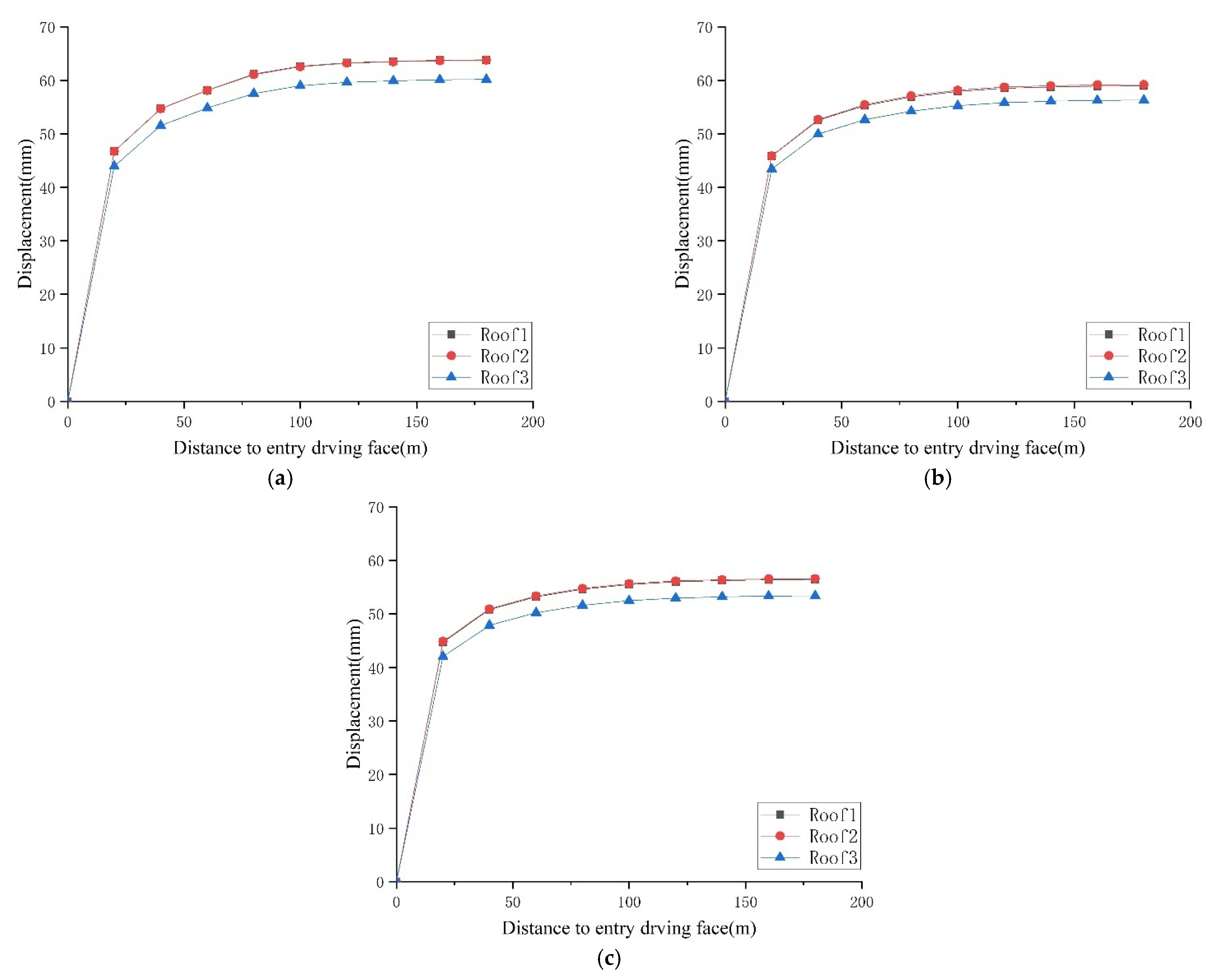

3.3. Evolution of Surrounding Rock Displacement of Goaf-Side Entry under Different Yield Pillar Widths and the Effect of Yield Pillar Size

3.3.1. Evolution of Roof Displacement during Goaf-Side Entry

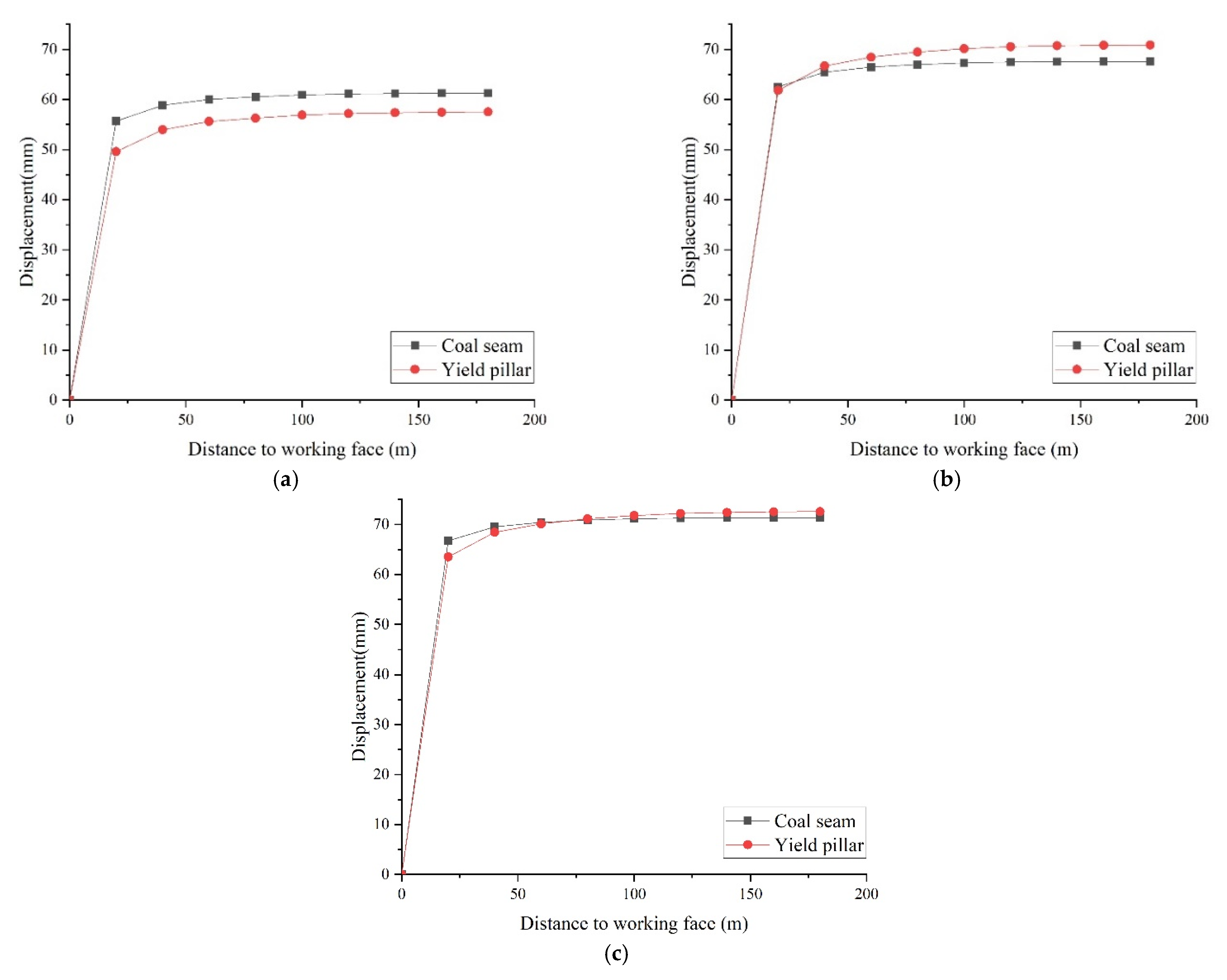

3.3.2. Displacement Evolution of Two Sides during Roadway Driving along the Goaf-Side

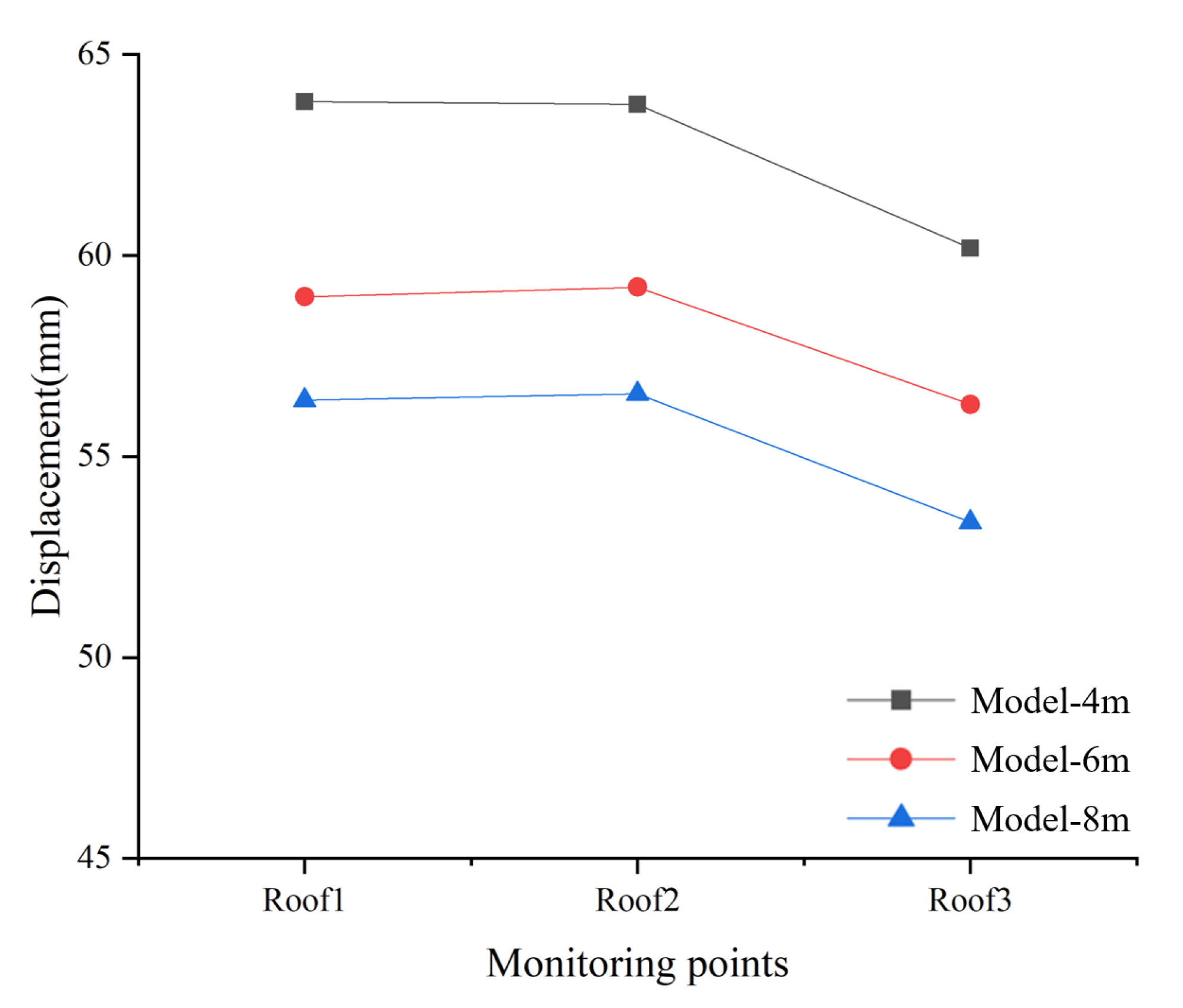

3.3.3. The Influence of Different Yield Pillar Width on the Displacement of Surrounding Rock during Roadway Driving

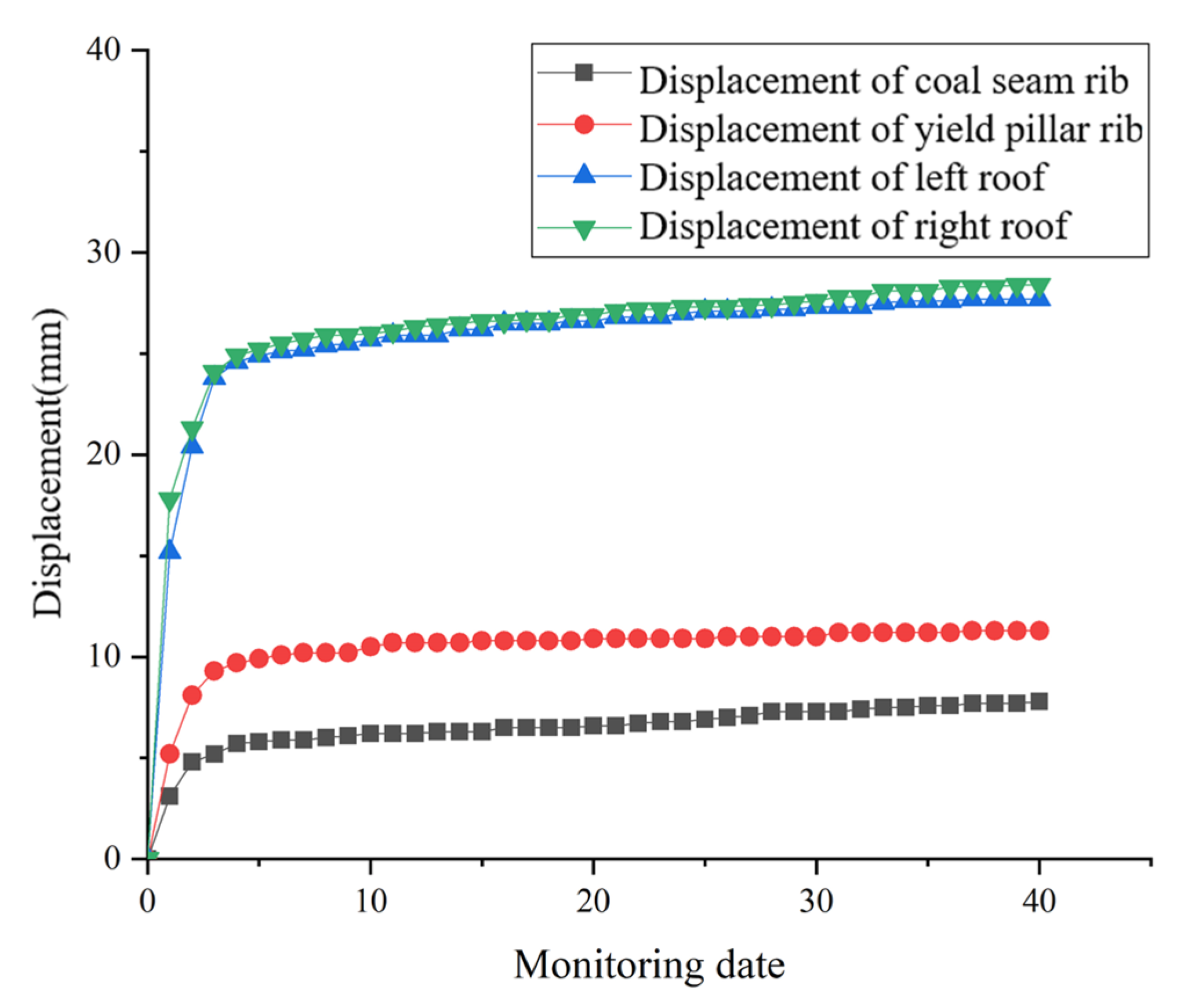

3.4. Field Monitoring and Observation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, L.; Liu, S. Respirable nano-particulate generations and their pathogenesis in mining workplaces: A review. Int. J. Coal Sci. Technol. 2021, 8, 179–198. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, P.; Cui, S.; Fan, M.; Qiu, Y. Mechanism and surrounding rock control of roadway driving along gob in shallow-buried, large mining height and small coal pillars by roof cutting. J. China Coal Soc. 2021, 46, 2254–2267. [Google Scholar]

- Colwell, M.; Hill, D.; Frith, R. ALTS II, A longwall gateroad design methodology for Australian collieries. In Proceedings of the 1st Australian Conference on Ground Control in Mining, Sydney, Australia, 10–13 November 2003; pp. 123–135. [Google Scholar]

- Qi, Q.; Li, Y.; Zhao, S.; Zhang, N.; Zheng, W.; Li, H.; Li, H. Seventy years development of coal mine rock burst in China: Establishment and consideration of theory and technology system. Coal Sci. Technol. 2019, 47, 1–40. [Google Scholar]

- Du, J.; Meng, X. Mining Science; China University of Mining and Technology Press: Xuzhou, China, 2009; pp. 122–130. [Google Scholar]

- Hou, C.; Li, X. Stability principle of large and small structures of surrounding rock in gob-side driving roadway of fully mechanized caving. J. China Coal Soc. 2001, 26, 1–7. [Google Scholar]

- Maleki, H.N. Ground response to longwall mining: A Case study of two-entry yield pillar evolution in weak rock. Colo. Sch. Mines Q. 1988, 83, 51. [Google Scholar]

- Maleki, H.N. An analysis of violent failures in US coal mines—Case studies. In Proceedings of Mechanics and Mitigation of Violent Failure in Coal and Hard-Rock Mines; Maleki, H., Wopat, P.F., Repsher, R.C., Tuchman, R.J., Eds.; SP 01-95; US Bureau of Mines: Washington, DC, USA, 1995; pp. 5–26. [Google Scholar]

- Xue, K.; Fu, B. Research and application of reasonable width of coal pillars in roadway excavation. J. Undergr. Space Eng. 2018, 14 (Suppl. 1), 403–408. [Google Scholar]

- Chen, W. Study on control technology of rockburst in coalmines of Western Erdos. Coal Sci. Technol. 2018, 46, 99–104. [Google Scholar]

- Zhang, G.; He, F. Asymmetric failure and control measures of large cross-section entry roof with strong mining disturbance and fully-mechanized caving mining. Chin. J. Rock Mech. Eng. 2016, 35, 806–818. [Google Scholar]

- Wang, D.; Li, S.; Wang, Q.; Li, W.; Wang, F.; Wang, H.; Peng, P.; Ren, G. Experimental study of reasonable coal pillar width in fully mechanized top coal caving face of deep thick coal seam. Chin. J. Rock Mech. Eng. 2014, 33, 539–548. [Google Scholar]

- Hou, C.; Mines, C.O. Key technologies for surrounding rock control in deep roadway. J. China Univ. Min. Technol. 2017, 46, 970–978. [Google Scholar]

- Wang, W.; Hou, C. Study of mechanical principle of floor heave of roadway driving along next goaf in fully mechanized sub-level caving face. J. Coal Sci. Eng. 2001, 7, 13–17. [Google Scholar]

- Wang, Y.; He, M.; Yang, J.; Fu, Q.; Gao, Y.; University, T. The structure characteristics and deformation of “short cantilever beam” using a non-pillar mining method with gob-side entry formed automatically. J. China Univ. Min. Technol. 2019, 48, 718–726. [Google Scholar]

- Mark, C.; Mclinda, G.M.; Dolinar, D.R. Analysis of rock bolting systems. In Proceedings of the 20th International Conference on Ground Control in Mining, Morgantown, WV, USA, 7–9 August 2001; pp. 123–125. [Google Scholar]

- Mark, C.; Dolimar, D.R. Development and application of the coal mine roof rating (CMRR)—A decade of experience. Int. J. Coal Geol. 2005, 46, 85–103. [Google Scholar] [CrossRef]

- Esterhuizen, G.S.; Gearhart, D.F.; Klemetti, T.; Dougherty, H.; van Dyke, M. Analysis of gateroad stability at two longwall mines based on field monitoring results and numerical model analysis. Int. J. Min. Sci. Technol. 2019, 29, 35–43. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int. J. Rock Mech. Min. Sci. 2012, 51, 24–34. [Google Scholar] [CrossRef]

- Bai, J.; Hou, C.; Huang, H. Numerical simulation study of stability of narrow coal pillar of roadway driven along the goaf. Chin. J. Rock Mech. Eng. 2004, 20, 3475–3479. [Google Scholar]

- Qian, M.; Shi, P.; Xu, J. Mining Pressure and Strata Control; China University of Mining and Technology Press: Xuzhou, China, 2010. (In Chinese) [Google Scholar]

- Tu, S.; Bai, Q.; Tu, H. Pillar size determination and panel layout optimization for fully mechanized faces in shallow seams. J. Min. Saf. Eng. 2011, 28, 505–510. [Google Scholar]

- Jiang, L.; Liu, H.; Lian, X.; Zhang, W. Research on rational width of coal-pillar in shallow-buried medium-thick coal-seam. Coal Min. Technol. 2012, 7, 105–108. [Google Scholar]

- Yavuz, H. An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int. J. Rock Mech. Min. Sci. 2004, 41, 193–205. [Google Scholar] [CrossRef]

- Esterhuizen, G.S.; Mark, C.; Murphy, M.M. Numerical model calibration for simulating coal pillars, gob and overburden response. In Proceedings of the 29th International Conference on Ground Control in Mining, Morgantown, WV, USA, 27–29 July 2010; pp. 1–12. [Google Scholar]

- Esterhuizen, G.S. A stability factor for supported mine entries based on numerical model analysis. In Proceedings of the 31st International Conference on Ground Control in Mining, Morgantown, WV, USA, 27–29 July 2012; pp. 1–9. [Google Scholar]

- Badr, S.A. Numerical Analysis of Coal Slender Pillars at Deep Longwall Mines. Ph.D. Thesis, Colorado School of Mines, Golden, CO, USA, 2004; pp. 23–56. [Google Scholar]

- Zhang, Z.; Bai, J.; Chen, Y.; Yan, S. An innovative approach for gob-side entry retaining in highly gassy fully-mechanized longwall top-coal caving. Int. J. Rock Mech. Min. 2015, 80, 1–11. [Google Scholar] [CrossRef]

- Li, W.; Bai, J.; Peng, S.; Wang, X.; Xu, Y. Numerical modeling for yield pillar design: A case study. Rock Mech. Rock Eng. 2013, 48, 305–318. [Google Scholar] [CrossRef]

- Piotr, M.; Zbigniew, N.; Tafida, B. A statistical analysis of geomechanical data and its effect on rock mass numerical modeling: A case study. Int. J. Coal Sci. Technol. 2021, 8, 312–323. [Google Scholar]

- Yan, S.; Bai, J.; Wang, X.; Huo, L. An innovative approach for gateroad layout in highly gassy longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2013, 59, 33–41. [Google Scholar] [CrossRef]

- Yang, X. Research and Application of Surrounding Rock Stability Control Technology in Soft Rock Roadway Influenced by Multiple Disturbances. Ph.D. Thesis, Shan Dong University of Science and Technology, Qingdao, China, 2020. [Google Scholar]

- Hoek, E.; Carranza-Torres, C.; Corkum, B. Hoek-Brown failure criterion—2002 edition. In Proceedings of the NARMS-Tac 2002, Toronto, ON, Canada, 7–10 July 2002; Volume 1, pp. 267–273. [Google Scholar]

- Jiang, L.; Zhang, P.; Chen, L.; Hao, Z.; Sainoki, A.; Mitri, H.S.; Wang, Q. Numerical approach for goaf-side entry layout and yield pillar design in fractured ground conditions. Rock Mech. Rock Eng. 2017, 50, 3049–3071. [Google Scholar] [CrossRef]

- Wang, M.; Bai, J. Failure mechanism and control of deep gob-side entry. Arab. J. Geosci. 2015, 8, 9117–9131. [Google Scholar] [CrossRef]

- Peng, S.S. Coal Mine Ground Control, 3rd ed.; Peng SS Publisher: Morgantown, WV, USA, 2008; pp. 229–267. [Google Scholar]

- Singh, R.; Mandal, P.K.; Singh, A.K.; Kumar, R.; Sinha, A. Optimal underground extraction of coal at shallow cover beneath surface/subsurface objects: Indian practices. Rock Mech. Rock Eng. 2008, 41, 421–444. [Google Scholar] [CrossRef]

- Hou, C. Ground Control of Roadways; China University of Mining & Technology Press: Xuzhou, China, 2013. [Google Scholar]

| Strata | Lithology | K (GPa) | G (GPa) | ρ (kg/m3) | φ (°) | C (MPa) | σt (MPa) |

|---|---|---|---|---|---|---|---|

| Roof | Sandy mudstone | 14.7 | 2.14 | 2350 | 31 | 2.4 | 1.7 |

| Medium sandstone | 20.8 | 1.26 | 2580 | 30 | 2.8 | 1.2 | |

| Sandy mudstone | 13.1 | 2.46 | 2420 | 31 | 3.0 | 2.0 | |

| Siltstone | 6.7 | 4.96 | 2720 | 36 | 3.89 | 2.93 | |

| Sandy mudstone | 7.4 | 1.08 | 2380 | 32 | 2.0 | 1.12 | |

| Coal seam | Coal | 3.16 | 2.46 | 1600 | 31 | 3.0 | 1.08 |

| Floor | Sandy mudstone | 6.2 | 1.8 | 2300 | 30 | 2.1 | 1.28 |

| sandstone | 12.2 | 2.4 | 2500 | 28 | 2.5 | 2.1 | |

| Sandy mudstone | 7.8 | 1.4 | 2350 | 31 | 2.1 | 0.8 | |

| Siltstone | 9.6 | 7.13 | 2720 | 37 | 4.13 | 2.85 | |

| Goaf | Goaf | 19.9 | 1 | 1700 | 30 | 0.001 | 0 |

| Type of Bolt | Bolt Length (mm) | Grout Length (mm) | Diameter (mm) | Tensile Strength (KN) |

|---|---|---|---|---|

| Rebar bolt | 2800 | 1400 | 22 | 335 |

| Roof cable bolt | 6300 | 3000 | 21.8 | 510 |

| Rib cable bolt | 4300 | 2000 | 21.8 | 510 |

| Pillar Width (m) | Number of Zones within 2 m from Entry Surface | Number of Tensile Failure Zones | Ratio of Tensile Failure (%) |

|---|---|---|---|

| 4 | 1248 | 400 | 32.05 |

| 6 | 1248 | 371 | 29.73 |

| 8 | 1248 | 358 | 28.69 |

| Pillar Width (m) | Average Roof Sinking during Excavating | The Average Subsidence and Displacement Ratio When the Distance of the Lagging Excavating Working Surface Is Le | ||

|---|---|---|---|---|

| Le = 20 m | Le = 60 m | Le = 100 m | ||

| 4 m | 62.30 mm | 45.80 mm 73.51% | 57.05 mm 91.57% | 61.40 mm 98.56% |

| 6 m | 57.95 mm | 45.05 mm 77.74% | 54.47 mm 93.99% | 57.11 mm 98.55% |

| 8 m | 55.26 mm | 43.91 mm 79.46% | 52.23 mm 94.52% | 54.52 mm 98.66% |

| Pillar Width (m) | Cumulative Displacement of Coal Seam | Displacement and Displacement Ratio of the Coal Seam When the Distance of the Lagging Excavating Working Surface Is Le | ||

|---|---|---|---|---|

| Le = 20 m | Le = 60 m | Le = 100 m | ||

| 4 m | 61.21 mm | 55.69 mm 90.98% | 60.04 mm 98.09% | 60.92 mm 99.53% |

| 6 m | 67.55 mm | 62.54 mm 92.58% | 66.57 mm 98.55% | 67.31 mm 99.64% |

| 8 m | 71.33 mm | 66.71 mm 93.52% | 70.44 mm 98.75% | 71.14 mm 99.73% |

| Pillar Width (m) | Cumulative Displacement of Yield Pillar | Displacement and Displacement Ratio of the Yield Pillar When the Distance of the Lagging Excavating Working Surface Is Le | ||

|---|---|---|---|---|

| Le = 20 m | Le = 60 m | Le = 100 m | ||

| 4 m | 57.36 mm | 49.59 mm 86.45% | 55.62 mm 96.97% | 56.90 mm 99.20% |

| 6 m | 70.73 mm | 61.83 mm 87.41% | 68.47 mm 96.80% | 70.15 mm 99.18% |

| 8 m | 72.41 mm | 63.51 mm 87.71% | 70.12 mm 96.84% | 71.81 mm 99.17% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Feng, H.; Tang, P.; Peng, Y.; Li, C.; Jiang, L.; Mitri, H.S. Influence of Yield Pillar Width on Coal Mine Roadway Stability in Western China: A Case Study. Processes 2022, 10, 251. https://doi.org/10.3390/pr10020251

Wang Q, Feng H, Tang P, Peng Y, Li C, Jiang L, Mitri HS. Influence of Yield Pillar Width on Coal Mine Roadway Stability in Western China: A Case Study. Processes. 2022; 10(2):251. https://doi.org/10.3390/pr10020251

Chicago/Turabian StyleWang, Qingwei, Hao Feng, Peng Tang, Yuting Peng, Chunang Li, Lishuai Jiang, and Hani S. Mitri. 2022. "Influence of Yield Pillar Width on Coal Mine Roadway Stability in Western China: A Case Study" Processes 10, no. 2: 251. https://doi.org/10.3390/pr10020251

APA StyleWang, Q., Feng, H., Tang, P., Peng, Y., Li, C., Jiang, L., & Mitri, H. S. (2022). Influence of Yield Pillar Width on Coal Mine Roadway Stability in Western China: A Case Study. Processes, 10(2), 251. https://doi.org/10.3390/pr10020251