Application Research of Soft Computing Based on Machine Learning Production Scheduling

Abstract

1. Introduction

2. Review of the Literature

3. Research Methodology

4. Modelling

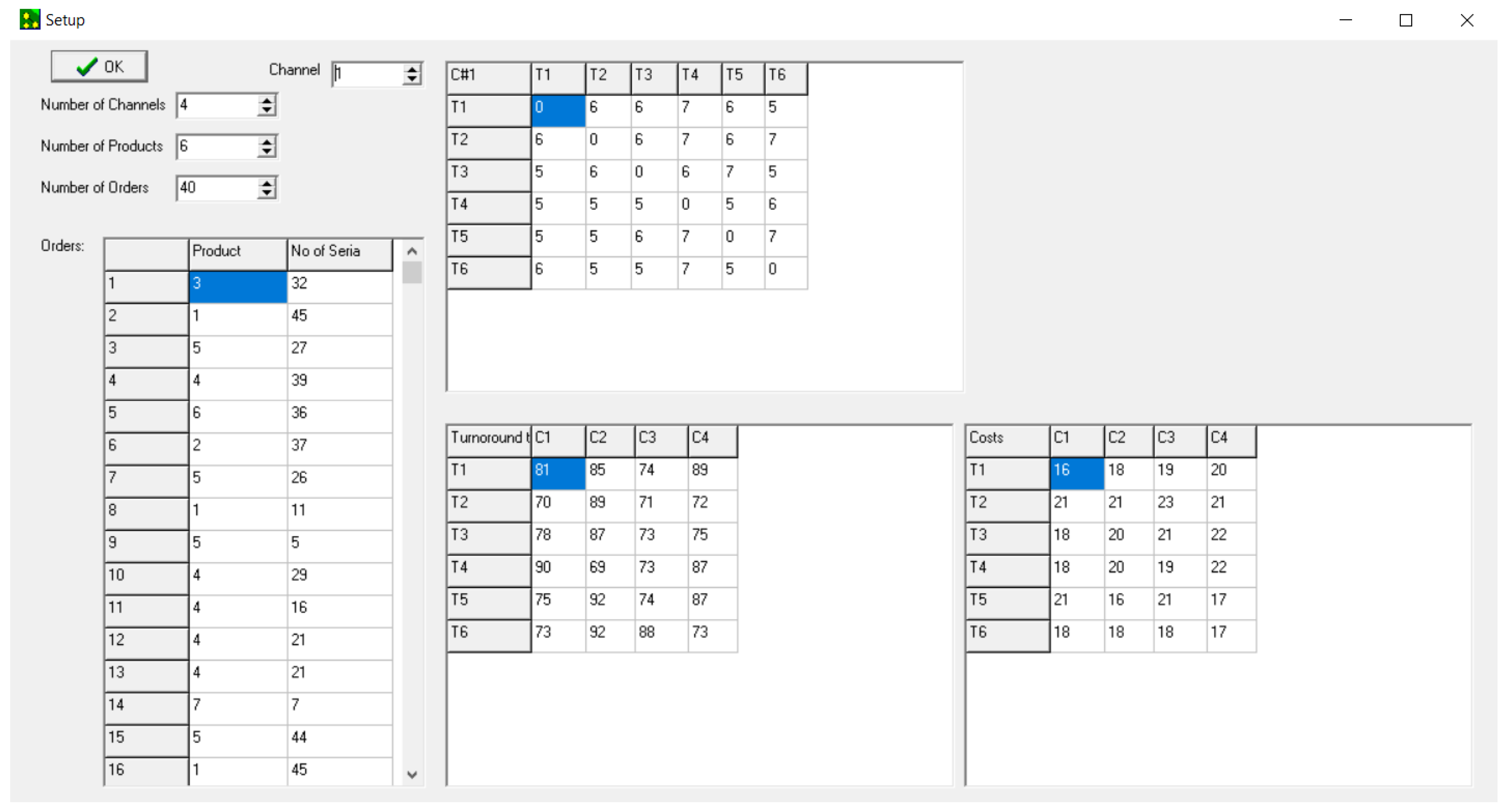

4.1. The Tested System

- Minimal lead time;

- Minimal manufacturing cost;

- The compromise objective function between time and cost.

4.2. The Mathematical Model

4.2.1. Constraints of the Model

4.2.2. The Objective Function

5. Description of the Heuristic Approach

5.1. Our Previous Solutions and Examinations

5.2. The Structure of the Chromosome

Denote

- (a)

- Crossover

- (b)

- Mutation

- (c)

- Selection

5.3. Convergence of the Process

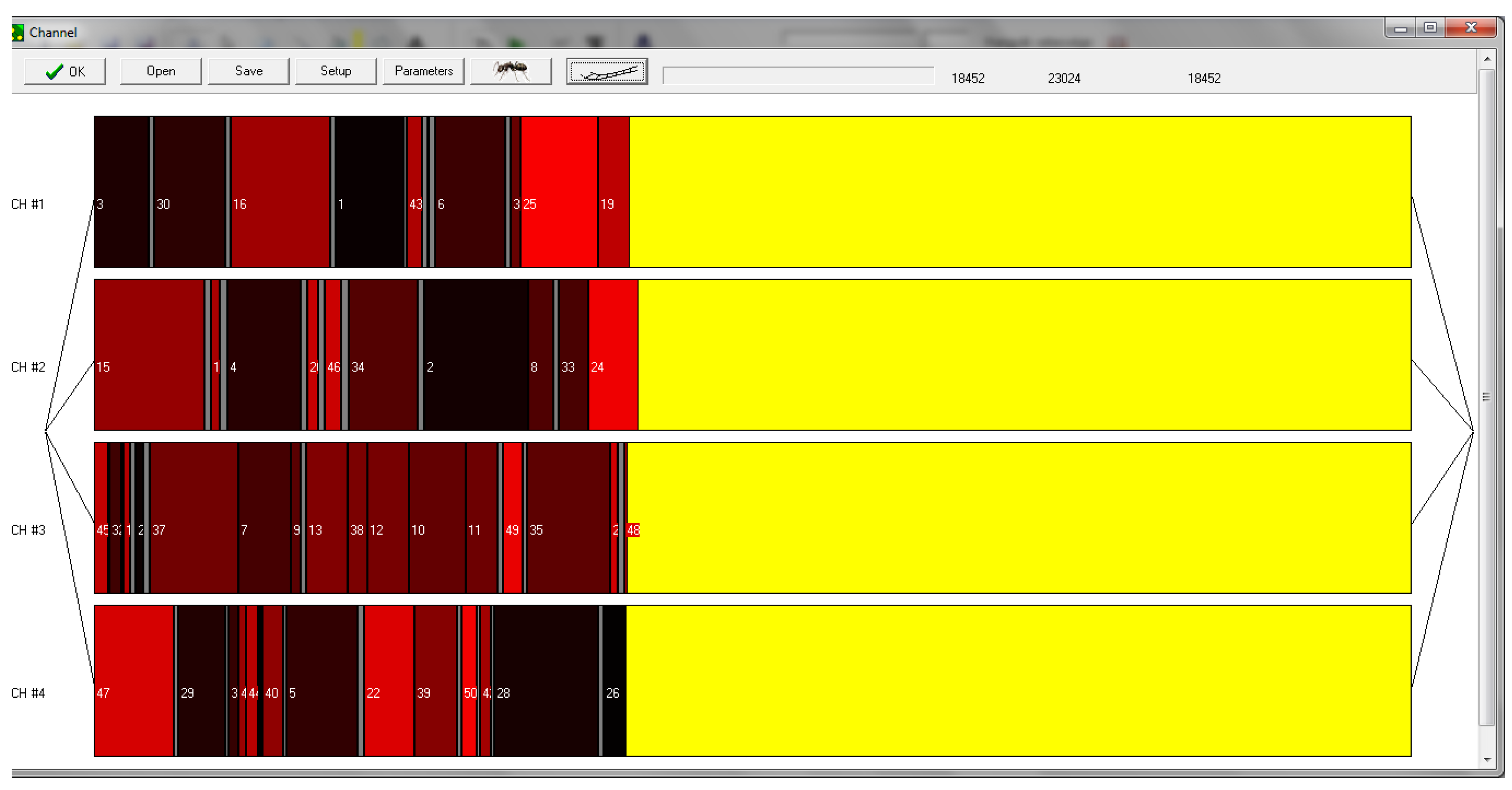

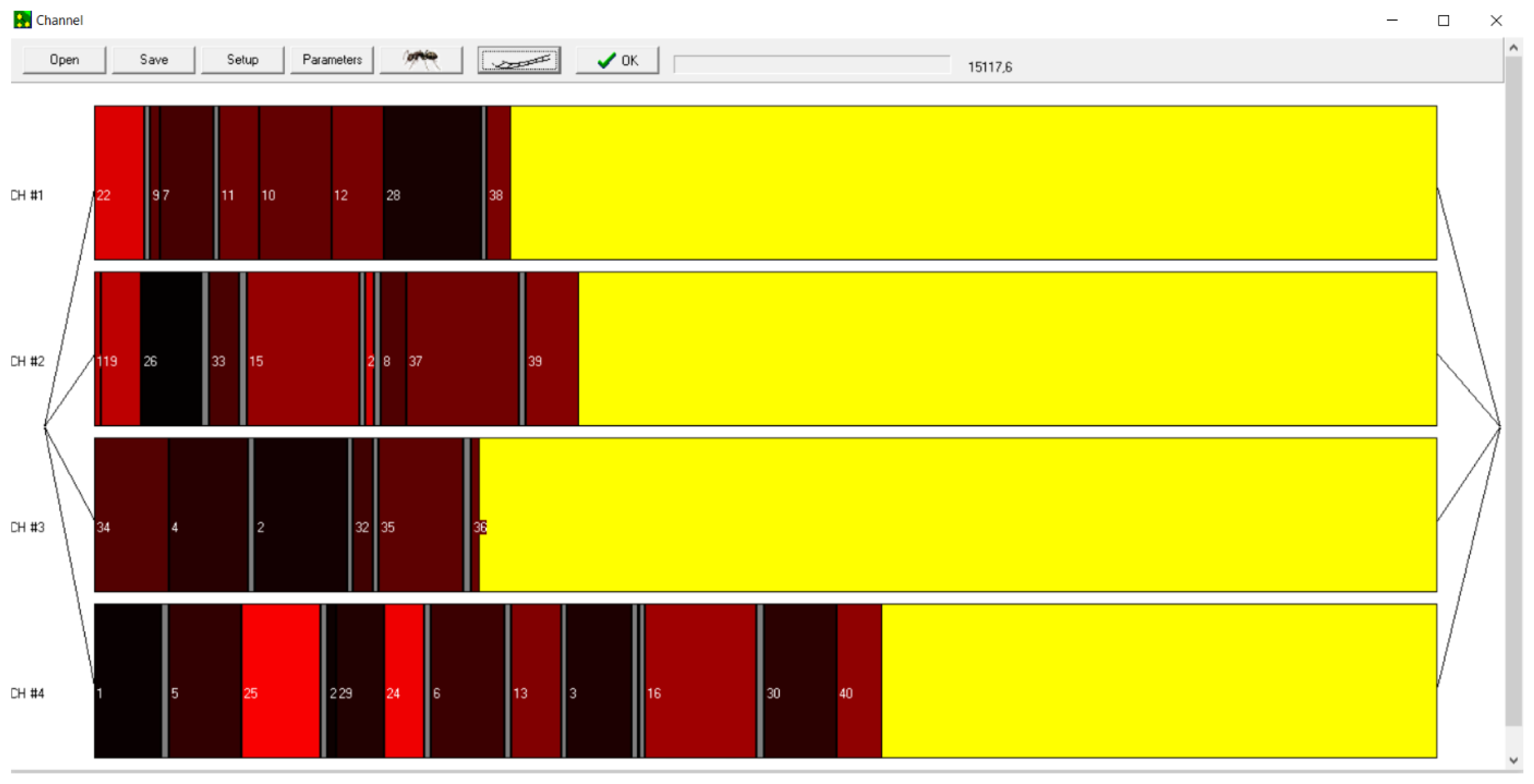

6. Discussions and Results

7. Efficiency of the Algorithm

8. Conclusions

8.1. Theoretical and Practical Implication

8.2. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Notation | Range | Explanation |

| the number of flexible production lines | ||

| the number of different product types | ||

| the number of orders waiting for manufacturing | ||

| i | the series number of the order | |

| j | the series number of the production line | |

| k | the manufacturing element | |

| the number of the series of order i | ||

| ID of production line j | ||

| the series j of the order i. | ||

| the total number of series of all orders | ||

| the number of the series Sij | ||

| the manufacturing cost of the product j on line i. | ||

| the turnaround time of product j on line i. | ||

| the resetting time and cost from series j to serial l on line i. | ||

| The manufacturing cost of the production line j | ||

| The resetting cost of the production line j | ||

| The total cost of the production line j | ||

| The manufacturing time of the production line j | ||

| The reset time of the production line j | ||

| The total manufacturing time of the production line j | ||

| The total objective function | ||

| Normalizing and at the same time weight factor Lead time parameter | ||

| Normalizing and at the same time weight factor Cost parameter |

References

- Zambon, I.; Cecchini, M.; Egidi, G.; Saporito, M.G.; Colantoni, A. Revolution 4.0: Industry vs. Agriculture in a Future Development for SMEs. Processes 2019, 7, 36. [Google Scholar] [CrossRef]

- Salah, B.; Khan, S.; Ramadan, M.; Gjeldum, N. Integrating the Concept of Industry 4.0 by Teaching Methodology in Industrial Engineering Curriculum. Processes 2020, 8, 1007. [Google Scholar] [CrossRef]

- Sevinç, A.; Gür, Ş.; Eren, T. Analysis of the Difficulties of SMEs in Industry 4.0 Applications by Analytical Hierarchy Process and Analytical Network Process. Processes 2018, 6, 264. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, H.; Wang, S.; Lan, M.; Zeng, M.; Zhang, S.; Yang, M.; Yin, S. An Optimization Approach Considering User Utility for the PV-Storage Charging Station Planning Process. Processes 2020, 8, 83. [Google Scholar] [CrossRef]

- Szentesi, S.; Illés, B.; Cservenák, Á.; Skapinyecz, R.; Tamás, P. Multi-Level Optimization Process for Rationalizing the Distribution Logistics Process of Companies Selling Dietary Supplements. Processes 2021, 9, 1480. [Google Scholar] [CrossRef]

- Liu, W.; Luo, F.; Liu, Y.; Ding, W. Optimal Siting and Sizing of Distributed Generation Based on Improved Nondominated Sorting Genetic Algorithm II. Processes 2019, 7, 955. [Google Scholar] [CrossRef]

- Ehyaei, M.A.; Ahmadi, A.; Rosen, M.A.; Davarpanah, A. Thermodynamic Optimization of a Geothermal Power Plant with a Genetic Algorithm in Two Stages. Processes 2020, 8, 1277. [Google Scholar] [CrossRef]

- Aydemir, E.; Koruca, H.I. A New Production Scheduling Module Using Priority-Rule Based Genetic Algorithm. Int. J. Simul. Model. 2015, 14, 450–462. [Google Scholar] [CrossRef]

- Akram, U.; Fülöp, M.T.; Tiron-Tudor, A.; Topor, D.I.; C˘apusneanu, S. Impact of Digitalization on Customers’ Well-Being in the Pandemic Period:Challenges and Opportunities for the Retail Industry. Int. J. Environ. Res. Public Health 2021, 18, 7533. [Google Scholar] [CrossRef]

- He, Y.; Hui, C.-W. A binary coding genetic algorithm for multi-purpose process scheduling: A case study. Chem. Eng. Sci. 2010, 65, 4816–4828. [Google Scholar] [CrossRef]

- Fülöp, M.T.; Szora Tamas, A.; Ivan, O.R.; Solovăstur, A.N. Regressive model regarding the necessary profit margin forecast for a new project in the construction field. Econ. Comput. Econ. Cybern. Stud. Res. 2020, 54, 181–198. [Google Scholar] [CrossRef]

- Salido, M.A.; Escamilla, J.; Giret, A.; Barber, F. A genetic algorithm for energy-efficiency in job-shop scheduling. Int. J. Adv. Manuf. Technol. 2015, 85, 1303–1314. [Google Scholar] [CrossRef]

- Gu, Z.; Chen, M.; Wang, C.; Zhuang, W. Static and Dynamic Analysis of a 6300 KN Cold Orbital Forging Machine. Processes 2020, 9, 7. [Google Scholar] [CrossRef]

- Zhang, R. Sustainable Scheduling of Cloth Production Processes by Multi-Objective Genetic Algorithm with Tabu-Enhanced Local Search. Sustainability 2017, 9, 1754. [Google Scholar] [CrossRef]

- Müller, J.M.; Däschle, S. Business Model Innovation of Industry 4.0 Solution Providers Towards Customer Process Innovation. Processes 2018, 6, 260. [Google Scholar] [CrossRef]

- Borowski, P. Innovative Processes in Managing an Enterprise from the Energy and Food Sector in the Era of Industry 4. Processes 2021, 9, 381. [Google Scholar] [CrossRef]

- Anser, M.; Khan, M.; Awan, U.; Batool, R.; Zaman, K.; Imran, M.; Sasmoko; Indrianti, Y.; Khan, A.; Bakar, Z. The Role of Technological Innovation in a Dynamic Model of the Environmental Supply Chain Curve: Evidence from a Panel of 102 Countries. Processes 2020, 8, 1033. [Google Scholar] [CrossRef]

- Shim, S.-O.; Park, K. Technology for Production Scheduling of Jobs for Open Innovation and Sustainability with Fixed Processing Property on Parallel Machines. Sustainability 2016, 8, 904. [Google Scholar] [CrossRef]

- Zhang, R.; Chiong, R. Solving the energy-efficient job shop scheduling problem: A multi-objective genetic algorithm with enhanced local search for minimizing the total weighted tardiness and total energy consumption. J. Clean. Prod. 2016, 112, 3361–3375. [Google Scholar] [CrossRef]

- Wadhwa, S.; Madaan, J.; Raina, R. A Genetic Algorithm Based Scheduling for a Flexible System. Glob. J. Flex. Syst. Manag. 2007, 8, 15–24. [Google Scholar] [CrossRef]

- Sakaguchi, T.; Kamimura, T.; Shirase, K.; Tanimizu, Y. GA Based Reactive Scheduling for Aggregate Production Scheduling. Manuf. Syst. Technol. New Front. 2008, 7, 275–278. [Google Scholar] [CrossRef]

- Dao, S.D.; Marian, R.M. Genetic Algorithms for Integrated Optimisation of Precedence-Constrained Production Sequencing and Scheduling. In Lecture Notes in Electrical Engineering; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2012; Volume 130, pp. 65–80. [Google Scholar]

- Ning, S.-S.; Wang, W.; Liu, Q.-L. An optimal scheduling algorithm for reheating furnace in steel production. Control Decis. 2006, 21, 1138–1142. [Google Scholar]

- Gong, Z.; Li, J.; Luo, Z.; Wen, C.; Wang, C.; Zelek, J. Mapping and Semantic Modeling of Underground Parking Lots Using a Backpack LiDAR System. IEEE Trans. Intell. Transp. Syst. 2021, 22, 734–746. [Google Scholar] [CrossRef]

- Ren, L.; Howard, D.; Jones, R.K. Mathematical Modelling of Biomechanical Interactions between Backpack and Bearer during Load Carriage. J. Appl. Math. 2013, 2013, 1–12. [Google Scholar] [CrossRef]

- Kim, J.H.; Ma, S.B.; Kim, S.; Choi, Y.S.; Kim, K.Y. Design and verification of a single-channel pump model based on a hybrid optimization technique. Processes 2019, 7, 747. [Google Scholar] [CrossRef]

- Li, C.; Zhai, R.; Liu, H.; Yang, Y.; Wu, H. Optimization of a heliostat field layout using hybrid PSO-GA algorithm. Appl. Therm. Eng. 2018, 128, 33–41. [Google Scholar] [CrossRef]

- Choudhary, A.; Kumar, M.; Gupta, M.K.; Unune, D.K.; Mia, M. Mathematical modeling and intelligent optimization of submerged arc welding process parameters using hybrid PSO-GA evolutionary algorithms. Neural Comput. Appl. 2019, 32, 5761–5774. [Google Scholar] [CrossRef]

- Xu, A.; Lu, Y.; Da, D.; Ti, N.; He, D. Hybrid direct hot charge rolling production for specific reheating furnace mode. J. Univ. Sci. Technol. Beijing 2012, 34, 1091–1096. [Google Scholar]

- Mao, K.; Pan, Q.; Tasgetiren, M.F. Lagrangian heuristic for scheduling a steelmaking-continuous casting process. In Proceedings of the 2013 IEEE Symposium on Computational Intelligence in Scheduling (CISched), Singapore, 16–19 April 2013; pp. 68–74. [Google Scholar]

- Hou, N.; He, F.; Zhou, Y.; Chen, Y. An efficient GPU-based parallel tabu search algorithm for hardware/software co-design. Front. Comput. Sci. 2020, 14, 1–18. [Google Scholar] [CrossRef]

- Burduk, A.; Musiał, K.; Kochańska, J.; Górnicka, D.; Stetsenko, A. Tabu search and genetic algorithm for production process scheduling problem. LogForum 2019, 15, 181–189. [Google Scholar] [CrossRef]

- Sun, L.; Luan, F.; Ying, Y.; Mao, K. Rescheduling optimization of steelmaking-continuous casting process based on the Lagrangian heuristic algorithm. J. Ind. Manag. Optim. 2017, 13, 1431–1448. [Google Scholar] [CrossRef][Green Version]

- Hu, H.X.; Lei, W.X.; Gao, X.; Zhang, Y. Job-Shop Scheduling Problem Based on Improved Cuckoo Search Algorithm. Int. J. Simul. Model. 2018, 17, 337–346. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, Y.; Luo, Y.; Zhang, S. Improved cuckoo search algorithm and its application to permutation flow shop scheduling problem. J. Algorithms Comput. Technol. 2020, 14, 1748302620962403. [Google Scholar] [CrossRef]

- Ghosh, T.K.; Das, S.; Barman, S.; Goswami, R. Job scheduling in computational grid based on an improved cuckoo search method. Int. J. Comput. Appl. Technol. 2017, 55, 138–146. [Google Scholar] [CrossRef]

- Wang, X.; Tang, L. Integration of batching and scheduling for hot rolling production in the steel industry. Int. J. Adv. Manuf. Technol. 2008, 36, 431–441. [Google Scholar] [CrossRef]

- Lambiase, F. Optimization of shape rolling sequences by integrated artificial intelligent techniques. Int. J. Adv. Manuf. Technol. 2013, 68, 443–452. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Sun, F.; Fang, B. Kernel regularized nonlinear dictionary learning for sparse coding. IEEE Trans. Syst. Man Cybern. Syst. 2017, 99, 1–10. [Google Scholar] [CrossRef]

- Liu, H.; Wu, Y.; Sun, F.; Fang, B.; Guo, D. Weakly Paired Multimodal Fusion for Object Recognition. IEEE Trans. Autom. Sci. Eng. 2017, 15, 784–795. [Google Scholar] [CrossRef]

- Leu, S.-S.; Hwang, S.-T. GA-based resource-constrained flow-shop scheduling model for mixed precast production. Autom. Constr. 2002, 11, 439–452. [Google Scholar] [CrossRef]

- Yan, S.; Lai, W. An optimal scheduling model for ready mixed concrete supply with overtime considerations. Autom. Constr. 2007, 16, 734–744. [Google Scholar] [CrossRef]

- Caridi, M.; Sianesi, A. Multi-agent systems in production planning and control: An application to the scheduling of mixed-model assembly lines. Int. J. Prod. Econ. 2000, 68, 29–42. [Google Scholar] [CrossRef]

- de Prada, C.; Grossmann, I.; Sarabia, D.; Cristea, S. A strategy for predictive control of a mixed continuous batch process. J. Process Control 2009, 19, 123–137. [Google Scholar] [CrossRef]

- Silva, A.F.D.; Marins, F.A.S.; Montevechi, J.A.B. Application of mixed binary goal programming in an enterprise in the sugar and energy sector. Gestão Produção 2013, 20, 321–336. [Google Scholar] [CrossRef]

- Lim, M.; Zhang, D. An integrated agent-based approach for responsive control of manufacturing resources. Comput. Ind. Eng. 2004, 46, 221–232. [Google Scholar] [CrossRef]

- Scarlat, E.; Boloş, M.; Popovici, I. Agent-based modeling in decision-making for project financing. J. Econ. Comput. Econ. Cybern. Stud. Res. 2011, 5–10, WOS:000292347200001. [Google Scholar]

- Rody, R.; Mahmudy, W.F.; Tama, I.P. Using Guided Initial Chromosome of Genetic Algorithm for Scheduling Production-Distribution System. J. Inf. Technol. Comput. Sci. 2019, 4, 26–32. [Google Scholar] [CrossRef][Green Version]

- Que, Y.; Zhong, W.; Chen, H.; Chen, X.; Ji, X. Improved adaptive immune genetic algorithm for optimal QoS-aware service composition selection in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 4455–4465. [Google Scholar] [CrossRef]

- Sharma, S.; Chadha, M.; Kaur, H. Multi-step crossover genetic algorithm for bi-criteria parallel machine scheduling problems. Int. J. Math. Oper. Res. 2021, 18, 71. [Google Scholar] [CrossRef]

- Li, S.; Yu, T.; Cao, X.; Pei, Z.; Yi, W.; Chen, Y.; Lv, R. Machine learning-based scheduling: A bibliometric perspective. IET Collab. Intell. Manuf. 2021, 3, 131–146. [Google Scholar] [CrossRef]

- Li, M.W.; Hong, W.C.; Geng, J.; Wang, J. Berth and quay crane coordinated scheduling using multiobjective chaos cloud particle swarm optimization algorithm. Neural Comput. Appl. 2017, 28, 3163–3182. [Google Scholar] [CrossRef]

- Lamghari, A.; Dimitrakopoulos, R.; A Ferland, J. A variable neighbourhood descent algorithm for the open-pit mine production scheduling problem with metal uncertainty. J. Oper. Res. Soc. 2014, 65, 1305–1314. [Google Scholar] [CrossRef]

- Koo, J.; Kim, B.-I. Some comments on “Optimization of production scheduling with time-dependent and machine-dependent electricity cost for industrial energy efficiency”. Int. J. Adv. Manuf. Technol. 2016, 86, 2803–2806. [Google Scholar] [CrossRef]

- Aghelinejad, M.; Ouazene, Y.; Yalaoui, A. Production scheduling optimisation with machine state and time-dependent energy costs. Int. J. Prod. Res. 2017, 56, 5558–5575. [Google Scholar] [CrossRef]

- Yao, M.-J.; Huang, J.-X. Solving the economic lot scheduling problem with deteriorating items using genetic algorithms. J. Food Eng. 2005, 70, 309–322. [Google Scholar] [CrossRef]

- Salga, P.; Szilágyi, R.; Herdon, M. Genetikus algoritmus alkalmazása a mezőgazdasági termelés optimalizálásában (The use of genetic algorithms in the optimization of agricultural production). In E-agrárium & E-vidék: Agrárinformatikai Nyári Egyetem és Agrárinformatikai Fórum; Magyar Agrárinformatikai Szövetség: Debrecen, Hungary, 2013; pp. 1–7. [Google Scholar]

- Capusneanu, S.; Topor, D.I.; Hint, M.S.; Ionescu, C.A.; Coman, M.D.; Paschia, L.; Nicolau, N.L.G.; Ivan, O.R. Mathematical model for identifying and quantifying the overall environmental cost. J. Bus. Econ. Manag. 2020, 21, 1307–1328. [Google Scholar] [CrossRef]

- Coita, I.F.; Cioban, S.; Mare, C. Is Trust a Valid Indicator of Tax Compliance Behaviour? A Study on Taxpayers’ Public Perception Using Sentiment Analysis Tools. In Proceedings of the 4th International Conference on Resilience and Economic Intelligence through Digitalization and Big Data Analytics, Bucharest, Romania, 10–11 June 2021; ICESS Springer in Business and Economics: Bucharest, Romania, 2021. [Google Scholar]

- Ionescu, C.A.; Fülöp, M.T.; Topor, D.I.; Căpușneanu, S.; Breaz, T.O.; Stănescu, S.G.; Coman, M.D. The New Era of Business Digitization through the Implementation of 5G Technology in Romania. Sustainability 2021, 13, 13401. [Google Scholar] [CrossRef]

- Gubán, M. Matematikai modellezés Az önfenntartó falugazdaság modellje a hálózati gazdaságban (Mathematical Modelling: The Model of the Self-Sustaining Village Economy in Network Economies); Budapesti Gazdasági Főiskola: Salgótarján, Hungary, 2005. [Google Scholar]

| 1 | 2 | … | … | … | s | ||||

| … | … | … |

| 2 | … | s | ||||

| … | ||||||

| 1 | 2 | 3 | 4 | 5 | |||||

| 0 | 10 | 1 | 4 | 1 | 3 | 0 | 2 | 1 | 4 |

| Line 0 | Series 4 | Series 1 | |

| Line 1 | Series 3 | Series 2 | Series 5 |

| 1 | 2 | 3 | 4 | 5 | |||||

| 0 | 10 | 1 | 4 | 1 | 3 | 0 | 2 | 1 | 4 |

| 1 | 2 | 3 | 4 | 5 | |||||

| 1 | 7 | 1 | 3 | 0 | 1 | 0 | 4 | 0 | 2 |

| 1 | 2 | 3 | 4 | 5 | |||||

| 0 | 10 | 1 | 3 | 0 | 1 | 0 | 4 | 1 | 4 |

| 1 | 2 | 3 | 4 | 5 | |||||

| 1 | 7 | 1 | 4 | 1 | 3 | 0 | 2 | 0 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fülöp, M.T.; Gubán, M.; Gubán, Á.; Avornicului, M. Application Research of Soft Computing Based on Machine Learning Production Scheduling. Processes 2022, 10, 520. https://doi.org/10.3390/pr10030520

Fülöp MT, Gubán M, Gubán Á, Avornicului M. Application Research of Soft Computing Based on Machine Learning Production Scheduling. Processes. 2022; 10(3):520. https://doi.org/10.3390/pr10030520

Chicago/Turabian StyleFülöp, Melinda Timea, Miklós Gubán, Ákos Gubán, and Mihály Avornicului. 2022. "Application Research of Soft Computing Based on Machine Learning Production Scheduling" Processes 10, no. 3: 520. https://doi.org/10.3390/pr10030520

APA StyleFülöp, M. T., Gubán, M., Gubán, Á., & Avornicului, M. (2022). Application Research of Soft Computing Based on Machine Learning Production Scheduling. Processes, 10(3), 520. https://doi.org/10.3390/pr10030520