Technical and Environmental Feasibility Study of the Co-Production of Crude Oil and Electrical Energy from Geothermal Resources: First Field Trial in Colombia

Abstract

:1. Introduction

2. Methodology

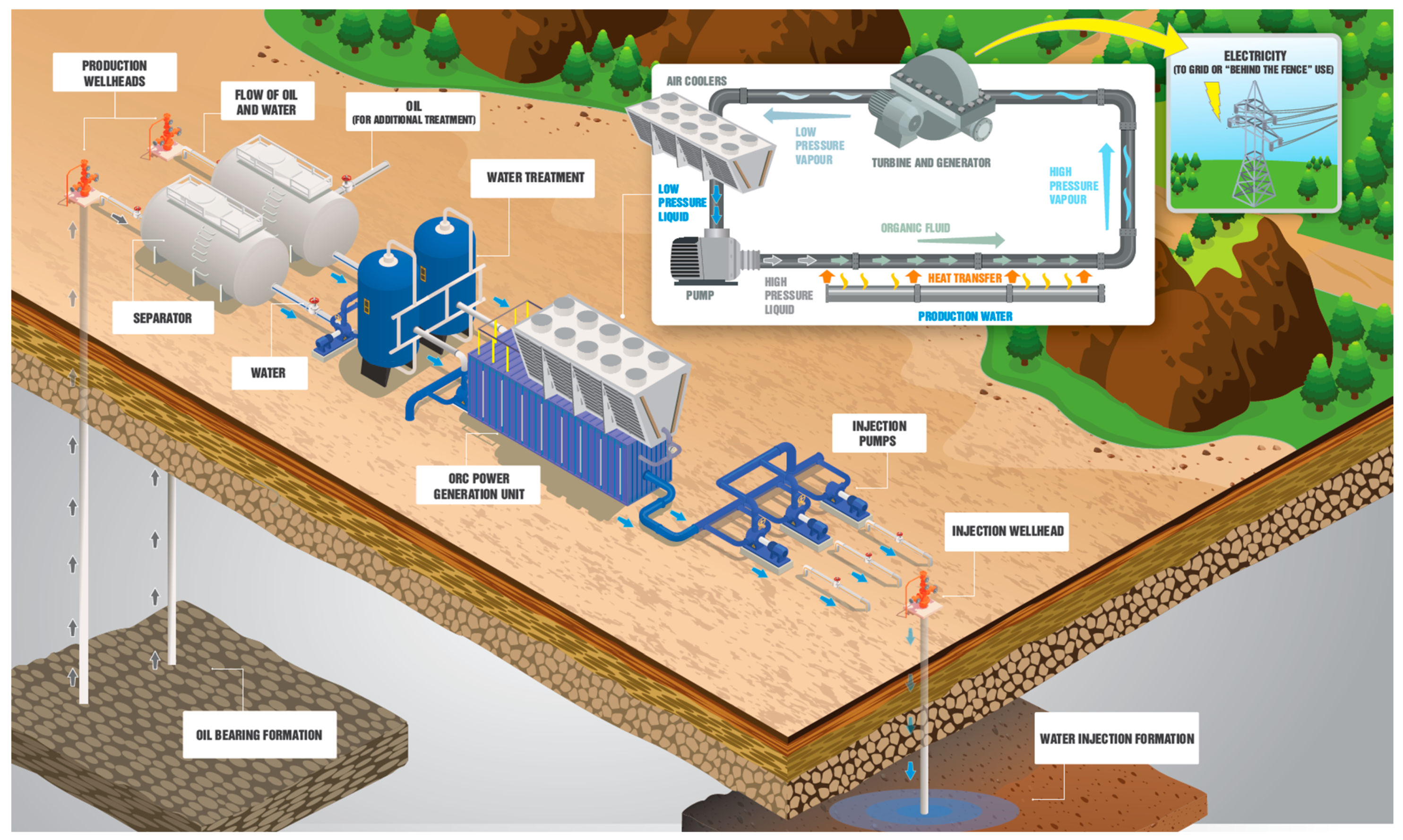

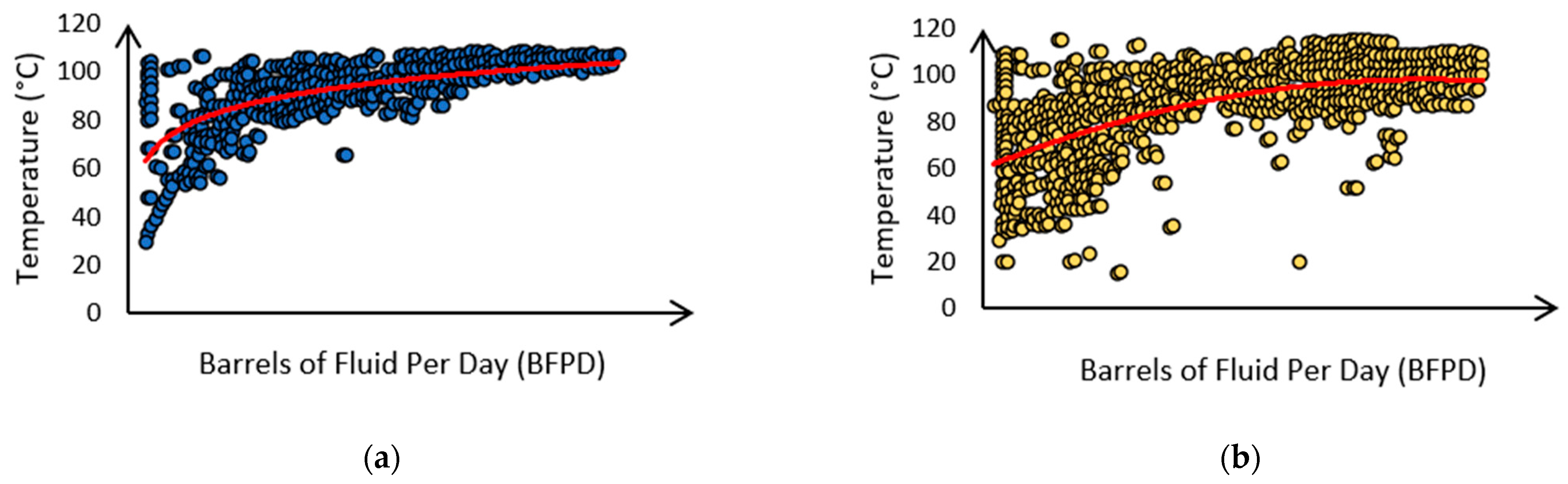

2.1. Estimation of Geothermal Potential in Two Colombian Oil Fields

2.2. Effect of Oilfield Geothermal Energy on Carbon Emissions Intensity Using the Life Cycle Analysis Approach

- Scenario 1: 100% of liquid fuel consumption is replaced by purchased gas.

- Scenario 2: 100% of liquid fuel consumption is replaced by field gas.

- Scenario 3: 100% of energy demands are supplied by purchased gas.

- Scenario 4: 100% of energy demands are supplied by field gas.

3. Results

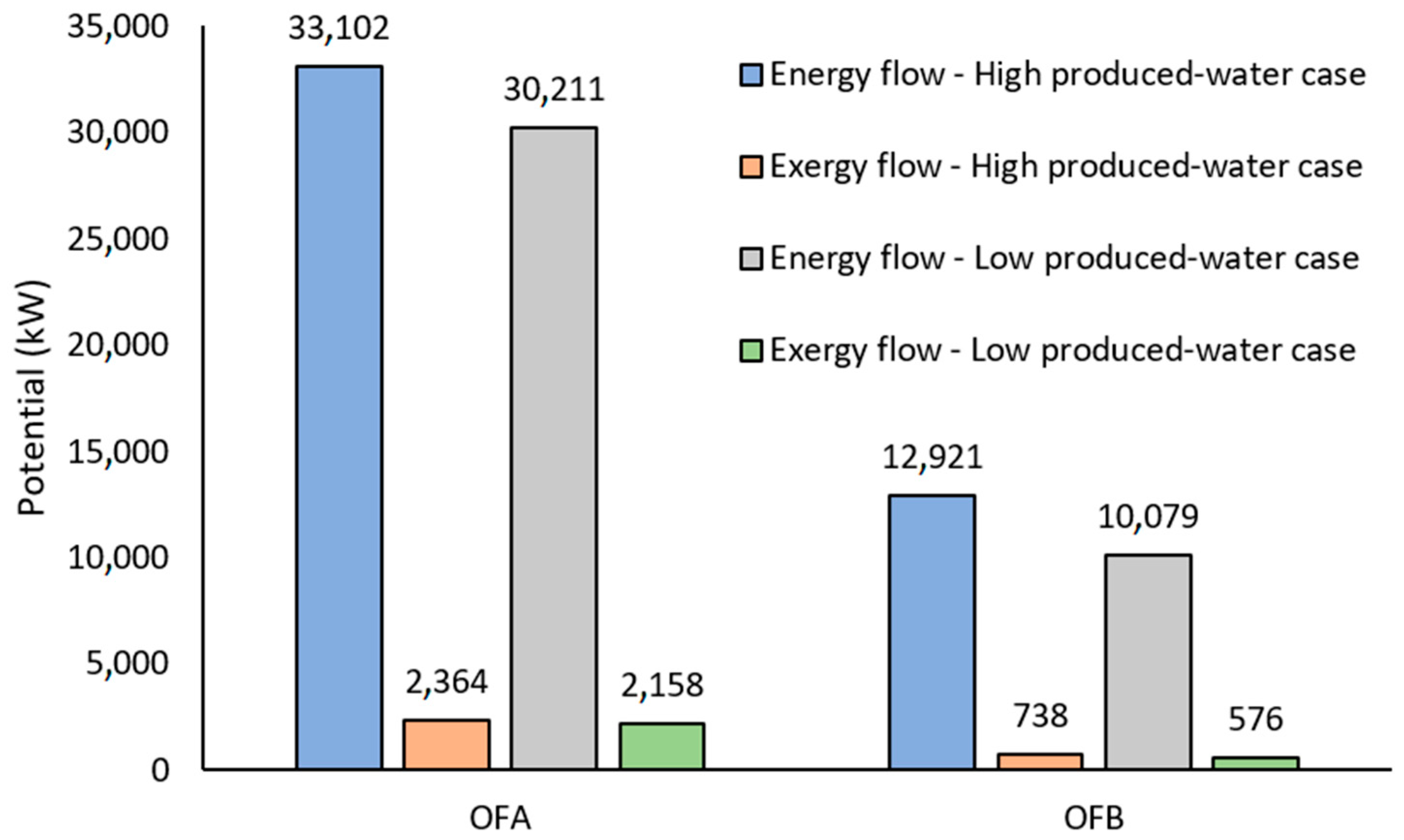

3.1. Geothermal Energy Potential

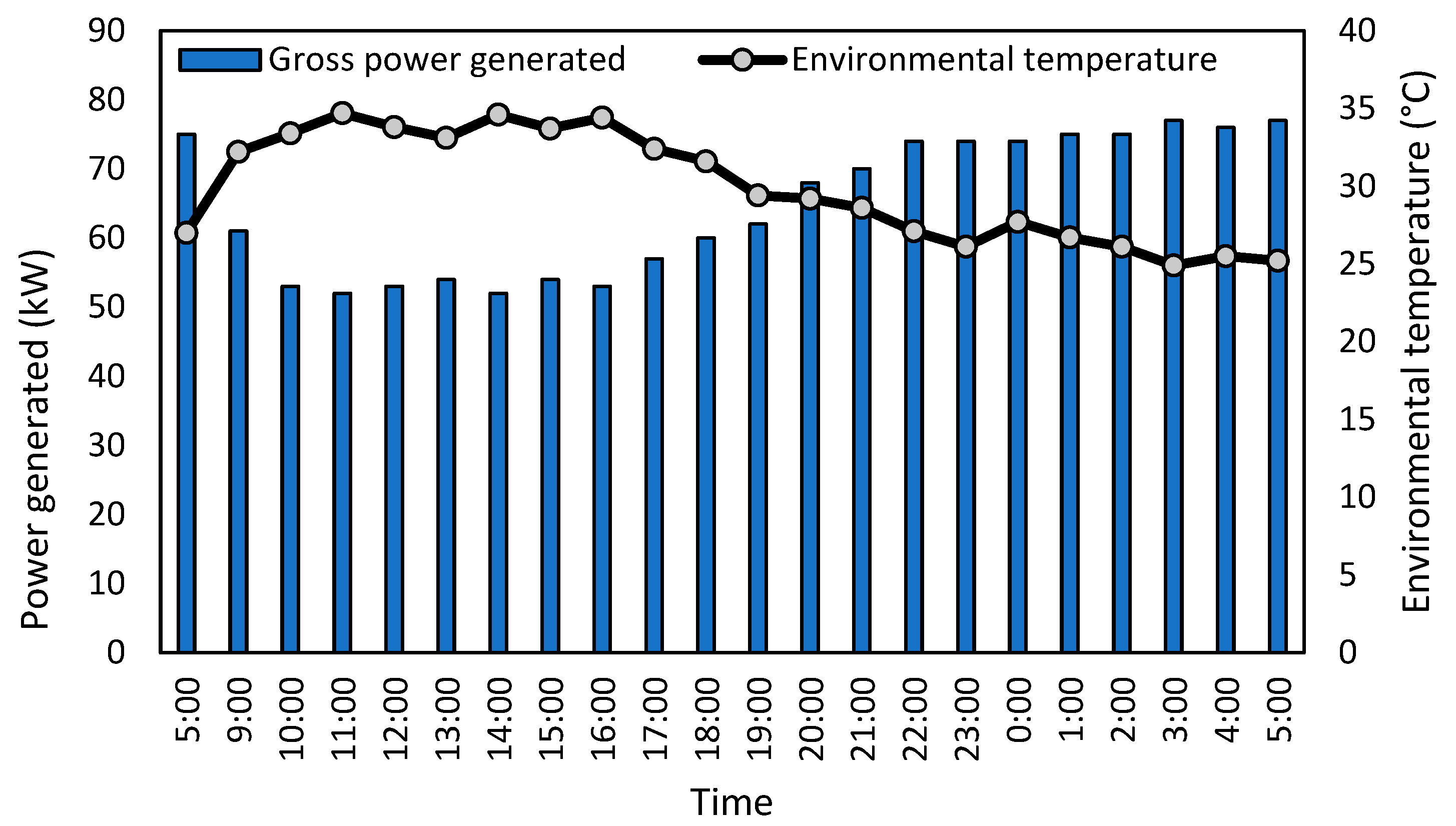

3.2. Production of the First Pilots in Colombia: Electrical Power Production

3.3. Carbon Footprint Calculation for the Two Colombian Oil Fields

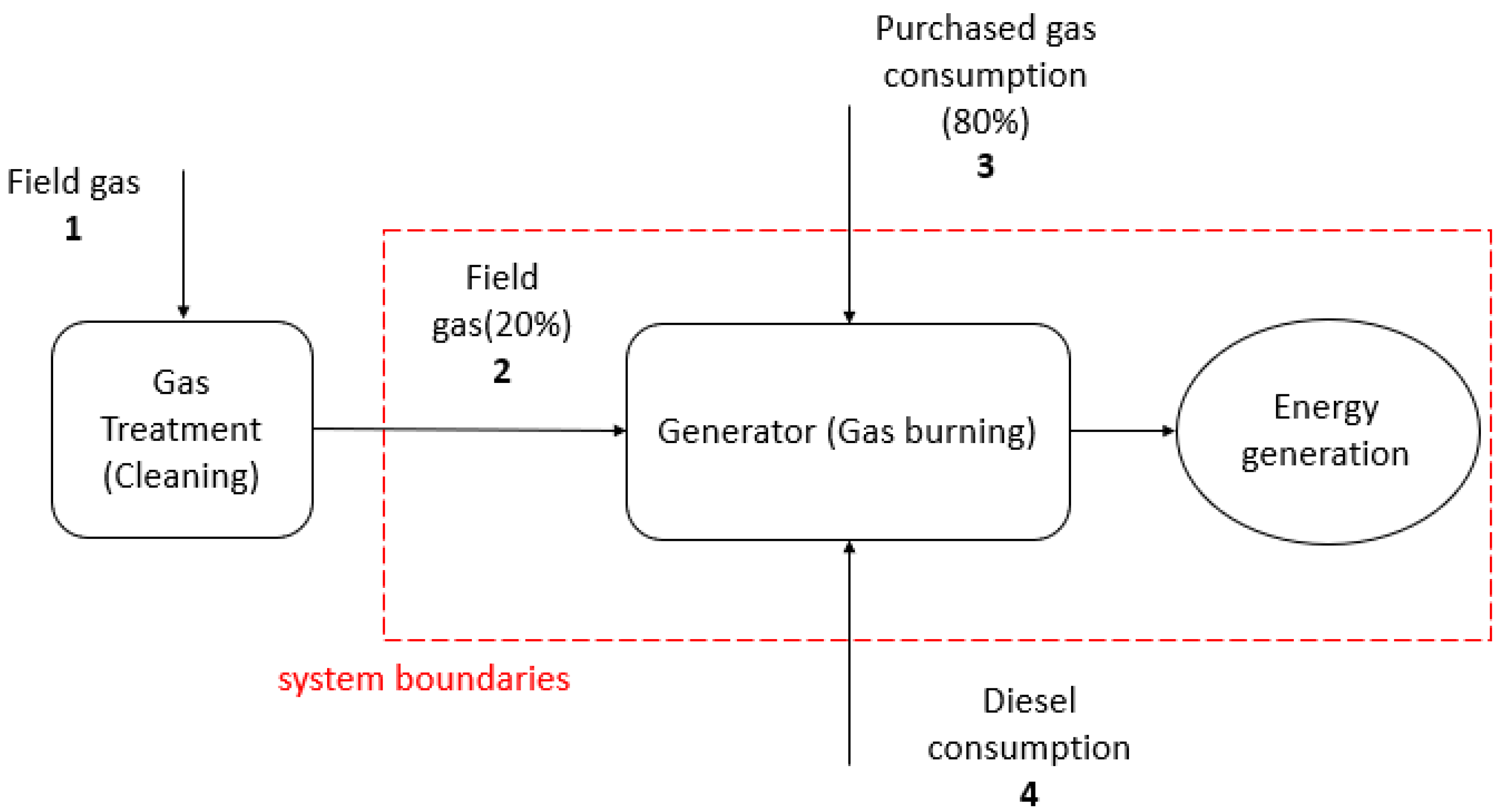

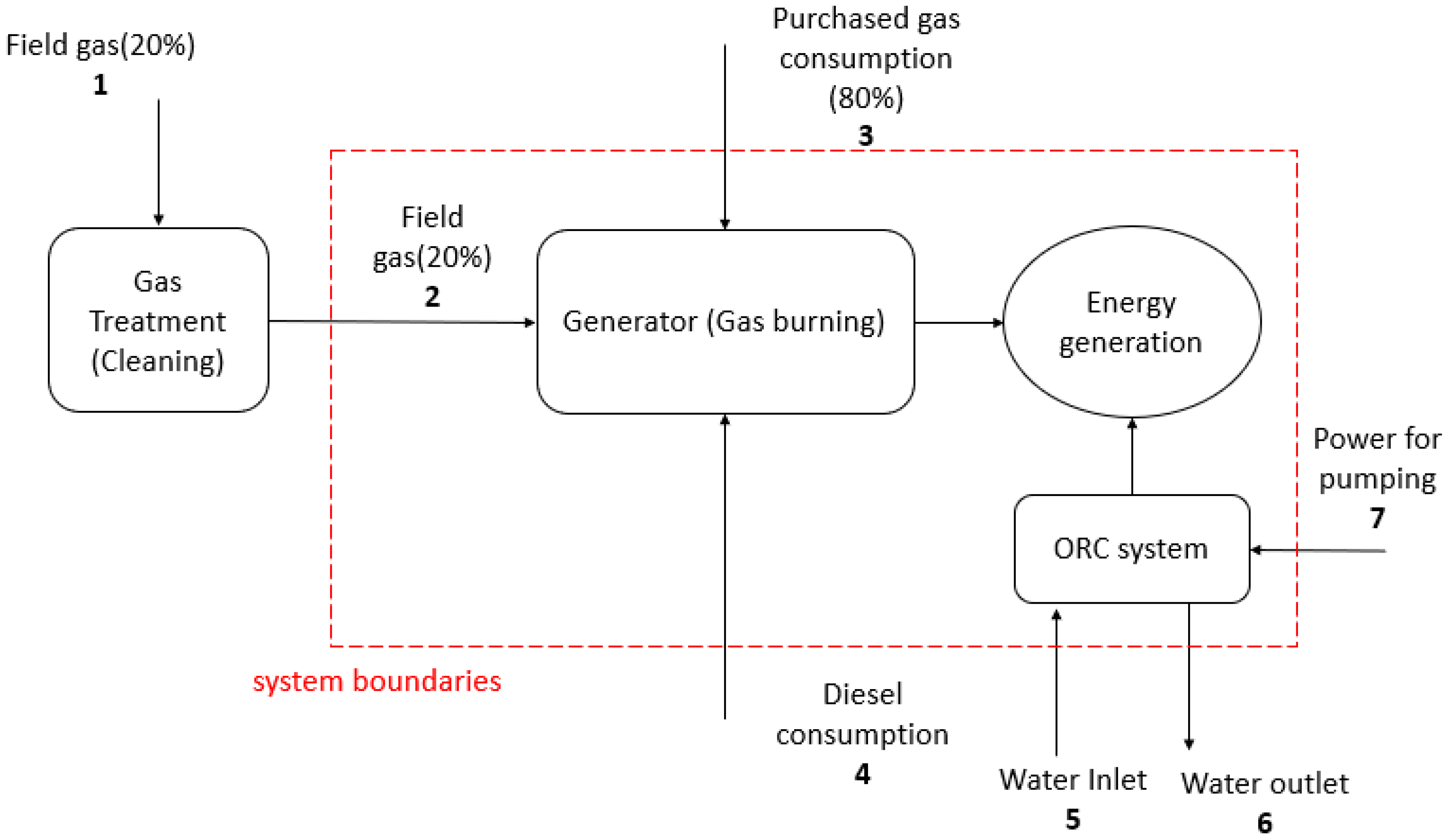

3.3.1. System Boundaries and Carbon Footprint Inventory Data

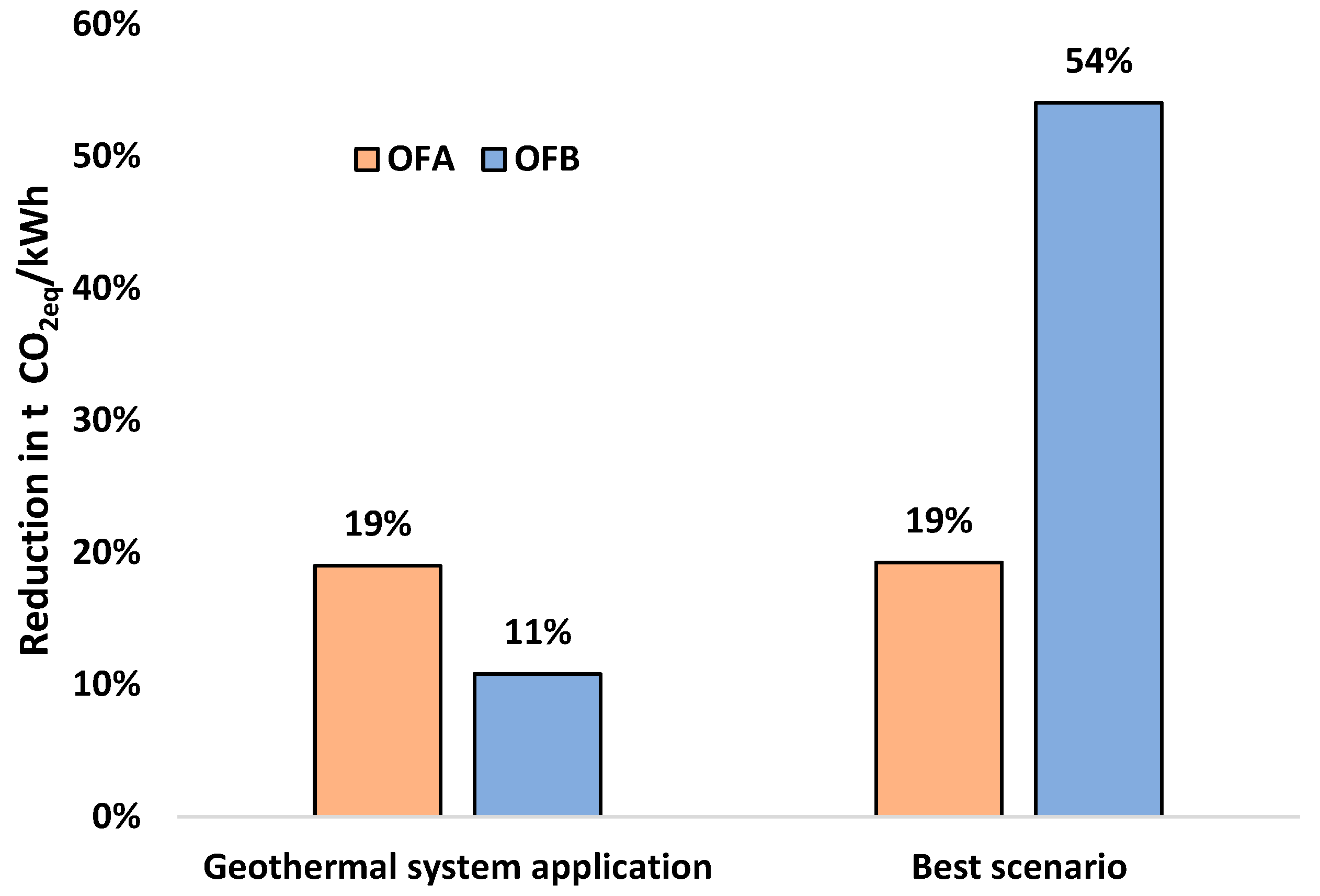

3.3.2. Carbon Footprint Accounting for Energy Production from Non-Renewable Resources and Geothermal Energy Co-Generation Systems

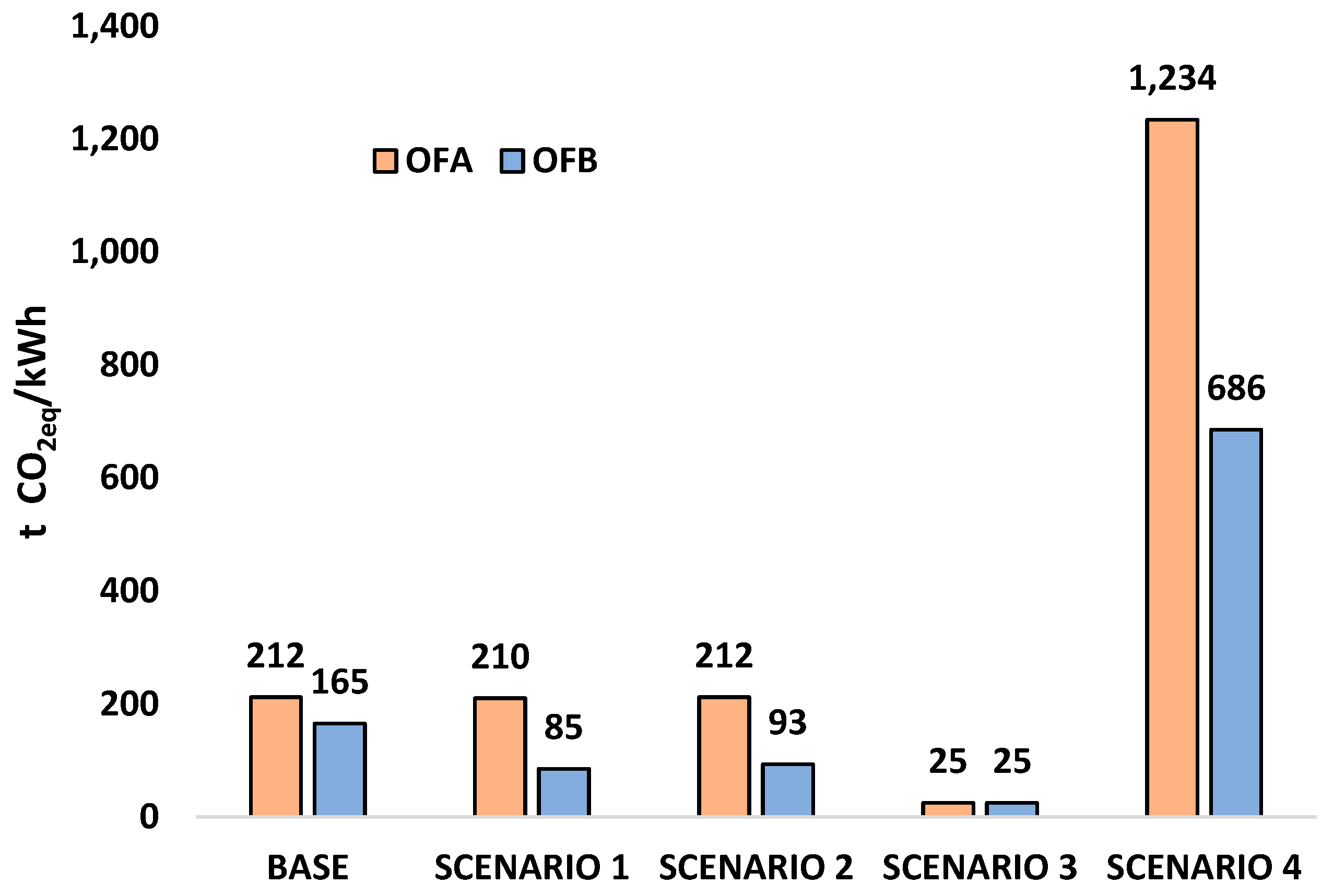

3.3.3. Effect of the Variation in Consumption of Non-Renewable Resources on the Carbon Footprint in the Geothermal Energy Co-Generation System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Vilches, A.; Gil Pérez, D.; Toscano, J.; Macías, O. La Transición Energética. Una Nueva Cultura de la Energía; OEI: Madrid, Spain, 2014; ISBN 978-84-7666-213-7. [Google Scholar]

- Vie, P.; Bonanni, A.; Lewiner, C.; Cozzens, R.; Modi, G.; Klingberg, A.; Lindhaus, J.; Lemaitre, E.; Sinha, N.; Ghosh, A. World Energy Markets Observatory-Wemo 2020, 22 edition, November 2020. France. Available online: https://inis.iaea.org/search/searchsinglerecord.aspx?recordsFor=SingleRecord&RN=51124578 (accessed on 27 January 2020).

- EPA. Global Grenhouse Gas Emissions Data. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 27 January 2020).

- Agreement, P. Adoption of the Paris Agreement’ fccc/cp/2015/L; UNFCCC: Bonn, Germany, 2015; Volume 9. [Google Scholar]

- UNFCCC. The 2021 United Nations Climate Change Conference. In Proceedings of the 2021 United Nations Climate Change Conference, Glasgow, UK, 31 October–13 November 2021. [Google Scholar]

- Álvarez-Espinosa, A.C.; Ordóñez, D.A.; Nieto, A.; Wills, W.; Romero, G.; Calderón, S.L.; Hernández, G.; Argüello, R.; Delgado-Cadena, R. Economic Evaluation of Colombia’s Commitment at COP21. Desarro. Soc. 2017, 79, 15–54. [Google Scholar] [CrossRef]

- CAMPETROL. Transformación Energética en Colombia; Unavisión de Campetrol: Quito, Ecuador, 2019. [Google Scholar]

- Radomes, A.A., Jr.; Arango, S. Renewable energy technology diffusion: An analysis of photovoltaic-system support schemes in Medellín, Colombia. J. Clean. Prod. 2015, 92, 152–161. [Google Scholar] [CrossRef]

- García, C. Mapa Energético de Colombia 2019–2050. Available online: https://www1.upme.gov.co/DemandaEnergetica/PEN_documento_para_consulta.pdf (accessed on 27 January 2020).

- Caspary, G. Gauging the future competitiveness of renewable energy in Colombia. Energy Econ. 2009, 31, 443–449. [Google Scholar] [CrossRef]

- Alfaro, C. Improvement of Perception of the Geothermal Energy as A Potential Source of Electrical Energy in Colombia, Country Update. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 15–24 April 2015; pp. 19–24. [Google Scholar]

- Alfaro, C.; Ponce, P.; Monsalve, M.L.; Ortiz, I.; Franco, J.V.; Ortega, A.; Torres, R.; Gómez, D. A Preliminary Conceptual Model of Azufral Geothermal System, Colombia. In Proceedings of the World Geothermal Congress, Melbourne, Australia, 15–24 April 2015. [Google Scholar]

- Arias-Gaviria, J.; Carvajal-Quintero, S.X.; Arango-Aramburo, S.J.R.E. Understanding dynamics and policy for renewable energy diffusion in Colombia. Renew. Energy 2019, 139, 1111–1119. [Google Scholar] [CrossRef]

- Salazar, S.S.; Muñoz, Y.; Ospino, A. Analysis of geothermal energy as an alternative source for electricity in Colombia. Geotherm. Energy 2017, 5, 27. [Google Scholar] [CrossRef] [Green Version]

- Bachu, S.; Ramon, J.C.; Villegas, M.E.; Underschultz, J.R. Geothermal regime and thermal history of the Llanos Basin, Colombia. AAPG Bull. 1995, 79, 116–128. [Google Scholar] [CrossRef]

- Lozano, E.J.G. Hot springs and geothermal energy in Colombia. Geothermics 1988, 17, 377–379. [Google Scholar] [CrossRef]

- Marzolf, N.C. Emprendimiento de la Energía Geotérmica en Colombia. Available online: https://publications.iadb.org/publications/spanish/document/Emprendimiento-de-la-energ%C3%ADa-geot%C3%A9rmica-en-Colombia.pdf (accessed on 27 January 2020).

- Mejía, E.; Rayo, L.; Méndez, J.; Echeverri, J. Geothermal development in Colombia. In Short Course VI on Utilization of Low- and Medium-Enthalpy Geothermal Resources and Financial Aspects of Utilization; UNU-GTP LaGeo: Santa Tecla, El Salvador, 2014. [Google Scholar]

- Moreno-Rendón, D.A.; López-Sánchez, J.; Blessent, D. Geothermal Energy in Colombia as of 2018. Ing. Univ. 2020, 24, 1–27. Available online: https://10.11144/Javeriana.iyu24.geic. (accessed on 27 January 2020). [CrossRef]

- Leitch, A.; Haley, B.; Hastings-Simon, S. Can the oil and gas sector enable geothermal technologies? Socio-technical opportunities and complementarity failures in Alberta, Canada. Energy Policy 2019, 125, 384–395. [Google Scholar] [CrossRef]

- Toth, A.N.; Szucs, P.; Pap, J.; Nyikos, A.; Fenerty, D.K. Converting Abandoned Hungarian Oil and Gas Wells into Geothermal Sources. In Proceedings of the 43rd Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 12–14 February 2018. [Google Scholar]

- Watson, S.M.; Falcone, G.; Westaway, R. Repurposing hydrocarbon wells for geothermal use in the UK: The onshore fields with the greatest potential. Energies 2020, 13, 3541. [Google Scholar] [CrossRef]

- Nugroho, W.; Hermawan, S.; Lazuardi, B.; Mirza, R. Drilling Problems Mitigation in Geothermal Environment, Case Studies of Stuck Pipe and Lost Circulation. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 17–19 October 2017. [Google Scholar]

- Harris, B. A CFD Study on the Extraction of Geothermal Energy from Abandoned Oil and Gas Wells. Master’s Thesis, McMaster University, Hamilton, ON, Canada, 2017. [Google Scholar]

- Kharseh, M.; Al-Khawaja, M.; Hassani, F. Optimal utilization of geothermal heat from abandoned oil wells for power generation. Appl. Therm. Eng. 2019, 153, 536–542. [Google Scholar] [CrossRef]

- Wang, S.; Yan, J.; Li, F.; Hu, J.; Li, K. Exploitation and utilization of oilfield geothermal resources in China. Energies 2016, 9, 798. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Yuan, B.; Ji, G.; Wu, X. A comprehensive review of geothermal energy extraction and utilization in oilfields. J. Pet. Sci. Eng. 2018, 168, 465–477. [Google Scholar]

- Choi, Y.; Lee, C.; Song, J. Review of renewable energy technologies utilized in the oil and gas industry. Int. J. Renew. Energy Res. 2017, 7, 592–598. [Google Scholar]

- Raos, S.; Ilak, P.; Rajšl, I.; Bilić, T.; Trullenque, G. Multiple-criteria decision-making for assessing the enhanced geothermal systems. Energies 2019, 12, 1597. [Google Scholar] [CrossRef] [Green Version]

- Chiasson, A.D. Geothermal Heat Pump and Heat Engine Systems: Theory and Practice; John Wiley & Sons: London, UK, 2016. [Google Scholar]

- Liu, X.; Falcone, G.; Alimonti, C.J.E. A systematic study of harnessing low-temperature geothermal energy from oil and gas reservoirs. Energy 2018, 142, 346–355. [Google Scholar] [CrossRef] [Green Version]

- Gosnold, W.; Mann, M.; Salehfar, H. Challenges in Implementing a Multi-Partnership Geothermal Power Plant; University of North Dakota: Grand Forks, ND, USA, 2017. [Google Scholar]

- Gosnold, W.; Crowell, A.; Nordeng, S.; Mann, M. Co-produced and low-temperature geothermal resources in the Williston Basin. GRC Trans. 2015, 39, 2015. [Google Scholar]

- Vraa, H.; Picklo, M.; Hertz, E.; Gosnold, W. Geothermal Energy Utilization of Multi-Well Oil Pads via the Application Of Organic Rankine Cycle Systems. Geotherm. Resour. Counc. Trans. 2019, 43, 1078–1084. [Google Scholar]

- Gosnold, W.; LeFever, R.; Klenner, R.; Mann, M. Geothermal Power form Coproduced Fluids in the Williston Basin. In Proceedings of the Geothermal Resources Council 2010 Annual Meeting, Sacramento, CA, USA, 24–27 October 2010. [Google Scholar]

- Gosnold, W.; Abudureyimu, S.; Tisiryapkina, I.; Wang, D.; Ballesteros, M. The Potential for Binary Geothermal Power in the Williston Basin. GRC Trans. 2019, 43, 114–126. [Google Scholar]

- Gosnold, W.; Mann, M.; Salehfar, H. The UND-CLR binary geothermal power plant. GRC Trans. 2017, 41, 1824–1834. [Google Scholar]

- Bennett, K.; Horne, R.N.; Li, K. Power Generation Potential from Coproduced Fluids in the Los Angeles Basin; Stanford University: Stanford, CA, USA, 2012. [Google Scholar]

- Singh, H.; Falcone, G.; Volle, A.; Guillon, L. Harnessing Geothermal Energy from Mature Onshore Oil Fields, The Wytch Farm Case Study. In Proceedings of the 42nd Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 13–15 February 2017; pp. 13–15. [Google Scholar]

- Milliken, M. Geothermal Resources at Naval Petroleum Reserve-3 (NPR-3), Wyoming. In Proceedings of the Thirty-Second Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 22–24 January 2007. [Google Scholar]

- Nordquist, J.; Johnson, L. Production of Power from the Co-Produced Water of Oil Wells, 3.5 Years of Operation. In Proceedings of the Geothermal Resources Council Transactions, Geothermal Resources Council 2012 Annual Meeting, 2012, Reno, NV, USA, 30 September–8 October 2012; pp. 207–210. [Google Scholar]

- Johnson, L.; Simon, D.L. Electrical Power from An Oil Production Waste Stream. In Proceedings of the Thirty-Forth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 9–11 February 2009. [Google Scholar]

- Reinhardt, T.; Johnson, L.A.; Popovich, N.; Poplar, N. Systems for Electrical Power from Coproduced and Low Temperature Geothermal Resources. In Proceedings of the 36th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 31 January–2 February 2011. [Google Scholar]

- Xin, S.; Liang, H.; Hu, B.; Li, K. A 400 kW geothermal power generator using co-produced fluids from Huabei oilfield. Geotherm. Resour. Counc. Trans. 2012, 36, 219–223. [Google Scholar]

- Li, T.; Liu, Q.; Xu, Y.; Dong, Z.; Meng, N.; Jia, Y.; Qin, H. Techno-economic performance of multi-generation energy system driven by associated mixture of oil and geothermal water for oilfield in high water cut. Geothermics 2021, 89, 101991. [Google Scholar] [CrossRef]

- Gutiérrez Pulido, H.; Vara Salazar, R.d.l. Análisis y Diseño de Experimentos; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Akhmadullin, I. Utilization of Co-Produced Water from Oil Production: Energy Generation Case. In Proceedings of the SPE Health, Safety, Security, Environment, & Social Responsibility Conference-North America, New Orleans, LA, USA, 18–20 April 2017. [Google Scholar]

- Augustine, C.; Falkenstern, D.M. An Estimate of the Near-Term Electricity-Generation Potential of Coproduced Water From Active Oil and Gas Wells. SPE J. 2014, 19, 530–541. [Google Scholar] [CrossRef]

- Auld, A.; Hogg, S.; Berson, A.; Gluyas, J. Power production via North Sea hot brines. Energy 2014, 78, 674–684. [Google Scholar] [CrossRef] [Green Version]

- Banks, J.; Willems, C.J.; Cowper, A.; Nadkarni, K.; Poulette, S.; Van Allen, C. Geothermal Power Potential of the Virginia Hills Oil Field, Part of the Swan Hills Carbonate Complex; Alberta, Canada. In Proceedings of the World Geothermal Congress, Reykjavik, Iceland, 27 April 2020. [Google Scholar]

- Li, T.; Zhu, J.; Zhang, W. Cascade utilization of low temperature geothermal water in oilfield combined power generation, gathering heat tracing and oil recovery. Appl. Therm. Eng. 2012, 40, 27–35. [Google Scholar] [CrossRef]

- Yang, Y.; Huo, Y.; Xia, W.; Wang, X.; Zhao, P.; Dai, Y. Construction and preliminary test of a geothermal ORC system using geothermal resource from abandoned oil wells in the Huabei oilfield of China. Energy Econ. 2017, 140, 633–645. [Google Scholar] [CrossRef]

- Tester, J.; Anderson, B. Impact of Enhanced Geothermal Systems (egs) on the United States in the 21st Century. In The Future of Geothermal Energy; Massachusetts Institute of Technology: Cambridge, MA, USA, 2006. [Google Scholar]

- Pratt & Whitney Power Systems Organic Rankine Cycle Technology. Available online: https://www.prnewswire.com/news-releases/pratt--whitneys-waste-heat-to-power-organic-rankine-cycle-solutions-now-eligible-for-the-california-self-generation-incentive-program-133537828.html (accessed on 5 February 2020).

- Sanyal, S.K.; Butler, S.J. Geothermal Power Capacity from Petroleum Wells–Some Case Histories of Assessment. Proceedings of World Geothermal Congress, Bali, Indonesia, 2–30 April 2010; pp. 25–30. [Google Scholar]

- McKenna, J.; Blackwell, D.; Moyes, C.; Patterson, P.D. Geothermal electric power supply possible from Gulf Coast, midcontinent oil field waters. Oil 2005, 103, 34–40. [Google Scholar]

- Gosnold, W.D. Electric Power Generation from Low to Intermediate Temperature Resources; University of North Dakota: Grand Forks, ND, USA, 2015. [Google Scholar]

- Rahman, M.M.; Canter, C.; Kumar, A. Greenhouse gas emissions from recovery of various North American conventional crudes. Energy 2014, 74, 607–617. [Google Scholar] [CrossRef]

- Nassar, Y.F.; Salem, M.A.; Iessa, K.R.; AlShareef, I.M.; Ali, K.A.; Fakher, M.A. Estimation of CO 2 emission factor for the energy industry sector in Libya: A case study. Environ. Dev. Sustain. 2021, 23, 13998–14026. [Google Scholar] [CrossRef]

- Mesa, S.L.; Orjuela, J.M.; Ramírez, A.T.O.; Sandoval, J.-A. Review of the current state of wastewater management in the Colombian oil industry. Gestión Ambiente 2018, 21, 87. [Google Scholar] [CrossRef] [Green Version]

- Vélez, F.; Segovia, J.J.; Martín, M.C.; Antolín, G.; Chejne, F.; Quijano, A. A technical, economical and market review of organic Rankine cycles for the conversion of low-grade heat for power generation. Renew. Sustain. Energy Rev. 2012, 16, 4175–4189. [Google Scholar] [CrossRef]

- Zabek, D.; Penton, J.; Reay, D.J. Optimization of waste heat utilization in oil field development employing a transcritical Organic Rankine Cycle (ORC) for electricity generation. Appl. Therm. Eng. 2013, 59, 363–369. [Google Scholar] [CrossRef]

- Dickson, M.H.; Fanelli, M. Geothermal Energy: Utilization and Technology; Routledge: New York, NY, USA, 2013. [Google Scholar]

- Calm, J.M.; Hourahan, G.C. Physical, Safety, and Environmental Data for Current and Alternative Refrigerants. In Proceedings of the 23rd International Congress of Refrigeration (ICR2011), Prague, Czech Republic, 21–26 August 2011; pp. 21–26. [Google Scholar]

- Federation, W.E. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- IPCC. IPCC Guidelines for National Greenhouse Gas Inventories: Reference Manual; Intergovernmental Panel on Climate Change (IPCC): Kanagawa, Japan, 1996. [Google Scholar]

- Hamburg, I. Umberto LCA+; ifu: Hamburg, Germany, 2017. [Google Scholar]

- Bejan, A. Fundamentals of exergy analysis, entropy generation minimization, and the generation of flow architecture. Int. J. Energy Res. 2002, 26, 545–565. [Google Scholar] [CrossRef]

- Chacartegui, R.; Sánchez, D.; Muñoz, J.; Sánchez, T. Alternative ORC bottoming cycles for combined cycle power plants. Appl. Energy 2009, 86, 2162–2170. [Google Scholar] [CrossRef]

- Feng, Y.; Hung, T.; Greg, K.; Zhang, Y.; Li, B.; Yang, J. Thermoeconomic comparison between pure and mixture working fluids of organic Rankine cycles (ORCs) for low temperature waste heat recovery. Energy Convers. Manag. 2015, 106, 859–872. [Google Scholar] [CrossRef]

- Alfaro, C.; Rueda-Gutiérrez, J.; Casallas, Y.; Rodríguez, G.; Malo, J. Approach to the geothermal potential of Colombia. Geothermics 2021, 96, 102169. [Google Scholar] [CrossRef]

- Bu, X.; Ma, W.; Li, H. Geothermal energy production utilizing abandoned oil and gas wells. Renew. Energy 2012, 41, 80–85. [Google Scholar] [CrossRef]

- Barbier, E. Geothermal energy technology and current status: An overview. Renew. Sustain. Energy Rev. 2002, 6, 3–65. [Google Scholar] [CrossRef]

- Daneshipour, M.; Rafee, R. Nanofluids as the circuit fluids of the geothermal borehole heat exchangers. Int. Commun. Heat Mass Transf. 2017, 81, 34–41. [Google Scholar] [CrossRef]

- Junrong, L.; Rongqiang, L.; Zhixue, S. Exploitation and utilization technology of geothermal resources in oil fields. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–24 April 2015. [Google Scholar]

| Parameter | OFA | OFB |

|---|---|---|

| Total alkalinity (mg CaCO3 L−1) | 335.0 ± 3.8 | 271.5 ± 3.1 |

| Chlorides (mg Cl L−1) | 7624.8 ± 38.1 | 3941.9 ± 19.7 |

| Conductivity (uS cm−1) | 21,600.0 ± 130.0 | 10,760.0 ± 65.0 |

| pH | 7.2 ± 0.2 | 7.6 ± 0.2 |

| Total dissolved solids (mg TDS L−1) | 16,686.7 ± 83.4 | 7710.7 ± 46.3 |

| Oil Field | Enthalpy (kJ kg−1) | Entropy (kJ kg−1 K−1) |

|---|---|---|

| OFA | 420.01 | 1.3087 |

| OFB | 368.89 | 1.1694 |

| Time | Water Flow (kg s−1) | Thermal Power (kWt) | ||

|---|---|---|---|---|

| 5:44 | 35.8 | 1803 | 4% | 22% |

| 9:02 | 30.7 | 1548 | 4% | 20% |

| 10:00 | 30.7 | 1548 | 3% | 20% |

| 11:00 | 30.7 | 1548 | 3% | 20% |

| 12:00 | 30.7 | 1548 | 3% | 18% |

| 13:02 | 35.1 | 1767 | 3% | 17% |

| 14:00 | 35.1 | 1767 | 3% | 18% |

| 15:00 | 35.1 | 1767 | 3% | 18% |

| 16:00 | 35.1 | 1767 | 3% | 19% |

| 17:00 | 35.1 | 1767 | 3% | 20% |

| 18:00 | 32.9 | 1662 | 4% | 26% |

| 19:00 | 26.4 | 1332 | 5% | 24% |

| 20:00 | 31.8 | 1603 | 4% | 25% |

| 21:00 | 30.5 | 1537 | 5% | 24% |

| 22:00 | 31.6 | 1594 | 5% | 25% |

| 23:00 | 31.4 | 1581 | 5% | 24% |

| 0:00 | 32.7 | 1649 | 5% | 26% |

| 1:00 | 29.7 | 1496 | 5% | 26% |

| 2:00 | 30.0 | 1511 | 5% | 26% |

| 3:00 | 31.3 | 1575 | 5% | 25% |

| 4:00 | 31.4 | 1584 | 5% | 31% |

| 5:00 | 26.2 | 1321 | 6% | 22% |

| Stream | 2 | 3 | 4 | Energy Production * | |||

|---|---|---|---|---|---|---|---|

| Oil Field | Volumetric | Energy | Volumetric | Energy | Volumetric | Energy | Energy |

| (m3) | (MJ) | (m3) | (MJ) | (m3) | (MJ) | (MJ) | |

| OFA | 96,319 | 3,926,929 | 385,276 | 15,707,716 | 0.75 | 27610 | 4,924,800 |

| OFB | 55,821 | 2,275,814 | 223,283 | 9,103,257 | 3.25 | 119,235 | 3,132,000 |

| Stream | 2 | 3 | 4 | 5 | 6 | 7 | Energy Production * | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Volumetric | Energy | Volumetric | Energy | Volumetric | Energy | Volumetric | Volumetric | Energy | Energy | |

| Oil Field | (m3) | (MJ) | (m3) | (MJ) | (m3) | (MJ) | (m3) | (m3) | (MJ) | (MJ) |

| OFA | 69,269 | 2,824,112 | 385,276 | 15,707,716 | 0.75 | 27,610 | 194,400 | 194,400 | 94,970 | 4,924,800 |

| OFB | 22,636 | 922,874 | 223,283 | 9,103,257 | 3.25 | 119,235 | 194,400 | 194,400 | 94,970 | 3,132,000 |

| Oil Field | Energy Production from Non-Renewable Resources (Tons CO2eq/kWh) | Geothermal Energy Co-Generation System (Tons CO2eq/kWh) | Percentage Reduction in Carbon Footprint (%) |

|---|---|---|---|

| OFA | 260 | 212 | 19 |

| OFB | 185 | 165 | 11 |

| Non-Renewable Resource | OFA | OFB |

|---|---|---|

| Diesel | 0.95% | 6.64% |

| Field gas | 90.14% | 80.15% |

| Purchased gas consumption | 8.91% | 13.21% |

| Non-Renewable Resource | OFA | OFB |

|---|---|---|

| Diesel | 1.16% | 11.09% |

| Field gas | 87.25% | 63.21% |

| Water Pumping * | 11.59% | 25.7% |

| Scenarios Evaluated | Purchased Gas | Field Gas | |||

|---|---|---|---|---|---|

| (m3) | (MJ) | (m3) | (MJ) | ||

| Scenario 1 | OFA | 385,959 | 15,608,185 | 69,269 | 28,241,113 |

| OFB | 226,232 | 9,148,808 | 22,636 | 922,874 | |

| Scenario 2 | OFA | 385,276 | 15,580,575 | 69,947 | 2,851,722 |

| OFB | 223,283 | 9,029,573 | 25,561 | 1,042,109 | |

| Scenario 3 | OFA | 455,794 | 18,432,298 | 0 | 0 |

| OFB | 249,052 | 10,071,682 | 0 | 0 | |

| Scenario 4 | OFA | 0 | 0 | 452,104 | 18,432,298 |

| OFB | 0 | 0 | 247,037 | 10,071,682 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Céspedes, S.; Cano, N.A.; Foo, G.; Jaramillo, D.; Martinez, D.; Gutiérrez, M.; Pataquiba, J.; Rojas, J.; Cortés, F.B.; Franco, C.A. Technical and Environmental Feasibility Study of the Co-Production of Crude Oil and Electrical Energy from Geothermal Resources: First Field Trial in Colombia. Processes 2022, 10, 568. https://doi.org/10.3390/pr10030568

Céspedes S, Cano NA, Foo G, Jaramillo D, Martinez D, Gutiérrez M, Pataquiba J, Rojas J, Cortés FB, Franco CA. Technical and Environmental Feasibility Study of the Co-Production of Crude Oil and Electrical Energy from Geothermal Resources: First Field Trial in Colombia. Processes. 2022; 10(3):568. https://doi.org/10.3390/pr10030568

Chicago/Turabian StyleCéspedes, Santiago, Natalia A. Cano, Gordon Foo, David Jaramillo, Daniel Martinez, Manuel Gutiérrez, Javier Pataquiba, Juan Rojas, Farid B. Cortés, and Camilo A. Franco. 2022. "Technical and Environmental Feasibility Study of the Co-Production of Crude Oil and Electrical Energy from Geothermal Resources: First Field Trial in Colombia" Processes 10, no. 3: 568. https://doi.org/10.3390/pr10030568