Low-Cost and Efficient Solution for the Automation of Laboratory Scale Experiments: The Case of Distillation Column

Abstract

:1. Introduction

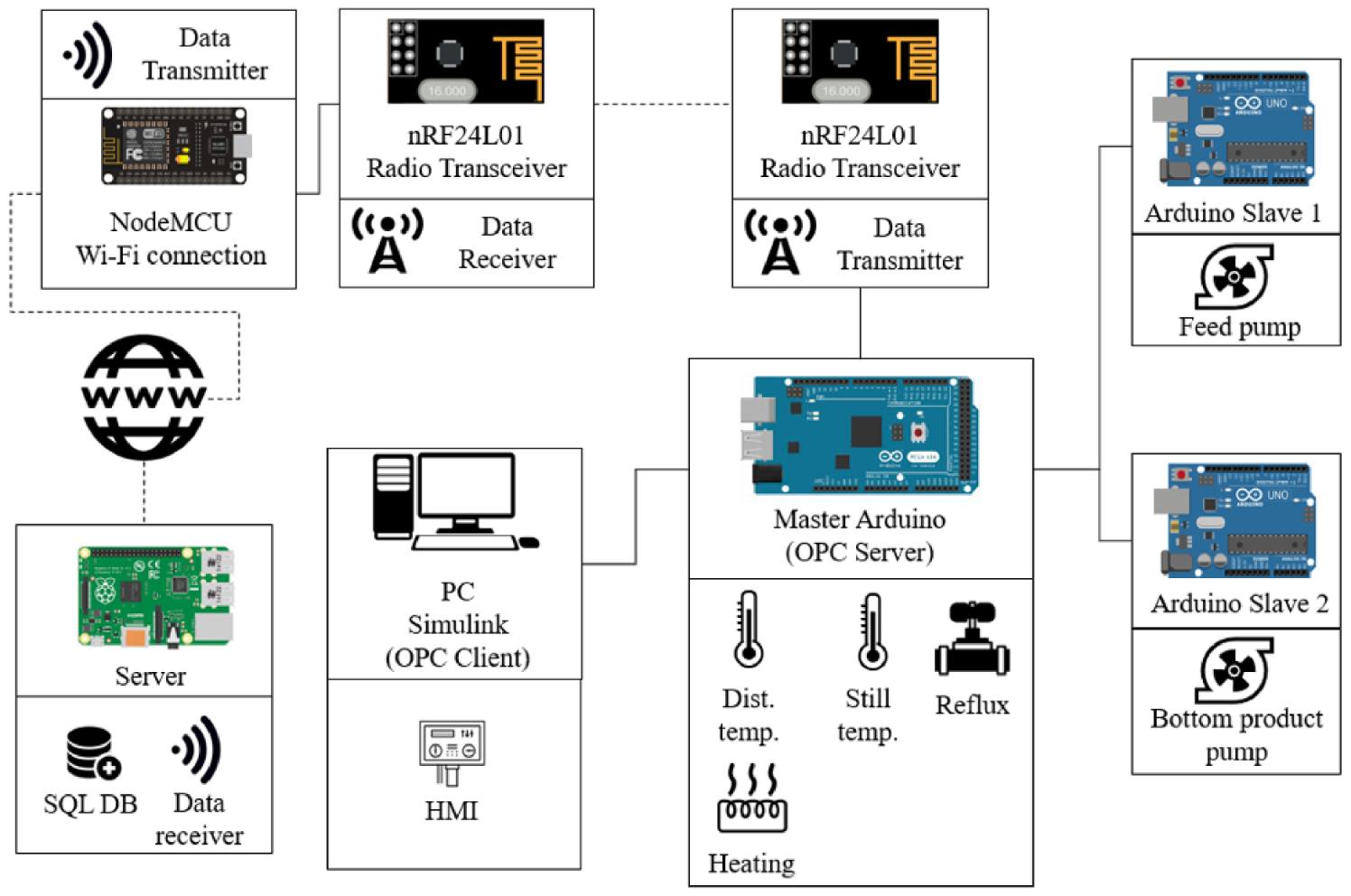

2. Methods and Experimental Setup

2.1. System Investigated and Controlled

2.2. The Concept of the Control Structure and the Controlled System

2.3. Controller Tuning Methods Applied

3. Results

3.1. Open Loop Behavior

3.2. On-Off Reflux Ration Control

3.3. Comparison of the Selected Controller Tuning Methods

3.4. Study of Dynamic Operation with Set Point Changes

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barber, R.; Horra, M.; Crespo, J. Control practices using Simulink with arduino as low cost hardware. IFAC Proc. Vol. 2013, 46, 250–255. [Google Scholar] [CrossRef]

- Drost, S.; de Kruif, B.J.; Newport, D. Arduino control of a pulsatile flow rig. Med. Eng. Phys. 2018, 51, 67–71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grassini, S.; Corbellini, S.; Parvis, M.; Angelini, E.; Zucchi, F. A simple Arduino-based eis system for in situ corrosion monitoring of metallic works of art. Measurement 2018, 114, 508–514. [Google Scholar] [CrossRef]

- Karami, M.; McMorrow, G.V.; Wang, L. Continuous monitoring of indoor environmental quality using an arduino-based data acquisition system. J. Build. Eng. 2018, 19, 412–419. [Google Scholar] [CrossRef]

- Kim, B.; You, D.; Kim, Y.-J.; Oh, I.; Choi, S. Motorized smart pipette for handheld operation of a microfluidic blood plasma separator. Sens. Actuators B Chem. 2018, 267, 581–588. [Google Scholar] [CrossRef]

- Rubio-Gomez, G.; Corral-Gomez, L.; Soriano, J.A.; Gomez, A.; Castillo-Garcia, F.J. Vision based algorithm for automated determination of smoke point of diesel blends. Fuel 2019, 235, 595–602. [Google Scholar] [CrossRef]

- Blum, J. Exploring Arduino, Tools and Techniques for Engineering Wizardry; Wiley Book Company: Hoboken, NJ, USA, 2020. [Google Scholar]

- González, I.; Calderón, A.J. Integration of open source hardware Arduino platform in automation systems applied to Smart Grids/Micro-Grids. Sustain. Energy Technol. Assess. 2019, 36, 100557. [Google Scholar] [CrossRef]

- Luyben, W.L. Process Modeling, Simulation and Control for Chemical Engineers, 2nd ed.; McGraw-Hill Higher Education: New York, NY, USA, 1989. [Google Scholar]

- Grosdidier, P.; Morari, M.; Holt, B.R. Closed-loop properties from steady-state gain information. Ind. Eng. Chem. Fundam. 1985, 24, 221–235. [Google Scholar] [CrossRef]

- Skogestad, S.; Morari, M.; Doyle, J.C. Robust control of ill conditioned plants: High-purity distillation. IEEE Trans. Autom. Control 1988, 33, 1092–1105. [Google Scholar] [CrossRef] [Green Version]

- Skogestad, S.; Morari, M. Implications of large regalements on control performance. Ind. Eng. Chem. Res. 1987, 26, 2323–2330. [Google Scholar] [CrossRef]

- Luyben, W.L. Distillation Design and Control Using Aspen Simulation, 1st ed.; John Wiley & Sons: Bethlehem, PA, USA, 2006. [Google Scholar]

- Mizsey, P. Process Control Systems; Typotex: Budapest, Hungary, 2009; ISBN 978-963-279-475-4. [Google Scholar]

- Veseli, V.; Ilka, A. Gain-scheduled PID controller design. J. Process Control 2013, 8, 1141–1148. [Google Scholar] [CrossRef]

- Rugh, W.L.; Shamma, J.S. Research on gain scheduling. Automatica 2000, 36, 1401–1425. [Google Scholar] [CrossRef]

- Shannon, C.E. Communication in the presence of noise. Proc. IRE 1949, 37, 10–21. [Google Scholar] [CrossRef]

- Ziegler, J.G.; Nichols, N.B. Optimum settings for automatic controllers. Trans. ASME 1942, 64, S759–S768. [Google Scholar] [CrossRef]

- Cohen, G.H.; Coon, G.A. Theoretical consideration of retarded control. Trans. ASME 1953, 75, 827–834. [Google Scholar]

- Lin, F.; Brandt, R.D.; Saikalis, G. Self-tuning of PID controllers by adaptive interaction. In Proceedings of the 2000 American Control Conference, ACC, Chicago, IL, USA, 28–30 June 2000. [Google Scholar]

- An, S.; Yuan, S.; Li, H. Self-tuning of PID. In Proceedings of the IEEE Chinese Guidance, Navigation and Control Conference, Nanjing, China, 12–14 August 2016; pp. 1547–1552. [Google Scholar]

| Parameter | Open Loop, Z-N (Oppelt) | Matlab PID Tuner | Cohen-Coon Tuning | Gain Scheduling | Self-Tuning Nr. 5 | Self-Tuning Nr. 6 |

|---|---|---|---|---|---|---|

| Rise time (s) | 4920 | 1045 | 1383 | 1682 | 1399 | 1512 |

| Overshoot (°C) | 2.65 | 10.64 | 18.26 | 3.31 | 3.25 | 1.7 |

| Settling time (s) | 11,030 | 5400 | 3700 | 4950 | 3627 | 3064 |

| Integral Square Error, (°C) | 5.04 × 106 | 2.19 × 106 | 2.96 × 106 | 2.26 × 106 | 1.99 × 106 | 2.64 × 106 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enyedi, F.; Do Thi, H.T.; Szanyi, A.; Mizsey, P.; Toth, A.J.; Nagy, T. Low-Cost and Efficient Solution for the Automation of Laboratory Scale Experiments: The Case of Distillation Column. Processes 2022, 10, 737. https://doi.org/10.3390/pr10040737

Enyedi F, Do Thi HT, Szanyi A, Mizsey P, Toth AJ, Nagy T. Low-Cost and Efficient Solution for the Automation of Laboratory Scale Experiments: The Case of Distillation Column. Processes. 2022; 10(4):737. https://doi.org/10.3390/pr10040737

Chicago/Turabian StyleEnyedi, Florian, Huyen Trang Do Thi, Agnes Szanyi, Peter Mizsey, Andras Jozsef Toth, and Tibor Nagy. 2022. "Low-Cost and Efficient Solution for the Automation of Laboratory Scale Experiments: The Case of Distillation Column" Processes 10, no. 4: 737. https://doi.org/10.3390/pr10040737

APA StyleEnyedi, F., Do Thi, H. T., Szanyi, A., Mizsey, P., Toth, A. J., & Nagy, T. (2022). Low-Cost and Efficient Solution for the Automation of Laboratory Scale Experiments: The Case of Distillation Column. Processes, 10(4), 737. https://doi.org/10.3390/pr10040737