Drying Biomass with a High Water Content—The Influence of the Final Degree of Drying on the Sizing of Indirect Dryers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Material

2.2. Experimental Dryer

2.3. Experiment Evaluation

2.4. Determination of Drying Rate

2.5. Determination of the Required Dryer Size

3. Results and Discussion

3.1. Results of Drying Tests

3.2. Evaluation of Drying Rates

3.3. Effect of Final Degree of Drying on the Size of the Dryer

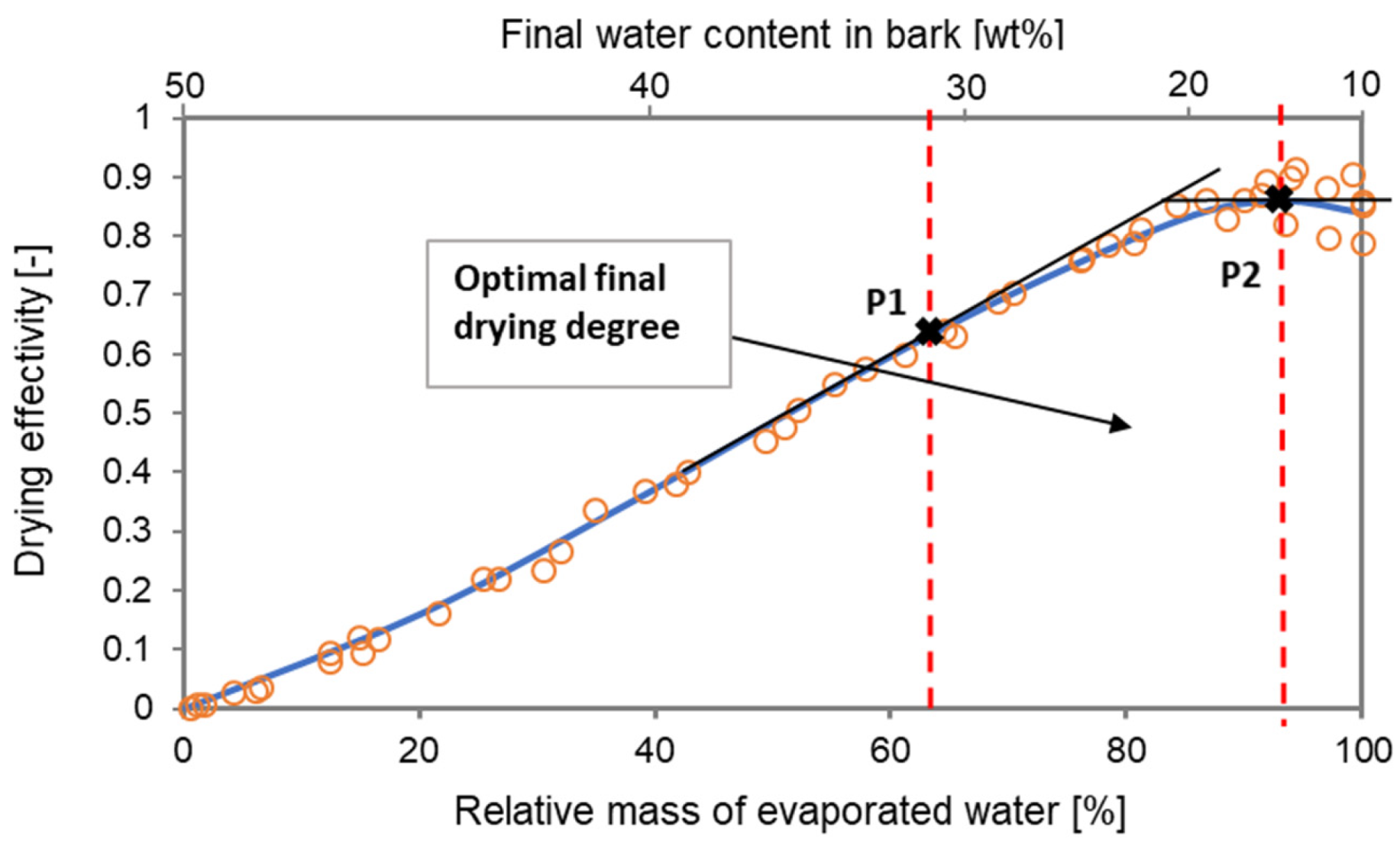

3.4. The Drying Process Effectivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eurostat. Renewable Energy Statistics. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Renewable_energy_statistics (accessed on 15 November 2021).

- Bioenergy Europe. Available online: https://bioenergyeurope.org/article/301-bioenergy-europe-s-new-brochure-we-are-renewable-energy-champions.html (accessed on 12 November 2021).

- Scarlat, N.; Dallemand, J.; Taylor, N.; Banja, M. Brief on Biomass for Energy in the European Union; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Ross, C. Biomass Drying and Dewatering for Clean Heat & Power; NorthWest CHP Application Center: Olympia, WA, USA, 2008. [Google Scholar]

- Jirjis, R. Storage and drying of wood fuel. Biomass Bioenergy 1995, 9, 181–190. [Google Scholar] [CrossRef]

- Murugan, P.; Dhanushkodi, S.; Sudhakar, K.; Wilson, V.H. Industrial and Small-Scale Biomass Dryers: An Overview. Energy Eng. 2021, 118, 435–446. [Google Scholar] [CrossRef]

- Kung, K.S.; Ghoniem, A.F. Multi-scale analysis of drying thermally thick biomass for bioenergy applications. Energy 2019, 187, 15989. [Google Scholar] [CrossRef]

- Wade, A. Report on Biomass Drying Technology; National Renewable Energy Laboratory: Golden, CO, USA, 1998. [Google Scholar]

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-Firing, 1st ed.; Earthscan: Sterling, VA, USA, 2008. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, X.; Han, X.; Li, G.; Yan, J. Using pre-drying technology to improve the exergetic efficiency of bioenergy utilization process with combustion: A case study of a power plant. Appl. Therm. Eng. 2017, 127, 1416–1426. [Google Scholar] [CrossRef]

- Gebreegziabher, T.; Oyedun, A.; Hui, C. Optimum biomass drying for combustion—A modeling approach. Energy 2013, 53, 67–73. [Google Scholar] [CrossRef]

- Liu, Y.; Aziz, M.; Kansha, Y.; Bhattacharya, S.; Tsutsumi, A. Application of the self-heat recuperation technology for energy saving in biomass drying system. Fuel Process. Technol. 2014, 117, 66–74. [Google Scholar] [CrossRef]

- Wallin, E.; Fornell, R.; Räftegård, O.; Walfridson, T.; Benson, J. Design and Integration of Heat Recovery in Combination with Solar and Biomass-based Heating in a Drying Plant. Chem. Eng. Trans. 2020, 81, 1387–1392. [Google Scholar] [CrossRef]

- Mujumdar, A. Handbook of Industrial Drying, 3rd ed.; CRC/Taylor & Francis: Boca Raton, FL, USA, 2007. [Google Scholar] [CrossRef]

- Fagernäs, L.; Brammer, J.; Wilén, C.; Lauer, M.; Verhoeff, F. Drying of biomass for second generation synfuel production. Biomass Bioenergy 2010, 34, 1267–1277. [Google Scholar] [CrossRef]

- Havlik, J.; Dlouhy, T. Integration of Biomass Indirect Dryers into Energy Systems. J. Chem. Eng. Jpn. 2017, 50, 792–798. [Google Scholar] [CrossRef]

- Wang, J.; Salman, C.; Wang, B.; Li, H.; Thorin, E. Integrating sludge drying in biomass fueled CHP plants. Energy Ecol. Environ. 2021, 6, 1–12. [Google Scholar] [CrossRef]

- McIlveen-Wright, D.; Huang, Y.; Rezvani, S.; Redpath, D.; Anderson, M.; Dave, A.; Hewitt, N. A technical and economic analysis of three large scale biomass combustion plants in the UK. Appl. Energy 2013, 112, 396–404. [Google Scholar] [CrossRef]

- Adamski, R.; Siuta, D.; Kukfisz, B.; Mitkowski, P.T.; Szaferski, W. Influence of process parameters in superheated steam drying on fire and explosion parameters of woody biomass. Fuel Process. Technol. 2021, 211, 106597. [Google Scholar] [CrossRef]

- Strömberg, B. Fuel Handbook; Värmeforsk Service AB: Stockholm, Sweden, 2006. [Google Scholar]

- Hofmann, N.; Mendel, T.; Schulmeyer, F.; Kuptz, D.; Borchert, H.; Hartmann, H. Drying effects and dry matter losses during seasonal storage of spruce wood chips under practical conditions. Biomass Bioenergy 2018, 111, 196–205. [Google Scholar] [CrossRef]

- Leoni, E.; Mancini, M.; Aminti, G.; Picchi, G. Wood Fuel Procurement to Bioenergy Facilities: Analysis of Moisture Content Variability and Optimal Sampling Strategy. Processes 2021, 9, 359. [Google Scholar] [CrossRef]

- Holmberg, A.; Wadsö, L.; Stenström, S. Water vapor sorption and diffusivity in bark. Dry. Technol. 2015, 34, 150–160. [Google Scholar] [CrossRef]

- He, X.; Wang, L. Experimental Determination and Modeling of Drying Process of Woody Biomass. IOP Conf. Ser. Earth Environ. Sci. 2020, 552, 012016. [Google Scholar] [CrossRef]

- Vandenbroek, R. Biomass combustion for power generation. Biomass Bioenergy 1996, 11, 271–281. [Google Scholar] [CrossRef]

- Herz, F.; Mitov, I.; Specht, E.; Stanev, R. Experimental study of the contact heat transfer coefficient between the covered wall and solid bed in rotary drums. Chem. Eng. Sci. 2012, 82, 312–318. [Google Scholar] [CrossRef]

- Herz, F.; Mitov, I.; Specht, E.; Stanev, R. Influence of operational parameters and material properties on the contact heat transfer in rotary kilns. Int. J. Heat Mass Transf. 2012, 55, 7941–7948. [Google Scholar] [CrossRef]

- Lybaert, P. Wall-particles heat transfer in rotating heat exchangers. Int. J. Heat Mass Transf. 1987, 30, 1663–1672. [Google Scholar] [CrossRef]

- Tsotsas, E.; Schlunder, E.U. Contact Drying of Mechanically Agitated Particulate Material in the Presence of Inert Gas. Chem. Eng. Process. Process Intensif. 1986, 20, 277–285. [Google Scholar] [CrossRef]

- Esotsas, E.; Metzger, T.; Gnielinski, V.; Schlünder, E.U. Drying of Solid Materials. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010; pp. 11–13. [Google Scholar] [CrossRef]

- Chen, S.; Wang, F.; Milhé, M.; Arlabosse, P.; Liang, F. Experimental and theoretical research on agitated contact drying of sewage sludge in a continuous paddle dryer. Dry. Technol. 2016, 34, 1979–1990. [Google Scholar] [CrossRef] [Green Version]

- Schlünder, E.U.; Mollekopf, N. Vacuum contact drying of free flowing mechanically agitated particulate material. Chem. Eng. Process. Process Intensif. 1984, 18, 93–111. [Google Scholar] [CrossRef]

- Havlík, J.; Dlouhý, T. Indirect Dryers for Biomass Drying—Comparison of Experimental Characteristics for Drum and Rotary Configurations. ChemEngineering 2020, 4, 18. [Google Scholar] [CrossRef] [Green Version]

| C daf | wt%, daf | 51.75 |

| H daf | wt%, daf | 5.97 |

| O daf | wt%, daf | 41.82 |

| S daf | wt%, daf | 0.03 |

| N daf | wt%, daf | 0.43 |

| Ash db | wt%, db | 2.8 |

| W | wt% | ~50 |

| HHV daf | kJ/kg | 20,550 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Havlík, J.; Dlouhý, T.; Pitel’, J. Drying Biomass with a High Water Content—The Influence of the Final Degree of Drying on the Sizing of Indirect Dryers. Processes 2022, 10, 739. https://doi.org/10.3390/pr10040739

Havlík J, Dlouhý T, Pitel’ J. Drying Biomass with a High Water Content—The Influence of the Final Degree of Drying on the Sizing of Indirect Dryers. Processes. 2022; 10(4):739. https://doi.org/10.3390/pr10040739

Chicago/Turabian StyleHavlík, Jan, Tomáš Dlouhý, and Ján Pitel’. 2022. "Drying Biomass with a High Water Content—The Influence of the Final Degree of Drying on the Sizing of Indirect Dryers" Processes 10, no. 4: 739. https://doi.org/10.3390/pr10040739

APA StyleHavlík, J., Dlouhý, T., & Pitel’, J. (2022). Drying Biomass with a High Water Content—The Influence of the Final Degree of Drying on the Sizing of Indirect Dryers. Processes, 10(4), 739. https://doi.org/10.3390/pr10040739