Targeting on Different Characteristic Continuous Variables in Process Transition for Ethylene Column with Wide-Range Feed Fluctuation

Abstract

:1. Introduction

2. Problem Presentation

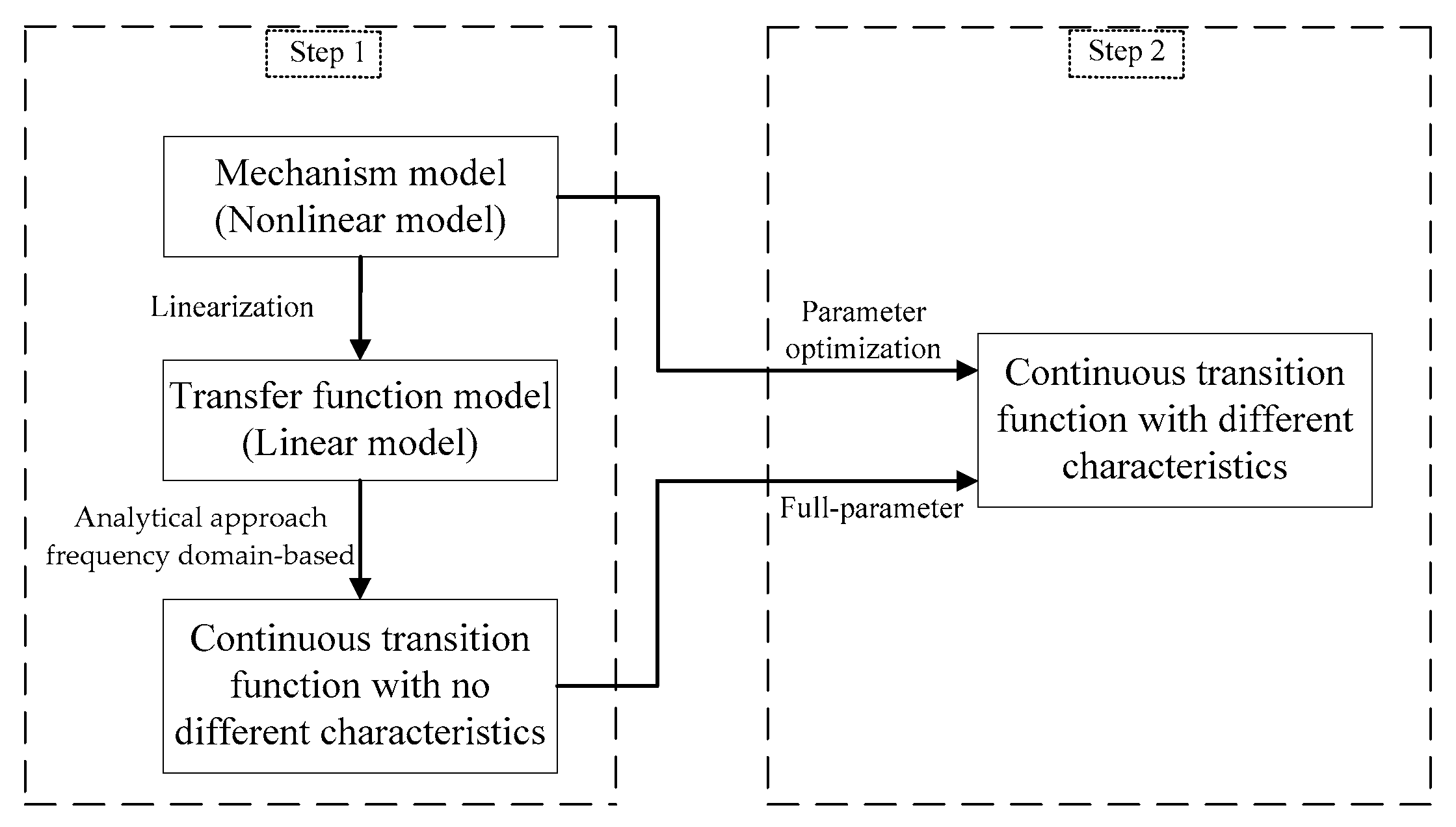

2.1. Process Transition Strategy with Different Characteristics

2.2. Continuous Process Transition Strategy with No Different Characteristics

3. Continuous Process Transition Strategy with Different Characteristics

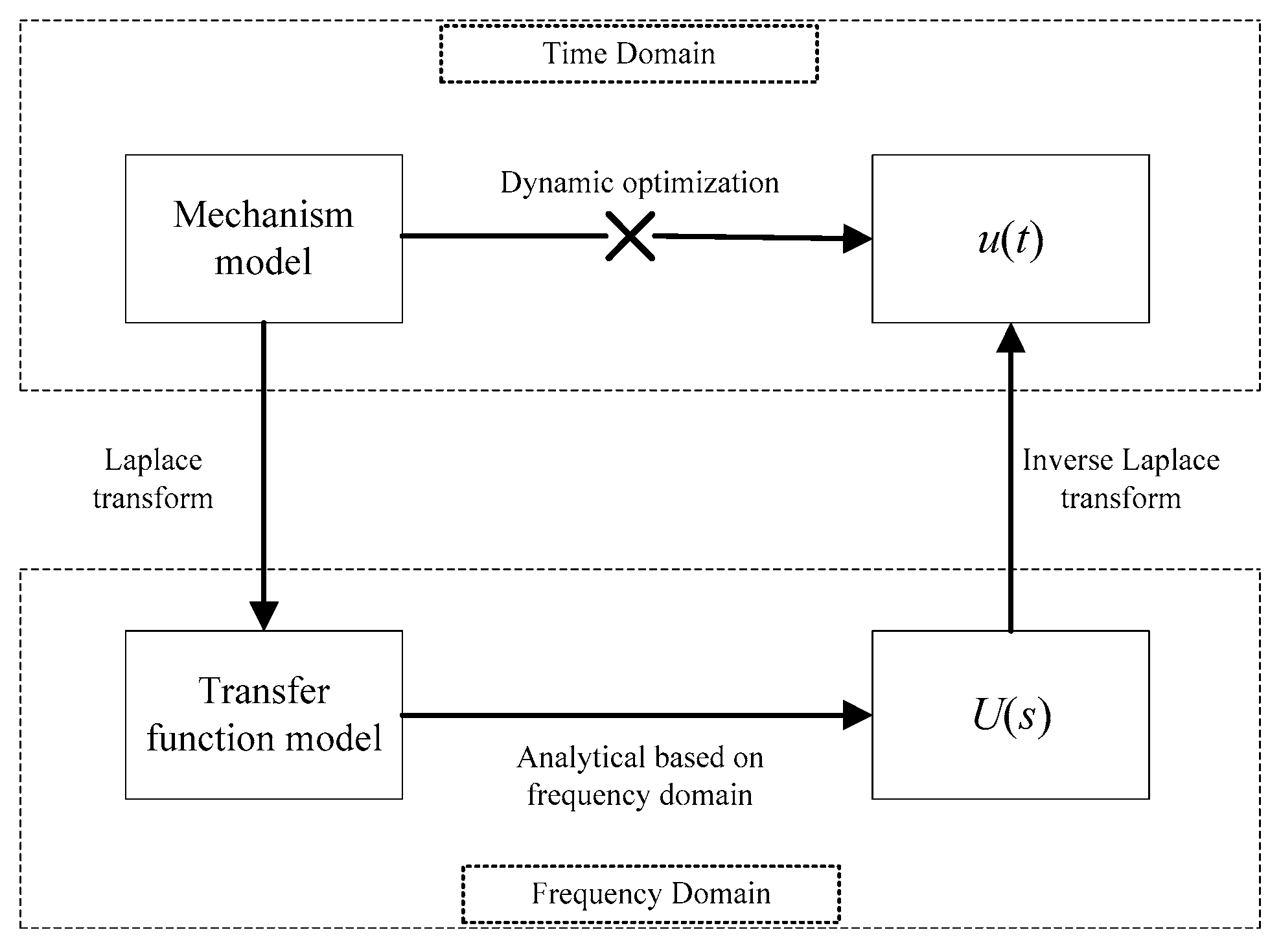

3.1. Solution Method of Continuous Process Transition Strategy with Different Characteristics

3.2. Transition Strategy for Ethylene Column

3.3. Results and Discussion

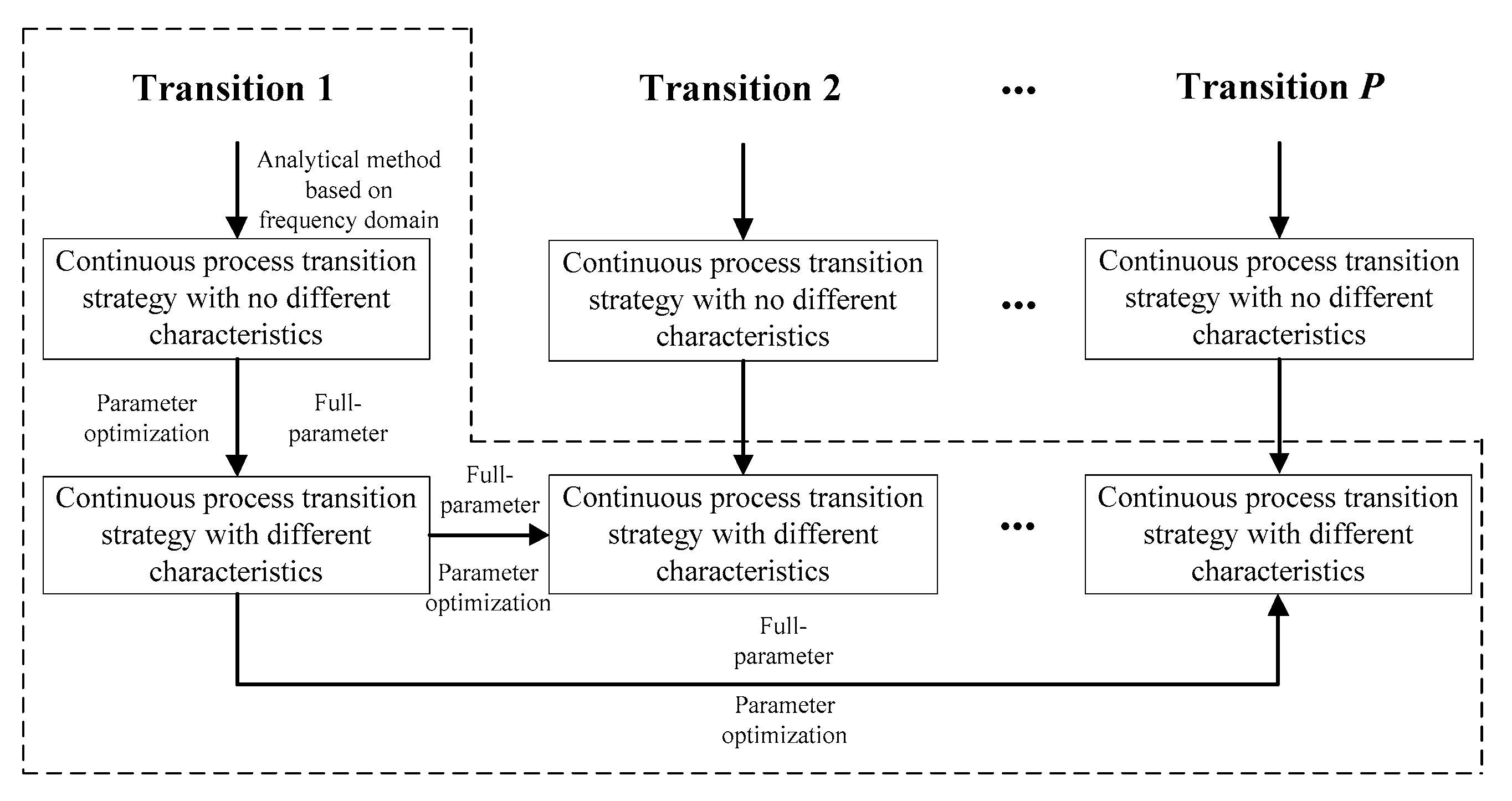

4. Extending to Wide Fluctuating throughput with Composition

4.1. Efficient Solutions for Different Transition Processes

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pittman, W.; Mentzer, R.; Mannan, M.S. Communicating costs and benefits of the chemical industry and chemical technology to society. J. Loss. Prev. Process Ind. 2015, 35, 59–64. [Google Scholar] [CrossRef]

- Kessler, T.; Kunde, C.; Linke, S.; McBride, K.; Sundmacher, K.; Kienle, A. Systematic Selection of Green Solvents and Process Optimization for the Hydroformylation of Long-Chain Olefines. Processes 2019, 7, 882. [Google Scholar] [CrossRef] [Green Version]

- Luo, X.L.; Zhao, X.Y.; Wu, B.; Sun, L. Online detection and control of ethylene column abnormal condition. CIESC J. 2014, 65, 4517–4523. [Google Scholar]

- Xu, Y.; Li, J.; Cui, G.M.; Zhang, G.H.; Yang, Q.G. An improved treble-level assisting optimization strategy to enhance algorithm search ability in heat exchanger network design. J. Taiwan Inst. Chem. Eng. 2021, 129, 162–170. [Google Scholar] [CrossRef]

- Pokutsa, A.; Ohkubo, K.; Zaborovski, A.; Bloniarz, P. UV-induced oxygenation of toluene enhanced by Co (acac)(2)/9-mesityl-10-methylacridinium ion/N-hydroxyphthalimide tandem. Asia-Pac. J. Chem. Eng. 2021, 16, e2714. [Google Scholar] [CrossRef]

- Zhao, C.; Huang, B. A Full-condition Monitoring Method for Nonstationary Dynamic Chemical Processes with Cointegration and Slow Feature Analysis. AIChE J. 2018, 64, 1662–1681. [Google Scholar] [CrossRef]

- Tang, X.J.; Yang, B.; Li, H.G. Deep learning approaches to complex chemical process control manipulating strategies. CIESC J. 2021, 72, 4830–4837. [Google Scholar]

- Qian, X.; Jia, S.K.; Huang, K.J.; Chen, H.S.; Yuan, Y.; Zhang, L. Optimal design of Kaibel dividing wall columns based on improved particle swarm optimization methods. J. Clean Prod. 2020, 273, 123041. [Google Scholar] [CrossRef]

- Kajero, O.T.; Chen, T.; Yao, Y.; Chuang, Y.C.; Wong, D.S.H. Meta-modelling in chemicalprocess system engineering. J. Taiwan Inst. Chem. Eng. 2017, 73, 135–145. [Google Scholar] [CrossRef]

- Chen, C.B.; Luo, X.L.; Wang, T.Y.; Liu, D.J. Minimum motive steam consumption on full cycle optimization with cumulative fouling consideration for MED-TVC desalination system. Desalination 2021, 507, 115017. [Google Scholar] [CrossRef]

- Wang, Z.H.; Zhao, J.S.; Shang, H. A hybrid fault diagnosis strategy for chemical process startups. J. Process Control. 2012, 22, 1287–1297. [Google Scholar] [CrossRef]

- Chen, S.; Kumar, A.; Wong, W.C.; Chiu, M.S.; Wang, X.N. Hydrogen value chain and fuel cells within hybrid renewable energy systems: Advanced operation and control strategies. Appl. Energy 2019, 233, 321–337. [Google Scholar] [CrossRef]

- Song, G.; Zhao, Y.C.; Qiu, T.; Lu, G.M.; Zhao, J.S. Recent progress in energy saving and emission reduction technologies in startup and shutdown processes of ethylene plants. J. Chem. Ind. Eng. 2014, 65, 2696–2703. [Google Scholar]

- Aydin, E.; Bonvin, D.; Sundmacher, K. Toward Fast Dynamic Optimization: An Indirect Algorithm That Uses Parsimonious Input Parameterization. Ind. Eng. Chem. Res. 2018, 57, 10038–10048. [Google Scholar] [CrossRef]

- Huang, D.; Luo, X.L. Process transition based on dynamic optimization with the case of a throughput-fluctuating ethylene column. Ind. Eng. Chem. Res. 2018, 57, 6292–6302. [Google Scholar] [CrossRef]

- Cao, X.Y.; Xu, F.; Luo, X.L. A novel strategy of continuous process transition and wide range throughput fluctuating ethylene column. J. Taiwan Inst. Chem. Eng. 2021, 121, 61–73. [Google Scholar] [CrossRef]

- Woinaroschy, A. Time-Optimal Control of Startup Distillation Columns by Iterative Dynamic Programming. Ind. Eng. Chem. Res. 2008, 47, 4158–4169. [Google Scholar] [CrossRef]

- Anand, P.; Venkateswarlu, C.; Rao, M.B. Multistage dynamic optimization of a copolymerization reactor using differential evolution. Asia-Pac. J. Chem. Eng. 2013, 8, 687–698. [Google Scholar] [CrossRef]

- Ren, Z.F.; Xu, C.; Ou, Y.S. Dynamic optimization of trajectory for ramp-up current profile in tokamak plasma. Asia-Pac. J. Chem. Eng. 2016, 11, 918–929. [Google Scholar] [CrossRef]

- Lu, X.F.; Wang, Y.J.; Liu, L. Optimal Ascent Guidance for Air-Breathing Launch Vehicle Based on Optimal Trajectory Correction. Math. Probl. Eng. 2013, 3013, 313197. [Google Scholar] [CrossRef] [Green Version]

- Luus, R. Optimal control by dynamic programming using systematic reduction in grid size. Int. J. Control 1990, 51, 995–1013. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Mo, Y.B. Dynamic Optimization of Chemical Processes Based on Modified Sailfish Optimizer Combined with an Equal Division Method. Processes 2021, 9, 1806. [Google Scholar] [CrossRef]

- Binder, T.; Cruse, A.; Villar, C.A.C.; Marquardt, W. Dynamic optimization using a wavelet based adaptive control vector parameterization strategy. Comput. Chem. Eng. 2000, 24, 1201–1207. [Google Scholar] [CrossRef]

- Chen, X.; Du, W.L.; Tianfield, H.; Qi, R.B.; He, W.L.; Qian, F. Dynamic Optimization of Industrial Processes With Nonuniform Discretization-Based Control Vector Parameterization. IEEE Trans. Autom. Sci. Eng. 2014, 11, 1289–1299. [Google Scholar] [CrossRef]

- Hartwich, A.; Marquardt, W. Dynamic optimization of the load change of a large-scale chemical plant by adaptive single shooting. Comput. Chem. Eng. 2010, 34, 1873–1889. [Google Scholar] [CrossRef]

- Curtain, R.; Morris, K. Transfer functions of distributed parameter systems: A tutorial. Automatica 2009, 45, 1101–1116. [Google Scholar] [CrossRef]

- Engelien, H.K.; Larsson, T.; Skogestad, S. Implementation of Optimal Operation for Heat Integrated Distillation Columns. Chem. Eng. Res. Des. 2003, 81, 277–281. [Google Scholar] [CrossRef] [Green Version]

- Choi, Y.; An, N.; Hong, S.; Cho, H.; Lim, J.; Han, I.S.; Moon, I.; Kim, J. Time-series clustering approach for training data selection of a data-driven predictive model: Application to an industrial bio 2, 3-butanediol distillation process. Comput. Chem. Eng. 2022, 161, 107758. [Google Scholar] [CrossRef]

- Kwon, H.; Oh, K.C.; Choi, Y.; Chung, Y.G.; Kim, J. Development and application of machine learning-based prediction model for distillation column. Int. J. Intell. Syst. 2021, 36, 1970–1997. [Google Scholar] [CrossRef]

- Jiang, A.P.; Shao, Z.J.; Chen, X.; Fang, X.Y.; Geng, D.Z.; Zheng, X.Q.; Qian, J.X. Simulation and optimization of distillation column sequence in large-scale ethylene production. CIESC J. 2006, 57, 2128–2134. [Google Scholar]

- Skogestad, S. Dynamics and control of distillation columns—A critical survey. Model Identif. Control 1997, 18, 177–217. [Google Scholar] [CrossRef] [Green Version]

- Huang, D.; Zhao, M.S.; Luo, X.L. Analyzing time-lag effect of downcomer for control of ethylene column. CIESC J. 2016, 11, 4696–4704. [Google Scholar]

- Asteasuain, M.; Tonelli, S.M.; Brandolin, A.; Bandoni, J.A. Dynamic simulation and optimisation of tubular polymerisation reactors in gPROMS. Comput. Chem. Eng. 2001, 25, 509–515. [Google Scholar] [CrossRef]

- Liu, G.M.; Wang, W.P. Calculation for freezing points of methanol aqueous solution based on property analysis of Aspen Plus. Chem. Eng. 2013, 6, 63–65. [Google Scholar]

| Variable | Description |

|---|---|

| State variable | |

| Manipulated variable | |

| Driving variable | |

| Driving trajectory of driving variable | |

| Equation of objective function | |

| Physical model of plant | |

| superscripts | Steady-state value before transition |

| superscripts | Steady-state value after transition |

| Type of Variable | Name of Variable | Unit | Current Data | Target Data |

|---|---|---|---|---|

| Input variable | Feed flowrate | kmol/h | 798.034 | 998.034 |

| Side draw flowrate | kmol/h | 642.856 | 804.501 | |

| Bottom reboiler consumption | kJ/h | |||

| 1st middle reboiler consumption | kJ/h | |||

| 2nd middle reboiler consumption | kJ/h | |||

| Output variable | Ethylene product composition | % | 99.90 | 99.90 |

| Reflux ratio | - | 4.606 | 4.676 | |

| Operating pressure | Mpa | 1.63 | 1.63 | |

| Side draw temperature | K | 237.10 | 237.11 | |

| Bottom temperature | K | 257.30 | 257.34 |

| Parameter | Unit | A-FD | TSO-FD | A-FD (New Transition) | TSO-FD (New Transition) | |

|---|---|---|---|---|---|---|

| kmol/h | 222.314 | 222.447 | 236.941 | 236.896 | ||

| kmol/h | 60.3523 | 60.3521 | 57.946 | 57.934 | ||

| h | 1.526 | 1.612 | 1.544 | 1.521 | ||

| h | 0.216 | 0.199 | 0.171 | 0.166 | ||

| kJ/h | ||||||

| kJ/h | ||||||

| h | 1.620 | 1.477 | ||||

| h | 0.117 | 0.256 | ||||

| J | - | |||||

| Maximum deviation | % | |||||

| Mean-square error | - | |||||

| Type of Variable | Name of Variable | Unit | Current Data | Target Data |

|---|---|---|---|---|

| Input variable | Feed flowrate | kmol/h | 798.034 | 998.034 |

| Ethylene composition of feed | % | 83.04 | 84.04 | |

| Ethane composition of feed | % | 16.80 | 15.80 | |

| Methane composition of feed | % | 0.15 | 0.15 | |

| Hydrogen composition of feed | % | 0.01 | 0.01 | |

| Side draw flowrate | kmol/h | 642.856 | 821.487 | |

| Bottom reboiler consumption | kJ/h | |||

| 1st middle reboiler consumption | kJ/h | |||

| 2nd middle reboiler consumption | kJ/h | |||

| Output variable | Ethylene product composition | % | 99.90 | 99.90 |

| Reflux ratio | - | 4.606 | 4.628 | |

| Operating pressure | MPa | 1.63 | 1.63 | |

| Side draw temperature | K | 237.10 | 237.11 | |

| Bottom temperature | K | 257.30 | 258.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.-Y.; Xu, F.; Luo, X.-L. Targeting on Different Characteristic Continuous Variables in Process Transition for Ethylene Column with Wide-Range Feed Fluctuation. Processes 2022, 10, 796. https://doi.org/10.3390/pr10040796

Cao X-Y, Xu F, Luo X-L. Targeting on Different Characteristic Continuous Variables in Process Transition for Ethylene Column with Wide-Range Feed Fluctuation. Processes. 2022; 10(4):796. https://doi.org/10.3390/pr10040796

Chicago/Turabian StyleCao, Xin-Yi, Feng Xu, and Xiong-Lin Luo. 2022. "Targeting on Different Characteristic Continuous Variables in Process Transition for Ethylene Column with Wide-Range Feed Fluctuation" Processes 10, no. 4: 796. https://doi.org/10.3390/pr10040796

APA StyleCao, X.-Y., Xu, F., & Luo, X.-L. (2022). Targeting on Different Characteristic Continuous Variables in Process Transition for Ethylene Column with Wide-Range Feed Fluctuation. Processes, 10(4), 796. https://doi.org/10.3390/pr10040796