Numerical Simulation and Experimental Test of the Sliding Core Dynamics of a Pressure Controlled Jet Crushing Tool for Natural Gas Hydrate Exploitation

Abstract

:1. Introduction

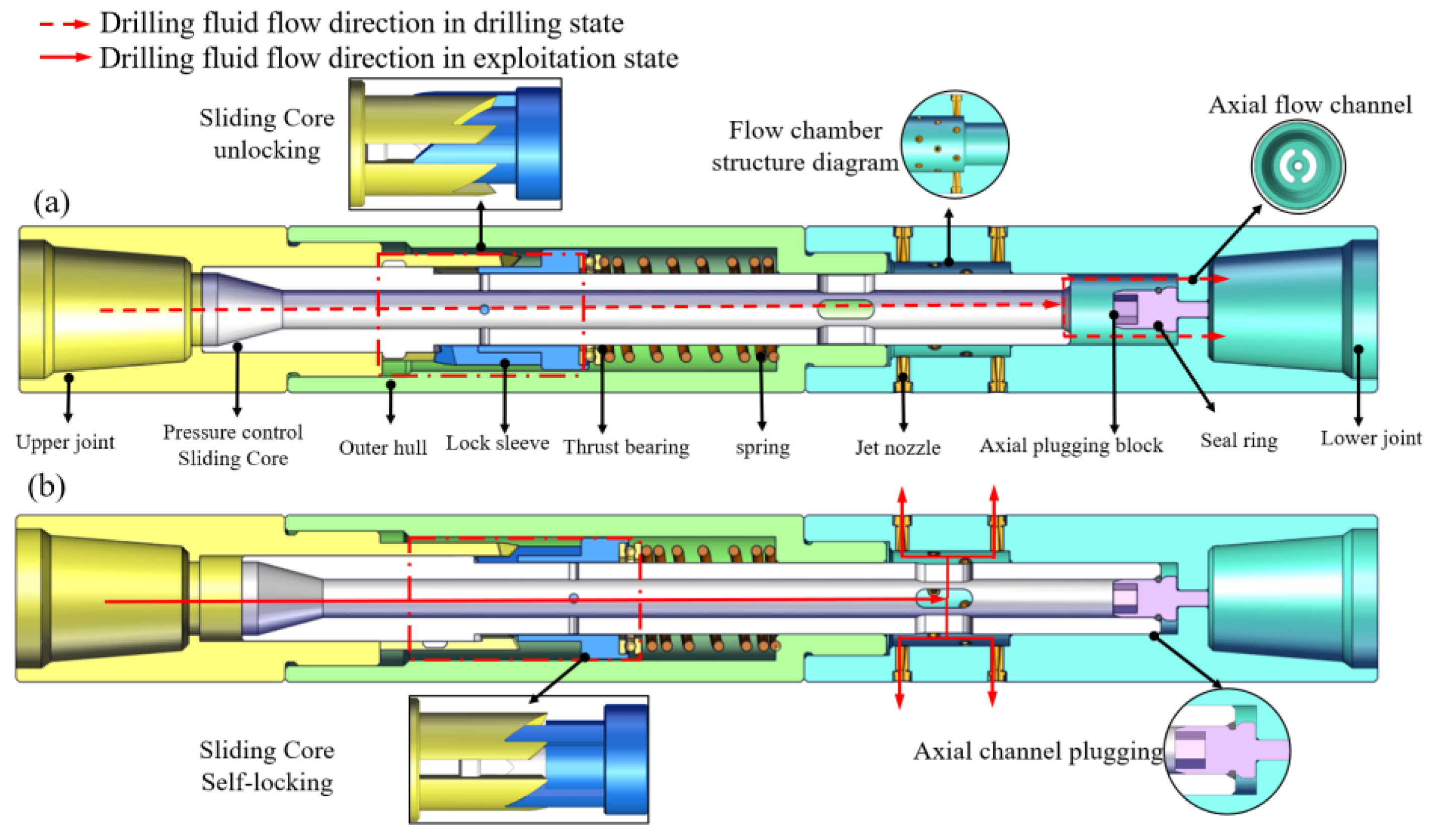

2. Working Mechanism of PJCT

2.1. Working Process of PJCT

- Horizontal well drilling state: The flow rate of the drilling fluid is small and the driving force on the sliding core is less than the preload of the spring. The jet hole on the sliding core is blocked by the outer cylinder and is not connected with the jet nozzle. The drilling fluid flows down through the axial flow channel and flows out through the end of the bit for drilling.

- Drag back tool string and jet crushing state: The down hole string is dragged back, and the drilling fluid rate is increased at the same time. The driving force of the sliding core gradually increases and then the compression spring further moves downward. At this time, the jet hole on the sliding core is exposed and connected with the jet nozzle, and the axial flow channel is blocked by the axial plugging block. The high-pressure drilling fluid starts the jet crushing operation through the jet nozzle. Meanwhile, the self-locking mechanism can avoid the fluctuation of the sliding core caused by the change in the drilling fluid rate and realizes the stability of the breaking process.

- Multi-angle directional mining: when the dragging and acquisition of the drill string is completed, the drilling fluid rate is gradually reduced to 0 L/min, and then the drilling fluid flow is increased to the jet breaking flow again. During this time, the self-locking mechanism is unlocked, and then the drilling fluid flow is reduced. The sliding core rebounds under the action of spring force. The jet nozzle is closed and drilling fluid flows again towards the bit end through the PJCT. Then the whole down hole tool will change in another direction at the bottom of the wellbore to repeat horizontal well drilling and drag back the tool string and jet crushing. Finally, multi-angle, large-scale mining can be realized.

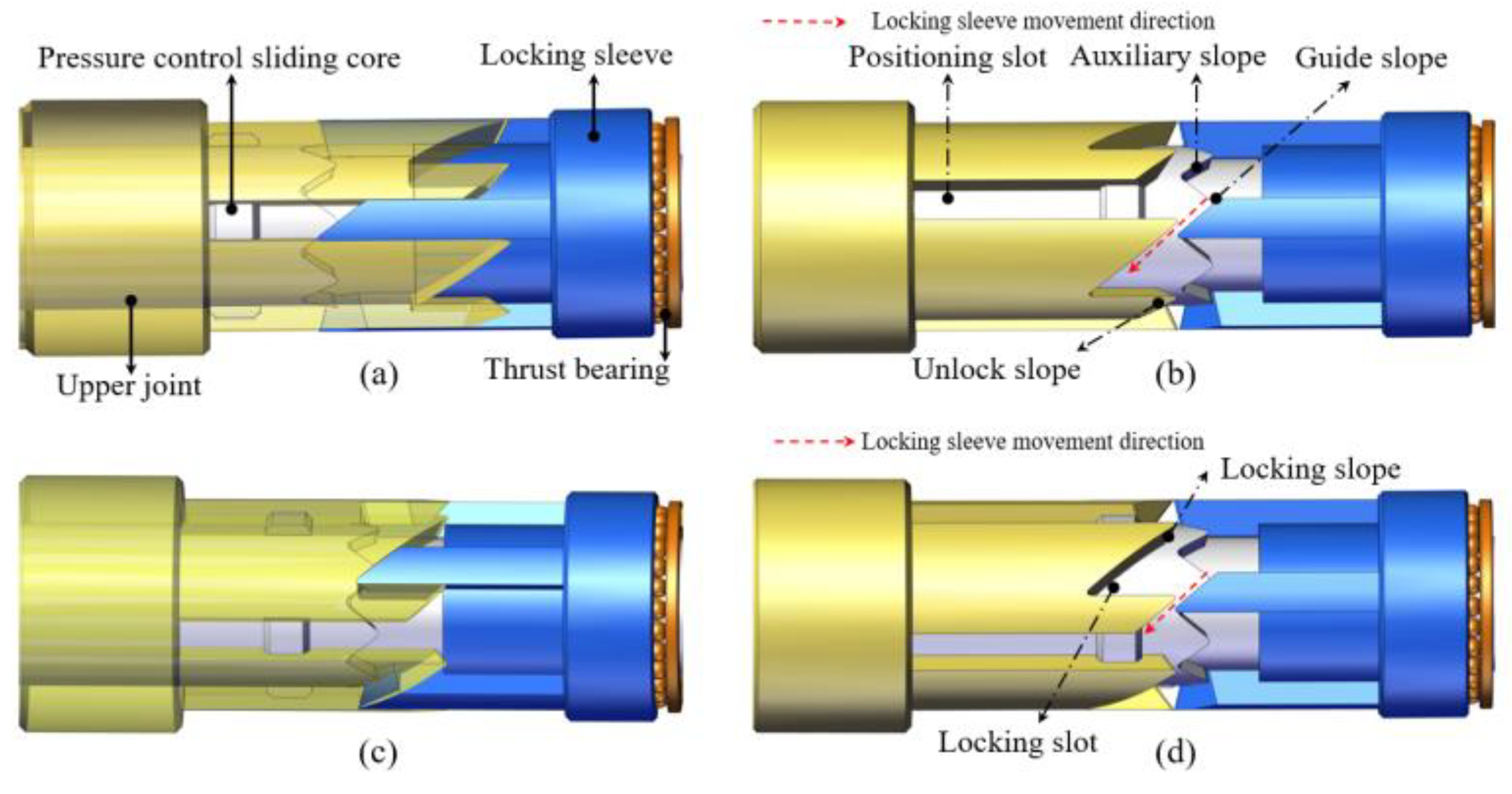

2.2. Working Process of the Self-Locking Mechanism

- When the solid-state fluidized exploitation is in the horizontal well drilling state, the self-locking mechanism is in the initial state, as shown in Figure 3a. The locking sleeve is located in the positioning slot, and the guide slope is located in the middle of the auxiliary slope.

- When the solid-state fluidized exploitation is in the jet crushing state, the drilling fluid flow is increased to the self-locking mechanism opening flow. The sliding core pulls the locking sleeve out of the positioning slot under the action of the drilling fluid, the locking sleeve moves along the auxiliary slope to the lowest end of the auxiliary slope and turns to a certain angle under the action of the thrust bearing as shown in Figure 3b.

- When the drilling fluid flow suddenly decreases or fluctuates, the locking sleeve moves along the locking slope to the lowest end of the locking slot under the action of the spring and the thrust bearing. The self-locking mechanism enters the self-locking state as shown in Figure 3c.

- When the jet crushing state is completed, the self-locking mechanism needs to be released from the locked state. First, the drilling fluid flow is reduced to 0 L/min and then the flow to the jet crushing flow is loaded. After that, the drilling fluid flow is gradually reduced to 0 L/min. In this process, the locking sleeve is pushed out of the locking slot, and the locking sleeve moves along the auxiliary slope to the lowest end of the auxiliary slope under the action of the sliding core, as shown in Figure 3d. After that, the locking sleeve enters the positioning slot along the unlock-slope, and the self-locking mechanism returns to the initial state as shown in Figure 3a. So far, the self-locking mechanism has carried out a complete working process.

3. Motion Analysis of the Sliding Core

3.1. Mathematical Model

- Consider the sliding core as a rigid body and ignore its small deformation;

- Consider the gravity of the sliding core and the friction between the sliding core and the parts of PJCT.

3.2. Numerical Simulation

4. Dynamic Simulation Results

4.1. Motion Law of the Sliding Core under Different Spring Stiffness and Flow Rate

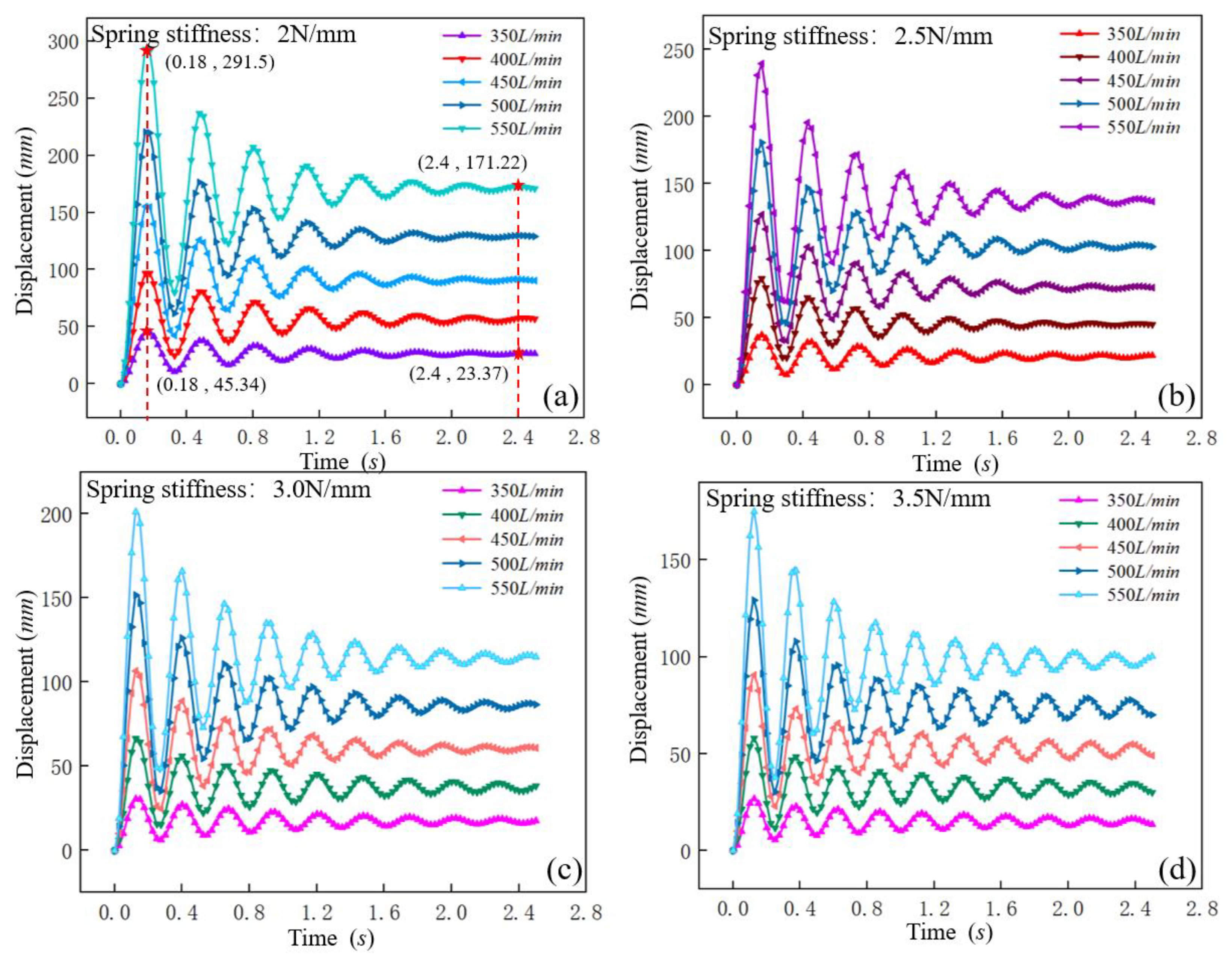

4.1.1. Displacement Change Law of the Sliding Core

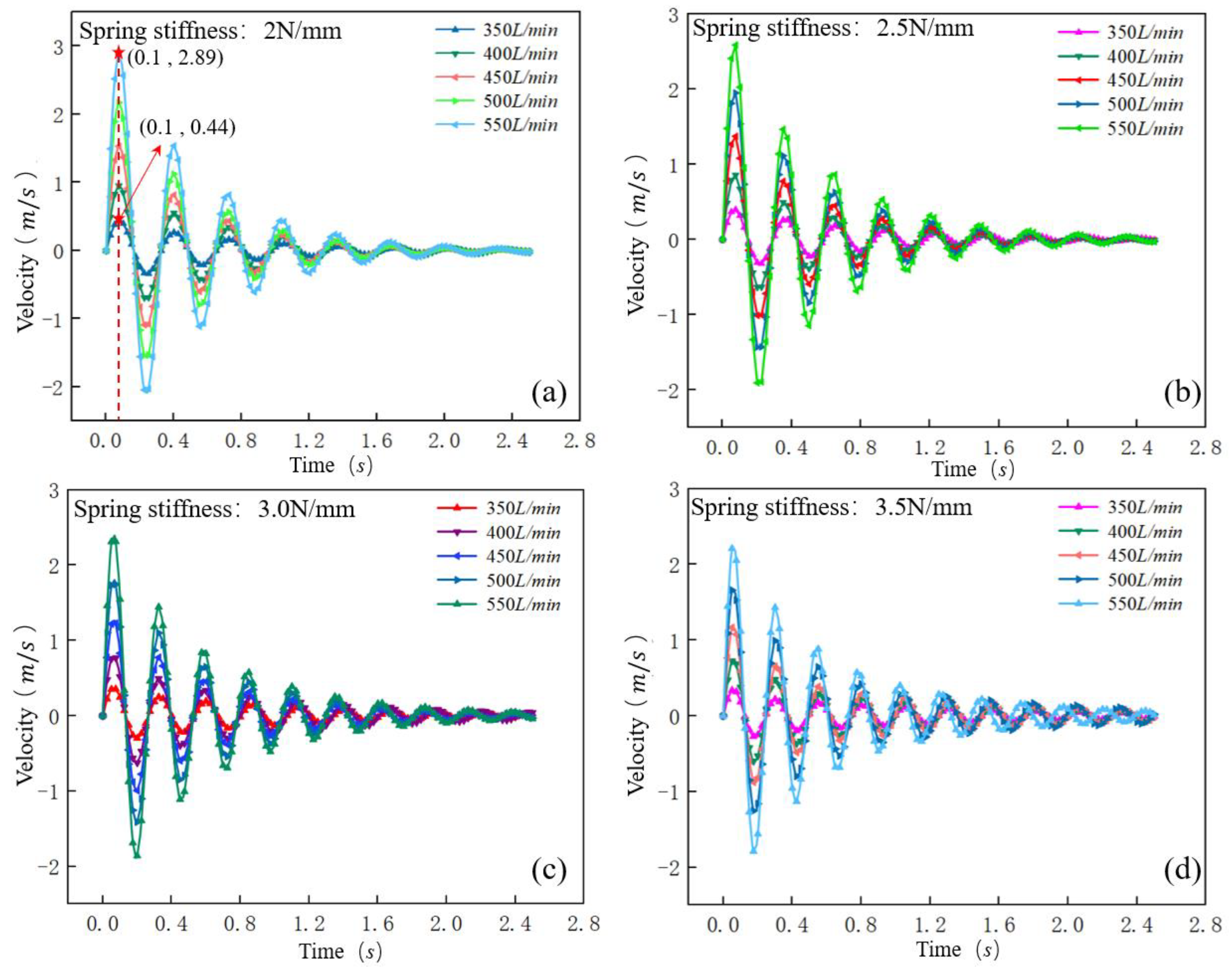

4.1.2. Velocity Change Law of Sliding Core

4.2. Motion Law of the Sliding Core under Different Friction Coefficients

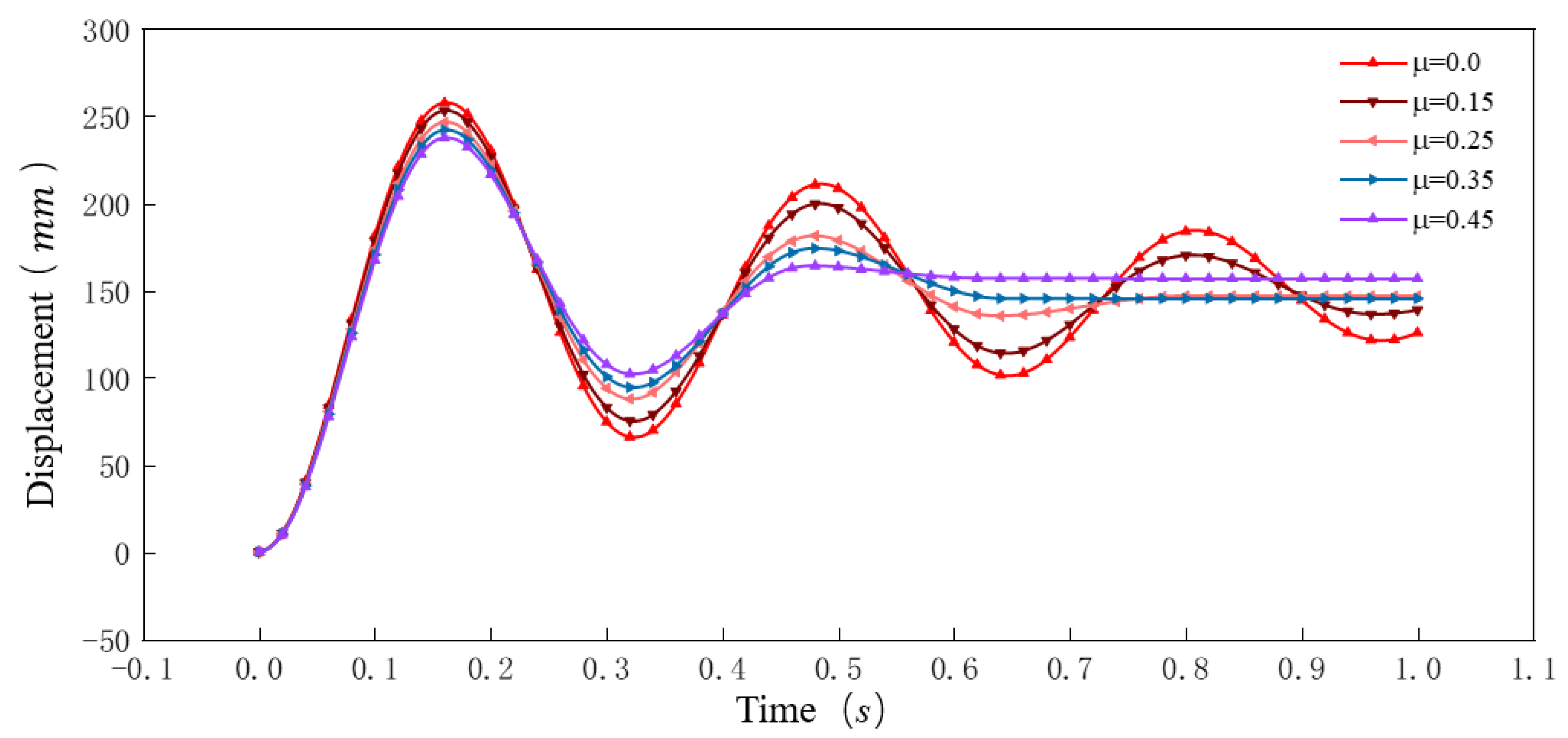

4.2.1. Displacement Change Law of the Sliding Core

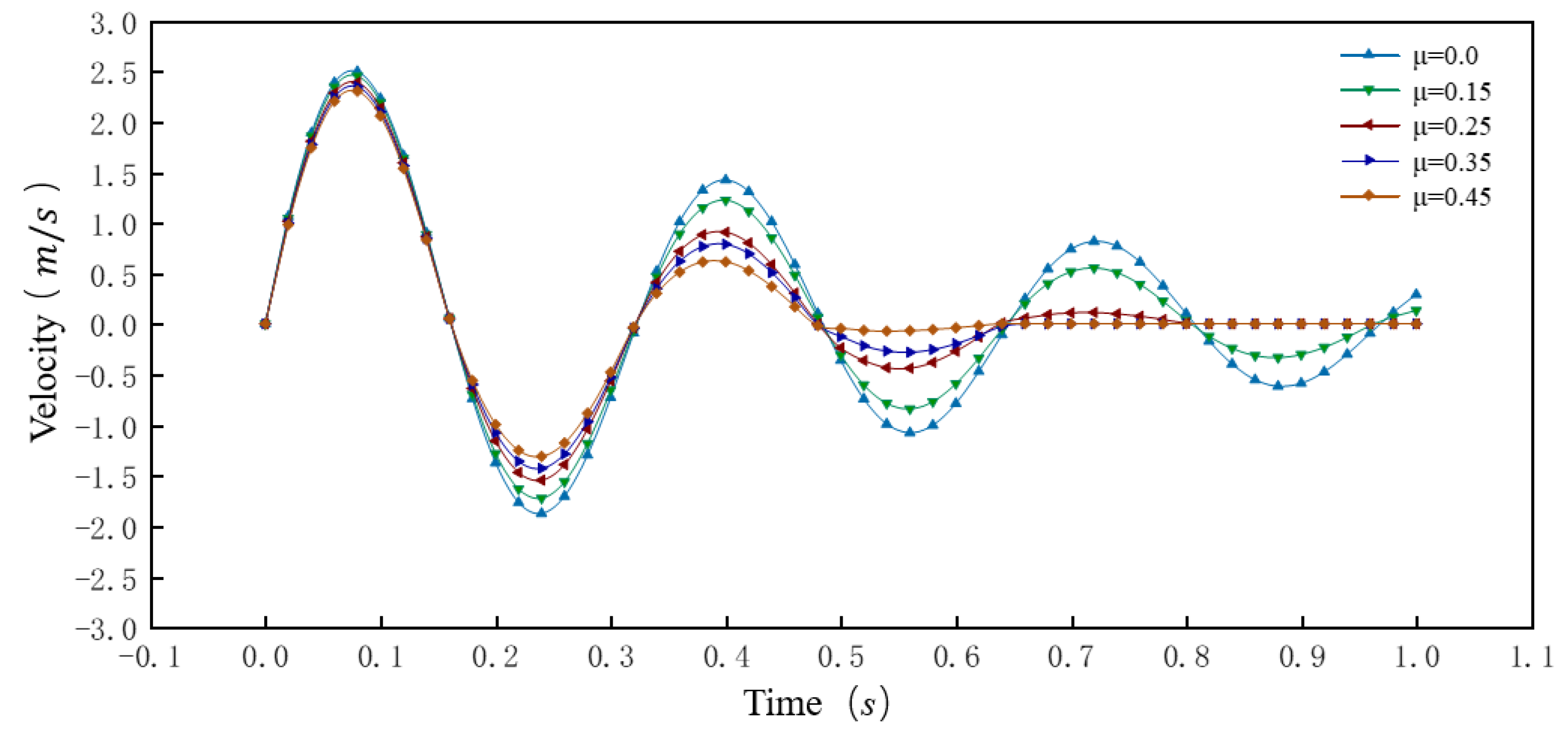

4.2.2. Velocity Change Law of the Sliding Core

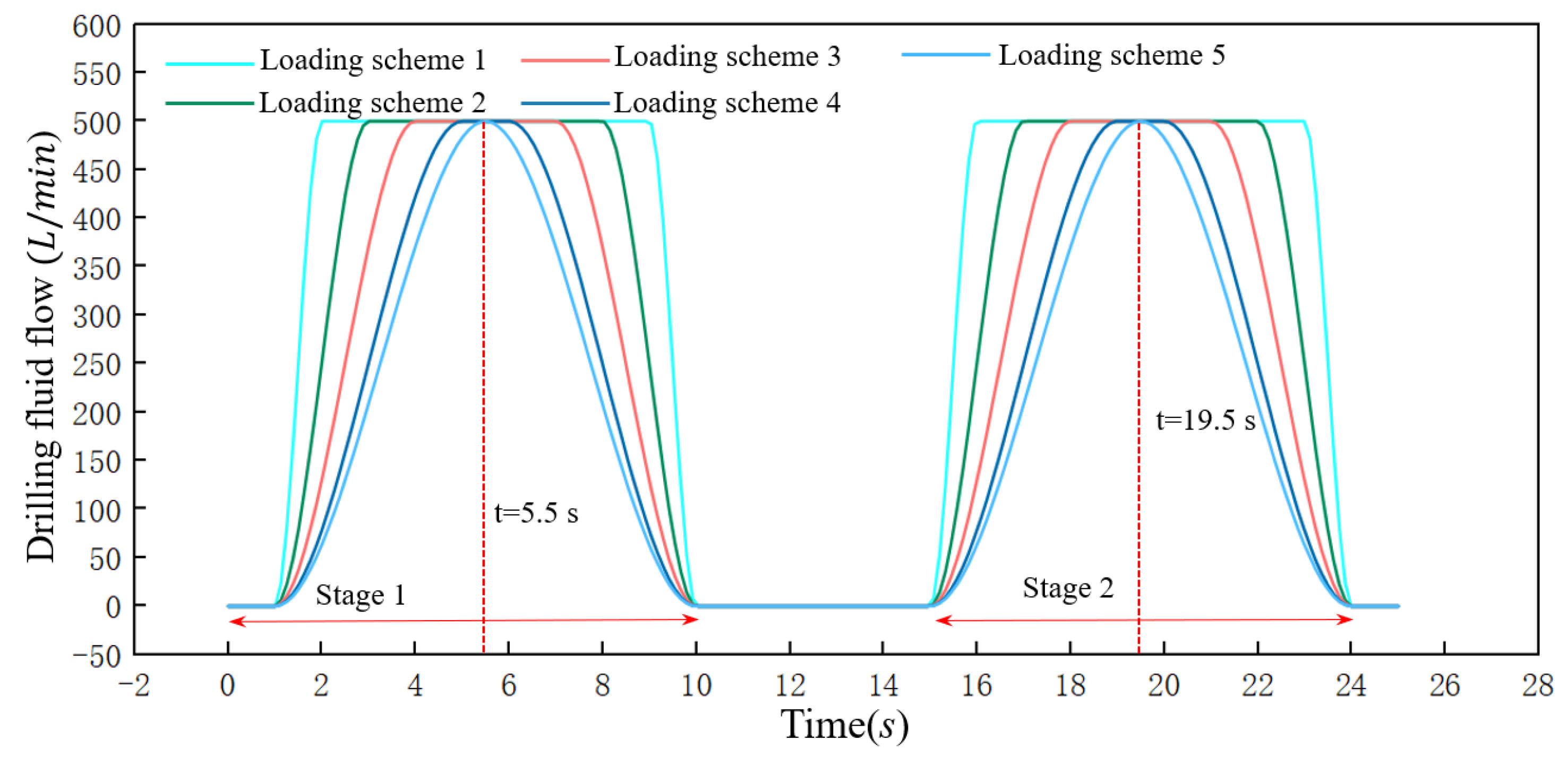

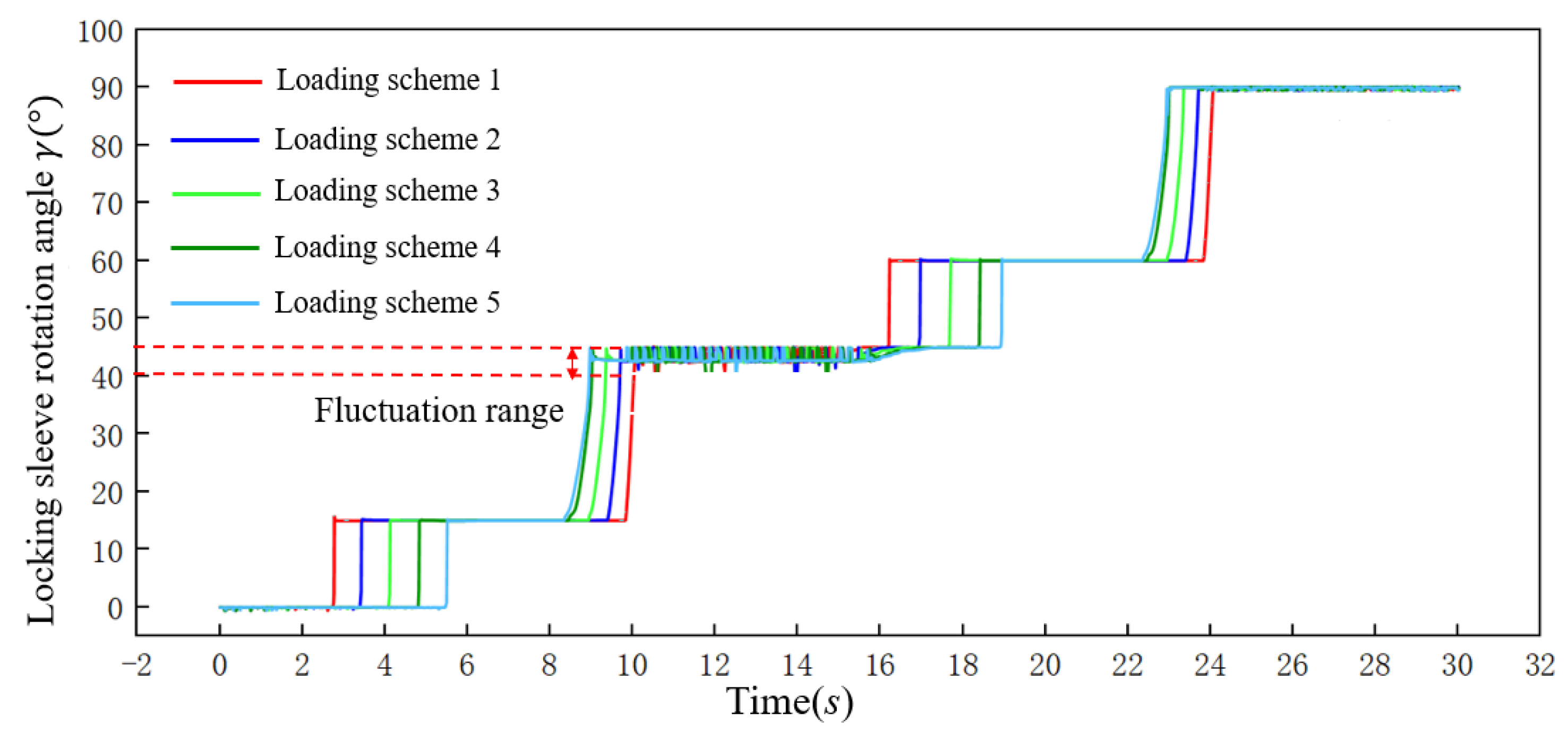

4.3. Motion Law of the Sliding Core under Different Flow Rate Loading Schemes

5. Experiment Test

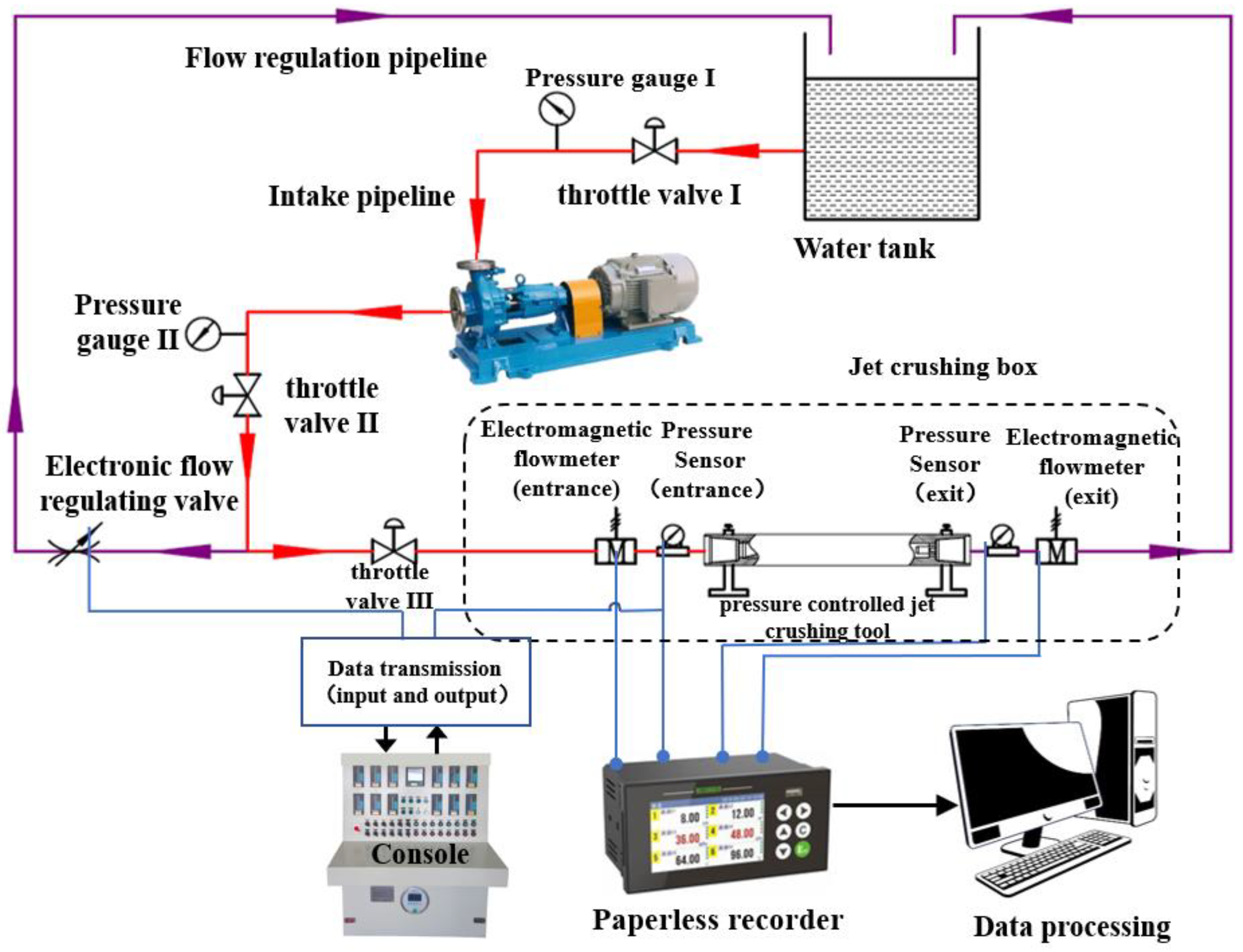

5.1. Experimental Principle

- (1)

- When the inlet flow rate is less than 300 L/min, the opening of the electronic flow control valve can increase by 7% each time. When the flow rate is stable, the corresponding experimental data and experimental phenomena should be observed and recorded before continuous adjustment.

- (2)

- When the inlet flow rate is between 300 L/min and 400 L/min, the opening of the electronic flow control valve can be increased by 5% each time. When the flow rate is stable, the corresponding experimental data and experimental phenomena can be observed and recorded before continuous adjustment.

- (3)

- When the flow rate is greater than 400 L/min, the opening of the electronic flow control valve can be increased by 3% each time, and the flow rate can be gradually increased until the nozzle is fully open.

5.2. Experimental Phenomena and Analysis

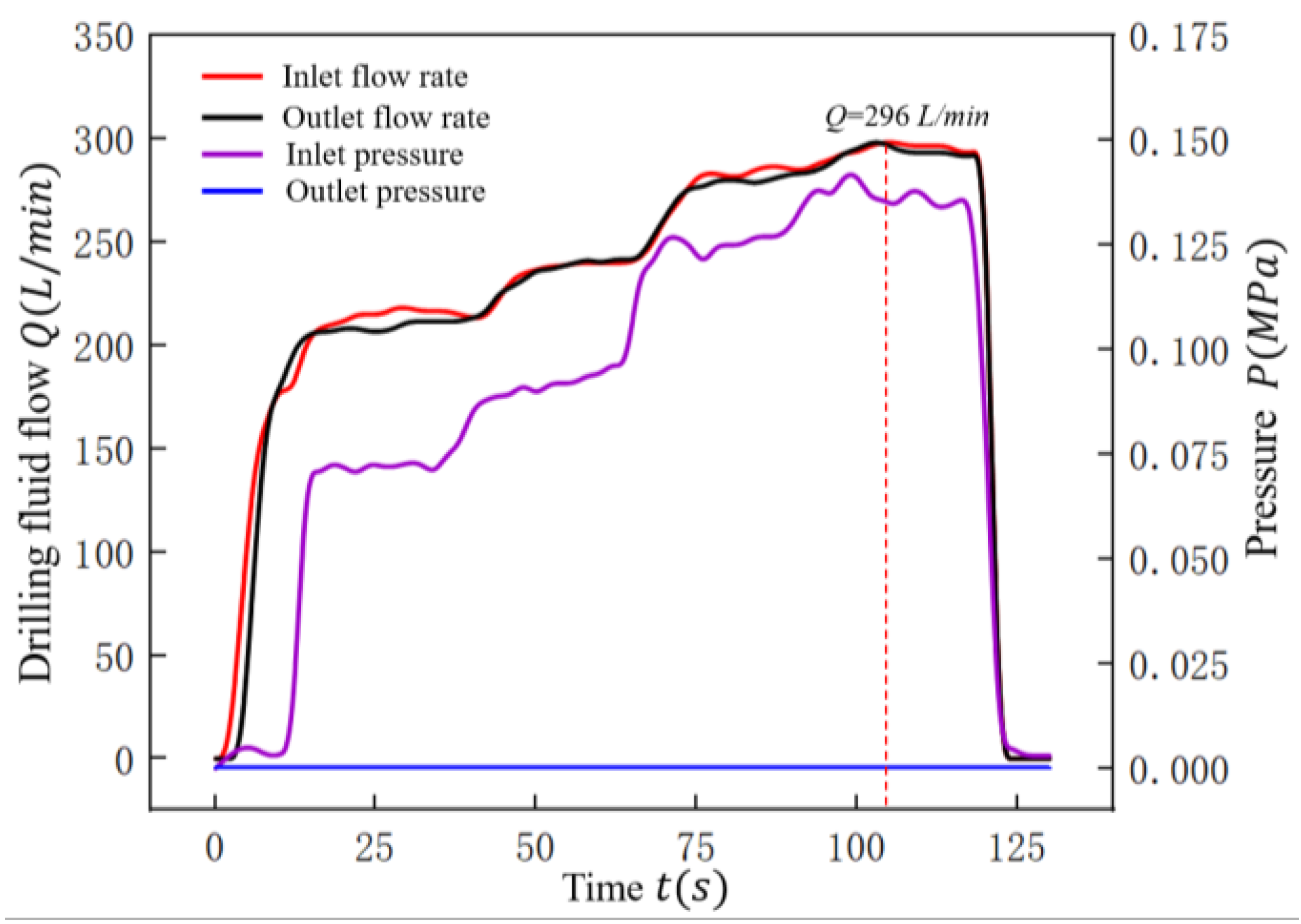

5.2.1. Experiment I

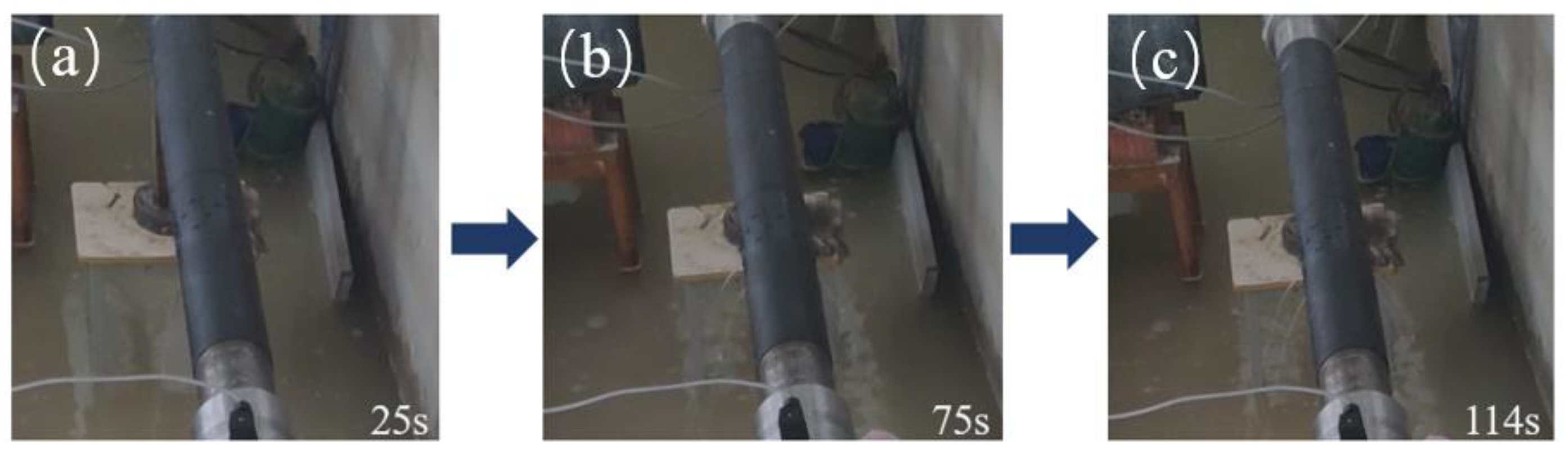

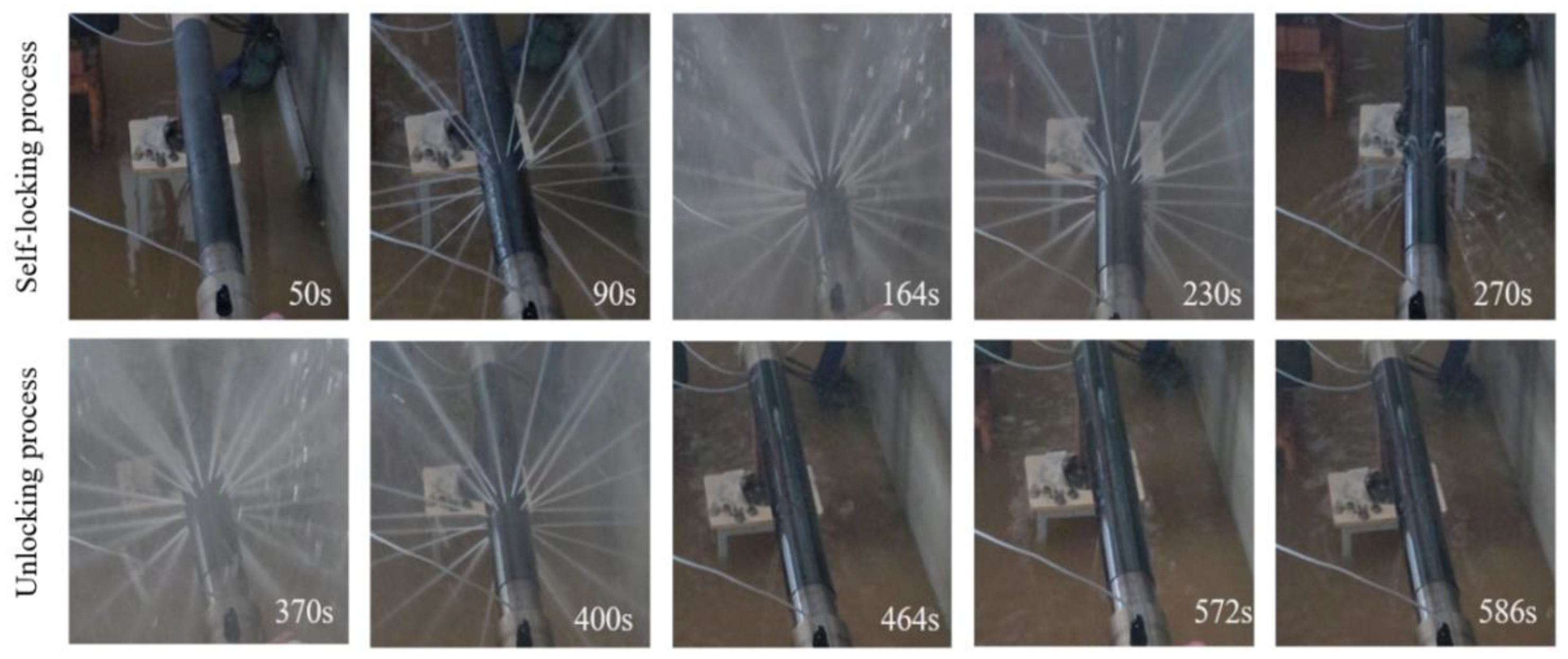

5.2.2. Experiment II and Experiment III

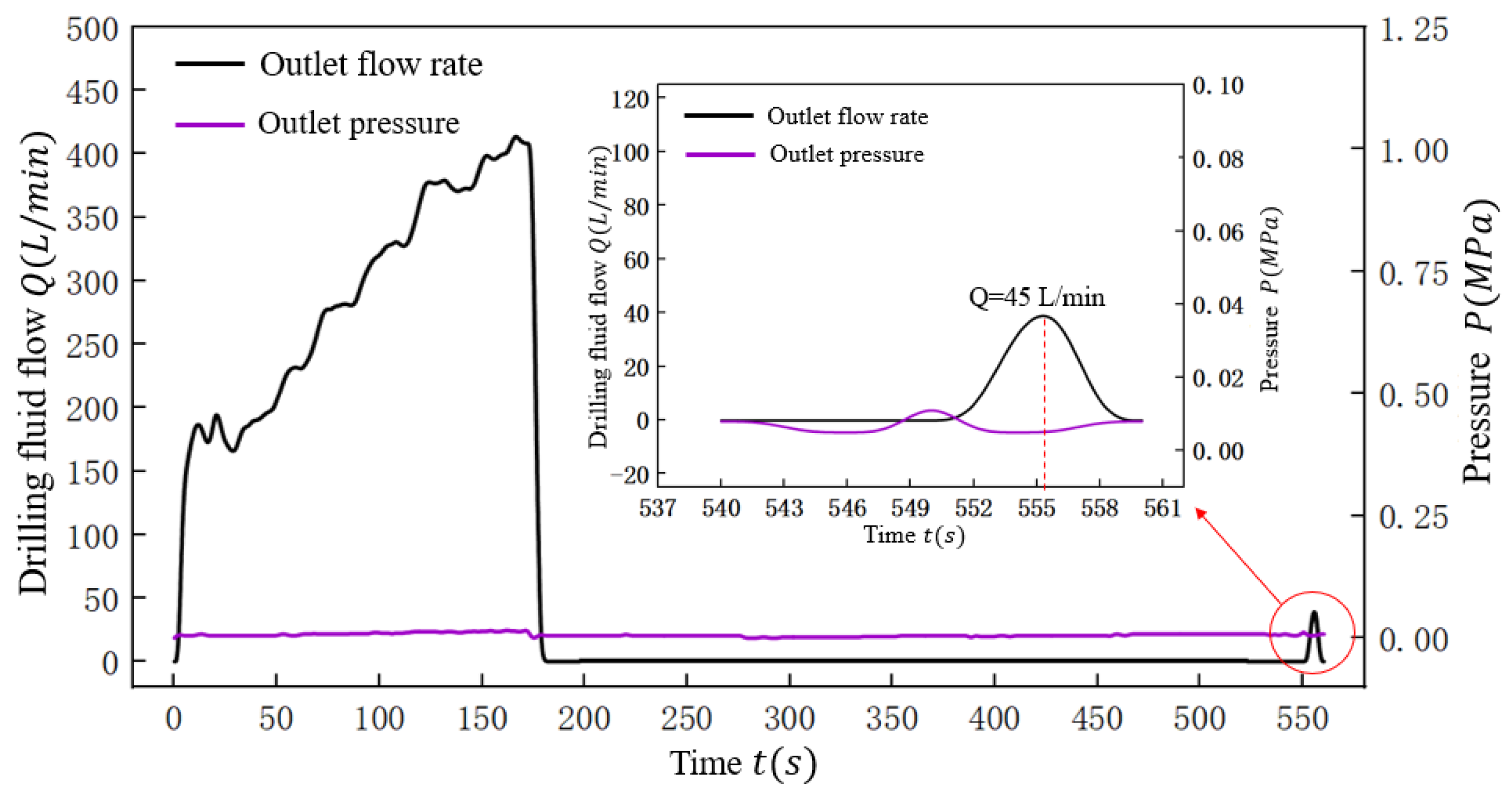

5.2.3. Experiment IV

6. Conclusions and Discussion

- (1)

- As the flow rate of drilling fluid increased, the time from fluctuating to stable for the sliding core was almost unchanged under the same spring stiffness, which indicated that the stability time of the sliding core fluctuation was independent of the drilling fluid flow level. As the spring stiffness increased, the fluctuation range of the sliding core was also smaller, but the time for the sliding core to stabilize increased at the same flow rate, which indicated that the stability of the sliding core decreases.

- (2)

- As the friction coefficient between the parts increased, the fluctuation range of the velocity and displacement of the sliding core became smaller under the same flow rate and spring stiffness. Therefore, the recommendation for the selection of the sliding core material is that the friction between the sliding core and the remaining parts should be controlled while ensuring the rapid response of the sliding core.

- (3)

- The verification experiment showed that the PJCT would not open the jet nozzle under a normal drilling flow of 300 L/min. When the drilling fluid flow reached 455 L/min or the inlet pressure drop reached about 0.9 MPa, the PJCT could stably complete the self-locking and unlocking functions and the self-locking mechanism had the prospect of application to other down hole tools for oil and gas exploitation.

- (4)

- In future research, a kind of PJCT with a suction port will be proposed. This type of PJCT jet crushing-propeller recovery model will be established by analyzing the relationship between the nozzle installation position and the suction port, which can provide a theoretical basis for advancing the solid-state fluidized exploitation of natural gas hydrates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, S.W.; Li, Q.P.; Lv, X.; Fu, Q.; Zhu, J.L. Key issues in development of offshore natural gas hydrate. Front. Energy 2020, 14, 433–442. [Google Scholar] [CrossRef]

- Pinkert, S. Dilation behavior of gas-saturated methane-hydrate bearing sand. Energies 2019, 12, 2937. [Google Scholar] [CrossRef] [Green Version]

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353–359. [Google Scholar] [CrossRef]

- Makogon, Y.F. Natural gas hydrates–A promising source of energy. J. Nat. Gas Sci. Eng. 2010, 2, 49–59. [Google Scholar] [CrossRef]

- Wang, G.R.; Zhong, L.; Zhou, S.W.; Liu, Q.; Li, Q.; Fu, Q.; Huang, R. Jet breaking tools for natural gas hydrate exploitation and their support technologies. Nat. Gas Ind. 2018, 5, 312–318. [Google Scholar] [CrossRef]

- Fitzgerald, G.C.; Castaldi, M.J.; Zhou, Y. Large scale reactor details and results for the formation and decomposition of methane hydrates via thermal stimulation dissociation. J. Pet. Sci. Eng. 2012, 94, 19–27. [Google Scholar] [CrossRef]

- Ota, M.; Abe, Y.; Watanabe, M. Methane recovery from methane hydrate using pressurized CO2. Fluid Phase Equilib. 2005, 228, 553–559. [Google Scholar] [CrossRef]

- Aghajari, H.; Moghaddam, M.H.; Zallaghi, M. Study of effective parameters for enhancement of methane gas production from natural gas hydrate reservoirs. Green Energy Environ. 2019, 4, 453–469. [Google Scholar] [CrossRef]

- Giraldo, C.; Klump, J.; Clarke, M. Sensitivity analysis of parameters governing the recovery of methane from natural gas hydrate reservoirs. Energies 2014, 7, 2148–2176. [Google Scholar] [CrossRef] [Green Version]

- Qorbani, K.; Kvamme, B.; Kuznetsova, T. Using a reactive transport simulator to simulate CH4 production from bear island basin in the Barents Sea utilizing the depressurization method. Energies 2017, 10, 187. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Pan, D.; Yang, L.; Zhang, H.; Li, B.; Jin, C.; Zhong, X. Investigation into the water jet erosion efficiency of hydrate-bearing sediments based on the arbitrary Lagrangian-Eulerian method. Appl. Sci. 2019, 9, 182. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.W.; Zhao, J.; Li, Q.Y.; Chen, W.; Zhou, J.; Wei, N.; Sun, W. Optimal design of the engineering parameters for the first global trial production of marine natural gas hydrates through solid fluidization. Nat. Gas Ind. 2018, 5, 118–131. [Google Scholar] [CrossRef]

- Zhou, S.W.; Chen, W.; Li, Q.P. The green solid fluidization development principle of natural gas hydrate stored in shallow layers of deep water. China Offshore Oil Gas 2014, 26, 1–7. [Google Scholar]

- Wei, N.; Sun, W.; Meng, Y.; Liu, A.; Zhao, J.; Zhou, S.W.; Li, Q.Y. Multiphase non equilibrium pipe flow behaviors in the solid fluidization exploitation of marine natural gas hydrate reservoir. Energy Sci. Eng. 2018, 6, 760–782. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Yao, J.X.; Wang, G.R.; Lin, Z.; He, Y.F.; Liu, Q.Y. Development and laboratory experiments of pressure-controlled sliding sleeves for injection and crushing operations in the exploitation of deep sea shallow non diagenetic marine gas hydrates. Nat. Gas Ind. 2020, 40, 186–194. [Google Scholar]

- Tang, Y.; Yao, J.X.; He, Y.; Sun, P.; Jing, X. Study on pressure-controlled sliding sleeve of jet breaking for natural gas hydrate mining based on throttle pressure drop principle. Energy Sci. Eng. 2020, 8, 1422–1437. [Google Scholar] [CrossRef]

- Tang, Y.; Huang, S.X.; Yao, J.X.; Liu, Q.Y.; Wang, G.R.; Zhou, S.W. An Automatic Jet Breaking Tool for Solid-State Fluidized Exploitation of Natural Gas Hydrate. CN Patent Application No. CN110700801A, 17 January 2020. [Google Scholar]

- Zou, L.; Hu, G.Z.; Wen, H.B.; Xu, X.J.; Pu, F. Effect of Spring Stiffness Coefficient on the Performance of One Way Valve Closed. Fluid Mach. 2017, 45, 47–51. [Google Scholar]

- Klas, R.; Habán, V.; Rudolf, P. Analysis of in-line check valve with respect to the pipeline dynamics. Eur. Phys. J. Conf. 2017, 143, 02051. [Google Scholar] [CrossRef]

- Wang, J.Z.; Chen, E.F.; Yu, W.J.; Ye, C.; Song, B.F. Mechanism of self-excited vibration and dynamic stability for pneumatic valves. J. Aerosp. Power 2014, 9, 1490–1497. [Google Scholar]

- Li, Y.; Jiao, Z.; Wu, S. Flow characteristics analysis and optimization design of high frequency reciprocation pump applying check valve to rectification. J. Mech. Eng. 2013, 49, 154–163. [Google Scholar] [CrossRef]

- Lai, Z.; Karney, B.; Yang, S.; Wu, D.; Zhang, F. Transient performance of a dual disc check valve during the opening period. Ann. Nucl. Energy 2017, 1, 15–22. [Google Scholar] [CrossRef]

- Xiang, B.P.; Yin, G.F.; Zeng, X.W.; Zang, H.B. Research on Open and Close Characteristics of Passive Shuttle-type Anti-water-attack Check Valve. Key Eng. Mater. 2011, 474, 2290–2295. [Google Scholar] [CrossRef]

- Lee, T.S.; Low, H.T.; Nguyen, D.T.; Neo, W.R.A. Experimental study of check valves performances in fluid transient. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2009, 223, 61–69. [Google Scholar] [CrossRef]

- Mo, N. Engineering Fluid Mechanics; Huazhong University of Science and Technology Press: Wuhan, China, 2009; pp. 145–147. [Google Scholar]

- Xie, Z. Engineering Fluid Mechanics, 4th ed.; Metallurgical Industry Press: Beijing, China, 2013; pp. 135–138. [Google Scholar]

| Constraint Vice Name | Parts Name | Contact Name | Parts Name |

|---|---|---|---|

| Cylindrical pair | Slide core, lock sleeve | Contact 1 | Slide core, lock sleeve |

| Sliding pair | Slide core, upper joint | Contact 2 | Upper joint, lock sleeve |

| Cylindrical pair | Lock sleeve, upper joint | Contact 3 | Slide core, lower joint |

| Fixed pair | Upper joint | Contact 4 | Upper joint, Slide core |

| Fixed pair | Lower joint | Contact 5 | Lower joint, lock sleeve |

| Experiment Number | Flow Loading Scheme (L/min) | Experiment Purpose |

|---|---|---|

| I | 0~300 | Verify whether the jet nozzle is opened during normal drilling |

| II | 0~470~0~100~0 | Verify whether the PJCT is fully opened and self-locked at 470 L/min |

| III | 0~470~0 | Verify whether the PJCT can be unlocked at 470 L/min |

| IV | 0~470~0~470~0~300~0 | Verify whether the PJCT can complete self-locking and unlocking in a continuous cycle |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Zhao, P.; Li, X.; Fang, X.; Yang, P. Numerical Simulation and Experimental Test of the Sliding Core Dynamics of a Pressure Controlled Jet Crushing Tool for Natural Gas Hydrate Exploitation. Processes 2022, 10, 1033. https://doi.org/10.3390/pr10051033

Tang Y, Zhao P, Li X, Fang X, Yang P. Numerical Simulation and Experimental Test of the Sliding Core Dynamics of a Pressure Controlled Jet Crushing Tool for Natural Gas Hydrate Exploitation. Processes. 2022; 10(5):1033. https://doi.org/10.3390/pr10051033

Chicago/Turabian StyleTang, Yang, Peng Zhao, Xushen Li, Xiaoyu Fang, and Pu Yang. 2022. "Numerical Simulation and Experimental Test of the Sliding Core Dynamics of a Pressure Controlled Jet Crushing Tool for Natural Gas Hydrate Exploitation" Processes 10, no. 5: 1033. https://doi.org/10.3390/pr10051033

APA StyleTang, Y., Zhao, P., Li, X., Fang, X., & Yang, P. (2022). Numerical Simulation and Experimental Test of the Sliding Core Dynamics of a Pressure Controlled Jet Crushing Tool for Natural Gas Hydrate Exploitation. Processes, 10(5), 1033. https://doi.org/10.3390/pr10051033