Microstructure Evolution of Inertia Friction Welded Joints of TC21 Titanium Alloy

Abstract

:1. Introduction

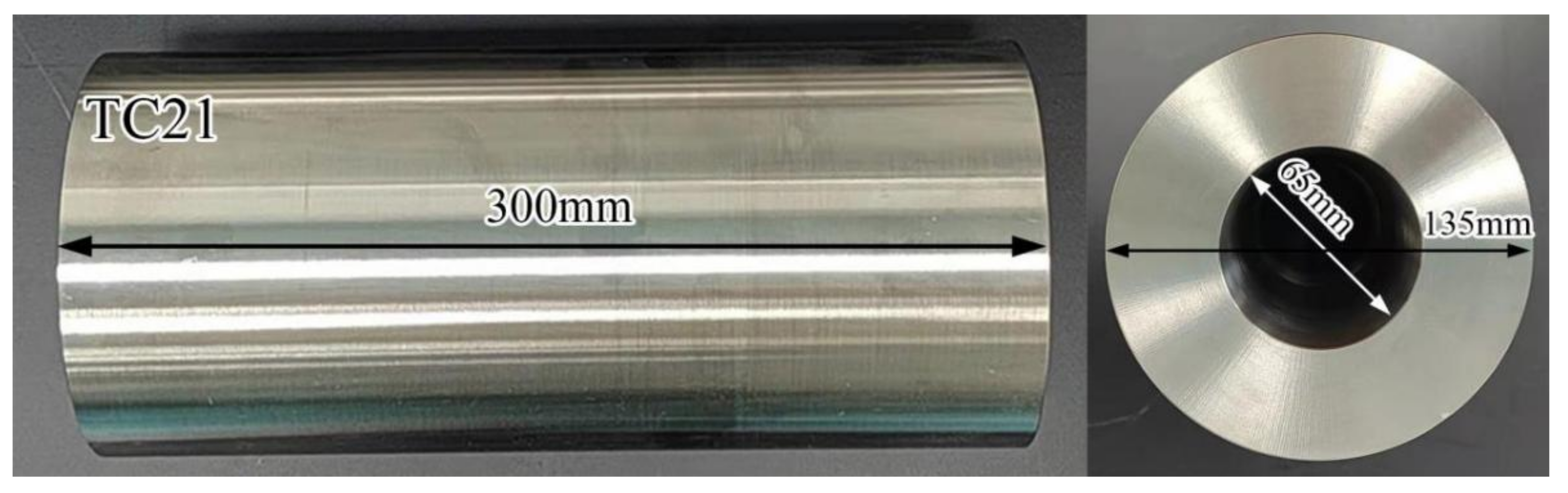

2. Materials and Methods

3. Results and Discussion

3.1. Appearance and Microstructure of the Overall IFW Joint

3.2. SEM Results of IFW Joint Microstructure

3.3. Results of Crystal Orientation Analysis of the IFW Joint

3.4. Phase Analysis Results of the IFW Joint

3.5. Element Analysis Results of the IFW Joint

4. Conclusions

- (1)

- The shapes of ”large-size equiaxial β grains”, with ranges of hundreds of micrometers existing in the BM, have completely disappeared in the WZ of the IFW joint. While the shape of “large-size equiaxial β grains” still remains in the TMAZ and HAZ, but severe deformation of equiaxial β grains is found in the TMAZ due to the effect of rotating friction force.

- (2)

- Fine equiaxial grains with the size of 20–30 μm are formed in the WZ of the IFW joint. However, there are no fine equiaxial grains observed in the TMAZ and HAZ. It is believed that recrystallization in the WZ results in the formation of the fine equiaxial grains.

- (3)

- The BM zone consists of α + β two phases with original lamellar α phases with the width of 1–4 μm. In the WZ zone of joint, BM original α phases have completely disappeared. Instead, a very fine α + β lamellar microstructure is formed in the WZ and the width of fine lamellar α phases in the WZ is even less than 0.1 μm. Moreover, BM original α phases partially remain in the TMAZ and completely remain in the HAZ, and secondary α phases are precipitated on the BM original β base in the TMAZ and HAZ.

- (4)

- EBSD crystal orientation analysis shows that the basketweave microstructure has been destroyed in the TMAZ and WZ. XRD results indicate that (100) crystal orientation becomes dominant for α-phase in the WZ, and peak relative intensity of the β phase becomes much lower and some peaks of β phase even disappear completely in the WZ, revealing that the proportion of β phase in the WZ zone decreases greatly. The tested proportion of β phase decreases from 14.4% in the BM to 3.8% in WZ.

- (5)

- EDS results show there are aggregations of Mo, Nb, and Cr (stabilizing elements of β phase) at β phase area in the BM. However, in the WZ, element aggregation could not be found, and element distribution is homogeneous in the WZ, which is consistent with the decrease in β phase proportion in the WZ and very fine α + β lamellar microstructure of the WZ. It is believed that the recrystallization under high force and heat conditions, and no element aggregation under the rapid cooling condition after welding process, are responsible for the formation of fine grain microstructure and high α phase proportion in the weld zone of IFW joints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Chandra, S.; Rashid, R.A.R.; Palanisamy, S.; Ding, S. Machinability of Additively Manufactured Titanium Alloys: A Comprehensive Review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Mi, G.B.; Huang, X.; Cao, J.X.; Cao, C.X.; Huang, X.S. Frictional Ignition of Ti40 Fireproof Titanium Alloys for Aero-Engine in Oxygen-Containing Media. Trans. Nonferrous Met. Soc. China 2013, 23, 2270–2275. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and Issues in the Application of Titanium Alloys for Aerospace Components. Metals 2020, 10, 6. [Google Scholar] [CrossRef]

- Li, Z.H.; Zhao, S.S.; Li, Z.J.; Wang, M.; Wu, F.Y.; Wang, H.Y.; Zhou, J. Investigation on Mechanical Properties of Inertia Friction Welded Joints of TC21 Titanium Alloy. Processes 2022, 10, 752. [Google Scholar] [CrossRef]

- Jones, R. Fatigue Crack Growth and Damage Tolerance. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 463–483. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Qu, H.L.; Feng, L. Development of damage-tolerance type of TC21 Titanium Alloy with High Strength and High Toughness. Titan. Ind. Prog. 2004, 1, 22–24. [Google Scholar]

- Zhu, Z.S.; Wang, X.N.; Tong, L. Study of New Titanium Alloy used for Chinese Aerospace Structure Applications. Titan. Ind. Prog. 2007, 6, 28–32. [Google Scholar]

- Hui, L.; Zhao, Y.S.; Zhou, S.; An, J.L.; Wang, L. Analysis of Corrosion Fatigue Properties of Notched Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2020, 49, 2706–2711. [Google Scholar]

- Song, J.W.; Tan, C.S.; Sun, Q.Y.; Xiao, L.; Zhao, Y.Q.; Sun, J. Effect of Step-Quenching on Microstructure and Mechanical Properties of Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2019, 48, 1260–1266. [Google Scholar]

- Tan, C.S.; Fan, Y.D.; Li, X.J.; Huang, C.W.; He, J.H.; Zhang, G.J. Effect of the Multiscale Lamellar on Mechanical Properties of Tc21 Titanium Alloy. Rare Met. Mater. Eng. 2021, 50, 4410–4417. [Google Scholar]

- Muhrat, A.; Puga, H.; Barbosa, J. Low-Temperature Brazing of Titanium Using Al-Based Filler Alloys. Adv. Mater. Sci. Eng. 2018, 2018, 4570120. [Google Scholar] [CrossRef] [Green Version]

- Auwal, S.T.; Ramesh, S.; Yusof, F.; Manladan, S.M. A Review on Laser Beam Welding of Titanium Alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 1071–1098. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.; Kokawa, H. Friction-Stir Welding and Processing of Ti-6al-4v Titanium Alloy: A Review. J. Mater. Sci. Technol. 2018, 34, 58–72. [Google Scholar] [CrossRef]

- Mo, D.F.; Song, T.F.; Fang, Y.J.; Jiang, X.S.; Luo, C.Q.; Simpson, M.D.; Luo, Z.P. A Review on Diffusion Bonding between Titanium Alloys and Stainless Steels. Adv. Mater. Sci. Eng. 2018, 2018, 8701890. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Zhang, C.; Zhou, J.; Liang, W.; Li, Y. Analysis of the Microstructure and Mechanical Properties During Inertia Friction Welding of the near-Alpha Ta19 Titanium Alloy. Chin. J. Mech. Eng. 2020, 33, 88. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Peng, Y.; Ma, X. Microstructure and Tensile Strength of Aluminum/Stainless Steel Joint Welded by Inertia Friction and Continuous Drive Friction. Weld. World 2020, 64, 1799–1809. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.; Jin, F. Effect of Welding Parameters on High-Temperature Tensile and Fatigue Properties of Fgh96 Inertia Friction Welded Joints. Weld. World 2019, 63, 1033–1053. [Google Scholar] [CrossRef]

- Ouyang, D.L.; Du, H.M.; Cui, X.; Lu, S.Q.; Dong, X.J. Influence of Β Heat Treatment on Lamellar Microstructure Evolution of Ti-6al-2zr-1mo-1v Alloy. Trans. Mater. Heat Treat. 2016, 38, 233–237. [Google Scholar]

- Palanivel, R.; Dinaharan, I.; Laubscher, R. Assessment of Microstructure and Tensile Behavior of Continuous Drive Friction Welded Titanium Tubes. Mater. Sci. Eng. A 2017, 687, 249–258. [Google Scholar] [CrossRef]

- Huang, K.; Loge, R. A Review of Dynamic Recrystallization Phenomena in Metallic Materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Turner, R.; Howe, D.; Thota, B.; Ward, R.; Basoalto, H.; Brooks, J. Calculating the Energy Required to Undergo the Conditioning Phase of a Titanium Alloy Inertia Friction Weld. J. Manuf. Process. 2016, 24, 186–194. [Google Scholar] [CrossRef]

- Foul, A.; Aranas, C.; Guo, B.; Jonas, J.J. Dynamic Transformation of A → B Titanium at Temperatures below the B-Transus in Commercially Pure Titanium. Mater. Sci. Eng. A 2018, 722, 156–159. [Google Scholar] [CrossRef]

- Yuan, B.G.; Zheng, Y.; Wang, Y.J.; Gong, L.Q. Hydrogen Absorption Characteristics and Microstructural Evolution of Tc21 Titanium Alloy. Trans. Nonferrous Met. Soc. China 2016, 26, 599–606. [Google Scholar] [CrossRef]

| Al | Mo | Nb | Sn | Zr | Cr | Fe | O | C | N | H | Si | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.35 | 2.75 | 2.09 | 2.03 | 2.06 | 1.48 | 0.098 | 0.099 | 0.020 | 0.017 | 0.002 | ≤0.13 | Bal. |

| Initial Rotating Speed (RPM) | Moment of Inertia (kg·m2) | Friction Pressure (MPa) | Upsetting Pressure (MPa) |

|---|---|---|---|

| 700 | 388 | 76 | 102 |

| Element | Ti | Al | Mo | Zr | Sn | Nb | Cr | |

|---|---|---|---|---|---|---|---|---|

| Spot 1 (BM β phase) | Weight(%) | 76.4 | 5.1 | 6.5 | 2.4 | 2.3 | 3.0 | 4.3 |

| Atomic(%) | 79.3 | 9.4 | 3.4 | 1.3 | 1.0 | 1.6 | 4.2 | |

| Spot 2 (BM α phase) | Weight(%) | 86.3 | 7.4 | 0 | 1.9 | 2.3 | 1.6 | 0.6 |

| Atomic(%) | 84.1 | 12.7 | 0 | 1.0 | 0.9 | 0.8 | 0.5 | |

| Spot 1 (WZ β phase) | Weight(%) | 82.6 | 6.7 | 2.8 | 2.2 | 2.5 | 1.5 | 1.7 |

| Atomic(%) | 82.3 | 11.8 | 1.4 | 1.1 | 1.0 | 0.8 | 1.6 | |

| Spot 2 (WZ α phase) | Weight(%) | 82.8 | 6.4 | 2.8 | 2.1 | 2.5 | 1.6 | 1.7 |

| Atomic(%) | 82.7 | 11.4 | 1.4 | 1.1 | 1.0 | 0.8 | 1.6 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Li, Z.; Zhao, S.; Li, Z.; Tang, W.; Wu, F.; Zhou, J. Microstructure Evolution of Inertia Friction Welded Joints of TC21 Titanium Alloy. Processes 2022, 10, 1086. https://doi.org/10.3390/pr10061086

Wang H, Li Z, Zhao S, Li Z, Tang W, Wu F, Zhou J. Microstructure Evolution of Inertia Friction Welded Joints of TC21 Titanium Alloy. Processes. 2022; 10(6):1086. https://doi.org/10.3390/pr10061086

Chicago/Turabian StyleWang, Hongying, Zihao Li, Shengsheng Zhao, Zhijun Li, Weijie Tang, Fayu Wu, and Jun Zhou. 2022. "Microstructure Evolution of Inertia Friction Welded Joints of TC21 Titanium Alloy" Processes 10, no. 6: 1086. https://doi.org/10.3390/pr10061086

APA StyleWang, H., Li, Z., Zhao, S., Li, Z., Tang, W., Wu, F., & Zhou, J. (2022). Microstructure Evolution of Inertia Friction Welded Joints of TC21 Titanium Alloy. Processes, 10(6), 1086. https://doi.org/10.3390/pr10061086