Analysis and Research on the Automatic Control Systems of Oil–Water Baffles in Horizontal Three-Phase Separators

Abstract

:1. Introduction

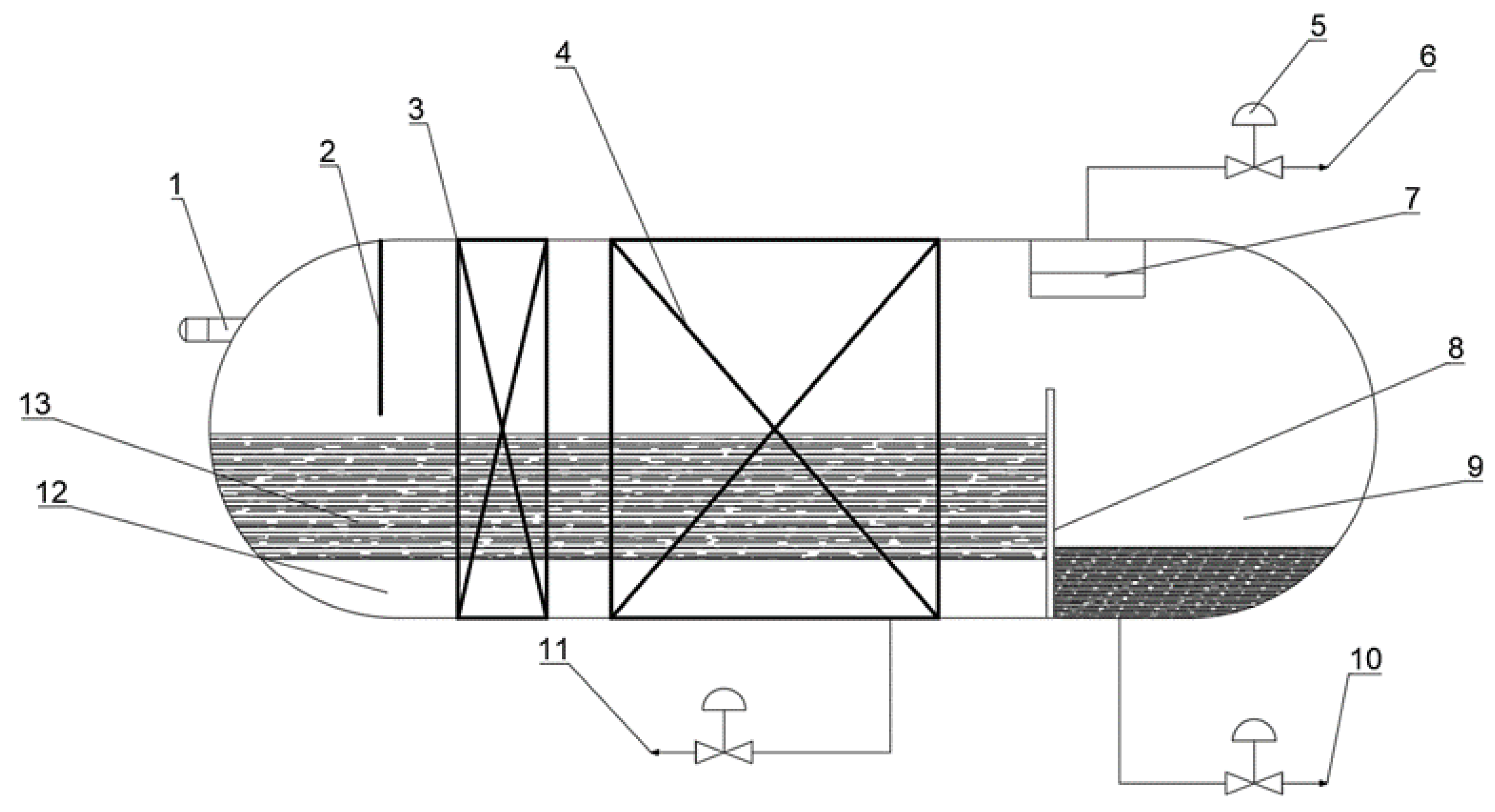

2. Overview of the Three-Phase Separator

2.1. The Working Principle of the Three-Phase Separator

2.2. Classification of Three-Phase Separators

3. Analysis of Motion Process of Oil–Water Separation

3.1. Calculation of Water Drop Settlement Height in Oil Layer

3.2. Calculation of Suspended Height of Oil Droplets in Water Layer

3.3. Calculation of Droplet Horizontal Motion Distance

4. Establishment of Mathematical Model of Optimum Oil–Water Interface Height of Separator

4.1. Mathematical Modeling Idea of Optimal Oil–Water Interface Height

4.2. Basic Assumptions

4.3. Establishment of Mathematical Model

4.3.1. Calculation of Water Phase Outlet Flow

4.3.2. Calculation of Oil Phase Outlet Flow

4.3.3. Calculation of the Cross-Sectional Area of the Gas Phase Space

4.3.4. Mathematical Model

4.4. Setting of Constraints

5. Design of Automatic Control of Three-Phase Separator

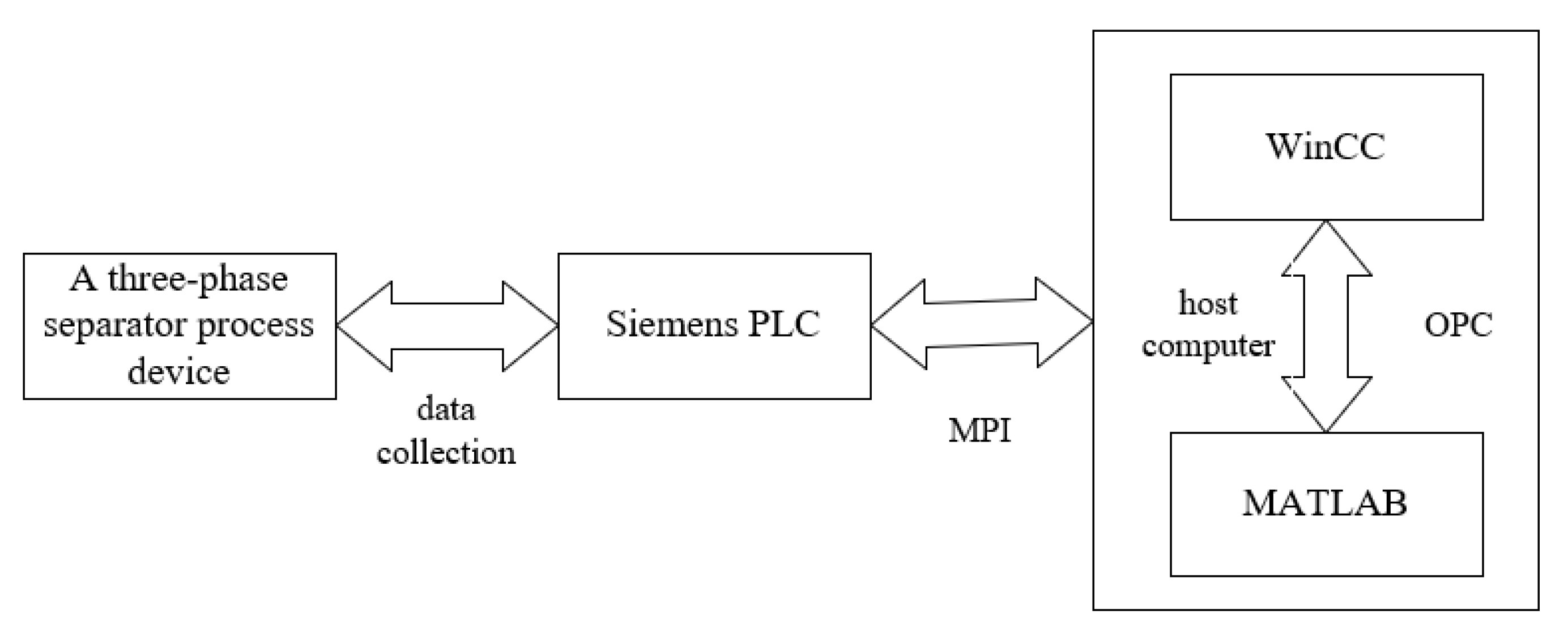

5.1. Composition of the Control System

5.2. PLC System Hardware

5.3. Configuration Software

5.4. Fuzzy Optimization Control Software

5.4.1. OPC Communication

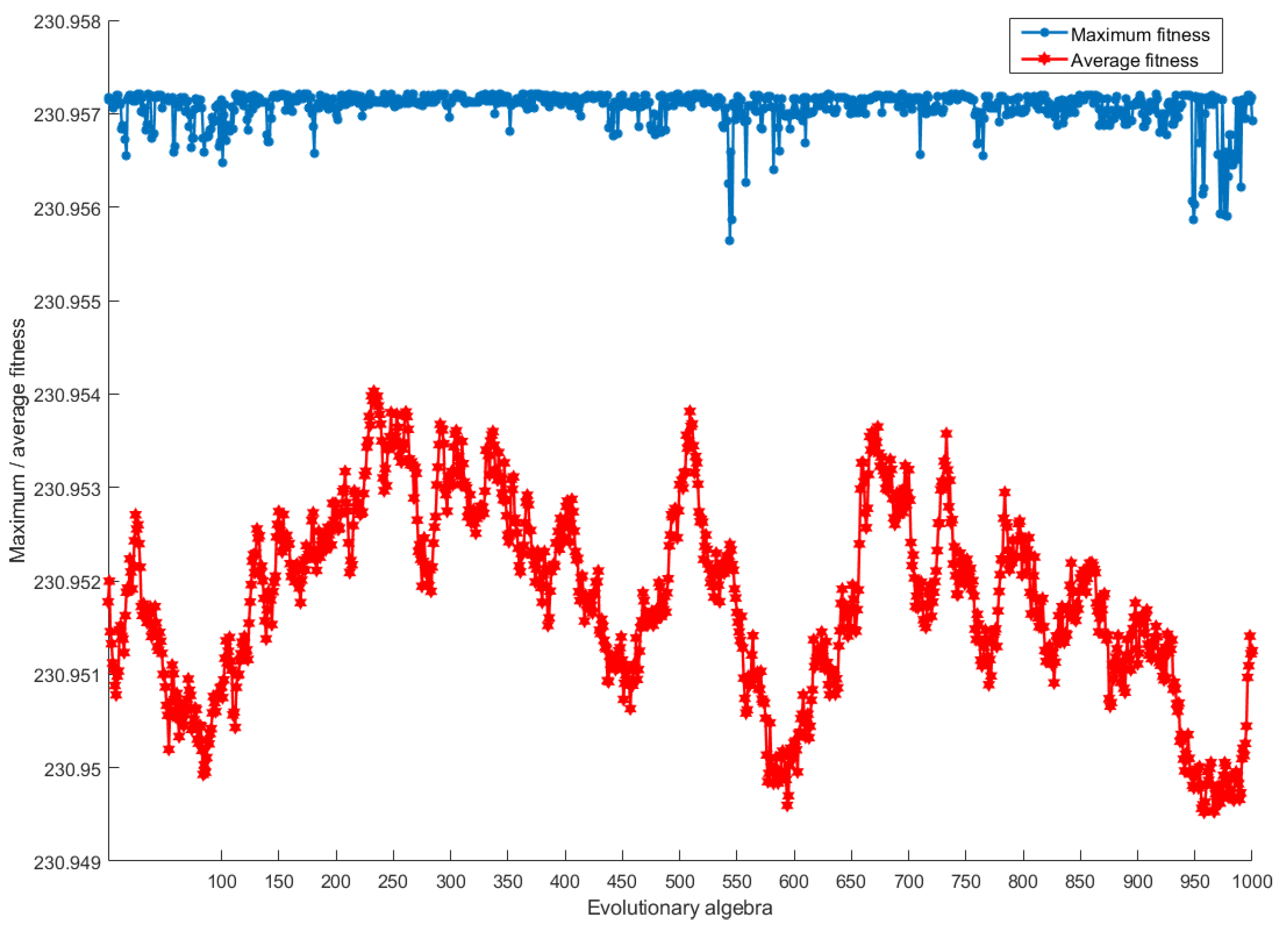

5.4.2. Mathematical Algorithm

6. Discussion

6.1. Basic Data

6.2. Result Analysis

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Diameter of settled water droplet | |

| The floating diameter of oil droplets in the water layer | |

| Viscosity of water phase | |

| The viscosity of the crude oil | |

| Water phase density | |

| Oil phase density | |

| Axial area of separator | |

| Gas phase space cross-sectional area | |

| Liquid phase cross-sectional area of separator | |

| Drag coefficient of droplet movement, dimensionless | |

| Inner diameter of separator | |

| Critical diameter of oil droplet | |

| Critical particle size of water droplets | |

| Liquid phase height of separator | |

| Gas phase sectional area height of separator | |

| Sectional area and height of separator oil phase | |

| Oil water interface height of separator | |

| The height of dimensionless oil–water interface | |

| The effective length of the separator | |

| Infinite area of water passage | |

| MATLAB | Matrix Laboratory |

| OPC | Object Linking and Embedding(OLE) for Process Control |

| PID | Proportion Integration Differentiation |

| PLC | Programmable Logic Controller |

| Inlet flow | |

| Functional relationship between total liquid flow at outlet and | |

| Functional relationship between oil phase outlet flow and | |

| Functional relationship between water phase outlet flow and | |

| The sewage treatment capacity of the separator | |

| Oil, water droplet horizontal movement time | |

| Water droplet settling velocity | |

| The floating velocity of oil droplets | |

| The horizontal flow velocity of the water phase | |

| Horizontal velocity of oil droplets | |

| Floating speed of oil droplets | |

| Oil, water droplet horizontal flow rate | |

| WinCC | Windows Control Center |

References

- Qi, G. Design and development of optimal control system for three-phase separator. Foreign Electron. Meas. Technol. 2021, 40, 78–81. [Google Scholar]

- Bai, Y.; Zhang, R. Application of oil gas water three-phase separator in Oilfield. Chem. Manag. 2020, 12, 215–216. [Google Scholar]

- Guo, S.; Wu, J.; Yu, Y.; Dong, L. Research progress of oil gas water three-phase separator. Pet. Mach. 2016, 44, 104–108. [Google Scholar]

- Zhang, Y.; Yang, J.; Lei, K.; Ma, L. Theoretical analysis and interface height control of three-phase oil-water separator. Chem. Manag. 2022, 1, 136–139. [Google Scholar]

- Xiao, R.; Wang, Q. Understanding and practice of oil gas water three-phase separator. Oilfield Surf. Eng. 1993, 7, 23–27. [Google Scholar]

- Lv, Y.; He, L.; Ding, S.; Guo, X.; Cheng, H. Study on droplet size and pressure drop in crude oil water dispersion. J. Eng. Thermophys. 2013, 34, 472–475. [Google Scholar]

- Powers, M.L. Analysis of Gravity Separation in Freewater Knockouts. Spe Prod. Eng. 1990, 5, 52–58. [Google Scholar] [CrossRef]

- Lu, D.; Ji, X. Automatic Control Principle and Design; Shanghai Science and Technology Press: Shanghai, China, 1978. [Google Scholar]

- Gao, R. Development of Dynamic Simulation System for Oil Field Combined Station; China University of Petroleum: Beijing, China, 2011. [Google Scholar]

- Jiao, B. Research on Control System of Horizontal Three-Phase Separator for Oil, Gas and Water; Jilin University: Changchun, China, 2012. [Google Scholar]

- Wang, Z.; Zhou, B.; Wang, W. Design of intelligent measurement and control system of fire tube furnace based on PLC. Electron. Meas. Technol. 2020, 43, 119–125. [Google Scholar]

- Fu, J.; Xu, M. Design of vertical stable carrying platform based on PLC. Foreign Electron. Meas. Technol. 2020, 39, 113–116. [Google Scholar]

- Zhu, J. Design of water level fuzzy control system based on WinCC and MATLAB. Mech. Eng. Autom. 2015, 4, 183–184. [Google Scholar]

- Fu, P. Design of control system based on OPC MATLAB and Siemens 1215c PLC. Shandong Ind. Technol. 2014, 24, 147. [Google Scholar]

- Chen, G.; Xie, H.; Lu, X. Application of Matlab genetic algorithm toolbox in nonlinear optimization. Comput. Technol. Dev. 2008, 18, 246–248. [Google Scholar]

- Li, M. Explain in Detail the Application of MATLAB in Optimization Calculation; Electronic Industry Press: Beijing, China, 2011. [Google Scholar]

- Wang, J. Research on Fuzzy Optimization Technology of Production and Operation Parameters of Oil and Gas Gathering and Transportation System; Northeast Petroleum University: Daqing, China, 2017; pp. 7–12. [Google Scholar]

- Hong, X.; Shen, S. Application and theoretical basis of PID control. Control. Eng. 2003, 10, 37–42. [Google Scholar]

- Backi, C.J.; Skogestad, S. A simple dynamic gravity separator model for separation efficiency evaluation incorporating level and pressure control. In Proceedings of the American Control Conference(ACC), Seattle, WA, USA, 24–26 May 2017; pp. 2823–2828. [Google Scholar]

| Item | Data | Item | Data |

|---|---|---|---|

| Separator Size (mm) | 3200 × 14,000 | Design Capacity (m3/d) | 10,000 |

| Liquid Phase Section Height (m) | 2.73 | Crude Oil Density (kg/m3) | 853.6 |

| Operating Pressure (MPa) | 0.3 | Water Phase Density (kg/m3) | 1000 |

| Operating Temperature (℃) | 50 | Water Phase Residence Time (min) | 24 |

| Crude Oil Viscosity (mPa·s) | 6.59 | Oil Phase Residence Time (min) | 100 |

| Water Phase Viscosity (mPa·s) | 0.6 |

| Date | Temperature (℃) | Pressure (MPa) | Oil Output (m3) | Water Output (m3) | Liquid Inlet (m3) |

|---|---|---|---|---|---|

| 6.16 | 50 | 0.3 | 760 | 7649 | 8409 |

| 6.17 | 50 | 0.3 | 728 | 7636 | 8364 |

| 6.18 | 50 | 0.3 | 669 | 7656 | 8325 |

| 6.19 | 50 | 0.3 | 865 | 7724 | 8589 |

| 6.20 | 50 | 0.3 | 644 | 7596 | 8240 |

| 6.21 | 50 | 0.3 | 857 | 7658 | 8515 |

| 6.22 | 50 | 0.3 | 822 | 7667 | 8489 |

| 6.23 | 50 | 0.3 | 599 | 7611 | 8210 |

| 6.24 | 50 | 0.3 | 454 | 7581 | 8035 |

| 6.25 | 50 | 0.3 | 820 | 7615 | 8435 |

| 6.26 | 50 | 0.3 | 736 | 7673 | 8409 |

| 6.27 | 50 | 0.3 | 655 | 7605 | 8260 |

| 6.28 | 50 | 0.3 | 595 | 7549 | 8144 |

| 6.29 | 50 | 0.3 | 618 | 7573 | 8191 |

| 6.30 | 50 | 0.3 | 636 | 7767 | 8403 |

| Average value | 50 | 0.3 | 697.2 | 7637.3 | 8334.5 |

| Operating Temperature (℃) | Operating Pressure (MPa) | Oil–Water Baffle Height (m) | Sewage Outlet Flow (m3/s) | Oil Phase Outlet Flow (m3/s) | Dehydration Efficiency (%) | |

|---|---|---|---|---|---|---|

| Before optimization | 50 | 0.3 | 2.2 | 0.8838 | 0.00807 | 91.63 |

| After optimization | 50 | 0.3 | 2.0691 | 0.17959 | 0.00805 | 95.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, F.; Huang, K.; Li, H.; Huang, C. Analysis and Research on the Automatic Control Systems of Oil–Water Baffles in Horizontal Three-Phase Separators. Processes 2022, 10, 1102. https://doi.org/10.3390/pr10061102

Wu F, Huang K, Li H, Huang C. Analysis and Research on the Automatic Control Systems of Oil–Water Baffles in Horizontal Three-Phase Separators. Processes. 2022; 10(6):1102. https://doi.org/10.3390/pr10061102

Chicago/Turabian StyleWu, Feng, Kun Huang, Haotian Li, and Cheng Huang. 2022. "Analysis and Research on the Automatic Control Systems of Oil–Water Baffles in Horizontal Three-Phase Separators" Processes 10, no. 6: 1102. https://doi.org/10.3390/pr10061102

APA StyleWu, F., Huang, K., Li, H., & Huang, C. (2022). Analysis and Research on the Automatic Control Systems of Oil–Water Baffles in Horizontal Three-Phase Separators. Processes, 10(6), 1102. https://doi.org/10.3390/pr10061102