Experimental Study of Dynamic Mechanical Properties of Water-Saturated Coal Samples under Three-Dimensional Coupled Static–Dynamic Loadings

Abstract

:1. Introduction

2. Experiments

2.1. Coal Sample Processing and Determination of Basic Physical Parameters

2.2. Test Equipment and Scheme

3. Experimental Results and Analysis

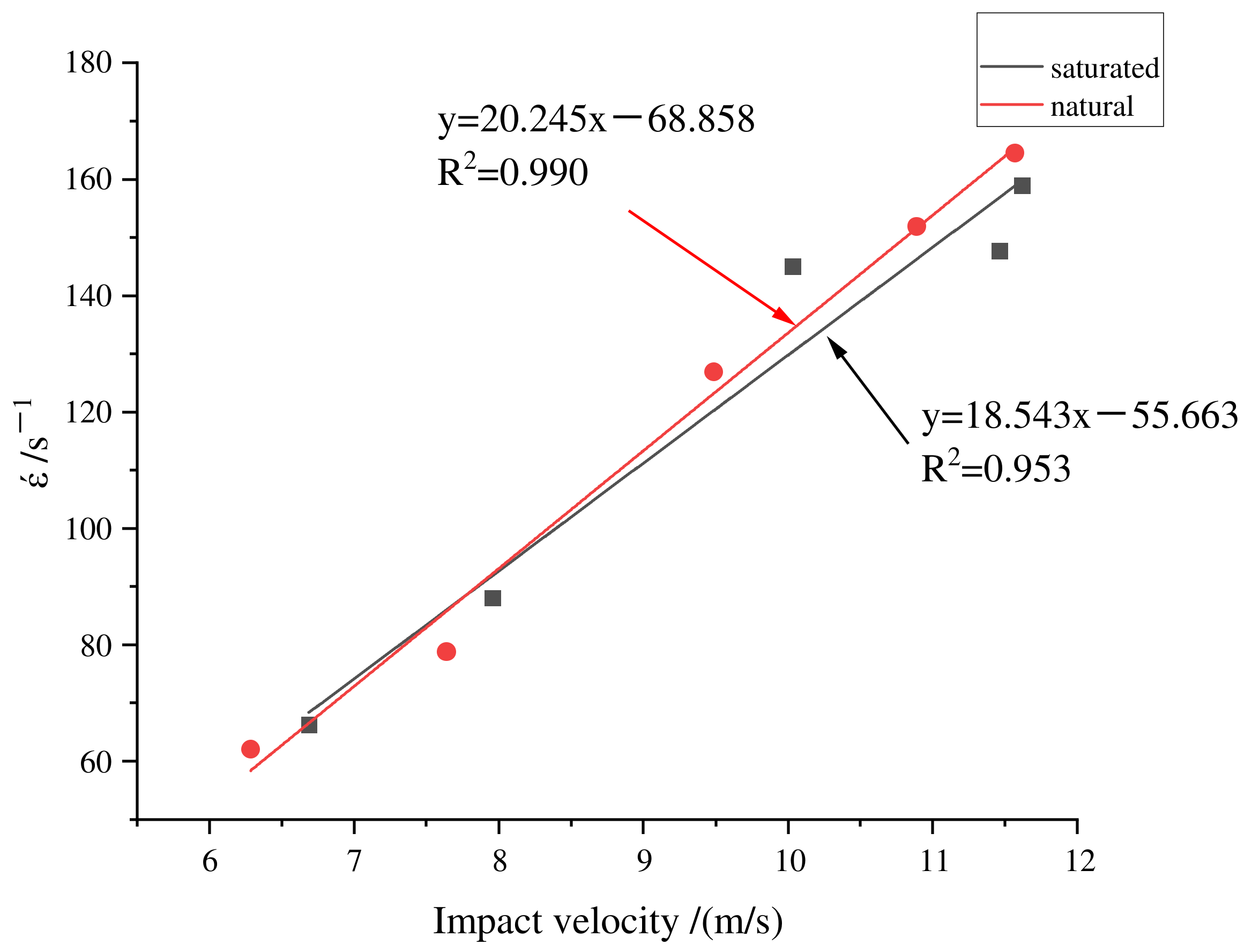

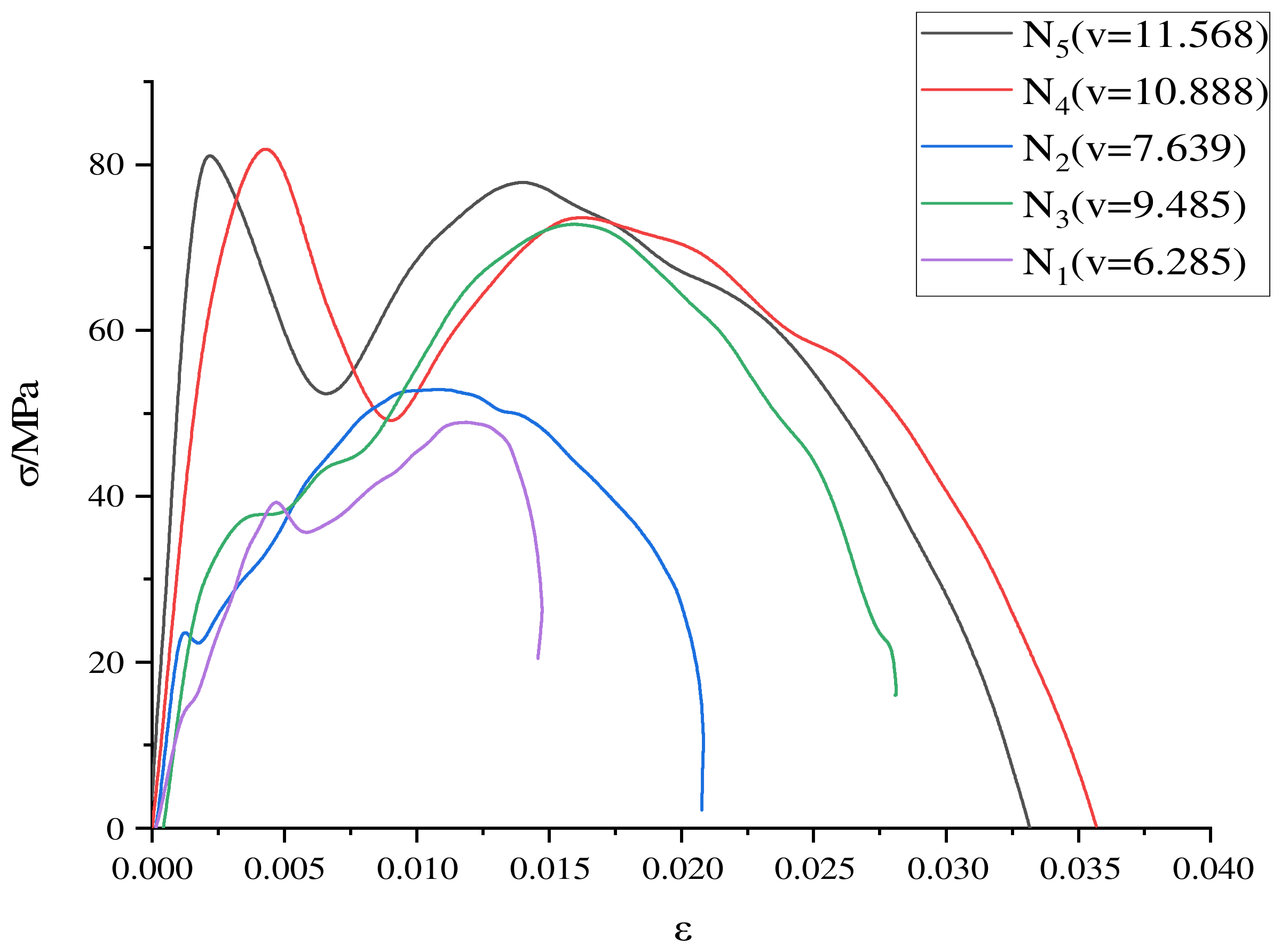

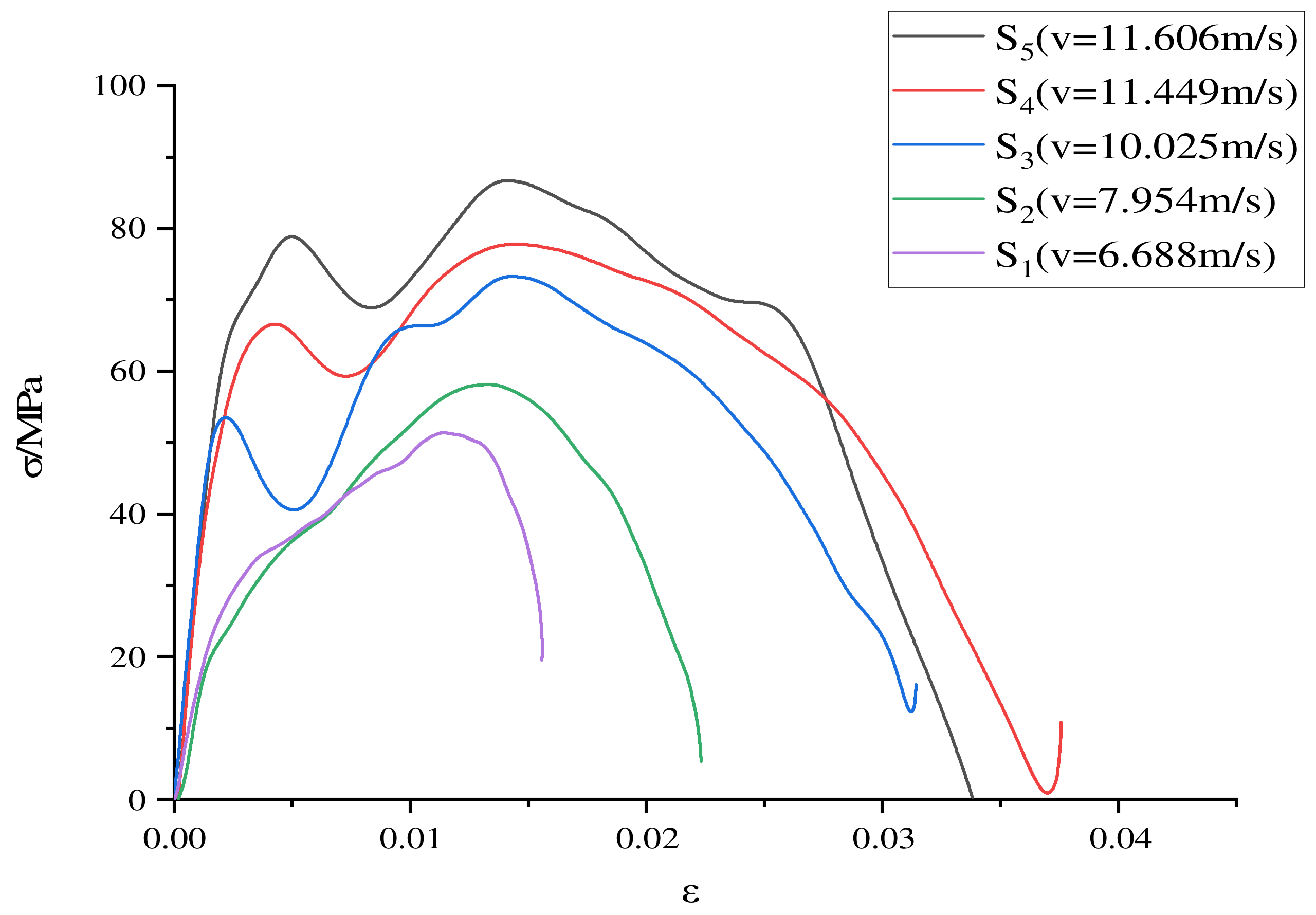

3.1. Strength Characteristics

3.2. The Deformation Characteristics

3.3. Energy Dissipation Analysis

4. Failure Mode and Fractal of Coal Sample

4.1. Coal Rock Failure Mode

4.2. Fractal Characteristics of Coal Fragmentation

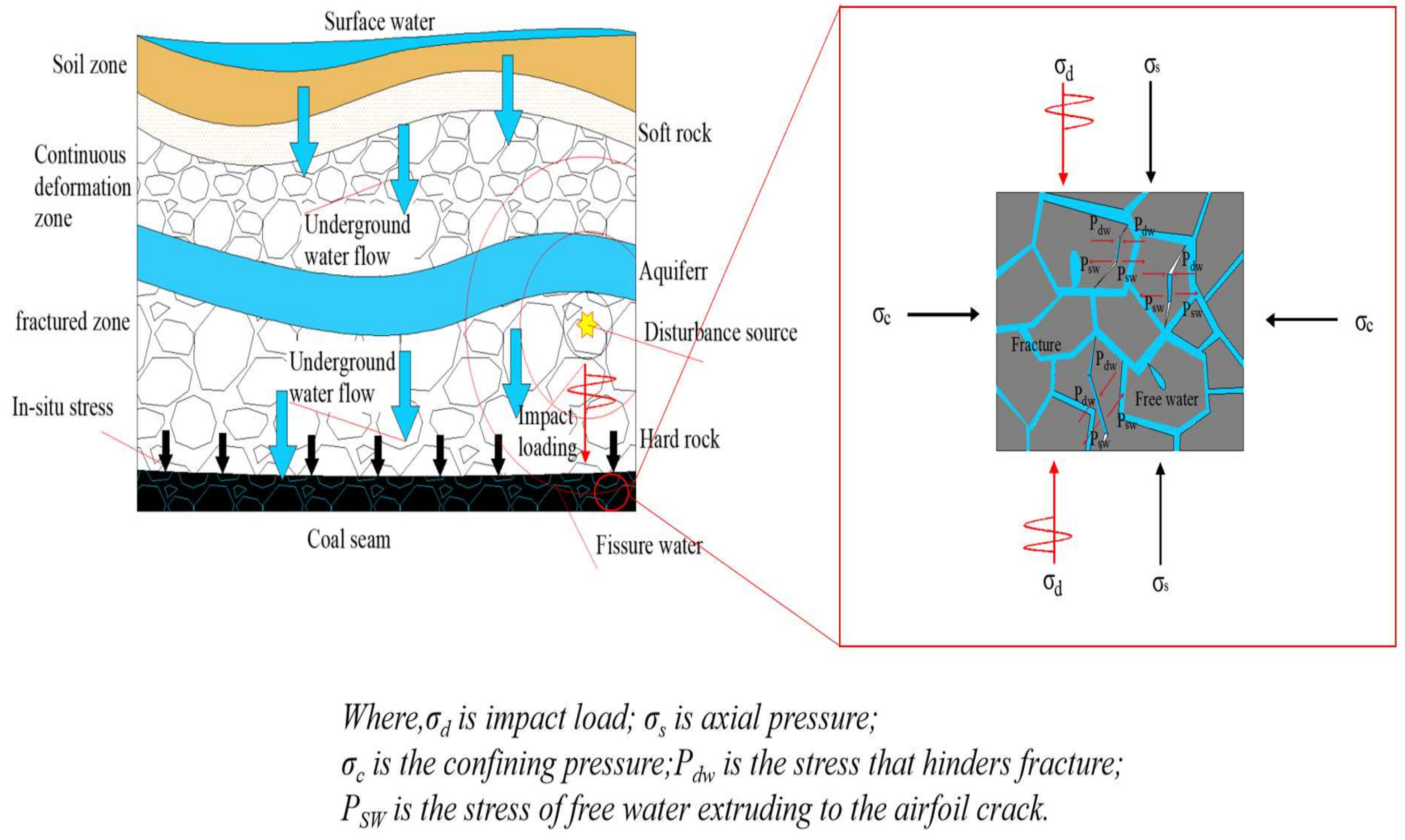

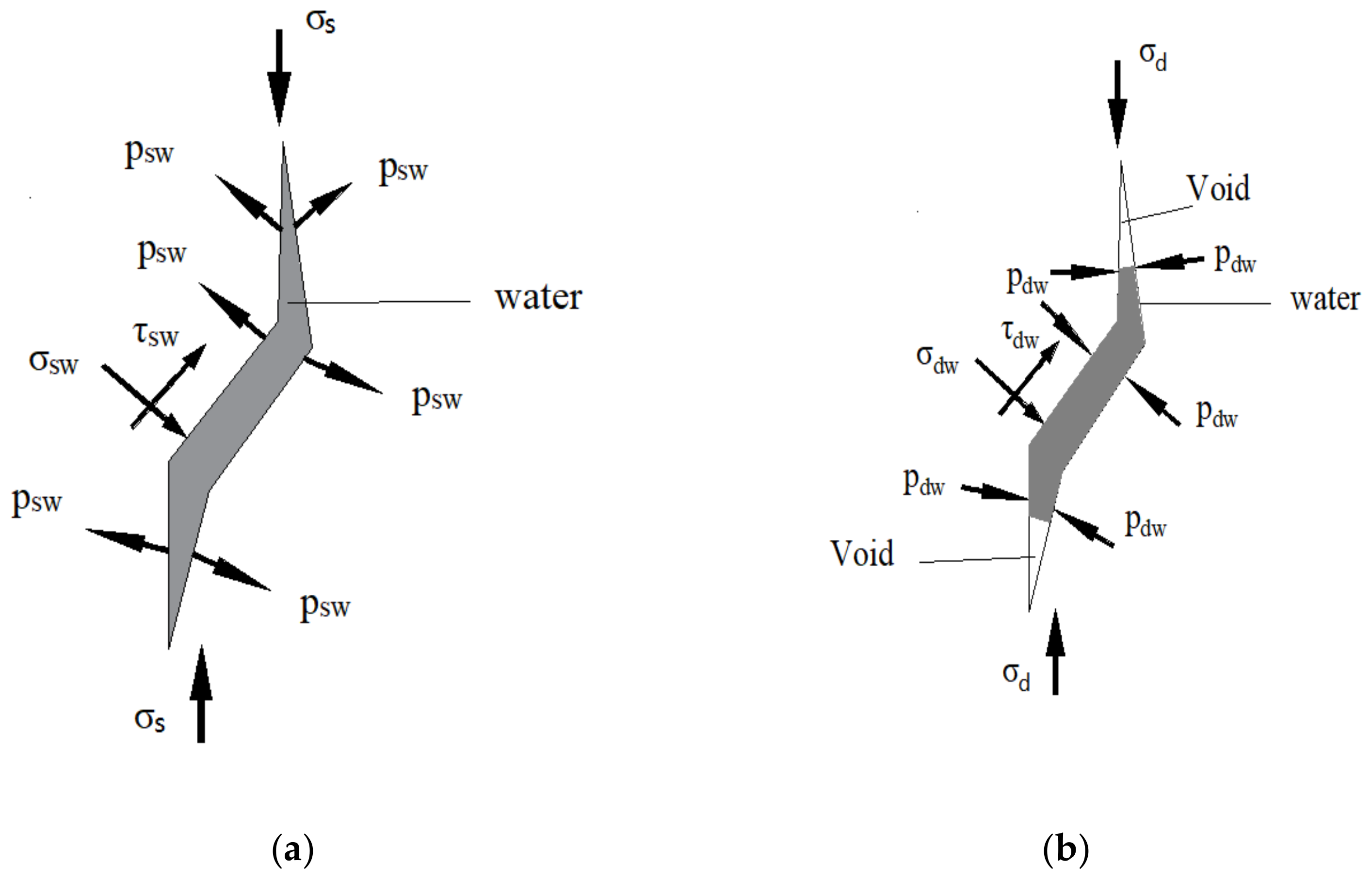

5. Discussion on Dynamic Failure Mechanism of Water-Bearing Coal

6. Conclusions

- (1)

- There is a good linear relationship between the peak stress of coal and the strain rate in both the natural state and the saturated state. In both states, the crack development goes through three stages: elastic deformation stage, plastic deformation stage, and unloading stage. When the impact rate reaches a certain value, there is a double peak phenomenon, and the curve shows a certain leap. The critical impact velocity of curve jump is about 9.485~10.025 m/s. Under the same strain rate, the peak stress in the saturated state is ca. 2.684% higher than that in natural state.

- (2)

- The secant modulus of the two states increases linearly with the rise in strain rate. The secant modulus and strain rate of coal samples in the natural state have a large discrete relationship. On the contrary, the secant modulus and strain rate of coal samples in a saturated state have a good linear relationship, indicating that the secant modulus of saturated coal samples is more sensitive to the strain rate effect Under the same strain rate, the secant modulus of the saturated coal sample is 2.309% higher than that of the natural state.

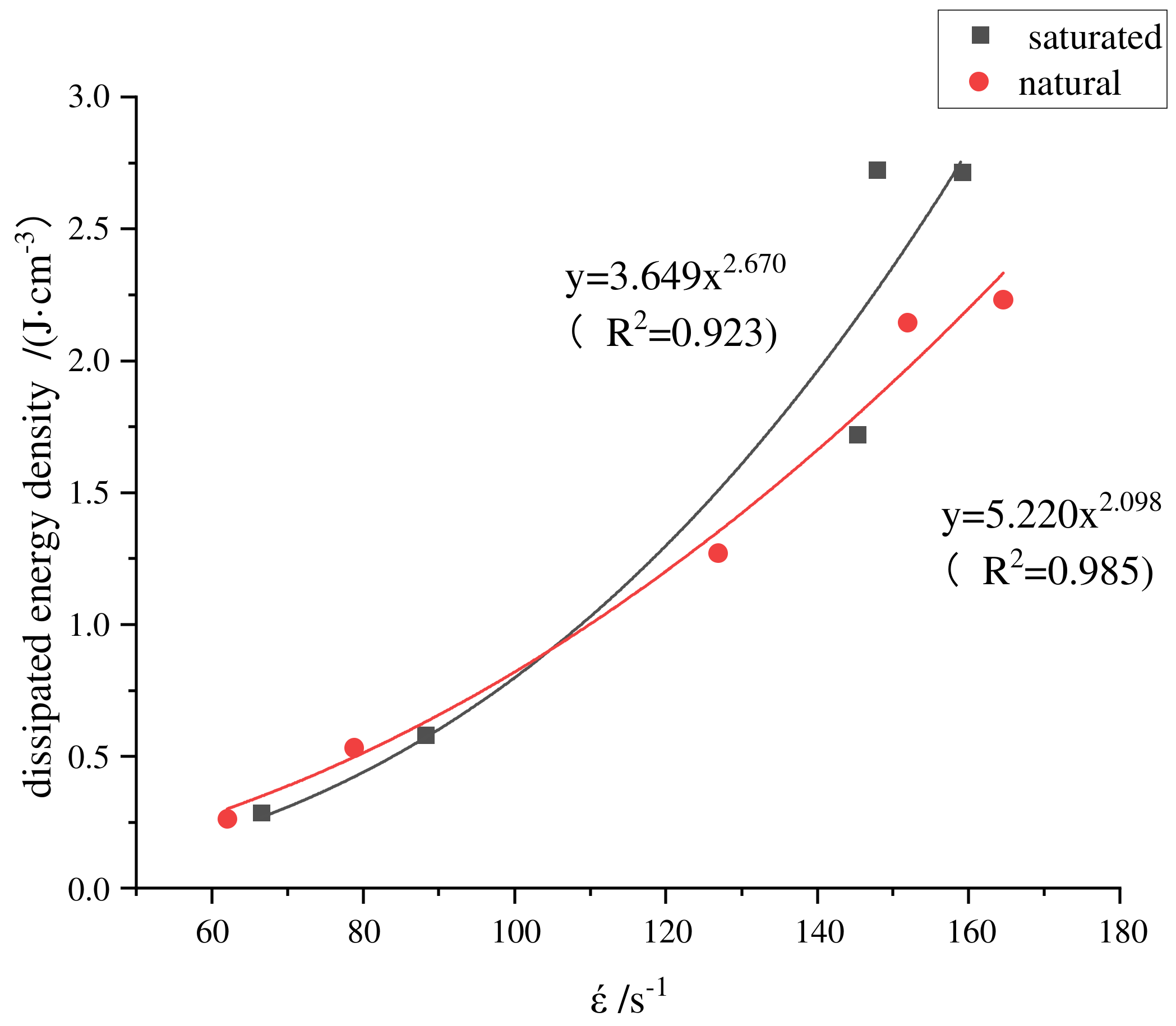

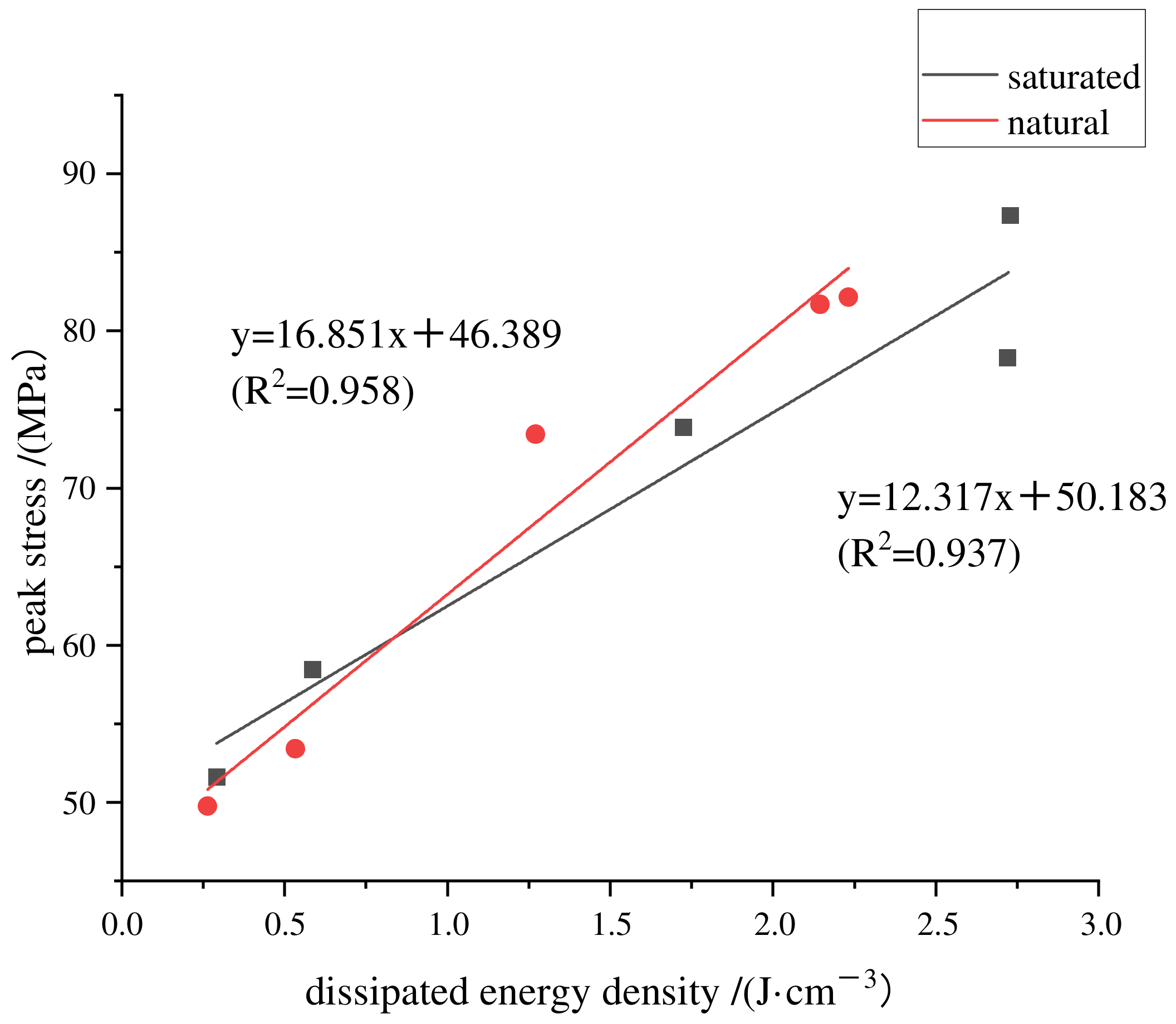

- (3)

- The absorption energy and energy consumption density of saturated and natural coal samples increase with the rise in the strain rate, and they show a well-defined power–function relationship. According to the relationship between absorbed energy and strain rate, when the impact load is too large, the more absorbed energy there is, the more easily broken coal rock is. Under the same strain rate, the energy absorbed by coal and rock specimens in the saturated state is higher than that in the natural state. With the continuous increase in absorbed energy in coal and rock specimens, deformation hysteresis occurs, thus greatly improving the dynamic strength of coal and rock specimens.

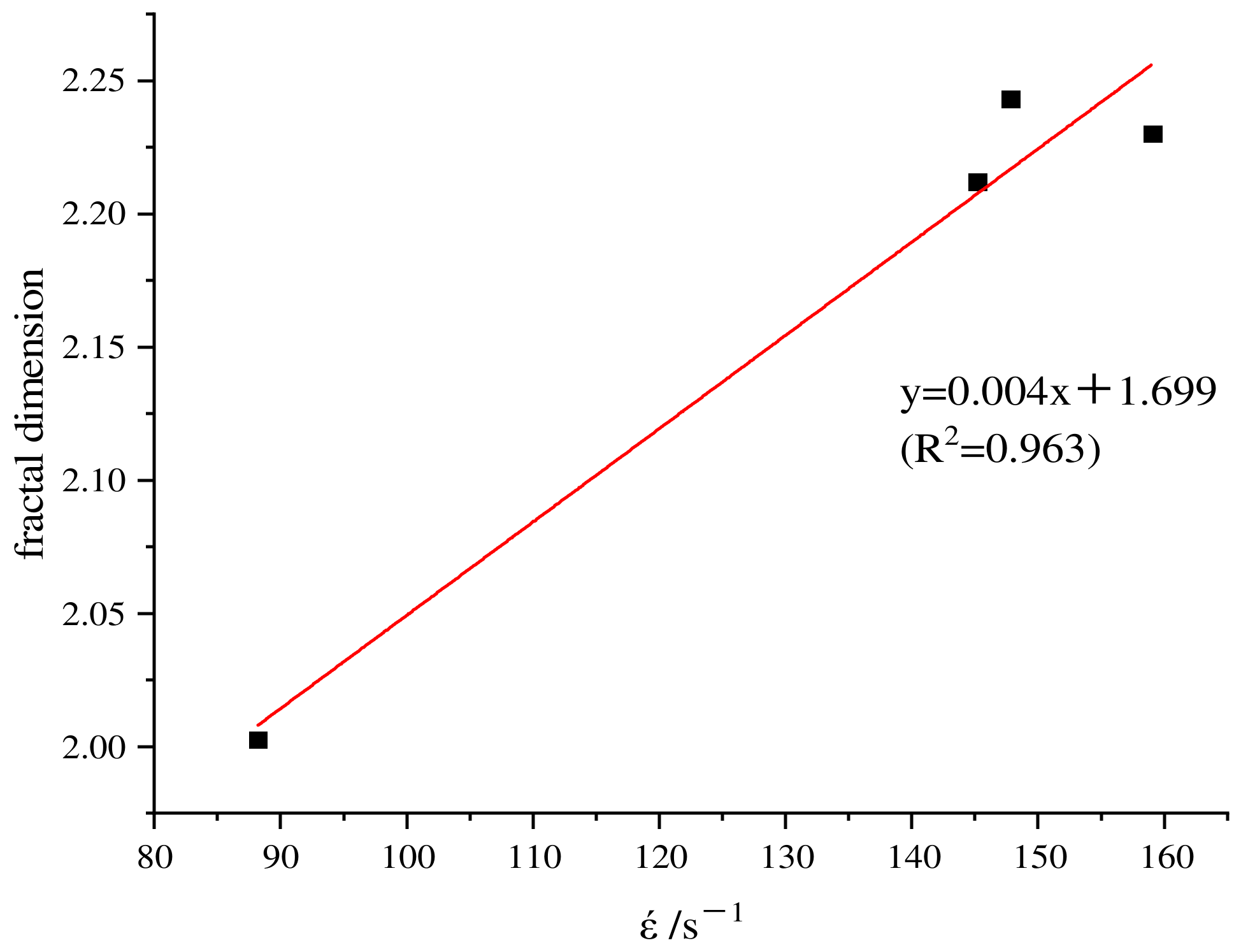

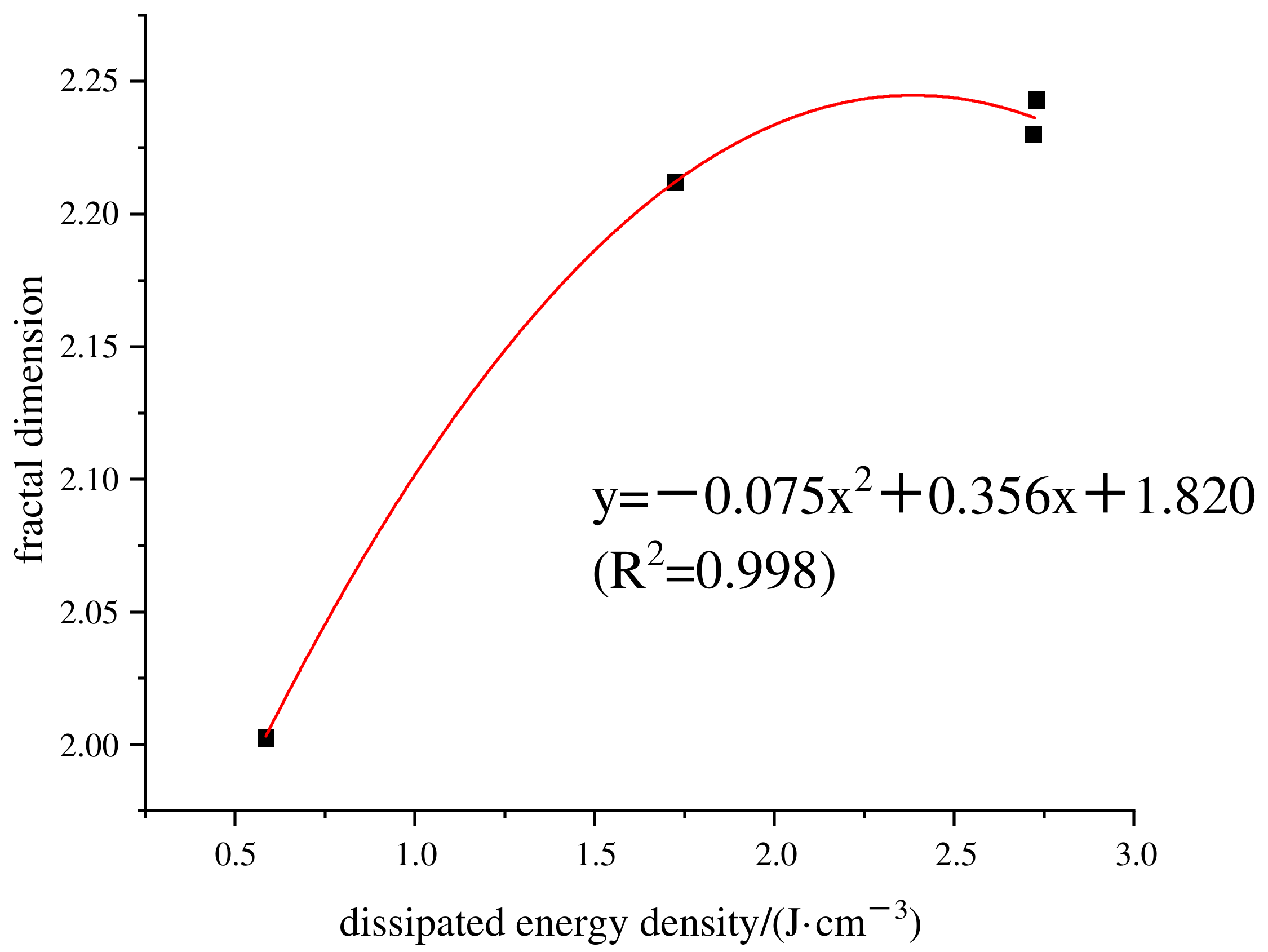

- (4)

- The fractal dimension of saturated coal increases with the rise in the strain rate and energy consumption density, showing a strong linear and quadratic relationship, respectively. The cohesive force generated by free water and the Stefan effect jointly hinder the expansion of coal and rock fractures under dynamic loading, thus reinforcing the compressive strength of coal and rock.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xie, H.P.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar]

- Abu-Hamdeh, N.H.; Daqrouq, K.; Mebarek-Oudina, F. Simulation and Analysis with Wavelet Transform Technique and the Vibration Characteristics for Early Revealing of Cracks in Structures. Math. Probl. Eng. 2021, 2021, 6626232. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G. Water-weakening behavior of Hawkesbury sandstone in brittle regime. Eng. Geol. 2014, 178, 91–101. [Google Scholar] [CrossRef]

- He, M.C. Present state and perspective of rock mechanics in deep mining engineering. In Chinese Society for Rock Mechanics and Engineering, Proceedings of the 8th Rock Mechanics and Engineering Conference; Science Press: Beijing, China, 2004; pp. 88–94. [Google Scholar]

- Qian, Q.H. The current development of nonlinear rock mechanics: The mechanics problems of deep rock mass. In Chinese Society for Rock Mechanics and Engineering, Proceedings of the 8th Rock Mechanics and Engineering Conference; Science Press: Beijing, China, 2004; pp. 10–17. [Google Scholar]

- Xie, H.P. Research review of the state key research development program of China:Deep rock mechanics and mining theory. J. China Coal Soc. 2019, 44, 1283–1305. [Google Scholar] [CrossRef]

- Feucht, L.J.; Logan, J.M. Effects of chemically active solutions on shearing behavior of a sandstone. Tectonophysics 1990, 175, 159–176. [Google Scholar] [CrossRef]

- Karfakis, M.G.; Akram, M. Effects of chemical solutions on rock fracturing. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 1253–1259. [Google Scholar] [CrossRef]

- Da Silva, M.R.; Schroeder, C.; Verbrugge, J.-C. Unsaturated rock mechanics applied to a low-porosity shale. Eng. Geol. 2008, 97, 42–52. [Google Scholar] [CrossRef]

- Liu, Y.; Yin, G.; Li, M.; Zhang, D.; Huang, G.; Liu, P.; Liu, C.; Zhao, H.; Yu, B. Mechanical Properties and Failure Behavior of Dry and Water-Saturated Anisotropic Coal Under True-Triaxial Loading Conditions. Rock Mech. Rock Eng. 2020, 53, 4799–4818. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Maruvanchery, V.; Liu, G. Water effects on rock strength and stiffness degradation. Acta Geotech. 2016, 11, 713–737. [Google Scholar] [CrossRef]

- Duda, M.; Renner, J. The weakening effect of water on the brittle failure strength of sandstone. Geophys. J. Int. 2012, 192, 1091–1108. [Google Scholar] [CrossRef] [Green Version]

- Cao, K.W.; Ma, L.Q.; Wu, Y.; Spearing, A.S.; Khan, N.M.; Hussain, S.; Rehman, F.U. Statistical damage model for dry and saturated rock under uniaxial loading based on infrared radiation for possible stress prediction. Eng. Fract. Mech. 2022, 260, 108134. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, S.W.; Li, H.M.; Gong, S.; Liu, Z.M. Analysis of the Dynamic Impact Mechanical Characteristics of Prestressed Saturated Fractured Coal and Rock. Adv. Civ. Eng. 2019, 2019, 5125923. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.D.; Cheng, Y.; Jiao, Y.Y.; Zhang, G.H.; Zhang, W.S.; Ou, G.Z.; Tan, F. Experimental study on the effect of water on mechanical properties of swelling mudstone. Eng. Geol. 2021, 295, 106448. [Google Scholar] [CrossRef]

- Verstrynge, E.; Adriaens, R.; Elsen, J.; Van Balen, K. Multi-scale analysis on the influence of moisture on the mechanical behavior of ferruginous sandstone. Constr. Build. Mater. 2013, 54, 78–90. [Google Scholar] [CrossRef]

- Kim, E.; Hossein, C. Effect of water saturation and loading rate on the mechanical properties of Red and Buff Sandstones. Int. J. Rock Mech. Min. Sci. 2016, 88, 23–28. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Cao, W.; Li, X.; Xiong, C. Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech. Rock Eng. 2016, 49, 3009–3025. [Google Scholar] [CrossRef]

- Rossi, P.; Van Mier JG, M.; Boulay, C.; Le Maou, F. The dynamic behavior of concrete: Influence of free water. Mater. Struct. 1992, 25, 509–514. [Google Scholar] [CrossRef]

- Wang, W.; Wang, H.; Li, D.Y.; Li, H.M.; Liu, Z.M. Strength and failure characteristics of natural and water-saturated coal specimens under static and dynamic loads. J. Shock. Vib. 2018, 2018, 3526121. [Google Scholar] [CrossRef] [Green Version]

- Cai, X.; Zhou, Z.L.; Du, X.M. Water-induced variations in dynamic behavior and failure characteristics of sandstone subjected to simulated geo-stress. Int. J. Rock Mech. Min. Sci. 2020, 130, 104339. [Google Scholar] [CrossRef]

- Ross, C.A.; Jerome, D.M.; Tedesco, J.W.; Hughes, M.L. Moisture and strain rate effects on concrete strength. ACI Mater. J. 1996, 93, 293–300. [Google Scholar]

- Wang, B.; Li, X.B. Micro-mechanics analysis of static and dynamic compressive strength of saturated rock under uniaxial load. Explos. Shock. Waves 2012, 32, 423–431. [Google Scholar]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Wang, K.; Feng, G.R.; Bai, J.W.; Guo, J.; Shi, X.D.; Cui, B.Q.; Song, C. Dynamic behaviour and failure mechanism of coal subjected to coupled water-static-dynamic loads. Soil Dyn. Earthq. Eng. 2022, 153, 107084. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, S.W.; Liu, K.; Wang, S.; Li, D.Y.; Li, H.M. Experimental study on dynamic strength characteristics of water-saturated coal under true triaxial static-dynamic combination loadings. Chin. J. Rock Mech. Eng. 2019, 38, 2010–2020. [Google Scholar] [CrossRef]

- Yuan, P.; Ma, R.Q. Split hopkinson pressure bar test and analysis of coal mine sandstone with various moisture contents. Chin. J. Rock Mech. Eng. 2015, 34, 2888–2893. [Google Scholar] [CrossRef]

- Wang, B.; Li, X.; Yin, T.; Ma, C.; Yin, Z.; Li, Z. Spilt Hopkinson pressure bar (SHPB) experiments on dynamic strength of water-saturated sandstone. Chin. J. Rock Mech. Eng. 2010, 29, 1003–1009. [Google Scholar]

- Kim, E.; Stine, M.A.; de Oliveira, D.B.M. Effects of water content and loading rate on the mechanical properties of Berea Sandstone. J. South. Afr. Inst. Min. Metall. 2019, 119, 1077–1082. [Google Scholar] [CrossRef]

- Reviron, N.; Reuschlé, T.; Bernard, J.-D. The brittle deformation regime of water-saturated siliceous sandstones. Geophys. J. Int. 2009, 178, 1766–1778. [Google Scholar] [CrossRef] [Green Version]

- Shan, R.L.; Cheng, R.Q.; Xu, H.L.; Yu, H.H. Experimental study on dynamic constitutive characteristics of anthracite in Yunjialing Coal Mine. In Proceedings of the 9th National Rock Dynamics Academic Conference, Wuhan, China, 14–18 August 2005; pp. 62–66. [Google Scholar]

- Xie, B.J.; Cui, Y.G.; Wang, J.G. Experimental Study on Mechanics Properties of Coal Impact Damage. J. Coal Mine Saf. 2013, 44, 18–21. [Google Scholar] [CrossRef]

- Fu, Y.K.; Xie, B.J.; Wang, Q.F. Dynamic mechanics constitutive model of coal. J. China Coal Soc. 2013, 38, 1769–1774. [Google Scholar] [CrossRef]

- Cai, M.F. Rock Mechanics and Engineering, 2nd ed.; Science Press: Beijing, China, 2013. [Google Scholar]

- Gong, F.Q.; Li, X.B.; Liu, X.L. Preliminary experimental study of characteristics of rock subjected to 3D coupled static and dynamic loads. Chin. J. Rock Mech. Eng. 2011, 30, 1179–1190. [Google Scholar]

- Liu, X.H.; Zhang, R.; Liu, J.F. Dynamic test study of coal rock under different strain rates. J. China Coal Soc. 2012, 37, 1528–1534. [Google Scholar] [CrossRef]

- Lundberg, B. A split Hopkinson bar study of energy absorption in dynamic rock fragmentation. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1976, 13, 187–197. [Google Scholar] [CrossRef]

- Li, X.B.; Gu, D.S. Rock Impact Dynamics; Central South University of Technology Press: Changsha, China, 1994; pp. 2–93. [Google Scholar]

- Ping, Q.; Luo, X.; Ma, Q.Y.; Yuan, P. Broken energy dissipation characteristics of sandstone specimens under impact loading. Chin. J. Rock Mech. Eng. 2015, 34, 4197–4203. [Google Scholar] [CrossRef]

- Wang, Q.S.; Li, X.B. Fractal characteristics of granite fracture under dynamic and static combined loading. J. Exp. Mech. 2009, 24, 587–591. [Google Scholar]

- Grady, D.E.; Kipp, M.E. Geometric statistics and dynamic fragmentation. J. Appl. Phys. 1985, 58, 1210–1222. [Google Scholar] [CrossRef]

- Yang, J.; Jin, Q.K.; Huang, F.L. Rock Explosion Theory Model and Numerical Calculation; Science Press: Beijing, China, 1999. (In Chinese) [Google Scholar]

- Wang, W.; Li, H.M.; Gu, H.L.; Wang, C.A. Feature Analysis of energy dissipation of water-bearing coal samples under coupled static-dynamic loading. Chin. J. Rock Mech. Eng. 2015, 34, 3965–3971. [Google Scholar] [CrossRef]

- Li, H.B.; Zhao, J.; Li, T.J. Study of dynamic uniaxial compressive strength of rock material using sliding crack model. Chin. J. Rock Mech. Eng. 2001, 20, 315–319. [Google Scholar]

- Wang, W.; Li, H.M.; Gu, H.L. Experimental study of strength characteristics of water-saturated coal specimens under 3Dcoupled static-dynamic loadings. Chin. J. Rock Mech. Eng. 2017, 36, 2406–2414. [Google Scholar] [CrossRef]

- Zheng, D.; Li, Q. An explanation for rate effect of concrete strength based on fracture toughness including free water viscosity. Eng. Fract. Mech. 2004, 71, 2319–2327. [Google Scholar] [CrossRef]

| Saturation Status | Sample Number | Mass/(g) | Height /(mm) | Diameter /(mm) | Longitudinal Wave /(m·s−1) | Density /(g/cm−3) |

|---|---|---|---|---|---|---|

| Natural | N1 | 77.93 | 29.81 | 50.27 | 1.31 | 1.32 |

| N2 | 78.45 | 29.52 | 50.35 | 1.44 | 1.34 | |

| N3 | 79.52 | 30.33 | 50.53 | 1.16 | 1.31 | |

| N4 | 81.28 | 30.22 | 50.44 | 1.68 | 1.35 | |

| N5 | 79.19 | 30.32 | 50.33 | 1.11 | 1.31 | |

| Saturated | S1 | 79.93 | 30.27 | 50.54 | 1.34 | 1.32 |

| S2 | 80.41 | 30.07 | 50.28 | 1.39 | 1.35 | |

| S3 | 78.20 | 29.87 | 50.18 | 1.17 | 1.32 | |

| S4 | 83.74 | 30.00 | 50.36 | 1.65 | 1.38 | |

| S5 | 73.71 | 28.75 | 50.25 | 1.12 | 1.29 |

| Saturation Status | Sample Number | Axial Pressure /(MPa) | Confining Pressure /(MPa) | Impact Velocity /(m/s) | Mean Strain rate/(s−1) | Peak Stress /(MPa) | Secant Modulus /(MPa) |

|---|---|---|---|---|---|---|---|

| Natural | N1 | 10 | 10 | 6.285 | 62.055 | 49.776 | 9459.530 |

| N2 | 10 | 10 | 7.639 | 78.813 | 53.426 | 10,096.349 | |

| N3 | 10 | 10 | 9.485 | 126.906 | 73.437 | 11,525.246 | |

| N4 | 10 | 10 | 10.888 | 151.917 | 81.697 | 53,721.647 | |

| N5 | 10 | 10 | 11.568 | 164.559 | 82.160 | 32,387.804 | |

| Saturated | S1 | 10 | 10 | 6.688 | 66.522 | 51.727 | 13,514.515 |

| S2 | 10 | 10 | 7.954 | 88.234 | 58.557 | 9025.420 | |

| S3 | 10 | 10 | 10.025 | 145.127 | 73.921 | 34,935.049 | |

| S4 | 10 | 10 | 11.449 | 147.749 | 78.323 | 30,045.407 | |

| S5 | 10 | 10 | 11.606 | 158.980 | 87.358 | 32,439.570 |

| Saturation Status | Sample Number | Incident Energy/J | Reflected Energy/J | Transmitted Energy/J | Absorbed Energy/J | Energy Dissipation Density(J·com−3) |

|---|---|---|---|---|---|---|

| Natural | N1 | 30.071 | 8.808 | 5.713 | 15.550 | 0.263 |

| N2 | 60.518 | 22.840 | 6.389 | 31.289 | 0.533 | |

| N3 | 143.593 | 53.915 | 12.451 | 77.227 | 1.270 | |

| N4 | 246.402 | 100.721 | 16.246 | 129.434 | 2.145 | |

| N5 | 276.028 | 128.038 | 13.466 | 134.524 | 2.231 | |

| Saturated | S1 | 35.485 | 11.543 | 6.217 | 17.724 | 0.292 |

| S2 | 69.715 | 27.270 | 7.527 | 34.917 | 0.585 | |

| S3 | 190.641 | 75.122 | 13.881 | 101.639 | 1.721 | |

| S4 | 281.135 | 96.075 | 19.788 | 165.272 | 2.723 | |

| S5 | 288.907 | 117.958 | 16.280 | 154.668 | 2.714 |

| Saturated Status | Sample Number | Diameter/mm | Gross Mass/g | α | Fractal Dimension | R2 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 20 | 10 | 3 | 2 | 1 | ||||||

| Saturated | S1 | 0 | 0 | 0 | 0 | 0 | 0 | 79.2 | / | / | / |

| S2 | 26.3 | 16.1 | 4 | 1.8 | 1.3 | 0.9 | 79.8 | 0.997 | 2.003 | 0.951 | |

| S3 | 32.8 | 13.6 | 11.9 | 4.2 | 2.6 | 2 | 74 | 0.788 | 2.212 | 0.965 | |

| S4 | 39.9 | 36.3 | 18.3 | 7 | 4.8 | 3.5 | 73.2 | 0.77 | 2.23 | 0.991 | |

| S5 | 21.6 | 9.9 | 7.2 | 2.9 | 1.9 | 1.5 | 83.1 | 0.757 | 2.243 | 0.971 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.; Wei, S.; Lei, Z.; Li, C.; Zhang, L.; Huang, X.; Xu, S. Experimental Study of Dynamic Mechanical Properties of Water-Saturated Coal Samples under Three-Dimensional Coupled Static–Dynamic Loadings. Processes 2022, 10, 1181. https://doi.org/10.3390/pr10061181

Huang C, Wei S, Lei Z, Li C, Zhang L, Huang X, Xu S. Experimental Study of Dynamic Mechanical Properties of Water-Saturated Coal Samples under Three-Dimensional Coupled Static–Dynamic Loadings. Processes. 2022; 10(6):1181. https://doi.org/10.3390/pr10061181

Chicago/Turabian StyleHuang, Cong, Shanyang Wei, Zhen Lei, Cai Li, Lin Zhang, Xiaomin Huang, and Shiqing Xu. 2022. "Experimental Study of Dynamic Mechanical Properties of Water-Saturated Coal Samples under Three-Dimensional Coupled Static–Dynamic Loadings" Processes 10, no. 6: 1181. https://doi.org/10.3390/pr10061181

APA StyleHuang, C., Wei, S., Lei, Z., Li, C., Zhang, L., Huang, X., & Xu, S. (2022). Experimental Study of Dynamic Mechanical Properties of Water-Saturated Coal Samples under Three-Dimensional Coupled Static–Dynamic Loadings. Processes, 10(6), 1181. https://doi.org/10.3390/pr10061181