Characterization of Slaughterhouse Wastewater and Development of Treatment Techniques: A Review

Abstract

:1. Introduction

2. SWW: Characteristics and Environmental/Public Health Impacts

2.1. Characteristics of SWW—Physical, Chemical, Biological

2.1.1. Physical/Chemical Characteristics

2.1.2. Biological Activity

2.2. Environmental Health and Toxicity Impacts

2.2.1. Environmental Health

2.2.2. Environmental Diversity

2.2.3. Toxicity

2.2.4. Chemical Activities

2.3. Public Health Impacts

3. Methods of Treatment

3.1. Biological Treatment of SWW

3.1.1. Anaerobic Processes

3.1.2. Aerobic and Combined Anaerobic/Aerobic Processes

3.1.3. Phytoremediation/Constructed Wetlands Processes

| Process: Anaerobic Digestion | Significant Results | Advantages | Disadvantages | Reference |

| Two down-flow high-rate anaerobic bioreactors: Down-flow expanded granular bed reactor (DEGBR) and static granular bed reactor (SGBR) | 95% removal of BOD5, COD, and FOG during peak performance days for both reactors | DEGBR displayed a more consistent and significant production of biogas than the SGBR | SGBR took more than 50 days to reach a 95% removal of FOG as opposed to the DEGBR (14 days) | [56] |

| Anerobic mono-digestion | COD, sCOD, and BOD removal efficiency of 49.93, 65.85, and 82.22%, respectively | Stable reactor with VFA/TA ratio < 0.4 | Organic matter residual requires post-treatment to meet effluent standards | [57] |

| Anaerobic co-digestion of SWW with hydrolyzed grease | 75% SWW and 25% hydrolyzed grease led to biogas yield of 0.6 L/g COD introduced | Optimum digester conditions observed at 25% hydrolyzed grease | Increasing the OLR from 2.0 to 2.5 g COD/L-d led to a decrease in the biogas production | [58] |

| Co-digestion of SWW with WMS (waste mixed sludge) | Higher values of BMP of 735 NLCH4/kg were obtained vs. with an SWW: WMS = 40% and TS = 4% | The maximum biomethane generation of 550 NLCH4/kg VS was achieved for an OLR = 1.5 kgVS/m3-day | SWW:WMS = 40% appears as a limiting value above which system will start to have a significant decrease in efficiency | [59] |

| Addition of purple non-sulfur bacteria (PNSB) to treat SWW | Treatment of wastewater with PNSB simultaneously produces effluent containing plant growth promoting bacteria | Can reduce sCOD in SWW by 85–90% and release sufficient amounts of 5-aminolevulinic acid for use in agriculture | Indigenous PNSB were not able to compete with other heterotrophs in the SWW | [60] |

| FOG co-digestion with SWW | Optimal conditions were 10% of FOG, resulting in 66% CODtremoval biodegradability and specific BMP of 562 and 777 mLCH4-g−1 CODsremoved | At 5–10% FOG, HABs (Hydrolytic acidogenic bacteria) were highly active leading to an increase in methanogenic activity | Sedimentation time and temperature must be controlled in order to achieve adequate sedimentation capacity | [61] |

| Laboratory scale upflow anaerobic sludge blanket (UASB) | COD removal was approximately 90% at OLR 0.4 g/L d−1; 5 L/d of biogas was obtained. | Concentration of VFAs was low; HRT of 1 day was sufficient to remove greater than 70% of COD | COD removal dropped to below 50% when the loading rate increased to 15 g/L d−1 | [39] |

| Poultry SWW as both the inoculum and substrate for the biological production of hydrogen | SWW inoculum has potential for bio-H2 production, as it produced CH4-free biogas containing 50–60% H2 | The inoculum is adaptable to the use of glycerine as a substrate | Requires a longer acclimatization period when using glycerine as a substrate than sucrose | [63] |

| Granular sludge from UASB | SWW presented higher proportions of organic substrate molecules for the methanogenesis than sanitary sewage sludge thus facilitating the production of the highest biogas | Methane generation was directly proportional to the acetate concentrations used; biogas production highest when using only SWW or a mix of SWW and sewage sludge | High organic load may destabilize the metabolic process of methane generation | [64] |

| Low-cost tubular digesters producing biogas from SWW | Low-cost tubular digesters with biofilm carriers are effective for OLR < 0.5 kg COD/m3-d of biogas production, and for 0.25 kg COD/m3-d | COD removal achieves values above 70% from HRT > 19 d | Low-cost biofilm carriers might not be scalable to full-scale digesters | [65] |

| Combined anaerobic system consisting of three pilot-scale anaerobic baffled reactors (ABRs) in the first stage and three anaerobic filters (AFs) | Optimum HRT and OLR were 24 h and 7 kg COD/m3/d and 36 h and 1 kg COD/m3/d in ABR and AF reactor, respectively | Removal efficiencies for COD ranged from 83% to 86% for ABR and 63% to 79% for AF reactors | Removal efficiency decreased at a considerably lower HRT (12 h) and a high OLR (10 kg/m3/d) | [66] |

| CO2 Capture of Biogas Using Chlorella vulgaris | AD able to remove 63% of COD. Biogas composition of slaughterhouse wastewater after incubation for 15 days was 52.70% air, 46.85% CH4, and 0.45% of CO2 | C. vulgaris enhanced CO2 removal from biogas up to 7%. | Growth of microalgae can be inhibited by the low percentage of CO2; percentage of CO2 provides sufficient support to microalgae growth if the concentration was above 15% | [67] |

| Biosynthesized iron nanoparticles (NPs) from water treatment sludge in anerobic digestion | Addition of iron NPs improved the biogas production and shortened the lag phase | Highest biogas yield was obtained from 9 mg L−1 of additive, which corresponds to improved COD removal efficiency to 42% | Application of NPs would be very costly; further research needed for scale-up and process optimization | [68] |

| Anaerobic digestion with addition of trace elements | Addition of Fe, Ni, Co, Mn, and Mo resulted in enhanced degradation of SWW, higher biogas production, and improved process stability | Higher OLRs and lower HRTs were achieved in comparison to control digesters | Large-scale operators need to manage waste streams to minimize solid loadings | [69] |

| Airlift membrane bioreactor (AL-MBR) for on-site treatment of SWW | Removal efficiencies of COD and TN were 95 ± 1.9% and 70 ± 3.3%, respectively, at a hydraulic retention time (HRT) of 2.5 days | AL-MBR provided a consistent flux of 18 LMH/bar at low pressures (0.8 bar) without regular membrane cleaning; energy consumption was 14% lower than an average cross flow MBR | A higher recycle flow could inhibit denitrification; at lower recycle flow, NO3–N was not transferred adequately to the anoxic tank | [71] |

| Batch bioreactors with purple phototrophic bacteria | 91.9% removal of sCOD, 70.1% removal of sTN, 90.9% removal of PO4 under phototrophic conditions | Phototrophic conditions produced valuable carbohydrate and protein byproducts | sCOD and PO4 removal rate constants were five-fold lower in chemotrophic conditions | [85] |

| Static granular bed reactor (SGBR) coupled with single-stage nitrification-denitrification (SND) bioreactor and ultrafiltration membrane module (ufMM) system | Average COD, ortho-phosphate, TSS, and TDS removal efficiencies of 91%, 51%, 97% and 52%, respectively, achieved over 52 days | ufMMs operated in dead-end filtration mode were able to further reduce the COD and TSS by an average of 65% and 54%, respectively | Final effluent not compliant with the industrial wastewater discharge standards for PO43− and NH4+-N | [86] |

| Process: Combined Anaerobic/Aerobic | Significant Results | Advantages | Disadvantages | Reference |

| Sequencing Batch Reactor (SBR) in aerobic/anaerobic sequential mode | Average percent removals of 85 to 90% of sCOD, N, and P | Excellent sludge settling (SVI30 < 100 mL/g) | Operational strategy and temperature variability have a significant impact on microbial community dynamics and granule growth | [74] |

| Intermittently Aerated Sequencing Batch Reactors | Optimum aeration rates were 0.6, 0.8, and 1.2 L air/min at the average OLRs of 0.61, 0.82, and 1.02 gCOD/L-d | Partial nitrification-denitrification efficiencies were between 61 and 70% at the optimum aeration rates | Highest N2O generation in the non-aeration period was observed at the optimum aeration rates | [75] |

| Novel acrylic fiber carrier with conventional activated sludge (AS + BF (biofilm reactor)) | The combined attached and suspended growth system supports aerobic and anaerobic conditions and efficiently removed BOD and COD | COD and BOD5 removal were 97.5% and 99.1%, respectively, using the AS + BF system | AS only showed removal of COD and BOD5 of 84.3%, 98.8% (only marginally lower than AS + BF) | [72] |

| Anoxic–aerobic biological reactors followed by UV disinfection | Total ammoniacal nitrogen (TAN) removal ranged within 83–99%, TN removal up to 90% | 3-log reduction of fecal coliforms possible after UV disinfection | Non-diluted samples were toxic to microalgae | [73] |

| Batch and anaerobic sequential batch reactors | 87.8% COD removal at OLR of 1.16 to 2.16 kg/m3-day | BMP of 0.23 LCH4/Ldigester-day | Faster OLR leads to bioreactor destabilization | [87] |

| Process: Physico-Remediation | Significant Results | Advantages | Disadvantages | Reference |

| Use of mixed algal species from SWW to remove OM and nutrients | Removal of TOC, TN, and TP of 89.6, 70.2, and 96.2%, respectively | Optimal removal achieved with undiluted SWW and mixed algal (eukaryotic and cyanobacterial culture) photo-bioreactors | Cyanobacterial species played a more effective role than the eukaryotic species in the treatment of SWW | [76] |

| SWW used for algal biomass production for pollutant removal | Sufficient nutrient removal efficiencies (23–42%, 18–48%) and pollutant load efficiencies (17–31%, 7–29%) | Optimal algal growth observed at 50% SWW | Use of photobioreator is costly and energy-intensive; more research needed for scale-up | [78] |

| Phycoremediation using eleven algal cultures for SWW | Removal percentages 73, 89, 90, and 85% for sCOD, NO3–N, NH4+–N, and PO43−, respectively | Most cultures showed good performance for biomass production (0.78–1.16 g/L) | Most of the contaminants were above the discharge limit in treated SWW | [79] |

| Marine protist (Chilean Thraustochytrid (TH) strain) used for SWW treatment | COD reduced by 56.29%, O&G reduced by 99%, and TN, TP, and total iron decreased by 63%, 98%, and 60%, respectively | Nutrients and trace metals are beneficially usable by THs for their growth and biomass production | Biomass production significantly affected by media composition (e.g., trace metals); omitting trace metals negatively impacts growth | [80] |

| Process: Constructed Wetlands | Significant Results | Advantages | Disadvantages | Reference |

| Constructed wetlands for removal of COD, TSS, TDS, BOD5, nitrate, and phosphate from SWW | Removal percentages of phosphate, COD, BOD5, nitrate, TDS, and TSS were 77.5%, 93.3%, 68%, 71.3%, and 88.7% respectively | Significant reductions in pollutants observed after 9 days retention time | Average effluent concentrations of certain parameters did not meet maximum permissible limit standards for safe discharge of industrial wastewater to the inland water surface | [81] |

| Constructed wetlands for COD and ammonia removal from SWW | Percent removal COD and ammonia were 85% and 80%, respectively | All plant stages (early, optimum, and harvest) show similar removal of pollutants | Difficult to determine optimal plant for removing pollutants due to competing physical, chemical, and biological processes occurring | [82] |

3.2. Physical Treatment of SWW

3.3. Chemical/Physicochemical Treatment of SWW

3.3.1. Coagulation Processes

3.3.2. Electrochemical Processes

3.4. Advanced Oxidation Processes (AOP) of SWW

3.4.1. Fenton Processes

3.4.2. Combined Biological/AOPs

3.4.3. Combined Physical and Chemical Processes/AOPs

4. Critical Assessment and Future Research

4.1. Biological Processes

4.2. Physical and Physical/Chemical Processes

4.3. AOPs

4.4. Future Research

5. Conclusions

6. Highlights

- SWW discharged into the environment can have significant impacts on public health and the environment

- SWW contains high strength and recalcitrant pollutants that require more advanced treatments prior to disposal

- Combined processes treatment for SWW are more effective than stand-alone treatment

- A modernization of treatment facilities for SWW should include anaerobic digestion and AOPs

Author Contributions

Funding

Conflicts of Interest

References

- Take Action for the Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 30 May 2022).

- Bustillo-Lecompte, C.F.; Mehrvar, M. Treatment of actual slaughterhouse wastewater by combined anaerobic–aerobic processes for biogas generation and removal of organics and nutrients: An optimization study towards a cleaner production in the meat processing industry. J. Clean. Prod. 2017, 141, 278–289. [Google Scholar] [CrossRef]

- Olaniran, E.I.; Sogbanmu, T.O.; Saliu, J.K. Biomonitoring, physico-chemical, and biomarker evaluations of abattoir effluent discharges into the Ogun River from Kara Market, Ogun State, Nigeria, using Clarias gariepinus. Environ. Monit. Assess. 2019, 191, 44. [Google Scholar] [CrossRef] [PubMed]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Slaughterhouse wastewater characteristics, treatment, and management in the meat processing industry: A review on trends and advances. J. Environ. Manag. 2015, 161, 287–302. [Google Scholar] [CrossRef]

- Al-Mutairi, N.; Hamoda, M.; Al-Ghusain, I. Coagulant selection and sludge conditioning in a slaughterhouse wastewater treatment plant. Bioresour. Technol. 2004, 95, 115–119. [Google Scholar] [CrossRef]

- Liew, Y.X.; Chan, Y.J.; Manickam, S.; Chong, M.F.; Chong, S.; Tiong, T.J.; Lim, J.-W.; Pan, G.T. Enzymatic pretreatment to enhance anaerobic bioconversion of high strength wastewater to biogas: A review. Sci. Total Environ. 2020, 713, 136373. [Google Scholar] [CrossRef]

- Metcalf, L.; Eddy, H.P.; Tchobanoglous, G. Wastewater Engineering: Treatment, Disposal, and Reuse; McGraw-Hill: New York, NY, USA, 1991; Volume 4. [Google Scholar]

- Al-Mutairi Nayef, Z. Coagulant toxicity and effectiveness in a slaughterhouse wastewater treatment plant. Ecotoxicol. Environ. Saf. 2006, 65, 74–83. [Google Scholar] [CrossRef]

- Yildirim, N.C.; Tanyol, M.; Serdar, O.; Yildirim, N. Gammarus pulex as a Model Organism to Assess the Residual Toxicity of Slaughterhouse Wastewater Treated by Electrocoagulation Process. Bull. Environ. Contam. Toxicol. 2019, 103, 447–452. [Google Scholar] [CrossRef]

- Madureira, J.; Melo, R.; Pimenta, A.I.; Verde, S.C.; Borrely, S.I. Evaluation of e-beam irradiation effects on the toxicity of slaughterhouse wastewaters. Environ. Technol. 2018, 39, 873–877. [Google Scholar] [CrossRef]

- Kim, H.J.; Won, C.H.; Kim, H.W. Pathogen deactivation of glow discharge cold plasma while treating organic and inorganic pollutants of slaughterhouse wastewater. Water Air Soil Pollut. 2018, 229, 237. [Google Scholar] [CrossRef]

- Aleksić, N.; Nešović, A.; Šušteršič, V.; Gordić, D.; Milovanovic, D. Slaughterhouse water consumption and wastewater characteristics in the meat processing industry in Serbia. Desalin. Water Treat. 2020, 190, 98–112. [Google Scholar] [CrossRef]

- Sonowal, D.; Hussain, P.; Sonowal, S.; Barua, A.G.; Hussain, J.; Chutia, J. Physicochemical properties of slaughterhouse wastewater in and around Guwahati City. Int. J. Chem. Stud. 2018, 6, 1875–1877. [Google Scholar]

- Azzopardi, E.A.; Boyce, D.E.; Thomas, D.W.; Dickson, W.A. Colistin in burn intensive care: Back to the future? Burns 2013, 9, 7–15. [Google Scholar] [CrossRef] [PubMed]

- Savin, M.; Bierbaum, G.; Blau, K.; Parcina, M.; Sib, E.; Smalla, K.; Schmithausen, R.; Heinemann, C.; Hammerl, J.A. Colistin-resistant Enterobacteriaceae isolated from process waters and wastewater from German poultry and pig slaughterhouses. Front. Microbiol. 2020, 11, 575391. [Google Scholar] [CrossRef] [PubMed]

- Inderbinen, M.N. Assessment of the occurrence of MCR producing Enterobacteriaceae in Swiss and imported poultry meat. J. Food Sci. Technol. 2017, 1, 137–141. [Google Scholar] [CrossRef] [Green Version]

- Meiramkulova, K.; Devrishov, D.; Zhumagulov, M.; Arystanova, S.; Karagoishin, Z.; Marzanova, S.; Kydyrbekova, A.; Mkilima, T.; Li, J. Performance of an Integrated Membrane Process with Electrochemical Pre-Treatment on Poultry Slaughterhouse Wastewater Purification. Membranes 2020, 10, 256. [Google Scholar] [CrossRef]

- Afsharnia, M.; Naraghi, B.; Mardaneh, J.; Kianmehr, M.; Biglari, H. The data of Escherichia coli strains genes in different types of wastewater. Data Brief 2018, 21, 763–766. [Google Scholar] [CrossRef]

- Ayaz, N.D.; Gencay, Y.E.; Erol, I. Phenotypic and genotypic antibiotic resistance profiles of Escherichia coli O157 from cattle and slaughterhouse wastewater isolates. Ann. Microbiol. 2015, 65, 1137–1144. [Google Scholar] [CrossRef]

- Um, M.M.; Barraud, O.; Kérourédan, M.; Gaschet, M.; Stalder, T.; Oswald EBibbal, D. Comparison of the incidence of pathogenic and antibiotic-resistant Escherichia coli strains in adult cattle and veal calf slaughterhouse effluents highlighted different risks for public health. Water Res. 2016, 88, 30–38. [Google Scholar] [CrossRef]

- Savin, M.; Bierbaum, G.; Hammerl, J.A.; Heinemann, C.; Parcina, M.; Sib EKreyenschmidt, J. Antibiotic-resistant bacteria and antimicrobial residues in wastewater and process water from German pig slaughterhouses and their receiving municipal wastewater treatment plants. Sci. Total Environ. 2020, 727, 138788. [Google Scholar] [CrossRef]

- Barel, M.; Hizlisoy, H.; Gungor, C.; Dishan, A.; Disli, H.B.; Al, S.; Onmaz, N.E.; Yildirim, Y.; Gonulalan, Z. Escheria coli serogroups in slaughterhouses: Antibiotic susceptibility and molecular typing of isolates. Int. J. Food Microbiol. 2022, 371, 109673. [Google Scholar] [CrossRef]

- Bibbal, D.; Um, M.M.; Diallo, A.A.; Kérourédan, M.; Dupouy, V.; Toutain, P.L.; Bousquet-Mélouc, A.; Oswaldad, E.; Brugère, H. Mixing of Shiga toxin-producing and enteropathogenic Escherichia coli in a wastewater treatment plant receiving city and slaughterhouse wastewater. Int. J. Hyg. Environ. Health 2018, 221, 355–363. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, F.; Hmaied, F.; Matei, I.; Chirila, F.; Fit, N.; Yahya, M.; Jebri, S.; Amairia, S.; Hamdi, M. Occurrence of Staphylococcus spp. and investigation of fecal and animal viral contaminations in livestock, river water, and sewage from Tunisia and Romania. Environ. Monit. Assess. 2020, 192, 206. [Google Scholar] [CrossRef] [PubMed]

- Lass, A.; Ma, L.; Kontogeorgos, I.; Xueyong, Z.; Li, X.; Karanis, P. Contamination of wastewater with Echinococcus multilocularis–possible implications for drinking water resources in the QTP China. Water Res. 2020, 170, 115334. [Google Scholar] [CrossRef] [PubMed]

- Savin, M.; Bierbaum, G.; Schmithausen, R.; Heinemann, C.; Kreyenschmidt, J.; Schmoger SAkbaba, I.; Kasbohrer, A.; Hammerl, J.A. Slaughterhouse wastewater as a reservoir for extended-spectrum β-lactamase (ESBL)-producing, and colistin-resistant Klebsiella spp. and their impact in a “One Health” perspective. Sci. Total Environ. 2022, 804, 150000. [Google Scholar] [CrossRef]

- Elmalı, M.; Can, H.Y. Antimicrobial susceptibility and virulence-associated genes in Campylobacter isolates from milk and wastewater in Hatay, Turkey. Ciência Rural 2019, 49. [Google Scholar] [CrossRef]

- Lye, Y.L.; Bong, C.W.; Lee, C.W.; Zhang, R.J.; Zhang, G.; Suzuki, S.; Chai, L.C. Anthropogenic impacts on sulfonamide residues and sulfonamide resistant bacteria and genes in Larut and Sangga Besar River, Perak. Sci. Total Environ. 2019, 688, 1335–1347. [Google Scholar] [CrossRef]

- Hatam-Nahavandi, K.; Mohebali, M.; Mahvi, A.H.; Keshavarz, H.; Khanaliha, K.; Tarighi, F.; Molaei-Rad, M.; Rezaeian, T.; Charehdar, S.; Salimi, M.; et al. Evaluation of Cryptosporidium oocyst and Giardia cyst removal efficiency from urban and slaughterhouse wastewater treatment plants and assessment of cyst viability in wastewater effluent samples from Tehran, Iran. J. Water Reuse Desalination 2015, 5, 372–390. [Google Scholar] [CrossRef] [Green Version]

- Cufaoglu, G.; Ayaz, N.D. Listeria monocytogenes risk associated with chicken at slaughter and biocontrol with three new bacteriophages. J. Food Saf. 2019, 39, E12621. [Google Scholar] [CrossRef]

- Fenaux, H.; Chassaing, M.; Berger, S.; Jeulin, H.; Gentilhomme, A.; Bensenane, M.; Bronowicki, J.P.; Gantzer, C.; Bertrand, I.; Schvoerer, B.; et al. Molecular features of Hepatitis E Virus circulation in environmental and human samples. J. Clin. Virol. 2018, 103, 63–70. [Google Scholar] [CrossRef]

- Sánchez-Alfonso, A.C.; Venegas, C.; Díez, H.; Méndez, J.; Blanch, A.R.; Jofre, J.; Campos, C. Microbial indicators and molecular markers used to differentiate the source of faecal pollution in the Bogotá River (Colombia). Int. J. Hyg. Environ. Health 2020, 225, 113450. [Google Scholar]

- Meiramkulova, K.; Temirbekova, A.; Saspugayeva, G.; Kydyrbekova, A.; Devrishov, D.; Tulegenova, Z.; Aubakirova, K.; Kovalchuk, N.; Meirbekov, A.; Mkilima, T. Performance of a combined treatment approach on the elimination of microbes from poultry slaughterhouse Wastewater. Sustainability 2021, 13, 3467. [Google Scholar] [CrossRef]

- Akanni, A.; Ogbiye, A.; Onakunle, O. The Impact assessment of abattoir waste facility discharge on water in Osogbo, Nigeria. Cogent Eng. 2019, 6, 1614317. [Google Scholar] [CrossRef]

- Aniebo, A.O.; Wekhe, S.N.; Okoli, I.C. Abattoir blood waste generation in Rivers State and its environmental implications in the Niger Delta. Chem. Toxicol. Environ. 2009, 91, 619–625. [Google Scholar] [CrossRef]

- Milanović, M.; Mihajlović, I.; Pap, S.; Brborić, M.; Đogo, M.; Grujić Letić, N.; Nježić, Z.; Milić, N. Necessity of meat-processing industry’s wastewater treatment—A one-year trial in Serbia. Desalin. Water Treat. 2015, 57, 15806–15812. [Google Scholar] [CrossRef]

- Yaakob, M.A.; Mohamed, R.M.S.R.; Al-Gheethi, A.; Tiey, A.; Kassim, A.H.M. Optimising of Scenedesmus sp. biomass production in chicken slaughterhouse wastewater using response surface methodology and potential utilisation as fish feeds. Environ. Sci. Pollut. Res. 2019, 26, 12089–12108. [Google Scholar] [CrossRef]

- Nurcholis; Muchlis, D. Preliminary Study of Contamination Wastewater on Environment in Slaughterhouse of Merauke City. In Proceedings of the the 3rd International Conference on Energy, Environmental and Information System (ICENIS 2018), Semarang, Indonesia, 14–15 August 2018. [Google Scholar]

- Musa, M.A.; Idrus, S.; Hasfalina, C.M.; Daud, N.N.N. Effect of organic loading rate on anaerobic digestion performance of mesophilic (UASB) reactor using cattle slaughterhouse wastewater as substrate. Int. J. Environ. Res. Public Health 2018, 15, 2220. [Google Scholar] [CrossRef] [Green Version]

- USEPA. Technical Development Document for the Final Effluent Limitations Guidelines and Standards for the Meat and Poultry Products Point Source Category. 2004; Volume 40 CFR 43. Available online: https://www.epa.gov/sites/default/files/2015-11/documents/meat-poultry-products_tdd_2004_0.pdf (accessed on 30 May 2022).

- Freedman, B. Environmental Science: A Canadian Perspective; Dalhousie University Libraries Digital Editions; Dalhousie University: Halifax, NS, Canada, 2018. [Google Scholar]

- Bystrzejewska-Piotrowska, G.; Golimowski, J.; Urban, P.L. Nanoparticles: Their potential toxicity, waste and environmental management. Waste Manag. 2009, 29, 2587–2595. [Google Scholar] [CrossRef]

- Tölgyessy, J. Human exposure to toxic and hazardous substances in water, air and soil (Environmental biochemistry and toxicology). Part of volume. Chemistry of Water, Air, and Soil: Environmental Aspects. Stud. Environ. Sci. 1993, 53, 724–832. [Google Scholar]

- Kim, Y.; Farnazo, D.M. Toxicity characteristics of sewage treatment effluents and potential contribution of micropollutant residuals. J. Ecol. Environ. 2017, 41, 39. [Google Scholar] [CrossRef] [Green Version]

- Topal, M.; Arslan Topal, E.I. Phytoremediaton of priority substances (Pb and Ni) by Phragmites australis exposed to poultry slaughterhouse wastewater. Int. J. Phytoremediat. 2020, 22, 857–862. [Google Scholar] [CrossRef]

- Bustillo-Lecompte, C.F.; Mehrvar, M.; Quinones-Bolanos, E. Combined anaerobic-aerobic and UV/H2O2 processes for the treatment of synthetic slaughterhouse wastewater. J. Environ. Sci. Health Part A 2013, 48, 1122–1135. [Google Scholar] [CrossRef] [PubMed]

- Pereira, E.L.; de Paiva, T.C.B.; Da Silva, F.T. Physico-chemical and ecotoxicological characterization of slaughterhouse wastewater resulting from green line slaughter. Water Air Soil Pollut. 2016, 227, 199. [Google Scholar] [CrossRef]

- Ogbonna, D.N.; Ideriah, T.J.K.; Nwachukwu, M.I. Biodegradation of polycyclic aromatic hydrocarbons by associated microbes from abattoir wastes in the Niger delta, Nigeria. J. Microbiol. Res. 2012, 2, 157–169. [Google Scholar]

- Silano, V.; Baviera, J.M.B.; Bolognesi, C.; Brüschweiler, B.J.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Lampi, E. Evaluation of the safety and efficacy of the organic acids lactic and acetic acids to reduce microbiological surface contamination on pork carcasses and pork cuts. EFSA J. 2018, 16, 5482. [Google Scholar]

- Bello, Y.O.; Oyedemi, D.T.A. Impact of abattoir activities and management in residual neighborhoods: A case study of Ogbomoso, Nigeria. J. Soc. Sci. 2017, 19, 121–127. [Google Scholar]

- Wiyarno, Y.; Widyastuti, S. Isolation and Identification Odorous Chemical Markers of Wastewater Poultry Slaughterhouse. Procedia Environ. Sci. 2015, 23, 400–406. [Google Scholar] [CrossRef] [Green Version]

- America, E. Slaughterhouses Are Polluting Our Waterways. 2020. Available online: https://environmentamerica.org/feature/ame/slaughterhouse-map (accessed on 30 May 2022).

- Wang, L.K.; Hung, Y.T.; Lo, H.H.; Yapijakis, C. Waste Treatment in the Food Processing Industry; CRC Press: Boca Raton, FL, USA, 2006; ISBN 0849372364/9780849372360. [Google Scholar]

- Palomares-Rodríguez, C.; Martínez-Guido, S.I.; Apolinar-Cortés, J.; del Carmen Chávez-Parga, M.; García-Castillo, C.C.; Ponce-Ortega, J.M. Environmental, technical, and economic evaluation of a new treatment for wastewater from slaughterhouses. Int. J. Environ. Res. 2017, 11, 535–545. [Google Scholar] [CrossRef]

- Del Nery, V.; Damianovic, M.H.Z.; Moura, R.B.; Pozzi, E.; Pires, E.C.; Foresti, E. Poultry slaughterhouse wastewater treatment plant for high quality effluent. Water Sci. Technol. 2016, 73, 309–316. [Google Scholar] [CrossRef]

- Njoya, M.; Basitere, M.; Ntwampe, S.K.O.; Lim, J.W. Performance evaluation and kinetic modeling of down-flow high-rate anaerobic bioreactors for poultry slaughterhouse wastewater treatment. Environ. Sci. Pollut. Res. 2021, 28, 9529–9541. [Google Scholar] [CrossRef]

- Adou, K.E.; Alle, O.A.; Kouakou, A.R.; Adouby, K.; Drogui, P.; Tyagi, R.D. Anaerobic mono-digestion of wastewater from the main slaughterhouse in Yamoussoukro (Côte d’Ivoire): Evaluation of biogas potential and removal of organic pollution. J. Environ. Chem. Eng. 2020, 8, 103770. [Google Scholar] [CrossRef]

- Affes, M.; Aloui, F.; Hadrich, F.; Loukil, S.; Sayadi, S. Effect of bacterial lipase on anaerobic co-digestion of slaughterhouse wastewater and grease in batch condition and continuous fixed-bed reactor. Lipids Health Dis. 2017, 16, 195. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salehiyoun, A.R.; Di Maria, F.; Sharifi, M.; Norouzi, O.; Zilouei, H.; Aghbashlo, M. Anaerobic co-digestion of sewage sludge and slaughterhouse waste in existing wastewater digesters. Renew. Energy 2020, 145, 2503–2509. [Google Scholar] [CrossRef]

- Bunraksa, T.; Kantachote, D. The potential use of purple nonsulfur bacteria to simultaneously treat chicken slaughterhouse wastewater and obtain valuable plant growth promoting effluent and their biomass for agricultural application. Biocatal. Agric. Biotechnol. 2020, 28, 10. [Google Scholar] [CrossRef]

- Agabo-García, C.; Solera, R.; Perez, M. First approaches to valorizate fat, oil and grease (FOG) as anaerobic co-substrate with slaughterhouse wastewater: Biomethane potential, settling capacity and microbial dynamics. Chemosphere 2020, 259, 127474. [Google Scholar] [CrossRef] [PubMed]

- Musa, M.A.; Idrus, S. Effect of Hydraulic Retention Time on the Treatment of Real Cattle Slaughterhouse Wastewater and Biogas Production from HUASB Reactor. Water 2020, 12, 490. [Google Scholar] [CrossRef] [Green Version]

- Cripa, F.B.; Arantes, M.K.; Sequinel, R.; Fiorini, A.; Rosado, F.R.; Alves, H.J. Poultry slaughterhouse anaerobic ponds as a source of inoculum for biohydrogen production. J. Biosci. Bioeng. 2020, 129, 77–85. [Google Scholar] [CrossRef]

- Almeida, S.; Horta, E.F.; Castro, M.C.A.A.; Crespi, M.S.; Maintinguer, S.I. Thermal characterization of granular sludges from biologic treatments and its application to the generation of biogas. J. Therm. Anal. Calorim. 2019, 138, 3803–3810. [Google Scholar] [CrossRef]

- Martí-Herrero, J.; Alvarez, R.; Flores, T. Evaluation of the low technology tubular digesters in the production of biogas from slaughterhouse wastewater treatment. J. Clean. Prod. 2018, 199, 633–642. [Google Scholar] [CrossRef]

- Yousefi, Z.; Behbodi, M.; Mohammadpour, R.A. Slaughterhouse wastewater treatment by combined anaerobic baffled reactor and anaerobic filter: Study of OLR and HRT optimization in ABR/AF reactors. Environ. Health Eng. Manag. J. 2018, 5, 137–142. [Google Scholar] [CrossRef]

- Oktavitri, N.I.; Yustita, F.N.; Pratiwi, W.B.; Isnadina, D.R.M. Unsterilized tofu wastewater as media for Chlorella vulgaris: Effect of dilution on cultivation. Ecol. Environ. Conserv. 2019, 25, 81–85. [Google Scholar]

- Yazdani, M.; Ebrahimi-Nik, M.; Heidari, A.; Abbaspour-Fard, M.H. Improvement of biogas production from slaughterhouse wastewater using biosynthesized iron nanoparticles from water treatment sludge. Renew. Energy 2018, 135, 496–501. [Google Scholar] [CrossRef]

- Schmidt, T.; McCabe, B.K.; Harris, P.W.; Lee, S. Effect of trace element addition and increasing organic loading rates on the anaerobic digestion of cattle slaughterhouse wastewater. Bioresour. Technol. 2018, 264, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Panizio, R.M.; Calado, L.F.D.C.; Lourinho, G.; de Brito, P.S.D.; Mees, J.B. Potential of Biogas Production in Anaerobic Co-digestion of Opuntia ficus-indica and Slaughterhouse Wastes. Waste Biomass-Valorization 2019, 11, 4639–4647. [Google Scholar] [CrossRef]

- Do, A.T.; Bach, D.Q.; Do, U.K.; Prieto, A.; Lan Huong, H.T. Performance of airlift MBR for on-site treatment of slaughterhouse wastewater in urban areas of Vietnam. Water Sci. Technol. 2016, 74, 2245–2251. [Google Scholar] [CrossRef] [PubMed]

- Baker, B.R. Explore the pollution load of slaughterhouse wastewater and their treatment potential using biofilm reacto. Int. J. Sci. Eng. Res. 2016, 7, 1757–1761. [Google Scholar]

- Svierzoski, N.D.S.; Matheus, M.C.; Bassin, J.P.; Brito, Y.D.; Mahler, C.F.; Webler, A.D. Treatment of a slaughterhouse wastewater by anoxic-aerobic biological reactors followed by UV-C disinfection and microalgae bioremediation. Water Environ. Res. 2020, 93, 409–420. [Google Scholar] [CrossRef]

- Dobbeleers, T.; Caluwé, M.; Dockx, L.; Daens, D.; D’aes, J.; Dries, J. Biological nutrient removal from slaughterhouse wastewater via nitritation/denitritation using granular sludge: An onsite pilot demonstration. J. Chem. Technol. Biotechnol. 2020, 95, 111–122. [Google Scholar] [CrossRef]

- Pan, F.; Yu, Y.; Xu, A.; Xia, D.; Sun, Y.; Cai, Z.; Liu, W.; Fu, J. Application of magnetic OMS-2 in sequencing batch reactor for treating dye wastewater as a modulator of microbial community. J. Hazard. Mater. 2017, 340, 36–46. [Google Scholar] [CrossRef]

- Taşkan, E. Performance of mixed algae for treatment of slaughterhouse wastewater and microbial community analysis. Environ. Sci. Pollut. Res. 2016, 23, 20474–20482. [Google Scholar] [CrossRef]

- Vikneswara, A.S.; Mohamed, R.M.S.R.; Al-Gheethi, A.A.S.; Kassim, A.H.M.; Othman, N. Removal of nutrients from meat processing wastewater through the phycoremediation process. In Management of Greywater in Developing Countries; Springer: Cham, Germany, 2019; pp. 245–263. [Google Scholar]

- Azam, R.; Kothari, R.; Singh, H.M.; Ahmad, S.; Ashokkumar, V.; Tyagi, V.V. Production of algal biomass for its biochemical profile using slaughterhouse wastewater for treatment under axenic conditions. Bioresour. Technol. 2020, 306, 123116. [Google Scholar] [CrossRef]

- Chawla, P.; Malik, A.; Sreekrishnan, T.R.; Dalvi, V.; Gola, D. Selection of optimum algae via wastewater combination. Environ. Technol. Innov. 2020, 18, 100758. [Google Scholar] [CrossRef]

- DHipp, M.P.V.; Rodríguez, D.S. Bioremediation of piggery slaughterhouse wastewater using the marine protist, Thraustochytrium kinney VAL-B1. J. Adv. Res. 2018, 12, 21–26. [Google Scholar]

- Keerthana, K.; Thivyatharsan, R. Constructed wetland for slaughterhouse wastewater treatment. AGRIEAST J. Agric. Sci. 2018, 12, 7–15. [Google Scholar] [CrossRef]

- Ramdani, F.; Prasetya, A.; Purnomo, C.W. Removal of pollutants from chicken slaughterhouse wastewater using constructed wetland system. IOP Conf. Ser. Earth Environ. Sci. 2019, 399, 012085. [Google Scholar] [CrossRef]

- Gutiérrez-Sarabia, A.; Fernández-Villagómez, G.; Martínez-Pereda, P.; Rinderknecht-Seijas, N.; Poggi-Varaldo, H.M. Slaughterhouse wastewater treatment in a full-scale system with constructed wetlands. Water Environ. Res. 2004, 76, 334–343. [Google Scholar] [CrossRef] [PubMed]

- Kataki, S.; Chatterjee, S.; Vairale, M.G.; Dwivedi, S.K.; Gupta, D.K. Constructed wetland, an eco-technology for wastewater treatment: A review on types of wastewater treated and components of the technology (macrophyte, biolfilm and substrate). J. Environ. Manag. 2021, 283, 111986. [Google Scholar] [CrossRef]

- Mata-De-La-Vega, J.F.; Akizuki, S.; Sakai, H.D.; Cuevas-Rodríguez, G. Slaughterhouse wastewater treatment using purple phototrophic bacteria: A comparison between photoheterotrophic and chemoheterotrophic conditions. Biochem. Eng. J. 2021, 179, 108273. [Google Scholar] [CrossRef]

- Rinquest, Z.; Basitere, M.; Ntwampe, S.K.O.; Njoya, M. Poultry slaughterhouse wastewater treatment using a static granular bed reactor coupled with single stage nitrification-denitrification and ultrafiltration systems. J. Water Process Eng. 2019, 29, 100778. [Google Scholar] [CrossRef]

- Ripoll, V.; Agabo-García, C.; Solera, R.; Perez, M. Anaerobic digestion of slaughterhouse waste in batch and anaerobic sequential batch reactors. Biomass Conv. Bioref. 2022. [Google Scholar] [CrossRef]

- Obotey Ezugbe, E.; Rathilal, S. Review membrane technologies in wastewater treatment: A review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef]

- Coskun, T.; Debik, E.; Kabuk, H.A.; Manav Demir, N.; Basturk, I.; Yildirim, B.; Temizel, D.; Kucuk, S. Treatment of poultry slaughterhouse wastewater using a membrane process, water reuse, and economic analysis. Desalination Water Treat. 2015, 57, 4944–4951. [Google Scholar] [CrossRef]

- Almandoz, M.C.; Pagliero, C.L.; Ochoa, N.A.; Marchese, J. Composite ceramic membranes from natural aluminosilicates for microfiltration applications. Ceram. Int. 2015, 41, 5621–5633. [Google Scholar] [CrossRef]

- Abdurahman, N.H.; Rosli, Y.M.; Azhari, N.H.; Bari, H.A. The potential of ultrasonic membrane anaerobic systems in treating slaughterhouse wastewater. J. Water Reuse Desalination 2015, 5, 293–300. [Google Scholar] [CrossRef] [Green Version]

- Goswami, K.P.; Pugazhenthi, G. Treatment of poultry slaughterhouse wastewater using tubular microfiltration membrane with fly ash as key precursor. J. Water Process Eng. 2020, 37, 101361. [Google Scholar] [CrossRef]

- FDel Real-Olvera, J.; Rustrian-Portilla, E.; Houbron, E.; Landa-Huerta, F.J. Adsorption of organic pollutants from slaughterhouse wastewater using powder of Moringa oleiferaseeds as a natural coagulant. Desalination Water Treat. 2015, 57, 9971–9981. [Google Scholar] [CrossRef]

- Garduño-Pineda, L.; Linares-Hernández, I.; Solache-Ríos, M.J.; Teutli-Sequeira, A.; Martínez-Miranda, V. Removal of inorganic chemical species and organic matter from slaughterhouse wastewater via calcium acetate synthesized from eggshell. J. Environ. Sci. Health Part A 2019, 54, 295–305. [Google Scholar] [CrossRef]

- Prazeres, A.R.; Fernandes, F.; Madeira, L.; Luz, S.; Albuquerque, A.; Simões, R.; Beltrán, F.J.; Jerónimo, E.; Rivas, J. Treatment of slaughterhouse wastewater by acid precipitation (H2SO4, HCl and HNO3) and oxidation (Ca(ClO)2, H2O2 and CaO2). J. Environ. Manag. 2019, 250, 109558. [Google Scholar] [CrossRef]

- Da Silva, F.M.; de Souza Araújo, I.; Vieira, T.H.; Orssatto, F.; Eyng, E.; Frare, L.M.; Baraldi, I.J. Application of electrocoagulation as treatment of slaughterhouse and packing plant wastewater. Desalination Water Treat. 2020, 195, 137–147. [Google Scholar] [CrossRef]

- Meiramkulova, K.; Zhumagulov, M.; Saspugayeva, G.; Jakupova, Z.; Mussimkhan, Ð. Treatment of poultry slaughterhouse wastewater with combined system. Potravinarstvo Slovak J. Food Sci. 2020, 13, 706–712. [Google Scholar] [CrossRef] [Green Version]

- Deshpande, A.M.; Satyanarayan, S.; Ramakant, S. Treatment of high-strength pharmaceutical wastewater by electrocoagulation combined with anaerobic process. Water Sci. Technol. 2010, 61, 463–472. [Google Scholar] [CrossRef]

- Bazrafshan, E.; Biglari, H.; Mahvi, A.H. Phenol removal by electrocoagulation process from aqueous solutions. Fresenius Environ. Bull. 2012, 21, 364–371. [Google Scholar]

- Yusoff, M.S.; Azwan, A.M.; Zamri, M.F.M.A.; Aziz, H.A. Removal of colour, turbidity, oil and grease for slaughterhouse wastewater using electrocoagulation method. AIP Conf. Proc. 2017, 1892, 040012. [Google Scholar] [CrossRef]

- Dlangamandla, C.; Ntwampe, S.K.O.; Basitere, M. A bioflocculant-supported dissolved air flotation system for the removal of suspended solids, lipids and protein matter from poultry slaughterhouse wastewater. Water Sci. Technol. 2018, 78, 452–458. [Google Scholar] [CrossRef] [PubMed]

- Reátegui-Romero, W.; Tuesta-Tinoco, S.A.; De la Cruz, C.E.O.; Huamán-Ccopa, J.A.; King-Santos, M.E.; Estrada-Huamaní, E.F.; Bulege-Gutierrez, W.; Yuli-Posadas, R.A. Electrocoagulation in batch mode for the removal of the chemical oxygen demand of an effluent from slaughterhouse wastewater in Lima Peru: Fe and Al electrodes. Desalination Water Treat. 2020, 202, 206–218. [Google Scholar] [CrossRef]

- Meiramkulova, K.; Jakupova, Z.; Orynbekov, D.; Tashenov, E.; Kydyrbekova, A.; Mkilima, T.; Inglezakis, V.J. Evaluation of electrochemical methods for poultry slaughterhouse wastewater treatment. Sustainability 2020, 12, 5110. [Google Scholar] [CrossRef]

- Alfonso-Muniozguren, P.; Cotillas, S.; Boaventura, R.A.; Moreira, F.C.; Lee, J.; Vilar, V.J. Single and combined electrochemical oxidation driven processes for the treatment of slaughterhouse wastewater. J. Clean. Prod. 2020, 270, 121858. [Google Scholar] [CrossRef]

- Ozturk, D.; Yilmaz, A.E. Treatment of slaughterhouse wastewater with the electrochemical oxidation process: Role of operating parameters on treatment efficiency and energy consumption. J. Water Process Eng. 2019, 31, 100834. [Google Scholar] [CrossRef]

- Guihong, L.; Bin, L.; Qiang, F.; Junhua, Y.; Haiyan, Q.; Mingqing, C.; Ping, Y. Pig Slaughterhouse Wastewater Treatment via Catalytic supercritical Water Oxidation (CSCWO). Oxid. Commun. 2015, 38, 1909–1914. [Google Scholar]

- Eryuruk, K.; Tezcan Un, U.; Bakır Ogutveren, U. Electrochemical treatment of wastewaters from poultry slaughtering and processing by using iron electrodes. J. Clean. Prod. 2018, 172, 1089–1095. [Google Scholar] [CrossRef]

- Abdelhay, A.; Jum’h, I.; Abdulhay, E.; Al-Kazwini, A.; Alzubi, M. Anodic oxidation of slaughterhouse wastewater on boron-doped diamond: Process variables effect. Water Sci. Technol. 2017, 76, 3227–3235. [Google Scholar] [CrossRef]

- Christwardana, M.; Prabowo, A.K.; Tiarasukma, A.P.; Ariyanti, D. Microbial Fuel Cells for Simultaneous Electricity Generation and Organic Degradation from Slaughterhouse Wastewater. Int. J. Renew. Energy Dev. 2016, 5, 107–112. [Google Scholar] [CrossRef] [Green Version]

- Mkilima, T. Treatment of livestock slaughterhouse wastewater by the electrochemical method using stainless steel and copper electrodes. Environ. Qual. Manag. 2022, 1–13. [Google Scholar] [CrossRef]

- Tong, S.; Zhang, S.; Zhao, Y.; Feng, C.; Hu, W.; Chen, N. Hybrid zeolite-based ion-exchange and sulfur oxidizing denitrification for advanced slaughterhouse wastewater treatment. J. Environ. Sci. 2022, 113, 219–239. [Google Scholar] [CrossRef] [PubMed]

- Campos, S.; Salazar, R.; Arancibia-Miranda, N.; Rubio, M.A.; Aranda, M.; García, A.; Sepúlveda, P.; Espinoza, L.C. Nafcillin degradation by heterogeneous electro-Fenton process using Fe, Cu and Fe/Cu nanoparticles. Chemosphere 2020, 247, 125813. [Google Scholar] [CrossRef] [PubMed]

- João, J.J.; Silva, C.S.D.; Vieira, J.L.; Silveira, M.F.D. Treatment of swine wastewater using the Fenton process with ultrasound and recycled iron. Rev. Ambient. Água 2020, 15, 2453. [Google Scholar] [CrossRef]

- Vidal, J.; Huiliñir, C.; Salazar, R. Removal of organic matter contained in slaughterhouse wastewater using a combination of anaerobic digestion and solar photoelectro-Fenton processes. Electrochim. Acta 2016, 210, 163–170. [Google Scholar] [CrossRef]

- Brooms, T.; Apollo, S.; Otieno, B.; Onyango, M.S.; Kabuba, J.; Ochieng, A. Integrated anaerobic digestion and photodegradation of slaughterhouse wastewater: Energy analysis and degradation of aromatic compounds. J. Mater. Cycles Waste Manag. 2020, 22, 1227–1236. [Google Scholar] [CrossRef]

- Naderi, K.V.; Bustillo-Lecompte, C.F.; Mehrvar, M.; Abdekhodaie, M.J. Combined UV-C/H2O2-VUV processes for the treatment of an actual slaughterhouse wastewater. J. Environ. Sci. Health Part B 2017, 52, 314–325. [Google Scholar] [CrossRef]

- Fard, M.B.; Mirbagheri, S.A. Removal of TCOD and phosphate from slaughterhouse wastewater using Fenton as a post-treatment of an UASB reactor. J. Environ. Health Sci. Eng. 2020, 18, 10. [Google Scholar]

- Dechthummarong, C.; Wongpankamol, P. Electric Discharge Plasma in Air Bubbles for Effluent Wastewater Treatment from Chicken Slaughterhouse. In Proceedings of the 15th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Rai, Thailand, 18–21 July 2018; pp. 274–277. [Google Scholar]

- Bustillo-Lecompte, C.; Ghafoori, S.; Mehrvar, M. Photochemical degradation of an actual slaughterhouse wastewater by continuous UV/H2O2 photoreactor with recycle. J. Environ. Chem. Eng. 2016, 4, 719–732. [Google Scholar] [CrossRef]

- Davarnejad, R.; Nasiri, S. Slaughterhouse wastewater treatment using an advanced oxidation process: Optimization study. Environ. Pollut. 2017, 223, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Treatment of an actual slaughterhouse wastewater by integration of biological and advanced oxidation processes: Modeling, optimization, and cost-effectiveness analysis. J. Environ. Manag. 2016, 182, 651–666. [Google Scholar] [CrossRef] [PubMed]

- Vidal, J.; Carvajal, A.; Huiliñir, C.; Salazar, R. Slaughterhouse wastewater treatment by a combined anaerobic digestion/solar photoelectro-Fenton process performed in semicontinuous operation. Chem. Eng. J. 2019, 378, 122097. [Google Scholar] [CrossRef]

- Kanafin, Y.N.; Makhatova, A.; Meiramkulova, K.; Poulopoulos, S.G. Treatment of a poultry slaughterhouse wastewater using advanced oxidation processes. J. Water Process Eng. 2022, 47, 102694. [Google Scholar] [CrossRef]

- Pan, F.; Xu, A.; Xia, D.; Yu, Y.; Chen, G.; Meyer, M.; Zhao, D.; Huang, C.; Wu, Q.; Fu, J. Effects of octahedral molecular sieve on treatment performance, microbial metabolism, and microbial community in expanded granular sludge bed reactor. Water Res. 2015, 87, 127–136. [Google Scholar] [CrossRef] [PubMed]

- Alfonso-Muniozguren, P.; Bohari, M.H.; Sicilia, A.; Avignone-Rossa, C.; Bussemaker, M.; Saroj, D.; Lee, J. Tertiary treatment of real abattoir wastewater using combined acoustic cavitation and ozonation. Ultrason. Sonochem. 2020, 64, 104986. [Google Scholar] [CrossRef]

| Microbe | Resistance | Author |

|---|---|---|

| Escherichia coli | Antibiotic-resistant | [15,18,19,20,21,22] |

| Escherichia coli | N/A | [13,23,24] |

| Echinococcus multilocularis | N/A | [25] |

| Enterococcus faecium | Vancomycin-resistant | [21] |

| Klebsiella spp. | Antibiotic-resistant | [15,21,26] |

| Enterobacter cloacae | Antibiotic-resistant | [21] |

| Citrobacter spp. | Antibiotic-resistant | [21] |

| Acinetobacter calcoaceticus-baumannii | N/A | [21] |

| Campylobacter | Antibiotic-resistant | [27] |

| Sulfonamide bacteria | Antibiotic-resistant | [28] |

| Shiga toxin-producing Escherichia coli | N/A | [23] |

| Staphylococcus sp. | N/A | [13,24] |

| Staphylococcus sp. | Methicillin-resistant | [21] |

| Streptococcus sp. | N/A | [13] |

| Cryptosporidium oocyst | N/A | [29] |

| Giardia cyst | N/A | [29] |

| Listeria monocytogenes | N/A | [30] |

| HEV RNA genotype 3 | N/A | [31] |

| Hepatitis E virus (HEV) | N/A | [24] |

| Somatic coliphages | N/A | [24] |

| F-specific RNA bacteriophages | N/A | [24] |

| Bovine enterovirus (BEV) | N/A | [24] |

| Bacteroides | N/A | [32] |

| Salmonella coliphages | N/A | [33] |

| Pseudomonas aeruginosa | N/A | [33] |

| Staphylococcus aureus | N/A | [33] |

| Enterococcus sp. | N/A | [33] |

| Process | Significant Results | Advantage | Disadvantage | Reference |

|---|---|---|---|---|

| UF, NF, and RO membrane processes for COD and conductivity removal | COD removal efficiencies were 90% for NF and 97.4% for RO, and conductivities decreased by 51.7% for NF and 96.6% for RO | Best alternative was the RO process; UF + RO is most cost-effective | RO and NF without pre-treatment were not effective | [89] |

| Composite ceramic membranes (CM) from natural aluminosilicates | Bacterial removal and COD rejection were 99.4% and 91%, respectively | CM developed also shows high hydraulic permeability | Pre-treatment needed to remove solids and fats (addition of chemical flocculants and secondary biological treatment) | [90] |

| Ultrasonic membrane anaerobic system | The removal efficiency of COD was 94.8–96.5% with hydraulic retention times of 308.6–8.7 days | Methane gas production rate was 0.24–0.56 L/g COD/d | Methane content generally declined with increasing OLR | [91] |

| Process | Significant Results | Advantage | Disadvantage | Reference |

|---|---|---|---|---|

| EO and EO-related processes for removal of COD, SS, and color | EO/H2O2 and EO/UVC reduced COD and SS below effluent limits | Pre-ozonation combined with UV processes improved organics removal | Pretreatment (grit removal, degreasing, biological treatment, and settling) necessary | [104] |

| Acid precipitation and oxidation for removal of pollutants | Effective removal of COD, turbidity, TP, solids, BOD5 with both acid precipitation (41 to 99%) and oxidation (71 to 100%) | Oxidation processes more effective than acid precipitation at removing turbidity and TP | Despite high removal efficiencies, post-treatment required to meet standards | [95] |

| EO processes for removal of COD, TOC, TN, TSS, and color | At optimum conditions, TSS, TOC, COD, TN, and color removal efficiencies were 99.5%, 88.0%, 92.2%, 93.5%, and 99.9%, respectively | Most effective treatment was 0.025 M NaCl, 25 °C, pH = 7.03, 4.73 mA/cm2 current density, and 4 h reaction time | Full mineralization of organics takes 4 h; large volumes of effluent will result in impractical treatment time | [105] |

| Removal of inorganic chemical species and organic matter via calcium acetate | Removal efficiencies for TSS, turbidity, color, Fe, Cu, and Na were 82%, 76%, 81%, 54%, 70%, and 15%, respectively | Treatment also removed 99% fecal and total coliforms, 26% COD, and 74% TOC | High pH needed for removal of certain contaminants (e.g., phosphates), low pH needed for removal of others (e.g., Fe) | [94] |

| Cold plasma pathogen deactivation and removal of inorganic and organic pollutants | COD, TN, and TP removal efficiencies were 78–93, 51–92, and 35–83%, respectively. Bacteria could be removed by as much as 98% in all the operating conditions tested and toxicity unit dramatically decreased to less than 1 (96% removal) | Effective organic oxidation is possible even under high OLR | Proper residence time (>4 days) needed for sufficient reduction of toxicity unit | [11] |

| Catalytic supercritical water oxidation (CSCWO). | COD removal of 86% at t = 9 min, T = 430 °C, oxidation coefficient = 0.8, CODinitial = 3000 mg/L | Adding Na2CO3 catalyst improved COD removal to 99.8% | Addition of catalyst requires higher temperature (500 °C) | [106] |

| Electrocoagulation in continuous flow mode with and without adding hydrogen peroxide | COD removal was 95.48%; optimal conditions are a current density of 50 mA cm−2, an initial pH of 3, a flow rate of 0.027 L min−1, and the presence of 0.2 M H2O2, and 0.5 g L−1 polyelectrolyte | Most efficient pH was original pH of the wastewater (approximately 7), which eliminates the chemical adjustment of pH if only using electrocoagulation method | pH adjustment required to increase COD removal efficiency from an electrocoagulation process to peroxi-electrocoagulation process | [107] |

| Electrochemical oxidation | Results showed that raising the applied current density to3.83 mA/cm2 has a 100% COD removal, 90% color removal, and 80% turbidity removal | COD removal percentage of 100% was obtained after an electrolysis time of 200 min; improved and more economical method than results reported in other literature | pH adjustment required for optimal treatment | [108] |

| Preliminary settling tank followed by chemical coagulation followed by electrocoagulation | Supplemental process as electrocoagulation is essential for enhanced effluent quality to meet standards | Adopting the electrocoagulation process is economical | Removal efficiencies increased by increasing coagulant dose and electrical potential, which requires more chemical usage and electricity | [99] |

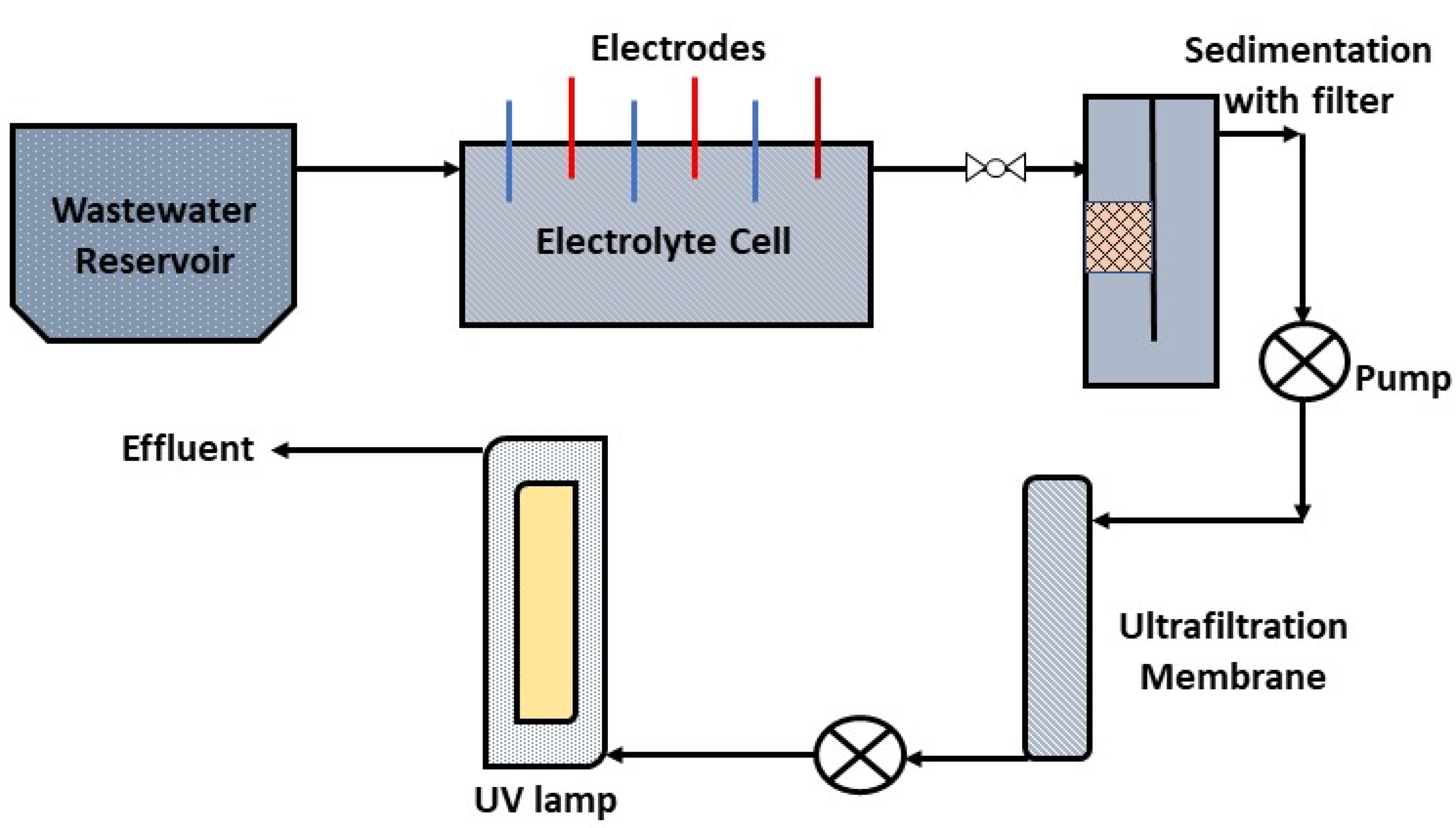

| Electrochemical (pre-treatment) followed by integrated membrane filtration treatment system (UF and RO) | Highly effective for the removal of some turbidity, color, TSS, total iron, aluminum, COD, and BOD; with removal efficiency ranging from 71 to 85% | High removal efficiency of total iron and aluminum reduces scaling of mineral salts onto the membrane surface, maintaining the design flux | Lower removal efficiencies of nitrate, nitrite, ammonium; EC pre-treatment unit necessary to achieve nickel removal efficiency of approximately 52.06% | [33] |

| Electrochemical (aluminium–graphite and aluminium –titanium electrodes) | Both electrodes achieved high removal efficiency from turbidity, color, nitrite, phosphates, and COD, with removal efficiency 88% to 100% after 40 min. | Inert character of graphite electrode led to lower operating cost | Although aluminum–titanium outperformed aluminum–graphite, it is more costly than graphite due to inert character of graphite | [103] |

| Microbial fuel cells | COD removal in SWW was 67.9% and pH increased from 5.9 to 7.5 due to treatment process. | Considered green technology since electricity is a by-product and rumen microbes used as biocatalyst; pH also increased from 5.9 to 7.5 due to fast consumption of protons to cathodes than generation of protons in anodes | Microbial system must be optimized; microbes need sufficient food for growth whereas excessive substrate may not be beneficial for the process and lowers power density generation | [109] |

| Electrochemical (pre-treatment) followed by membrane filtration and UV treatments (UF and UV) | Combined treatment led to the removal of almost all the microorganisms in the wastewater with 99.86% to 100% efficiency | High-efficiency microbial elimination | Combined treatment required for optimal removal | [33] |

| Electrochemical method using stainless steel and copper electrodes | 85% to 92% removal efficiency of TSS, color, turbidity, BOD, COD, and TOC after 60 min of contact time | Lower operating cost than aluminum electrodes ($0.49/m3 compared to $3.85/m3) | Low removal of ammonia (60%) even at longest contact time | [110] |

| Zeolite-based ion-exchange and sulfur oxidizing denitrification | NO3–N removal efficiency of 100% | Meets effluent requirements for NH4+–N and lower SO42− accumulation | Conventional secondary pre-treatment is needed | [111] |

| Process | Significant Results | Advantage | Disadvantage | Reference |

|---|---|---|---|---|

| Combined system: electrocoagulation, UF, and photochemical system as UV sterilization | Treatment lasted 40 min; BOD, COD, and phosphates had removal efficiency of almost 100%; microbiological colonies were all eradicated | Use of aluminum and graphite electrode combination proved to be effective during the EC process | Water from 3 different sections of poultry SWW was used (defeathering, evisceration, cooling) and tested separately; removal of nitrates was only 71% for evisceration water | [118] |

| Combined AOP system: UV-C/H2O2–VUV system | Optimum conditions to achieve TOC removal of 46.19% and minimum H2O2 residual of 1.05% were TOCo of 213 mg/L, H2O2 of 450 mg/L, and irradiation time of 9 min | Maximize TOC removal while minimizing H2O2 residuals; experimental results matched response surface methodology modeling | Biological treatment must be considered prior to the use of the UV-C/H2O2–VUV system, especially at TOC concentrations higher than 350 mg/L | [116] |

| Combined system: anerobic digestion followed by solar photoelectro-Fenton (SPEF) process | Combination of processes produced a mineralized, clarified, odorless effluent, without TSS and with a COD removal of 97% | Almost complete mineralization was achieved with a high efficiency; uses UV radiation from the sun | Methane production is low compared to previously reported values | [114] |

| UV/H2O2 with recycle | TOC removal of 81% and a minimum H2O2 residual <2% found at 24 mg/L influent TOC, 860 mg/L influent H2O2 concentration, 15 mL/min flow rate, and 0.18 recycle ratio | Experimental results matched response surface methodology modelling; recycle ratio is found to be significant in minimizing the H2O2 residual | Conditions must be optimized: as the influent TOC concentration increases, the percent TOC removal decreases. Conversely, there is an optimum influent TOC concentration value at which the H2O2 residual is minimum | [120] |

| Electro-Fenton | Optimum conditions found at pH of 4.38, reaction time of 55.60 min, H2O2/Fe2+ molar ratio of 3.73, current density of 74.07 mA/cm2, volume ratio of H2O2/PSW of 1.63 mL/L for 92.37% COD removal | Electro-Fenton method advantages include large amount of pollutant removal, small amount of sludge production, short reaction time, easy operation, low energy consumption; real SWW used in experiments | Optimal conditions required for different pollutants | [121] |

| Combined system: anaerobic baffled reactor, aerobic AS reactor, and a UV/H2O2 photoreactor with recycle in continuous mode at laboratory scale | TOC and TN removals of 91.29 and 86.05%, respectively, maximum CH4 yield of 55.72%, and minimum H2O2 residual of 1.45% in the photoreactor effluent were found at optimal operating conditions | Actual SWW used in experiment | The minimum total retention time was determined to be 10 h with individual residence times of 6.82 h, 2.40 h, and 47 min in the ABR, AS bioreactor, and UV/H2O2 photoreactor | [122] |

| Combined system: anaerobic digestion and photodegradation | Achieved > 92% removal of the aromatic compounds, color, TOC, and COD; anaerobic digestion as a stand-alone process removed up to 80% COD; photodegradation, as a post-treatment to the AD, removed 92% of the aromatic compounds | BMP could supplement up to 20% of the electricity requirement by the energy-intensive photodegradation process; AD process was also able to remove the FOG and color | AD and photodegradation were not found to have great results when tested as standalone treatments—needs to be used as combined system; photocatalysis is considered energy-intensive | [115] |

| Fenton process with ultrasound | Optimum conditions were pH = 3, hydrogen peroxide concentration 90 mg L−1, and a nail unit (2.7 g); in these conditions, color, turbidity, COD, and BOD5 removal of 98, 98.2, 84.6, and 98%, respectively, were achieved. | Higher removal of organic load and nutrients in a shorter time when compared with biological systems; uses recycled nails as iron sources for the ultrasound-assisted Fenton process | Removal efficiency decreases as the pH increases; oils and grease removal was only 70% for ultrasound-assisted Fenton process | [113] |

| Combined system: upflow anaerobic sludge blanket reactor and AOP | UASB removal efficiency of TCOD and phosphate were 62.2% and 36.5%, respectively; combined method removed CODt and phosphate up to 98.6% and 90.5%, respectively | Fenton process indicates an appropriate performance in removing CODt and phosphate; can remove up to 99.3% turbidity | Long initial set-up for UASB reactor to stabilize conditions for use (120 days for biomass growth and 30 more days to be stabilized); requires acidic conditions and optimal dose of H2O2 | [117] |

| Combined system: semicontinuous upflow anaerobic sludge blanket (UASB) reactor and solar photoelectron-Fenton (SPEF) | UASB reactor achieved up to 70% COD removal for the highest organic loading rate of 8.15 g COD L−1 d−1 | SPEF is less costly; proposed semicontinuous processes eliminate at least 91% of the total COD | Low efficiency of suspended solid removal in anaerobic digestor; variable range of removable in combined process | [123] |

| AOPS with hydrogen peroxide and potassium persulfate as oxidants | 74% TOC removal with UV/H2O2; 85% TOC removal with UV/K2S2O8 | Effluent quality of UV/K2S2O8 treatment was below discharge limits | Pilot scale testing needed to determine feasibility of UV/K2S2O8 treatment at a larger scale | [124] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ng, M.; Dalhatou, S.; Wilson, J.; Kamdem, B.P.; Temitope, M.B.; Paumo, H.K.; Djelal, H.; Assadi, A.A.; Nguyen-Tri, P.; Kane, A. Characterization of Slaughterhouse Wastewater and Development of Treatment Techniques: A Review. Processes 2022, 10, 1300. https://doi.org/10.3390/pr10071300

Ng M, Dalhatou S, Wilson J, Kamdem BP, Temitope MB, Paumo HK, Djelal H, Assadi AA, Nguyen-Tri P, Kane A. Characterization of Slaughterhouse Wastewater and Development of Treatment Techniques: A Review. Processes. 2022; 10(7):1300. https://doi.org/10.3390/pr10071300

Chicago/Turabian StyleNg, Mary, Sadou Dalhatou, Jessica Wilson, Boniface Pone Kamdem, Mercy Bankole Temitope, Hugues Kamdem Paumo, Hayet Djelal, Aymen Amine Assadi, Phuong Nguyen-Tri, and Abdoulaye Kane. 2022. "Characterization of Slaughterhouse Wastewater and Development of Treatment Techniques: A Review" Processes 10, no. 7: 1300. https://doi.org/10.3390/pr10071300