Abstract

Liquefied natural gas (LNG), as cleaner transitional energy than coal, is becoming increasingly prominent in the energy structure of various countries based on their low-carbon background, and its demand has grown rapidly worldwide. Storage tanks are the most commonly used LNG storage facilities. Owing to a variety of internal composition and external environmental factors, the instability phenomenon of LNG in the tanks may occur during storage, leading to potential safety risks. An in-depth understanding of the stratification and rollover behavior of LNG is therefore required to ensure and promote efficient utilization and stable storage of LNG. This paper provides a comprehensive review of the current state of LNG stratification and rollover behavior. The factors for causing LNG stratification and rollover behavior in the storage tanks are summarized, methods for characterizing stratification and rollover behavior are discussed, and measures for inhibiting the instability phenomenon of LNG in the tanks are highlighted. Future researchers should conduct further work in enriching the factors affecting the stratification and rollover behavior, improving characterization methods, and developing inhibition measures to ensure the safe and stable storage of LNG.

1. Introduction

With the implementation of carbon peaking and carbon neutrality policies, the energy structure dominated by fossil fuels is shifting [1,2,3]. It is urgent to find some sustainable energy to cope with the long-term controversy of its enormous energy consumption, aiming to achieve the goal of low carbon [4,5]. Natural gas (NG) plays an increasingly important role in countries’ energy systems due to its characteristics of large reserves, less pollution, and efficient conversion [6,7,8]. Liquefied natural gas (LNG) refers to the low-temperature liquid mixture of hydrocarbon and non-hydrocarbon by the cryogenic freezing process at −162 °C after pre-treating NG and removing impurities, which has a volume around 1/600 that of the natural gas at room temperature [9,10,11]. The liquefaction of natural gas is not only conducive to the efficient storage of natural gas but also provides a safer and more economical way for natural gas transportation [12,13,14]. As a consequence, the industry is accelerating to meet the global utilization of LNG, and global LNG demand is expected to grow by 45% by 2040 [15].

The increased demand for LNG has contributed to the multiplication of production sites and the innovation of production processes, as well as to the diversification of LNG composition and density [16,17,18]. However, there are clear requirements for the composition of the gas produced from the natural gas source, and according to the European standard EN 1160, LNG should have a methane content of more than 75% and a nitrogen content of less than 5% [19,20,21]. In order to give full play to the utilization value of the available facilities [22], the storage of LNG from different sources in the same storage tank could be considered [23,24]. However, due to the different properties of the constituent LNGs, instability can occur when they are mixed for storage, which can lead to major safety concerns and accidents. Hundreds of such incidents have been reported over the last 50 years, but this number is still underestimated [25,26,27]. It is therefore vital that LNG instability incidents are fully investigated to ensure their safe storage.

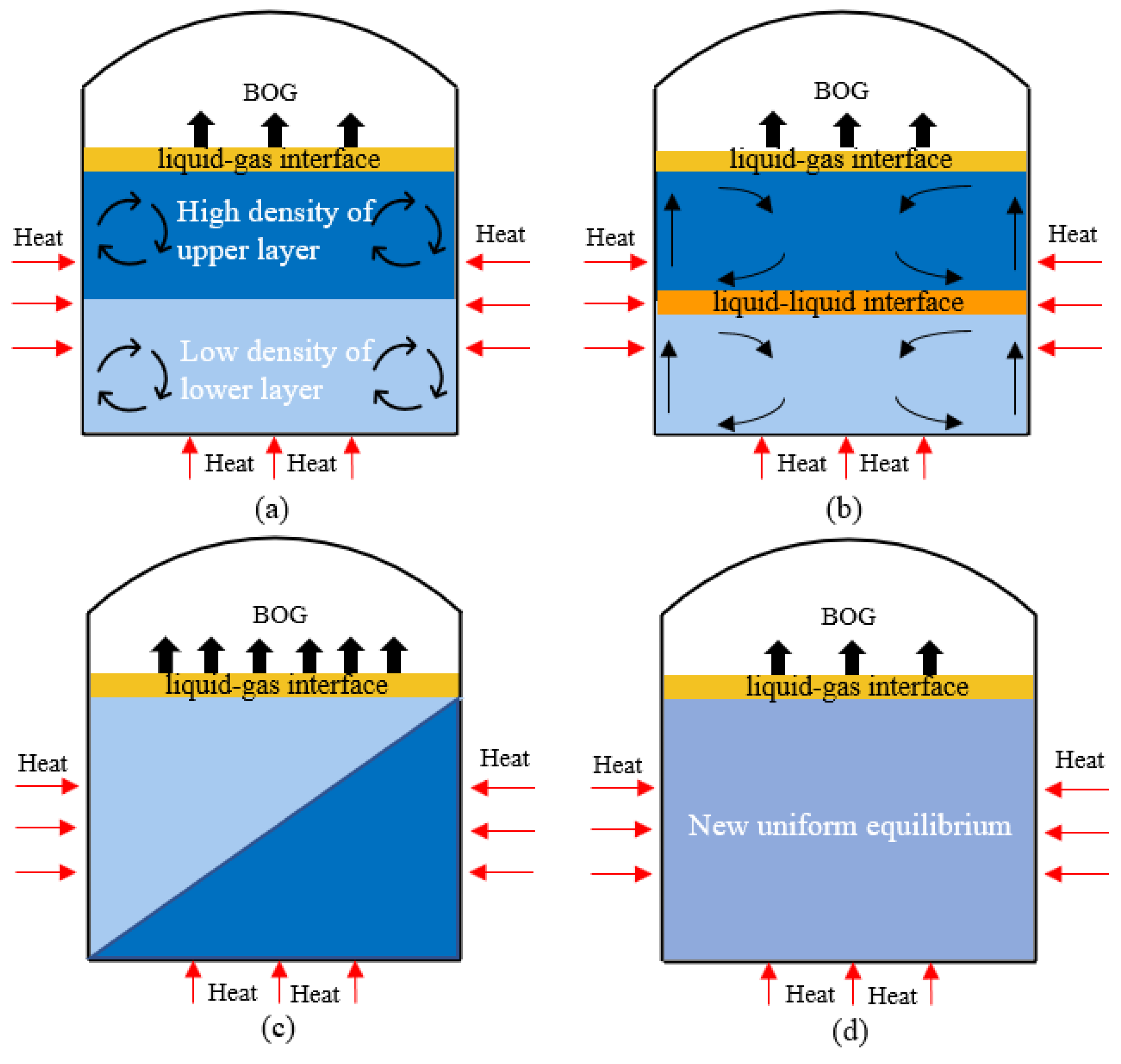

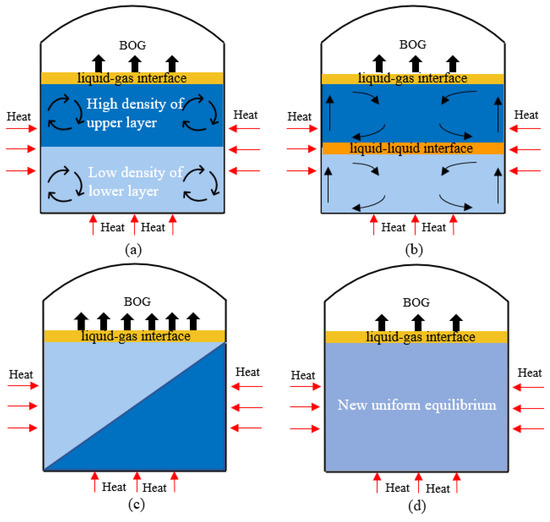

In the storage process of the LNG, stratification and rollover are the main factors causing instability in LNG storage tanks [28,29]. The LNG surface will continuously evaporate due to heat leakage in the storage tank, thus changing its original component, density, and temperature. The temperatures are slowly increasing, which eventually causes the lower layer density to decrease and the upper layer density to increase, and the LNG begins to stratify, as shown in Figure 1a. Then, the LNG in the lower layer of the storage tank cannot move to the gas–liquid partition interface to complete evaporation due to stratification, and the heat can only be transferred to the upper LNG with low density through the liquid–liquid interface. With the heat transfer and convection, the lower-layer LNG gradually becomes superheated; meanwhile, the density decreases. The bottom layer temperature rapidly rises to a maximum value and then drops, and the stratification gradually forms, as shown in Figure 1b. All accumulated superheat in the lower layer is then released from the free surface by evaporation, resulting in rapid mixing of the lower and upper LNG layers. The amount of boil-off gas increases abruptly and linearly reaches a maximum value and then gradually decreases. Other parameters, such as the temperature and density of the upper and lower layers, tend to stabilize at a specific value after a gradual convergence. The drastic change in parameters during this period is the biggest challenge faced by LNG storage tanks. This process is called LNG rollover as shown in Figure 1c. Finally, the LNG in the tank reached a new uniform equilibrium in temperature and density, as shown in Figure 1d [30,31]. Therefore, the prediction and control of instability problems during LNG tank storage are of great importance for the efficient and safe use of LNG.

Figure 1.

LNG stratification and rollover mechanism in the storage tank. (a) LNG stratification; (b) LNG interlayer penetration; (c) LNG rollover; (d) the new uniform equilibrium in temperature and density. This figure is adapted from [31].

In this paper, the current knowledge on the stratification and rollover behavior of LNG is reviewed. The factors affecting LNG stratification and rollover are summarized, the characterization methods of this behavior are discussed, and the measures to inhibit stratification and rollover are highlighted. This has positive significance and reference value for enriching the theoretical understanding of LNG instability and promoting the safe operation of large-scale LNG storage tanks in the terminal.

2. Factors Affecting Stratification and Rollover Behavior

2.1. Effect of Nitrogen Content

The components and properties of LNG produced from different gas sources vary, and there is a grading of the superiority and inferiority of the resource grade. There are clear international requirements for the nitrogen content of LNG production; otherwise, it will not only affect the calorific value of LNG after gasification but also have a driving effect on the occurrence of instability behaviors such as stratification and rollover. The preferential evaporation of nitrogen leads to a decrease in the density of LNG, which will no longer move back to the bottom of the tank but will remain at the gas–liquid interface, thus forming a thin liquid layer of lesser density and causing a stratification of the LNG in the tank. Włodek [32] compared the boil-off gas (BOG) generation with three types of LNG—light, heavy, and nitrogen-containing LNG (2.2% nitrogen)—at a fixed pressure of 1.3 bar. In his study, the nitrogen-containing LNG was first evaporated because it has a lower boiling temperature than the other two LNGs. This caused LNG stratification, which led to a rollover due to the density decrease in the surface of LNG. The results reveal that the nitrogen fraction in BOG was up to 40%, and this affected significantly the LNG parameters that could result in the stratification of LNG and eventually rollover.

2.2. Effect of Filling Method

When filling LNG liquid in the storage tank, the appropriate filling method should be selected according to the density difference between the filling liquid and the remaining liquid. When the filled liquid is close to the density of the residual liquid, the bottom filling way should be selected; when the density of the filled liquid is significantly greater than the residual liquid in the tank, the top filling way should be selected; when the density of the filled liquid is significantly less than the residual liquid in the tank, the bottom filling way should be selected. Pu et al. [33] investigated the effect of filling port velocity, height, length, angle, and pipe diameter on the delamination behavior by simulating them, and the results show that the optimal velocity is about 5 m/s. When the filling flow rate is certain, the filling port pipe diameter should be determined according to the optimal flow rate. When the lighter fluid is filled, the filling port angle is best at 0°, and a low filling port height is more profitable; when the heavy fluid is filled, the filling port angle is best in the range of 45°−60°.

2.3. Effect of Storage Tank Capacity

As the intermediate link between upstream and downstream, the LNG storage tank is the core facility of the terminal [34,35]. In order to meet the safe and stable operation of the terminal, storage tanks of different specifications are usually set to store and distribute LNG [24,27,36,37]. Unstable behavior, such as delamination and tumbling behavior, can occur in every type of tank capacity [38,39]. Most research that analyzes and predicts the stratification and rollover behavior is usually performed with fixed-capacity tanks, which cannot account for the effect of tank capacity on the LNG stratification and rollover behavior. In response to this deficiency, Cheng et al. [40] simulated the evolution of stratification and rollover behavior at 1000 m3, 1200 m3, 1400 m3, 1600 m3, and 1800 m3 tank capacities based on the mathematical model developed. It was found that the stratification and rollover phenomena calculated for different tank capacities were the same, but the time required for rollover was different for different tank capacities with different stratification density differences. The capacity of the tanks in this study was set at smaller intervals, and the differences in the generation of stratification and rollover phenomena were smaller. For this reason, Qu et al. [41] selected 5000 m3, 30,000 m3, and 160,000 m3 of the LNG storage tanks for investigation. It was found that the increase in tank capacity increased the number of vortices and enhanced the interaction between vortices. Therefore, under the same initial density difference, the larger the tank capacity, the worse the stability of LNG, and the smaller the critical density difference corresponding to tank rollover. This is attributed to the fact that the fluctuation has a slight interference on the flow field of a small capacity tank. However, this study is somewhat deficient in considering the duration of stratification and rollover that occur when storing LNG in other tank capacities. In addition, the effect of the aspect ratio of the tank on the stratification and rollover behavior is also a key factor to be considered in future research.

2.4. Effect of Heat Leakage

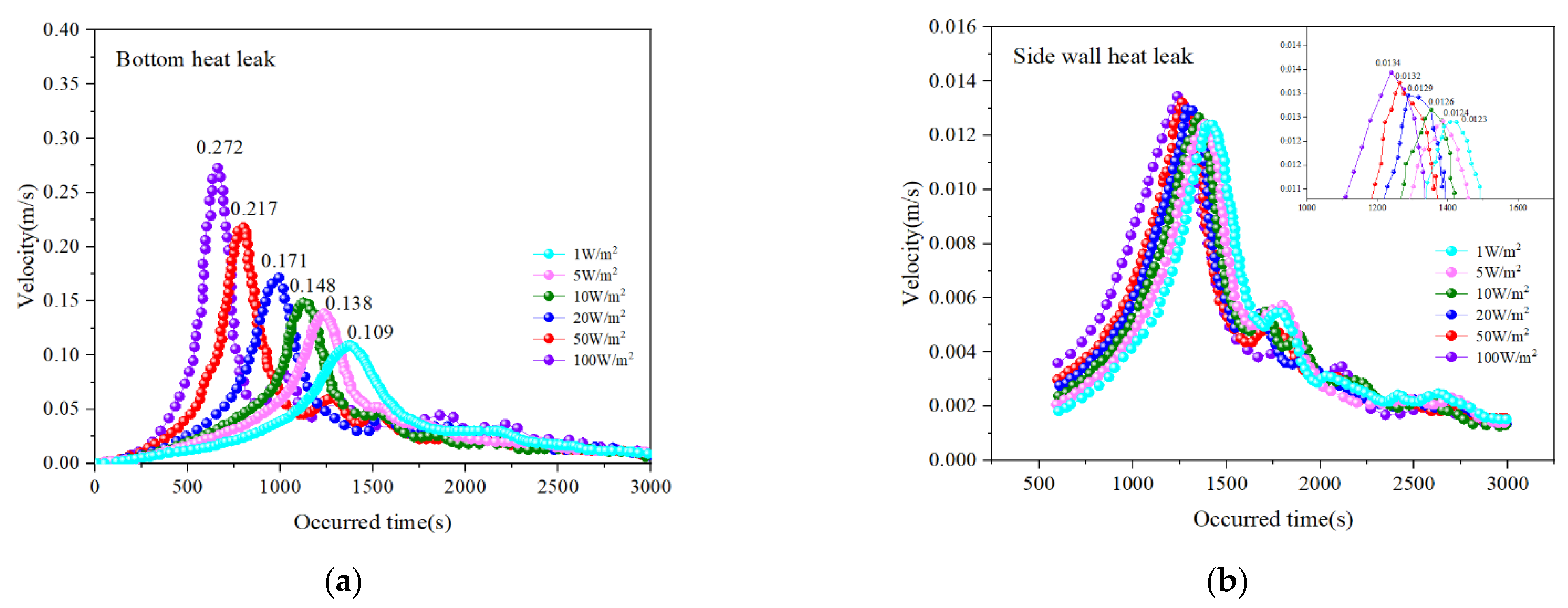

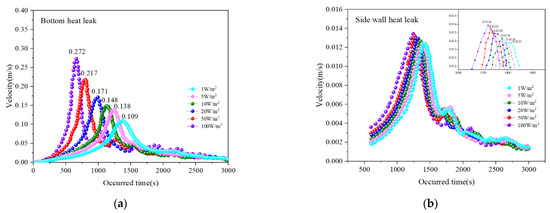

Heat leakage is one of the potential factors leading to the stratification and rollover phenomenon of LNG in storage tanks [42]. The main heat leakage of LNG storage tanks is concentrated at the bottom of the tanks, the heat leakage at the bottom of the tanks can even reach more than 49.06% of the total heat leakage, and for the same amount of heat leakage, the effect of heat leakage from the bottom of the tank on the stratification and rollover behavior is greater than that of heat leakage from the sidewalls of the tank [35,43]. Thus, some researchers have shown that, in comparison, the cold insulation performance of the tank wall and roof insulation components is better than that of the bottom cold insulation materials [44]. Li et al. [45] found through calculations and experiments that heat leakage from storage tanks can rapidly lead to thermal stratification of the liquid. In addition, they also confirmed that the heat leakage at the bottom of the tank was dominant compared to the heat leakage position of the sidewall, with the exception of the upper region of the liquid. However, the effect of heat leakage quantity variation was not considered in this study. Subsequently, Belmedani et al. [46] reported their experimental study of thermal stratification with varying heat leakage quantity to investigate the disturbance velocity and temperature distribution of LNG liquid in a low-temperature storage tank. It was found that high heat leakage quantity would lead to obvious thermal stratification and strong rollover. Based on the research of Li and Belmedani et al., and considering the change in the heat leakage position and heat leakage quantity, Wang et al. [31] used a 16 × 104 m3 LNG tank as a model (the tank diameter was 80 m, and the height of upper and lower liquid layers was 2 m, respectively) and neglected the effect of tank wall thickness. It was found that the effect of heat leakage at the bottom of the tank on the stratification and rollover behavior is greater than that of the tank wall by looking at the velocity at the interface monitoring points, which is the same as that of Li et al.; however, the overall effect of heat leakage from the tank sidewall became smaller as the heat leakage increased. Figure 2a,b show the vertical velocity at the interface monitoring points by numerical simulation, where the flow velocity at the monitoring points varied very little with increasing sidewall heat leakage and the time of rollover was similar.

Figure 2.

Effect of heat leak at the bottom (a) and the side wall (b) on vertical velocity of interface monitoring points on the rollover process. This figure is adapted from [31].

2.5. Effect of Temperature Difference between Layers

Although the temperature difference between the wall of the LNG cryogenic storage and the liquid inside the tank has a great effect on the LNG stratification and rollover behavior, the effect of the temperature difference between layers cannot be ignored [47]. Sun et al. took into account the multi-component and variable physical properties of LNG and developed a model of a 16,000 m3 LNG storage tank to simulate the effect of the temperature difference between layers on stratification and rollover behavior [48]. The simulation results show that rollover occurred when the heat leakage at the bottom was 10 W/m2 and the temperature difference between the upper and lower layers was greater than 0.2 K; the larger the temperature difference, the easier and more intense the rollover was.

2.6. Effect of Layering Characteristics

In addition to the effect of tank capacity, heat leakage, and interlayer temperature difference on LNG stratification and rollover behavior, stratification characteristics also have a non-negligible effect on LNG instability [49,50,51]. Wang et al. [52] formulated a two-dimensional CFD model to study LNG stratification and rollover behavior. They concluded that the greater the stratification height, the greater the probability of rollover behavior and the more violent the rollover event. However, the static pressure effect was not considered in the model, and the effects of stratification density difference and the number of stratification layers were neglected. A CFD investigation of rollover in a 5000 m3 LNG storage tank was performed by Zakaria et al. [53] The initial density differences between the bottom and the top were set at 30, 15, and 7 kg/m3 to determine when the rollover behavior in the tank occurred. They found that the larger the initial density difference between the layers, the later the rollover. However, the evolutionary process between the stratified layers was not considered in the study, and the effect of the mixed-phase factors on the rollover was not considered in the model. Li et al. [54] introduced the rollover coefficient to characterize the intensity of rollover when studying the effect of stratification density difference on rollover behavior, which was a considerable contribution to the study of the rollover phenomenon. The actual situation showed that LNG from different batches and origins had different properties, and when new LNG liquids were filled into the storage tank, all of them formed multiple layers with different temperatures and densities. Bu et al. [55] synthesized the shortcomings of previous studies and further investigated the effect of the number of stratified layers on the rollover behavior and found that the evolutionary process of rollover of three-layered LNG structures was essentially the same as that of two-layered ones, which were divided into three stages. A slight difference was that when the three-layer LNG rollover ended, the liquid in the storage tank returned to a stable state, and the density difference of the liquid in the adjacent layers decreased, showing a structure of light at the top and heavy at the bottom. Under the same storage tank conditions, the speed of the upper interface and the lower interface of the three layers with the same density difference was greater than that of the two layers. Furthermore, the mixing process between the three layers was a little more complicated than between the two layers, and the whole rollover process took a relatively long time.

3. Characterization of Stratification and Rollover Behavior

The characterization of LNG stratification and rollover behavior is usually performed by theoretical models, experimental studies, and numerical simulations, and some common understandings to investigate the LNG stratification and rollover occurrence time, criticality relationships, and evolution law have also been developed [27,34,56].

3.1. Theoretical Model of Stratification and Rollover Behavior

The stratification and rollover of LNG as a complex and dangerous phenomenon has been troubling for workers. Several model studies have been implemented to better characterize this behavior. The theoretical model has undergone the development process of a two-stage model, three-stage model, and four-stage model.

3.1.1. C-G Model

In 1972, Chatterjee and Geist proposed the first theoretical model of LNG rollover [57]. The LNG and BOG in this model were considered to be a mixture of methane, ethane, and nitrogen. The study results show that the severity of rollover increased with the increase of density difference between layers. Many scholars have improved on this model, but most of these models used two-component diffusion and assumed that the layered interface did not move during the rollover process, which differed greatly from the actual situation.

3.1.2. HSM Model

The model proposed by Heestad, Shipman, and Meader was based on the C-G model [58]. It was assumed that the LNG in the storage tank was divided into n-liquid layers, and the components of LNG were divided into methane, ethane, propane, n-butane, and nitrogen. However, all these models also used two-component diffusion and assumed that the stratification interface did not move during the rollover process, ignoring the internal motion condition of the liquid-phase fluid and the parameter distribution, which limited the accuracy of the model. The established model is as follows:

- (1)

- Bottom floor

Mass conservation equation:

Energy conservation equation:

- (2)

- i = 2nd floor to n − 1 floor

Mass conservation equation:

Energy conservation equation:

- (3)

- Top floor

Mass conservation equation:

Energy conservation equation:

where is the mole fraction of component j transferred from the bottom layer to layer i; is the liquid-phase mole fraction of component j in layer i; is the mass flow rate transmitted from the bottom layer to the i layer; is the flow rate of bottom liquid reflux; is the molar concentration of layer i liquid; is the molar heat capacity of layer i liquid; is the turbulent mass transfer coefficient of components between i and i + 1 layers; is the heat transfer coefficient of the interface between liquid layer i and i + 1; D is the diffusion coefficient; is the temperature at which the bottom liquid reaches layer i; is the temperature when the liquid-phase enthalpy of the substance is zero, taken as 99.82 K; is the evaporation rate at the gas–liquid interface; is the mole fraction of component j in the gas phase; is the heat leakage flux at the tank bottom; is the heat leakage flux of the tank top; is the heat leakage flux from the tank wall to the liquid phase; is the heat leakage flux from the tank wall to the gas phase; is the enthalpy of evaporation; Q is the total heat transfer rate from the environment to the gas phase; is the thickness of the ith layer of liquid; A is the cross-sectional area of the storage tank.

3.1.3. Bates–Morrison Model

In the three-stage model, the stratification and tumbling process of LNG is divided into three stages: fixed interface stage, mobile interface stage, and rollover stage. Bates–Morrison model divided the LNG in the storage tank into upper and lower layers based on the HSM model, and the fixed interface and moving interface stages before rollover were calculated, respectively [59]. This model simplified the fluid analysis process by reasonably extending the fixed partition interface to the partition interface movement case. Compared with the two-stage model, the model was greatly improved and represented the latest achievement and highest level of research on stratification and rollover phenomenon abroad, but it ignored the effect of evaporation rate on the results.

(1) The first stage of stratification: fixed interface stage

The mass and energy diffusion equation of LNG upper layer in the storage tank:

where u and l are the upper and lower layers of LNG liquid stratification in the storage tank, Mol is the molar mass of LNG, A is a cross-sectional area, yi and xi are mole fractions of component i in LNG in upper and lower layers, h and k are heat diffusion coefficient and mass diffusion coefficient, respectively, ΔT is the temperature difference between two LNG layers, and Vi is a mole fraction of component i evaporated.

(2) The second stage of stratification: interface moving stage

In this stage, diffusion convection and entrainment are present between the two layers of LNG in the storage tank. In the model, assuming that the upper liquid is carried to the lower layer, the formula of density difference and temperature difference between the upper and lower layers at this stage is as follows:

where ρ is liquid density, uu is the speed at which the sub-interface moves upward when only the entrainment from the upper layer to the lower layer occurs, ul is the speed at which the interface moves downward when only the entrainment from the upper layer to the lower layer occurs, hu and hl are the depth of upper and lower layers, C0 is the proportion of the liquid from the lower layer into the upper layer that remains in the upper layer without evaporation, and t is time.

3.1.4. Four-Stage Model

In the four-stage model, the stratification and rollover process of LNG is divided into four stages: fixed interface stage, upper layer entrainment lower layer stage, central jet penetration interface stage, and rollover stage. In China, Qin [60] made the following improvements based on the Bates–Morrison model.

(1) The effect of evaporation rate is considered in the calculation of upper layer density in the second stage:

(2) It is considered that the entrainment flow is independent of the movement of the upper layer and the lower layer and is only related to the characteristics of the disturbance at the interface and the density difference on both sides of the interface, and the layered interface should decrease rapidly.

If the velocity and radius of disturbance are U and L, respectively, and the dimensionless density difference is , dimensionless parameters can be defined .

When the dimensionless parameter Fr < Frc, Equation (11) is corrected as:

When the dimensionless parameter Fr > Frc, Equation (11) is corrected as:

The phenomena of interface accelerated decline and lower layer temperature decline in the moving interface stage are explained better in this model, and the analysis and planning of the stratification and rollover process in the storage tank are optimized. Gradually, the models of LNG stratification and rollover in storage tanks are systematized and theorized, which are closer to the actual situation, and the prediction of stratification and rollover phenomena of LNG in storage tanks is becoming increasingly accurate. However, the limitation of the theoretical models is that the evolution of the stratification and rollover phenomena in the tank cannot be shown directly and objectively.

In addition, Deshpande [61], Zhao [62], Wang [63], and Zhao [64] developed new models to predict and characterize LNG stratification and rollover behavior in storage tanks, and the models are summarized in Table 1.

Table 1.

Summary of LNG stratification and rollover model.

In Deshpande model, is layer thickness of the lower layer, m; is upper thickness of the upper layer, m; is molar flow rate from cargo to lower layer, kg·mol/s; A is cross-sectional area of the tank, m2; is turbulent mass transfer coefficient, kg·mol/m2/s; is mole fraction of species i in the bulk liquid phase in lower layer; is the mole fraction of species i in the bulk liquid phase in upper layer; is the average molecular weight of LNG in the lower layer, kg/kg·mol; is molar vapourization rate from the upper layer (boil-off rate), kg·mol/m2/s; is the average molecular weight of LNG in the upper layer, kg/kg·mol; is layer thickness of vapor space, m.

In the Zhao model, C is the heat capacity matrix; K is the heat conduction matrix; P is the temperature load array.

In the Wang model, x, y, b, and r are dimensionless parameters in which ; x is directly proportional to the intensity of convection; the same relationship exists between y and temperature difference; z is proportional to the distortion of the vertical temperature profile from linearity, a positive value indicating the strongest gradients near the boundaries; r is the ratio of and ; is the critical Rayleigh number .

In the Zhao model, A is the fluid mass matrix; B is the fluid stiffness matrix; F is the node load vector of a fluid element.

3.2. Experimental Study on Stratification and Rollover Behavior

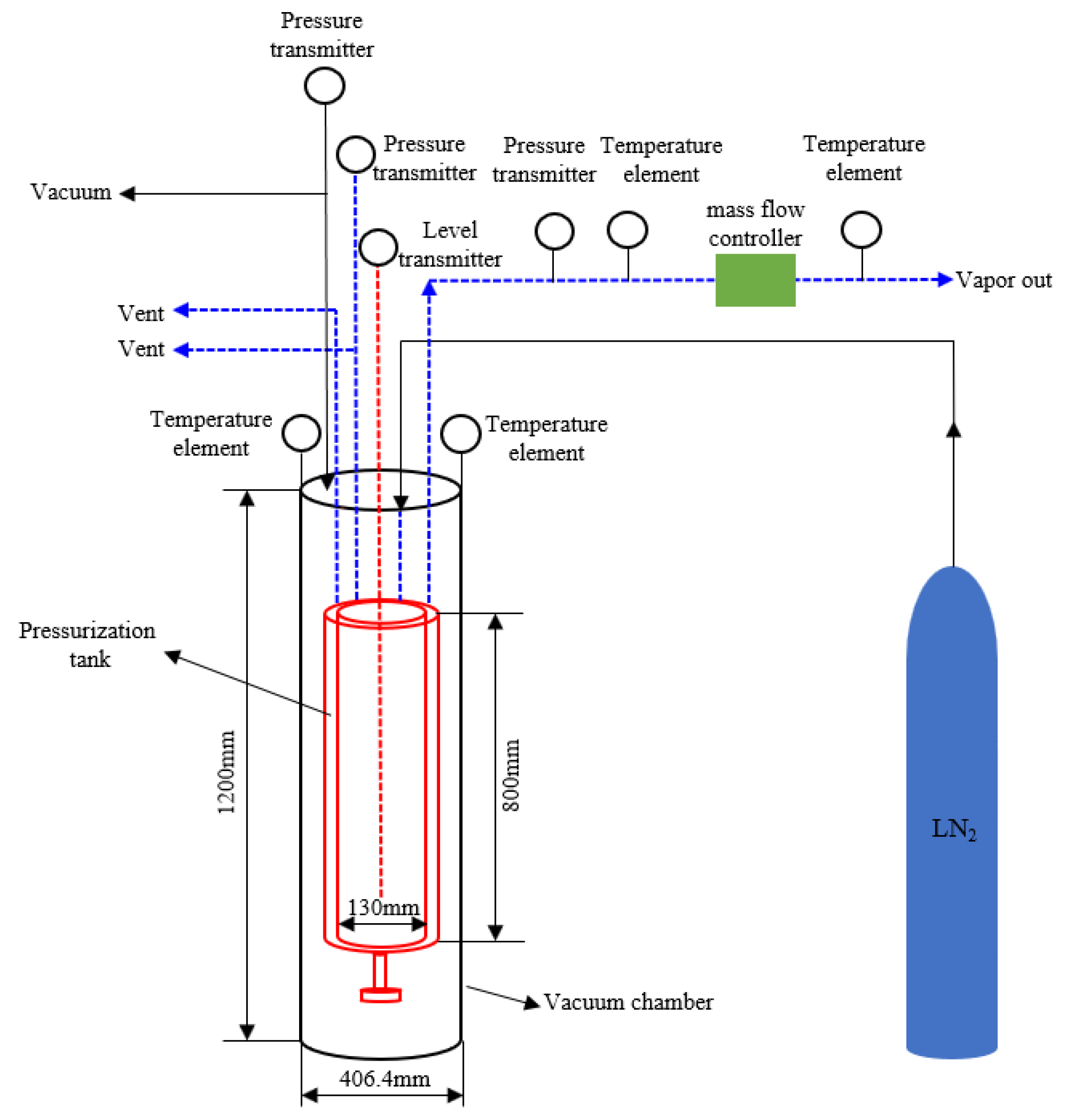

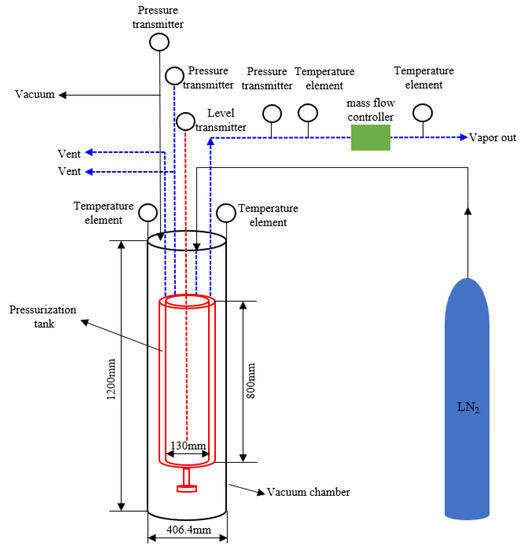

Theoretical models have been progressively improved, but they could not be predicted accurately for certain situations, and sometimes theoretical models could not reveal the actual stratification and rollover phenomena due to incomplete considerations [65]. The whole process of stratification and rollover can be characterized more visually through experimental studies. Sugawara et al. [66] studied the stratification and rollover phenomena of LNG from different gas sources in a 500 mm diameter tank. The results show that the temperature and components of both the upper and lower LNG layers changed with the convective motion of the respective layers, and the stratification interface decreased rapidly before the two liquid layers were completely mixed. The relationship between evaporation rate and fluid superheat was obtained by Muro et al. [67] using stratified liquids made of methane, ethane, and propane, which were experimented with in stainless steel vacuum storage tanks. Marcel et al. [68] carried out rollover experiments using abandoned LNG storage tanks, which demonstrated that the interface was essentially stationary at the initial stage of stratification, and the interface moved rapidly downward when rollover occurred. Munakata et al. [69] conducted experiments on cylindrical and rectangular gas storage tanks to investigate the effect of initial concentration difference on rollover time and found that the mixing strength and interface descent velocity of liquid in cylindrical storage tanks were large and the time was short. Shi et al. [70] conducted flow visualization and tracking experiments in a two-dimensional rectangular slot. A downward shift of the partition interface before rollover was found, and the greater the ratio of heat flow density between the bottom and sidewalls was, the greater the mixing strength of rollover. Kang et al. [71] performed experiments to analyze the thermodynamic behavior of the tank during stratification. The experimental setup is shown in Figure 3, which consisted of a pressurization tank, a vacuum chamber, a flow control system, a temperature detection system, and a pressure monitoring system. The aspect ratio was changed by controlling the air inlet. The thermal material used for the setup was SUS304. The vacuum chamber was 406.4 mm in diameter, 1200 mm in height, and 8 mm in thickness. The pressurization tank had an inner diameter of 130 mm, a height of 800 mm, and a thickness of 5.1 mm. The four tubes connected to the pressurization tank had internal diameters of 3/8 in. Among the four tubes, one was used to inject liquid nitrogen, and the rest emit gas. They found that the thermal stratification was significantly influenced by the thermal aspect ratio determined by the filling level of the storage tank, and the thermodynamic behaviors of a thermally stratified system were considerably different from those predicted by the homogeneous model. Therefore, the equipment designed based on the homogeneous model will be somewhat more conservative than necessary. Although the whole process of LNG stratification and rollover has been observed by previous experimental studies, it is difficult to analyze and reveal the microscopic evolution process in experiments.

Figure 3.

Schematic diagram of the experimental apparatus. This figure is adapted from [71].

3.3. Numerical Simulation of Stratification and Rollover Behavior

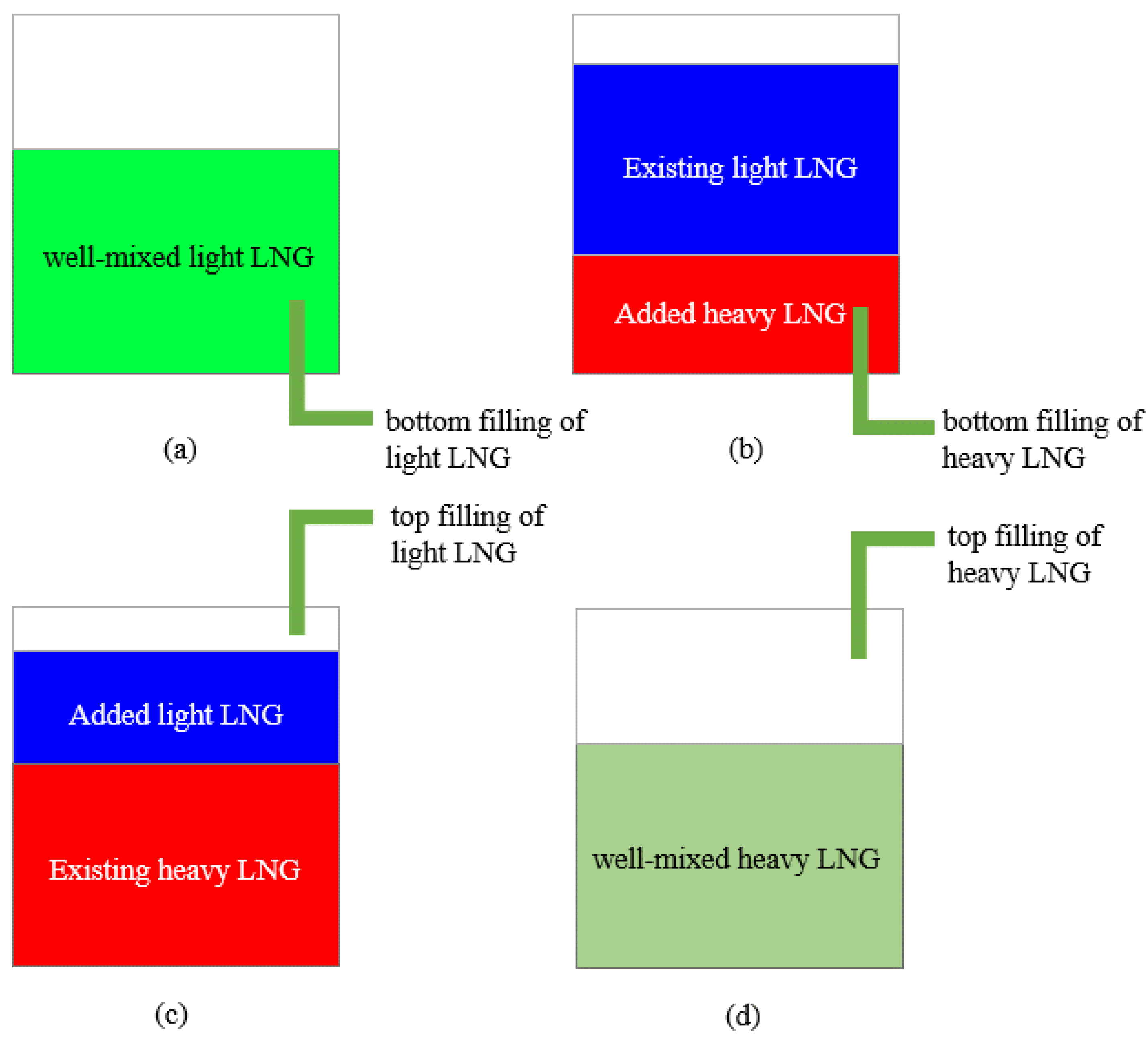

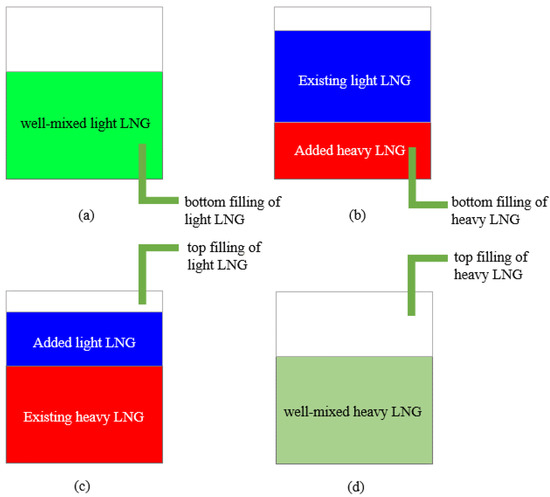

With the rapid development of computer technology, numerical simulation has become an effective method to calculate the heat and mass transfer of a large number of unstable and complex processes, which can make up for the shortcomings of theoretical models and macroscopic experiments. Saleem et al. [72] used ANSYS Fluent multiphase species migration model to simulate the conditions that produce stratification and the rollover phenomenon in the liquid-phase mainstream region of LNG after stratification. Figure 4a shows a no-stratification, well-mixed condition of existing LNG and lighter LNG filled from the bottom into an LNG tank. Figure 4d also shows a no-stratification, well-mixed mixture of existing LNG and heavier LNG filled from the top into an LNG tank. It was found that no stratification occurred for both filling light LNG from the bottom of the tank and filling heavy LNG from the top of the tank. Figure 4b shows stratified LNG layers in the LNG tank. The top layer was the existing light LNG layer. The bottom layer was the added layer of heavy LNG. Similarly, the phenomenon of stratified LNG layers in the LNG tank is shown in Figure 4c. The bottom layer was the existing heavy LNG layer. The top layer was added to the light LNG layer. It was found that these two conditions produced a more pronounced stratification in the LNG tank, which proves that when light LNG is present in the tank, the newly added light LNG is suitable for bottom filling. When heavy LNG is present in the tank, the newly added heavy LNG is suitable for top filling. Sha et al. [73] investigated the dynamic characteristics of the initial liquid-phase space during rollover of stratified multi-composition liquids and the inducing factors of instability by numerical simulations. The simulation results show that the stability of the whole liquid-phase space was drastically reduced by natural convection when heat leakage from the tank wall dominated. The instability in the central region was due to the density gradient caused by horizontal reciprocating flow and local backflow vortex, while the liquid-phase instability near the wall was due to the effect of high-temperature buoyancy flow. Furthermore, the stability of the liquid phase near the wall was found to be one to two orders of magnitude smaller than that in the central region. In this case, the rollover phenomenon would be a gradual rolling process over a short period of time, rather than an immediate mixing of the two layers.

Figure 4.

Density contours after 7 h of filling operation for a density difference of 2.5 kg/m3 between the heel and refilled LNG for (a) bottom filling of light LNG, (b) bottom filling of heavy LNG, (c) top filling of light LNG, and (d) top filling of heavy LNG. This figure is adapted from [72].

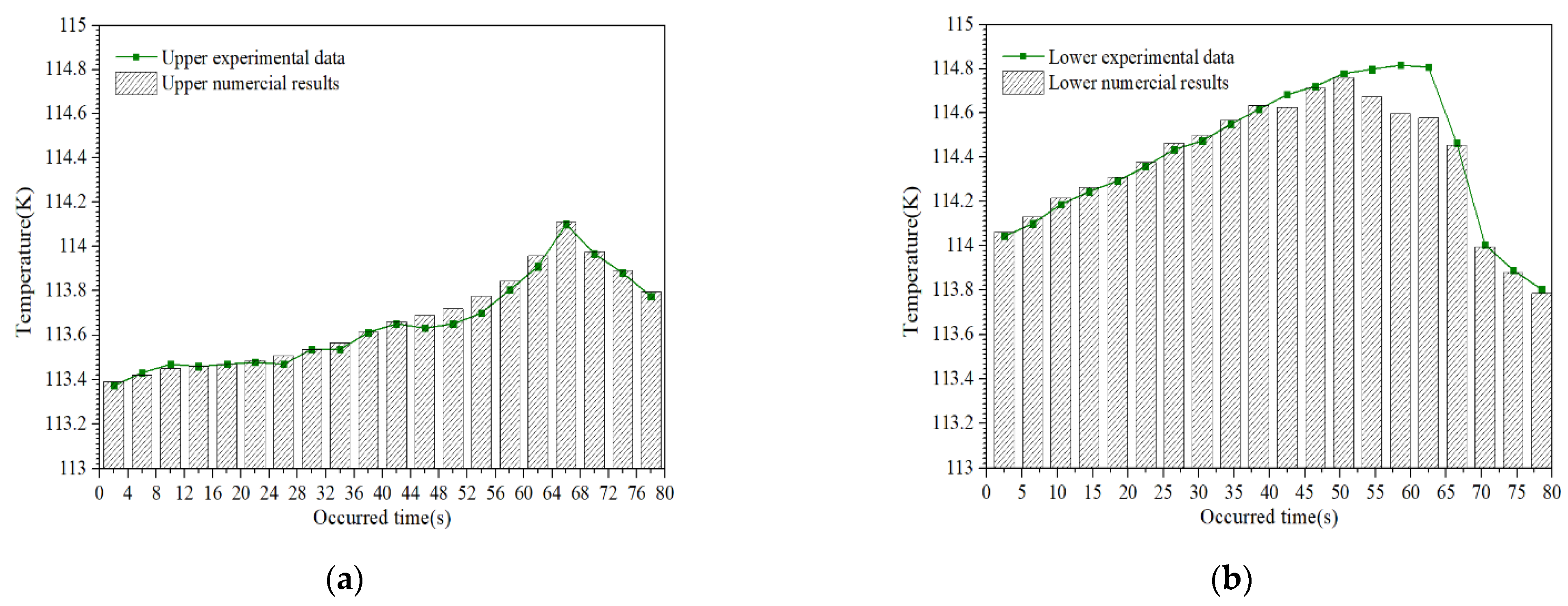

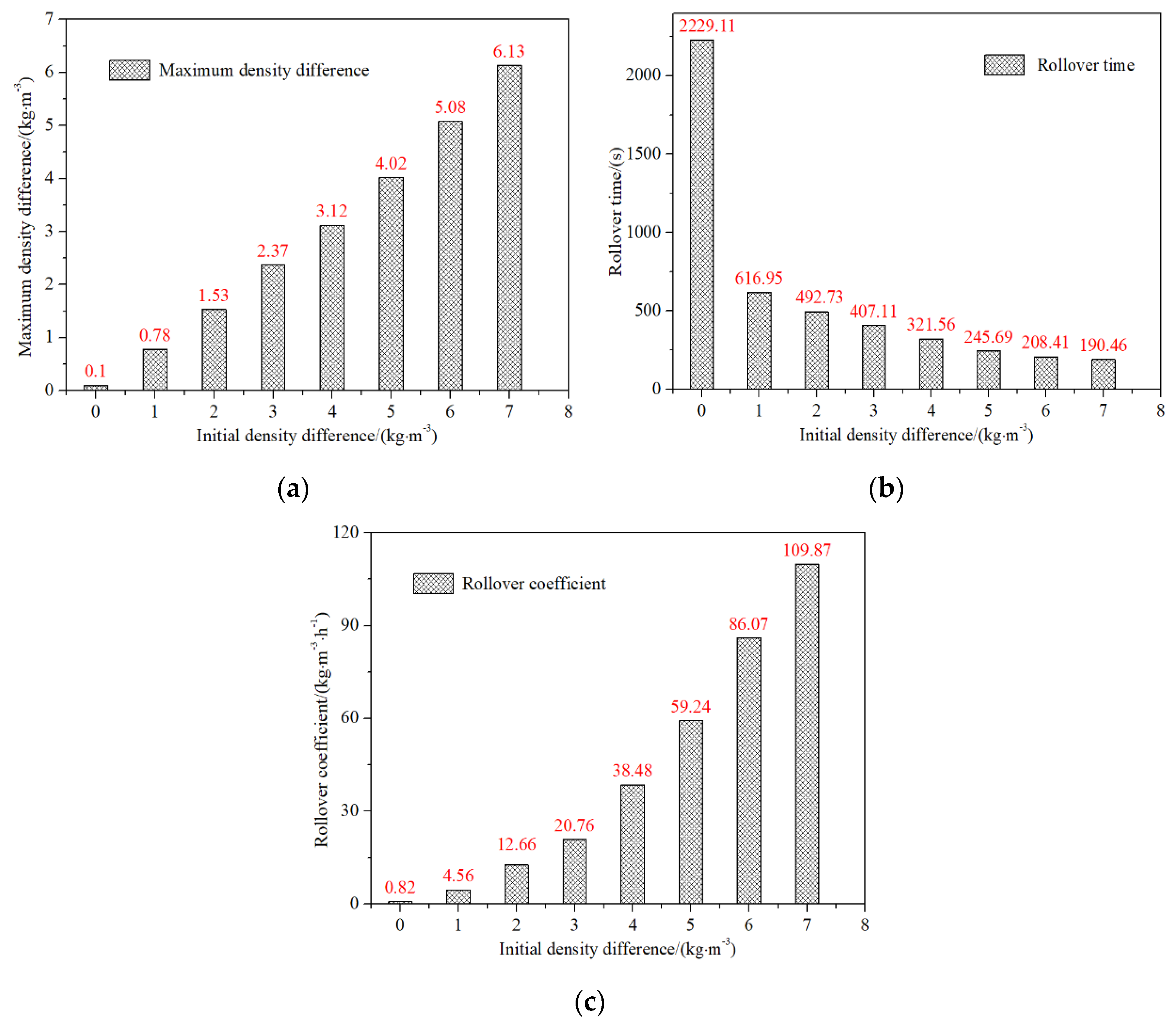

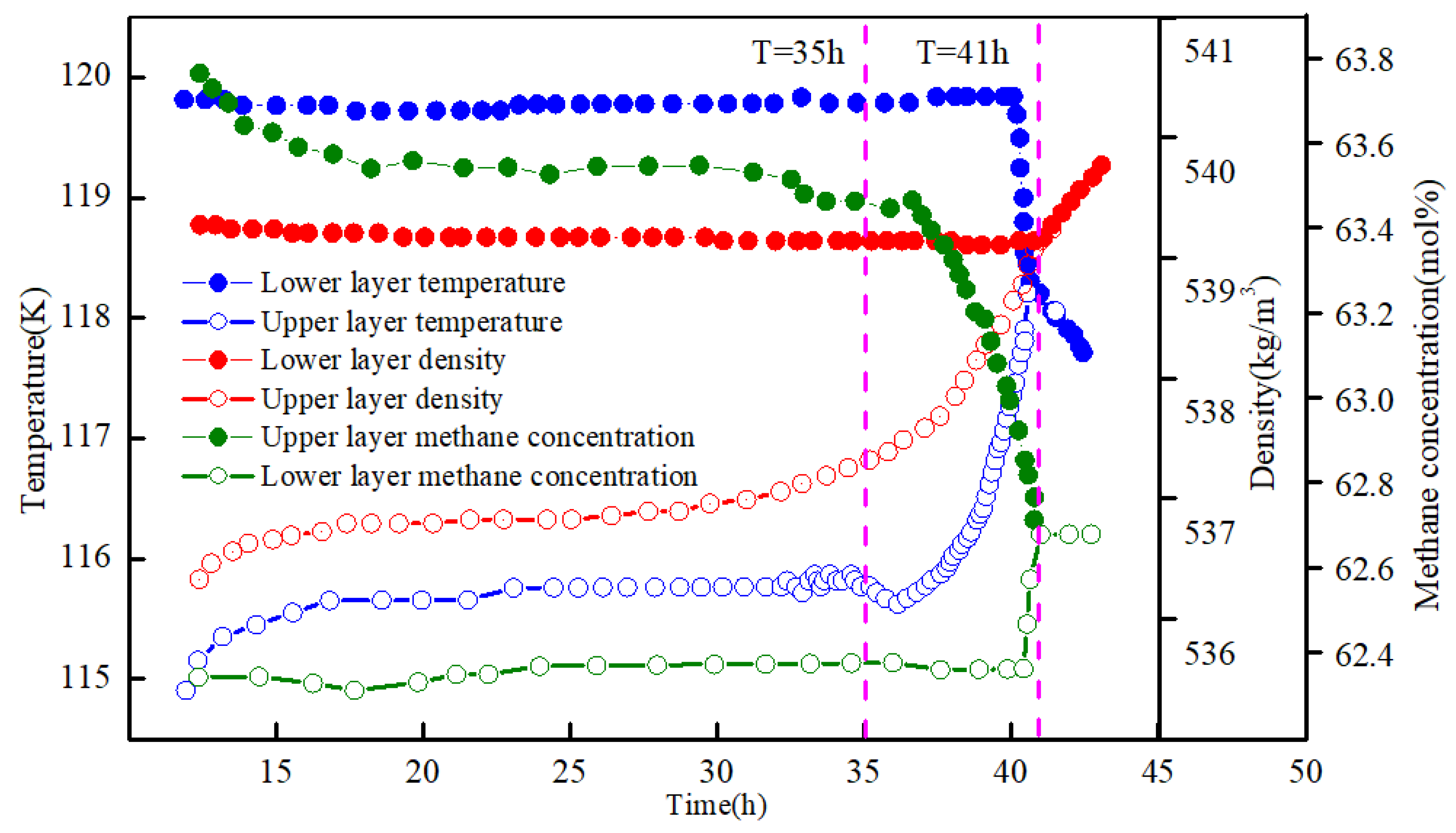

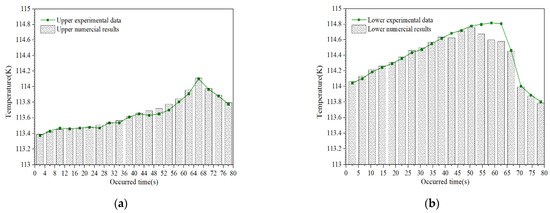

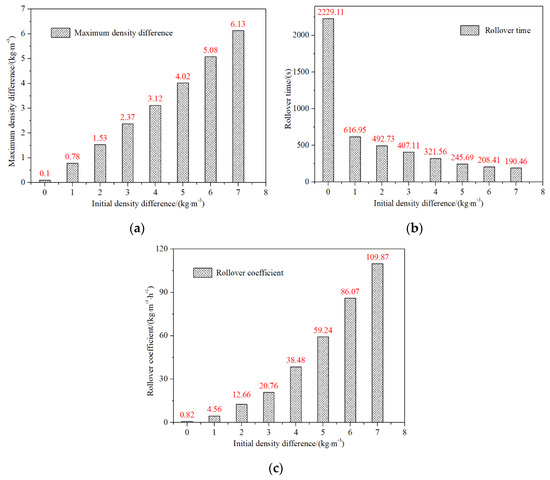

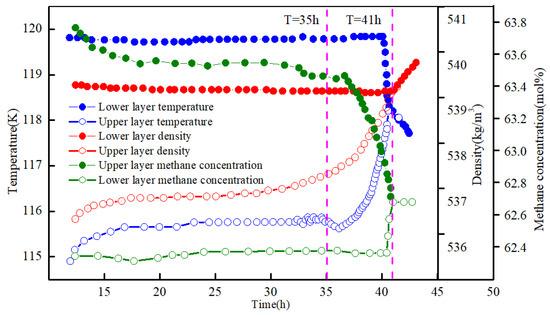

The experimental results were recreated using numerical simulations by Wang et al. [31]. The changes in the temperature field of the upper and lower layers during the stratification and rollover process were simulated, where the laboratory was conducted in an 80 L cylindrical glass tank. In the process of numerical simulation, the temperature and density of upper and lower layers were 113.3 K, 425.84 kg/m3 and 114.2 K, 424.53 kg/m3, respectively, the pressure in the tank was 0.2 MPa, the heat leakage at the bottom of the tank was 10 W/m2, the upper and lower layers were each 2 m, and the velocity was a no-slip condition. The results show that for the upper layer of liquid, the temperature raised continuously as the simulation time proceeded, and there was a decreasing trend at 66 s. The errors between the simulation results and experimental data were less than 5%. For the lower layer of liquid, the overall temperature was higher than the upper layer of liquid, and the temperature kept increasing with the simulation time, but the temperature decreased at 62.5 s in the experimental data, while the temperature decreased at 50 s in the simulation results, and the overall error between the experimental data and the simulation results was less than 6.8%, as shown in Figure 5. Bi et al. [74] used Fluent software to conduct numerical simulation on the rollover process of the main part of the LNG liquid phase in the storage tank under different initial density differences. It revealed the variation law of rollover in the LNG storage tank with the initial density difference, and the critical density difference area of 160,000 m3 storage tank was 2–4 kg/m3 by calculation. As can be seen from Figure 6a,b, with the increase in the initial density difference, the maximum density difference in the rollover process gradually increased in a linear relationship, and the rollover time gradually decreased. The rollover coefficient, which can be used as the standard of LNG rollover strength in the tank, was defined and was obtained by dividing the absolute value of the difference between the maximum density difference and the initial density difference during the rollover process by the rollover time. The rollover coefficient was positively correlated with the intensity of rollover. Moreover, in the range of initial density difference of 0–2 kg/m3, the rollover coefficient varied in a small range, and when the initial density difference was greater than 4 kg/m3, the rollover coefficient increased significantly, indicating that the degree of rollover is more violent; therefore, it can be considered that the initial density difference of 2–4 kg/m3 is a turning zone for the violent increase in rollover intensity, that is, the critical region of density difference, as shown in Figure 6c. Cheng et al. [40] used numerical simulation to analyze the effects of environmental heat leakage, the relative position of stratification, density difference, and tank volume on stratification and rollover. The simulation results reflect that when the heat leakage intensity was small, the rollover time was significantly shortened with the increase in heat leakage. When the heat leakage intensity exceeded a certain value, increasing the heat leakage intensity did not obviously affect the time of the rollover. The main liquid-phase area of LNG with upper heavy and lower light structure would first adjust the stratification position and then roll under the condition of heat leakage of the storage tank; therefore, the time required to reach the rollover was longer than that of upper light and lower heavy structure. Hubert et al. [75] developed a special solver within the framework of the open-source CFD toolbox OpenFOAM to predict the rollover process in the main liquid phase. The developed solver was used to predict the famous rollover accident of the La Spezia LNG storage tank. The simulation results are presented in Figure 7. It can be seen from the figure that at 35 h, the temperature and density of the lower liquid started to change with an increasing trend, while the methane concentration in the lower liquid started to decrease, which indicated that the rollover occurred at this time. From 35 h to 41 h, the phenomenon of rollover occurred most significantly at this time, and violent movements occurred between the upper and lower liquids. When the time was 41 h, the temperature, density, and methane concentration of the upper and lower liquids reached an equilibrium value, which was the end of the rollover phenomenon and the uniform mixing between the layers. The simulated prediction results are 12.5% higher than the actual rollover time, but lower than 15%, indicating the accuracy of the developed special solver for the rollover phenomenon. Compared with the experimental data, the proposed numerical method had a better prediction effect.

Figure 5.

Comparison between the numerical results and experimental data. (a) Upper layer; (b) lower layer. This figure is adapted from [31].

Figure 6.

Relation of maximum density difference, rollover time, and rollover coefficient of the storage tank with initial density difference. (a) Maximum density difference; (b) rollover time; (c) rollover coefficient. This figure is adapted from [74].

Figure 7.

Variations of temperatures, methane concentrations, and densities during La Spezia incident. This figure is adapted from [75].

4. Inhibition of Stratification and Rollover Behavior

4.1. Construction and Operation of Storage Tanks

The construction and operation of LNG storage tanks is the foundation of the entire LNG terminal and plays a pivotal role in the whole project [76,77]. Suitable storage tank construction is the initial step in inhibiting stratification and rollover behavior [78,79]. When designing and constructing LNG storage tanks, the construction of the foundation and rigid structure of the tank should be carried out in strict accordance with the available standards and specifications [80,81,82], and the maximum local ambient temperature should be taken into account as far as possible when calculating the cold insulation performance of the storage tanks so as to reserve sufficient margin for the safe storage time of the tanks, as reflected in Wang’s study [83]. Under the premise of the necessary infrastructure and structure, the cold insulation layer, as well as the thermal corner protection, should be carried out in strict accordance with the design. The construction should avoid the increase in thermal conductivity of the cold insulation layer caused by the entry of moisture, which has a direct impact on the stratification and rollover behavior in the storage tank. The selection of cold insulation materials is therefore crucial for the operation of LNG storage tanks. The selection of cold insulation materials shall meet the requirements of good cold insulation performance, small expansion coefficient, good moisture absorption, good water vapor permeability resistance, stable chemical properties, etc. Commonly used cold insulation materials include polyurethane foam, expanded perlite, foam glass block, elastic fiber mat, etc. Furthermore, the smooth operation of the storage tank is a significant part of ensuring the safe storage of LNG. It was found that the density difference of more than 0.5 kg/m3 and the temperature difference of more than 0.2 °C between two adjacent layers of LNG would cause stratification and rollover phenomenon in the research of Bi et al. [84]; thereby, the variations in pressure and temperature in the storage tank should be monitored in real-time.

4.2. Processing and Storage of LNG

The components and properties of LNG produced by different gas sources vary, and the grade of the resource is clearly graded [85,86]. There are clear international requirements for the components of the produced LNG. The nitrogen content in LNG should not exceed 1% [87]; otherwise, it will not only affect the calorific value of LNG after gasification but also have a driving effect on the occurrence of stratification and rollover behavior in the LNG storage tank [88]. In studying the effect of nitrogen content on stratification and rollover behavior, Arjomandnia et al. [89] investigated and found that the loss of nitrogen preferentially led to density differences between the layers. When the nitrogen content in LNG is too high, the liquid nitrogen will collect at the bottom of the storage tank under the effect of gravity, prompting the liquid to evolve toward stratification, which will affect the safe storage of LNG in the storage tank. Moreover, the density difference is the most important factor causing rollover, and the density of LNG varies from one gas source to another. Saleem et al. [72] found that for newly filled LNG, stratification and rollover occurred shortly afterward due to the difference in density from the previous old LNG; thus, the different gas source LNG should be separated during storage to diminish the stratification attributed to the density difference and avoid the rollover phenomenon.

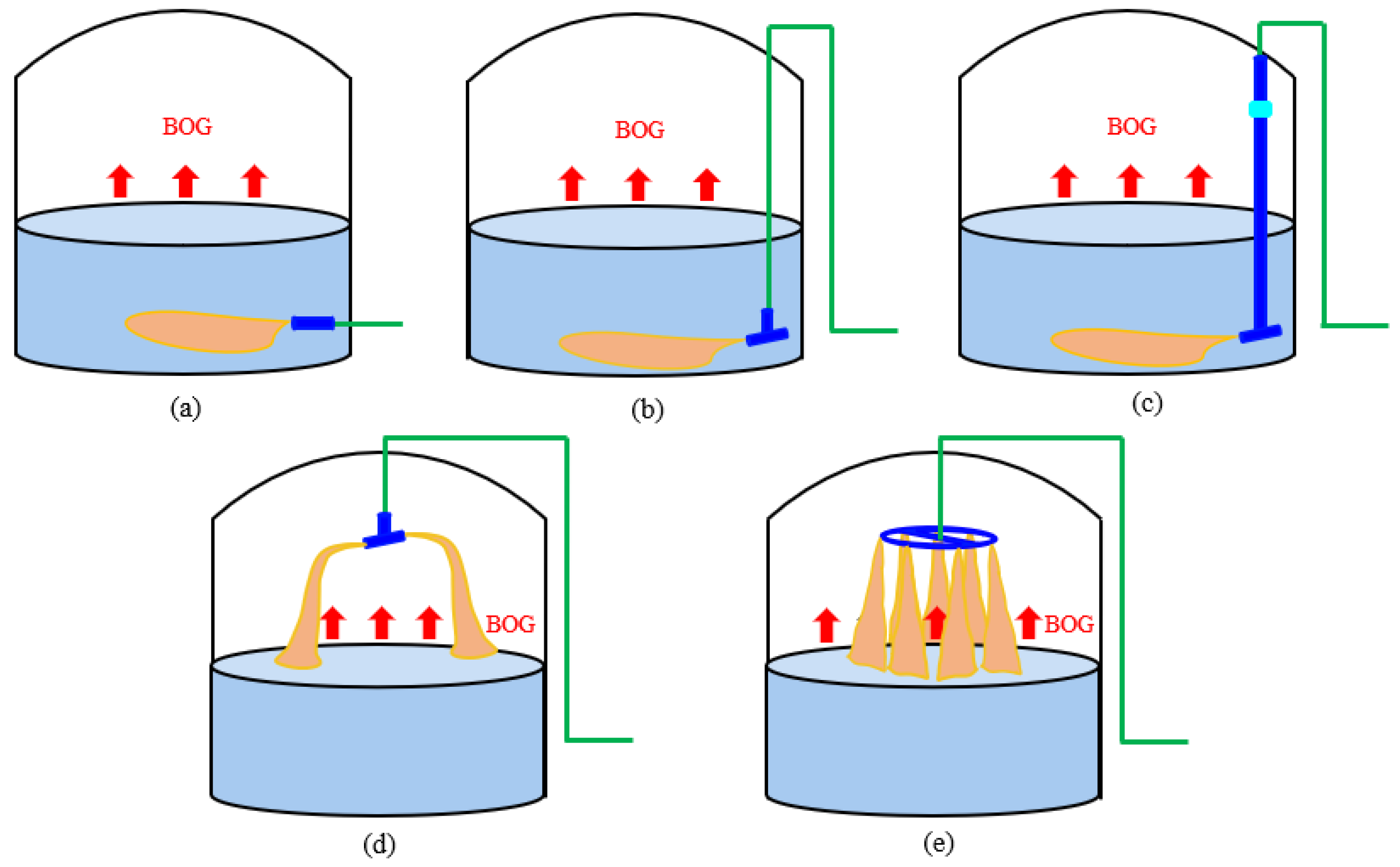

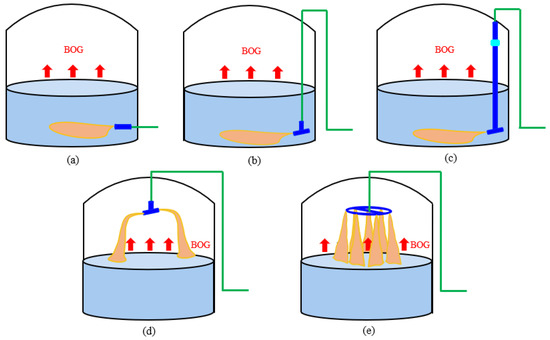

4.3. Filling Methods of LNG

When filling LNG liquid, the appropriate filling method should be selected according to the density difference between the liquid being filled and the residual liquid in the storage tank [90]. When the liquid filled is close to the density of the residual liquid, the bottom filling should be selected. When the density of the filling liquid is significantly greater than the residual liquid in the tank, the top filling should be recommended [91,92]. When the density of the filling liquid is significantly less than the residual liquid in the tank, the bottom filling should be used. Koyama et al. [93] investigated the process of filling storage tanks with LNG of different densities using a numerical model and concluded that the density difference caused by different filling methods could lead to potential stratification. It is worth noting that the filling rate of LNG storage tanks cannot be too large or too small, and the optimal filling volume should be chosen as much as possible to make full use of the tank volume for storage and to have a longer safe storage time, hence gaining more flexible operation time for full station operation. The following forms of LNG filling equipment are commonly used, as shown in Figure 8 [94]. For injecting less dense LNG liquids, the bottom horizontal radial-fill equipment and bottom T-fill equipment were more suitable, and they both injected lighter LNG liquids into the tank from the bottom, which could make the light LNG mix evenly with the existing LNG in the tank, and can reduce the occurrence of the rollover phenomenon. For injecting denser LNG liquids, it was more beneficial to choose top T-fill equipment and top ring-fill equipment, both of which injected the heavy LNG liquid on top of the existing LNG in the tank so that the two types of LNG could be mixed evenly. The occurrence of a rollover accident was effectively avoided.

Figure 8.

Commonly used LNG filling equipment types. (a) Horizontal radial-fill equipment; (b) bottom T-fill equipment; (c) bottom T-fill equipment with gas-phase funnel; (d) top T-fill equipment; (e) top ring-fill equipment. This figure is adapted from [94].

4.4. Circulation and Mixing of LNG in Storage Tanks

During the long-time storage of LNG, the static evaporation phenomenon will occur, which enhances the evaporated LNG gas and the pressure in the storage tank [95]. The gas generated from the storage tank should be re-liquefied together with the LNG liquid through the external recirculation equipment and sent back to the tank for storage [96,97]. Wu et al. [98] proposed to circulate the liquid in the tank by stirrers and mixing pumps to enhance the convection between LNG liquids in the tank, to diminish the density difference and temperature difference during the LNG storage process in time, and to prevent and eliminate the generation of stratification. Moreover, Zhang et al. [99] suggested the use of equipment such as mixing nozzles and porous tubes for LNG filling to make the liquid mix more uniformly, thus extending the time for safe storage of LNG in the storage tank.

5. Conclusions and Prospect

Stratification and rollover issues require special attention as one of the most common safety issues during LNG storage. This paper provides a comprehensive review of the progress of research on LNG stratification and rollover behavior in storage tanks. LNG storage tanks as the core equipment of receiving terminals are usually set with different tank capacities to meet the storage and distribution requirements, but the frequency and possibility of LNG destabilization at different tank capacities are different; therefore, the tank capacity also becomes one of the factors affecting LNG stratification and rollover behavior. The heat leakage from the storage tank is caused by the change in the cold-holding properties of the cold insulation components, which may allow the external heat to penetrate the cryogenic storage tank leading to stratification. After stratification, the temperature difference between the layers, the density difference between the layers, the height of the layers, and the number of layers also have a significant effect on driving the rollover behavior of LNG. In addition, the effect of the aspect ratio of the tank and the variation of the pressure inside the tank on the stratification and rollover behavior is something that needs to be further considered in future studies.

It has been a common practice for a long time to reveal and characterize LNG stratification and rollover behavior in storage tanks mainly by predictive models, experimental means, and numerical simulations. The general idea has been formed, and the analysis of influencing factors has been mutually certified by modeling, experiments, and numerical simulations, but the development and improvement of characterization means still need to be explored in more depth. In recent years, many scholars have used genetic algorithms and neural networks in combination to optimize neural networks using the global search function of genetic algorithms. Therefore, the development of multi-component liquid stratification and rollover neural network prediction models considering the factors affecting stratification and rollover will be a novel characterization tool in the future.

Instability accidents of LNG are becoming more frequent as the demand for clean energy increases, and the prevention and suppression of stratification and rollover behavior of LNG in storage tanks are critical for its safe storage. Commonly used measures to inhibit stratified rollover behavior are highlighted in this review, which includes construction and operation of storage tanks, processing, and storage of LNG, filling methods of LNG, circulation, and mixing of LNG in storage tanks. In the future, more inhibition measures should be developed to help the efficient utilization and storage safety of LNG. In particular, future work on stratification and rollover suppression measures should focus on real-time analysis of the spatial movement pattern of the gas phase in the tank, the establishment of an accident probability system, and automatic churning and emptying devices to determine and eliminate unstable behavior.

Author Contributions

Conceptualization, B.H. and J.L.; investigation and writing—original draft preparation, B.H. and J.L.; writing—review and editing, T.G. and S.F.; Supervision and project administration, C.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the “Basic scientific research business expenses of colleges and Universities”, SJQHB202102.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this review are available in article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pfoser, S.; Schauer, O.; Costa, Y. Acceptance of LNG as an alternative fuel: De-terminants and policy implications. Energy Policy 2018, 120, 259–267. [Google Scholar] [CrossRef]

- Schinas, O.; Butler, M. Feasibility and commercial considerations of LNG-fueled ships. Ocean Eng. 2016, 122, 84–96. [Google Scholar] [CrossRef]

- Song, H.Q.; Ou, X.M.; Yuan, J.H.; Yu, M.X.; Wang, C. Energy consumption and green-house gas emissions of diesel/LNG heavy-duty vehicle fleets in China based on a bottom-up model analysis. Energy 2017, 140, 966–978. [Google Scholar] [CrossRef]

- Hekkert, M.P.; Hendriks, F.H.J.F.; Faaij, A.P.C.; Neelis, M.L. Natural gas as an alternative to crude oil in automotive fuel chains well-to-wheel analysis and transition strategy development. Energy Policy 2005, 33, 579–594. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, B.; Liu, T. Tech-Economic Assessment of Power Transmission Options for Large-Scale Offshore Wind Farms in China. Processes 2022, 10, 979. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.J.; Jia, W.L.; Wang, K. Study on the Heat Transfer Characteristics of an Ambient Air Vaporizer with Multi-Component Fluids. Processes 2022, 10, 851. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Xiang, L.M.; Dubey, S.; Choo, F.H.; Duan, F. Cold utilization systems of LNG: A review. Renew. Sustain. Energy Rev. 2017, 79, 1171–1188. [Google Scholar] [CrossRef]

- Park, C.; Lee, C.-J.; Lim, Y.; Lee, S.; Han, C. Optimization of recirculation operating in liquefied natural gas receiving terminal. J. Taiwan Inst. Chem. Eng. 2010, 41, 482–491. [Google Scholar] [CrossRef]

- Hairuddin, A.A.; Yusaf, T.; Wandel, A.P. A review of hydrogen and natural gas addition in diesel HCCI engines. Renew. Sustain. Energy Rev. 2014, 32, 739–761. [Google Scholar] [CrossRef]

- Yang, L.N.; Han, J.K.; Wang, N.Y. Development situation of LNG terminals in China. Oil Gas Storage Transp. 2016, 11, 1148–1153. [Google Scholar]

- Sun, Z.G. Natural gas storage and transportation technology and its application and development prospect. Oil Gas Storage Transp. 2006, 25, 17–21. [Google Scholar]

- Soujoudi, R.; Manteufel, R. Thermodynamic, Economic and Environmental Analyses of Ammonia-Based Mixed Refrigerant for Liquefied Natural Gas Pre-Cooling Cycle. Processes 2021, 9, 1298. [Google Scholar] [CrossRef]

- Wang, Z.; Han, F.; Ji, Y.L.; Li, W.H. Combined Analysis of Parameter Sensitivity and Exergy for Natural Gas Liquefaction in Cryogenic Fuel Production Process. Processes 2020, 8, 561. [Google Scholar] [CrossRef]

- Burel, F.; Taccani, R.; Zuliani, N. Improving sustainability of maritime transport through utilization of Liquefied Natural Gas (LNG) for propulsion. Energy 2013, 57, 412–420. [Google Scholar] [CrossRef]

- Qu, S. Safety Issues and Development Prospects of LNG Storage. Petrochem. Ind. Technol. 2018, 25, 194. [Google Scholar]

- Mattia, C.; Gianmaria, P.; Chiara, V.; Giuseppe, M.; Ernesto, S. Large eddy simulation for the rapid phase transition of LNG. Saf. Sci. 2021, 133, 105001. [Google Scholar]

- Cheng, J.S. Brandon Jun Overview of the development of world LNG industry. Nat. Gas Ind. 2000, 20, 101–105. [Google Scholar]

- Miana, M.; Hoyo, R.D.; Rodrigálvarez, V. Comparison of evaporation rate and heat flow models for prediction of Liquefied Natural Gas (LNG) ageing during ship transportation. Fuel 2016, 177, 87–106. [Google Scholar] [CrossRef]

- Lisowski, E.; Czyiycki, W. Transport and storage of LNG in container tanks. KONES Powertrain Transp. 2011, 18, 193–201. [Google Scholar]

- Haddar, M.; Hammami, M.; Baccar, M. Numerical study of steady natural convection in a liquefied natural gas cylindrical storage tank equipped with baffles. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 234, 709–721. [Google Scholar] [CrossRef]

- Vikse, M.; Watson, H.A.J.; Gundersen, T.; Barton, P.I. Simulation of Dual Mixed Refrigerant Natural Gas Liquefaction Processes Using a Nonsmooth Framework. Processes 2018, 6, 193. [Google Scholar] [CrossRef]

- Liu, C.G. Influence of natural gas quality on LNG production. Mod. Salt Chem. Ind. 2021, 48, 53–54. [Google Scholar]

- Xu, X.X.; Chen, W.P.; Yu, J.H. Transportation mode and characteristics of liquefied natural gas. Oil Gas Storage Transp. 2006, 3, 6–11. [Google Scholar]

- Qiao, G.F.; Li, Y.X.; Zhang, K.M.; Li, D. Present situation and development prospect of liquefied natural gas industry in China. Oil Gas Storage Transp. 2005, 24, 1–4. [Google Scholar]

- Song, L.Y.; Deng, J.J.; Lu, J.S.; Wang, B.; Xue, D.W. Transient Response Analysis of Multi-layer Sloshing Fluid in LNG Tank. J. Phys.: Conf. Ser. 2021, 2076, 012024. [Google Scholar] [CrossRef]

- Lin, B.; Kuang, Y. Natural gas subsidies in the industrial sector in China: National and regional perspectives. Appl. Energy 2020, 260, 114329. [Google Scholar] [CrossRef]

- Cheng, D.; Gu, A.Z. Storage stratification of liquefied natural gas. Cryog. Technol. 1997, 1, 13–15. [Google Scholar]

- Ye, Z.Z.; Mo, X.Y.; Zhao, L. MINLP Model for Operational Optimization of LNG Terminals. Processes 2021, 9, 599. [Google Scholar] [CrossRef]

- Wang, W.C.; Li, Y.X.; Sun, F.F.; Zang, L.L. Analysis on Influencing Factors of pressure and evaporation rate in large LNG storage tank. Nat. Gas Ind. 2010, 30, 87–92. [Google Scholar]

- Wang, Z.H.; Sharafian, A.; Mérida, W. Thermal stratification and rollover phenomena in liquefied natural gas tanks. Energy 2022, 238, 121994. [Google Scholar] [CrossRef]

- Wang, Z.; Han, F.; Liu, Y.X.; Li, W.H. Evolution Process of Liquefied Natural Gas from Stratification to Rollover in Tanks of Coastal Engineering with the Influence of Baffle Structure. J. Mar. Sci. Eng. 2021, 9, 95. [Google Scholar] [CrossRef]

- Włodek, T. Prediction of boil off rate in liquefied natural gas storage processes. In Proceedings of the 17th International Multidisciplinary Scientific Geoconference SGEM, Vienna, Austria, 27–29 December 2017. [Google Scholar]

- Pu, L.; Sun, F.T.; Han, M.J.; Shao, X.Y. Numerical simulation study on filling and diversion stratification of large LNG storage tanks. Chem. Eng. 2017, 45, 67–73. [Google Scholar]

- Choi, S.W.; Lee, W.I.I.; Kim, H.S. Numerical analysis of convective flow and thermal stratification in a cryogenic storage tank. Numer. Heat Transfer, Part A. 2017, 71, 402–422. [Google Scholar] [CrossRef]

- Churchill, S.W. Heat leakage and wall temperature profiles for above ground low-temperature storage tanks. Chem. Eng. Prog. 1962, 58, 55–60. [Google Scholar]

- Chen, Q.S.; Wegrzyn, J.; Prasad, V. Analysis of temperature and pressure changes in liquefied natural gas (LNG) cryogenic tanks. Cryogenics 2004, 44, 701–709. [Google Scholar] [CrossRef]

- Seo, M.; Jeong, S.K. Analysis of self-pressurization phenomenon of cryogenic fluid storage tank with thermal diffusion model. Cryogenics 2010, 50, 549–555. [Google Scholar] [CrossRef]

- Bates, S.; Morrison, D.S. Modelling the behaviour of stratified liquid natural gas in storage tanks: A study of the rollover phenomenon. Int. Heat Mass Transf. 1997, 40, 1875–1884. [Google Scholar] [CrossRef]

- Bralewski, A.; Wolanin, J. Analysis of threats involving Liquefied Natural Gas (LNG)—Review of literature sources. Saf. Fire Technol. 2019, 53, 32–53. [Google Scholar] [CrossRef]

- Cheng, X.D.; Xu, J.; Qiao, G.F. Analysis on Influencing Factors of stratification and rollover in large LNG storage tank. J. Chem. Ind. Eng. Soc. China 2009, 60, 2990–2996. [Google Scholar]

- Qu, S.L.; Li, Y.X.; Li, Z.L.; Wang, W.C.; Hu, Q.H.; Zhang, H.W. Numerical simulation of tumbling model and tumbling phenomenon in LNG storage tank. Oil Gas Storage Transp. 2015, 34, 258–261. [Google Scholar]

- Joseph, J.; Agrawal, G.; Agarwal, D.K.; Pisharady, J.C.; Kumar, S.S. Effect of insulation thickness on pressure evolution and thermal stratification in a cryogenic tank. Appl. Therm. Eng. 2017, 111, 1629–1639. [Google Scholar] [CrossRef]

- Shi, J.; Bi, M.; Yang, X. Experimental research on thermal stratification of liquefied gas in tanks under external thermal attack. Exp. Therm. Fluid Sci. 2012, 41, 77–83. [Google Scholar] [CrossRef]

- Wang, Z.; Sharafian, A.; Mérida, W. Non-equilibrium thermodynamic model for liquefied natural gas storage tanks. Energy 2020, 190, 116412. [Google Scholar] [CrossRef]

- Li, X.D.; Xie, G.F.; Wang, R. Experimental and numerical investigations of fluid flow and heat transfer in a cryogenic tank at loss of vacuum. Heat Mass Transf. 2010, 46, 395–404. [Google Scholar] [CrossRef]

- Belmedani, M.; Belgacem, A.; Rebiai, R. Analysis of natural convection in liquid nitrogen under storage conditions. Appl. Sci. 2008, 8, 2544–2552. [Google Scholar] [CrossRef]

- Lin, W.; Gong, Y.; Gao, T.; Gu, A.; Lu, X. Experimental studies on the thermal stratification and its influence on BLEVEs. Exp. Therm. Fluid Sci. 2010, 34, 972–978. [Google Scholar] [CrossRef]

- Chakraborty, S.; Dutta, P.; Das, S.K. Studies on thermal stratification phenomenon in LH2 storage vessel. Heat Transf. Eng. 2004, 2, 54–66. [Google Scholar]

- Sun, F.T.; Pu, L.; Qi, D. Numerical study on delamination failure and rollover process of large LNG storage tank. Low Temp. Eng. 2017, 1, 47–53. [Google Scholar]

- Baker, N.; Creed, M. Stratification and rollover in liquefied natural gas storage tanks. Process Saf. Environ. Prot. 1996, 74, 25–30. [Google Scholar]

- Zhao, X.D.; Zhang, Z.G. Influence of Stratified Density Difference of Storage Liquid on Rollover in LNG Storage Tank. Gas Heat. 2018, 38, 18–21. [Google Scholar]

- Wang, Z.; Cai, W.J.; Shen, P.S.; Hong, W.; Wang, X.L. Numerical investigation of stratification and rollover characteristics for LNG tanks. In Proceedings of the 2019 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019. [Google Scholar]

- Zakaria, Z.; Baslasl, M.S.O.; Samsuri, A.; Ismail, I.; Supee, A.; Haladin, N.B. Rollover Phenomenon in Liquefied Natural Gas Storage Tank. Fail. Anal. Prev. 2019, 19, 1439–1447. [Google Scholar] [CrossRef]

- Li, Y.X.; Li, Z.L.; Wang, W.C. Simulating on rollover phenomenon in LNG storage tanks and determination of the rollover threshold. J. Loss Prev. Process Ind. 2015, 37, 132–142. [Google Scholar] [CrossRef]

- Bu, Y.C.; Wang, N.; Zhao., X.D. X.D. Two layer and three layer model simulation of large LNG tank rollover. Gas Heat. 2019, 39, 13–16. [Google Scholar]

- Kulitsa, M.; Wood, D.A. LNG rollover challenges and their mitigation on Floating Storage and Regasification Units: New perspectives in assessing rollover consequences. Loss Prev. Process Ind. 2018, 54, 352–372. [Google Scholar] [CrossRef]

- Chatterjee, N.; Geist, J.M. Effects of stratification on boil-off rates in LNG tanks. Pipeline Gas J. 1972, 199, 7. [Google Scholar]

- Heestand, J.; Shipman, C.W.; Meader, J.W. A predictive model for rollover in stratified LNG tanks. AIChE J. 1983, 29, 199–207. [Google Scholar] [CrossRef]

- Bates, S.; Morrison, D.S. LNG Rollover computational and Mathematical Aspects. In Proceedings of the 11th LNG Conference, Birmingham, UK, 3–6 July 1995. [Google Scholar]

- Qin, Z.H.; Gu, A.Z. Study on vortex model of liquefied natural gas. J. Shanghai Jiaotong Univ. 1999, 8, 40–44. [Google Scholar]

- Deshpande, K.B.; Zimmerman, W.B.; Tennant, M.T.; Webster, M.B. Optimization methods for the real-time inverse problem posed by modelling of liquefied natural gas storage. Chem. Eng. J. 2011, 170, 44–52. [Google Scholar] [CrossRef][Green Version]

- Zhao, B.; Shi, C.J.; Yang, X.F.; Gao, D.K.; Xu, L.Z.; Zhang, Y.Y. Temperature field analysis of liquid stratification for LNG tank based on orthogonal ridgelet finite element method. J. Therm. Anal. Calorim. 2016, 125, 557–562. [Google Scholar] [CrossRef]

- Wang, J.J.; Ma, X.Q. Chaotic behavior of LNG after stratification in main stream region of storage tank. Front. Energy Power Eng. China 2008, 2, 514–518. [Google Scholar] [CrossRef]

- Zhao, B.; Han, S.; Xu, I.; Shi, C.; Zhang, Y. Rollover mechanism methodology of LNG tank with gas-liquid stratification based on Curvelet Finite element method and large eddy simulation technology. J. Appl. Fluid Mech. 2018, 11, 779–786. [Google Scholar] [CrossRef]

- Shi, J.; Ren, J.; Liu, P.; Bi, M. Experimental research on the effects of fluid and heater on thermal stratification of liquefied gas. Exp. Therm. Fluid Sci. 2013, 50, 29–36. [Google Scholar] [CrossRef]

- Sugawara, Y.; Kubota, A.; Muraki, S. Rollover test in LNG tank and simulation model. Adv. Cryog. Eng. 1984, 29, 805–881l. [Google Scholar]

- Muro, M.; Yoshiwa, M.; Yasuda, Y. Experimental and analytical study of the rollover phenomenon using LNG. In Proceeding of the International Cryogenic Engineering Conference, Tokyo, Japan, 22–25 April 1986. [Google Scholar]

- Marcel, O. Measurement of the velocity of natural convection movements in an LNG storage tank. In Proceedings of the Gas Technology Conference, Amsterdam, The Netherlands, 21–22 May 1990. [Google Scholar]

- Munakata, T.; Tanasawa, I. Numerical Study on Effect of Initial Concentration Difference on Onset of Rollover. Trans. Jpn. Soc. Mech. Eng. 1994, 60, 3512–3518. [Google Scholar] [CrossRef][Green Version]

- Shi, J.Q.; Beduz, C.; Scurlock, R.G. Numerical modeling and flow visualization of mixing of stratified layers and rollover in LNG. Cryogenics 1993, 3, 1116–1124. [Google Scholar] [CrossRef]

- Kang, M.; Kim, J.; You, H.; Chang, D. Experimental investigation of thermal stratification in cryogenic tanks. Exp. Therm. Fluid Sci. 2018, 96, 371–382. [Google Scholar] [CrossRef]

- Saleem, A.; Farooq, S.; Karimi, I.A.; Banerjee, R. CFD Analysis of Stratification and Rollover Phenomena in an Industrial-Scale LNG Storage Tank. Ind. Eng. Chem. Res. 2020, 59, 14126–14144. [Google Scholar] [CrossRef]

- Sha, W.; Ren, J.J.; Wang, C.; Bi, M.S.; Bo, Y.F.; Sha, W.; Ren, J.; Wang, C.; Bi, M.; Bo, Y. Dynamic characteristics of the initial interface in stratified multi-composition liquid tanks during rollover. Appl. Therm. Eng. 2018, 145, 396–406. [Google Scholar] [CrossRef]

- Bi, Y.J.; Wang, W.C.; Li, Y.X.; Li, Z.L.; Hu, Q.H.; Li, B.F. Rollover simulation and critical density difference of LNG storage tank. Oil Gas Storage Transp. 2015, 34, 254–257. [Google Scholar]

- Hubert, A.; Dembele, S.; Denissenko, P.; Wen, J. Predicting Liquefied Natural Gas (LNG) rollovers using Computational Fluid Dynamics. J. Loss Prev. Process Ind. 2019, 62, 103922. [Google Scholar] [CrossRef]

- Maksimov, V.l.; Nagornova, T.A.; Glazyrin, V.P.; Shestakov, I.A. Analysis of influence of heat insulation on the thermal regime of storage tanks with liquefied natural gas. EPJ Web Conf. 2016, 110, 01042. [Google Scholar] [CrossRef]

- Wang, H.R.; Ma, X.X. Delamination and rollover in liquefied natural gas (LNG) storage containers. Low Temp. Eng. 2006, 1, 50–54. [Google Scholar]

- Wang, Q.G.; Lei, B.; Zhang, G.F.; Li, Z.C.; Li, A.H. Research Progress on stratification and rollover prediction of LNG storage process. Saf. Health Environ. 2016, 16, 1–4. [Google Scholar]

- Wang, Y.; Zhang, S.W. Present research and development of stratification and rollover phenomenon in LNG storage tank. Cryog. Supercond. 2016, 44, 30–32. [Google Scholar]

- Peng, M.; Ding, Y. Thermal insulation performance and cold insulation system of full containment LNG storage tanks. Nat. Gas Ind. 2012, 32, 94. [Google Scholar]

- Lin, W.S.; Gu, A.Z.; Li, P.Y. Progress of research on LNG stratification and rollover phenomenon. Vac. Cryog. 2000, 3, 125–132. [Google Scholar]

- Versluijs, P. Storage Tank Stratification/Rollover Alarm Management. EW 2011, 110, 24–28. [Google Scholar]

- Wang, P.; Cui, X.F.; Qiao, H.P.; Wang, Y.N. Preventive measures for liquid stratification and rollover of large LNG storage tank. Pet. Eng. Constr. 2022, 48, 1–4. [Google Scholar]

- Bi, H.S.; Zhang, Q.L.; Yun, Z.Q.; Li, H.Y.; Wang, Z.Q.; Wu, Z.W. Numerical simulation and influencing factors analysis of large LNG tank rollover. Nat. Gas Oil 2020, 38, 39–43. [Google Scholar]

- Wang, H. Potential hazards of LNG and preventive measures. Nat. Gas Oil 2007, 25, 1–2. [Google Scholar]

- Lukaszewski, M.W.; Zimmerman, W.B.J.; Tennant, M.T.; Webster, M.B. Application of inverse methods based algorithms to Liquefied Natural Gas (LNG) storage management. Chem. Eng. Res. Des. 2013, 91, 457–463. [Google Scholar] [CrossRef]

- Chen, S.Q.; Xu, J.; Dong, X.Z.; Zhang, H.L.; Gao, Q.; Tan, C.Q. Pinch point analysis of heat exchange for liquid nature gas (LNG) cryogenic energy using in air separation unit. Int. J. Refrig. 2017, 90, 264–276. [Google Scholar] [CrossRef]

- Wen, J.G.; Wu, X.F. Rollover mechanism and preventive measures of LNG storage tank. Oil Gas Storage Transp. 2012, 31, 157–159. [Google Scholar]

- Arjomandnia, P.; Tade, M.O.; Pareek, V.; May, E.F. Analysis of available data from liquefied natural gas rollover incidents to determine critical stability ratios. AIChE J. 2014, 60, 362–374. [Google Scholar] [CrossRef]

- Wang, L.G.; Liu, Y. LNG tumbling mechanism and preventive measures in large storage tanks. Nat. Gas Ind. 2008, 5, 97–99. [Google Scholar]

- Roh, S.; Son, G. Numerical study of natural convection in a liquefied natural gas tank. Mech. Sci. Technol. 2012, 26, 3133–3140. [Google Scholar] [CrossRef]

- Roh, S.; Son, G.; Song, G.; Bae, J. Numerical study of transient natural convection in a pressurized LNG storage tank. Appl. Therm. Eng. 2013, 52, 209–220. [Google Scholar] [CrossRef]

- Koyama, K.; Tamura, S.; Ono, O. CFD Simulation on LNG Storage Tank to Improve Safety and Reduce Cost. Syst. Modeling Simul. 2007, 8, 39–43. [Google Scholar]

- Li, Z.L. Analysis on the Critical Criterion of Rollover and Its Influence Factors in the LNG Storage Tank. Master’s Thesis, China University of Petroleum (EastChina), Qingdao, China. May 2014.

- Sun, H.D.; Nie, X.F. Rollover phenomenon and prevention in LNG transportation. World Shipp. 2007, 30, 23–24. [Google Scholar]

- Cai, J.G.; Yang, W.F.; Kan, A.K. Rolling phenomenon of liquefied natural gas and its prevention measures navigation technology. Mar. Technol. 2007, 1, 20–21. [Google Scholar]

- Liu, Q. Talking about the tumbling phenomenon in LNG tank and its preventive measures. Petrochem. Design. Navig. Technol. 2015, 3, 42–44. [Google Scholar]

- Wu, Y.; Liu, W.; Zhang, X.L.; Luo, H.; Wu, J. Rollover phenomenon and preventive measures in LNG storage and transportation. Pipeline Technol. Equip. 2009, 6, 9–12. [Google Scholar]

- Zhang, C.W.; Lv, G.F.; Zhuang, F. Causes and prevention of liquefied gas rollover in LNG storage tank. Pet. Eng. Constr. 2012, 37, 66–68. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).