Design of a Laboratory Test Equipment for Measuring and Testing Mobile Energy Means with Simulation of Operating Conditions

Abstract

:1. Introduction

2. Materials and Methods

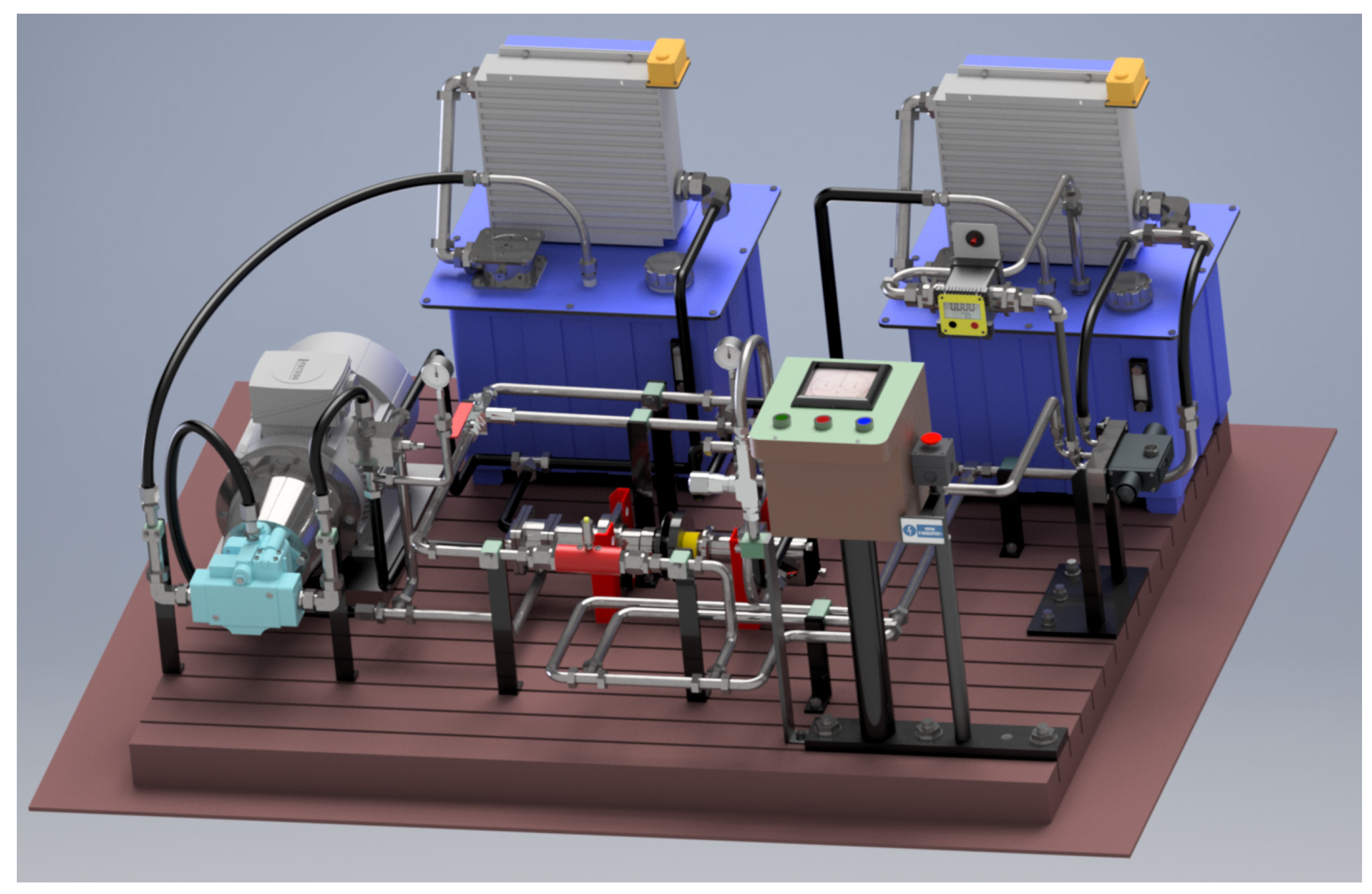

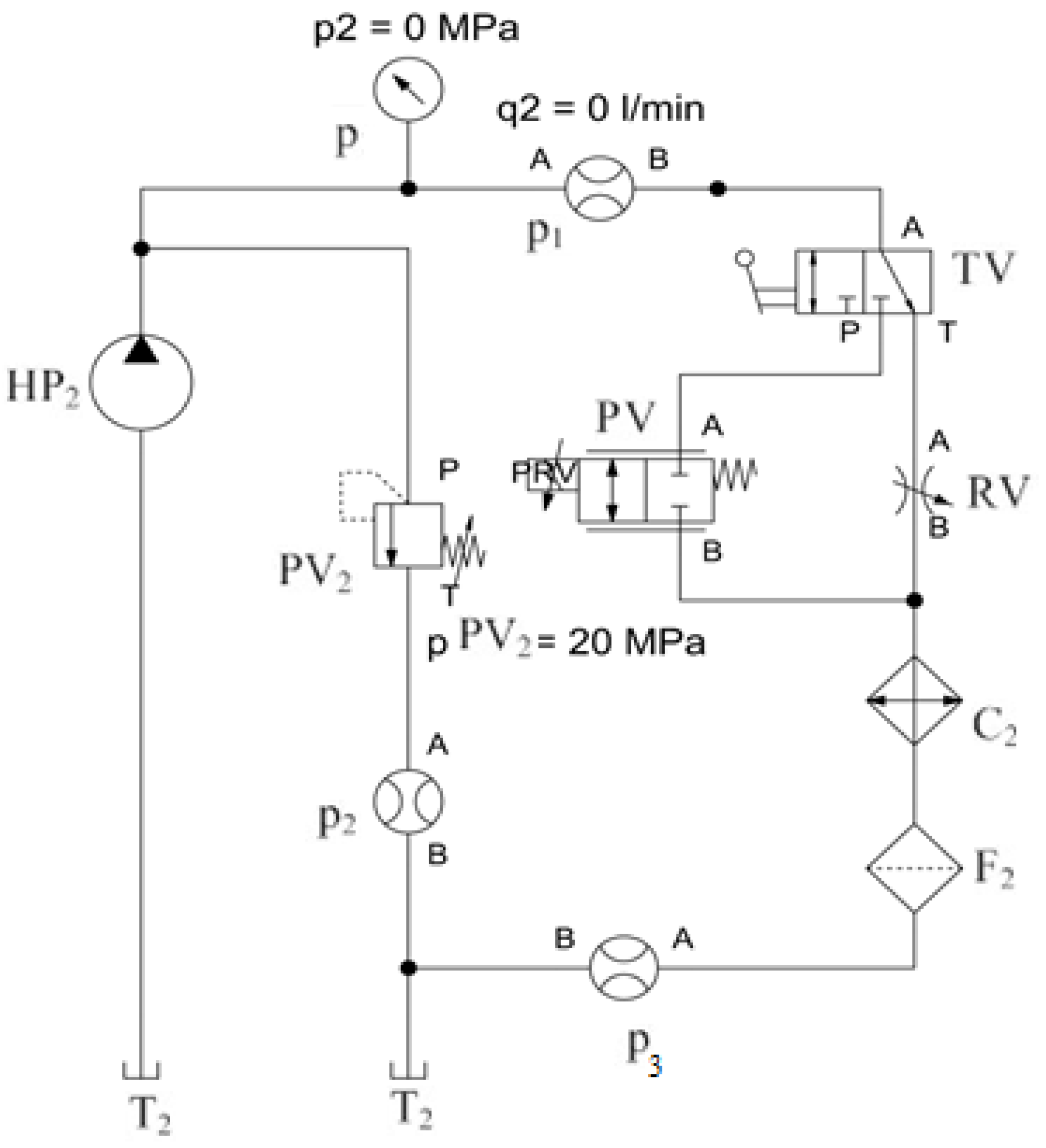

Design of Laboratory Test Equipment

3. Results

3.1. Measurement of Hydrostatic Transducer Flow on the Designed Laboratory Test Equipment

3.2. Hydrostatic Transducer Flow Measurement—Simulation

4. Discussion

5. Conclusions

- on the basis of the designed laboratory test equipment, it is possible to shorten the time of operational tests of hydrostatic transducers, hydraulic fluids and hydraulic elements;

- using the designed laboratory test equipment, we are able to design various types of measuring chains, the task of which will be testing elements of hydraulic circuits or hydraulic fluids;

- using the designed laboratory test equipment, we can perform repeated tests in laboratory conditions with the same or different operating loads;

- it is possible to simultaneously test the parameters of two hydrostatic transducers in the laboratory test equipment;

- on the basis of the acquired knowledge and results of measurements of the hydrostatic transducer, it is possible to make changes in the structures of the devices in question even before they are introduced into the production process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Košinár, M.; Kuric, I. Monitoring of CNC machine tool accuracy. New Product Development in Business to Business Marketing a Relational Perspective. In Proceedings of the 1st International Conference on Quality and Innovation in Engineering and Management, Cluj-Napoca, Romania, 17–19 March 2011; pp. 115–118. [Google Scholar]

- Kuric, I.; Zajačko, I.; Císar, M. Analytical Intelligence tools for multicriterial of CNC machines. Adv. Sci. Technol. Res. J. 2016, 10, 59–64. [Google Scholar] [CrossRef] [Green Version]

- Kučera, M.; Aleš, Z.; Pexa, M. Detection and Characterization of Wear Particles of Universal Tractor Oil Using of Particles Size Analyser. Agron. Res. 2016, 14, 1351–1360. [Google Scholar]

- Zastempowski, M. Test Stands with Energy Recovery System for Machines and Hydraulic Transmission. J. Res. Appl. Agric. Agric. Eng. 2013, 58, 188–191. [Google Scholar]

- Kučera, M.; Majdan, R.; Abrahám, R.; Kučera, M.; Hass, P. Analysis of the effect of loading process on tribological system properties. Acta Univ. Agric. Silvic. Mendel. Brun. 2016, 64, 825–833. [Google Scholar]

- Simikič, M.; Dedovič, N.; Savin, L.; Tomič, M.; Ponjičan, O. Power delivery efficiency of a wheeled tractor at oblique drawbar force. Soil Tillage Res. 2014, 141, 32–43. [Google Scholar] [CrossRef]

- Tóth, F.; Fürstenzeller, A.; Rusnák, J.; Bošanský, M.; Kadnár, M. The possibilities of using ecological liquids in tribological gliding systems with a selected surface created by the radial welding technology. Acta Technol. Agric. 2019, 22, 134–139. [Google Scholar] [CrossRef] [Green Version]

- Hujo, Ľ.; Čorňák, Š.; Tkáč, Z.; Jánošová, M. Laboratory Research of Transmission-Hydraulic Fluid, Praha. In Proceedings of the 7th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 17–19 September 2019; pp. 17–20. [Google Scholar]

- Majdan, R.; Tkáč, Z.; Abrahám, R.; Szabó, M.; Halenár, M.; Rášo, M. Proposal for filtration system for biodegradable lubricants in agricultural tractors. Agron. Res. 2016, 14, 1395–1405. [Google Scholar]

- Majdan, R.; Tkáč, Z.; Abrahám, R.; Kollárová, K.; Vitázek, I.; Halenár, M. Filtration systems design for universal oils in agricultural tractors. Tribol. Ind. 2017, 39, 547–558. [Google Scholar] [CrossRef] [Green Version]

- Puškár, M.; Brestovič, T.; Jasminská, N. Numerical simulation and experimental analysis of acoustic wave influences on brake mean effective pressure in thrust-ejector inlet pipe of combustion engine. Int. J. Veh. Des. 2015, 67, 63–67. [Google Scholar] [CrossRef]

- Hujo, Ľ.; Jablonický, J.; Tkáč, Z. Návrh Inovatívneho Laboratórneho Simulačného Zariadenia na Skúšanie Hydrostatických Prevodníkov a Hydraulických Kvapalín, 1st ed.; SUA: Nitra, Slovakia, 2017; 140p.

- Halenár, M.; Kuchar, P. Research of biodegradable fluid during operating test. MendelNet 2017. In Proceedings of the 24th International PhD Students Conference, Brno, Czech Republic, 8–9 November 2017; pp. 784–788. [Google Scholar]

- Kumbár, V.; Dostál, P. Oils degradation in agricultural machinery. Acta Univ. Agric. Silvic. Mendel. Brun. 2013, 61, 1297–1303. [Google Scholar] [CrossRef] [Green Version]

- Kopiláková, B.; Turza, J.; Hujo, Ľ.; Kosiba, J. Evaluation of Hydraulic Resistance in Various Liquids and Temperature. Tribol. Ind. 2017, 39, 129–135. [Google Scholar] [CrossRef] [Green Version]

- Csillag, J.; Petrovič, A.; Vozárová, V.; Bilčík, M.; Božiková, M.; Holota, T. Comparasion of rheological properties of new and used biolubricants. In Proceedings of the 7th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 17–19 September 2019; pp. 103–108. [Google Scholar]

- Kopiláková, B.; Zápotočný, J.; Eckert, M. Methodology for measuring and assessing static characteristics of liquid elements. Univ. Rev. 2019, 13, 8–15. [Google Scholar]

- Kaszkowiak, J.; Borowski, S.; Kaszkowiak, E.; Dulcet, E.; Zastempowski, M.; Hujo, Ľ. Systemy filtrowania spowietrza w ukladach zasilania silników spalinowych maszyn roboczych. Logistyka 2015, 4, 1893–1898. [Google Scholar]

- Kosiba, J.; Čorňák, Š.; Glos, J.; Jablonický, J.; Vozárová, V.; Petrovič, A.; Csillag, J. Monitoring Oil Degradation During Operating Tests. Agron. Res. 2016, 14, 1626–1634. [Google Scholar]

- Tkáč, Z.; Drabant, Š.; Majdan, R.; Cvíčela, P. Testing stands for laboratory tests of hydrostatic pump of agricultural machinery. Res. Agric. Eng. 2008, 54, 127–141. [Google Scholar] [CrossRef] [Green Version]

- Tkáč, Z.; Čorňák, Š.; Cviklovič, V.; Kosiba, J.; Glos, J.; Jablonický, J.; Bernát, R. Research of biodegradable fluid impacts on operation of tractor hydraulic system. Acta Technol. Agric. 2017, 20, 42–45. [Google Scholar] [CrossRef] [Green Version]

- Hujo, Ľ.; Nosian, J.; Zastempowski, M.; Kosiba, J.; Kaszkowiak, J.; Michalides, M. Laboratory Test of the Hydraulic Pump Operating Load with Monitoring of Changes in the Physical Properties. Meas. Control 2021, 54, 243–251. [Google Scholar] [CrossRef]

- Čorňák, Š. Identification of Operating Fluids with Fingerprint Method Utilization. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; pp. 2048–2053. [Google Scholar]

- Kučera, M.; Aleš, Z.; Ivandič, Z.; Hujo, Ľ. Possibility of Hydraulic Fluids with a Low Environmental Impact Application in Agricultural and Transport Machinery. J. Cent. Eur. Agric. 2013, 14, 1592–1601. [Google Scholar] [CrossRef]

- Puškár, M.; Jahnátek, A.; Kuric, I.; Kádárová, J.; Kopas, M.; Šoltésová, M. Complex analysis focused on influence of biodiesel and its mixture on regulated and unregulated emissions of motor vehicles with the aim to protect air quality and environment. Air Qual. Atmos. Health 2019, 12, 855–864. [Google Scholar] [CrossRef]

| Parameter | Unit | PARAMO HM 46 |

|---|---|---|

| Point of fluidity | °C | −27 |

| Flash point | °C | Over 190 |

| Inflammability | – | IV. hazard class |

| Vapor pressure at 20 °C | Pa | <10 |

| Relative density at 15 °C | 865 | |

| Solubility | - | Insoluble in water |

| Auto-ignition temperature | °C | Over 320 |

| Kinematic viscosity at 40 °C | 41.4–50.6 | |

| Explosive properties | – | It is not explosive |

| Oxidizing properties | – | It is not oxidizing |

| Parameter | Unit | Value |

|---|---|---|

| Rated rotation | 1500 | |

| Maximum rotation | 3200 | |

| Minimum rotation | 450 | |

| Maximal pressure at the inlet | 0.05 | |

| Minimum inlet pressure | 0.03 | |

| Nominal outlet pressure | 20 | |

| Maximum outlet pressure | 23 | |

| Geometric volume | 0.02546 | |

| Maximum oil viscosity | 1200 | |

| Minimum oil viscosity | 10 | |

| Maximum oil temperature | °C | 80 |

| Minimum oil temperature | −20 |

| Input Data | |

|---|---|

| Measuring range, dm3·min−1 | Operating pressure, MPa |

| 1.2–20 | 40 |

| 6.0–60 | 40 |

| 15.0–300 | 40 |

| 40.0–600 | 31.5 |

| Input Data | |

| Output signal, allowed load resistance | 4–20 mA, RLmax = (UB − 10 V/20 mA, Kω) |

| Accuracy | 2% real value |

| Additional Data | |

| Compensated temperature range | −20 until + 70 + °C |

| Operating temperature range | −20 until + 70 + °C |

| Fluid temperature range | −20 until + 90 + °C |

| Protection class | IP 65 |

| Supply voltage | 10–32 V |

| Residual ripple of the supply voltage | 5% |

| Viscosity range | 1–100 mm2·s−1 |

| Calibration viscosity | 30 mm2·s−1 |

| Parameter | Unit | Value |

|---|---|---|

| Protection class | - | IP 55 |

| Rated power | 11 | |

| Rated voltage | ||

| Rated current | ||

| Nominal speed |

| Volume, | No-Load Flow, | Maximum Pressure | Speed of Rotation, | Weight, | ||||

|---|---|---|---|---|---|---|---|---|

| 0.022 | 25.5 MPa | Min. | Max. | |||||

| 22.0 | 26.4 | 33.0 | 39.6 | 300 | 2000 | 13 | ||

| Parameter | Unit | Value |

|---|---|---|

| Pressure range | MPa | 5–25 |

| Weight | kg | 1.470 |

| Flow | dm3·rpm | 90 |

| Maximum pressure | MPa | 35 |

| Parameter | Unit | Value |

|---|---|---|

| Nominal pressure | MPa | 25 |

| Maximum pressure | MPa | 35 |

| Geometric volume | dm3 | 0.0285 |

| Rated speed of rotation | rpm | 2700 |

| Maximum rotation speed | rpm | 4800 |

| Nominal flow rate | dm3·rpm | 52.8 |

| Maximum flow | dm3·rpm | 128.4 |

| Weight | kg | 12.5 |

| Parameter | Unit | Value |

|---|---|---|

| Filtration | µ | 25 |

| Filter material | - | cellulose |

| Maximum flow | dm3·rpm | 110 |

| Maximum working pressure | MPa | 0.3 |

| Burst pressure | MPa | 1 |

| Bypass valve pressure | MPa | 0.15 |

| Filter cartridge symbol | - | CRE050CV1 |

| Parameter | Unit | Value |

|---|---|---|

| Typ | - | 2024 K 230–400 60–49 ASP |

| Tension | V | 230/400 |

| Power | kW | 0.105/0.145 |

| Protection class | - | IP 44 |

| Thermal protection | - | no |

| Rotation speed of fan | rpm | 2500/2650 |

| Maximum oil pressure in the system, operating pressure | MPa | 2 |

| Weight | kg | 11 |

| Parameter | Unit | Value |

|---|---|---|

| Maximum flow | dm3·rpm | 80 |

| Weight | kg | 1.080 |

| Maximum pressure | MPa | 28 |

| Parameter | Unit | Value |

|---|---|---|

| Pressure limits | MPa | Ports P, A, B = 31.5 T = 21 |

| Maximum flow at Δp = 1 MPa | dm3·rpm | Ports P, A, B = 45 T = 60 |

| Maximum flow at Δp = 3 MPa | dm3·rpm | Ports P, A, B = 80 T = 105 |

| Maximum flow at Δp = 7 MPa | dm3·rpm | Ports P, A, B = 120 T = 160 |

| Response time | ms | <40 |

| Hysteresis | 5% | |

| Repeatability | - | 1% |

| Ambient temperature | °C | −20 until + 70 |

| Recommended viscosity at 40 °C | mm2·s−1 | 15–100 |

| Oil temperature | °C | −20 until + 80 |

| Maximum Solenoid Current at 3.8–4.1 Ω | A | 2.6 |

| Maximum Solenoid Current at 2.2–2.4 Ω | A | 3.25 |

| Maximum Solenoid Current at 12–12.5 Ω | A | 1.2 |

| Maximum Length (Base), mm | Maximum Width (Base), mm | Maximum Height, mm |

|---|---|---|

| 1930 | 1130 | 830 |

| Parameter | Rotation Speed n, rpm | ||

|---|---|---|---|

| 250 | 500 | 750 | |

| Arithmetic mean | 5.694 | 12.286 | 18.747 |

| Standard error | 0.1765 | 0.0613 | 0.0055 |

| Median | 5.76 | 12.3 | 18.76 |

| Modus | 5.85 | 12.3 | 18.76 |

| Standard deviation | 0.1 | 0.1 | 0.1 |

| Selection variance | 0.031 | 0.003 | 0.003 |

| Pointiness | −1.255 | −0.023 | −0.041 |

| Skewness | −0.532 | −0.008 | 0.20 |

| Range | 0.60 | 0.35 | 0.34 |

| Minimum | 5.3 | 12.13 | 18.59 |

| Maximum | 5.9 | 12.39 | 18.85 |

| Confidence limit (90.0%) | 0.008 | 0.003 | 0.002 |

| Rotation Speed, n, rpm | Arithmetic Mean Flow Rate, Q, dm3·rpm | Flow Efficiency η, |

|---|---|---|

| 250 | 5.877 | 0.9233 |

| 500 | 12.334 | 0.9688 |

| 750 | 18.806 | 0.9848 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hujo, Ľ.; Nosian, J.; Borowski, S.; Markiewicz-Patalon, M.; Tomić, M.; Kožuch, P. Design of a Laboratory Test Equipment for Measuring and Testing Mobile Energy Means with Simulation of Operating Conditions. Processes 2022, 10, 1435. https://doi.org/10.3390/pr10081435

Hujo Ľ, Nosian J, Borowski S, Markiewicz-Patalon M, Tomić M, Kožuch P. Design of a Laboratory Test Equipment for Measuring and Testing Mobile Energy Means with Simulation of Operating Conditions. Processes. 2022; 10(8):1435. https://doi.org/10.3390/pr10081435

Chicago/Turabian StyleHujo, Ľubomír, Jozef Nosian, Sylwester Borowski, Marietta Markiewicz-Patalon, Milan Tomić, and Peter Kožuch. 2022. "Design of a Laboratory Test Equipment for Measuring and Testing Mobile Energy Means with Simulation of Operating Conditions" Processes 10, no. 8: 1435. https://doi.org/10.3390/pr10081435

APA StyleHujo, Ľ., Nosian, J., Borowski, S., Markiewicz-Patalon, M., Tomić, M., & Kožuch, P. (2022). Design of a Laboratory Test Equipment for Measuring and Testing Mobile Energy Means with Simulation of Operating Conditions. Processes, 10(8), 1435. https://doi.org/10.3390/pr10081435