Determination of Cetane Number from Fatty Acid Compositions and Structures of Biodiesel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Screening out Key Parameters for Determining the Cetane Number

2.2. Deriving Methods for a Predictive Formula of the Cetane Number

2.3. Verifying the Regression Formula

3. Results and Discussion

3.1. Effects of Key Independent Parameters on Fuel Characteristics

3.2. Derivation of Predictive Formula for the Cetane Number of Biodiesel

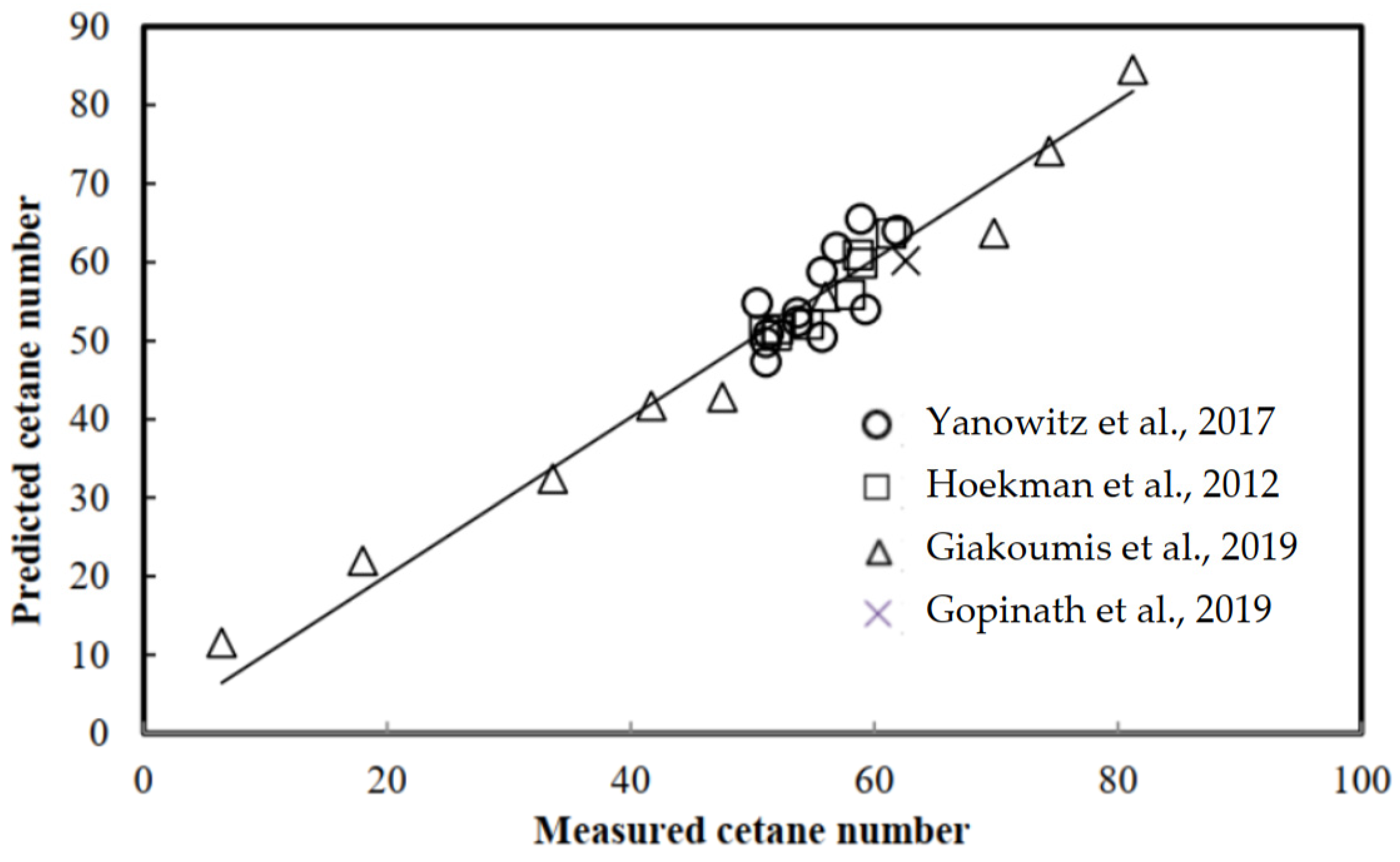

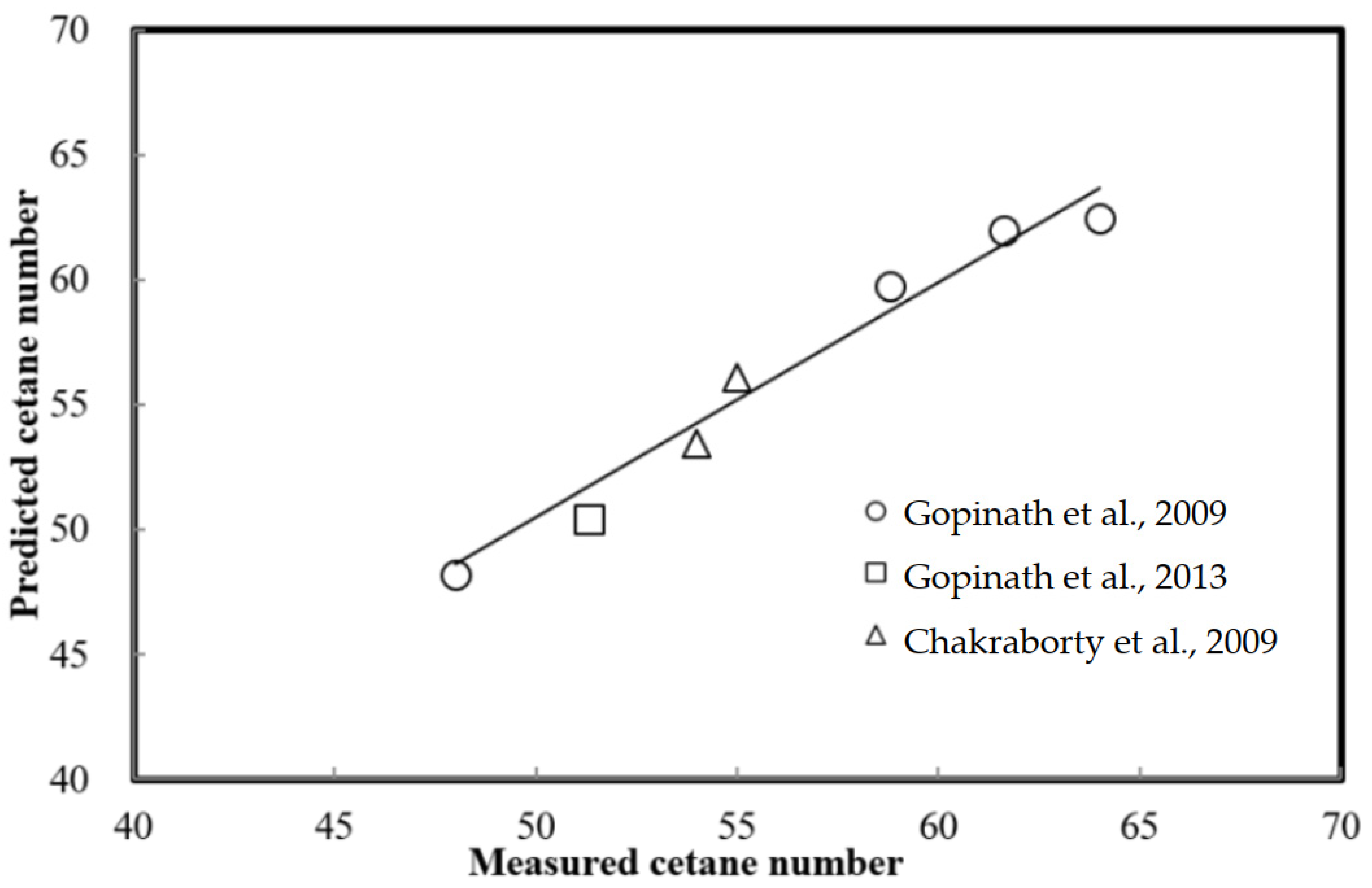

3.3. Verification of the Regression Formula

4. Conclusions

- The key parameters, which include characteristics of ester compositions and structures, were screened out to be the number of carbon atoms (NC), the allylic position equivalent (APE), and the double-bond equivalent (DBE), which influence cetane numbers of biodiesel more significantly and comprehensively than other parameters proposed in the literature.

- Either a higher APE or DBE of the biodiesel implies a higher unsaturation degree of the biodiesel. The cetane number of biodiesel was observed to increase with the NC while decreasing with the APE or the DBE.

- The predictive formula for the cetane number of biodiesel was successfully derived through quantitative analyses of various compositions of fatty acid methyl esters and their corresponding cetane numbers. Multiple linear regression analyses were conducted assisted by SPSS software to derive the regression coefficients and intercepts of the formula.

- The cetane number calculated by the predictive formula was found to be closer to the corresponding measured cetane numbers. The formula possesses superior prediction capability compared to other relevant formulae in the literature.

- The proposed predictive formula can more adequately predict the cetane number of biodiesel made from a variety of feedstock oils and significantly reduce the time and cost consumed for the engine test. The production procedures and operating conditions can be readily adjusted to meet biodiesel specifications.

- Those key parameters for cetane numbers would significantly influence other fuel properties, which require further extensive study. For example, the increase of the DBE might decrease the density and heating values of biodiesel.

- The C-C double bonds at the allylic position equivalent are prone to form unstable peroxides and thus have a weaker bond strength than other general hydrocarbon bonds.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kan, X.; Wei, L.; Li, X.; Li, H.; Zhou, D.; Yang, W.; Wang, C.H. Effects of the three dual-fuel strategies on performance and emissions of a biodiesel engine. Appl. Energy 2020, 262, 114542. [Google Scholar] [CrossRef]

- Lin, C.Y.; Ma, L. Fluid characteristics of biodiesel produced from palm oil with various initial water contents. Processes 2021, 9, 309. [Google Scholar] [CrossRef]

- Wu, P.C.; Lin, C.Y. Cost-benefit evaluation on promising strategies in compliance with low sulfur policy of IMO. J. Mar. Sci. Eng. 2020, 9, 3. [Google Scholar] [CrossRef]

- Dandu, M.S.R.; Nanthagopal, K. Tribological aspects of biofuels—A review. Fuel 2019, 258, 116066. [Google Scholar] [CrossRef]

- Kass, M.; Kaul, B.; Armstrong, B.; Szybist, J.; Lobodin, V. Stability, rheological and combustion properties of biodiesel blends with a very-low sulfur fuel oil (VLSFO). Fuel 2022, 316, 123365. [Google Scholar] [CrossRef]

- Lin, C.Y.; Ma, L. Effects of Water Removal from Palm Oil Reactant by Electrolysis on the Fuel Properties of Biodiesel. Processes 2022, 10, 115. [Google Scholar] [CrossRef]

- de Jesus, S.S.; Ferreira, G.F.; Moreira, L.S.; Filho, R.M. Biodiesel production from microalgae by direct transesterification using green solvents. Renew. Energy 2020, 160, 1283–1294. [Google Scholar] [CrossRef]

- Amoah, J.; Kahar, P.; Ogino, C.; Kondo, A. Bioenergy and biorefinery: Feedstock, biotechnological conversion, and products. Biotechnol. J. 2019, 14, 1800494. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.G.; Hassan, N.M.S.; Nabi, M.N. Recent development in the production of third generation biodiesel from microalgae. Energy Procedia 2019, 156, 53–58. [Google Scholar]

- Nguyen, V.H.; Duong, M.Q.; Nguyen, K.T.; Pham, T.V.; Pham, P.X. An extensive analysis of biodiesel blend combustion characteristics under a wide-range of thermal conditions of a cooperative fuel research engine. Sustainability 2020, 12, 7666. [Google Scholar] [CrossRef]

- Naser, N.; Sarathy, S.M.; Chung, S.H. Ignition delay time sensitivity in ignition quality tester (IQT) and its relation to octane sensitivity. Fuel 2018, 233, 412–419. [Google Scholar] [CrossRef] [Green Version]

- Korczewski, Z. Methodology for determining the elemental composition, as well as energy and ignition properties of the low-sulfur marine fuels. Combust. Engines 2021, 186, 96–102. [Google Scholar] [CrossRef]

- Knothe, G. A comprehensive evaluation of the cetane numbers of fatty acid methyl esters. Fuel 2014, 119, 6–13. [Google Scholar] [CrossRef]

- Bamgboye, A.I.; Hansen, A.C. Prediction of cetane number of biodiesel fuel from the fatty acid methyl ester (FAME) composition. Int. Agrophysics 2008, 22, 21–29. [Google Scholar]

- Gumus, S.; Ozcan, H.; Ozbey, M.; Topaloglu, B. Aluminum oxide and copper oxide nanodiesel fuel properties and usage in a compression ignition engine. Fuel 2016, 163, 80–87. [Google Scholar] [CrossRef]

- Zheng, Z.; Dong, F.; Guo, Y.; Liu, X.; Yang, Y.; Liu, H. Effect of fuels with different distillation temperatures on performance and emissions of a diesel engine run at various injection pressures and timings. J. Energy Eng. 2017, 143, 04016061. [Google Scholar] [CrossRef]

- Ashok, B.; Raj, R.T.K.; Nanthagopal, K.; Krishnan, R.; Subbarao, R. Lemon peel oil–A novel renewable alternative energy source for diesel engine. Energy Convers. Manag. 2017, 139, 110–121. [Google Scholar] [CrossRef]

- Sergeeva, Y.E.; Mostova, E.B.; Gorin, K.V.; Komova, A.V.; Konova, I.A.; Pojidaev, V.M.; Sineoky, S.P. Calculation of biodiesel fuel characteristics based on the fatty acid composition of the lipids of some biotechnologically important microorganisms. Appl. Biochem. Microbiol. 2017, 53, 807–813. [Google Scholar] [CrossRef]

- Noushabadi, A.S.; Dashti, A.; Raji, M.; Zarei, A.; Mohammadi, A.H. Estimation of cetane numbers of biodiesel and diesel oils using regression and PSO-ANFIS models. Renew. Energy 2020, 158, 465–473. [Google Scholar] [CrossRef]

- Yaşar, F. Comparision of fuel properties of biodiesel fuels produced from different oils to determine the most suitable feedstock type. Fuel 2020, 264, 116817. [Google Scholar] [CrossRef]

- Piloto-Rodríguez, R.; Sánchez-Borroto, Y.; Lapuerta, M.; Goyos-Pérez, L.; Verhelst, S. Prediction of the cetane number of biodiesel using artificial neural networks and multiple linear regression. Energy Convers. Manag. 2013, 65, 255–261. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Ceniceros, E.; Natarajan, M. Review of biodiesel composition, properties and specifications. Renew. Sustain. Energy Rev. 2012, 16, 143–169. [Google Scholar] [CrossRef]

- Mathew, B.C.; Thangaraja, J.; Sivaramakrishna, A. Combustion, performance and emission characteristics of blends of methyl esters and modified methyl esters of karanja and waste cooking oil on a turbocharged CRDI engine. Clean Technol. Environ. Policy 2019, 21, 1791–1807. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C.K. Estimation of biodiesel cetane number, density, kinematic viscosity and heating values from its fatty acid weight composition. Fuel 2018, 222, 574–585. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C.K. A comparative assessment of biodiesel cetane number predictive correlations based on fatty acid composition. Energies 2019, 12, 422. [Google Scholar] [CrossRef] [Green Version]

- Sajjad, N.; Orfali, R.; Perveen, S.; Rehman, S.; Sultan, A.; Akhtar, T.; Nazir, A.; Muhammad, G.; Mehmood, T.; Ghaffar, S.; et al. Biodiesel production from alkali-catalyzed transesterification of tamarindus indica seed oil and optimization of process conditions. Molecules 2022, 27, 3230. [Google Scholar] [CrossRef] [PubMed]

- Mujtaba, M.A.; Cho, H.M.; Masjuki, H.H.; Kalam, M.A.; Ong, H.C.; Gul, M.; Yusoff, M.N.A.M. Critical review on sesame seed oil and its methyl ester on cold flow and oxidation stability. Energy Rep. 2020, 6, 40–54. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Masjuki, H.H.; Kalam, M.A.; Noor, F.; Farooq, M.; Ong, H.C.; Razzaq, L. Effect of additivized biodiesel blends on diesel engine performance, emission, tribological characteristics, and lubricant tribology. Energies 2020, 13, 3375. [Google Scholar] [CrossRef]

- Giakoumis, E.G. Analysis of 22 vegetable oils’ physico-chemical properties and fatty acid composition on a statistical basis, and correlation with the degree of unsaturation. Renew. Energy 2018, 126, 403–419. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. A detailed investigation on the performance, combustion, and exhaust emission characteristics of a diesel engine running on the blend of diesel fuel, biodiesel and 1-heptanol (C7 alcohol) as a next-generation higher alcohol. Fuel 2020, 275, 117893. [Google Scholar] [CrossRef]

- Faizollahzadeh Ardabili, S.; Najafi, B.; Shamshirband, S. Fuzzy logic method for the prediction of cetane number using carbon number, double bounds, iodic, and saponification values of biodiesel fuels. Environ. Prog. Sustain. Energy 2019, 38, 584–599. [Google Scholar] [CrossRef]

- Hao, S.; Han, X.; Liu, H.; Jia, M. Prediction and sensitivity analysis of the cetane number of different biodiesel fuels using an artificial neural network. Energy Fuels 2021, 35, 17711–17720. [Google Scholar] [CrossRef]

- Bukkarapu, K.R.; Krishnasamy, A. Fourier Transform Infrared Spectroscopy Models to Predict Cetane Number of Different Biodiesels and Their Blends; SAE International in United States: Warrendale, PA, USA, 2020. [Google Scholar]

- Pandit, P.R.; Fulekar, M.H. Biodiesel production from microalgal biomass using CaO catalyst synthesized from natural waste material. Renew. Energy 2019, 136, 837–845. [Google Scholar] [CrossRef]

- Zhang, T.; Lang, X.; Dong, A.; Wan, X.; Gao, S.; Wang, L.; Wang, W. Difference of oxidation mechanism between light C3–C4 alkane and alkene over mullite YMn2O5 oxides’ catalyst. ACS Catal. 2020, 10, 7269–7282. [Google Scholar] [CrossRef]

- Premjit, Y.; Sruthi, N.U.; Pandiselvam, R.; Kothakota, A. Aqueous ozone: Chemistry, physiochemical properties, microbial inactivation, factors influencing antimicrobial effectiveness, and application in food. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1054–1085. [Google Scholar] [CrossRef] [PubMed]

- Yanowitz, J.; Ratcliff, M.A.; McCormick, R.L.; Taylor, J.D.; Murphy, M.J. Compendium of Experimental Cetane Numbers (No. NREL/TP-5400-67585); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2017. [Google Scholar]

- Zhu, L.; Cheung, C.S.; Huang, Z. Impact of chemical structure of individual fatty acid esters on combustion and emission characteristics of diesel engine. Energy 2016, 107, 305–320. [Google Scholar] [CrossRef] [Green Version]

- Hosseinzadeh, A.; Baziar, M.; Alidadi, H.; Zhou, J.L.; Altaee, A.; Najafpoor, A.A.; Jafarpour, S. Application of artificial neural network and multiple linear regression in modeling nutrient recovery in vermicompost under different conditions. Bioresour. Technol. 2020, 303, 122926. [Google Scholar] [CrossRef]

- Astivia, O.L.O.; Zumbo, B.D. Heteroskedasticity in Multiple Regression Analysis: What it is, How to Detect it and How to Solve it with Applications in R and SPSS. Pract. Assess. Res. Eval. 2019, 24, 1. [Google Scholar]

- Nimon, K. Regression commonality analysis: Demonstration of an SPSS solution. Mult. Linear Regres. Viewp. 2010, 36, 10–17. [Google Scholar]

- Gopinath, A.; Puhan, S.; Nagarajan, G. Relating the cetane number of biodiesel fuels to their fatty acid composition: A critical study. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2009, 223, 565–583. [Google Scholar] [CrossRef]

- Gopinath, A.; Sairam, K.; Velraj, R. Effect of Double Bond Equivalent of Biodiesels on their Heating Value and Cetane Number. Asian J. Chem. 2013, 25, 8732–8736. [Google Scholar] [CrossRef]

- Chakraborty, M.; Baruah, D.C.; Konwer, D. Investigation of Terminalia (Terminalia belerica Robx.) seed oil as prospective biodiesel source for North-East India. Fuel Process. Technol. 2009, 90, 1435–1441. [Google Scholar] [CrossRef]

- Adu-Mensah, D.; Mei, D.; Zuo, L.; Zhang, Q.; Wang, J. A review on partial hydrogenation of biodiesel and its influence on fuel properties. Fuel 2019, 251, 660–668. [Google Scholar] [CrossRef]

- Hamel, J.D.; Paquin, J.F. Activation of C–F bonds α to C–C multiple bonds. Chem. Commun. 2018, 54, 10224–10239. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Du, L.; Yan, L.; Park, S.; Qiu, Y.; Sokolowski, J.; Shao, Y. Oxygen evolution reaction in alkaline environment: Material challenges and solutions. Adv. Funct. Mater. 2022, 32, 2110036. [Google Scholar] [CrossRef]

- Carter, C.C.; Cundari, T.R. Activation of carbon-hydrogen bonds by complexes involving multiply bonded Group 13 elements. Polyhedron 2022, 219, 115797. [Google Scholar] [CrossRef]

- Fu, P.Q.; Kawamura, K.; Chen, J.; Charrìère, B.; Sempere, R. Organic molecular composition of marine aerosols over the Arctic Ocean in summer: Contributions of primary emission and secondary aerosol formation. Biogeosciences 2013, 10, 653–667. [Google Scholar] [CrossRef] [Green Version]

- Goga, G.; Chauhan, B.S.; Mahla, S.K.; Cho, H.M.; Dhir, A.; Lim, H.C. Properties and characteristics of various materials used as biofuels: A review. Mater. Today Proc. 2018, 5, 28438–28445. [Google Scholar] [CrossRef]

- Pinzi, S.; Leiva, D.; Arzamendi, G.; Gandia, L.M.; Dorado, M.P. Multiple response optimization of vegetable oils fatty acid composition to improve biodiesel physical properties. Bioresour. Technol. 2011, 102, 7280–7288. [Google Scholar] [CrossRef]

- Lapuerta, M.; Rodriguez-Fernandez, J.; Font de Mora, E. Correlation for the estimation of the cetane number of biodiesel fuels and implications on the iodine number. Energy Policy 2009, 37, 4337–4344. [Google Scholar] [CrossRef]

- Kumbhar, V.; Pandey, A.; Sonawane, C.R.; El-Shafay, A.S.; Panchal, H.; Chamkha, A.J. Statistical analysis on prediction of biodiesel properties from its fatty acid composition. Case Stud. Therm. Eng. 2022, 30, 101775. [Google Scholar] [CrossRef]

- Ramirez-Verduzco, L.F.; Rodriguez-Rodriguez, J.E.; Del Rayo Jaramillo-Jacob, A. Predicting cetane number, kinematic viscosity, density and higher heating value of biodiesel from its fatty acid methyl ester composition. Fuel 2012, 91, 102–111. [Google Scholar] [CrossRef]

- Li, R.; Herreros, J.M.; Tsolakis, A.; Yang, W. Machine learning regression based group contribution method for cetane and octane numbers prediction of pure fuel compounds and mixtures. Fuel 2020, 280, 118589. [Google Scholar] [CrossRef]

- Westbrook, C.K. Chemistry of biodiesel fuels based on soybean oil. In Biodiesel Fuels Based Edible Nonedible Feedstocks Wastes Algae; CRC Press: Boca Raton, FL, USA, 2021; pp. 459–476. [Google Scholar]

| Parameter | Coefficient | Standard Error |

|---|---|---|

| Intercept | −9.285 | 3.097 |

| NC | 5.212 | 0.249 |

| APE | −0.075 | 0.027 |

| DBE | −0.139 | 0.029 |

| Research Group | Prediction Equation | Comments | Ref. |

|---|---|---|---|

| Gopinath et al. | R2 = 95.3%, Standard error = 2.27 | [42] | |

| Piloto-Rodríguez et al. | 0.1Ot | R2 = 91.1%, Standard error = 4.6 | [21] |

| Giakoumis and Sarakatsanis | CN = 55.87 + 0.0747 × 1 + 0.098 × 2 + 0.164 × 3 + 0.176 × 40.050 × 5 + 0.001 × 6 0.140 × 7 0.273 × 8 | R2 = 89.6%, Standard error = 3.04 | [24] |

| Present study | R2 = 94.7%, Standard error = 3.486 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-Y.; Wu, X.-E. Determination of Cetane Number from Fatty Acid Compositions and Structures of Biodiesel. Processes 2022, 10, 1502. https://doi.org/10.3390/pr10081502

Lin C-Y, Wu X-E. Determination of Cetane Number from Fatty Acid Compositions and Structures of Biodiesel. Processes. 2022; 10(8):1502. https://doi.org/10.3390/pr10081502

Chicago/Turabian StyleLin, Cherng-Yuan, and Xin-En Wu. 2022. "Determination of Cetane Number from Fatty Acid Compositions and Structures of Biodiesel" Processes 10, no. 8: 1502. https://doi.org/10.3390/pr10081502

APA StyleLin, C.-Y., & Wu, X.-E. (2022). Determination of Cetane Number from Fatty Acid Compositions and Structures of Biodiesel. Processes, 10(8), 1502. https://doi.org/10.3390/pr10081502