Activated Carbon Modified by Ester Hydrolysis of Ethyl Acetate for Water Vapor Adsorption Enhancement

Abstract

:1. Introduction

2. Preparation and Surface Properties of Hydrophilic Activated Carbon

2.1. Surface Modification

2.2. Analysis and Test Methods of Modified Activated Carbon

2.2.1. BET

2.2.2. SEM

2.2.3. FT-IR

2.2.4. Boehm Titration

3. Water Vapor Adsorption Performance of Modified Activated Carbon

3.1. Activated Carbon Adsorption Theory

3.2. Static Adsorption Performance of Modified Activated Carbon for Water Vapor

4. Results and Discussion

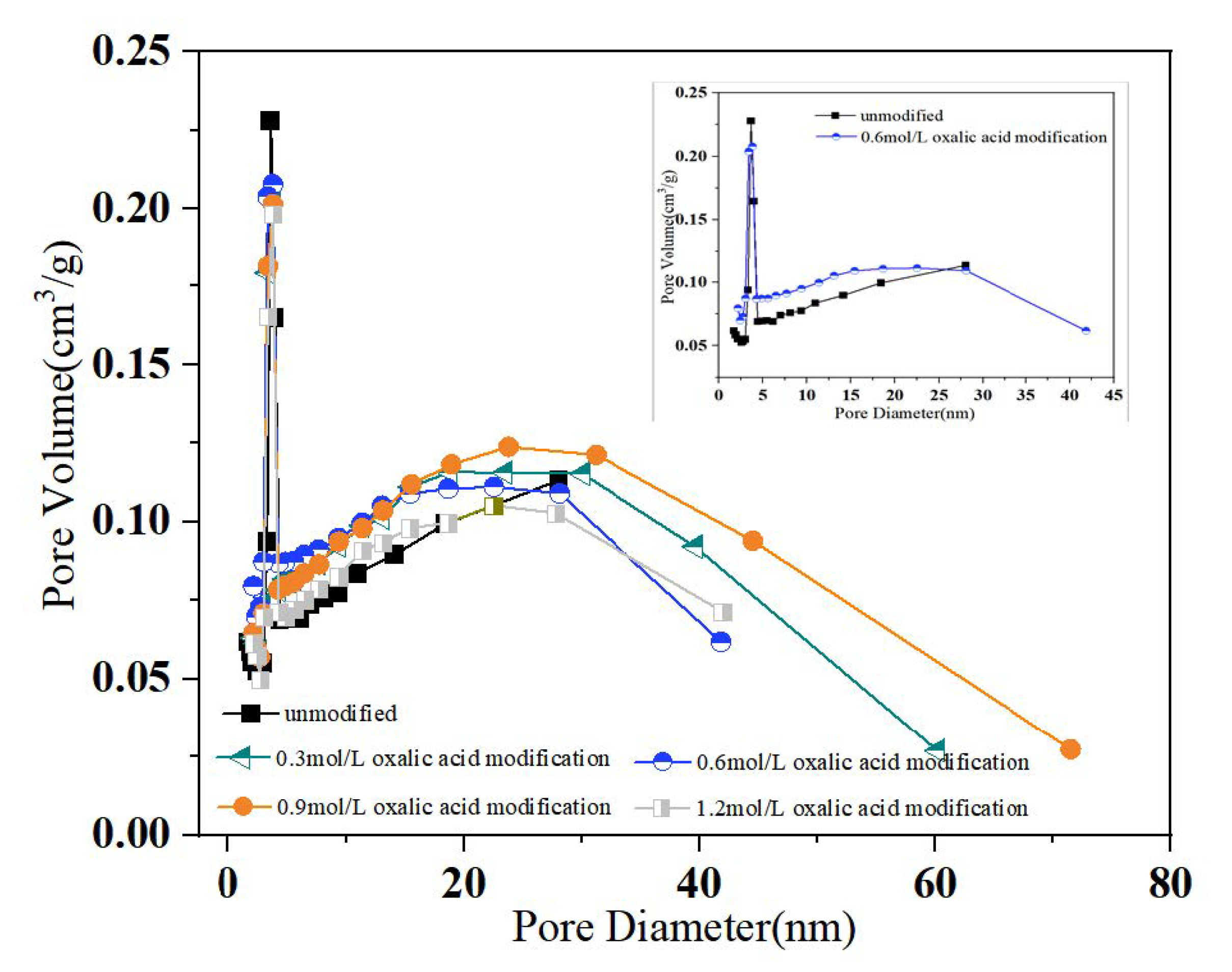

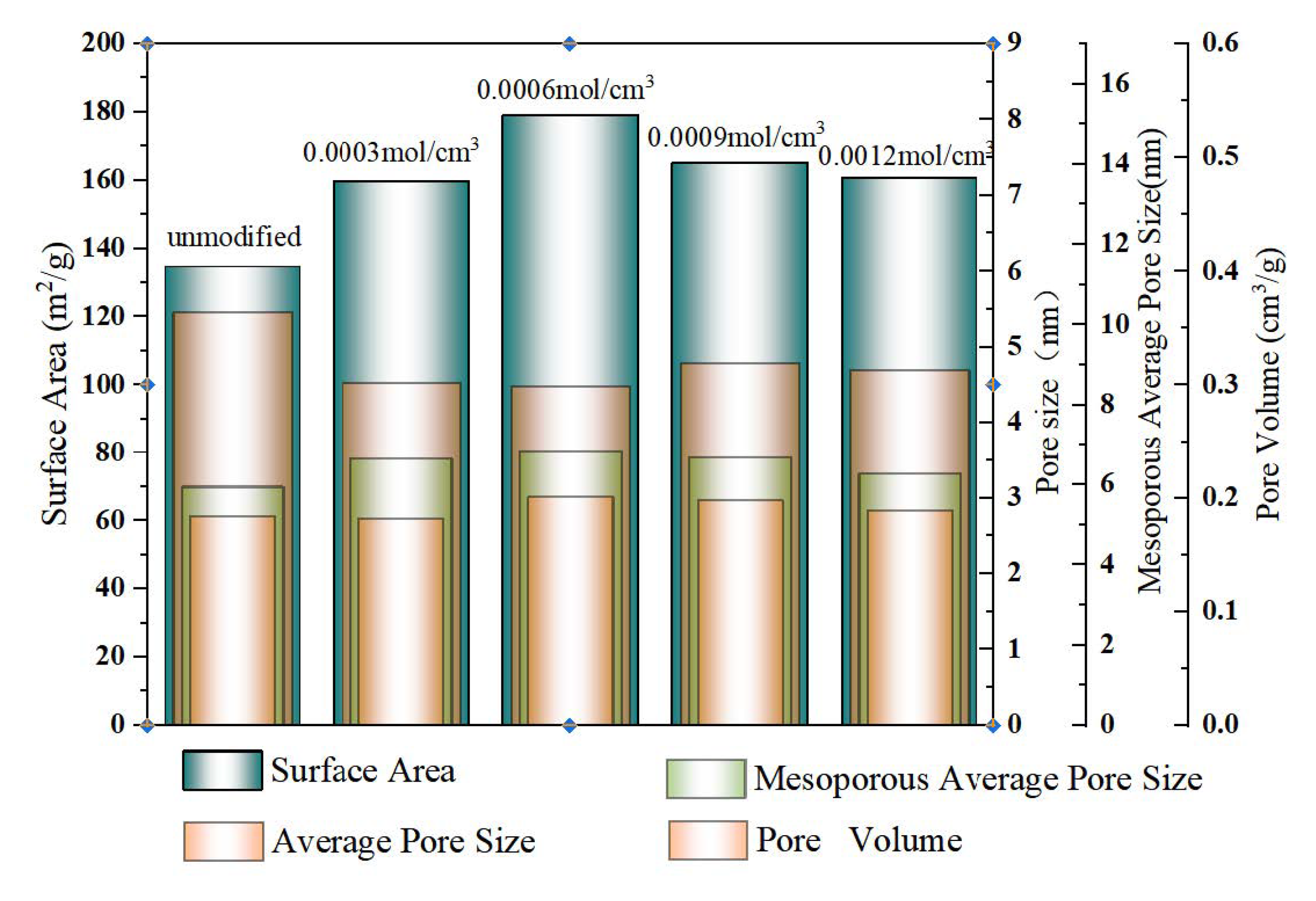

4.1. BET

4.2. SEM

4.3. FT-IR

4.4. Boehm Titration

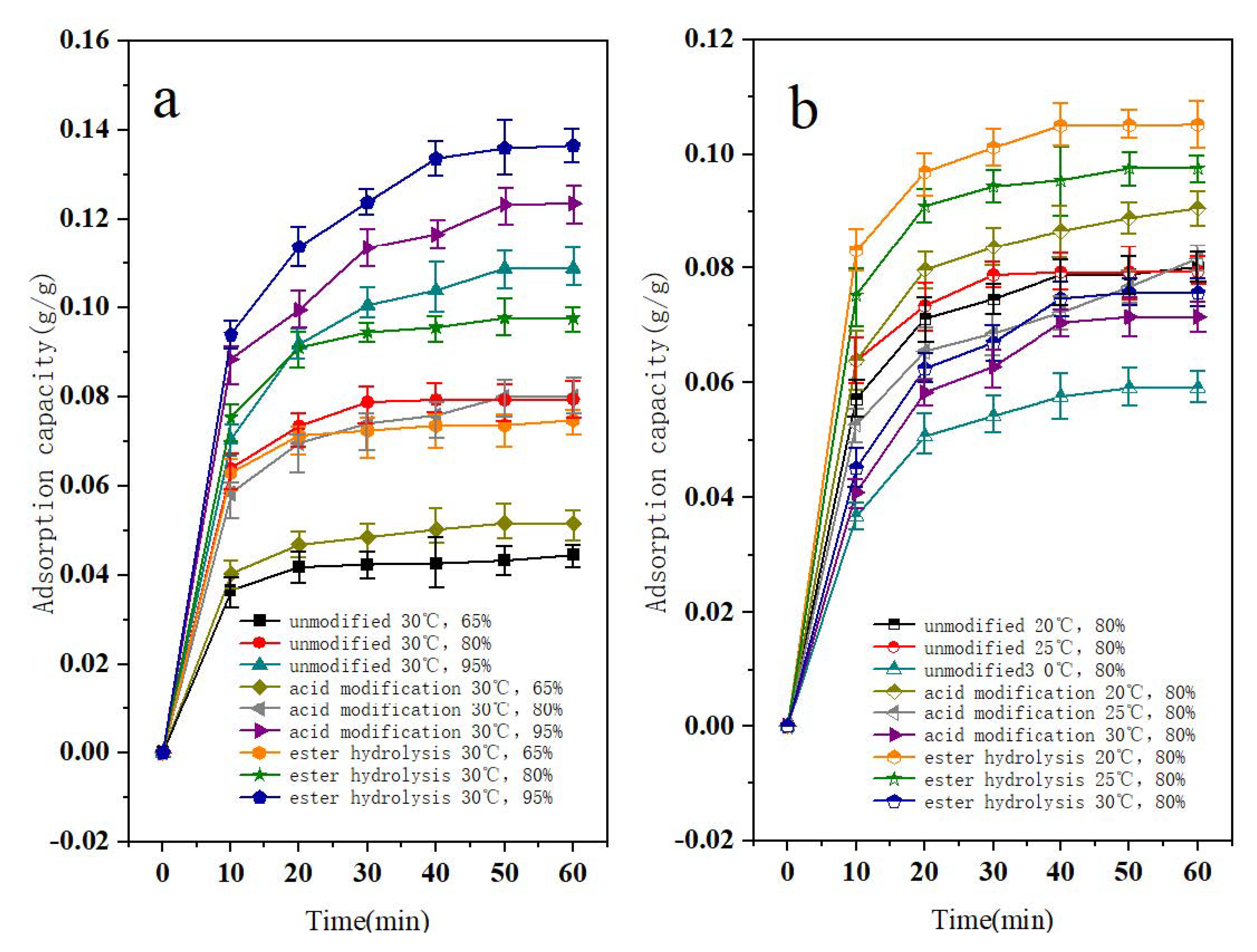

4.5. Data Analysis of Adsorption Performance of Modified Activated Carbon for Water Vapor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Macías-García, A.; Díaz-Díez, M.A.; Cuerda-Correa, E.M.; Olivares-Marín, M.; Gañan-Gómez, J. Study of the pore size distribution and fractal dimension of HNO3-treated activated carbons. Appl. Surf. Sci. 2006, 252, 5972–5975. [Google Scholar] [CrossRef]

- Pego, M.; Carvalho, J.; Guedes, D. Surface Modifications of Activated Carbon and Its Impact on Application. Surf. Rev. Lett. 2019, 26, 1830006. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, H.; Ye, G.; Fan, J.; Yao, F.; Wang, Y.; Jiao, Y.; Zhu, W.; Huang, H.; Ye, D. Key factors and primary modification methods of activated carbon and their application in adsorption of carbon-based gases: A review. Chemosphere 2022, 287 Pt 2, 131995. [Google Scholar] [CrossRef]

- Lesaoana, M.; Mlaba, R.P.V.; Mtunzi, F.M.; Klink, M.J.; Ejidike, P.; Pakade, V.E. Influence of inorganic acid modification on Cr(VI) adsorption performance and the physicochemical properties of activated carbon. S. Afr. J. Chem. Eng. 2019, 28, 8–18. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, J.; Shen, D.; Xiao, R.; Gu, S.; Zhao, M.; Liang, J. Removal of Pb(II) from water by the activated carbon modified by nitric acid under microwave heating. J. Colloid Interface Sci. 2016, 463, 118–127. [Google Scholar] [CrossRef] [PubMed]

- Girgis, B.S.; Attia, A.A.; Fathy, N.A. Modification in adsorption characteristics of activated carbon produced by H3PO4 under flowing gases. Colloids Surf. A Physicochem. Eng. Asp. 2007, 299, 79–87. [Google Scholar] [CrossRef]

- Wang, H.; Sun, Y.; Zhu, T.; Wang, W.; Deng, H. Adsorption of acetaldehyde onto carbide-derived carbon modified by oxidation. Chem. Eng. J. 2015, 273, 580–587. [Google Scholar] [CrossRef]

- Lemus, J.; Martin-Martinez, M.; Palomar, J.; Gomez-Sainero, L.; Gilarranz, M.A.; Rodriguez, J.J. Removal of chlorinated organic volatile compounds by gas phase adsorption with activated carbon. Chem. Eng. J. 2012, 211–212, 246–254. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.-J.; Ahn, H.-G. The adsorption and desorption characteristics of a binary component system of toluene and methylethylketone on activated carbon modified with phosphoric acid. Carbon 2010, 48, 2198–2202. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, Z.; Yang, J.; Chen, J.; Chen, K.; Yan, K.; Meng, X.; Zhang, X.; He, M. Study on the suppression mechanism of (NH4)2CO3 and SiC for polyethylene deflagration based on flame propagation and experimental analysis. Powder Technol. 2022, 399, 117193. [Google Scholar] [CrossRef]

- Xi, M.; Fu, X.; Yang, H.; He, C.; Fu, L.; Cheng, X.; Guo, J. Predicted a honeycomb metallic BiC and a direct semiconducting Bi2C monolayer as excellent CO2 adsorbents. Chin. Chem. Lett. 2021, 33, 2595–2599. [Google Scholar] [CrossRef]

- Bai, B.; Rao, D.; Chang, T.; Guo, Z. A nonlinear attachment-detachment model with adsorption hysteresis for suspension-colloidal transport in porous media. J. Hydrol. 2019, 578, 124080. [Google Scholar] [CrossRef]

- Michota, L.J.; Villieras, F. Surface area and porosity. Dev. Clay Sci. 2013, 5, 319–322. [Google Scholar]

- Bouraada, M.; Ouali, M.S.; de Ménorval, L.C. Dodecylsulfate and dodecybenzenesulfonate intercalated hydrotalcites as adsorbent materials for the removal of BBR acid dye from aqueous solutions. J. Saudi Chem. Soc. 2016, 20, 397–404. [Google Scholar] [CrossRef]

- Javadian, S.; Sadrpoor, S.M. Demulsification of water in oil emulsion by surface modified SiO2 nanoparticle. J. Pet. Sci. Eng. 2019, 184, 106547. [Google Scholar] [CrossRef]

- Yang, B.; Ruan, D.; Zhang, Y.; Wang, C.; Qiao, Z. Structural changes of activated carbon electrodes for EDLCs in the manufacturing process. Trans. Tianjin Univ. 2020, 26, 391–398. [Google Scholar] [CrossRef]

- Boehm, H.P. Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon 1994, 32, 759–769. [Google Scholar] [CrossRef]

- Boehm, H.P. Chemical Identification of Surface Groups. Adv. Catal. 1996, 16, 179–274. [Google Scholar]

- Goertzen, S.L.; Thériault, K.D.; Oickle, A.M.; Tarasuk, A.C.; Andreas, H.A. Standardization of the Boehm titration. Part I. CO2 expulsion and endpoint determination. Carbon 2010, 48, 1252–1261. [Google Scholar] [CrossRef]

- Oickle, A.M.; Goertzen, S.L.; Hopper, K.R.; Abdalla, Y.O.; Andreas, H.A. Standardization of the Boehm titration: Part II. Method of agitation, effect of filtering and dilute titrant. Carbon 2010, 48, 3313–3322. [Google Scholar] [CrossRef]

- Schönherr, J.; Buchheim, J.; Scholz, P.; Adelhelm, P. Boehm Titration Revisited (Part I): Practical Aspects for Achieving a High Precision in Quantifying Oxygen-Containing Surface Groups on Carbon Materials. C 2018, 4, 21. [Google Scholar] [CrossRef] [Green Version]

- Bai, B.; Wang, Y.; Rao, D.; Bai, F. The effective thermal conductivity of unsaturated porous media deduced by pore-scale sph simulation. Front. Earth Sci. 2022, 10, 943853. [Google Scholar] [CrossRef]

- Wang, J.; Ai, K.; Lu, L. Flame-retardant porous hexagonal boron nitride for safe and effective radioactive iodine capture. J. Mater. Chem. A 2019, 7, 16850–16858. [Google Scholar] [CrossRef]

- Chiang, H.L.; Huang, C.P.; Chiang, P.C.; You, J.H. Effect of metal additives on the physico-chemical characteristics of activated carbon exemplified by benzene and acetic acid adsorption. Carbon 1999, 37, 1919–1928. [Google Scholar] [CrossRef]

- Debarr, J.A.; Lizzio, A.A.; Daley, M.A. Adsorption of SO2 on Bituminous Coal Char and Activated Carbon Fiber. Energy Fuels 1997, 11, 267–271. [Google Scholar] [CrossRef]

- Long, C.; Li, Y.; Yu, W.; Li, A. Adsorption characteristics of water vapor on the hypercrosslinked polymeric adsorbent. Chem. Eng. J. 2012, 180, 106–112. [Google Scholar] [CrossRef]

- Yl, A.; Lla, B.; Qwa, B.; Xra, B.; Ma, A. Highly selective separation of acetic acid and hydrochloric acid by alkylamide based on double hydrogen bond coupling mechanism. Sep. Purif. Technol. 2021, 275, 119110. [Google Scholar]

- Ma, J.; Yang, Y.; Li, X.; Sui, H.; He, L. Mechanisms on the stability and instability of water-in-oil emulsion stabilized by interfacially active asphaltenes: Role of hydrogen bonding reconstructing. Fuel 2021, 297, 120763. [Google Scholar] [CrossRef]

- Nebol’sin, V.A.; Galstyan, V.; Silinac, Y.E. Graphene oxide and its chemical nature: Multi-stage interactions between the oxygen and graphene. Surf. Interfaces 2020, 21, 100763. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Ren, J.H.; Ju, M.C.; Chen, X.; Xu, J.M.; Wang, Z.; Meng, L.X.; Zhao, P.Y.; Wang, H. Construction of new alternative transmission sites by incorporating structure-defect metal-organic framework into sulfonated poly (arylene ether ketone sulfone)s. Int. J. Hydrogen Energy 2021, 46, 27193–27206. [Google Scholar] [CrossRef]

| Functional Group Type | Carboxyl Functional Group (mmol/g) | Lactone Functional Group (mmol/g) | Phenolic Hydroxyl Functional Group (mmol/g) | Total Acidic Oxygen-Containing Functional Group (mmol/g) | |

|---|---|---|---|---|---|

| Modification Method | |||||

| Unmodified | 0.1543 | 0.1245 | 0.2182 | 0.497 | |

| 0.0006 mol/cm3 oxalic acid modification | 0.2562 | 0.2132 | 0.322 | 0.7914 | |

| 0.0006 mol/cm3 oxalic acid modification and ester hydrolysis | 0.4322 | 0.5842 | 0.4213 | 1.4377 | |

| Functional Group Type | Carboxyl Functional Group Ratio | Lactone Group Functional Group Ratio | Phenol Hydroxyl Functional Group Ratio | Ratio of Total Acidic Oxygen-Containing Functional Groups |

|---|---|---|---|---|

| Modification Method | ||||

| 0.0006 mol/cm3 oxalic acid modification/Unmodified | 1.6604 | 1.7124 | 1.4757 | 1.5924 |

| 0.0006 mol/cm3 oxalic acid modification and ester hydrolysis/Unmodified | 2.8010 | 4.6924 | 1.9308 | 2.8928 |

| 0.0006 mol/cm3 oxalic acid modification and ester hydrolysis/0.0006 mol/cm3 oxalic acid modification | 1.6870 | 2.7402 | 1.3084 | 1.8167 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Zhang, H.; Ji, X.; Lan, Q.; Fan, Q. Activated Carbon Modified by Ester Hydrolysis of Ethyl Acetate for Water Vapor Adsorption Enhancement. Processes 2022, 10, 1527. https://doi.org/10.3390/pr10081527

Xu J, Zhang H, Ji X, Lan Q, Fan Q. Activated Carbon Modified by Ester Hydrolysis of Ethyl Acetate for Water Vapor Adsorption Enhancement. Processes. 2022; 10(8):1527. https://doi.org/10.3390/pr10081527

Chicago/Turabian StyleXu, Jinping, Hailin Zhang, Xu Ji, Qing Lan, and Quanhai Fan. 2022. "Activated Carbon Modified by Ester Hydrolysis of Ethyl Acetate for Water Vapor Adsorption Enhancement" Processes 10, no. 8: 1527. https://doi.org/10.3390/pr10081527