Mathematical Perspectives in the Variable Texture Products Cutting Process

Abstract

:1. Introduction

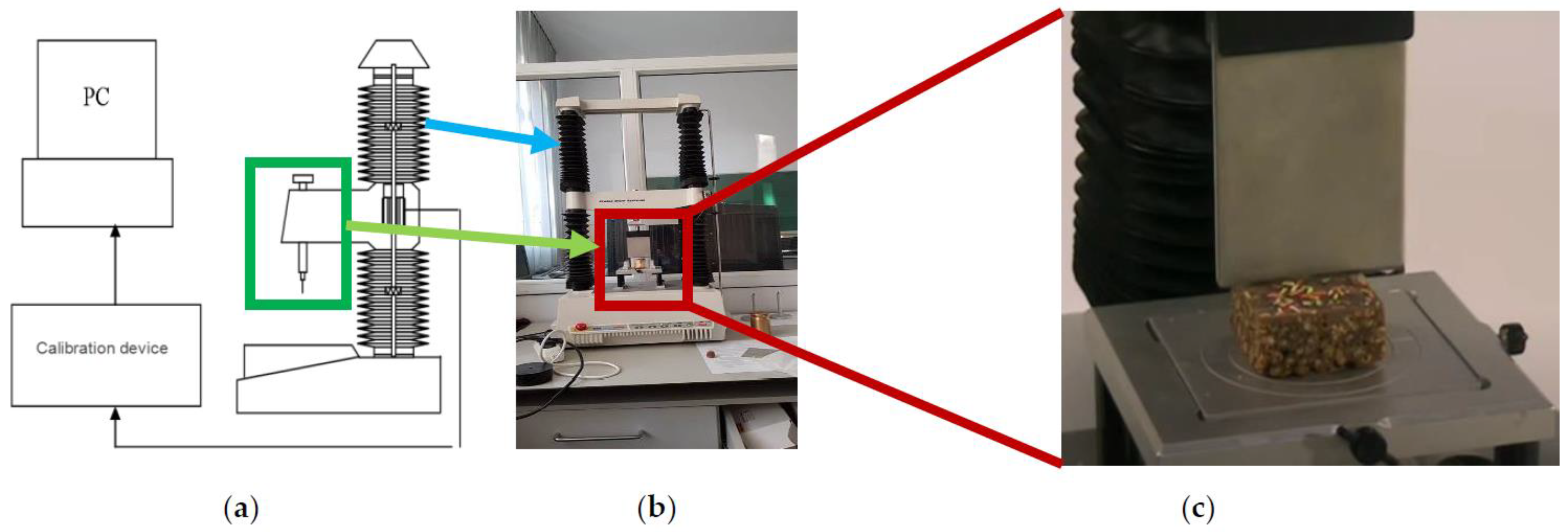

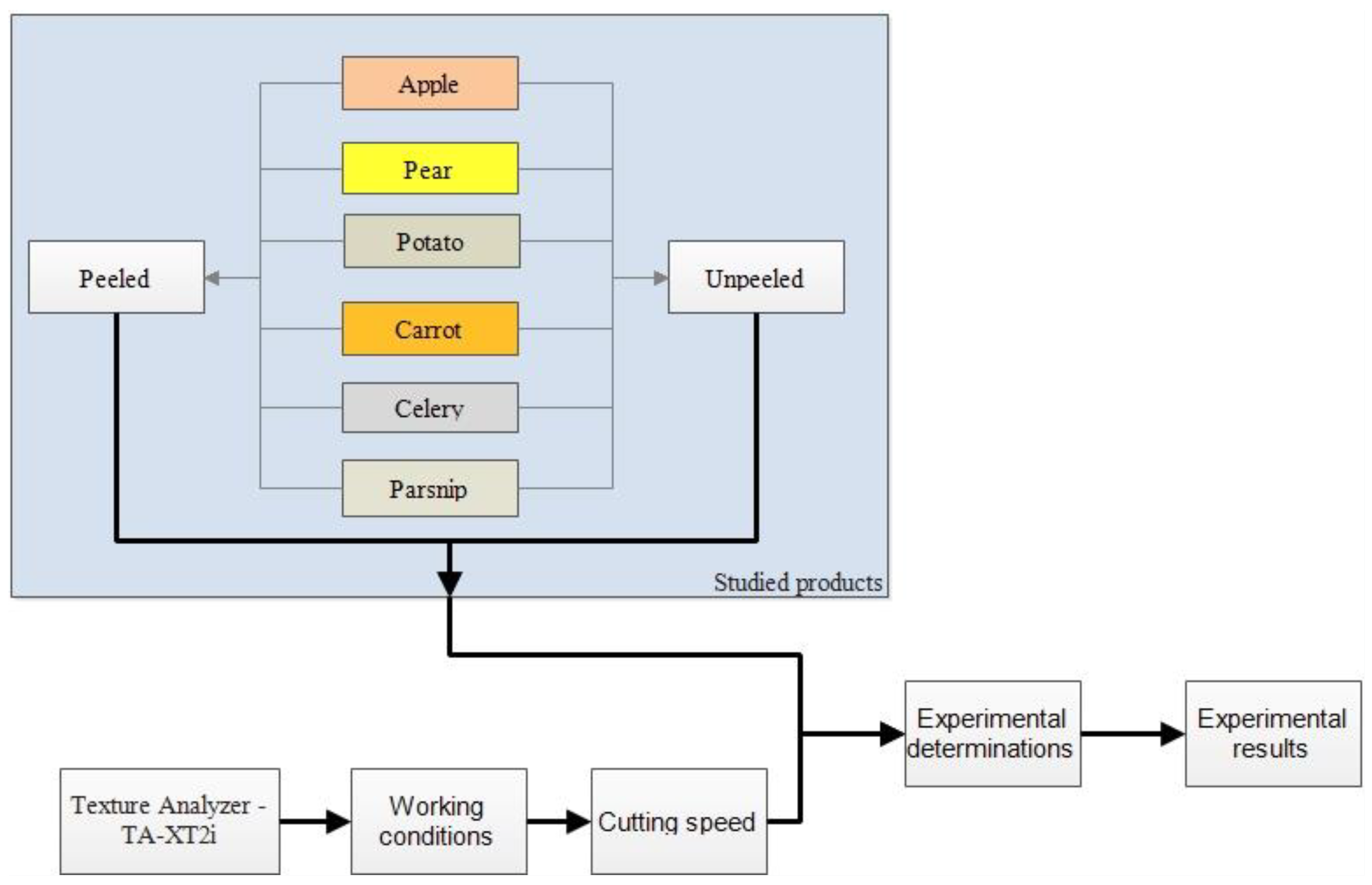

2. Materials and Methods

- -

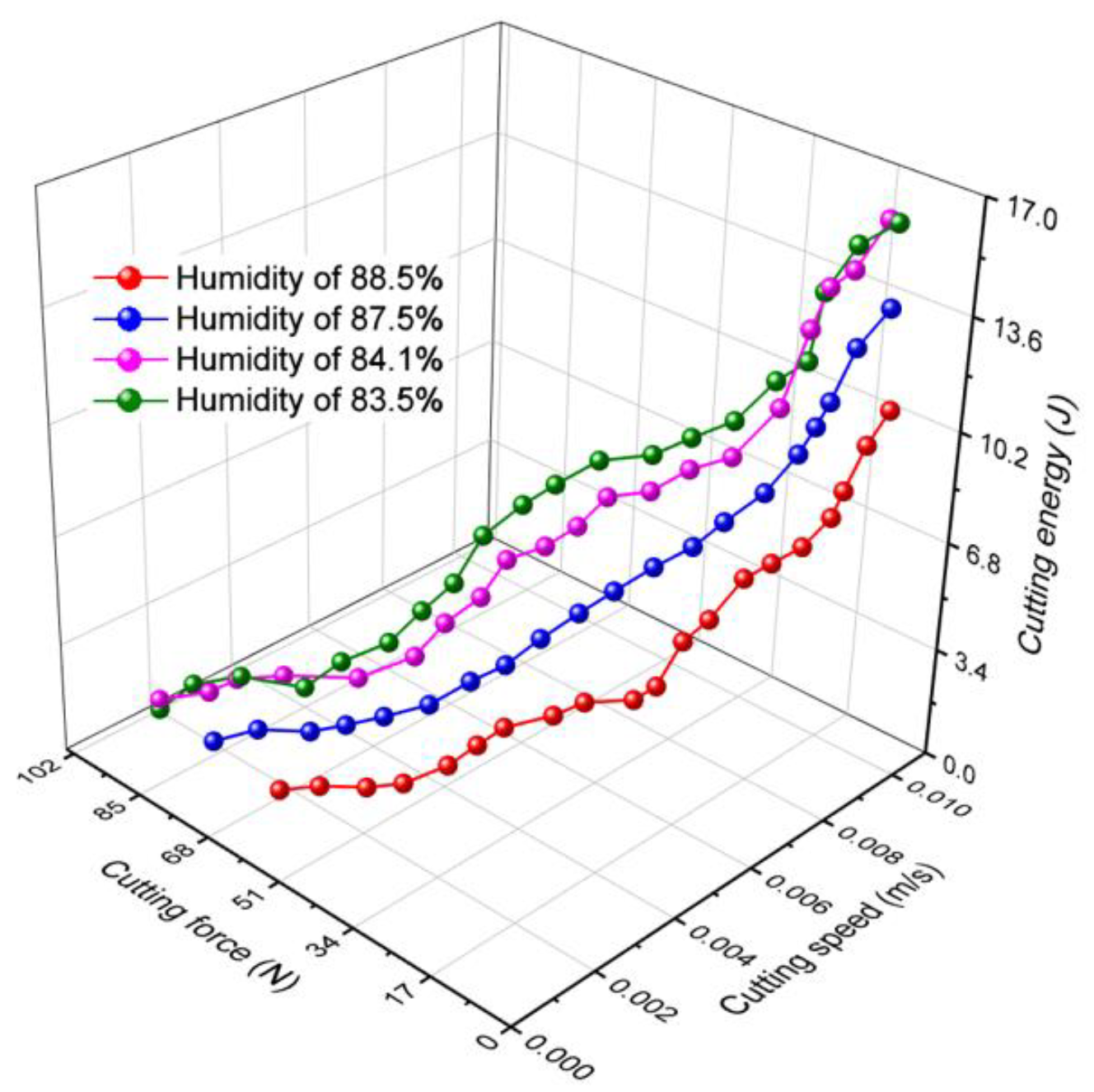

- The variation of their density is inversely proportional to the variation of the humidity in the case of the apple product used in these experimental determinations;

- -

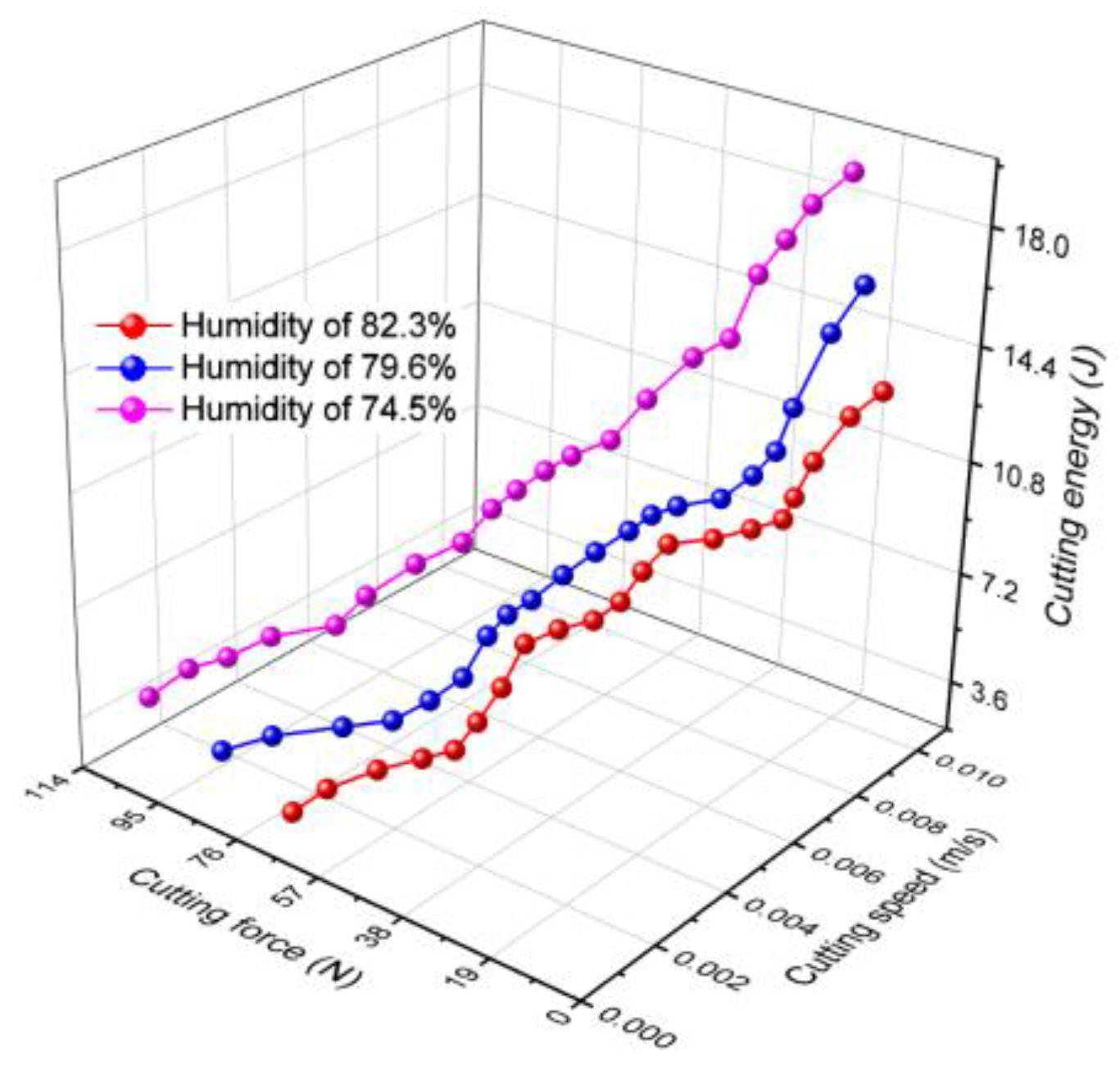

- In the case of the potato product, it was found that the lowest product density is associated with the highest humidity. The lowest value of the parameter studied was obtained for the next value of the density of the studied product, and for the highest value of the density, it was found that the humidity is higher by 5.1% compared to the minimum value;

- -

- Because we only have one sample of the other products used in the study, no relevant conclusions can be drawn.

3. Results

- -

- the textural properties of the products to be cut (humidity of the products) influence the cutting process; high cutting energy values have been obtained for products with low humidity;

- -

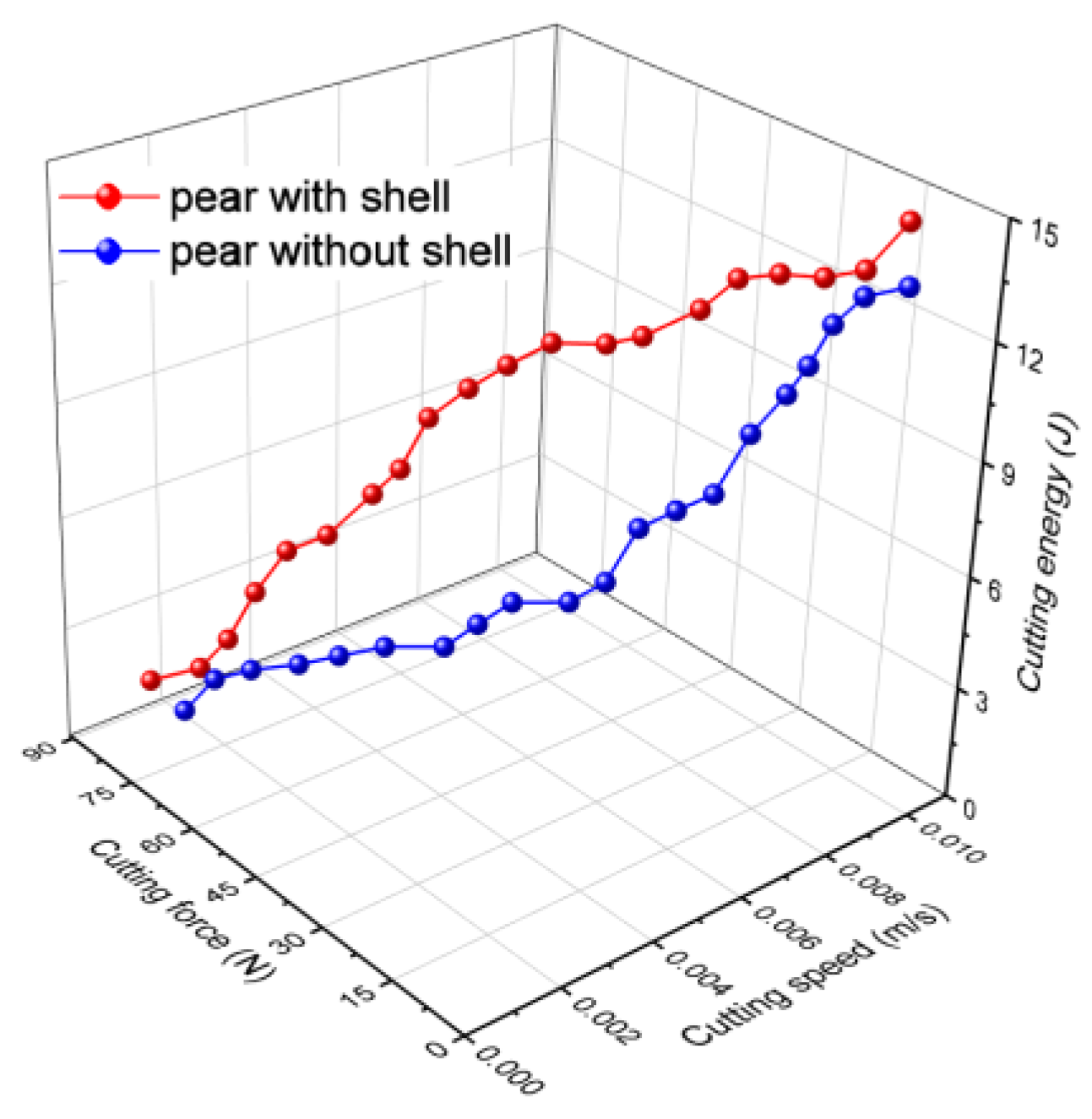

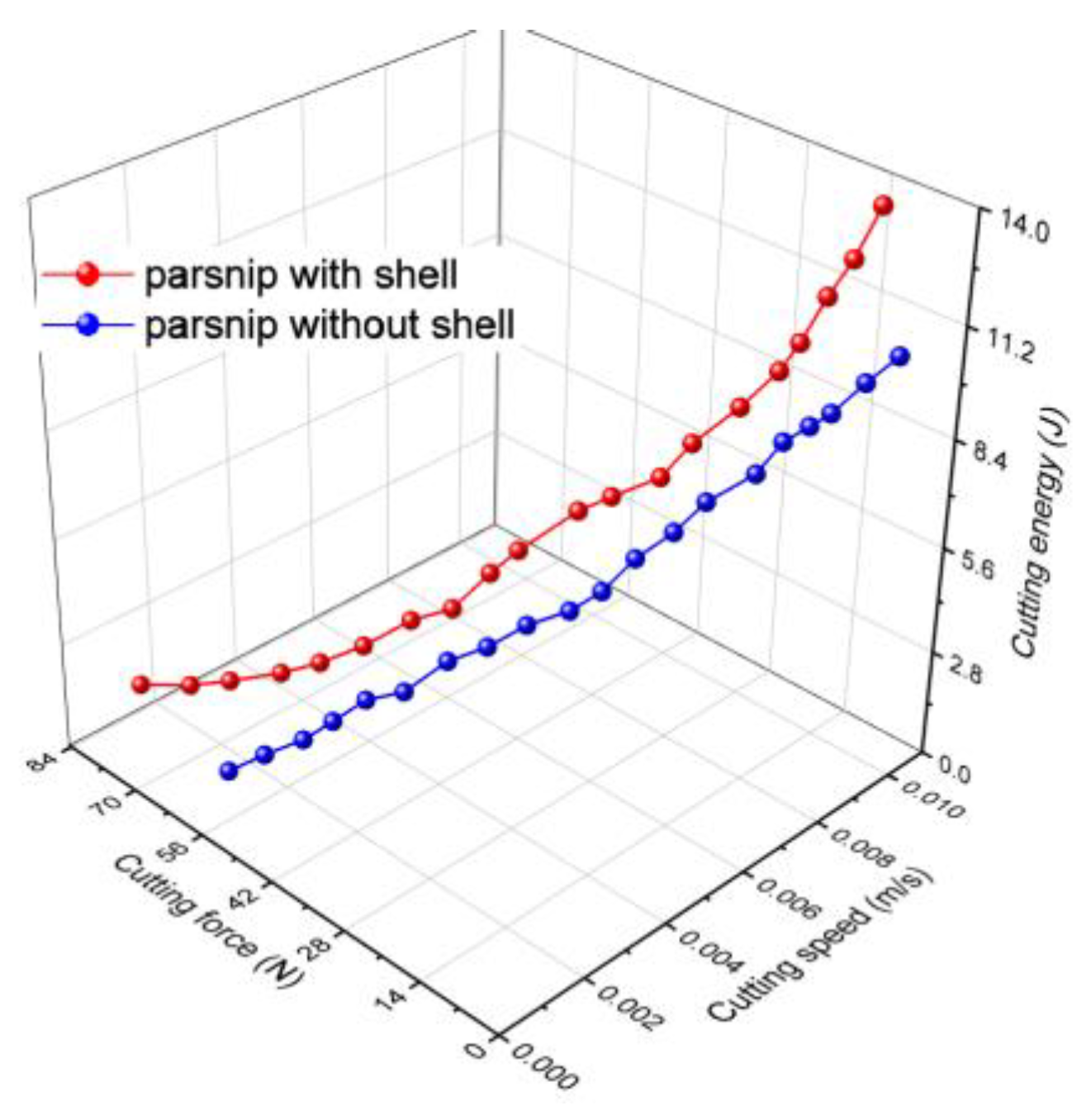

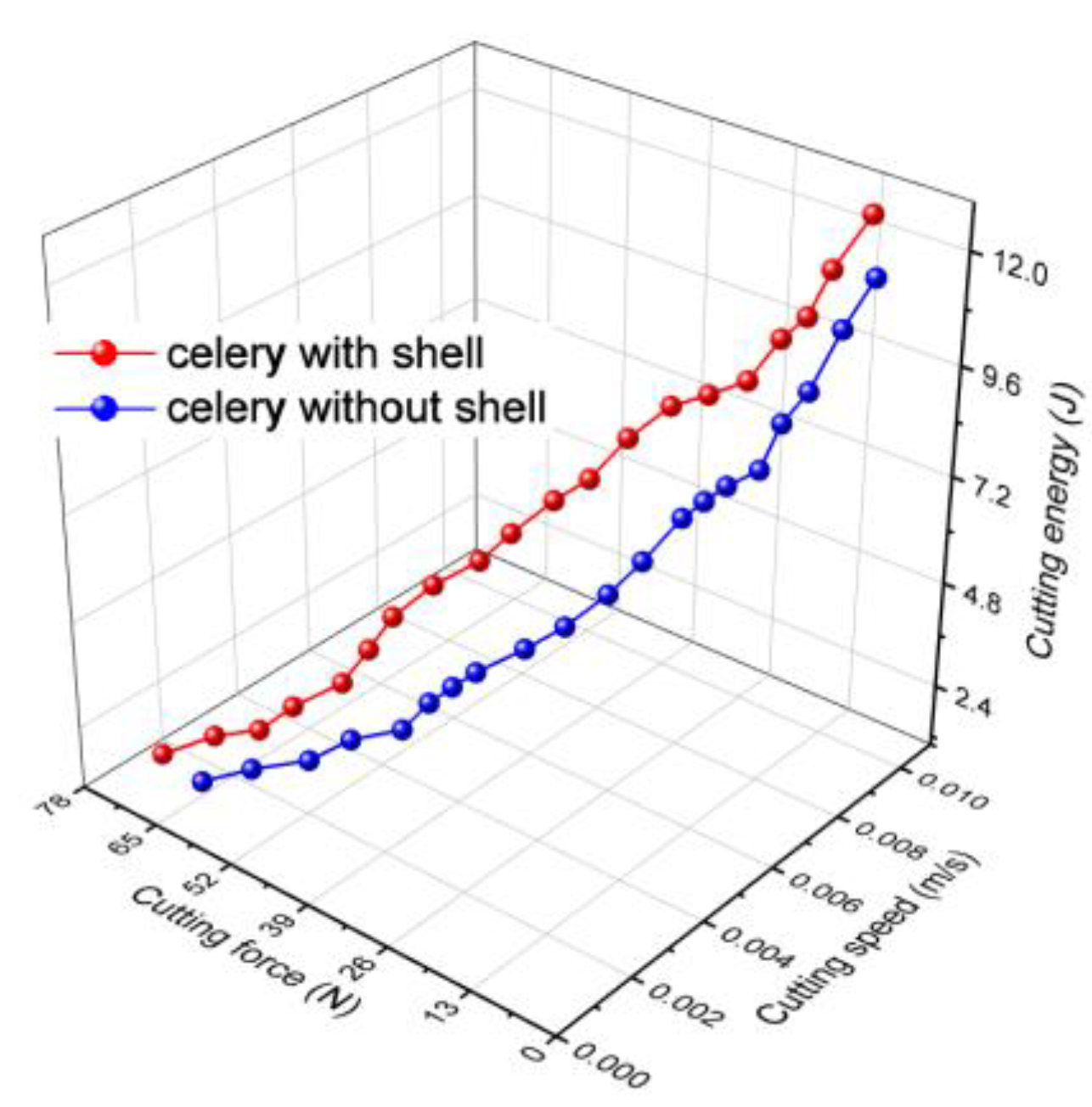

- The condition of the products to be cut has an impact on the cutting energy. According to the results of the experiments, when cutting unpeeled products, higher values of cutting energy were achieved than when cutting peeled products;

- -

- The condition of the products being cut affects the cutting energy. When examining the obtained data, it is evident that there are small variations in cutting energy for small values of cutting speed, which can be seen when comparing unpeeled and peeled products, suggesting that the cutting energy for the same products tends to increase in direct proportion to the cutting speed. This is also confirmed by numerous field research, such as in the case of wheat straw cutting [7];

- -

- Within the same species, cutting energy varies depending on variety, with the difference being mostly attributable to the textural characteristics, as shown in the case of celery, which has the biggest range of cutting energy observed, with its structure changing from the outside to the inside.

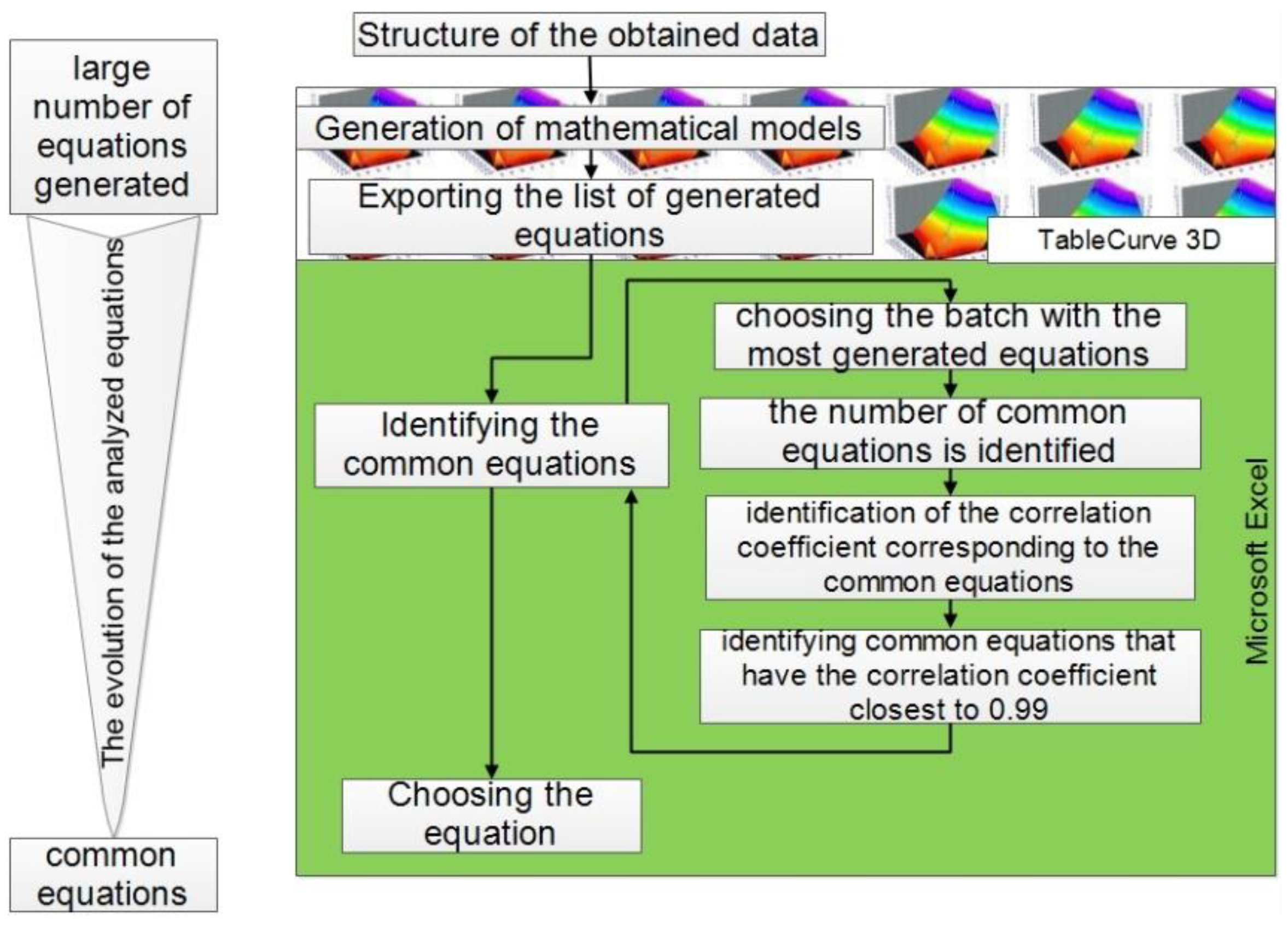

4. Generating Mathematical Equations

- The experimental values obtained are inserted into an excel file, and the data are arranged in separate columns;

- Table Curve 3D program allows the insertion of this excel file carrying data;

- The parameters corresponding to the three axes are selected where, on the OX (cutting speed) and OY (cutting force) axes, the input parameters are introduced, while on the OZ (cutting energy) axis the tracked parameter is introduced;

- Table Curve 3D software can generate equations that correlate to the values entered.

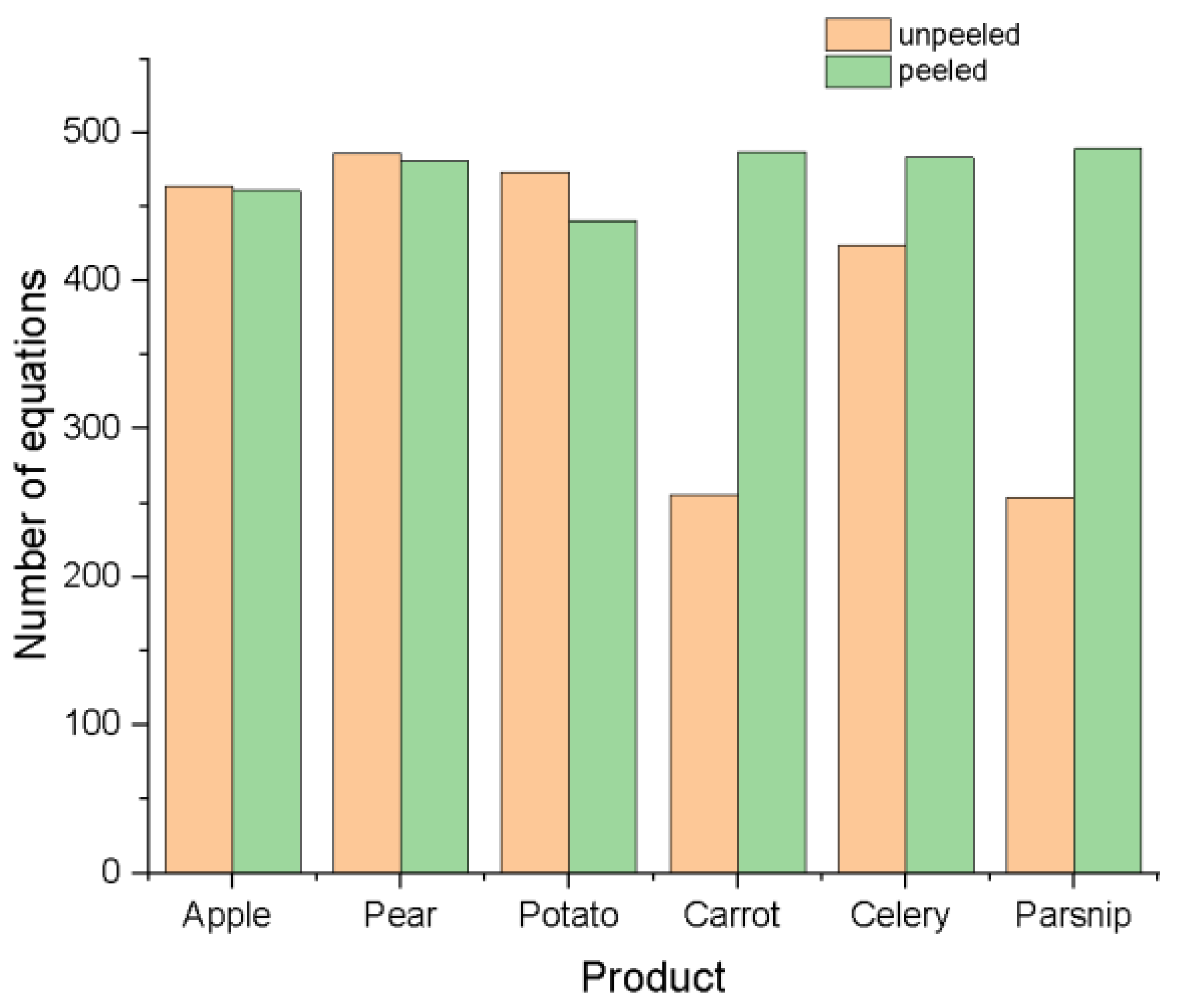

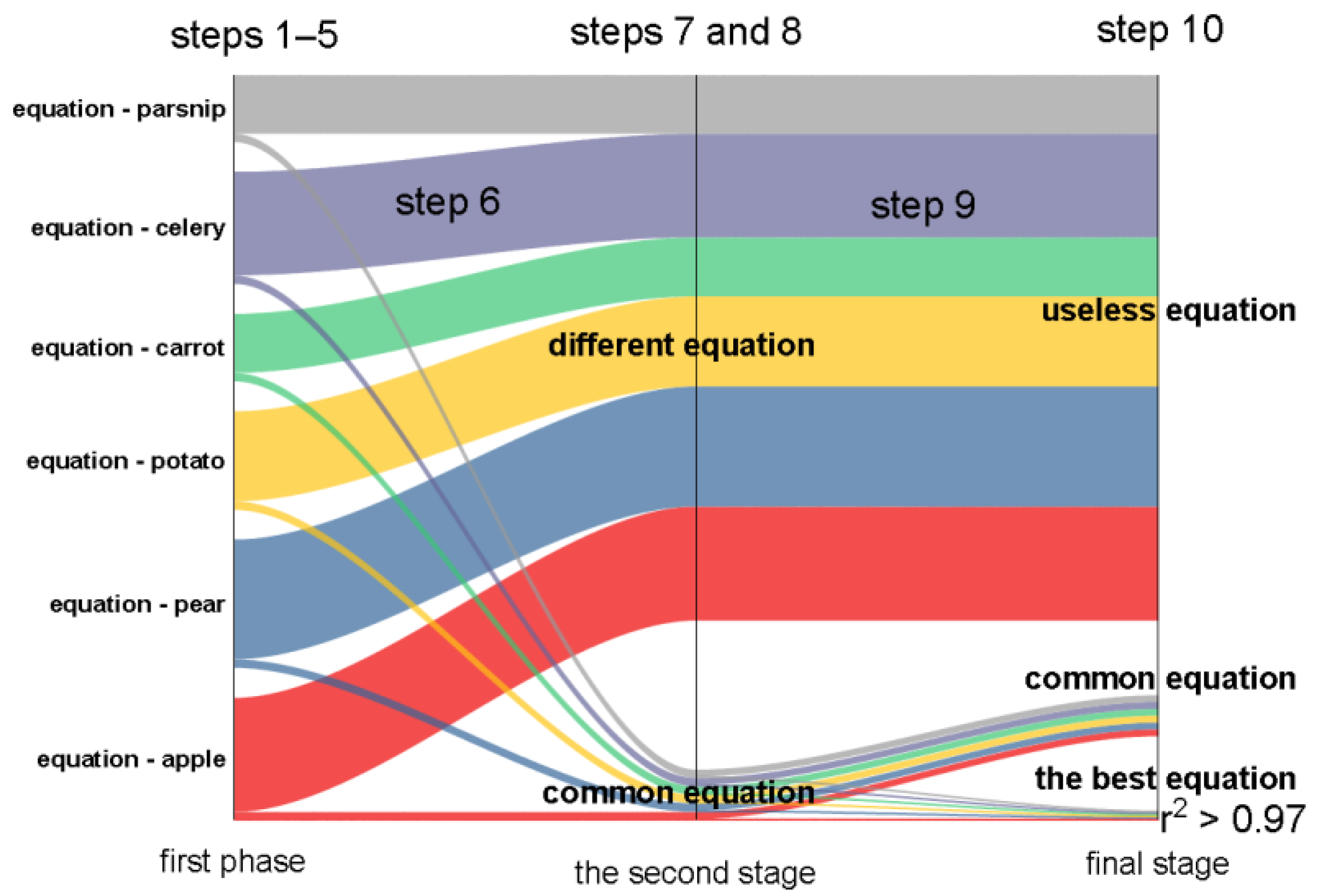

- Following the equations generated by Table Curve 3D software, a total of 5198 equations was generated, which were organized as follows: (Figure 12):

- -

- 2357 for products that have not been peeled;

- -

- 2841 is the number for peeled products.

- 6.

- A selection of common equations has been presented based on this facility, as follows:

- -

- A number of equations were generated for each group of experiments (with or without a peel) and for each sample in turn (apple, pear, potato, carrot, celery, and parsnip);

- -

- Within each experimental group (shell products—group a; peeled products—group b), a set of equations with the highest number of equations was chosen in comparison to the equations generated for the other samples (in our situation, we selected 486 equations for group A to correspond to the pear product and 489 equations for group B to correspond to the parsnip product;

- -

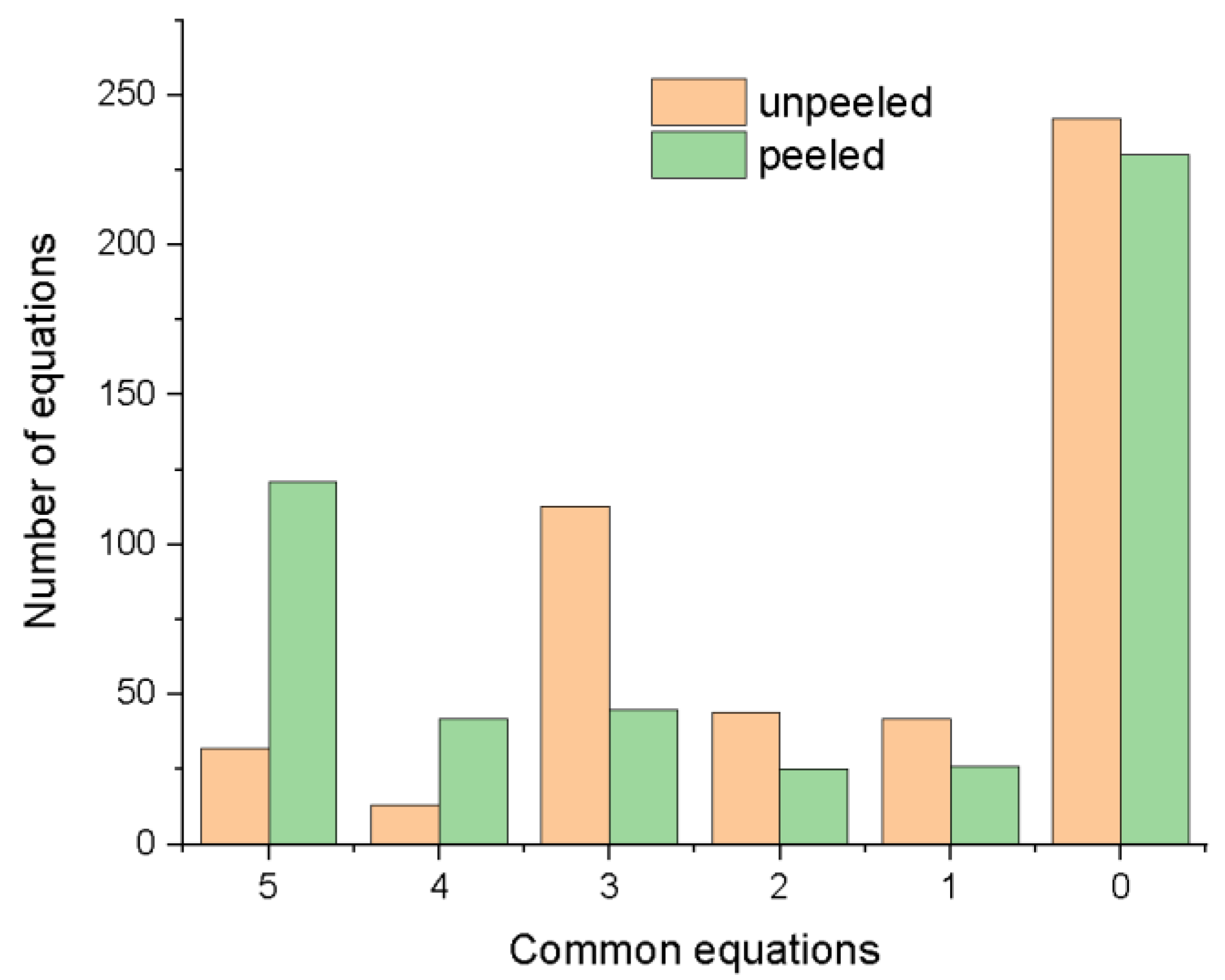

- In relation to this lot, similar equations (i.e., equations with the same identification number) have been identified, providing for preliminary filtering of the equations. The number of similar equations obtained from the study is shown in Figure 13. The number of similar equations identified in relation to the equations of the chosen reference lot is represented by numbers such as 5, 4, 3, 2, 1, and 0. (the lot with the most equations) (5—the equation is the same for all products; 0—the equation is unique to each product).

- 7.

- -

- for unpeeled products, the number of common equations was 32;

- -

- for peeled products, the number of common equations was 121;

- -

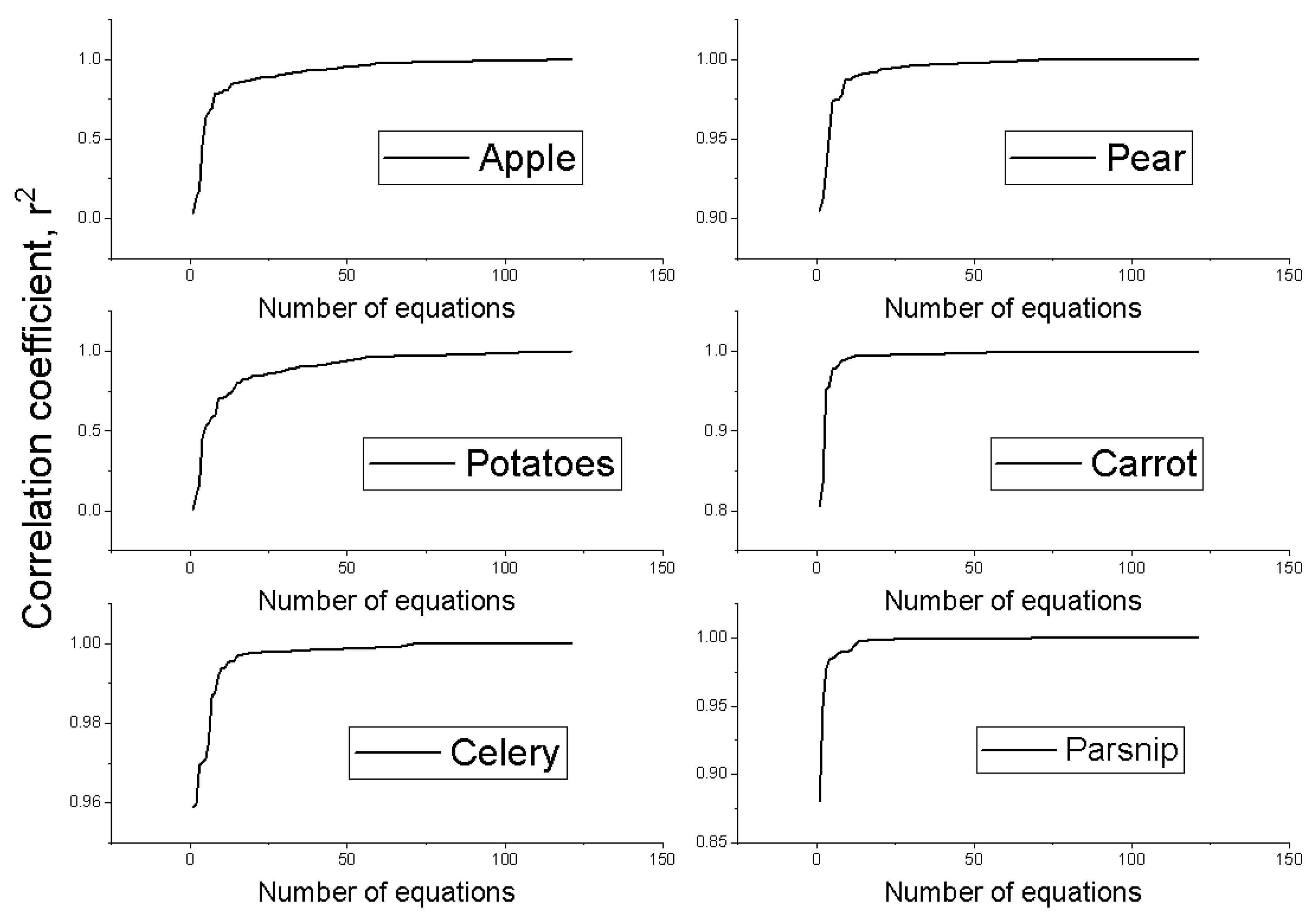

- Analyzing the distribution of the number of equations whose correlation coefficient is greater than 0.95 reveals:

- -

- In the case of unpeeled products, the highest number of equations was obtained for celery (32), followed by pear, parsnip, carrot, and apple, and the lowest number of equations was obtained for potato;

- -

- In the case of peeled products, the highest number of equations was obtained for celery (121), followed by parsnip, carrot, pear, and apple, and the lowest number of equations was obtained for potato.

- 8.

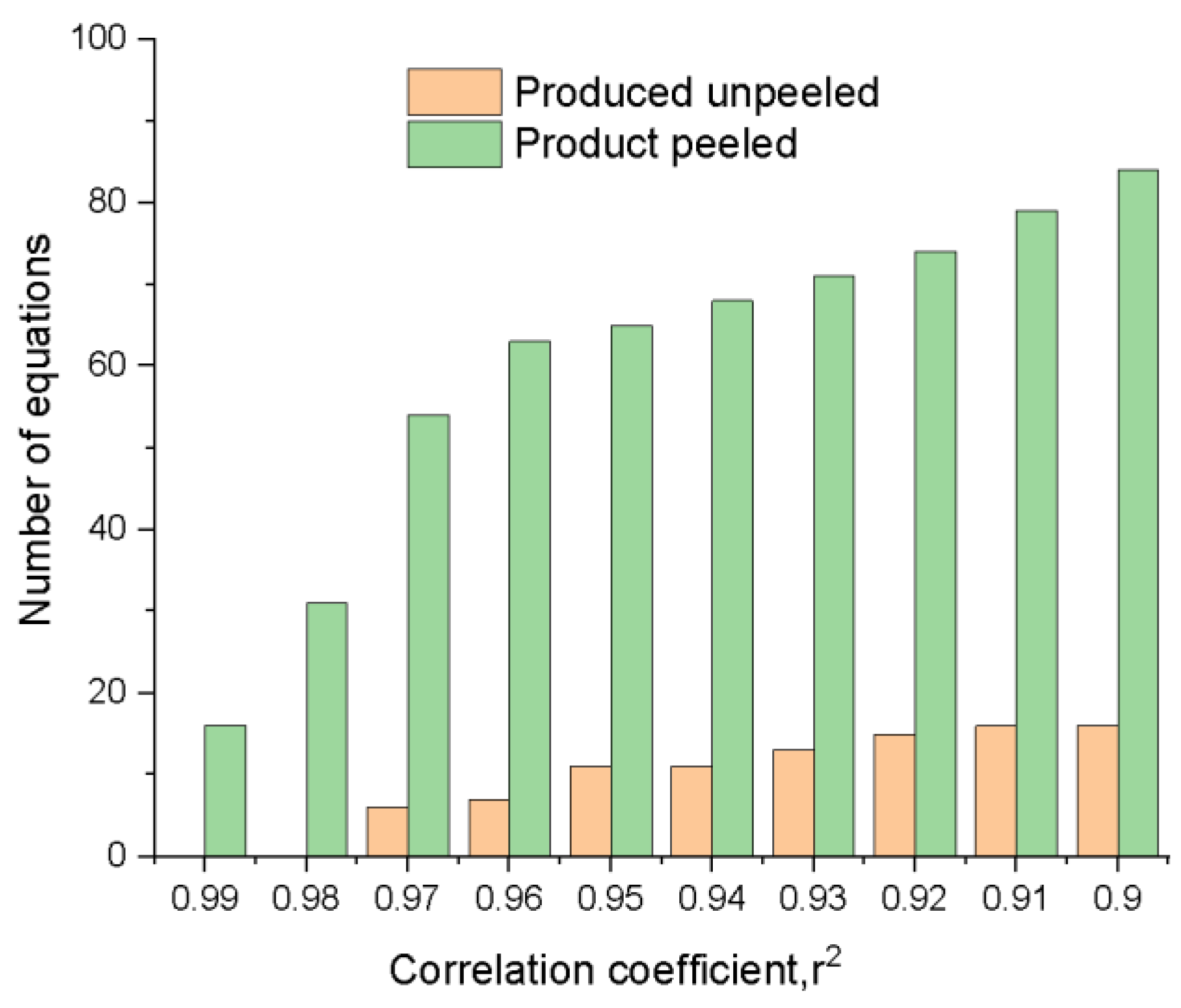

- As previously stated, our goal was to find a common equation, therefore we searched over the results more than once to identify the equations with the correlation coefficient, r2, which were closest to 0.99. In conclusion, for the range of values of the correlation coefficient r2 between 0.9 and 0.99, the number of equations available for solving the desired requirement has been graphically represented in Figure 16.

- 9.

- The evaluation of a group of common equations based on the value of the correlation coefficient r2 has been the next step. At this moment, the common equations were created to have the same correlation coefficient value. Followed by an analysis of the correlation coefficients corresponding to the common equations, a total of 6 equations for an r2 high of 0.97 have been discovered for the experimental batches of peeled products, and a number of 54 equations for the experimental group of unpeeled products.

- 10.

- When the values of the terms of the equation generated by the Table Curve 3D software are examined, it is discovered that some equation terms have a value bigger than e+8, meaning a thorough identification of the relevant term is difficult (since the entire value of the terms is necessary for the validation of the model). Following such an examination, only two possible equations remained out of the four common equations, whose model, in our situation, is provided by the logarithmic equations shown in Equations (3) and (4) (corresponding to equation number 145 and equation number 150—from the Table Curve 3D software database).

5. Conclusions

- -

- A number of agri-food products (fruit-apple, pear; root-potato, carrot, celery, and parsnip), peeled or unshelled, were used to determine the energy required for cutting vegetable products;

- -

- Only the density and humidity of the products used could be noted because of the diversity of the chosen products. Taking it into account, the apple has the lowest density (790 kg/m3), while the potato has the highest density (1060 kg/m3). When it regards humidity, potatoes have the lowest humidity (74.5%), and parsnips have the highest (89.5%);

- -

- The cutting process is influenced directly by the textural properties of the products used in these experimental evaluations:

- -

- The highest value of energy used to carry out the cutting process was obtained for the product with the lowest humidity, the peeled potato, whose humidity was 74.5% and 23.16 J, respectively, and the lowest value was obtained for unpeeled celery, respectively 11.44 J.

- -

- In regard to the humidity characteristic, it can be said that it has a direct and inversely proportional influence on the cutting energy value;

- -

- In terms of product character, both peeled and unpeeled, it is discovered that the energy required to cut peeled products is more than the energy necessary to cut unpeeled products, regardless of the type of the product used;

- -

- When the energy required to carry out the cutting process is examined in relation to the force used and the cutting device’s speed of movement, it is discovered that these characteristics have a direct impact on the parameter analyzed, independently of the type of the product used;

- -

- Using the Table Curve 3D software, the obtained data were utilized to produce mathematical equations;

- -

- An analysis methodology has been developed to identify a common equation for all experimental groups, which can be generalized to other types of experiments as well;

- -

- Following the working stages of the experimental data, it is found that:

- -

- For peeled products, where a total of 2357 equations were created, 32 common equations were generated, only 6 of which satisfied the criterion of r2 being larger than 0.97;

- -

- For unpeeled products, it resulted in a total of 2841 equations, 121 of which were common and 54 of which satisfied the requirement of r2 having larger than 0.97;

- -

- Following a visual examination of the Table Curve 3D program’s mathematical equations, which satisfied the two primary requirements:

- ○

- To have an r2> of 0.97 (6 equations for peeled products and 54 for unpeeled products);

- ○

- To have something in common with both peeled and unpeeled products;

- ○

- We had the option of choosing between two logarithmic equations;

- -

- Two common logarithmic equations describing the dependency between the cutting energy required to cut different types of products (peeled and/or unpeeled) depending on the cutting speed and force, and the dependency characteristic of the cutting process of hard-textured products, were identified following the analysis of the equations obtained using the Table Curve 3D software.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Earle, R.L. Unit Operations in Food Industry; The New Zealand Institute of Food Science and Technology: Palmerston North, New Zealand, 1983. [Google Scholar]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials; Gordon and Breach Science Publishers: New York, NY, USA, 1970. [Google Scholar]

- Bourne, M.C. Basic Principles of Food Texture Measurement; Lecture text of Dough Rheology and Baked Products Texture Workshop: Chicago, IL, USA, 1988. [Google Scholar]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Tabil, L.G.; Song, Y.; Iroba, K.L.; Meda, V. Grinding energy and physical properties of chopped and hammer-milled barley, wheat, oat, and canola straws. Biomass Bioenergy 2014, 60, 58–67. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Wolcott, M.P. Assessing the specific energy consumption and physical properties of comminuted Douglas-fir chips for bioconversion. Ind. Crops Prod. 2016, 94, 394–400. [Google Scholar] [CrossRef]

- Panainte, M.; Nedeff, V.; Burcă, G.; Savin, C.; Mosnegutu, E. Theoretical consideration regarding statistical calculus about distribution of size at particles at result from grinding process. MOCM 2004, 10, 83–88. [Google Scholar]

- Cadoche, L.; Lopez, G.D. Assessment of size-reduction as a preliminary step in the production of ethanol from lignocellulosic wastes. Biol. Wastes 1989, 30, 153–157. [Google Scholar] [CrossRef]

- Panainte, M.; Nedeff, V.; Moşneguţu, E. Analysis of grinding process at hammer mill. MOCM 2001, 7, 120–129. [Google Scholar]

- Panainte, M.; Dasic, P.; Nedeff, V.; Mosnegutu, E.; Savin, C. Modalities to determine the energy consomption for the grindin gat vegetables product with variable texture. MOCM 2007, 13, 239–248. [Google Scholar]

- Brennan, J.G. Food texture measurement. In Developments in Food Analysis Techniques; Elsevier Applied Science Publishers: London, UK, 1980; Volume 2. [Google Scholar]

- Ragni, L.; Berardinelli, A. Mechanical behaviour of apples and damage during sorting a packaging. J. Agric. Engng. Res. 2001, 78, 78–91. [Google Scholar]

- Panainte, M.; Nedeff, V.; Moşneguţu, E.; Savin, C.; Măcărescu, B.; Olaru, C. Determination of grinding energy to vegetable product through texture analysis method. MOCM 2007, 3, 128–134. [Google Scholar]

- Adapa, P.; Tabil, L.; Schoenau, G. Grinding performance and physical properties of non-treated and steam exploded barley, canola, oat and wheat straw. Biomass Bioenergy 2011, 35, 549–561. [Google Scholar] [CrossRef]

- Naimi, L.J.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Womac, A.R.; Lau, A.K.; Melin, S. Development of size reduction equations for calculating energy input for grinding lignocellulosic particles. Appl. Eng. Agric. 2013, 29, 93–100. [Google Scholar] [CrossRef]

- Karam, M.C.; Petit, J.; Zimmer, D.; Djantou, E.B.; Scher, J. Effects of drying and grinding in production of fruit and vegetable powders: A review. J. Food Eng. 2016, 188, 32–49. [Google Scholar] [CrossRef]

- Indira, T.N.; Bhattacharya, S. Grinding characteristics of some legumes. J. Food Eng. 2006, 76, 113–118. [Google Scholar] [CrossRef]

- Xiaoan, L.; Qinghong, L.; Fan, G.; Cong, H.; Peng, J.; Yonghua, Z. Effect of cutting styles on quality and antioxidant activity in fresh-cut pitaya fruit. Postharvest Biol. Technol. 2017, 124, 1–7. [Google Scholar]

- Bitra, V.S.P.; Womac, A.R.; Chevanan, N.; Miu, P.I.; Igathinathane, C.; Sokhansanj, S.; Smith, D.R. Direct mechanical energy measures of hammer mill comminution of switchgrass, wheat straw, and corn stover and analysis of their particle size distributions. Powder Technol. 2009, 193, 32–45. [Google Scholar] [CrossRef]

- Kratky, L.; Jirout, T. Modelling of particle size characteristics and specific energy demand for mechanical size reduction of wheat straw by knife mill. Biosyst. Eng. 2022, 197, 32–44. [Google Scholar] [CrossRef]

- Panainte, M.; Moşneguţu, E.; Savin, C.; Nedeff, V. Mărunţirea Produselor Agroalimentare; Meronia, Rovimed Publishers: Bacău, Romania, 2005. [Google Scholar]

- Panainte, M. Researches Regarding Optimizing the Grinding Process of Agrofood Products. Ph.D. Thesis, The “Gheorghe Asachi” Technical University of Iasi, Iași, Romania, 2008. [Google Scholar]

- Ladan, J.N.; Shahab, S. Data-based equation to predict power and energy input for grinding wheat straw, corn stover, switchgrass, miscanthus, and canola straw. Fuel Process. Technol. 2018, 173, 81–88. [Google Scholar]

- Wang, Y.L.J.; Barth, J.C.; Welsch, K.R.; McIntyre, V.; Wolcot, M.P. Effects of multi-stage milling method on the energy consumption of comminuting forest residuals. Ind. Crops Prod. 2022, 145, 111955. [Google Scholar]

- Flumignan, D.L.; Rezende, K.A.; Comunello, E.M.; Fietz, C.R. Empirical methods for estimating reference surface net radiation from solar radiation. Eng. Agrícola 2018, 38, 32–37. [Google Scholar] [CrossRef]

- Saruchi, S.A.; Ariff, M.H.M.; Zamzuri, H.; Hassan, N.; Nurbaiti, W. Artificial neural network for modelling of the correlation between lateral acceleration and head movement in a motion sickness study. IET Intell. Transp. Syst. 2018, 13, 340–346. [Google Scholar] [CrossRef]

- Paterson, C.; Clevers, H.; Bozic, I. Mathematical model of colorectal cancer initiation. Proc. Natl. Acad. Sci. USA 2022, 117, 20681–20688. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, S.; Kitawaki, T.; Oka, H. Mathematical equation of fusion index of tetanic contraction of skeletal muscles. J. Electromyogr. Kinesiol. 2010, 20, 284–289. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Liu, J.X.; Zhang, K. Establishment of a prediction model for the cut size of turbo air classifiers. Powder Technol. 2014, 254, 274–280. [Google Scholar] [CrossRef]

- Ageev, A.A.; Yakhontov, D.A.; Kadyrov, T.F.; Farakhov, M.M.; Lapteva, E.A. Mathematical equation of dispersed phase gas separation in a combined equipment. Chem. Petrol. Eng 2019, 55, 611–618. [Google Scholar] [CrossRef]

- Hwang, D.H.; Han, J.H.; Lee, J.; Lee, Y.; Kim, D. A mathematical equation for the separation behavior of a split type low-shock separation bolt. Acta Astronaut. 2019, 164, 393–406. [Google Scholar] [CrossRef]

- Ibyatov, R.I.; Kholpanov, L.P.; Akhmadiev, F.G.; Fazylzyanov, R.R. Mathematical modeling of phase separation of a multiphase medium. Theor. Found. Chem. Eng. 2006, 40, 339–348. [Google Scholar] [CrossRef]

- Song, J.F.; Hu, X.F. A mathematical equation to calculate the separation efficiency of streamlined plate gas-liquid separator. Sep. Purif. Technol. 2017, 178, 242–252. [Google Scholar] [CrossRef]

- Cobzaru, C.; Marinoiu, A.; Apostolescu, G.A.; Tataru-Farmus, R.E.; Cernatescu, C. Mathematical modeling for kinetics of Fe3+ exchange on pretreated analcime. Rev. Roum. De Chim. 2019, 64, 403–407. [Google Scholar] [CrossRef]

- Mosnegutu, E.; Panainte-Lehadus, M.; Nedeff, V.; Tomozei, C.; Barsan, N.; Chitimus, D.; Jasinski, M. Extraction of mathematical correlations applied in the aerodynamic separation of solid particles. Processes 2022, 10, 1234. [Google Scholar] [CrossRef]

- Xxx, Stable Micro Systems. Available online: https://www.stablemicrosystems.com (accessed on 13 March 2020).

- SYSTAT Software Inc. TableCurve 3D, Version 4.0. Available online: https://systatsoftware.com/downloads/download-tablecurve-3d/ (accessed on 13 March 2020).

| Item No. | Species | Variety | Maturity | Observation |

|---|---|---|---|---|

| 1. | Apple | Grave Steiner | Complete | Unpeeled |

| 2. | Apple | Grave Steiner | Complete | Peeled |

| 3. | Apple | Ida Red | Complete | Unpeeled |

| 4. | Apple | Ida Red | Complete | Peeled |

| 5. | Apple | Golden Delicious | Complete | Unpeeled |

| 6. | Apple | Golden Delicious | Complete | Peeled |

| 7. | Apple | Jonagold | Complete | Unpeeled |

| 8. | Apple | Jonagold | Complete | Peeled |

| 9. | Pear | Clapp’s Favorite | Ripen | Unpeeled |

| 10. | Pear | Clapp’s Favorite | Ripen | Peeled |

| Item No. | Species | Variety | Maturity | Observation |

|---|---|---|---|---|

| 1. | Potato | Désirée | Complete | Unpeeled |

| 2. | Potato | Désirée | Complete | Unpeeled |

| 3. | Potato | Sante | Complete | Unpeeled |

| 4. | Potato | Sante | Complete | Peeled |

| 5. | Carrot | Nassan | Complete | Unpeeled |

| 6. | Carrot | Nassan | Complete | Peeled |

| 7. | Celery | Victoria | Complete | Unpeeled |

| 8. | Celery | Victoria | Complete | Peeled |

| 9. | Parsnip | Long White | Complete | Unpeeled |

| 10. | Parsnip | Long White | Complete | Peeled |

| Item No. | Species | Density (kg/m3) | Humidity (%) |

|---|---|---|---|

| 1. | Apple | 790 | 88.5 |

| 2. | 846 | 87.5 | |

| 3. | 920 | 84.1 | |

| 4. | 930 | 83.5 | |

| 5. | Pear | 1028 | 85.1 |

| Item No. | Species | Density (kg/m3) | Humidity (%) |

|---|---|---|---|

| 1. | Potato | 1010 | 82.3 |

| 2. | 1050 | 74.5 | |

| 3. | 1060 | 79.6 | |

| 4. | Carrot | 1040 | 88.8 |

| 5. | Celery | 964 | 87.0 |

| 6. | Parsnip | 994 | 89.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panainte-Lehăduș, M.; Moșneguțu, E.; Bârsan, N.; Andrioai, G.; Tomozei, C.; Irimia, O. Mathematical Perspectives in the Variable Texture Products Cutting Process. Processes 2022, 10, 1603. https://doi.org/10.3390/pr10081603

Panainte-Lehăduș M, Moșneguțu E, Bârsan N, Andrioai G, Tomozei C, Irimia O. Mathematical Perspectives in the Variable Texture Products Cutting Process. Processes. 2022; 10(8):1603. https://doi.org/10.3390/pr10081603

Chicago/Turabian StylePanainte-Lehăduș, Mirela, Emilian Moșneguțu, Narcis Bârsan, Gabriela Andrioai, Claudia Tomozei, and Oana Irimia. 2022. "Mathematical Perspectives in the Variable Texture Products Cutting Process" Processes 10, no. 8: 1603. https://doi.org/10.3390/pr10081603

APA StylePanainte-Lehăduș, M., Moșneguțu, E., Bârsan, N., Andrioai, G., Tomozei, C., & Irimia, O. (2022). Mathematical Perspectives in the Variable Texture Products Cutting Process. Processes, 10(8), 1603. https://doi.org/10.3390/pr10081603