Experimental Investigation on Flow Behavior of Paste Slurry Transported by Gravity in Vertical Pipes

Abstract

:1. Introduction

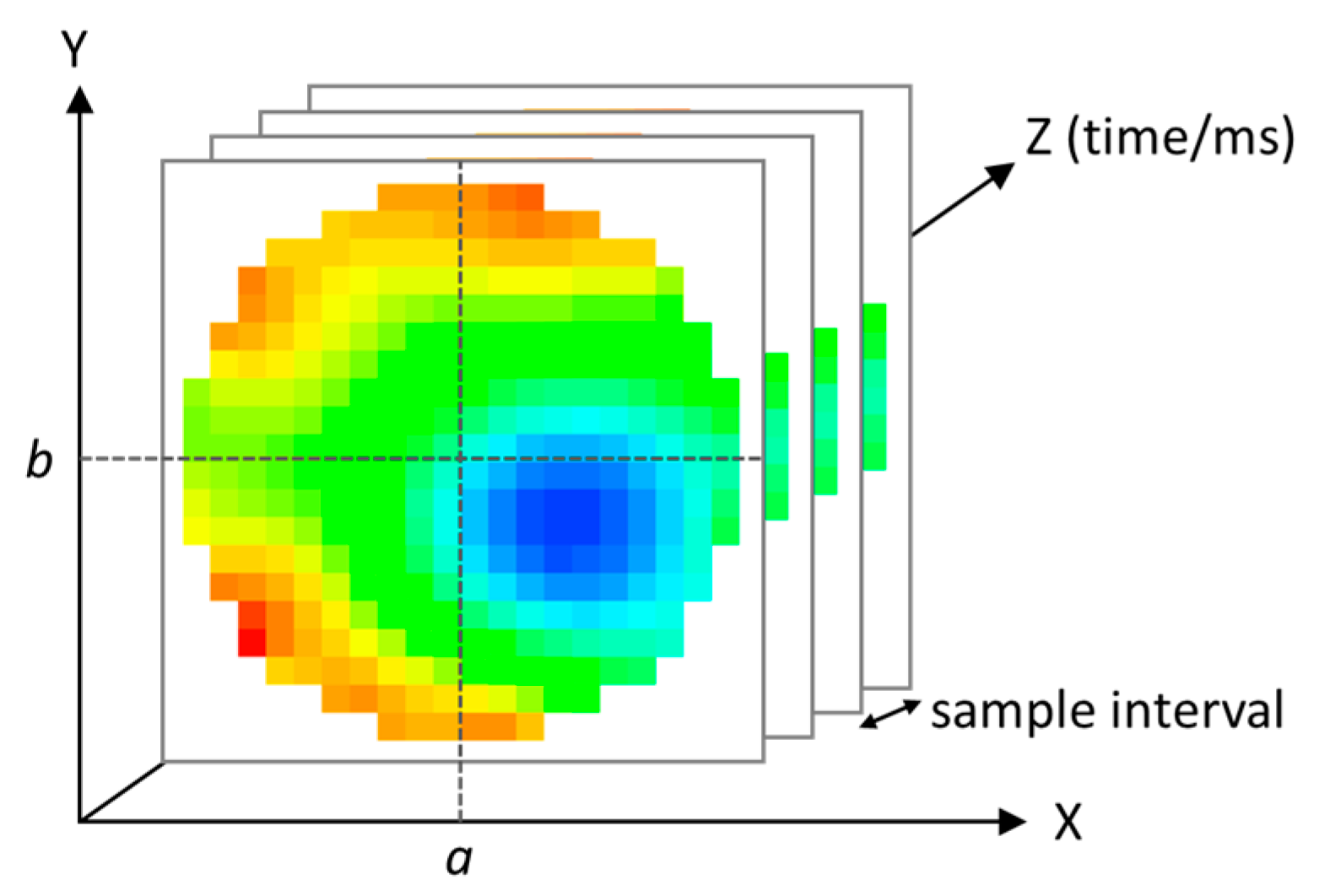

2. Experimental Setup and Methodology

2.1. Materials

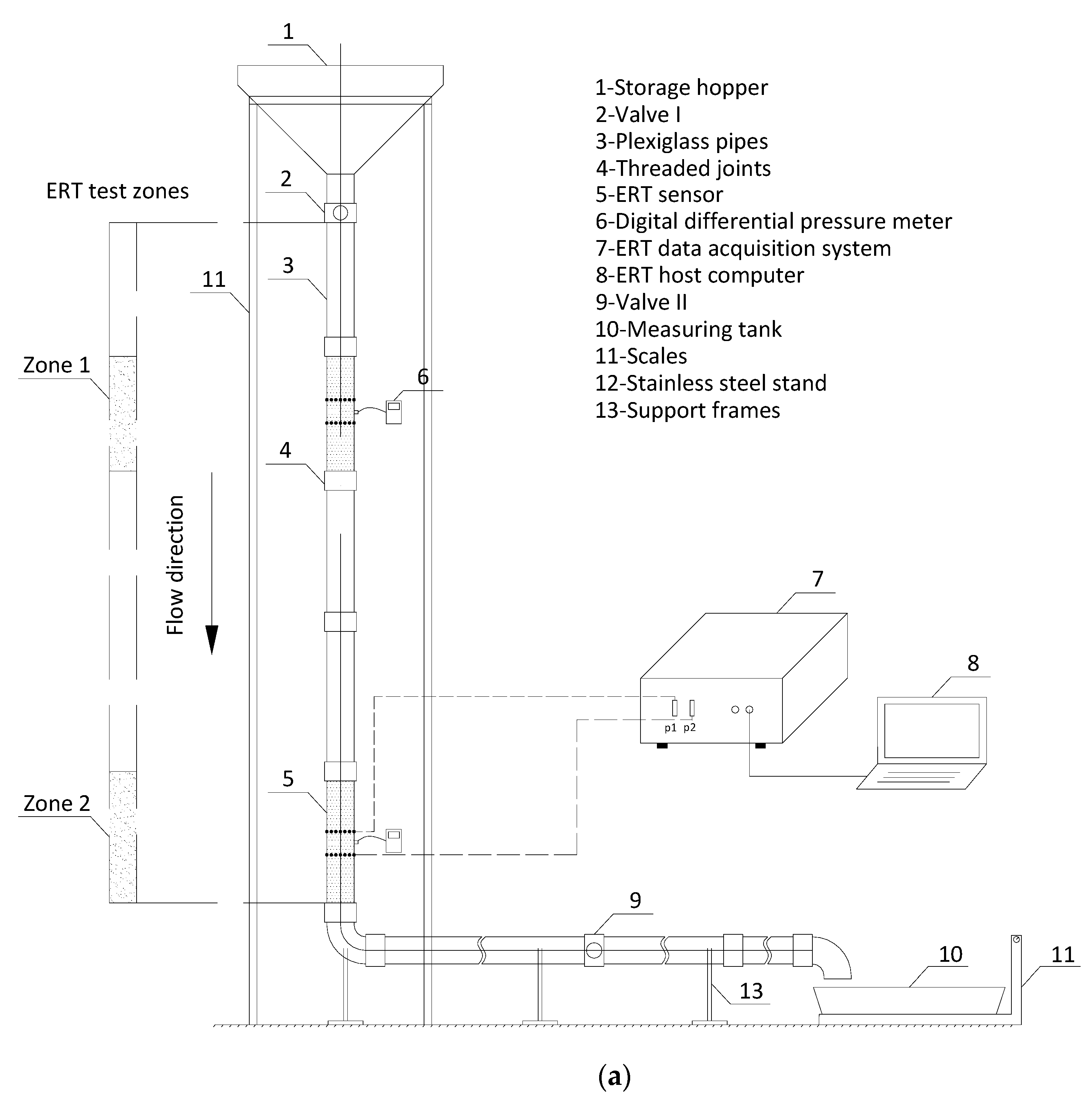

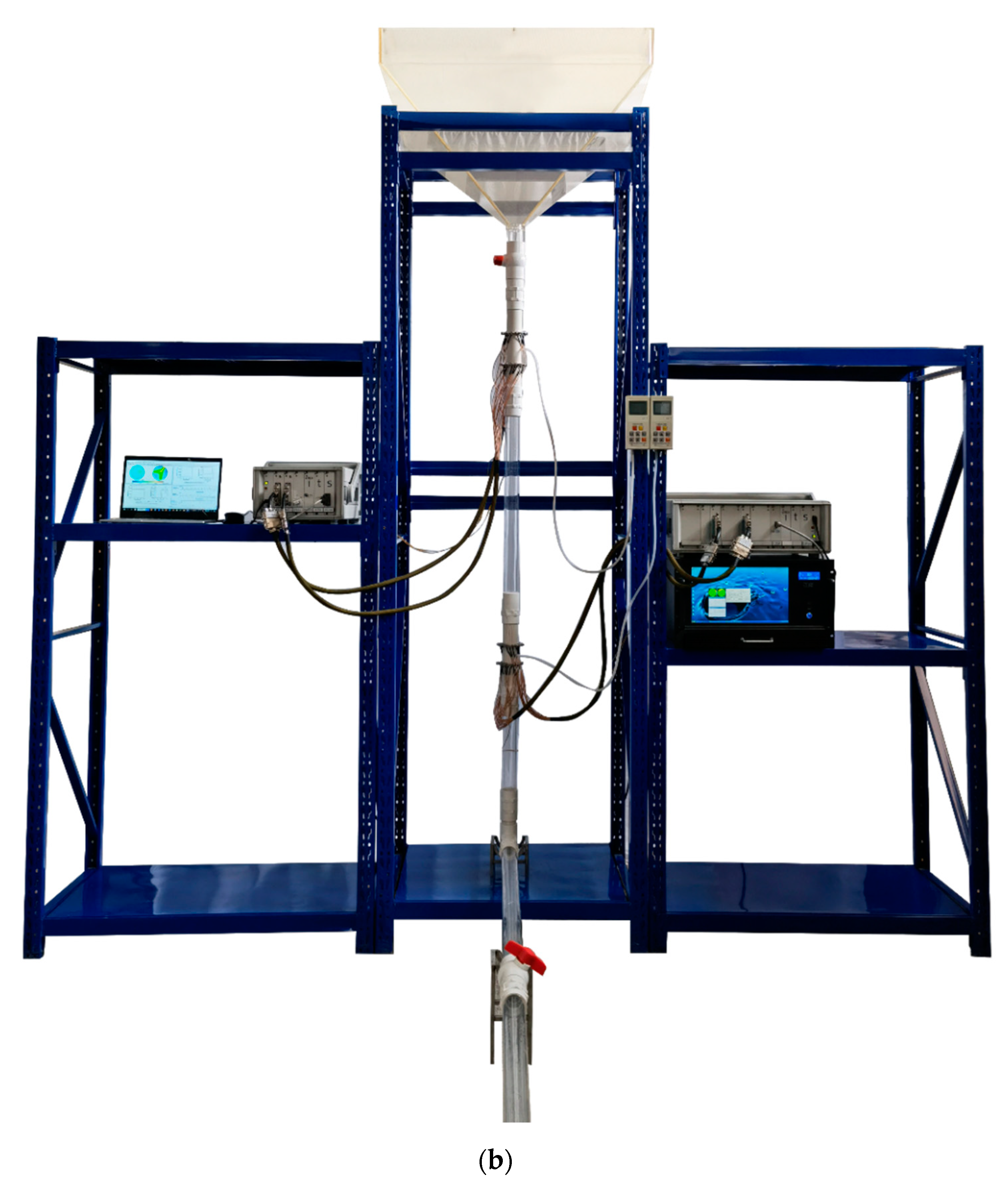

2.2. Experimental Setup

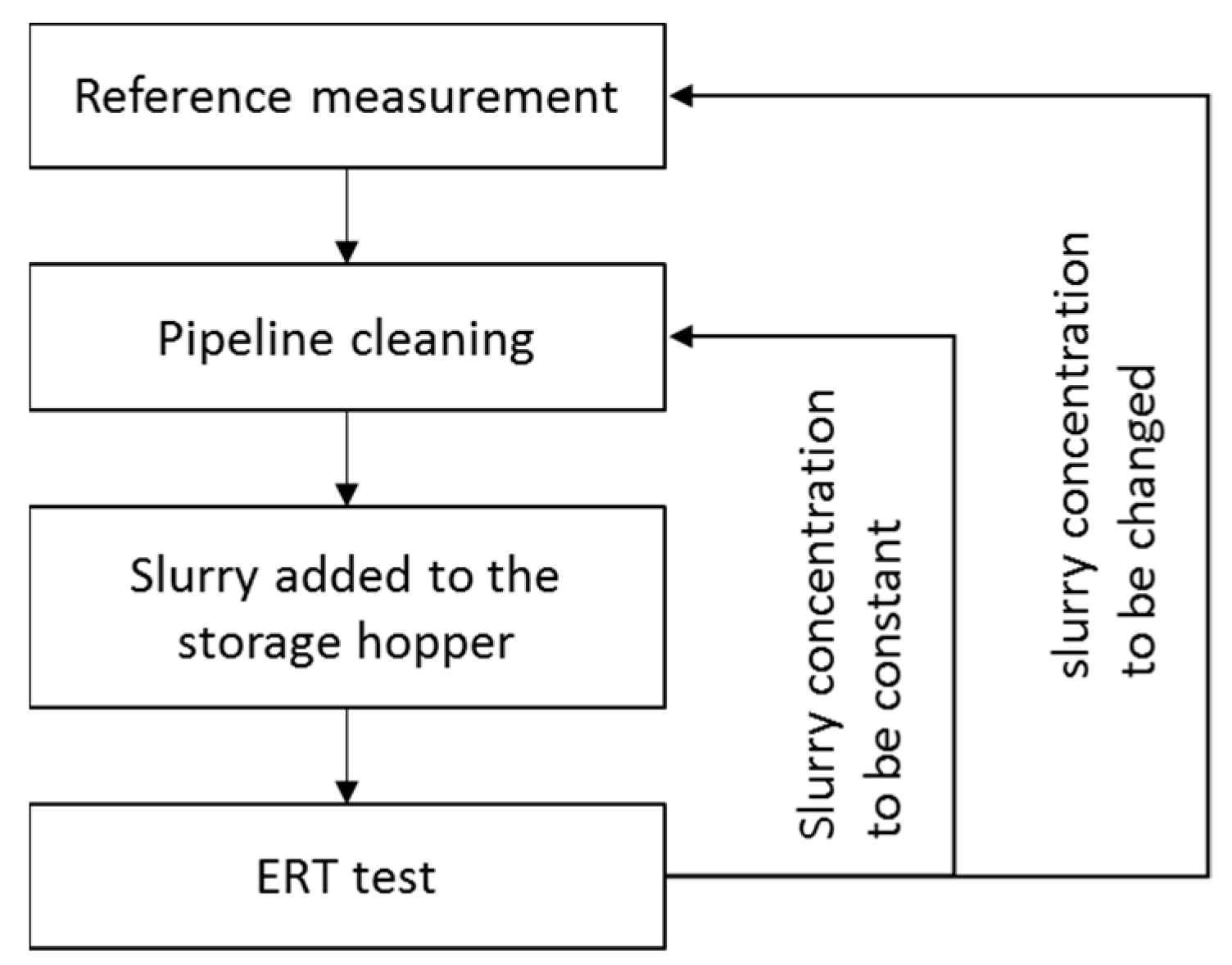

2.3. Experimental Procedure

3. Results and Discussions

3.1. Liquid Holdup

3.2. Flow Regimes

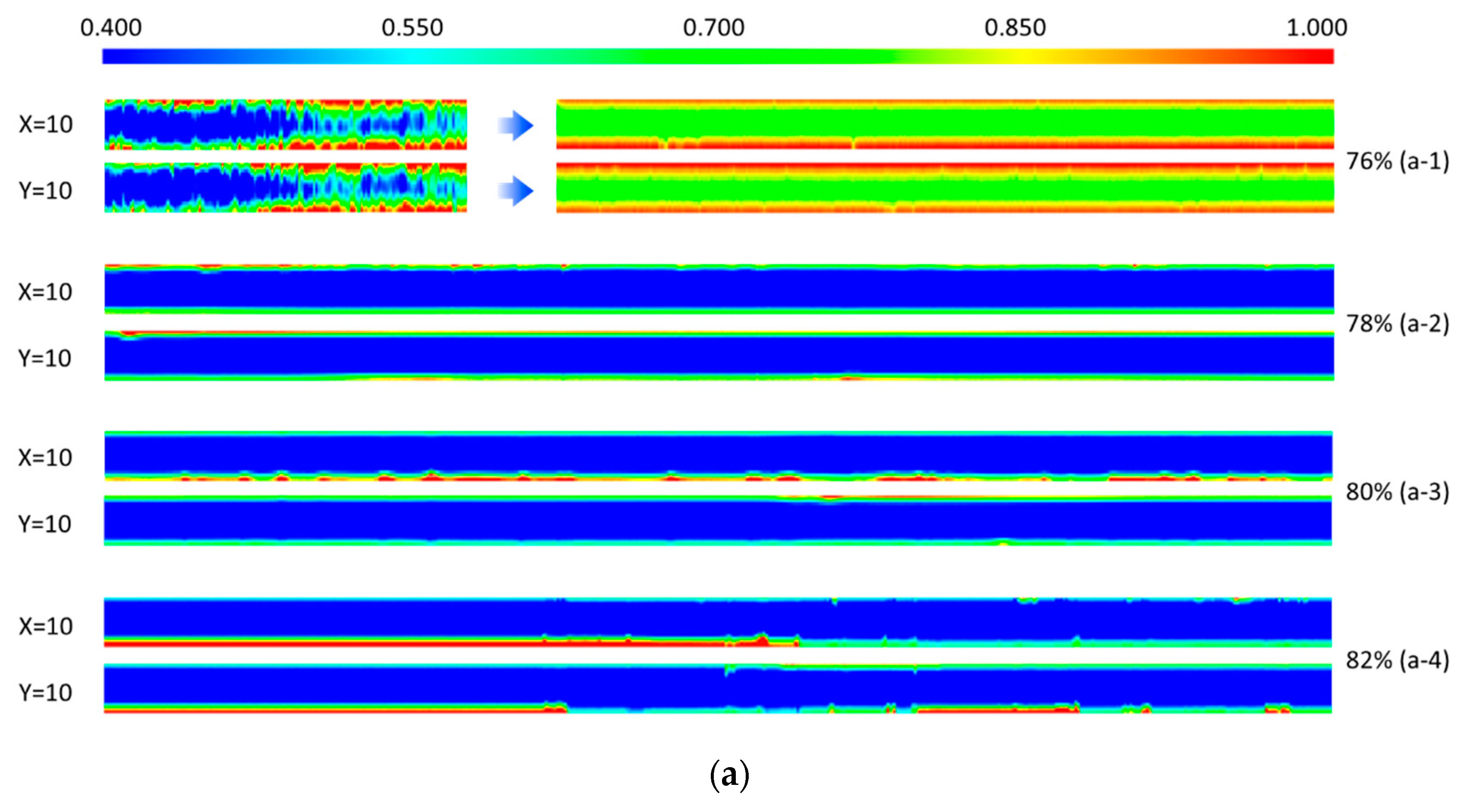

3.2.1. Flow Regimes of Slurry Flowing in S1

3.2.2. Flow Regimes of Slurry Flowing in S2

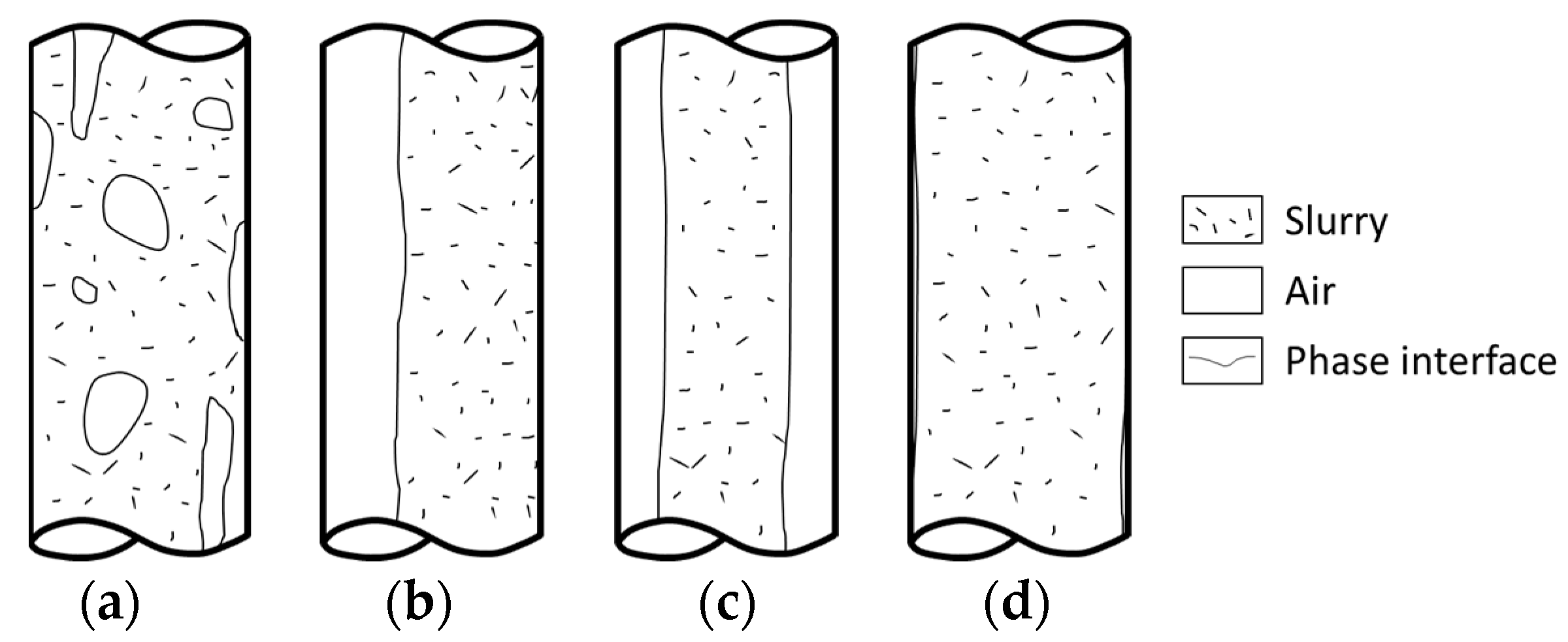

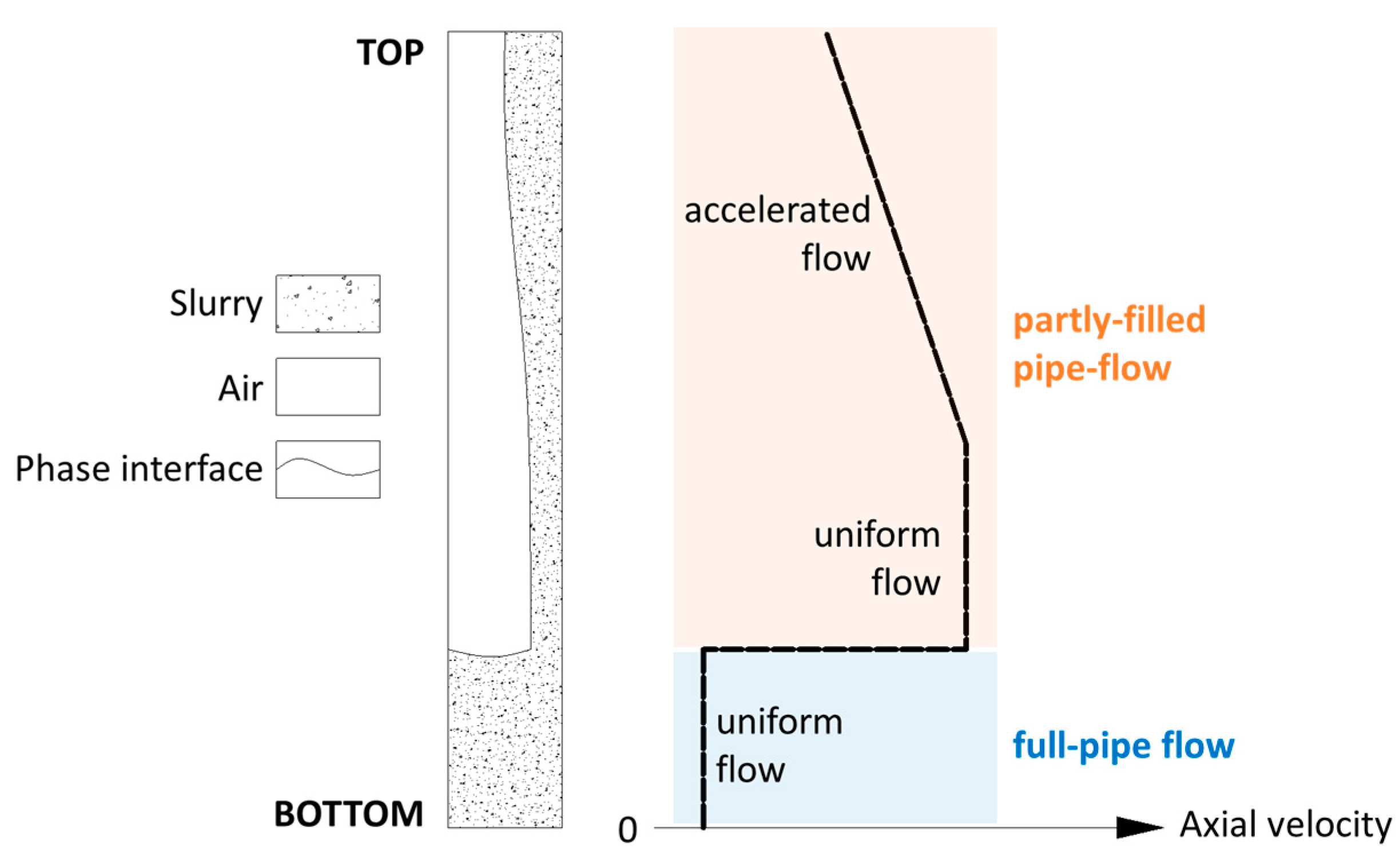

3.2.3. Typical Flow Regimes of Paste Slurry Flowing in Vertical Pipes

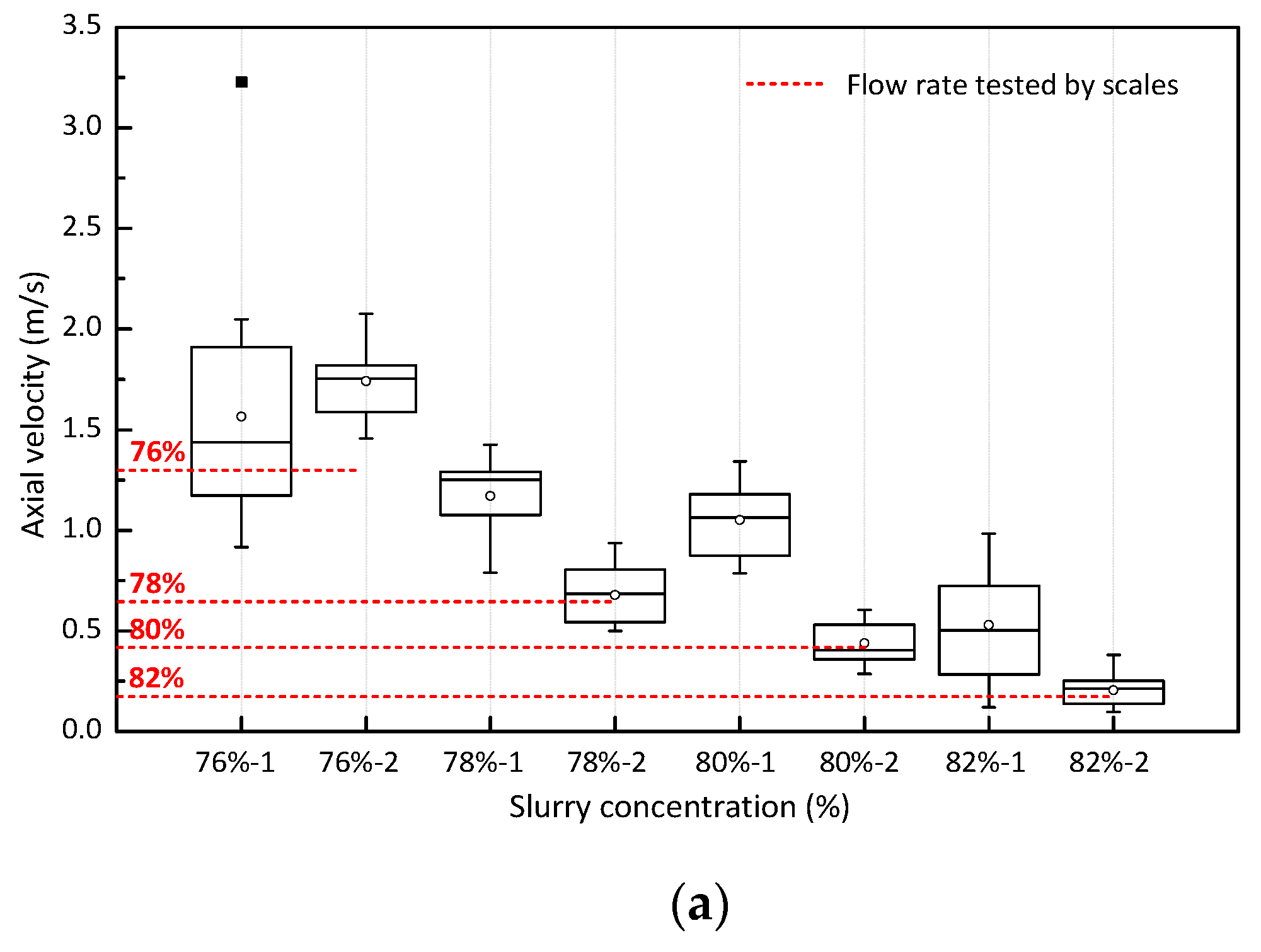

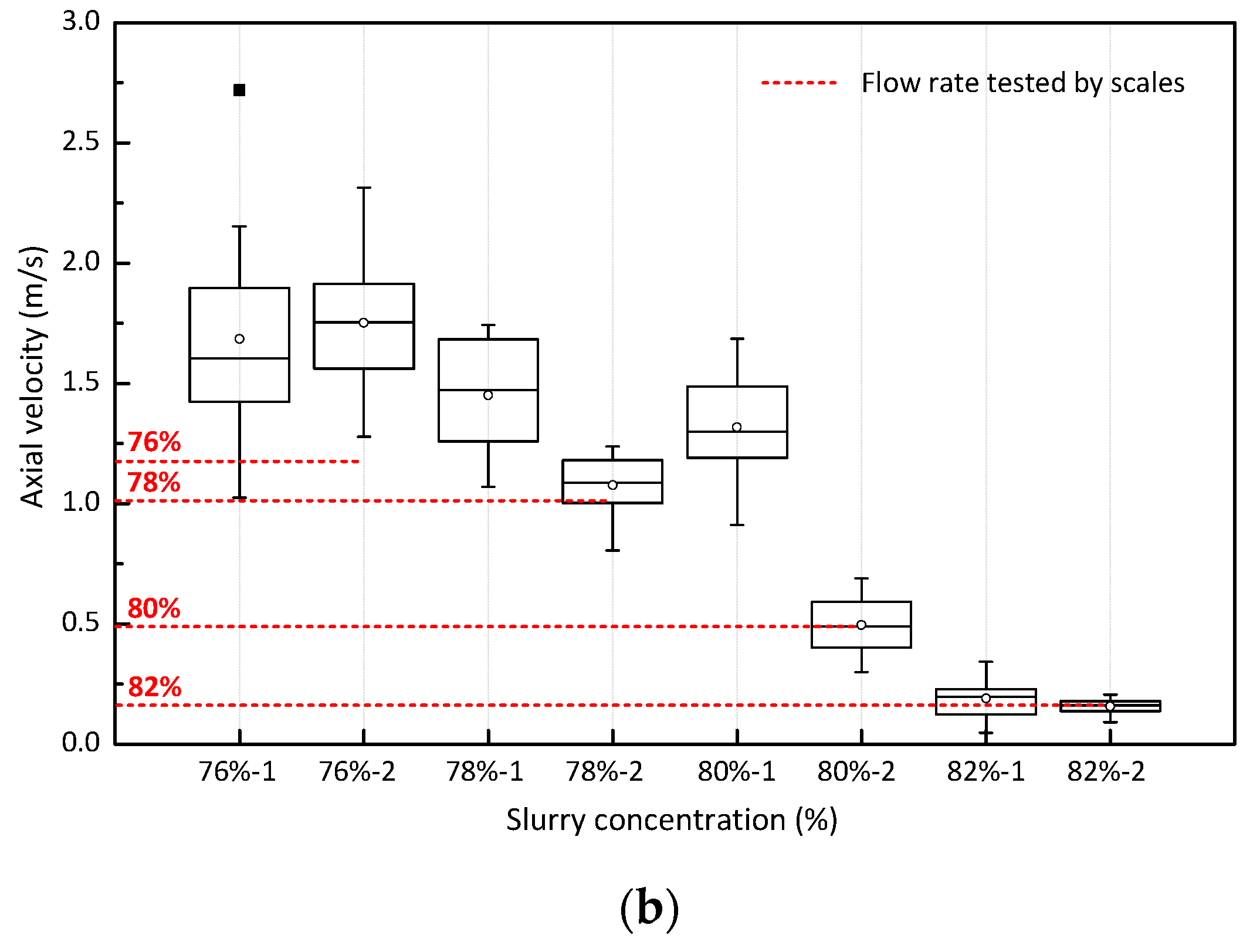

3.3. Axial Velocity

3.4. Pipe Pressure

4. Future Prospects

5. Conclusions

- (1)

- Four flow regimes, including mixed flow, stratified flow, columnar flow and full-pipe flow, are summarized based on reconstructed images from ERT. These flow regimes are very much affected by the slurry concentration.

- (2)

- When the slurry concentration was more than 78% in this experiment, full-pipe flow generally occurred in the position near the elbow that connects the vertical pipe and the horizontal pipe.

- (3)

- For the partly-filled pipe flow, the slurry first accelerates and then remains constant with the increase in the vertical pipe depth. The interface of partly-filled pipe flow and full-pipe flow is not stable, and water-hammer may occur due to the significant speed difference.

- (4)

- In the presence of S1-78%, S1-80% and S2-80%, the stable pressure of Zone 1 was −6.5 kPa, −5.8 kPa and −6.2 kPa, respectively. Namely, the upper part of the vertical pipe is generally under negative pressure which may lead to cavitation erosion.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Liu, B.; Gu, X.; Nehdi, M.L.; Zhang, L.V. Mechanochemical activation of iron ore tailing-based ternary supplementary cementitious materials. Constr. Build. Mater. 2022, 346, 128420. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Wu, A.; Kang, G. Wear law of Q345 steel under the abrasion–corrosion synergistic effect of cemented paste backfill. Constr. Build. Mater. 2022, 332, 127283. [Google Scholar] [CrossRef]

- Wu, A.; Ruan, Z.; Wang, J. Rheological behavior of paste in metal mines. Int. J. Miner. Metall. Mater. 2022, 29, 717–726. [Google Scholar] [CrossRef]

- Abdul-Hussain, N.; Fall, M. Thermo-hydro-mechanical behaviour of sodium silicate-cemented paste tailings in column experiments. Tunn. Undergr. Space Technol. 2012, 29, 85–93. [Google Scholar] [CrossRef]

- Yan, Z.; Yin, S.; Chen, X.; Wang, L. Rheological properties and wall-slip behavior of cemented tailing-waste rock backfill (CTWB) paste. Constr. Build. Mater. 2022, 324, 126723. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Jiang, H.; Fall, M.; Yilmaz, E.; Li, Y.; Yang, L. Effect of mineral admixtures on flow properties of fresh cemented paste backfill: Assessment of time dependency and thixotropy. Powder Technol. 2020, 372, 258–266. [Google Scholar] [CrossRef]

- Fall, M.; Adrien, D.; Célestin, J.C.; Pokharel, M.; Touré, M. Saturated hydraulic conductivity of cemented paste backfill. Miner. Eng. 2009, 22, 1307–1317. [Google Scholar] [CrossRef]

- Jewell, R.J.; Fourie, A.B. Paste and Thickened Tailings: A Guide; Australian Centre for Geomechanics, The University of Western Australia: Perth, Australia, 2006. [Google Scholar]

- Ranjith, P.G.; Zhao, J.; Ju, M.; de Silva, R.V.S.; Rathnaweera, T.D.; Bandara, A.K.M.S. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Emad, M.Z.; Mitri, H.; Kelly, C. State-of-the-art review of backfill practices for sublevel stoping system. Int. J. Min. Reclam. Environ. 2014, 29, 544–556. [Google Scholar] [CrossRef]

- Sinha, S.L.; Dewangan, S.K.; Sharma, A. A review on particulate slurry erosive wear of industrial materials: In context with pipeline transportation of mineral−slurry. Part. Sci. Technol. 2015, 35, 103–118. [Google Scholar] [CrossRef]

- Popescu, D.P.; Choo-Smith, L.P.; Flueraru, C.; Mao, Y.; Chang, S.; Disano, J.; Sherif, S.; Sowa, M.G. Optical coherence tomography: Fundamental principles, instrumental designs and biomedical applications. Biophys. Rev. 2011, 3, 155. [Google Scholar] [CrossRef]

- Iijima, M.; Taki, N.; Tatami, J. Operando observation of concentrated SiO2 suspensions by optical coherent tomography during flow curve measurements: The relationship between polymer dispersant structures and surface interactions. J. Colloid Interface Sci. 2022, 607, 290–297. [Google Scholar] [CrossRef]

- Abbagoni, B.M.; Yeung, H.; Lao, L. Non-invasive measurement of oil-water two-phase flow in vertical pipe using ultrasonic Doppler sensor and gamma ray densitometer. Chem. Eng. Sci. 2022, 248, 117218. [Google Scholar] [CrossRef]

- Salgado, C.M.; Dam, R.S.d.F.; Conti, C.d.C.; Salgado, W.L. Three-phase flow meters based on X-rays and artificial neural network to measure the flow compositions. Flow Meas. Instrum. 2021, 82, 102075. [Google Scholar] [CrossRef]

- Li, T.-Q.; McCarthy, K.L. Pipe flow of aqueous polyacrylamide solutions studied by means of nuclear magnetic resonance imaging. J. Non-Newtonian Fluid Mech. 1995, 57, 155–175. [Google Scholar] [CrossRef]

- Lev, E.; Boyce, C.M. Opportunities for Characterizing Geological Flows Using Magnetic Resonance Imaging. iScience 2020, 23, 101534. [Google Scholar] [CrossRef]

- Thorn, R.; Johansen, G.A.; Hammer, E.A. Recent developments in three-phase flow measurement. Meas. Sci. Technol. 1997, 8, 691–701. [Google Scholar] [CrossRef]

- Faraj, Y.; Wang, M. ERT Investigation on Horizontal and Vertical Counter-gravity Slurry Flow in Pipelines. Procedia Eng. 2012, 42, 588–606. [Google Scholar] [CrossRef]

- Qureshi, M.F.; Ali, M.H.; Ferroudji, H.; Rasul, G.; Khan, M.S.; Rahman, M.A.; Hasan, R.; Hassan, I. Measuring solid cuttings transport in Newtonian fluid across horizontal annulus using electrical resistance tomography (ERT). Flow Meas. Instrum. 2021, 77, 101841. [Google Scholar] [CrossRef]

- Rodgers, T.; Kowalski, A. An electrical resistance tomography method for determining mixing in batch addition with a level change. Chem. Eng. Res. Des. 2010, 88, 204–212. [Google Scholar] [CrossRef]

- Sharifi, M.; Young, B. Electrical resistance tomography (ERT) for flow and velocity profile measurement of a single phase liquid in a horizontal pipe. Chem. Eng. Res. Des. 2013, 91, 1235–1244. [Google Scholar] [CrossRef]

- Sharifi, M.; Young, B. 3-Dimensional spatial monitoring of tanks for the milk processing industry using electrical resistance tomography. J. Food Eng. 2011, 105, 312–319. [Google Scholar] [CrossRef]

- Sharifi, M.; Young, B. Electrical Resistance Tomography (ERT) applications to Chemical Engineering. Chem. Eng. Res. Des. 2013, 91, 1625–1645. [Google Scholar] [CrossRef]

- Dyakowski, T.; Jeanmeure, L.F.C.; Jaworski, A.J. Applications of electrical tomography for gas–solids and liquid–solids flows—A review. Powder Technol. 2000, 112, 174–192. [Google Scholar] [CrossRef]

- Polansky, J.; Wang, M. Vertical annular flow pattern characterisation using proper orthogonal decomposition of Electrical Impedance Tomography. Flow Meas. Instrum. 2018, 62, 281–296. [Google Scholar] [CrossRef]

- Tan, C.; Zhao, J.; Dong, F. Gas-water two-phase flow characterization with Electrical Resistance Tomography and Multivariate Multiscale Entropy analysis. ISA Trans. 2015, 55, 241–249. [Google Scholar] [CrossRef]

- Dong, F.; Xu, Y.; Xu, L.; Hua, L.; Qiao, X. Application of dual-plane ERT system and cross-correlation technique to measure gas–liquid flows in vertical upward pipe. Flow Meas. Instrum. 2005, 16, 191–197. [Google Scholar] [CrossRef]

- Giguère, R.; Fradette, L.; Mignon, D.; Tanguy, P. Characterization of slurry flow regime transitions by ERT. Chem. Eng. Res. Des. 2008, 86, 989–996. [Google Scholar] [CrossRef]

- Hashemi, S.; Sadighian, A.; Shah, S.; Sanders, R. Solid velocity and concentration fluctuations in highly concentrated liquid–solid (slurry) pipe flows. Int. J. Multiph. Flow 2014, 66, 46–61. [Google Scholar] [CrossRef]

- Mahmud, M.; Faraj, Y.; Wang, M. Visualisation and Metering of Two Phase Counter-gravity Slurry Flow using ERT. Procedia Eng. 2015, 102, 930–935. [Google Scholar] [CrossRef]

- Gharib, N.; Bharathan, B.; Amiri, L.; McGuinness, M.; Hassani, F.P.; Sasmito, A.P. Flow characteristics and wear prediction of Herschel-Bulkley non-Newtonian paste backfill in pipe elbows. Can. J. Chem. Eng. 2017, 95, 1181–1191. [Google Scholar] [CrossRef]

- Matoušek, V.; Krupička, J. One-dimensional modeling of concentration distribution in pipe flow of combined-load slurry. Powder Technol. 2014, 260, 42–51. [Google Scholar] [CrossRef]

- Machin, T.D.; Wei, H.; Greenwood, R.W.; Simmons, M.J.H. In-pipe rheology and mixing characterisation using electrical resistance sensing. Chem. Eng. Sci. 2018, 187, 327–341. [Google Scholar] [CrossRef]

- Feng, G.; Wang, Z.; Qi, T.; Du, X.; Guo, J.; Wang, H.; Shi, X.; Wen, X. Effect of velocity on flow properties and electrical resistivity of cemented coal gangue-fly ash backfill (CGFB) slurry in the pipeline. Powder Technol. 2022, 396, 191–209. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Wu, Y.; Lai, X.; Wang, P.; Song, K. Experimental investigation of solid-liquid two-phase flow in cemented rock-tailings backfill using electrical resistance tomography. Constr. Build. Mater. 2018, 175, 267–276. [Google Scholar] [CrossRef]

- Wu, D.; Yang, B.; Liu, Y. Pressure drop in loop pipe flow of fresh cemented coal gangue–fly ash slurry: Experiment and simulation. Adv. Powder Technol. 2015, 26, 920–927. [Google Scholar] [CrossRef]

- Doron, P.; Barnea, D. Pressure drop and limit deposit velocity for solid-liquid flow in pipes. Chem. Eng. Sci. 1995, 50, 1595–1604. [Google Scholar] [CrossRef]

- Fu, W.; Yu, J.; Xiao, Y.; Wang, C.; Huang, B.; Sun, B. A pressure drop prediction model for hydrate slurry based on energy dissipation under turbulent flow condition. Fuel 2022, 311, 122188. [Google Scholar] [CrossRef]

- Zhang, Q.; Cui, J.; Zheng, J.; Wang, X.; Wang, X. Wear mechanism and serious wear position of casing pipe in vertical backfill drill-hole. Trans. Nonferrous Met. Soc. China 2011, 21, 2503–2507. [Google Scholar] [CrossRef]

- Xiao, B.; Wen, Z.; Wu, F.; Li, L.; Yang, Z.; Gao, Q. A simple L-shape pipe flow test for practical rheological properties of backfill slurry: A case study. Powder Technol. 2019, 356, 1008–1015. [Google Scholar] [CrossRef]

- Zhang, Q.-L.; Hu, G.-Y.; Wang, X.-M. Hydraulic calculation of gravity transportation pipeline system for backfill slurry. J. Central South Univ. Technol. 2008, 15, 645–649. [Google Scholar] [CrossRef]

- Dickin, F.; Wang, M. Electrical resistance tomography for process applications. Meas. Sci. Technol. 1996, 7, 247–260. [Google Scholar] [CrossRef]

- Brown, B.H.; Barber, D.C.; Seagar, A.D. Applied potential tomography: Possible clinical applications. Clin. Phys. Physiol. Meas. 1985, 6, 109–121. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, S.; Spelay, R.; Sanders, R.; Hjertaker, B. A novel method to improve Electrical Resistance Tomography measurements on slurries containing clays. Flow Meas. Instrum. 2021, 80, 101973. [Google Scholar] [CrossRef]

| 76% | 77% | 78% | 79% | 80% | 81% | 82% | 83% | 84% | |

|---|---|---|---|---|---|---|---|---|---|

| Yield stress (Pa) | 7.16 | 14.84 | 15.49 | 22.04 | 35.25 | 56.69 | 79.96 | 114.85 | 197.82 |

| Bingham plastic viscosity (Pa·s) | 0.39 | 0.35 | 0.40 | 0.46 | 0.38 | 0.54 | 0.64 | 0.89 | 1.17 |

| S1-Zone 1 | S2-Zone 1 | S1-Zone 2 | S2-Zone 2 | |

|---|---|---|---|---|

| 76% | 0.75 | 0.50 | 0.31 | 0.32 |

| 78% | 0.39 | 0.36 | 0.93 | 0.99 |

| 80% | 0.34 | 0.26 | 0.94 | 0.93 |

| 82% | 0.33 | 0.94 | 0.33 | 0.94 |

| S1 | S2 | |||

|---|---|---|---|---|

| Mass Flow Rate (kg·s−1) | Mean Axial Velocity (m·s−1) | Mass Flow Rate (kg·s−1) | Mean Axial Velocity (m·s−1) | |

| 76% | 3.17 | 1.30 | 7.52 | 1.17 |

| 78% | 1.57 | 0.63 | 6.83 | 1.03 |

| 80% | 1.05 | 0.41 | 3.33 | 0.49 |

| 82% | 0.47 | 0.18 | 1.13 | 0.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wu, A.; Wang, M.; Ruan, Z. Experimental Investigation on Flow Behavior of Paste Slurry Transported by Gravity in Vertical Pipes. Processes 2022, 10, 1696. https://doi.org/10.3390/pr10091696

Wang J, Wu A, Wang M, Ruan Z. Experimental Investigation on Flow Behavior of Paste Slurry Transported by Gravity in Vertical Pipes. Processes. 2022; 10(9):1696. https://doi.org/10.3390/pr10091696

Chicago/Turabian StyleWang, Jiandong, Aixiang Wu, Mi Wang, and Zhuen Ruan. 2022. "Experimental Investigation on Flow Behavior of Paste Slurry Transported by Gravity in Vertical Pipes" Processes 10, no. 9: 1696. https://doi.org/10.3390/pr10091696

APA StyleWang, J., Wu, A., Wang, M., & Ruan, Z. (2022). Experimental Investigation on Flow Behavior of Paste Slurry Transported by Gravity in Vertical Pipes. Processes, 10(9), 1696. https://doi.org/10.3390/pr10091696