Thermodynamic and Economic Analysis of a High Temperature Cascade Heat Pump System for Steam Generation

Abstract

:1. Introduction

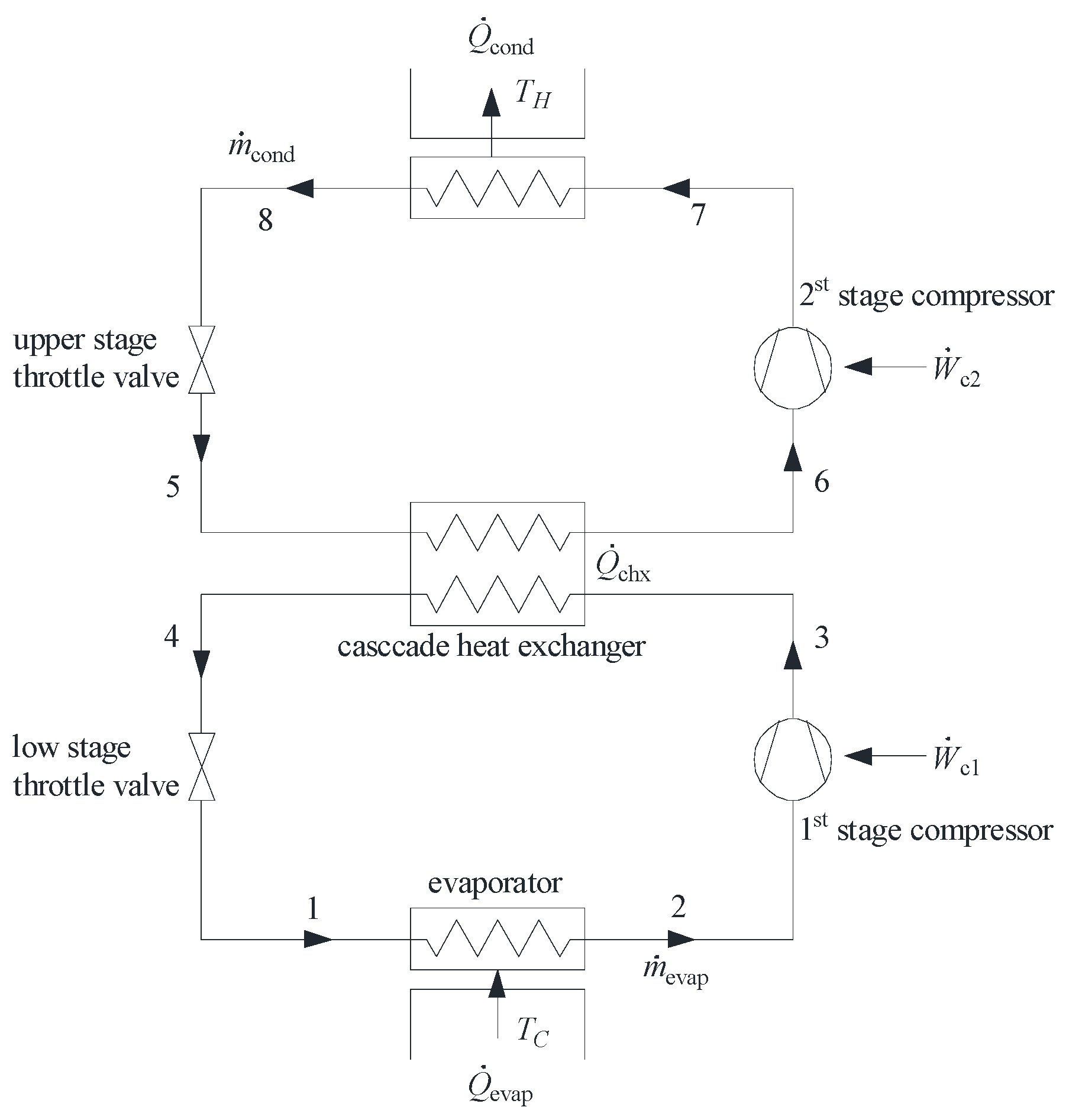

2. System Description

3. Model Establishment

3.1. Boundary Conditions and Assumptions

- (1)

- The working fluids in the cascade heat pump system are steady state.

- (2)

- The heat loss in heat exchangers and pipelines is ignored.

- (3)

- Refrigerants are saturated at the outlet of the evaporator and the condenser.

- (4)

- The pressure loss in heat exchangers and pipes is negligible.

- (5)

- (6)

- The expansion valve process is considered isenthalpic.

3.2. Model Establishment

3.2.1. Thermodynamics Analysis Model

3.2.2. Economic Analysis Model

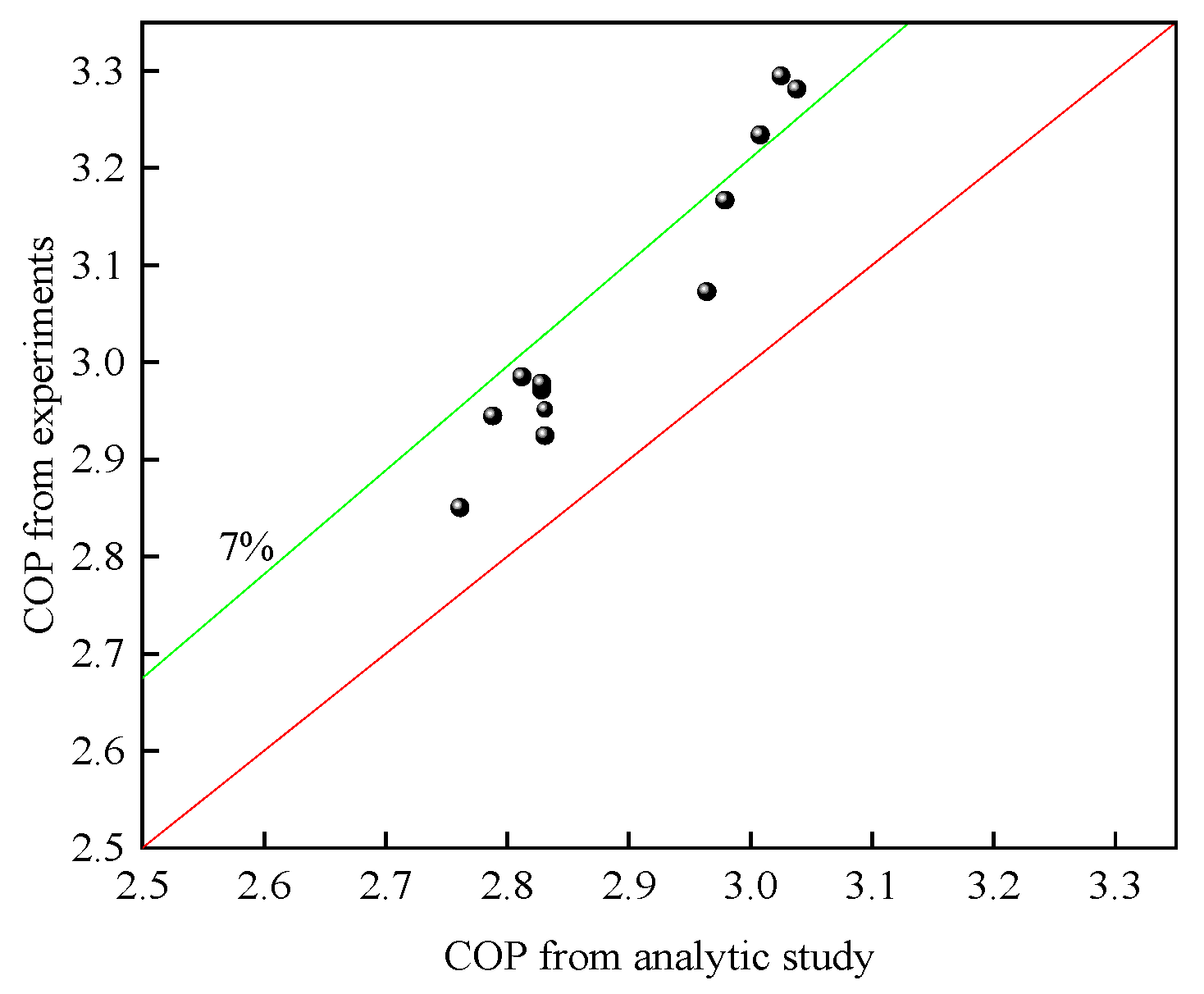

3.2.3. Model Validation

4. Results and Discussion

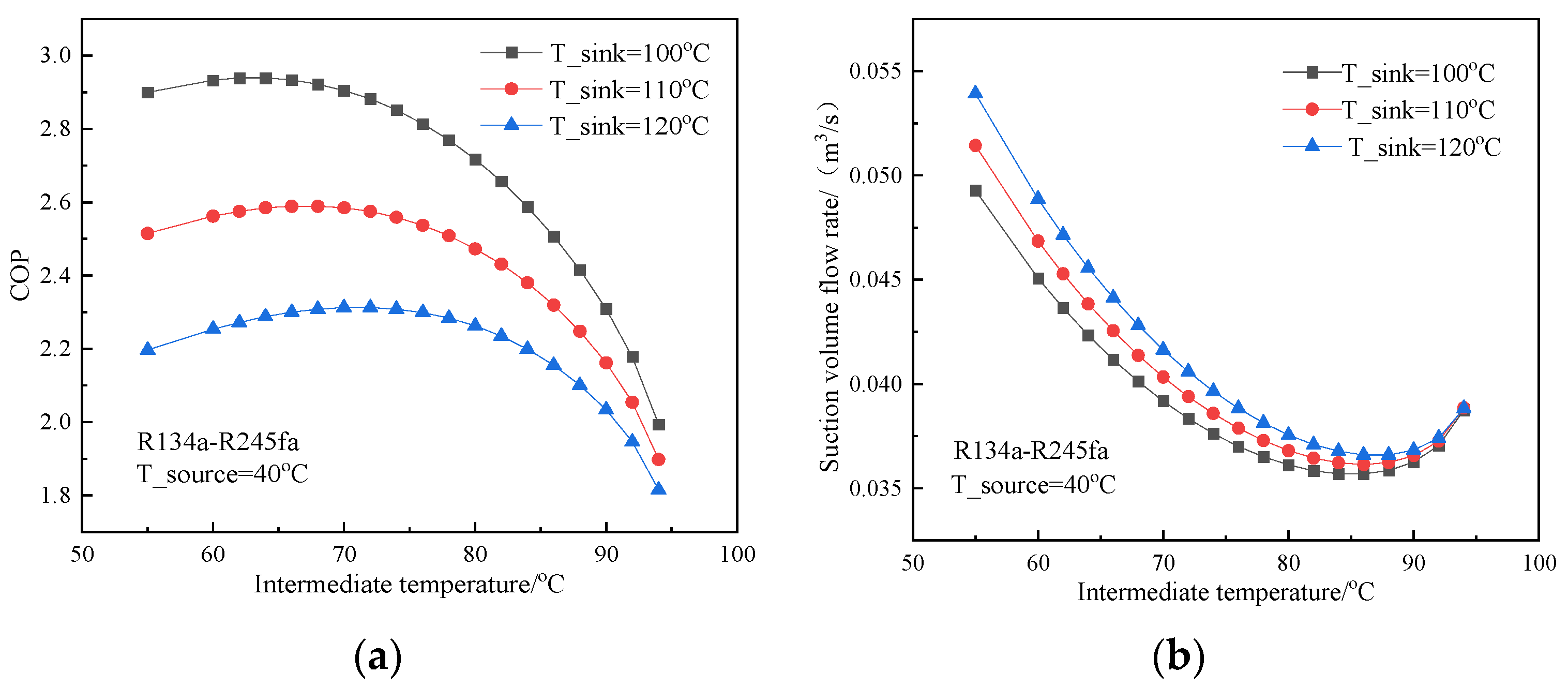

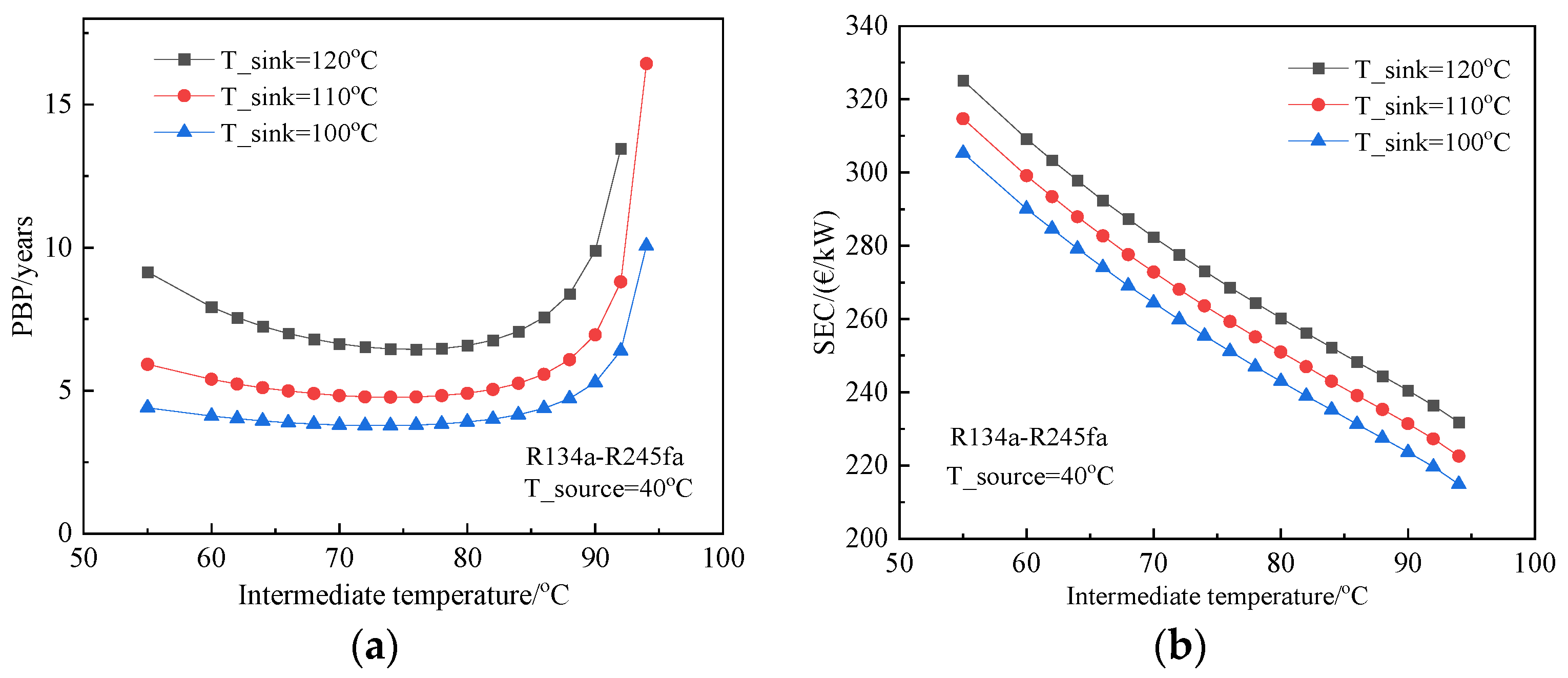

4.1. Effects of the Intermediate Temperature

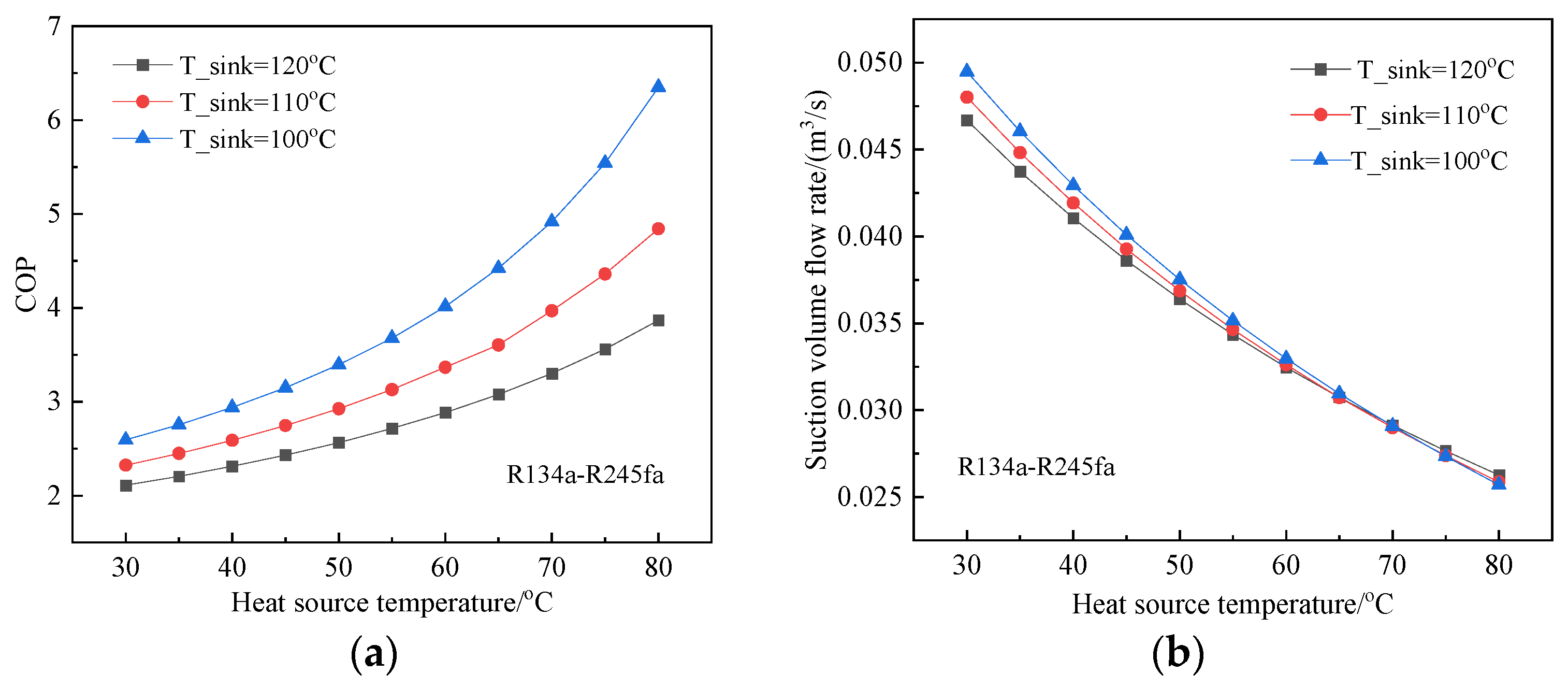

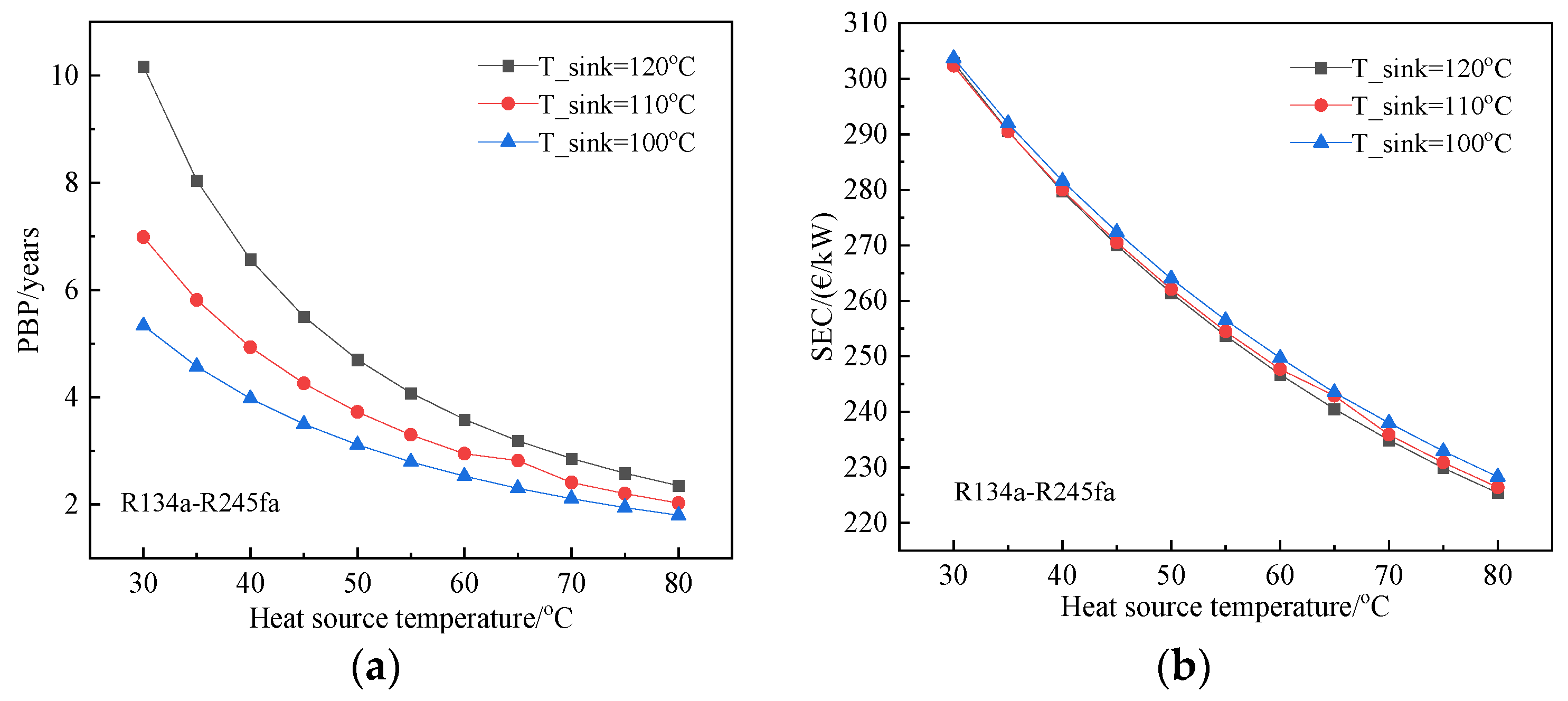

4.2. Effects of the Heat Source/Heat Sink Temperature

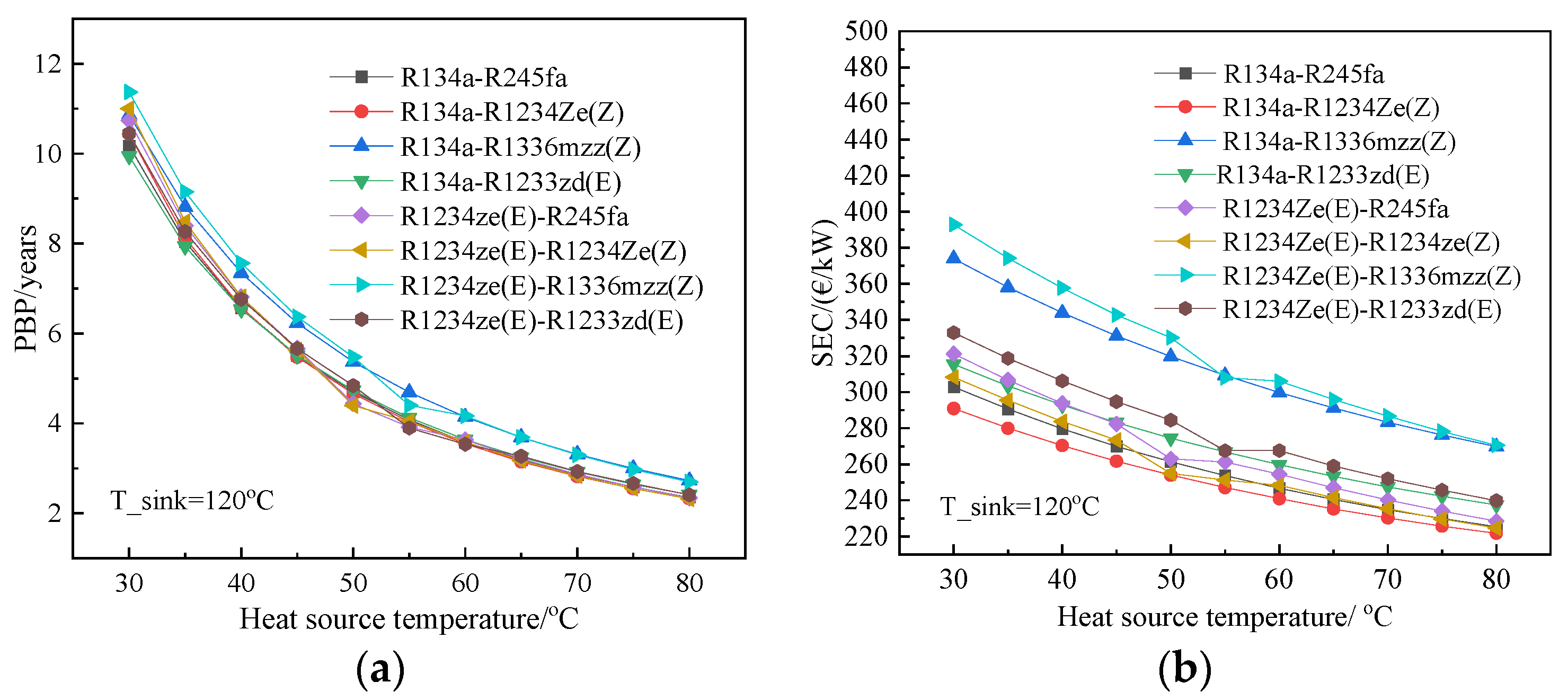

4.3. Effects of Working Fluid

4.4. Effects of Pinch Point Temperature Difference

4.5. Effects of Energy Price on the Payback Period

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclatures

| 1,2, …, 8 | thermodynamic state points |

| A | heat exchanger surface, m2 |

| B | operating time in a year, h/year |

| C | component cost, EUR |

| h | enthalpy, kJ/kg |

| k | heat transfer coefficient, kW/(m2·K) |

| mass flow rate, kg/s | |

| P | price, EUR |

| PBP | payback period, years |

| thermal capacity, kW | |

| SEC | specific equipment cost, EUR/kW |

| T | temperature, °C |

| volume flow rate, m3/s | |

| mechanical power, kW | |

| Abbreviations | |

| COP | coefficient of performance |

| GWP | global warming potential |

| HCFO | hydrochlorofluorocarbon |

| HEX | heat exchanger |

| HFO | hydrofluorocarbon |

| HTC | High-temperature circuit |

| HTHP | high-temperature heat pump |

| HTCHP | high-temperature cascade heat pump |

| IT | intermediate temperature |

| LMTD | logarithmic mean temperature difference |

| LTC | low temperature circuit |

| Subscripts | |

| aux | auxiliary equipment |

| c | compressor |

| chx | cascade heat exchanger |

| cond | condenser |

| el | electricity |

| eq | equipment |

| evap | evaporator |

| g | gas |

| p | project |

| pp | pinch point |

| ref | refrigerant |

| SC | subcooling |

| SH | superheating |

| sink | heat sink |

| source | heat source |

| Greek Symbols | |

| η | efficiency |

| v | specific volume, m3/kg |

References

- IEA. Net Zero by 2050-a Roadmap for the Global Energy Sector. 2021. Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 2 August 2022).

- Zhang, J.; Zhang, H.H.; He, Y.L.; Tao, W.Q. A comprehensive review on advances and applications of industrial heat pumps based on the practices in China. Appl. Energy 2016, 178, 800–825. [Google Scholar] [CrossRef]

- Park, H.; Kim, D.H.; Kim, M.S. Thermodynamic analysis of optimal intermediate temperatures in R134a–R410A cascade refrigeration systems and its experimental verification. Appl. Therm. Eng. 2013, 54, 319–327. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, H.S.; Kim, M.S. Optimal temperature between high and low stage cycles for R134a/R410A cascade heat pump based water heater system. Exp. Therm. Fluid Sci. 2013, 47, 172–179. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, M.S. The effect of water temperature lift on the performance of cascade heat pump system. Appl. Therm. Eng. 2014, 67, 273–282. [Google Scholar] [CrossRef]

- Wang, B.M.; Wu, H.G.; Li, J.F.; Xing, Z.W. Experimental investigation on the performance of NH3/CO2 cascade refrigeration system with twin-screw compressor. Int. J. Refrig. 2021, 32, 1358–1365. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Y.; Fang, L.; Yu, X.; Li, X.; Ying, S.; Zhang, Y. Performance analysis of a cascade high temperature heat pump using R245fa and BY-3 as working fluid. Appl. Therm. Eng. 2018, 140, 466–475. [Google Scholar] [CrossRef]

- Wang, W.Y.; Lia, Y.Y.; Hu, B. Real-time efficiency optimization of a cascade heat pump system via multivariable extremum seeking. Appl. Therm. Eng. 2020, 176, 115399. [Google Scholar] [CrossRef]

- Dai, B.M.; Liu, X.; Liu, S.C.; Zhang, Y.Y.; Zhong, D.; Feng, Y.N.; Nian, V.; Hao, Y. Dual-pressure condensation high temperature heat pump system for waste heat recovery: Energetic and exergetic assessment. Energy Convers. Manag. 2020, 218, 112997. [Google Scholar] [CrossRef]

- Yu, X.H.; Zhang, Y.F.; Kong, L.T.; Zhang, Y. Thermodynamic analysis and parameter estimation of a high temperature industrial heat pump using a new binary mixture. Appl. Therm. Eng. 2018, 131, 715–723. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.F.; Yu, X.H.; Guo, J.; Deng, N.; Dong, S.M.; He, Z.L.; Ma, X.L. Analysis of a high temperature heat pump using BY-5 as refrigerant. Appl. Therm. Eng. 2017, 127, 1461–1468. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M.; Schlemminger, C. Theoretical analysis of suitable fluids for high temperature heat pumps up to 125 °C heat delivery. Int. J. Refrig. 2018, 92, 185–195. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Arpagaus, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Bertsch, S.S. Advanced high temperature heat pump configurations using low GWP refrigerants for industrial waste heat recovery: A comprehensive study. Energy Convers. Manag. 2021, 229, 113752. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbr, J. Semi-empirical and environmental assessment of the low GWP refrigerant HCFO-1224yd(Z) to replace HFC-245fa in high temperature heat pumps. Int. J. Refrig. 2021, 127, 120–127. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Barragán, N. Comparative analysis of HFO-1234ze(E) and R-515B as low GWP alternatives to HFC-134a in moderately high temperature heat pumps. Int J Refrig. 2020, 124, 197–206. [Google Scholar] [CrossRef]

- Jiang, J.T.; Hu, B.; Wang, R.Z.; Liu, H.; Zhang, Z.P.; Li, H.B. Theoretical performance assessment of low-GWP refrigerant R1233zd(E) applied in high temperature heat pump system. Int. J. Refrig. 2021, 131, 897–908. [Google Scholar] [CrossRef]

- Fukuda, S.; Kondou, C.; Takata, N.; Koyama, S. Low GWP refrigerants R1234ze(E) and R1234ze(Z) for high temperature heat pumps. Int. J. Refrig. 2014, 40, 161–173. [Google Scholar] [CrossRef]

- Kosmadakis, G.; Arpagaus, C.; Neofytou, P.; Bertsch, S. Techno-economic analysis of high-temperature heat pumps with low-global warming potential refrigerants for upgrading waste heat up to 150 °C. Energy Convers. Manag. 2020, 226, 113488. [Google Scholar] [CrossRef]

- Kondou, C.; Koyam, S. Thermodynamic assessment of high-temperature heat pumps using Low-GWP HFO refrigerants for heat recovery. Int. J. Refrig. 2015, 53, 126–141. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Schiffmann, J.; Bertsch, S.S. Multi-temperature heat pumps: A literature review. Int. J. Refrig 2016, 69, 437–465. [Google Scholar] [CrossRef]

- Ommen, T.; Jensen, J.K.; Markussen, W.B.; Reinholdt, L.; Elmegaard, B. Technical and economic working domains of industrial heat pumps: Part 1—Single stage vapour compression heat pumps. Int. J. Refrig. 2015, 55, 168–182. [Google Scholar] [CrossRef] [Green Version]

- Amalfi, R.L.; Vakili-Farahani, F.; Thome, J.R. Flow boiling and frictional pressure gradients in plate heat exchangers. Part 2: Comparison of literature methods to database and new prediction methods. Int. J. Refrig. 2016, 61, 185–203. [Google Scholar] [CrossRef]

- Longo, G.A.; Righetti, G.; Zilio, C. A new computational procedure for refrigerant condensation inside herringbone-type Brazed Plate Heat Exchangers. Int. J. Heat Mass Transf. 2015, 82, 530–536. [Google Scholar] [CrossRef]

- Luo, C.; Gong, Y.L.; Ma, W.B. Research on the Heat Transfer Experiment of R245fa(In Chinese). J. Refrig. 2014, 3, 21–25. [Google Scholar] [CrossRef]

- Cao, X.Q.; Yang, W.W.; Zhou, F.; He, Y.L. Performance analysis of different high temperature heat pump systems for low-grade waste heat recovery. Appl. Therm. Eng. 2014, 71, 291–300. [Google Scholar] [CrossRef]

| Working Fluid | Chemical Formula | Group | M (g/mol) | tcr (°C) | Pcr (bar) | NBP (°C) | GWP | ODP | SG |

|---|---|---|---|---|---|---|---|---|---|

| R245fa | CHF2CH2CF3 | HFC | 134.05 | 154 | 36.5 | 15.3 | 858 | 0 | B1 |

| R1234ze(Z) | CF3CH=CHF | HFO | 114.04 | 150.1 | 35.3-39.7 | 9.7 | <1 | 0 | A2L (expected) |

| R1336mzz(Z) | CF3CH=CHCF3(Z) | HFO | 164.06 | 171.3 | 29 | 33.4 | 2 | 0 | A1 |

| R1233zd(E) | CF3CH=CHCl | HCFO | 130.50 | 166.5 | 37.7 | 18.3 | 1 | 0.0002 | A1 (expected) |

| Working Fluid | Chemical Formula | Group | M (g/mol) | tcr (°C) | Pcr (bar) | NBP (°C) | GWP | ODP | SG |

|---|---|---|---|---|---|---|---|---|---|

| R134a | C2H2F4 | HFC | 102.03 | 101.06 | 40.59 | −26.3 | 1430 | 0 | A1 |

| R1234ze(E) | C3F4H2 | HFO | 114.04 | 109.51 | 36.34 | −19.0 | 6 | 0 | A2L |

| Parameters | Reference Values | Boundary Conditions |

|---|---|---|

| Heat source temperature Tsource (°C) | 40 | 30~80 |

| Heat sink temperature Tsink (°C) | 120 | 100~120 |

| Superheating degree ΔTSH (°C) | 0 | |

| Subcooling degree ΔTSC (°C) | 0 | |

| Condenser pinch point temperature difference ΔTpp,sink (°C) | 4 | 4~10 |

| Evaporator pinch point temperature difference ΔTpp,source (°C) | 5 | 4~10 |

| Intermediate heat exchanger pinch point temperature difference ΔTpp,chx (°C) | 6 | 2~10 |

| Electricity cost (EUR/kWh) | 0.07 | 0.03~0.12 |

| Gas prices (EUR/m3) | 0.35 | 0.25~0.7 |

| Province | Electricity Price (Yuan/kWh) | Electricity Price (EUR /kWh) | Gas Price (Yuan/m3) | Gas Price (EUR /m3) | Energy Price Ratio | PBP |

|---|---|---|---|---|---|---|

| Yunnan | 0.532 | 0.078 | 3.31 | 0.485 | 1.63 | 3.3 |

| Guangdong | 0.608 | 0.089 | 3.45 | 0.5 | 1.79 | 3.8 |

| Guizhou | 0.541 | 0.079 | 3.05 | 0.45 | 1.8 | 4.3 |

| Liaoning | 0.529 | 0.077 | 2.95 | 0.434 | 1.81 | 4.6 |

| Jiangxi | 0.619 | 0.091 | 3.2 | 0.47 | 1.96 | 5.2 |

| Guangxi | 0.626 | 0.092 | 3.22 | 0.47 | 1.97 | 5.3 |

| Hainan | 0.636 | 0.093 | 3.15 | 0.46 | 2.04 | 6.2 |

| Jiangsu | 0.642 | 0.094 | 3.1 | 0.45 | 2.1 | 7 |

| Shandong | 0.617 | 0.09 | 3 | 0.44 | 2.08 | 7 |

| Heilongjiang | 0.586 | 0.086 | 2.8 | 0.41 | 2.12 | 8.1 |

| Jilin | 0.587 | 0.086 | 2.8 | 0.41 | 2.12 | 8.1 |

| Shanghai | 0.671 | 0.098 | 3 | 0.44 | 2.26 | 11.2 |

| Shanxi | 0.508 | 0.074 | 2.26 | 0.334 | 2.28 | 15.4 |

| Zhejiang | 0.664 | 0.097 | 2.86 | 0.42 | 2.35 | 16.3 |

| Hebei | 0.548 | 0.08 | 2.4 | 0.354 | 2.31 | 16.6 |

| Qinghai | 0.367 | 0.054 | 1.6 | 0.23 | 2.32 | 26 |

| Hubei | 0.612 | 0.09 | 2.53 | 0.377 | 2.45 | 33.6 |

| Neimenggu | 0.449 | 0.066 | 1.82 | 0.27 | 2.5 | 77.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Z.; Yao, Y.; Liu, G.; Ma, W.; Gong, Y. Thermodynamic and Economic Analysis of a High Temperature Cascade Heat Pump System for Steam Generation. Processes 2022, 10, 1862. https://doi.org/10.3390/pr10091862

Lu Z, Yao Y, Liu G, Ma W, Gong Y. Thermodynamic and Economic Analysis of a High Temperature Cascade Heat Pump System for Steam Generation. Processes. 2022; 10(9):1862. https://doi.org/10.3390/pr10091862

Chicago/Turabian StyleLu, Zhenneng, Yuan Yao, Guangping Liu, Weibin Ma, and Yulie Gong. 2022. "Thermodynamic and Economic Analysis of a High Temperature Cascade Heat Pump System for Steam Generation" Processes 10, no. 9: 1862. https://doi.org/10.3390/pr10091862

APA StyleLu, Z., Yao, Y., Liu, G., Ma, W., & Gong, Y. (2022). Thermodynamic and Economic Analysis of a High Temperature Cascade Heat Pump System for Steam Generation. Processes, 10(9), 1862. https://doi.org/10.3390/pr10091862