Evaluation of Relative Permittivity and Loss Factor of 3D Printing Materials for Use in RF Electronic Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Materials

2.2. Measuring of Dielectric Properties

2.3. Data Processing

2.4. Testing of the Presence of Defects in the Internal Structure of Samples

3. Results

4. Discussion

5. Conclusions

- The absence of polarization phenomena was proven for the tested colorless materials in the range of 1–100 MHz. This absence of the polarization phenomena was manifested by the insignificant frequency dependence of the dielectric properties of these materials;

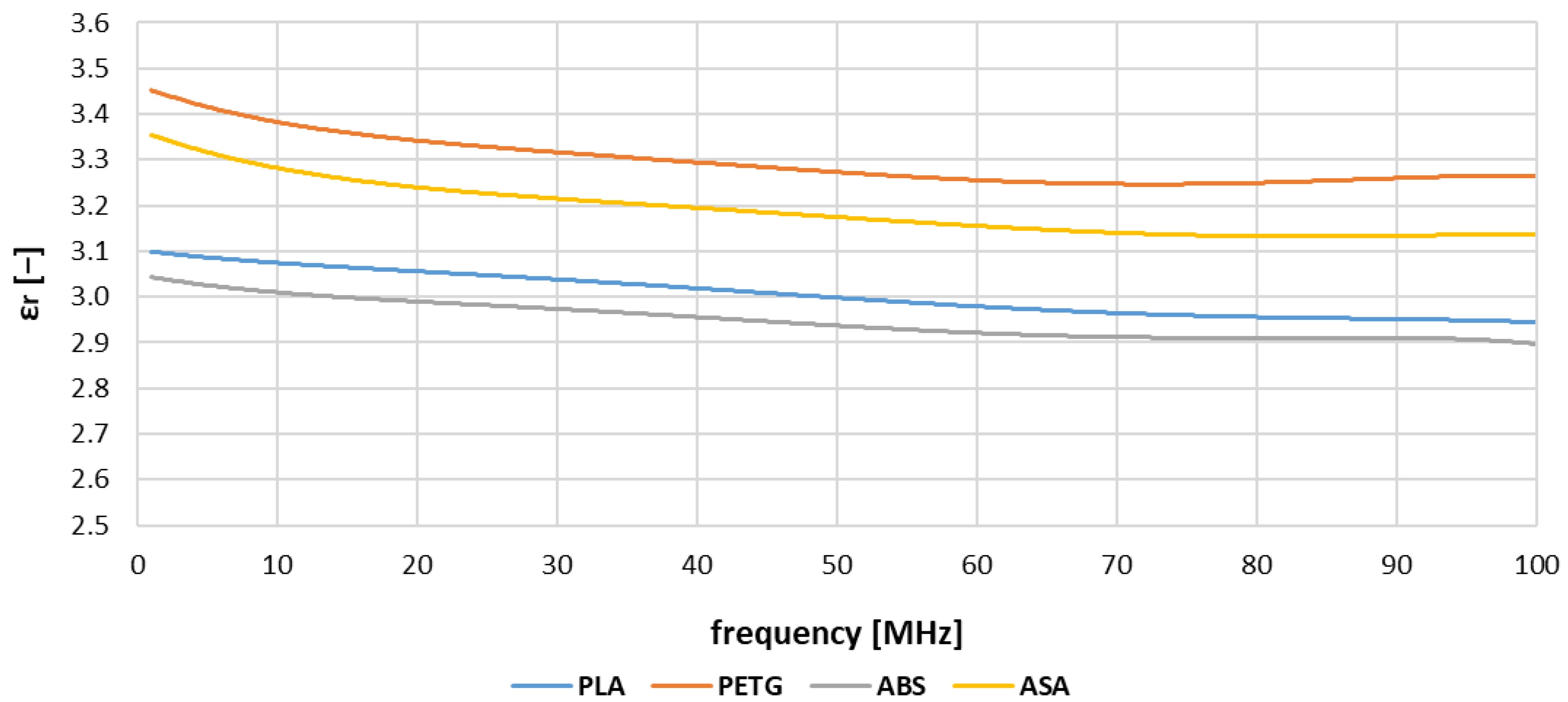

- The values of relative permittivity varied between 2.88–3.48 and the values of loss factor were in the range of 0.03–4.31%;

- In terms of relative permittivity, all the tested materials showed minimal frequency dependence in the entire measuring range with a slight tendency to decrease in the higher frequency range. The minimal values of relative permittivity reached ABS (2.95), PLA (3.00), and PLA-Silver (2.99), which proved nearly identical parameters. On the other hand, PLA-Metallic green reached a value of 0.36 higher than PLA. This phenomenon was probably caused by added pigment dye;

- In terms of the loss factor, PLA and ABS appeared to be more suitable for electrotechnical application due to lower values and lower frequency dependencies of the loss factor in all studied frequency ranges. The values of the loss factor of PLA and ABS were estimated at: 0.51%, 0.77% (1–19.9 MHz); 0.15%, 0.38% (20–59.9 MHz), and 0.07%, and 0.21% (60–100 MHz);

- PET-G and ASA showed higher values and frequency dependence of the loss factor, and, for this reason, these two materials were less useful for electrotechnical application;

- The loss factor of PLA-Silver and PLA-Metallic green had significant frequency dependence, which was evident at higher frequencies. This increase was most evident in the upper part of the frequency range (70–100 MHz). In these intervals, PLA-Silver and PLA-Metallic green reached the maximum values of loss factor (4.31% and 3.24%). Due to these facts, these materials were inferior for electrotechnical applications;

- Significant differences were observed between PLA (colorless), PLA-Silver, and PLA-Metallic green, considering the loss factor. They can be caused by pigment dye which increases the values and frequency dependence and brings limitations for the use of these materials in electrical applications;

- PLA and ABS were more suitable for electrotechnical applications. They reached the smallest values of relative permittivity and loss factor, and at the same time, they proved the minimal frequency dependence of the tested parameters on the studied frequency range;

- The presence of significant defects (air gaps) in the internal structure of the printed samples of ABS, ASA, PETG, and PLA, which would affect their dielectric properties, were not proven.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ning, F.; Cong, W.; Wei, J.; Wang, S.; Zhang, M. Additive Manufacturing of CFRP Composites Using Fused Deposition Modeling: Effects of Carbon Fiber Content and Length. In Proceedings of the ASME 2015 International Manufacturing Science and Engineering Conference MSEC2015, Charlotte, NC, USA, 8 June 2015; American Society of Mechanical Engineers: Charlotte, NC, USA, 2015. [Google Scholar]

- Vujović, I.; Šoda, J.; Kuzmanić, I.; Petković, M. Parameters Evaluation in 3D Spare Parts Printing. Electronics 2021, 10, 365. [Google Scholar] [CrossRef]

- Dichtl, C.; Sippel, P.; Krohns, S. Dielectric Properties of 3D Printed Polylactic Acid. Adv. Mater. Sci. Eng. 2017, 2017, 6913835. [Google Scholar] [CrossRef]

- Felício, J.M.; Fernandes, C.A.; Costa, J.R. Complex Permittivity and Anisotropy Measurement of 3D-Printed PLA at Microwaves and Millimeter-waves. In Proceedings of the 2016 22nd International Conference on Applied Electromagnetics and Communications (ICECOM), Dubrovnik, Croatia, 19–21 September 2016; Instituto Superior Técnico: Dubrovnik, Croatia, 2016; pp. 1–6. [Google Scholar]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Veselý, P.; Tichý, T.; Sefl, O.; Hornyová, E. Evaluation of dielectric properties of 3D printed objects based on printing resolution. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Patterson, A.E.; Pereira, T.R.; Allison, J.T.; Messimer, S.L. IZOD impact properties of full-density fused deposition modeling polymer materials with respect to raster angle and print orientation. In Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science; SAGE Publications Ltd.: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- FDM 3D Printing—Fused Deposition Modeling Ultimate Guide. Available online: https://electroloom.com/fdm-3d-printing-and-printer-guide/ (accessed on 19 August 2022).

- Espalin, D.; Muse, D.W.; Macdonald, E.; Wicker, R.B. 3D Printing multifunctionality: Structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978. [Google Scholar] [CrossRef]

- MacDonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R.B. 3D printing for the rapid prototyping of structural electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- Liu, Z.; Li, W.-D.; Wang, Y.-B.; Su, G.-Q.; Zhang, G.-J.; Cao, Y.; Li, D.-C. Topology optimization and 3D-printing fabrication feasibility of high voltage FGM insulator. In ICHVE 2016–2016 IEEE International Conference on High Voltage Engineering and Application; Institute of Electrical and Electronics Engineers Inc.: Chengdu, China, 2016; pp. 1–4. [Google Scholar]

- Colella, R.; Chietera, F.P.; Catarinucci, L. Analysis of FDM and DLP 3D-Printing Technologies to Prototype Electromagnetic Devices for RFID Applications. Sensors 2021, 21, 897. [Google Scholar] [CrossRef]

- Pizarro, F.; Salazar, R.; Rajo-Iglesias, E.; Rodriguez, M.; Fingerhuth, S.; Hermosilla, G. Parametric Study of 3D Additive Printing Parameters Using Conductive Filaments on Microwave Topologies. IEEE Access 2019, 7, 106814–106823. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. 3D-printed sensors: Current progress and future challenges. Sens. Actuators A Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Kalaš, D.; Šíma, K.; Kadlec, P.; Polanský, R.; Soukup, R.; Řeboun, J.; Hamáček, A. FFF 3D Printing in Electronic Applications: Dielectric and Thermal Properties of Selected Polymers. Polymers 2021, 13, 3702. [Google Scholar] [CrossRef]

- Lopes, A.J.; MacDonald, E.; Wicker, R.B. Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp. J. 2012, 18, 129–143. [Google Scholar] [CrossRef]

- Palmer, J.A.; Jokiel, B.; Nordquist, C.D.; Kast, B.A.; Atwood, C.J.; Grant, E.; Livingston, F.J.; Medina, F.; Wicker, R.B. Mesoscale RF relay enabled by integrated rapid manufacturing. Rapid Prototyp. J. 2006, 12, 148–155. [Google Scholar] [CrossRef]

- Le Sage, G.P. 3D Printed Waveguide Slot Array Antennas. IEEE Access 2016, 4, 1258–1265. [Google Scholar] [CrossRef]

- Rashidian, A.; Shafai, L.; Sobocinski, M.; Perantie, J.; Juuti, J.; Jantunen, H. Printable Planar Dielectric Antennas. IEEE Trans. Antennas Propag. 2016, 64, 403–413. [Google Scholar] [CrossRef]

- Helena, D.; Ramos, A.; Varum, T.; Matos, J.N. The Use of 3D Printing Technology for Manufacturing Metal Antennas in the 5G/IoT Context. Sensors 2021, 21, 3321. [Google Scholar] [CrossRef]

- Proesmans, R.; Verleysen, A.; Vleugels, R.; Veske, P.; De Gusseme, V.L.; Wyffels, F. Modular Piezoresistive Smart Textile for State Estimation of Cloths. Sensors 2021, 22, 222. [Google Scholar] [CrossRef]

- Kalas, D.; Suchy, S.; Kalcik, J.; Reboun, J.; Soukup, R.; Hamacek, A. Contacting of SMD Components on the Textile Substrates. In Proceedings of the International Spring Seminar on Electronics Technology, Demanovska Valley, Slovakia, 14–15 May 2020; pp. 1–6. [Google Scholar]

- Remaggi, G.; Zaccarelli, A.; Elviri, L. 3D Printing Technologies in Biosensors Production: Recent Developments. Chemosensors 2022, 10, 65. [Google Scholar] [CrossRef]

- Veselý, P.; Horynová, E.; Tichý, T.; Šefl, O. Study of electrical properties of 3D printed objects. In Proceedings of the International Student Scientific Conference Poster—22/2018; Husník, L., Ed.; Czech Technical University in Prague: Prague, Czech Republic, 2018; pp. 1–5. [Google Scholar]

- Kumar, S.R.; Sridhar, S.; Venkatraman, R.; Venkatesan, M. Polymer additive manufacturing of ASA structure: Influence of printing parameters on mechanical properties. In Proceedings of the 2nd International Conference on Recent Trends in Metallurgy, Materials Science and Manufacturing (IMME), Tiruchirappalli, India, 12–13 December 2019; pp. 1316–1319. [Google Scholar]

- Cojocaru, V.; Frunzaverde, D.; Miclosina, C.-O.; Marginean, G. The Influence of the Process Parameters on the Mechanical Properties of PLA Specimens Produced by Fused Filament Fabrication— A Review. Polymers 2022, 14, 886. [Google Scholar] [CrossRef]

- Maszybrocka, J.; Dworak, M.; Nowakowska, G.; Osak, P.; Łosiewicz, B. The Influence of the Gradient Infill of PLA Samples Produced with the FDM Technique on Their Mechanical Properties. Materials 2022, 15, 1304. [Google Scholar] [CrossRef]

- Le, T.-H.; Le, V.-S.; Dang, Q.-K.; Nguyen, M.-T.; Le, T.-K.; Bui, N.-T. Microstructure Evaluation and Thermal–Mechanical Properties of ABS Matrix Composite Filament Reinforced with Multi-Walled Carbon Nanotubes by a Single Screw Extruder for FDM 3D Printing. Appl. Sci. 2021, 11, 8798. [Google Scholar] [CrossRef]

- Deffenbaugh, P.I.; Rumpf, R.C.; Church, K.H. Broadband microwave frequency characterization of 3-d printed materials. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 2147–2155. [Google Scholar] [CrossRef]

- Havriliak, S.; Havriliak, S.J. Dielectric and Mechanical Relaxation in Materials, Analysis, Interpretation, and Application to Polymers; Hanser Publishers: Munich, Germany, 1997; pp. 378–400. [Google Scholar]

- Novac, O.C.; Maries, G.R.E.; Chira, D.; Novac, M. Study concerning the influence of the grinding percentage on some electrical properties of PA 6.6, POM and ABS by methods for determining relative permittivity and the dielectric dissipation factor. Mater. Plast. 2017, 54, 453–460. [Google Scholar] [CrossRef]

- Booth, J.C.; Whitley, M.; Rudd, C.; Kranz, M. Material Database for Additive Manufacturing Techniques; Defense Technical Information Center: Fort Belvoir, VA, USA, 2017; pp. 1–37.

- Ctibor, P.; Sedláček, J.; Papež, V.; Lukáč, F. Radiofrequency and Microwave Dielectric Properties of Plasma Sprayed and Annealed Thick Layers of Titanium Dioxide. J. Therm. Spray Technol. 2020, 29, 1718–1727. [Google Scholar] [CrossRef]

- Agilent Technologies Inc. Agilent E4991A RF Impedance/Material Analyzer Data Sheet; Agilent Technologies Inc.: Santa Clara, CA, USA, 2003; pp. 6–7. [Google Scholar]

- Agilent Technologies Inc. Agilent E4991A RF Impedance/Material Analyzer Installation and Quick Start Guide; Agilent Technologies Inc.: Santa Clara, CA, USA, 2012; pp. 73–80. [Google Scholar]

- Balakrishnan, N.K.; Koenig, K.; Seide, G. The Effect of Dye and Pigment Concentrations on the Diameter of Melt-Electrospun Polylactic Acid Fibers. Polymers 2020, 12, 2321. [Google Scholar] [CrossRef] [PubMed]

- Castro, F.; Santana, L.; Lino Alves, J. Extrusion-Based 3D Printing: Color Influence on Mechanical Properties of PLA Parts. In COBEM—26th International Congress of Mechanical Engineering at: Florianópolis, Brasil; Associacao Brasileira de Engenharia e Ciencias Mecanicas—ABCM: Florianópolis, Brasil, 2021. [Google Scholar]

| Sample Identification | Material | Color | Printing Temperature [°C] 1st Layer/Subsequent Layers | Filament Manufacturer | Filament Diameter | |

|---|---|---|---|---|---|---|

| Hot end | Bed | |||||

| PLA | PLA | colorless | 215/210 | 60/60 | FilamentPM | 1.75 mm |

| PLA-Silver | silver | |||||

| PLA-Metallic green | metallic green | |||||

| PET-G | PET-G | colorless | 230/240 | 90/90 | ||

| ABS | ABS | 255/255 | 110/110 | |||

| ASA | ASA | 260/260 | 110/110 | |||

| Sample Identification | 1–100 MHz | |

|---|---|---|

| εr | ||

| aver. [-] 1 | st. dev. [-] 2 | |

| PLA | 3.00 | 0.05 |

| PLA-Silver | 2.99 | 0.07 |

| PLA-Metallic green | 3.36 | 0.05 |

| PETG | 3.30 | 0.05 |

| ABS | 2.95 | 0.04 |

| ASA | 3.19 | 0.06 |

| Sample Identification | 1–19.9 MHz | 20–59.9 MHz | 60–100 MHz | |||

|---|---|---|---|---|---|---|

| tgδ | tgδ | tgδ | ||||

| aver. [%] 1 | st. dev. [%] 2 | aver. [%] 1 | st. dev. [%] 2 | aver. [%] 1 | st. dev. [%] 2 | |

| PLA | 0.51 | 0.12 | 0.15 | 0.09 | 0.07 | 0.03 |

| PLA-Silver | 1.38 | 0.43 | 2.28 | 0.15 | 3.13 | 0.45 |

| PLA-Metallic green | 0.75 | 0.08 | 0.80 | 0.07 | 1.63 | 0.65 |

| PETG | 1.74 | 0.17 | 1.24 | 0.12 | 1.04 | 0.03 |

| ABS | 0.77 | 0.13 | 0.38 | 0.10 | 0.21 | 0.02 |

| ASA | 1.88 | 0.05 | 1.62 | 0.11 | 1.34 | 0.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Picha, T.; Papezova, S.; Picha, S. Evaluation of Relative Permittivity and Loss Factor of 3D Printing Materials for Use in RF Electronic Applications. Processes 2022, 10, 1881. https://doi.org/10.3390/pr10091881

Picha T, Papezova S, Picha S. Evaluation of Relative Permittivity and Loss Factor of 3D Printing Materials for Use in RF Electronic Applications. Processes. 2022; 10(9):1881. https://doi.org/10.3390/pr10091881

Chicago/Turabian StylePicha, Tomas, Stanislava Papezova, and Stepan Picha. 2022. "Evaluation of Relative Permittivity and Loss Factor of 3D Printing Materials for Use in RF Electronic Applications" Processes 10, no. 9: 1881. https://doi.org/10.3390/pr10091881

APA StylePicha, T., Papezova, S., & Picha, S. (2022). Evaluation of Relative Permittivity and Loss Factor of 3D Printing Materials for Use in RF Electronic Applications. Processes, 10(9), 1881. https://doi.org/10.3390/pr10091881