Abstract

To lower maintenance costs and improve a metro company’s competitiveness, this research came up with an innovative technique using a considering sensitivity and analytic hierarchy process (CSAHP). Along with interviews with managers and workers at the Taipei Rapid Transit Corporation, this study was able to undertake quantitative analysis. To determine which subsystems and metro lines should be prioritized for outsourcing based on the CSAHP framework, we used the criterium decision plus (CDP) program. This research adds to the existing body of knowledge by advancing the existing analytic hierarchy process (AHP) technique and recommending the CSAHP strategy for assessment. According to the findings, the power supply system was the most in need of outsourcing, followed by air conditioning, firefighting, and elevator systems. When considering which of the four metro lines to outsource first, the blue line came out on top, followed by the red, green, and brown lines. By prioritizing the outsourcing of the power supply system as a result of this research, the Taipei Rapid Transit Corporation may cut the system’s maintenance expenditures from USD 1.57 million to USD 1.33 million, saving 15% on maintenance costs. Applying these findings can improve the economic benefits of outsourced maintenance for the Taipei Rapid Transit Corporation.

1. Introduction

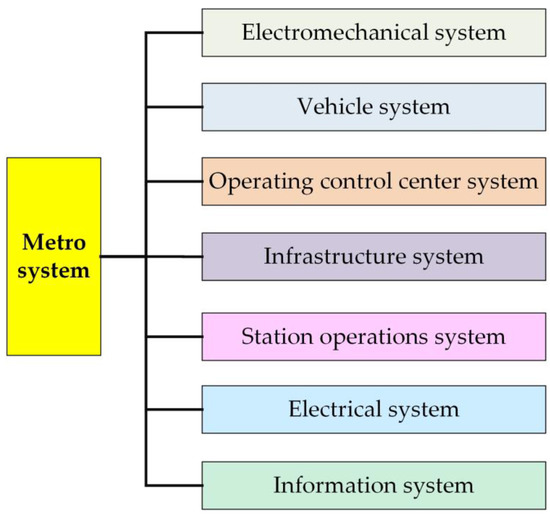

Metro systems are prevalent in various developed and developing countries, including the German subway [1], Singapore mass rapid transit [2], the mass transit railway in Hong Kong [3], and Taiwan mass rapid transit [4]. Large-scale metro network systems primarily include seven systems, i.e., the electromechanical, vehicle, operation control center, infrastructure, station operations, electrical, and information systems (as shown in Figure 1). However, the repair and maintenance of these systems require a large workforce and high costs. To reduce the operating costs of metro companies, outsourced maintenance is a favorable alternative, which considers reducing costs by downsizing personnel. Specifically, contracting work, outsourcing personnel, and dispatching services can help to reduce operating costs effectively and rapidly. The outsourcing strategy’s effective use can avoid an organization’s unlimited expansion and achieve the goal of reducing personnel and focusing on specialties. For example, when applying the personnel outsourcing and dispatching strategy in corporate administrative business, an organization can entrust a personnel dispatch company to hire the contracted personnel based on its internal seasonal and sudden workforce demands. Then, they can dispatch them to metro companies, thereby saving labor costs, labor and health insurance expenses, pension burdens, and other expenses.

Figure 1.

Schematic diagram of seven important systems of a metro company.

The metro system examined in this study includes seven systems: electromechanical [5], vehicle, operating control center, infrastructure, station operations, electrical, and information. First, the vehicle, operating control center, infrastructure, and electrical systems are closely associated with passenger safety [6,7]. Therefore, maintaining these four systems relies on the maintenance team of the metro company; outsourced maintenance is not recommended for these systems. Second, the Taipei Rapid Transit Corporation already has a stable outsourcing strategy for station operations and information systems. Therefore, the priority of maintenance outsourcing evaluated in this study focused on the subsystems of the metro company’s electromechanical system as the main subject.

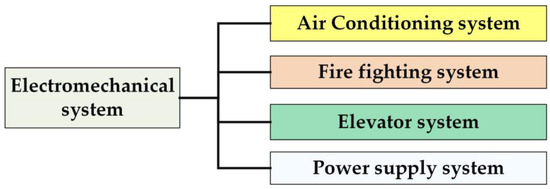

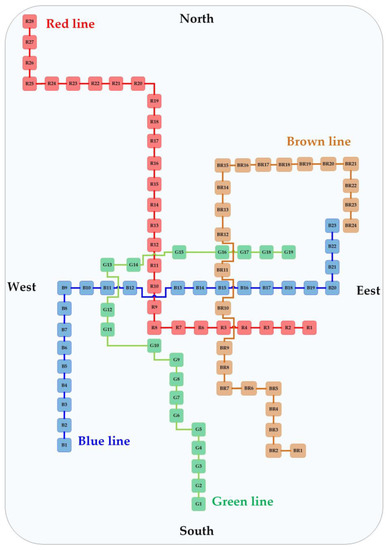

The electromechanical system consists of four subsystems: air conditioning, firefighting, elevator, and power supply (as shown in Figure 2). The importance of the electromechanical system is as follows: As a public service enterprise, the metro company is liable under criminal responsibility for fire safety. In addition, the electromechanical system’s air conditioning quality directly affects the metro company’s overall operation and service level. After considering the cost factor, labor costs, and multiple criteria affecting operating quality, this study evaluated the outsourcing priority of the electromechanical system’s four subsystems. Since the metro company owns multiple lines, i.e., the blue line, red line, green line, and brown line (as shown in Figure 3), this study evaluated the outsourcing priority of the metro lines as a subject.

Figure 2.

Schematic diagram of four subsystems of the electromechanical system of a metro company.

Figure 3.

Schematic diagram of four metro lines of the Taipei Rapid Transit Corporation.

Several studies regarding enterprise outsourcing [8,9,10,11,12,13,14] have found the following results. Zheng et al. discussed combining a decision tree with machine learning to evaluate security outsourcing. This could avoid the outflow of confidential information from within the company and facilitate encrypted technology sharing with the outsourced enterprise [8]. Ren et al. identified the items most suitable for outsourcing with economic benefits by studying the efficient exponentiating outsourcing strategy [9]. Tian et al. developed a deep neural network to enhance the security of information decryption on the Internet of Things (IoT) and the correctness of information obtained by outsourcers. The neural network can be applied to the actual IoT system [10]. To avoid errors in information decryption and even theft of relevant information in outsourcing, Wang et al. studied the outsourcing strategy of improving public integration and verification; this can enhance the security of information decryption by outsourcers and the correctness of decrypted information [11]. Villarreal et al. discussed the collaboration between business owners (taking a chemical manufacturer as an example) and outsourcers to solve the problems encountered with the aid of the outsourcer’s resources. The working benefits required by the business owner were achieved by reducing risks through collaboration, using a shared workplace, and setting work standards [12]. Tan et al. compared the two methods of manufacturing products by business owners and outsourcing products to other manufacturers. Under the proposed O model, business owners can obtain more economic benefits from the outsourcing method and shorten the manufacturing time and the costs of manufacturing products [13]. Cheng et al. discussed the information decryption assisted by outsourcers in developing IoT technology. Their study proposed the encryption method of ciphertext strategy to ensure no outflow of information when outsourcers decrypt information, which can enhance trust between business owners and outsourcers [14].

The analytic hierarchy process (AHP) has the following significant weaknesses. First, oversight in people’s thinking or difficulties in obtaining information can lead to unreasonable evaluation results. Second, when the feedback from interview experts and scholars varies considerably, it can affect the weight ratio of the AHP and result in the evaluation results not meeting the actual maintenance needs. Moreover, when there are more hierarchies and items to compare, interviewees can become confused, and their judgment accuracy can be reduced. This may lead to inaccurate evaluation results. Consequently, this study proposed the strategy of considering sensitivity and analytic hierarchy process (CSAHP) to analyze the outsourcing priority of four subsystems of the metro company’s electromechanical system (as shown in Figure 2) and the outsourcing priority of the metro lines (as shown in Figure 3). This study extended the AHP [15,16] and added sensitivity for judgments to make the evaluation results more consistent with the actual needs. Moreover, we conducted field interviews with supervisors and employees from the Taipei Rapid Transit Corporation for further analysis and evaluation. The interviews involved multiple topics, such as technology, costs, quality, management, the performance capacity of outsourcers, and economic benefits. Interview data were quantified by the criterium decision plus (CDP) software and evaluated by the CSAHP strategy proposed in this study. Based on the results obtained from the CSAHP strategy, the power supply system was identified as the subsystem with the highest outsourcing priority, followed by the air conditioning, firefighting, and elevator systems. The blue line was the highest outsourcing priority of the four metro lines, followed by the red, green, and brown lines. This study enabled outsourcing management decisions to suit the actual maintenance needs better. In addition, the economic benefits of outsourced maintenance can be improved by applying this study to the Taipei Rapid Transit Corporation.

Road life extension as a maintenance strategy was presented by Kresnanto et al. for Indonesia. Multiple roads need to be maintained, thus the AHP approach is used to evaluate traffic volume, road condition, policy, economic, and land use aspects and further determine the priority of road maintenance. This case is particularly applicable to road repair operations. Even so, the AHP technique still has flaws, making it challenging to identify evaluation blind spots [17]. According to Maliszewska et al., different kinds of maintenance work can be applied to the fuzzy analytic hierarchy process (FAHP). The significance of each assignment can be assessed using FAHP, then the leader’s top priorities can be determined. To prove this method’s effectiveness, however, true large-scale research is still required [18]. This study’s suggested CSAHP method analyzes the importance of outsourcing maintenance through the sensitivity elements. (i) Significant portion: outsourcing maintenance will be given priority in situations with high labor costs and low outsourcing costs in order to cut maintenance costs. (ii) Intangible component: outsourcing maintenance will take precedence in cases where there is high core technology and low emergency response capacity, since the metro company must continue to rely on the effectiveness of outsourcers to raise service quality. (iii) By giving the power supply system’s outsourcing work top priority, the metro corporation may cut the system’s maintenance expenditures, from USD 1.57 million to USD 1.33 million, saving 15% on maintenance costs.

2. Explaining the Metro System

2.1. A Brief Description of the Metro Company’s Seven Systems

- A.

- Brief business description of the electromechanical system

The electromechanical system includes the maintenance services of each line’s power supply, air conditioning, firefighting, and elevator systems. It also involves training electromechanical system maintenance personnel, cost management, and purchasing maintenance equipment and materials [5].

- a.

- Power supply system: the Taiwan Power Company provides a 161 kV power supply to the high-voltage transformer substation of the metro system and the power supply of different metro equipment voltages.

- b.

- Air conditioning system: includes the air conditioning systems in metro stations and maintenance workshops.

- c.

- Firefighting system: includes the firefighting systems in metro stations, maintenance workshops, and electric multiple units (EMUs).

- d.

- Elevator system: includes the elevator systems used by metro office buildings, maintenance workshops, and station passengers.

- B.

- Brief business description of the vehicle system

The vehicle system includes the maintenance services of the EMUs, rail motor cars, and workshop equipment of each line. It also involves training vehicle system maintenance personnel, cost management, and purchasing maintenance equipment and materials [19].

- C.

- Brief business description of the operating control center system

The operating control center includes the operation, scheduling, and monitoring of each line’s EMUs and rail motor cars. It handles EMU accidents and schedules strategy services. It also involves training vehicle dispatching personnel on the operating control center system, cost management, and purchasing maintenance equipment and materials [20].

- D.

- Brief business description of the infrastructure system

The infrastructure system includes the maintenance services of each line’s rails and civil engineering equipment. It also involves training infrastructure system maintenance personnel, cost management, and purchasing maintenance equipment and materials [21].

- E.

- Brief business description of the station operations system

This system includes each line’s automatic fare collection system, ticket system, pre-paid card services, and station management business. It also involves training the station operations system maintenance personnel and service personnel, cost management, and purchasing maintenance equipment and materials [22].

- F.

- Brief business description of the electrical system

The electrical system includes maintaining each line’s signal system and communication services. It also involves training the electrical system maintenance personnel, cost management, and purchasing maintenance equipment and materials [23].

- G.

- Brief business description of the information system

The information system includes promoting the digital transformation of equipment and developing and maintaining various application systems in the metro company. It also involves training the information system maintenance personnel, cost management, and purchasing maintenance equipment and materials [24].

2.2. Description of the Four Metro Lines of the Metro Company

Figure 3 shows the Taipei Rapid Transit Corporation’s four lines schematic diagram. First, the blue line consists of 23 stations from B1 to B23 and offers east–west transportation while boasting the largest passenger traffic volume. Second, the red line consists of 28 stations from R1 to R28. It provides passengers with transport between the city center and the northern part and has the second-largest traffic volume. Third, the green line has 19 stations from G1 to G19 and offers transportation between the city center and the southern part. Its traffic volume comes third. Fourth, in last place, is the brown line. It has 24 stations from R1 to R24 and offers transportation in the eastern part of the city.

3. The Proposed CSAHP Strategy

This study proposed a considering sensitivity and analytic hierarchy process (CSAHP) strategy based on the analytic hierarchy process (AHP). The AHP is primarily used in uncertain situations and for decision-making problems with multiple evaluation criteria. In general, developing the AHP systematizes complex problems, decomposes them at different hierarchies, identifies the context through quantitative calculations, and leads to a comprehensive evaluation [25,26]. In the AHP, a tree-like hierarchical structure can be utilized to decompose a complex decision-making problem into a hierarchy of several simple sub-problems, each of which can be analyzed independently. The hierarchy’s sub-problems can be of any kind, tangible or intangible, calculated or roughly estimated, clearly or vaguely understood, or anything that applies to the final decision making. Once the hierarchy is built, decision-making experts systematically evaluate the scale and assign weights to each part concerning its relative importance. Then, a pairwise comparison matrix is created, and the eigenvector and eigenvalue will be calculated. The eigenvector represents the priority of each part in each hierarchy. This can bring sufficient information to decision makers, organize the selection conditions or criteria, weights, and analyses of relevant decisions, and reduce the risk of decision errors.

The AHP evaluation scale, as a pairwise comparison between the indicator factors in each hierarchy, is roughly divided into five intensities: equally strong, weak strong, strong, very strong, and absolutely strong. The measurement values of 1, 3, 5, 7, and 9 of the nominal scale are given. Four scales are set between the five basic scales and are given the measurement values of 2, 4, 6, and 8. There are nine scales in total; the meaning represented by each scale is shown in Table 1.

Table 1.

Evaluation scale of the AHP and definition.

During the AHP operation procedure, the first step is to describe a problem. Next, influencing factors are identified, and a hierarchical structure is established. After that, the questionnaire items can be designed. The relative importance of the decision attributes among different hierarchies is identified based on the data collected from the questionnaire. A pairwise comparison matrix is created based on this data to calculate the matrix eigenvalues and eigenvectors. After the feedback check of the obtained data through consistency verification and hierarchical structure consistency verification, the weight of each indicator can be calculated to help select the best decision plan.

Create a pairwise comparison matrix first. The geometric mean of each person’s judgment value from the survey results can be used to generate a pairwise comparison matrix [17,25], which is expressed as follows.

The measurement of n factors’ comparison results is placed in the upper triangle part of the paired comparison matrix A, and the value of the lower triangle part is the reciprocal of the upper triangle part’s relative position value, aji = 1/aij. Among them, aji = wi/wj, w1, w2, and wn represent the influence weight of each level i factor on a specific level i-1 factor.

The normalization of the geometric mean of a column vector is expressed as follows.

where i, j = 1, 2…, n. The largest eigenvalue (λmax) is expressed as follows.

Furthermore, in order to confirm the suitability of the questionnaire, a consistency test on the eigenvectors must be performed, so the consistency index (C.I.) and consistency ratio (C.R.) must be calculated, as shown below.

where the random index (R.I.) is the inverted matrix generated by the evaluation scale of 1 to 9.

Finally, because the importance of different layers varies, it is necessary to verify that the entire hierarchical structure is consistent. The entire consistency ratio hierarchy (C.R.H.) is calculated by dividing the consistency index of the hierarchy (C.I.H.) by the random index of the hierarchy (R.I.H.), as shown in Equations (6)–(8). If the C.R.H. is less than 0.1, the overall consistency is acceptable. The overall weight is calculated as the basis for calculating priority after the entire hierarchical structure has been confirmed by consistency.

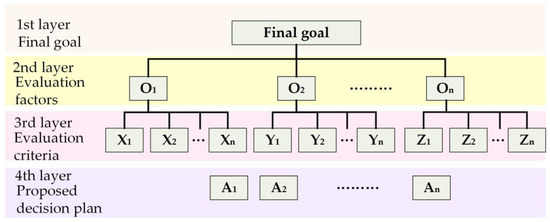

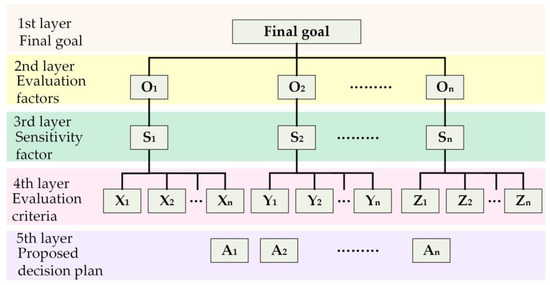

Figure 4 shows the AHP’s structural diagram. The 1st layer is the final goal, the 2nd layer is evaluation factors, the 3rd layer is evaluation criteria, and the 4th layer is the proposed decision plan. The AHP is a mature method often used by many researchers. However, it has the following weaknesses. First, regarding the AHP’s practical application, oversights in people’s thinking or difficulties in obtaining information can lead to unreasonable evaluation results. Second, when the opinions of interview experts and scholars vary considerably, it can affect the weight ratio of the strategy and lead to evaluation results that cannot truly reflect reality. Moreover, when there are more hierarchies and items to compare, interviewees can become confused, and their judgment accuracy can be reduced. This can lead to a gap between the evaluation results and the actual situation.

Figure 4.

Structural diagram of the AHP.

This study proposed a novel CSAHP strategy to enhance the AHP’s accuracy. As such, we performed an evaluation based on sensitivity factors to allow the evaluation results to reflect actual needs. Figure 5 is the schematic diagram of the proposed CSAHP strategy. The 1st layer is the final goal, the 2nd layer is evaluation factors, the 3rd layer is sensitivity factors, the 4th layer is evaluation criteria, and the 5th layer is the proposed decision plan.

Figure 5.

Structural diagram of the proposed CSAHP.

Figure 5 shows that the subject of the final goal in the 1st layer is the outsourcing priority of the electromechanical system’s subsystems. The evaluation factors in the 2nd layer include the O1 cost factor, O2 labor costs, and O3 affecting operating quality. The sensitivity factors in the 3rd layer include S1, S2, and S3, corresponding to O1 for the cost factor, O2 for labor costs, and O3 for affecting operating quality, respectively. The range of S1, S2, and S3 is between 0 and 1. The evaluation criteria in the 4th layer include X1 labor costs, X2 outsourcing costs, X3 differential costs, Y1 core technology, Y2 staff mobility, Z1 scheduling capacity, Z2 safety, Z3 service quality, and Z4 emergency response capacity. The proposed decision plan in the 5th layer includes the A1 power supply system, A2 firefighting system, A3 elevator system, and A4 air conditioning system.

Another subject of this study was the outsourcing priority of the metro lines. As shown in Figure 5, the subject of the final goal in the 1st layer is the outsourcing priority of the metro lines. The content in the 2nd, 3rd, and 4th layers is the same for the outsourcing priority of the electromechanical system’s subsystems. Finally, the proposed decision plan in the 5th layer covers the A1 blue line, A2 red line, A3 green line, and A4 brown line.

The structural diagram of the proposed CSAHP (as Figure 5) differs from the AHP (as Figure 4) in that the former added sensitivity factors to the 3rd layer (as Figure 5). These sensitivity factors can be adjusted according to the metro company’s management and quality strategies, i.e., the evaluation factors in the 2nd layer, such as the O1 cost factor, O2 labor costs, and O3 affecting operating quality. The weaknesses of the AHP can be improved with this new strategy to make decisions more closely aligned with the actual maintenance outsourcing needs.

First, the O1 cost factor contains X1 labor costs, X2 outsourcing costs, and X3 differential costs, and the relevant explanation is as follows. X1 labor costs of the metro company are employees’ salary, averaging USD 35,000 per year, plus employees’ salary of the outsourcer, averaging USD 25,000 per year. X2 outsourcing costs are the contracted outsourcing price of the electromechanical system’s four subsystems of the four metro lines. X3 differential costs are the difference between the costs of self-maintenance by the metro company and the contracted outsourcing price (as shown in Table 2).

Table 2.

Basic information on the actual outsourcing work of the four subsystems of the electromechanical system and the four lines of the metro company.

Second, O2 labor costs contain Y1 core technology and Y2 staff mobility, and the relevant explanation is as follows. Y1 core technology covers the following four aspects: (i) If the contractor cancels a contract or the contract expires, can metro company employees immediately take over the maintenance? (ii) This technology is rare and exhibits professionalism of the industry, and it takes a long time to enter and exit the industry (about 3 to 5 years). (iii) The system equipment dramatically influences the operation system. Further, if the operation is stopped due to failure, the metro company will suffer losses. (iv) This equipment maintenance technology cannot be replaced by other manufacturers. Y2 staff mobility represents the employee turnover rate of the outsourcer (as shown in Table 2).

Third, the relevant explanation regarding O3 affecting operating quality, Z1 scheduling capacity, Z2 safety, Z3 service quality, and Z4 emergency response capacity is as follows. Z1 scheduling capacity refers to the time it takes for maintenance personnel to reach the repair site after the contractor is notified by the metro company. Z2 safety refers to the number of times that deficiencies are found during the examination on the contractor by the metro company’s industrial safety department. Z3 service quality refers to the availability of the metro company’s equipment. Z4 emergency response capacity refers to the time taken by the maintenance personnel of the contractor to complete the repair work after arriving at the repair site (as shown in Table 2).

Finally, Table 2 [27] shows the actual outsourcing work for the electromechanical system’s four subsystems in 2020 and 2021, as well as the four metro lines in 2020 and 2021. The information in the table is based on the actual X1 labor costs, X2 outsourcing costs, X3 differential costs, Y1 core technology, Y2 staff mobility, Z1 scheduling capacity, Z2 safety, Z3 service quality, and Z4 emergency response capacity (as shown in Figure 5) of the metro company.

4. Analysis Results of Actual Outsourcing

This study evaluated the outsourcing priority of the electromechanical system’s four subsystems and the outsourcing priority of the metro company’s four lines through the CSAHP and the AHP. The results showed that the power supply system had the highest outsourcing priority of the electromechanical system’s four subsystems, followed by the air conditioning, firefighting, and elevator systems. The blue line had the highest outsourcing priority of the four metro lines, followed by the red, green, and brown lines. The CSAHP strategy adopted in this study enabled more flexible judgments based on sensitivity factors, and the evaluation results were adjusted to suit the actual needs. Unlike the fixed analytic method of the AHP, the proposed method can better meet the actual maintenance needs. The Taipei Rapid Transit Corporation can apply it to improve the economic benefits of outsourced maintenance. The following is a discussion of the analysis results of the electromechanical system’s four subsystems and the metro company’s four metro lines regarding outsourcing priority.

4.1. Outsourcing Priority Analysis Results of the Electromechanical System’s Four Subsystems

- A.

- AHP Analysis

This study included 110 people from the Taipei Rapid Transit Corporation who were involved in outsourcing-related work. There are 100 people left after keeping the valid questionnaire (including seven supervisors and scholars and 93 employees). As a result, AHP was used in this study to interview 100 people. The data (as shown in Table 2) were estimated by referring to the criteria, making pairwise comparisons, and using the geometric mean value to calculate the weight of each evaluation criterion and the weight of outsourcing priorities. These results were the basis for deciding which subsystem of the electromechanical system had the highest outsourcing priority.

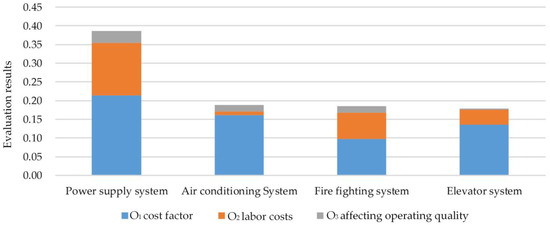

First, using the electromechanical system as an example, the weight and ranking of the evaluation factors in the 2nd layer were obtained through the AHP (as shown in Table 3 and Figure 4). The O1 cost factor had a weight of 0.679 and a ranking of 1; O2 labor costs had a weight of 0.255 and a ranking of 2; O3 affecting operating quality had a weight of 0.066 and a ranking of 3.

Table 3.

The weight and ranking of evaluation factors in the 2nd layer with the electromechanical system as an example.

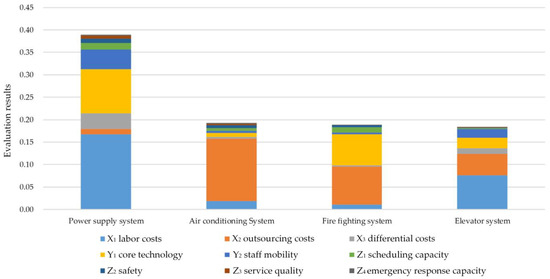

Second, using the electromechanical system as an example, the criterion weight, weight, and ranking of the evaluation criteria in the 3rd layer were obtained through the AHP (as shown in Table 4 and Figure 4). The criterion weight of X1 labor costs, X2 outsourcing costs, and X3 differential costs totaled 1. The criterion weight of Y1 core technology and Y2 staff mobility totaled 1. The criterion weight of Z1 scheduling capacity, Z2 safety, Z3 service quality, and Z4 emergency response capacity totaled 1. X1 labor costs had a weight of 0.363 and a ranking of 1; X2 outsourcing costs had a weight of 0.250 and a ranking of 2; X3 differential costs had a weight of 0.066 and a ranking of 5; Y1 core technology had a weight of 0.170 and a ranking of 3; Y2 staff mobility had a weight of 0.085 and a ranking of 4; Z1 scheduling capacity had a weight of 0.028 and a ranking of 6; Z2 safety had a weight of 0.021 and a ranking of 7; Z3 service quality had a weight of 0.013 and a ranking of 8; Z4 emergency response capacity had a weight of 0.004 and a ranking of 9.

Table 4.

The criterion weight, weight, and ranking of evaluation criteria in the 3rd layer with the electromechanical system as an example.

Table 5 shows the analysis of the outsourcing priority of the electromechanical system’s four subsystems. The evaluation criteria of each subsystem, including X1 labor costs, X2 outsourcing costs, X3 differential costs, Y1 core technology, Y2 staff mobility, Z1 scheduling capacity, Z2 safety, Z3 service quality, and Z4 emergency response capacity, were further multiplied by the corresponding items of the weights of the evaluation criteria in the 3rd layer. These were summed up to obtain the final evaluation result value. The evaluation result of the power supply system was 0.390, ranking 1st in outsourcing; the evaluation result of the air conditioning system was 0.192, ranking 2nd in outsourcing; the evaluation result of the firefighting system was 0.189, ranking 3rd in outsourcing; the evaluation result of the elevator system was 0.183, ranking 4th in outsourcing.

Table 5.

Analysis of outsourcing priority of the electromechanical system’s four subsystems.

Figure 6 shows the weights of the evaluation factors in the 2nd layer for the power supply, air conditioning, firefighting, and elevator systems. Figure 7 shows the weights of the evaluation criteria in the 3rd layer for the power supply, air conditioning, firefighting, and elevator systems. Figure 6 and Figure 7 were created based on Table 3 and Table 5, respectively. The evaluation result of the power supply system was 0.390, ranking 1st in outsourcing; the evaluation result of the air conditioning system was 0.192, ranking 2nd in outsourcing; the evaluation result of the firefighting system was 0.189, ranking 3rd in outsourcing; the evaluation result of the elevator system was 0.183, ranking 4th in outsourcing.

Figure 6.

The weights of evaluation factors in the 2nd layer of the power supply, air conditioning, firefighting, and elevator systems.

Figure 7.

The weights of evaluation factors in the 3rd layer of the power supply, air conditioning, firefighting, and elevator systems.

- B.

- Analysis through the CSAHP

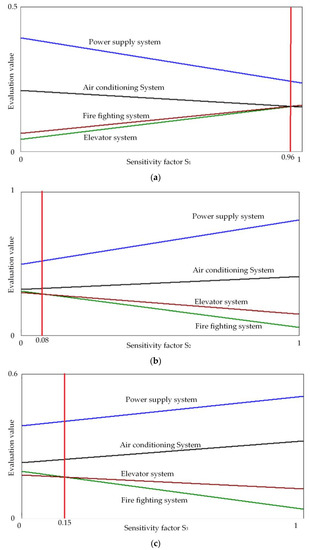

Figure 8a shows the sensitivity analysis of the power supply, air conditioning, firefighting, and elevator systems, where the X-axis is the sensitivity factor S1, Y-axis is the evaluation value. The sensitivity factor S1 was added to the O1 cost factor (as shown in Figure 5). When S1 ranged from 0 to 0.96, the outsourcing priority ranking was the power supply system, air conditioning system, firefighting system, and elevator system. When S1 ranged from 0.96 to 1, the outsourcing priority ranking was the power supply, firefighting, elevator, and air conditioning systems. Figure 8b shows the sensitivity analysis of the power supply, air conditioning, firefighting, and elevator systems, where the X-axis is the sensitivity factor S2, Y-axis is the evaluation value. The sensitivity factor S2 was added to the O2 labor costs (as shown in Figure 5). When S2 ranged from 0 to 0.08, the outsourcing priority ranking was the power supply system, air conditioning system, firefighting system, and elevator system. When S2 ranged from 0.08 to 1, the outsourcing priority ranking was the power supply, air conditioning, elevator, and firefighting systems. Figure 8c shows the sensitivity analysis of the power supply, air conditioning, firefighting, and elevator systems, where the X-axis is the sensitivity factor S3, Y-axis is the evaluation value, and the sensitivity factor S3 was added to O3 affecting operating quality (as shown in Figure 5). When S3 ranged from 0 to 0.15, the outsourcing priority ranking was the power supply system, air conditioning system, firefighting system, and elevator system. When S3 ranged from 0.15 to 1, the outsourcing priority ranking was the power supply, air conditioning, elevator, and firefighting systems.

Figure 8.

Sensitivity analysis of the power supply, air conditioning, firefighting, and elevator systems: (a) sensitivity factor S1 was added to O1 cost factor; (b) sensitivity factor S2 was added to O2 labor costs; (c) sensitivity factor S3 was added to O3 affecting operating quality.

This study applied the CSAHP strategy in the sensitivity analysis of the O1 cost factor, O2 labor costs, and O3 affecting operating quality. Sensitivity factors can be adjusted to the outsourcing needs to obtain results closer to the actual situation. When the metro company’s operation strategy changes or there is an emergency, sensitivity factors S1, S2, and S3 can be adjusted to meet the actual maintenance needs through the CSAHP strategy. Therefore, this method can consider both the costs and the operating quality. A brief description of the weaknesses of the AHP to be further improved is as follows: 1. In the AHP’s practical application, the defects in people’s thinking or difficulties in obtaining information can lead to unreasonable evaluation results. 2. When the opinions of interview experts and scholars vary considerably, it can affect the weight ratio of the strategy and lead to evaluation results that cannot truly reflect reality. 3. When there are more hierarchies and items to compare, interviewees can become confused, and their judgment accuracy can be reduced. This can lead to a gap between the evaluation results and the actual situation.

The CSAHP strategy assesses the importance of outsourcing maintenance using sensitivity factors, and the result of improving the company’s competitiveness is explained below. (i) Significant part: when labor costs are high and outsourcing costs are low, outsourcing maintenance will be prioritized to reduce maintenance costs. (ii) Intangible component: for high core technology and low emergency response capacity, outsourcing maintenance will be prioritized, as the metro corporation must still rely on the efficiency of outsourcers to improve service quality. (iii) By prioritizing power supply system outsourcing, the metro corporation can reduce power supply system maintenance costs from USD 1.57 million to USD 1.33 million, saving 15% on maintenance costs.

4.2. Analysis Results of the Outsourcing Priority of the Metro Company’s Four Lines

- A.

- AHP Analysis

This study used AHP to interview 100 Taipei Rapid Transit Corporation personnel. The data (as shown in Table 2) were estimated by referring to the criteria, and pairwise comparisons were made. The geometric mean value was taken and inputted into the CDP software to calculate each evaluation criterion’s weight and outsourcing priorities. The results were the basis for deciding which line had the highest outsourcing priority.

First, using the four lines as an example, the weight and ranking of the evaluation factors in the 2nd layer were obtained through the AHP (as shown in Table 6 and Figure 4). The O1 cost factor had a weight of 0.717 and a ranking of 1; O2 labor costs had a weight of 0.217 and a ranking of 2; O3 affecting operating quality had a weight of 0.066 and a ranking of 3.

Table 6.

The weight and ranking of evaluation factors in the 2nd layer with four lines as an example.

Second, using the four lines as an example, the criterion weight, weight, and ranking of the evaluation criteria in the 3rd layer were obtained through the AHP (as shown in Table 7 and Figure 4). The criterion weight of X1 labor costs, X2 outsourcing costs, and X3 differential costs totaled 1. The criterion weight of Y1 core technology and Y2 staff mobility totaled 1. The criterion weight of Z1 scheduling capacity, Z2 safety, Z3 service quality, and Z4 emergency response capacity totaled 1. X1 labor costs had a weight of 0.401 and a ranking of 1; X2 outsourcing costs had a weight of 0.250 and a ranking of 2; X3 differential costs had a weight of 0.066 and a ranking of 5; Y1 core technology had a weight of 0.140 and a ranking of 3; Y2 staff mobility had a weight of 0.077 and a ranking of 4; Z1 scheduling capacity had a weight of 0.027 and a ranking of 6; Z2 safety had a weight of 0.022 and a ranking of 7; Z3 service quality had a weight of 0.014 and a ranking of 8; Z4 emergency response capacity had a weight of 0.003 and a ranking of 9.

Table 7.

The criterion weight, weight, and ranking of evaluation criteria in the 3rd layer with four lines as an example.

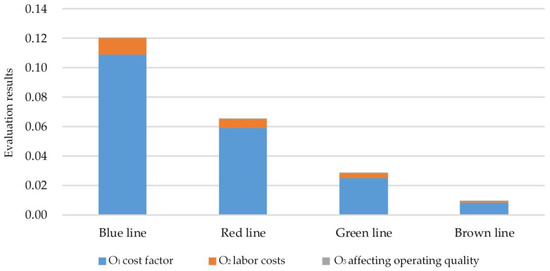

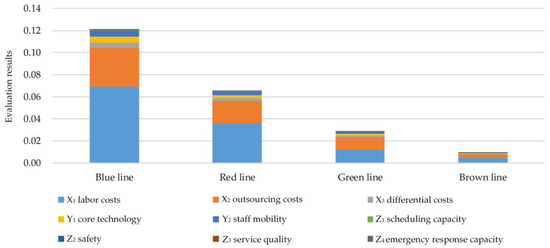

Table 8 shows the analysis of the outsourcing priority of the four metro lines. The evaluation criteria of each subsystem, including X1 labor costs, X2 outsourcing costs, X3 differential costs, Y1 core technology, Y2 staff mobility, Z1 scheduling capacity, Z2 safety, Z3 service quality, and Z4 emergency response capacity, were further multiplied by the corresponding items of the weights of the evaluation criteria in the 3rd layer. Then, they were summed up to obtain the final evaluation result value. The evaluation result of the blue line was 0.120, ranking 1st in outsourcing; the evaluation result of the red line was 0.065, ranking 2nd in outsourcing; the evaluation result of the green line was 0.028, ranking 3rd in outsourcing; the evaluation result of the brown line was 0.009, ranking 4th in outsourcing.

Table 8.

Analysis of outsourcing priority of the four metro lines.

Figure 9 shows the weights of the evaluation factors in the 2nd layer for the blue, red, green, and brown lines. Figure 10 shows the weights of the evaluation criteria in the 3rd layer for the blue, red, green, and brown lines. Figure 9 and Figure 10 were created based on Table 6 and Table 8, respectively. The evaluation result of the blue line was 0.120, ranking 1st in outsourcing; the evaluation result of the red line was 0.065, ranking 2nd in outsourcing; the evaluation result of the green line was 0.028, ranking 3rd in outsourcing; the evaluation result of the brown line was 0.009, ranking 4th in outsourcing.

Figure 9.

The weights of evaluation factors in the 2nd layer of the blue line, red line, green line, and brown line.

Figure 10.

The weights of evaluation factors in the 3rd layer of the blue line, red line, green line, and brown line.

- B.

- Analysis through the CSAHP

This study used the CSAHP strategy to analyze the outsourcing priority of the metro company’s four lines (as shown in Figure 5). When the sensitivity factor S1 was added to the O1 cost factor, with the range of S1 from 0 to 1, the outsourcing priority ranked as the blue line, red line, green line, then brown line. When the sensitivity factor S2 was added to the O2 labor costs, with the range of S2 from 0 to 1, the outsourcing priority ranked as the blue, red, green, then brown lines. When the sensitivity factor S3 was added into O3, affecting operating quality, with the range of S3 from 0 to 1, the outsourcing priority ranked as the blue, red, green, then brown lines.

In this study, sensitivity analysis of the O1 cost factor, O2 labor costs, and O3 affecting operating quality can be adjusted according to the outsourcing needs to obtain the outsourcing maintenance needs more closely associated with the actual situation. When the weights of sensitivity factors changed, the outsourcing priority ranking remained unchanged, which verifies that the evaluation method with the AHP was accurate, and the subsequent results meet the actual maintenance needs. When the metro company’s operation strategy changes or there is an emergency, sensitivity factors S1, S2, and S3 can be adjusted to the actual maintenance needs through the CSAHP strategy. Therefore, this method can consider both the costs and the operating quality.

5. Conclusions

The CSAHP strategy was primarily used to analyze the cost factor, labor costs, and affecting operating quality. When the metro company’s operation strategy changes or there is an emergency, sensitivity factors S1, S2, and S3 can be adjusted to meet actual maintenance needs. Therefore, this method can consider both the costs and the operating quality. When the sensitivity factor S1 was added to the cost factor, and S1 ranged from 0.96 to 1, the outsourcing priority ranked as the power supply system, firefighting system, elevator system, then air conditioning system. When the sensitivity factor S2 was added to labor costs and S2 ranged from 0.08 to 1, the outsourcing priority ranked as the power supply system, air conditioning system, elevator system, then firefighting system. Moreover, when the sensitivity factor S3 was added to affect operating costs, and S3 ranged from 0.15 to 1, the outsourcing priority ranked as the power supply system, air conditioning system, elevator system, then firefighting system. Lastly, the results of the outsourcing priority for the metro lines obtained through the CSAHP were identical to those obtained through the AHP. This is because there is a significant difference in the number of passengers and the length among the four lines of the metro company, resulting in a high weight ratio of the cost factor and limited influence that sensitivity factors can exert.

The CSAHP improved three weaknesses of the AHP. First, regarding the AHP’s practical application, defects in people’s thinking or difficulties in obtaining information can lead to unreasonable evaluation results. Second, when the opinions of interview experts and scholars vary considerably, it can affect the weight ratio of the strategy and lead to evaluation results that cannot truly reflect reality. Lastly, when there are more hierarchies and items to compare, interviewees can become confused, and their judgment accuracy is reduced. This can lead to a gap between the evaluation results and the actual situation. Finally, this study contributes to the prioritization of power supply system outsourcing work, which can help the metro corporation reduce the power supply system maintenance cost from USD 1.57 million to USD 1.33 million, saving 15% of maintenance costs.

In the future, the CSAHP strategy can be extended to vehicle-related enterprises to evaluate outsourced maintenance projects, which can reduce the operating costs of vehicle enterprises and enhance their competitiveness. The sensitivity factors were adjusted for items, such as the cost factor, labor costs, and affecting operating quality, in this study and can be extended to the next stage for evaluating outsourced maintenance projects.

Author Contributions

Conceptualization, S.-N.P., C.-Y.H. and H.-D.L.; methodology, S.-N.P., C.-Y.H. and H.-D.L.; software, S.-N.P.; validation, S.-N.P.; formal analysis, S.-N.P., C.-Y.H. and H.-D.L.; investigation, S.-N.P., C.-Y.H. and H.-D.L.; resources, S.-N.P.; data curation, S.-N.P.; writing—original draft preparation, S.-N.P., C.-Y.H. and H.-D.L.; writing—review and editing, S.-N.P., C.-Y.H. and H.-D.L.; visualization, S.-N.P., C.-Y.H. and H.-D.L.; supervision, C.-Y.H.; project administration, C.-Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science and Technology Council, Taiwan, grant number MOST 111-2221-E-003-012. This work was also supported by the National Taiwan Normal University Subsidy Policy for International Collaboration and Research Projects, the National Taiwan Normal University Subsidy Policy to Enhance Academic Research Projects, and the National Taiwan Normal University (NTNU), Taiwan.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Voigt, B.; Mierke, T.; Lorenz, U.; Kramer, K. 1MWh-battery for the Berlin subway system. In Proceedings of the 34th International Power Sources Symposium, Cherry Hill, NJ, USA, 25–28 June 1990. [Google Scholar] [CrossRef]

- Yang, W.-C.; Peng, L.-M.; Wang, L.-C. Computation Simulation on Aerodynamic Characteristic of PSD in Subway Platform. In Proceedings of the 2009 International Conference on Computer Engineering and Technology, Singapore, 22–24 January 2009; Volume 2, pp. 395–398. [Google Scholar] [CrossRef]

- Du, P.; Mao, B.; Liu, Z. Analysis of transfer station design in Hong Kong. In Proceedings of the 7th Advanced Forum on Transportation of China (AFTC 2011), Beijing, China, 22 October 2011. [Google Scholar] [CrossRef]

- Huang, L.-Y.; Liu, H.-D.; Lu, S.-D.; Hsu, C.-M. Novel Graphene Allocating Carbon–Copper Ratio Method for the Rail Vehicle Propulsion System Ground Carbon Brush. IEEE Access 2022, 10, 52890–52898. [Google Scholar] [CrossRef]

- Gong, X.; Chen, L. Design and Realization of Integrated Monitoring of Subway Electrical Equipment. In Proceedings of the 2017 International Conference on Computer Technology, Electronics and Communication (ICCTEC), Dalian, China, 19–21 December 2017. [Google Scholar] [CrossRef]

- Liu, H.; Xie, Y.; Liu, Y.; Nie, R.; Li, X. Mapping the Knowledge Structure and Research Evolution of Urban Rail Transit Safety Studies. IEEE Access 2019, 7, 186437–186455. [Google Scholar] [CrossRef]

- De Almeida, J.R.; Camargo, J.B.; Cugnasca, P.S. Software Safety in Subway and Air Traffic Control Applications. IEEE Lat. Am. Trans. 2008, 6, 106–113. [Google Scholar] [CrossRef]

- Zheng, Y.; Duan, H.; Wang, C.; Wang, R.; Nepal, S. Securely and Efficiently Outsourcing Decision Tree Inference. IEEE Trans. Dependable Secur. Comput. 2020, 19, 1841–1855. [Google Scholar] [CrossRef]

- Ren, Y.; Dong, M.; Qian, Z.; Zhang, X.; Feng, G. Efficient Algorithm for Secure Outsourcing of Modular Exponentiation with Single Server. IEEE Trans. Cloud Comput. 2018, 9, 145–154. [Google Scholar] [CrossRef]

- Tian, Y.; Njilla, L.; Yuan, J.; Yu, S. Low-Latency Privacy-Preserving Outsourcing of Deep Neural Network Inference. IEEE Internet Things J. 2020, 8, 3300–3309. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, C.; Xu, R.; Ding, J.; Liu, Z. Analysis and Enhancement of a Lattice-Based Data Outsourcing Scheme with Public Integrity Verification. IEEE Trans. Serv. Comput. 2020, 15, 2226–2231. [Google Scholar] [CrossRef]

- Segovia-Villarreal, M.; López-Pérez, L.; Ramón-Jerónimo, J.; Florez-Lopez, R. Analyzing Management Control Systems between Principal Owners of Facilities and Subsidiaries in the Chemical Industry. Processes 2021, 9, 1114. [Google Scholar] [CrossRef]

- Tan, H.; Cao, G.; He, Y.; Lu, Y. Channel Structure Choice for Remanufacturing under Green Consumerism. Processes 2021, 9, 1985. [Google Scholar] [CrossRef]

- Cheng, R.; Wu, K.; Su, Y.; Li, W.; Cui, W.; Tong, J. An Efficient ECC-Based CP-ABE Scheme for Power IoT. Processes 2021, 9, 1176. [Google Scholar] [CrossRef]

- Haji, M.; Kerbache, L.; Al-Ansari, T. Evaluating the Performance of a Safe Insulin Supply Chain Using the AHP-TOPSIS Approach. Processes 2022, 10, 2203. [Google Scholar] [CrossRef]

- Li, R.Y.M.; Chau, K.W.; Zeng, F.F. Ranking of Risks for Existing and New Building Works. Sustainability 2019, 11, 2863. [Google Scholar] [CrossRef]

- Kresnanto, N.C. Prioritizing District Road Maintenance Using AHP Method. In Proceedings of the Second International Conference of Construction, Infrastructure, and Materials; Springer: Singapore, 2022; pp. 363–371. [Google Scholar] [CrossRef]

- Patalas-Maliszewska, J.; Kłos, S. An Approach to Supporting the Selection of Maintenance Experts in the Context of Industry 4.0. Appl. Sci. 2019, 9, 1848. [Google Scholar] [CrossRef]

- Zhu, S.; Li, Y.; Liu, Y.; Li, S. Research on the Vibration Detection System of Subway Vehicle Doors Based on WiFi. In Proceedings of the 2022 6th International Conference on Automation, Control and Robots (ICACR), Shanghai, China, 23–25 September 2022; pp. 118–121. [Google Scholar] [CrossRef]

- Bajenaru, F. A modern informational system at the Bucharest subway’s control centre. In Proceedings of the 1998 International Conference on Developments in Mass Transit Systems Conf. Publ. No. 453), London, UK, 20–23 April 1998. [Google Scholar] [CrossRef]

- Yu, S.; Yougang, X.; Feifei, C.; Ping, Z. Interior Noise Prediction of Subway Cab Caused by Track Irregularities. In Proceedings of the 2010 International Conference on Optoelectronics and Image Processing, Haikou, China, 11–12 November 2010; Volume 1, pp. 642–645. [Google Scholar] [CrossRef]

- Qi, L.; Xin, Z.; Zhigang, Y.; Zhang, Y. An analysis of Park-and-Ride service at subway station across Beijing. In Proceedings of the 2019 5th International Conference on Transportation Information and Safety (ICTIS), Liverpool, UK, 14–17 July 2019; pp. 984–988. [Google Scholar] [CrossRef]

- Briso-Rodriguez, C.; Fratilescu, P.; Xu, Y. Path Loss Modeling for Train-to-Train Communications in Subway Tunnels at 900/2400 MHz. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1164–1168. [Google Scholar] [CrossRef]

- Zhao, H.; Dong, Y. The research about disseminating subway emergency information by BASS model. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Khan, A.W.; Khan, S.U.; Alwageed, H.S.; Khan, F.; Khan, J.; Lee, Y. AHP-Based Systematic Approach to Analyzing and Evaluating Critical Success Factors and Practices for Component-Based Outsourcing Software Development. Sustainability 2022, 10, 3982. [Google Scholar] [CrossRef]

- Chen, S.-C.; Lee, D.-S.; Huang, C.-Y. Evaluating the Sustainable Operating Performance of Electronics Industry Groups: Taiwanese Firms in Mainland China. Sustainability 2021, 13, 12030. [Google Scholar] [CrossRef]

- The Budgets Book; Metro corporation: Taipei, Taiwan, 2021.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).