Performance Analysis of a Hybrid of Solar Photovoltaic, Genset, and Hydro of a Rural-Based Power Mini-Grid: Case Study of Kisiizi Hydro Power Mini-Grid, Uganda

Abstract

:1. Introduction

1.1. Literature Review

- There was a power shortage in Uganda;

- There was a lack of power generation infrastructure of installed capacity;

- There was a need to raise the hydropower supply capacity;

- There was a need to export power as a result of implemented hydropower projects.

1.2. Kisiizi Hydropower Mini-Grid (KHPMG) as a Case Study

- Domestic customers. These are customers that use electricity for lighting, charging, ironing, playing music, and watching television;

- Commercial customers. These are customers who use electricity for business purposes, and these include Institutions such as schools, churches, and health centers. Small businesses, which include welding, Bakery, Wood workshop, Grain millers, Coffee hullers, Fuel stations, and Saloons.

2. Materials and Methods

2.1. Introduction and Literature Review

2.2. Case Study Area

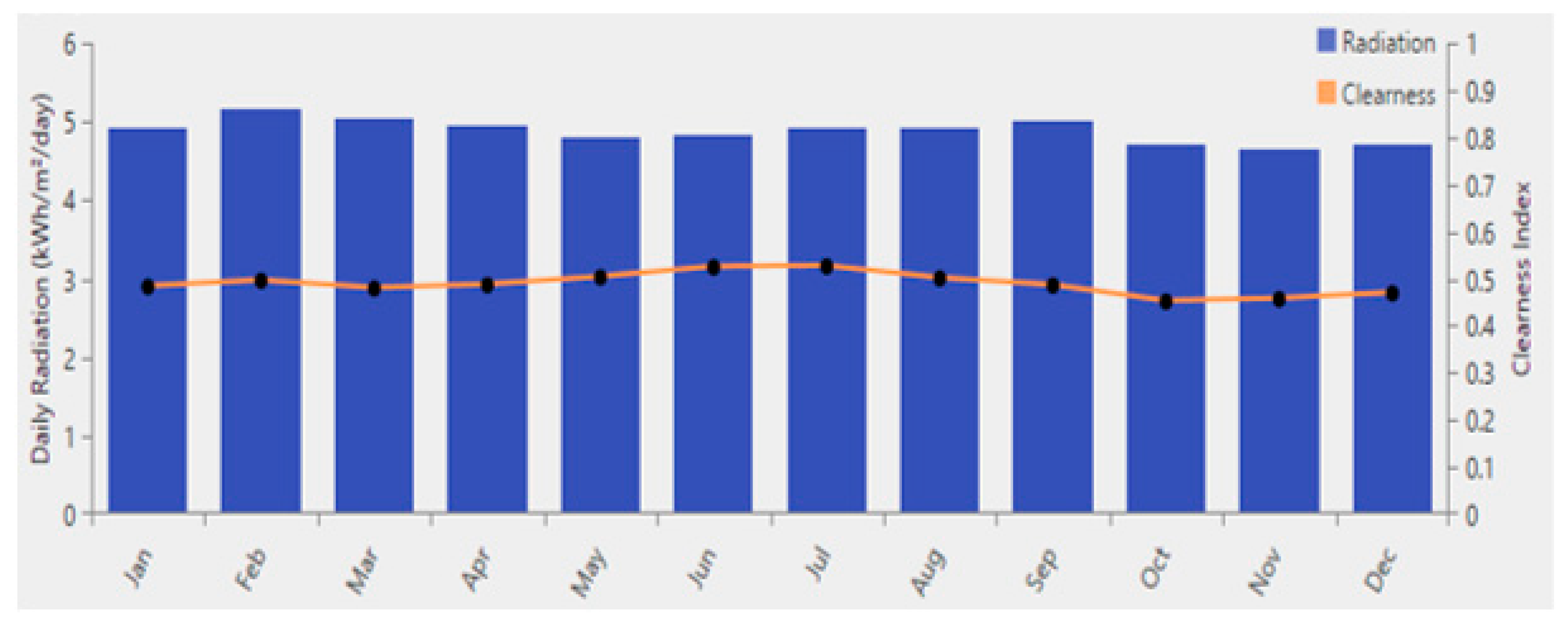

2.3. Design of a Hybrid of Solar PV, Diesel Generator, and Hydropower

2.4. Software Used: The Software Used Is HOMER pro × 64

2.5. Homer Economic Modeling

3. Results

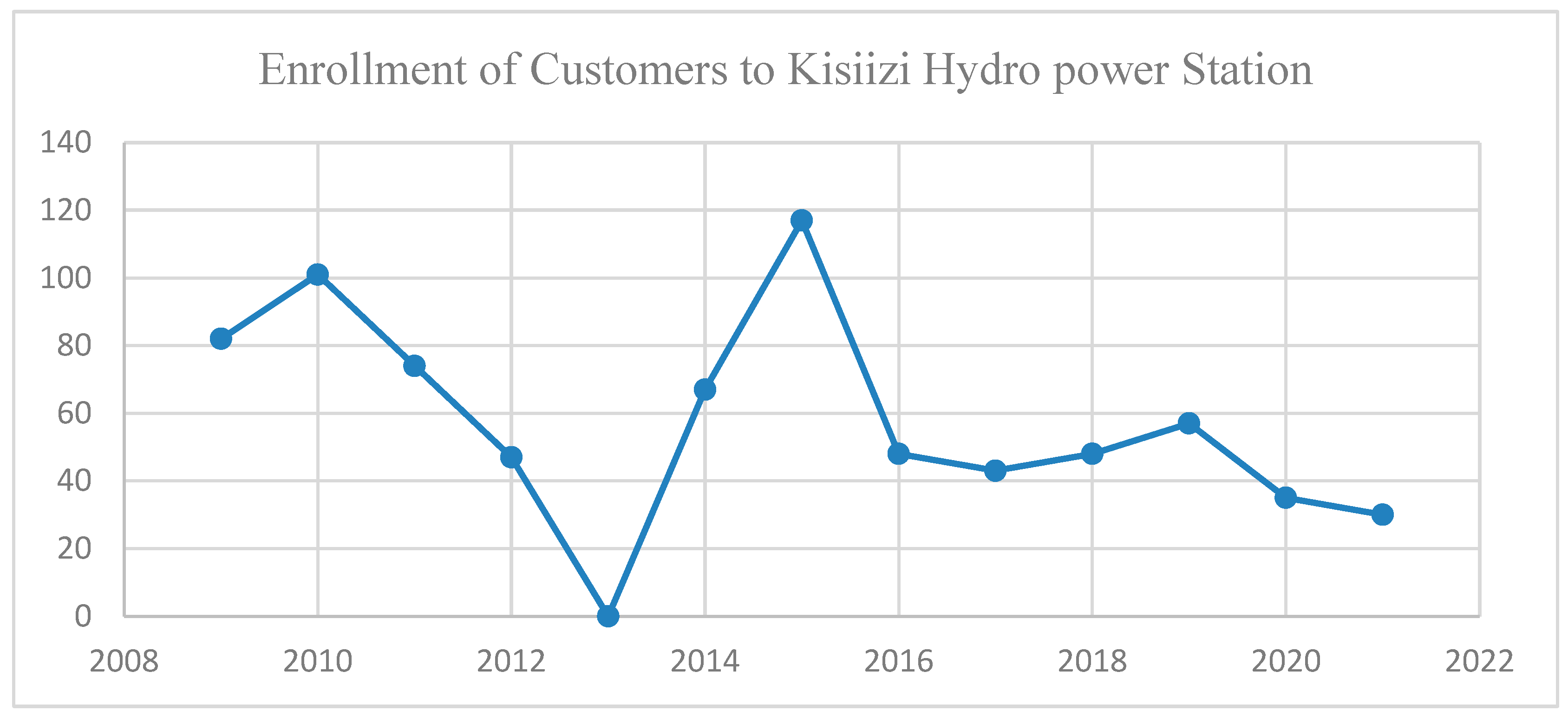

3.1. Customer Enrollment

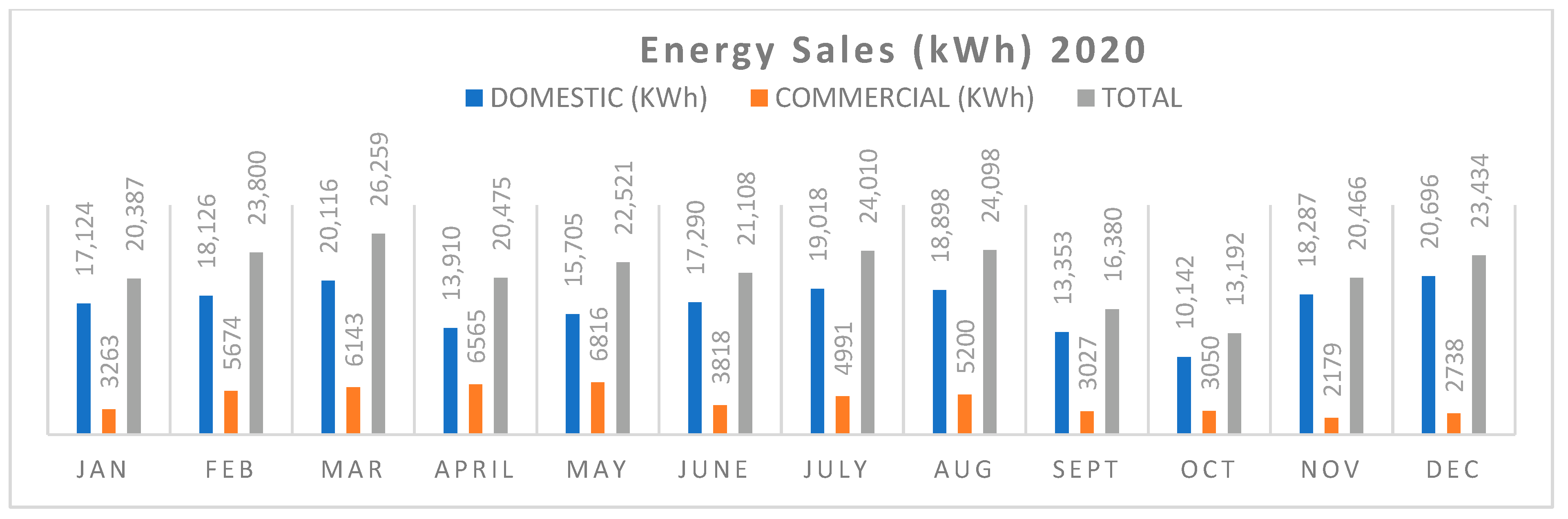

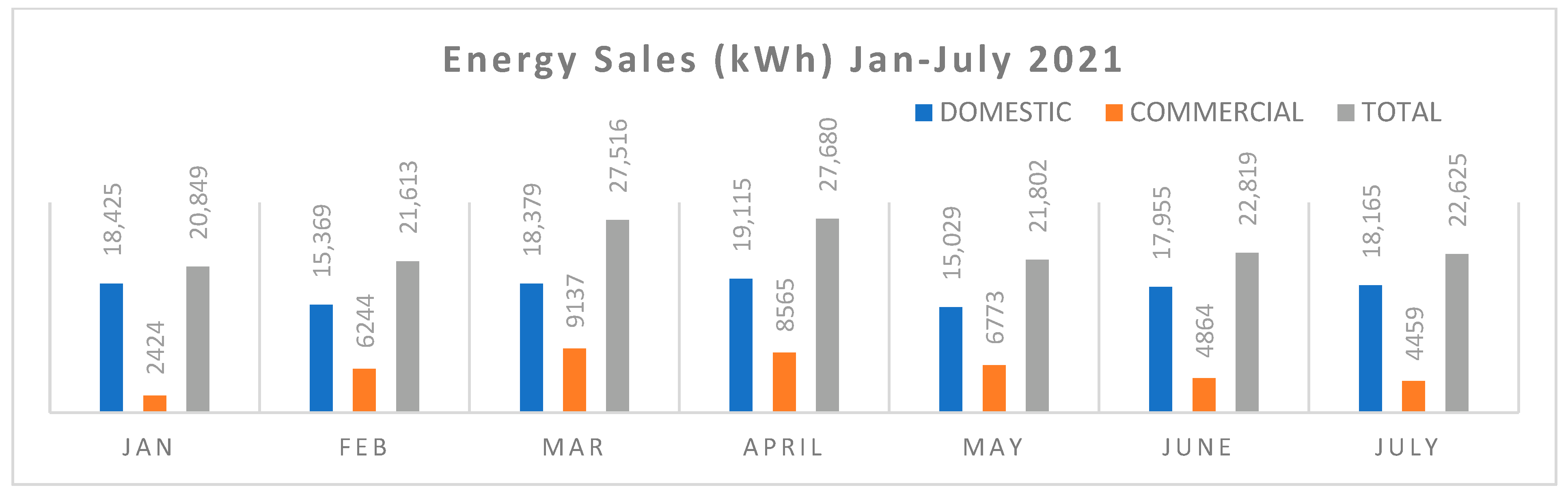

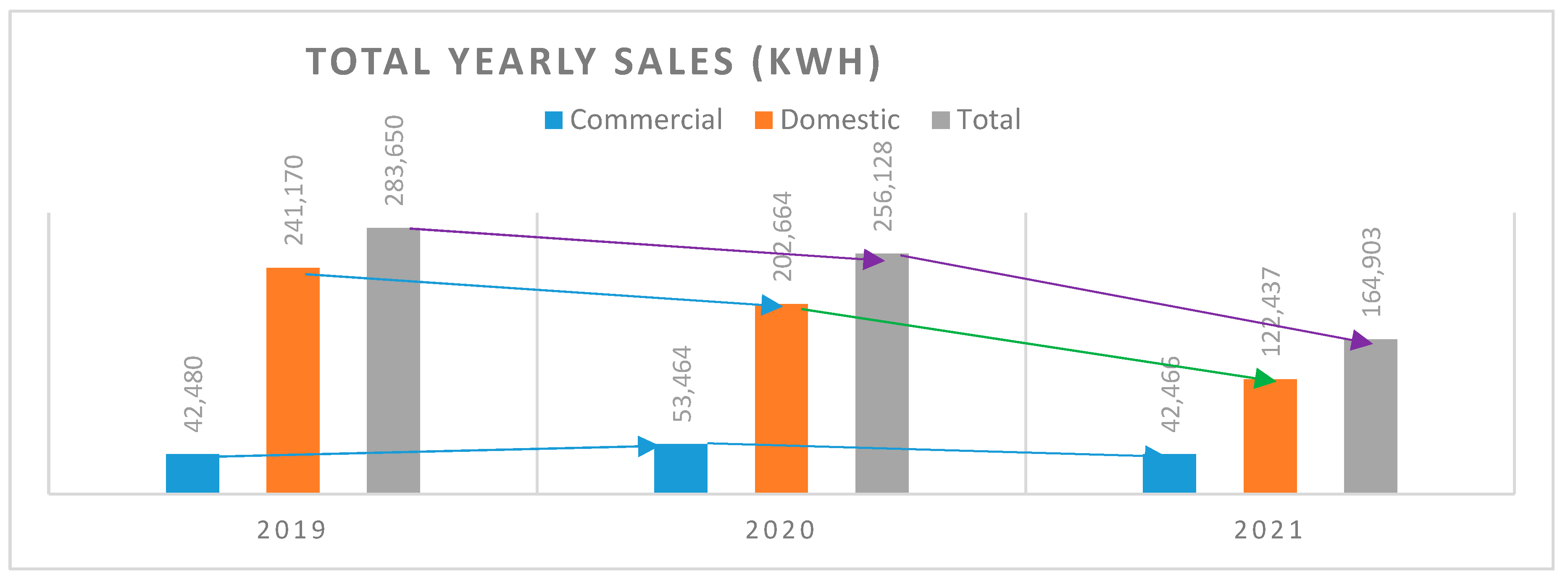

3.2. Energy Sale Analysis

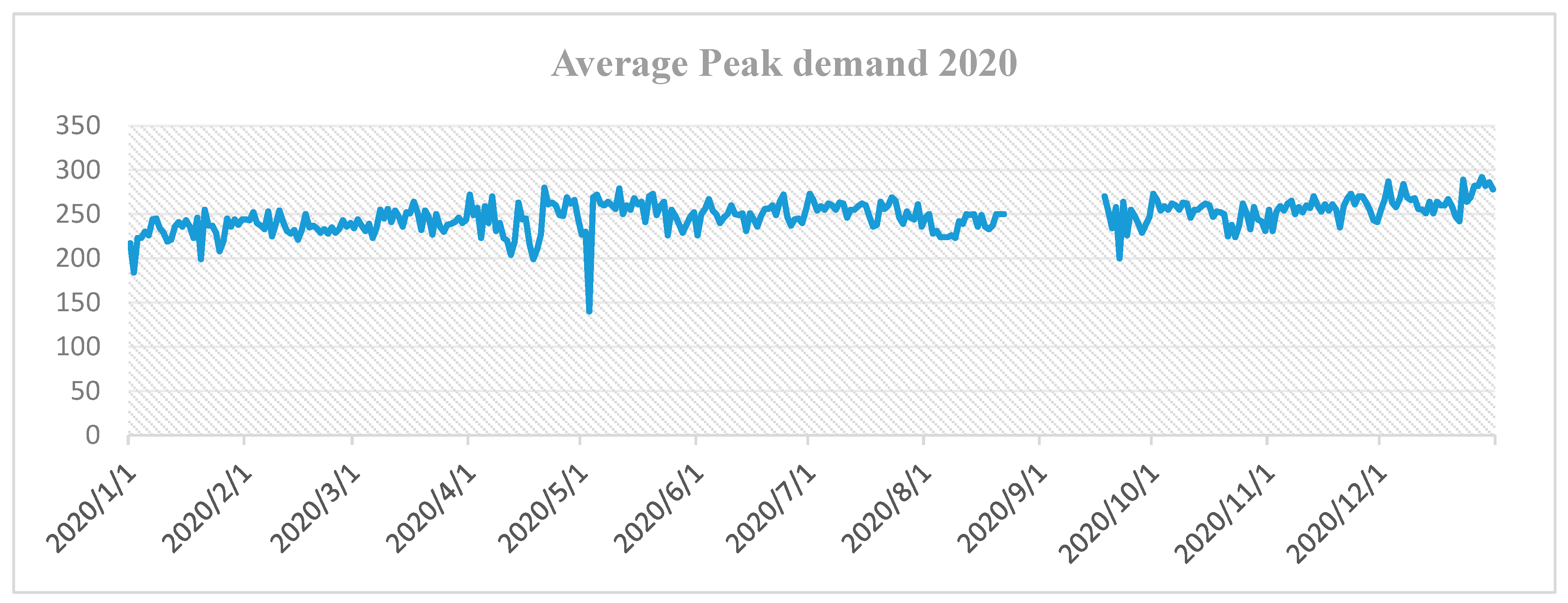

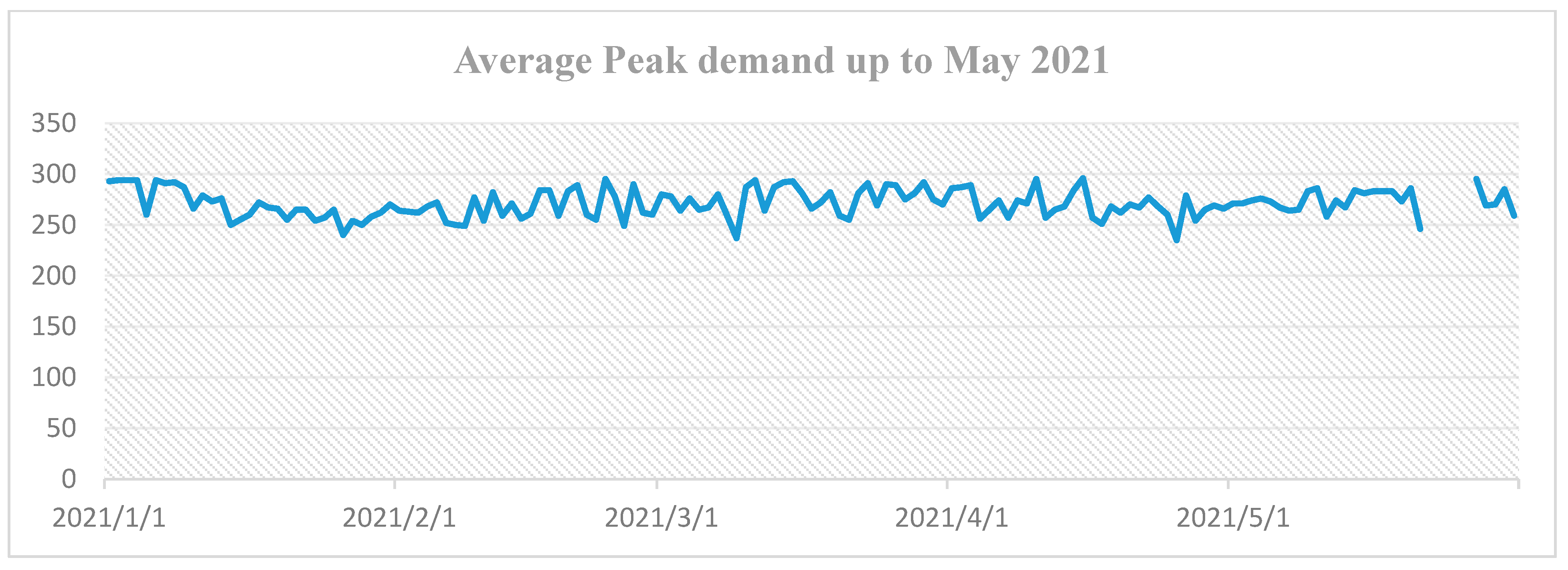

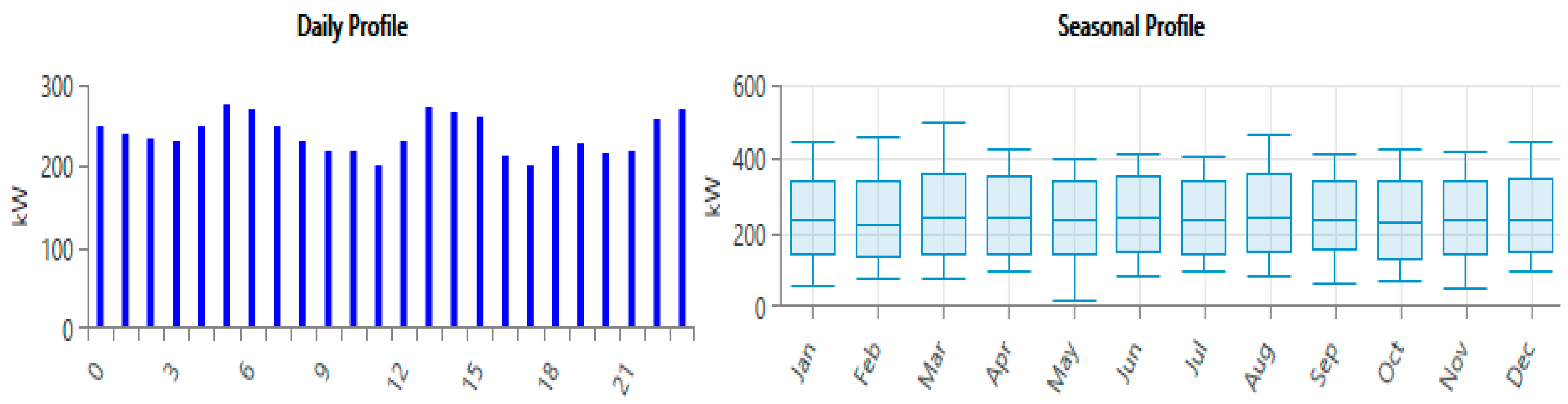

3.3. Peak Demand Analysis

4. Discussion

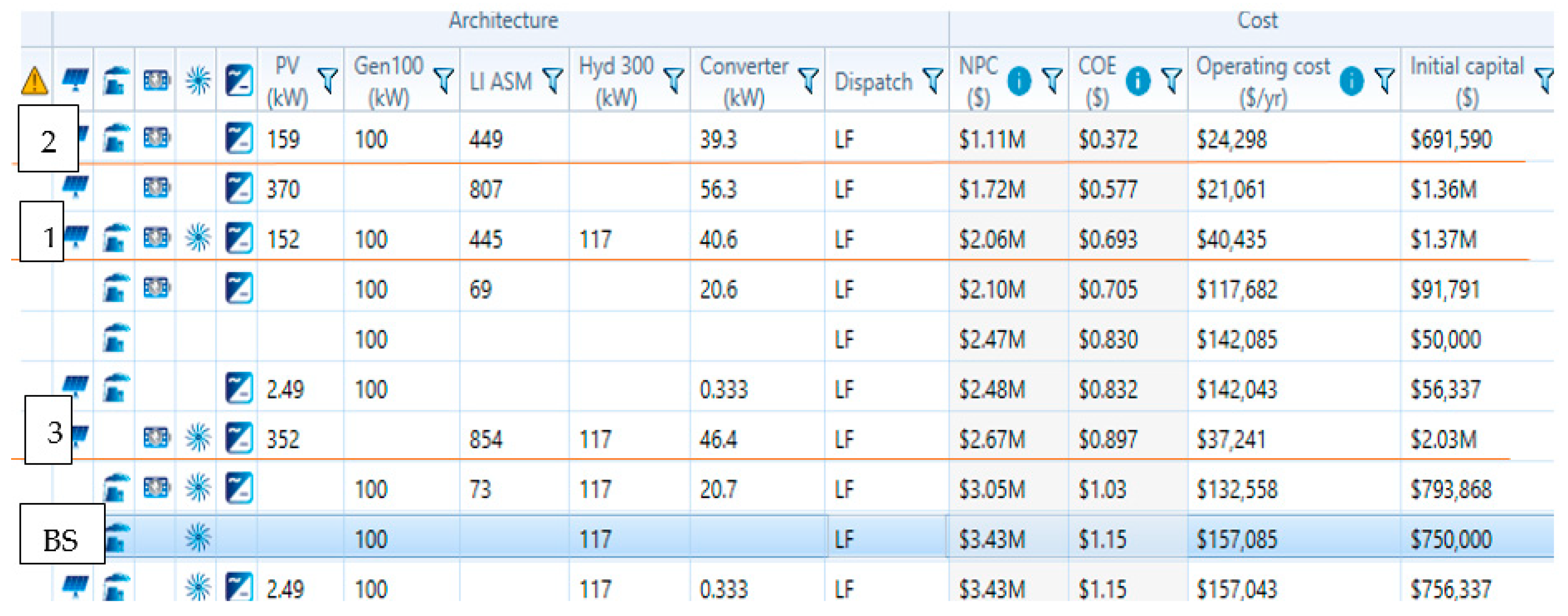

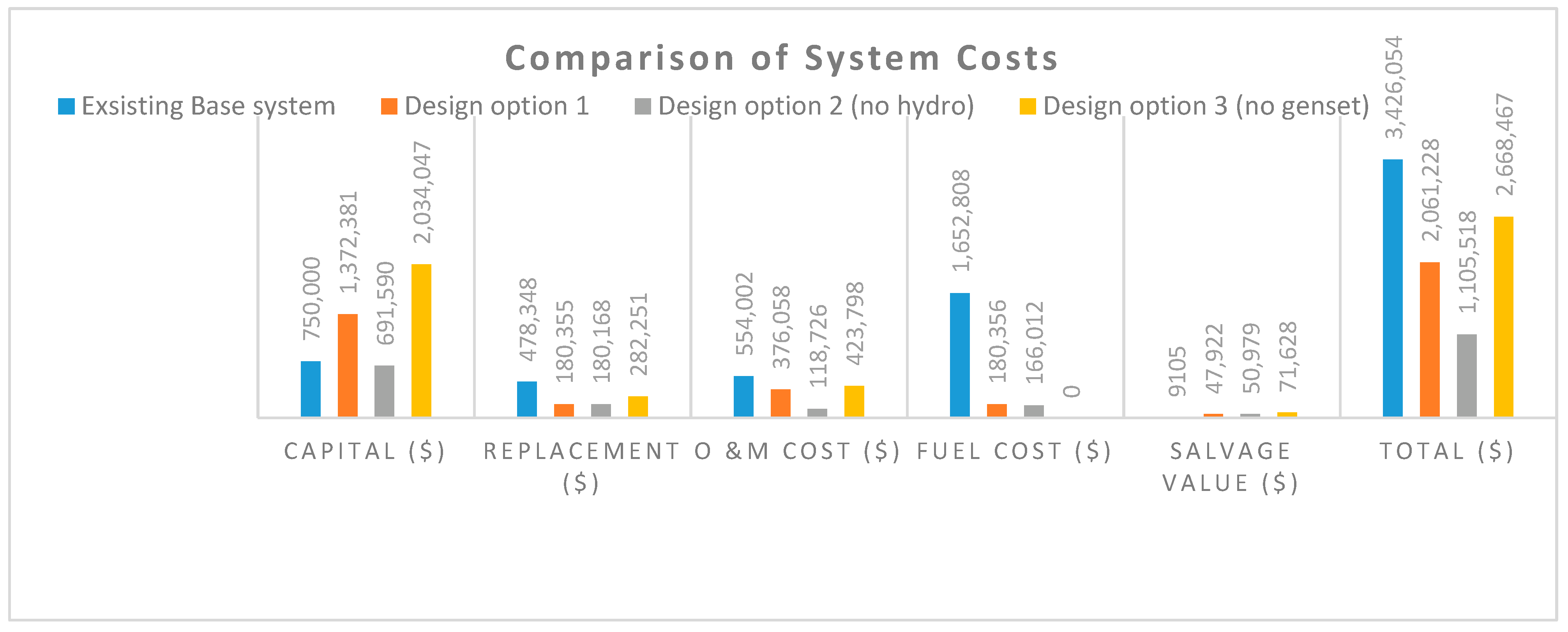

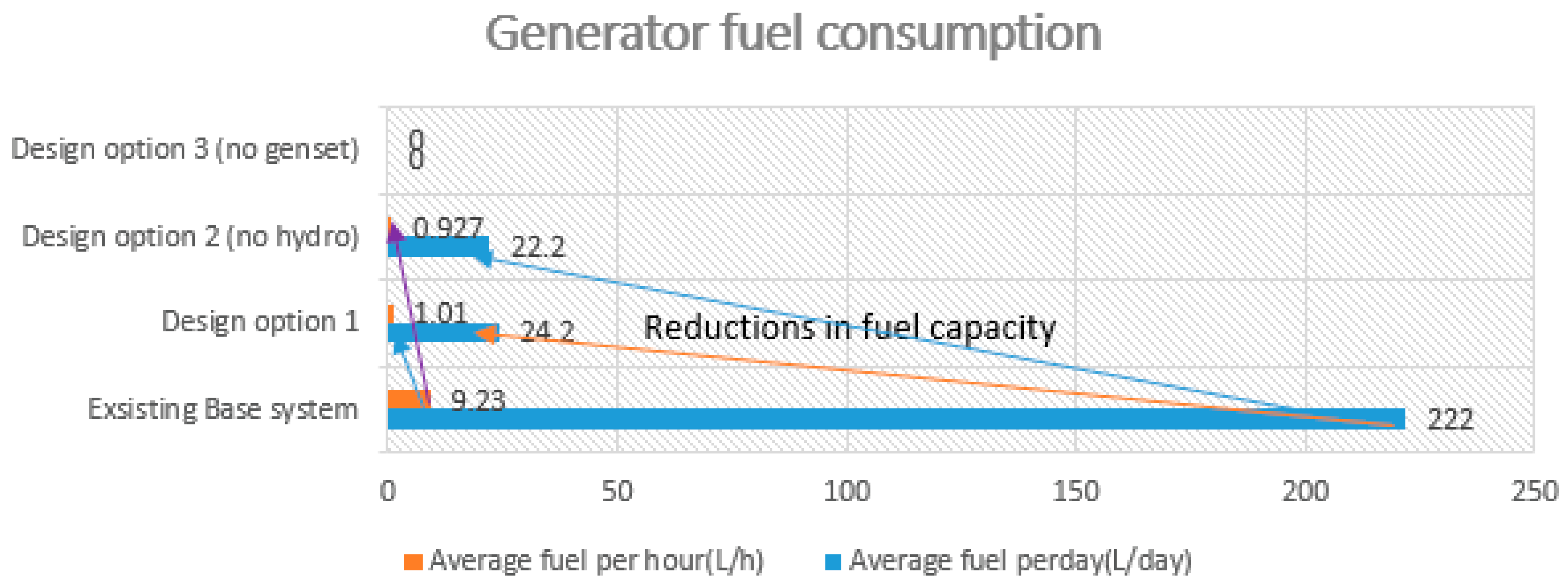

4.1. Technical Analysis

4.2. Economic Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Ppv | Output of PV array | Yg | Rated capacity of Generator | Crep | Replacement cost |

| Fpv | Pv derating factor | Nb | Number of batteries in a bank | Pg | Generator electrical output |

| Ypv | Rated capacity of PV array | i | Annual interest rate | F1 | Fuel curve slope |

| It | Global solar radiation | hnet | Net head of hydro | Lbf | Maximum life of a battery |

| Is | 1 kW/m2 standard | ρw | Density of water | φlt | Lifetime of a single battery |

| RFpv | Renewable fraction | h | Available head | φthr | Annual throughput Energy of battery |

| Epv | Energy output of PV | φt | Turbine flow rate | Can.t | Total annualized cost |

| Ean.t | Total annual energy | fh | Pipe head loss | Rcomp | Lifetime of the component |

| ᾐt | Turbine efficiency | Rproj | The project lifetime | Rrem | Remaining life of a component |

| Fo | Fuel curve intercept coefficient | N | Number of years taken |

References

- Authority, N.P. Uganda Vision 2040. Annu. Meet. Midwest Polit. Sci. 2007, 12, 1–7. [Google Scholar]

- Aburas, R.; Fromme, J.W. Household energy demand in Jordan. Energy Policy 1991, 19, 589–595. [Google Scholar] [CrossRef]

- Mawejje, J.; Mawejje, D.N. Electricity consumption and sectoral output in Uganda: An empirical investigation. J. Econ. Struct. 2016, 5, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Norton Rose Fulbright. Renewable Energy in Latin America. Renew. Energy World 2016, 10, 1–5. [Google Scholar]

- Lipscomb, M.; Mobarak, A.M.; Barham, T. Development Effects of Electrification: Evidence from the Topographic Placement of Hydropower Plants in Brazil. Am. Econ. J. Appl. Econ. 2013, 5, 200–231. [Google Scholar] [CrossRef] [Green Version]

- Africa Union. The African Union Agenda 2063: The Africa We Want. Afr. Union 2014, 92, 2014. [Google Scholar]

- United Nations. The Sustainable Development Goals Report 2016; United Nations: New York, NY, USA, 2016; pp. 1–64. [Google Scholar]

- du Plessis, V.; Beshiri, R.M.; Bollman, R.; Clemenson, H. Definitions of ‘“Rural”: Agricultural and Rural Working Paper Series; No. 61; Statistics Canada: Ottawa, ON, Canada, 2002. [Google Scholar]

- IFAD. Enabling Poor Rural People to Overcome Poverty in Burundi; IFAD: Rome, Italy, 2012. [Google Scholar]

- Nalumansi, H. To Examine the Problems That Hinder Community Development: Case Study Osukuru Sub County, Tororo District. Bachelor’s Thesis, Kampala International University, Kampala, Uganda, 2007. Available online: https://www.ptonline.com/articles/how-to-get-better-mfi-results (accessed on 11 October 2022).

- Mukwaya, P.; Bamutaze, Y.; Mugarura, S.; Benson, T. Rural-Urban Transformation in Uganda. J. Afr. Dev. 2012, 14, 169–194. [Google Scholar] [CrossRef]

- National Cassava Policy 2007–2012; NORPLAN (Uganda) Ltd: Kampala, Uganda, 2007.

- Isa, N.M.; Das, H.S.; Tan, C.W.; Yatim, A.H.M.; Lau, K.Y. A techno-economic assessment of a combined heat and power photovoltaic/fuel cell/battery energy system in Malaysia hospital. Energy 2016, 112, 75–90. [Google Scholar] [CrossRef]

- Bekelea, G.; Boneya, G. Design of a photovoltaic-wind hybrid power generation system for Ethiopian remote area. Energy Procedia 2012, 14, 1760–1765. [Google Scholar] [CrossRef] [Green Version]

- Ashour, A.; Mohamad, T.I.; Sopian, K.; Ludin, N.A.; Alzahrani, K.; Ibrahim, A. Performance optimization of a photovoltaic-diesel hybrid power system for Yanbu, Saudi Arabia. AIMS Energy 2021, 9, 1260–1273. [Google Scholar] [CrossRef]

- Benchraa, H.; Redouane, A.; El Harraki, I.; El Hasnaoui, A. Techno-economic feasibility study of a hybrid biomass/PV/diesel/battery system for powering the village of Imlil in High Atlas of Morocco. In Proceedings of the 2018 9th International Renewable Energy Congress, IREC 2018, Hammamet, Tunisia, 20–22 March 2018; pp. 1–6. [Google Scholar]

- Kaviani, A.K.; Riahy, G.H.; Kouhsari, S.M. Optimal design of a reliable hydrogen-based stand-alone wind/PV generating system, considering component outages. Renew. Energy 2009, 34, 2380–2390. [Google Scholar] [CrossRef]

- Shahzad, M.K.; Zahid, A.; Rashid, T.; Rehan, M.A.; Ali, M.; Ahmad, M. Techno-economic feasibility analysis of a solar-biomass off grid system for the electrification of remote rural areas in Pakistan using HOMER software. Renew. Energy 2017, 106, 264–273. [Google Scholar] [CrossRef]

- Kenfack, J.; Pascal, F.; Tamo, T.; Mayer, D. Microhydro-PV-hybrid system: Sizing a small hydro-PV-hybrid system for rural electrification in developing countries. Renew. Energy 2009, 34, 2259–2263. [Google Scholar] [CrossRef]

- Sayar, F. State of the Global Mini-grids Market Report 2020: Section 11 Case study–Uganda. J. Chem. Inf. Model. 2020, 53, 134–139. [Google Scholar]

- Ma, W.; Xue, X.; Liu, G. Techno-economic evaluation for hybrid renewable energy system: Application and merits. Energy 2018, 159, 385–409. [Google Scholar] [CrossRef]

- Olatomiwa, L.; Mekhilef, S.; Huda, A.S.N.; Sanusi, K. Techno-economic analysis of hybrid PV–diesel–battery and PV–wind–diesel–battery power systems for mobile BTS: The way forward for rural development. Energy Sci. Eng. 2015, 3, 271–285. [Google Scholar] [CrossRef]

- Katutsi, V.; Kaddu, M.; Migisha, A.G.; Rubanda, M.E.; Adaramola, M.S. Overview of hydropower resources and development in Uganda. AIMS Energy 2021, 9, 1299–1320. [Google Scholar] [CrossRef]

- Kavuma, C.; Sandoval, D.; de Dieu, H.K.J. Analysis of power generating plants and substations for increased Uganda’s electricity grid access. AIMS Energy 2021, 9, 178–192. [Google Scholar] [CrossRef]

- Kimera, R.; Okou, R.; Sebitosi, A.B.; Awodele, K.O. Considerations for a sustainable hybrid mini-grid system: A case for Wanale village, Uganda. J. Energy S. Afr. 2014, 25, 33–43. [Google Scholar] [CrossRef]

- Okou, R.; Niwagaba, E.; Kyahingwa, O.; Edimu, M.; Sebitosi, A.B. Considerations For Renewable Energy Mini-Grid Systems for Isolated Areas in Uganda. In Proceedings of the SIDA Regional Collaboration Conference, Bagamoyo, Tanzania, 18–20 February 2004. [Google Scholar]

- Ssenyimba, S.; Kiggundu, N.; Banadda, N. Designing a solar and wind hybrid system for small-scale irrigation: A case study for Kalangala district in Uganda. Energy Sustain. Soc. 2020, 10, 6. [Google Scholar] [CrossRef]

- Okoboi, G.; Mawejje, J. The impact of adoption of power factor correction technology on electricity peak demand in Uganda. J. Econ. Struct. 2016, 5, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Puglia, G.; Moroni, M.; Fagnani, R.; Comodi, G. A design approach of off-grid hybrid electric microgrids in isolated villages: A case study in Uganda. Energy Procedia 2017, 105, 3089–3094. [Google Scholar] [CrossRef]

- Okoboi, G.; Mawejje, J. Electricity peak demand in Uganda: Insights and foresight. Energy Sustain. Soc. 2016, 6, 29. [Google Scholar] [CrossRef] [Green Version]

- Comello, S.D.; Reichelstein, S.J.; Sahoo, A.; Schmidt, T.S. Enabling Mini-Grid Development in Rural India. World Dev. 2017, 93, 94–107. [Google Scholar] [CrossRef]

- Doso, O.; Gao, S. An overview of small hydro power development in India. AIMS Energy 2020, 8, 896–917. [Google Scholar] [CrossRef]

- Nakata, T.; Silva, D.; Rodionov, M. Application of energy system models for designing a low-carbon society. Prog. Energy Combust. Sci. 2011, 37, 462–502. [Google Scholar] [CrossRef]

- Elmanakhly, F.; DaCosta, A.; Berry, B.; Stasko, R.; Fowler, M.; Wu, X.Y. Hydrogen economy transition plan: A case study on Ontario. AIMS Energy 2021, 9, 775–811. [Google Scholar] [CrossRef]

- Micangeli, A.; Fioriti, D.; Cherubini, P.; Duenas-Martinez, P. Optimal design of isolated mini-grids with deterministic methods: Matching predictive operating strategies with low computational requirements. Energies 2020, 13, 4214. [Google Scholar] [CrossRef]

- Blum, N.U.; Wakeling, R.S.; Schmidt, T.S. Rural electrification through village grids-Assessing the cost competitiveness of isolated renewable energy technologies in Indonesia. Renew. Sustain. Energy Rev. 2013, 22, 482–496. [Google Scholar] [CrossRef]

- Gambino, V.; del Citto, R.; Cherubini, P.; Tacconelli, C.; Micangeli, A.; Giglioli, R. Methodology for the energy need assessment to effectively design and deploy mini-grids for rural electrification. Energies 2019, 12, 574. [Google Scholar] [CrossRef] [Green Version]

- Hailu, A.D.; Kumsa, D.K. Ethiopia renewable energy potentials and current state. AIMS Energy 2020, 9, 1–14. [Google Scholar] [CrossRef]

- Abbasi, K.R.; Hussain, K.; Abbas, J.; Adedoyin, F.F.; Shaikh, P.A.; Yousaf, H.; Muhammad, F. Analyzing the role of industrial sector’s electricity consumption, prices, and GDP: A modified empirical evidence from Pakistan. AIMS Energy 2020, 9, 29–49. [Google Scholar] [CrossRef]

- Yeshalem, M.T.; Khan, B. Design of an off-grid hybrid PV/wind power system for remote mobile base station: A case study. AIMS Energy 2017, 5, 96–112. [Google Scholar] [CrossRef]

- Antonanzas-Torres, F.; Antonanzas, J.; Blanco-Fernandez, J. Environmental impact of solar home systems in sub-saharan Africa. Sustainability 2021, 13, 9708. [Google Scholar] [CrossRef]

- Daniel, N.; Kim, J. A Study on Integrating SMRs into Uganda’s Future Energy System. Sustainability 2022, 14, 33. [Google Scholar] [CrossRef]

- MacLeod, M.; Eory, V.; Wint, W.; Shaw, A.; Gerber, P.J.; Cecchi, G.; Mattioli, R.; Sykes, A.; Robinson, T. Assessing the Greenhouse Gas Mitigation effect of removing bovine trypanosomiasis in Eastern Africa. Sustainability 2018, 10, 1633. [Google Scholar] [CrossRef] [Green Version]

- Fashina, A.; Mundu, M.; Akiyode, O.; Abdullah, L.; Sanni, D.; Ounyesiga, L. The Drivers and Barriers of Renewable Energy Applications and Development in Uganda: A Review. Clean Technol. 2019, 1, 3. [Google Scholar] [CrossRef] [Green Version]

- Japan International Cooperation Agency. Project for Master Plan Study on Hydropower Development in the Republic of Uganda, Final Report; Ministry of Energy and Mineral Development: Kampala, Uganda, 2011. [Google Scholar]

- Andrychowicz, M. Optimization of distribution systems by using RES allocation and grid development. In Proceedings of the 15th International Conference of European Energy Market, Łodź, Poland, 27–29 June 2018. [Google Scholar]

- Gilman, P.; Lilienthal, P. Micropower System Modeling; John Wiley Sons, Inc.: Hoboken, NJ, USA, 2006; pp. 379–418. [Google Scholar]

- Sawle, Y.; Gupta, S.C.; Bohre, A.K. Optimal sizing of standalone PV/Wind/Biomass hybrid energy system using GA and PSO optimization technique. Energy Procedia 2017, 117, 690–698. [Google Scholar] [CrossRef]

- Come Zebra, E.I.; van der Windt, H.J.; Nhumaio, G.; Faaij, A.P.C. A review of hybrid renewable energy systems in mini-grids for off-grid electrification in developing countries. Renew. Sustain. Energy Rev. 2021, 144, 111036. [Google Scholar] [CrossRef]

- Milone, D.; Curto, D.; Franzitta, V.; Guercio, A.; Cirrincione, M.; Mohammadi, A. An Economic Approach to Size of a Renewable Energy Mix in Small Islands. Energies 2022, 15, 2005. [Google Scholar] [CrossRef]

- Murphy, P.M.; Twaha, S.; Murphy, I.S. Analysis of the cost of reliable electricity: A new method for analyzing grid-connected solar, diesel and hybrid distributed electricity systems considering an unreliable electric grid, with examples in Uganda. Energy 2014, 66, 523–534. [Google Scholar] [CrossRef]

- Yimen, N.; Tchotang, T.; Kanmogne, A.; Abdelkhalikh Idriss, I.; Musa, B.; Aliyu, A.; Okonkwo, E.C.; Abba, S.I.; Tata, D.; Meva’a, L.; et al. Optimal Sizing and Techno-Economic Analysis of Hybrid Renewable Energy Systems—A Case Study of a Photovoltaic/Wind/Battery/Diesel System in Fanisau, Northern Nigeria. Processes 2020, 8, 1381. [Google Scholar] [CrossRef]

- Bassi, S.A.; Tange, I.; Holm, B.; Boldrin, A.; Rygaard, M. A multi-criteria assessment of water supply in Ugandan refugee settlements. Water 2018, 10, 1493. [Google Scholar] [CrossRef]

- Twaha, S.; Idris, M.H.; Anwari, M.; Khairuddin, A. Applying grid-connected photovoltaic system as an alternative source of electricity to supplement hydropower instead of using diesel in Uganda. Energy 2012, 37, 185–194. [Google Scholar] [CrossRef]

| S/N | Village Name | S/N | Village Name |

|---|---|---|---|

| 1 | Kisiizi (Kisiizi Lower) | 18 | Stage Nyarushanje |

| 2 | Binyena | 19 | Ibanda |

| 3 | Kisiizi Upper Trading Centre | 20 | Ngarama |

| 4 | Kamobwe | 21 | Ruyonza |

| 5 | Nshugyezi | 22 | Gomborora Headquaters |

| 6 | Omukikona | 23 | Ahamuginda |

| 7 | Kasikizi | 24 | Nyakaginga |

| 8 | Omukatooma | 25 | Rwentare |

| 9 | Kahanga | 26 | Nyakasa |

| 10 | Mucondo | 27 | Kicubanyungu |

| 11 | Rubirizi | 28 | Kahumiro |

| 12 | Rwere | 29 | Kanyinya |

| 13 | Nyarutuntu | 30 | Kyakabarisinga |

| 14 | Kasoni | 31 | Omukishanda |

| 15 | Mushunga | 32 | Kamira |

| 16 | Rutooma. A | 33 | Katobotobo |

| 17 | Rutooma. B |

| Analysis | Concern | Methodology |

|---|---|---|

| Performance analysis | Cause of system failure Mini-grid power output visa vie customer demands Cause of continuous load shedding Cause of fluctuations in customer enrollment Emission levels | Load demand analysis (Enrollment trend, Energy sales, and average peak demand) Field survey Data collection System sizing HOMER pro × 64 software Excel analysis |

| Systems Analysis | Initial cost Replacement cost Salvage value Operation and maintenance cost Fuel consumption Emissions Economic parameters (NPV, LCOE, and OC) | HOMER pro × 64 software |

| 1 | Grain Millers and Coffee Hullers (12) | |||||

|---|---|---|---|---|---|---|

| CFLs = Compact Fluorescent Lamps | ||||||

| Appliance | Power Rating (W) | Quantity | Hours Used (h) | Energy Use (Wh) | Total in Number | Total Energy Use a Day (Wh/d) |

| CFLs | 10 | 4 | 10 | 400 | ||

| Electric motor | 4000 | 1 | 2 | 8000 | ||

| 8400 | 12 | 100,800 | ||||

| 2 | Fuel stations (06) | |||||

| Fuel pump motor | 1000 | 1 | 12 | 12,000 | ||

| CFLs | 25 | 4 | 6 | 600 | ||

| Decoder | 60 | 1 | 6 | 360 | ||

| 12,960 | 6 | 77,760 | ||||

| 3 | Uganda Martyrs Polytechnic Institute (01) | |||||

| CFLs | 5 | 40 | 6 | 1200 | ||

| Printer | 60 | 1 | 1 | 60 | ||

| Desktop computer | 80 | 2 | 6 | 960 | ||

| Television | 40 | 1 | 2 | 80 | ||

| Photocopier | 80 | 1 | 1 | 80 | ||

| Workshop motor | 4000 | 1 | 1 | 4000 | ||

| 6380 | 1 | 6380 | ||||

| 4 | Schools (12) | |||||

| CFLs | 5 | 30 | 6 | 900 | ||

| Printer | 60 | 1 | 1 | 60 | ||

| Desktop computer | 80 | 1 | 6 | 480 | ||

| Television | 40 | 1 | 1 | 40 | ||

| Photocopier | 80 | 1 | 1 | 80 | ||

| 1560 | 12 | 18,720 | ||||

| 5 | Churches (07) | |||||

| CFLs | 5 | 20 | 4 | 400 | ||

| Address system | 1000 | 1 | 1 | 1000 | ||

| 1400 | 7 | 9800 | ||||

| 6 | Health centers (02) | |||||

| Fridge | 400 | 1 | 6 | 2400 | ||

| CFLs | 3 | 30 | 9 | 810 | ||

| Computer | 80 | 1 | 2 | 160 | ||

| Television | 40 | 1 | 8 | 320 | ||

| Printer | 60 | 1 | 1 | 60 | ||

| 3750 | 2 | 7500 | ||||

| 7 | Small and Medium Enterprises (12) | |||||

| Electric motor | 1000 | 1 | 1 | 1000 | ||

| Fridge | 400 | 1 | 2 | 800 | ||

| Decoder | 60 | 1 | 6 | 360 | ||

| Television | 40 | 1 | 5 | 200 | ||

| CFLs | 5 | 6 | 5 | 150 | ||

| 2510 | 12 | 30,120 | ||||

| 8 | Barber shops (saloons) (03) | |||||

| CFLs | 7 | 4 | 10 | 280 | ||

| Electric clipper | 15 | 1 | 6 | 90 | ||

| Hair drier | 1500 | 1 | 2 | 3000 | ||

| Decoder | 60 | 1 | 10 | 600 | ||

| Television | 40 | 1 | 10 | 400 | ||

| 4370 | 3 | 13,110 | ||||

| 9 | Domestic customers (649) | |||||

| CFLs | 5 | 5 | 4 | 100 | ||

| Television | 40 | 1 | 2 | 80 | ||

| Radio | 30 | 1 | 2 | 60 | ||

| 240 | 649 | 155,760 | ||||

| 10 | Kisiizi Hospital Domestic customers (133) | |||||

| CFLs | 5 | 5 | 5 | 125 | ||

| Television | 40 | 1 | 3 | 120 | ||

| Decoder | 60 | 1 | 1 | 60 | ||

| Laptop | 65 | 1 | 1 | 65 | ||

| 370 | 133 | 49,210 | ||||

| 11 | Kisiizi Hospital commercial customers (07) | |||||

| CFLs | 5 | 6 | 6 | 240 | ||

| Television | 40 | 1 | 6 | 240 | ||

| Fridge | 400 | 1 | 2 | 800 | ||

| Decoder | 60 | 1 | 1 | 60 | ||

| 1340 | 7 | 9380 | ||||

| Total energy demand per day | 478,540 kWh/day | |||||

| Hydro | Generator | ||||

|---|---|---|---|---|---|

| Item | Amount | Unit | Item | Amount | Unit |

| Capital cost | 700,000 | $ | Initial cost | 50,000 | $ |

| Replacement cost | 350,000 | $ | Replacement | 50,000 | $ |

| O&M cost | 150,000 | $ | O&M cost | 2 | $/op h |

| Lifetime | 25 | Years | Fuel price | 1.2 | $ |

| Available head | 29.8 | M | Min Load ratio | 25 | % |

| Design flow rate | 500 | L/s | Lifetime | 15,000 | h |

| Minimum flow ratio | 50 | % | |||

| Maximum flow ratio | 150 | % | |||

| Efficiency | 80 | % | |||

| Pipe head loss | 15 | % | |||

| Daily Peak Demand Averages | Monthly Average stream flow data | ||||

| Time | Peak Demand(kW) | Month | Stream flow(L/s) | ||

| 0:00 | 250 | JAN | 0.8 | ||

| 1:00 | 240 | FEB | 0.74 | ||

| 2:00 | 235 | MAR | 0.75 | ||

| 3:00 | 230 | APR | 0.56 | ||

| 4:00 | 250 | MAY | 0.88 | ||

| 5:00 | 275 | JUN | 0.71 | ||

| 6:00 | 270 | JUL | 0.67 | ||

| 7:00 | 249 | AUG | 0.67 | ||

| 8:00 | 230 | SEP | 0.71 | ||

| 9:00 | 220 | OCT | 0.91 | ||

| 10:00 | 220 | NOV | 0.87 | ||

| 11:00 | 200 | DEC | 0.81 | ||

| 12:00 | 231 | ||||

| 13:00 | 274 | Annual average 0.76 L/s | |||

| 14:00 | 268 | Residual flow rate 0.26 L/s | |||

| 15:00 | 261 | ||||

| 16:00 | 214 | ||||

| 17:00 | 202 | ||||

| 18:00 | 226 | ||||

| 19:00 | 227 | ||||

| 20:00 | 217 | ||||

| 21:00 | 219 | ||||

| 22:00 | 258 | ||||

| 23:00 | 270 | ||||

| (a) Electricity Production (%) | |||||||

| Generator (%) | PV | AC Primary Load (kWh/yr) | Excess Electricity (%) | Unmet Load (%) | Renewable Fraction (%) | ||

| Existing Base system | 100 | 0 | 174,667 | 21.5 | 0 | 0 | |

| Design option 1 | 10 | 90 | 174,667 | 20.7 | 0 | 86.2 | |

| (b) Generic Battery | |||||||

| Batteries No | Autonomy (h) | Lifetime throughput (kWh) | Expected life (yrs) | Energy in (kWh) | Energy out (kWh/y) | Losses (kWh/yr) | |

| Existing system | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Design option 1 | 445 | 16 | 1,393,862 | 15 | 96,840 | 89,010 | 8174 |

| (c) Generic 100 kW Fixed Generator | |||||||

| Operation (h/yr) | Operation life (yr) | Capacity factor (&) | Electricity production (kWh/y) | Fuel consumption (L) | SFC L/kWh | MEE (%) | |

| Existing system | 8760 | 1.71 | 25.4 | 222,617 | 80,850 (90.2%) | 0.363 | 28 |

| Design option 1 | 965 | 15.5 | 2.76 | 24,191 | 8822 (9.8%) | 0.365 | 27.9 |

| (d) PV System Generic Flat Plate | |||||||

| Rated capacity (KW) | Mean output (kW) | Capacity factor (%) | Hrs of Operation (h/yr) | Levelised cost ($/kWh) | |||

| Existing Base system | 0 | 0 | 0 | 0 | 0 | ||

| Design option 1 | 152 | 24.7 | 16.2 | 4380 | 0.103 | ||

| (e) System Converter Inverter/Rectifier | |||||||

| Rated capacity I/R(kW) | Capacity factor I/R (%) | operation I/R (h/yr) | Energy out I/R (kWh/y) | Energy in I/R (kWh/y) | Losses I/R (kWh/y) | ||

| Existing Base system | 0 | 0 | 0 | 0 | 0 | 0 | |

| Design option 1 | 40.6/40.6 | 43.4/1.02 | 8036/723 | 154,299/3632 | 162,420/3823 | 8121/191 | |

| (f) Systems’ Emissions | |||||||

| Carbon dioxide (kg/y) | Carbon monoxide (kg/y) | Unburnt carbons (kg/y) | Particulate matter (kg/y) | Sulpher dioxide (kg/y) | Nitrogen oxides (kg/y) | ||

| Existing Base system | 211,470 | 1439 | 58.2 | 5.76 | 518 | 115 | |

| Design option 1 | 23,076 | 157 | 6.35 | 0.628 | 56.6 | 12.6 | |

| Component | Capital ($) | Replacement ($) | O&M ($) | Fuel ($) | Salvage ($) | Total ($) |

|---|---|---|---|---|---|---|

| Hydro 300kW | 700,000 | 0 | 255,536 | 0 | 0 | 955,536 |

| Genset 100kW | 50,000 | 30,654 | 32,879 | 180,356 | 8915 | 284,974 |

| Battery(1kWh) Li-Ion | 229,620 | 143,206 | 87,472 | 0 | 34,845 | 425,453 |

| Flat plate PV | 380,572 | 0 | 171 | 0 | 0 | 380,742 |

| System converter | 12,189 | 6495 | 0 | 0 | 4162 | 14,522 |

| System | 1,372,387 | 180,355 | 376,058 | 180,356 | 47,922 | 2,061,228 |

| (a) Electricity Production (%) | |||||||

| Generator (%) | PV | AC Primary Load (kWh/yr) | Excess Electricity (%) | Unmet Load (%) | Renewable Fraction (%) | ||

| Existing Base system | 100 | 0 | 174,667 | 21.5 | 0 | 0 | |

| Design option 2 | 8.9 | 91.1 | 174,667 | 23.3 | 0 | 87.3 | |

| (b) Generic battery | |||||||

| Batteries No | Autonomy (h) | Lifetime throughput (kWh) | Expected life (yrs) | Energy in (kWh) | Energy out (kWh/y) | Losses (kWh/yr) | |

| Existing system | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Design option 2 | 449 | 16.1 | 1,405,991 | 15 | 97,701 | 89,785 | 8254 |

| (c) Generic 100 kW fixed generator | |||||||

| Operation (h/yr) | Operation life (yr) | Capacity factor (&) | Electricity production (kWh/y) | Fuel consumption (L) | SFC L/kWh | MEE (%) | |

| Existing system | 8760 | 1.71 | 25.4 | 222,617 | 80,850 (90.2%) | 0.363 | 28 |

| Design option 2 | 889 | 16.9 | 2.54 | 22,259 | 8121 | 0.365 | 27.9 |

| (d) PV system Generic flat plate | |||||||

| Rated capacity (KW) | Mean output (kW) | Capacity factor (%) | Hrs of Operation (h/yr) | Levelised cost ($/kWh) | |||

| Existing Base system | 0 | 0 | 0 | 0 | 0 | ||

| Design option 2 | 159 | 25.9 | 16.2 | 4380 | 0.103 | ||

| (e) System converter Inverter/Rectifier | |||||||

| Rated capacity I/R(kW) | Capacity factor I/R (%) | operation I/R (h/yr) | Energy out I/R (kWh/y) | Energy in I/R (kWh/y) | Losses I/R (kWh/y) | ||

| Existing Base system | 0 | 0 | 0 | 0 | 0 | 0 | |

| Design option 2 | 39.3/39.3 | 45.3/0.961 | 8094/666 | 155,888/3306 | 164,093/3480 | 8205/174 | |

| (f) Systems’ Emissions | |||||||

| Carbon dioxide (kg/y) | Carbon monoxide (kg/y) | Unburnt carbons (kg/y) | Particulate matter (kg/y) | Sulpher dioxide (kg/y) | Nitrogen oxides (kg/y) | ||

| Existing Base system | 211,470 | 1439 | 58.2 | 5.76 | 518 | 115 | |

| Design option 2 | 21,241 | 145 | 5.85 | 0.578 | 52.1 | 11.6 | |

| Component | Capital ($) | Replacement ($) | O&M ($) | Fuel ($) | Salvage ($) | Total ($) |

|---|---|---|---|---|---|---|

| Genset 100 kW | 50,000 | 29,398 | 30,290 | 166,013 | 11,799 | 263,901 |

| Battery (1 kWh) Li-Ion | 231,684 | 144,493 | 88,258 | 0 | 35,158 | 429,277 |

| Flat plate PV | 398,126 | 0 | 178 | 0 | 0 | 398,305 |

| System converter | 11,780 | 6277 | 0 | 0 | 4022 | 14,035 |

| System | 691,590 | 180,168 | 118,726 | 166,013 | 50,979 | 1,105,518 |

| (a) Electricity Production (%) | |||||||

| Generator (%) | PV | AC Primary Load (kWh/yr) | Excess Electricity (%) | Unmet Load (%) | Renewable Fraction (%) | ||

| Existing Base system | 100 | 0 | 174,667 | 21.5 | 0 | 0 | |

| Design option 3 | 0 | 500,478 | 174,554 | 61.5 | 0.0648 | 100 | |

| (b) Generic battery | |||||||

| Batteries No | Autonomy (h) | Lifetime throughput (kWh) | Expected life (yrs) | Energy in (kWh) | Energy out (kWh/y) | Losses (kWh/yr) | |

| Existing system | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Design option 3 | 854 | 30.6 | 1,544,386 | 15 | 107,519 | 98,683 | 8970 |

| (c) PV system Generic flat plate | |||||||

| Rated capacity (KW) | Mean output (kW) | Capacity factor (%) | Hrs of Operation (h/yr) | Levelised cost ($/kWh) | |||

| Existing Base system | 0 | 0 | 0 | 0 | 0 | ||

| Design option 3 | 352 | 57.1 | 16.2 | 4380 | 0.103 | ||

| (d) System converter Inverter/Rectifier | |||||||

| Rated capacity I/R (kW) | Capacity factor I/R (%) | operation I/R (h/yr) | Energy out I/R (kWh/y) | Energy in I/R (kWh/y) | Losses I/R (kWh/y) | ||

| Existing Base system | 0 | 0 | 0 | 0 | 0 | 0 | |

| Design option 3 | 46.4/0 | 42.9/0 | 8760/0 | 174,554/0 | 183,741/0 | 9187/0 | |

| Component | Capital ($) | Replacement ($) | O&M ($) | Fuel ($) | Salvage ($) | Total ($) |

|---|---|---|---|---|---|---|

| Hydro 300 kW | 700,000 | 0 | 255,536 | 0 | 0 | 955,536 |

| Battery (1 kWh) Li-Ion | 440,664 | 74,827 | 167,868 | 0 | 66,871 | 816,487 |

| Flat plate PV | 879,450 | 0 | 394 | 0 | 0 | 879,844 |

| System converter | 13,933 | 7424 | 0 | 0 | 4757 | 16,599 |

| System | 2,034,047 | 282,251 | 423,798 | 0 | 71,628 | 266,8467 |

| Base System | Design Option 1 | Design Option 2 (No Hydro) | Design Option 3 (No Genset) | |

|---|---|---|---|---|

| Total NPC ($) | 3,426,054.0 | 2,061,228.0 | 1,105,518.0 | 2,668,467.0 |

| LCOE ($) | 1.15 | 0.6927 | 0.3715 | 0.8974 |

| OC ($) | 157,084.7 | 40,435.36 | 24,297.62 | 37,240.55 |

| Economic Parameter | Design Option 1 | Design Option 2 (No Hydro) | Design Option 3 (No Genset) |

|---|---|---|---|

| Present worth ($) | 1,364,826 | 2,320,536 | 757,587 |

| Annual worth ($/yr) | 80,115 | 136,216 | 44,470 |

| Return on Investment (%) | 14.7 | 0.0 | 5.3 |

| Internal Rate of Return (%) | 18.8 | N/A | 8.0 |

| Simple Pay Back (yr) | 5.26 | N/A | 9.88 |

| Discounted Pay Back (yr) | 5.72 | N/A | 11.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cartland, R.; Sendegeya, A.-M.; Hakizimana, J.d.D.K. Performance Analysis of a Hybrid of Solar Photovoltaic, Genset, and Hydro of a Rural-Based Power Mini-Grid: Case Study of Kisiizi Hydro Power Mini-Grid, Uganda. Processes 2023, 11, 175. https://doi.org/10.3390/pr11010175

Cartland R, Sendegeya A-M, Hakizimana JdDK. Performance Analysis of a Hybrid of Solar Photovoltaic, Genset, and Hydro of a Rural-Based Power Mini-Grid: Case Study of Kisiizi Hydro Power Mini-Grid, Uganda. Processes. 2023; 11(1):175. https://doi.org/10.3390/pr11010175

Chicago/Turabian StyleCartland, Richard, Al-Mas Sendegeya, and Jean de Dieu Khan Hakizimana. 2023. "Performance Analysis of a Hybrid of Solar Photovoltaic, Genset, and Hydro of a Rural-Based Power Mini-Grid: Case Study of Kisiizi Hydro Power Mini-Grid, Uganda" Processes 11, no. 1: 175. https://doi.org/10.3390/pr11010175