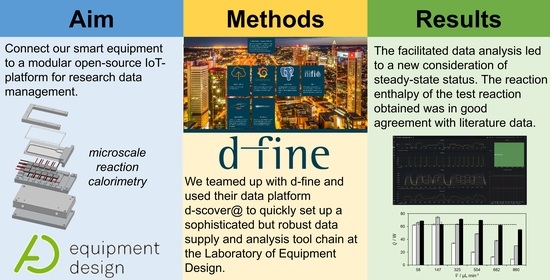

Data Management of Microscale Reaction Calorimeter Using a Modular Open-Source IoT-Platform

Abstract

:1. Introduction

- data are assigned a globally unique and persistent identifier (F1),

- the protocol is open, free, and universally implementable (A1.1),

- the protocol allows for an authentication and authorization procedure where necessary (A1.2),

- data use vocabularies that follow FAIR principles (I2),

- data are released with a clear and accessible data usage license (R1.1),

- data meet domain-relevant community standards (R1.3).

2. Materials and Methods

2.1. Open-Source IoT-Platform

2.2. Microscale Flow Reaction Calorimeter

2.2.1. Experimental Setup and Data Acquisition

2.2.2. Process and Calorimetric Data

2.3. Case Study: Hydrolysis of Acetic Anhydride

2.4. Experimental Procedure

3. Results

3.1. Acquisition and Monitoring of the Microcalorimeter’s Process Data Using d-scover@

- The voltage of the SEs must not fluctuate more than 0.25 mV for = 30, 40 °C, 0.50 mV for = 50 °C, and 0.75 mV for = 60 °C, in the last 30 s.

- The temperature at the reactor outlet must not fluctuate more than 0.5 °C in the last 180 s due to the delayed behavior.

3.2. Calorimetric Data Management Using d-scover@

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and List of Symbols

| AcOH | acetic acid |

| Ac2O | acetic anhydride |

| BCI | Department of Biochemical and Chemical Engineering, TU Dortmund University |

| starting concentration of component i, mol L−1 | |

| concentration in feed 1, mol L−1 | |

| concentration in feed 2, mol L−1 | |

| activation energy, J mol−1 | |

| ETL | Extract-Transform-Load |

| FAIR | Findable, Accessible, Interoperable and Re-usable |

| mixing enthalpy, J mol−1 | |

| reaction enthalpy, J mol−1 | |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| frequency factor, [(m3 mol−1)n−1 s−1] | |

| OPC UA | Open Platform Communications Unified Architecture |

| PLC | programmable logic controller |

| heat amount, J | |

| ingoing convective heat flux, W | |

| outgoing convective heat flux, W | |

| heat loss, W | |

| heat of reaction, W | |

| heat flux measured by SE, W | |

| SE | Seebeck element |

| time, s | |

| temperature, K | |

| ambient temperature, K | |

| inlet temperature of feed 1, K | |

| inlet temperature of feed 2, K | |

| outlet temperature of product stream, K | |

| thermoelectric voltage, V | |

| volumetric flow rate, m3 s−1 | |

| volumetric flow rate of feed 1, m3 s−1 | |

| volumetric flow rate of feed 2, m3 s−1 | |

| conversion, - |

References

- Rückert, T. The IoT Paves the Way for a Networked Economy. In The Internet of Things: Industrie 4.0 Unleashed; Sendler, U., Ed.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 221–232. ISBN 9783662549049. [Google Scholar]

- Knoll, S.; Jusner, C.E.; Sagmeister, P.; Williams, J.D.; Hone, C.A.; Horn, M.; Kappe, C.O. Autonomous Model-Based Experimental Design for Rapid Reaction Development. React. Chem. Eng. 2022, 7, 2375–2384. [Google Scholar] [CrossRef]

- Wilkinson, M.D.; Dumontier, M.; Aalbersberg, I.J.; Appleton, G.; Axton, M.; Baak, A.; Blomberg, N.; Boiten, J.W.; da Silva Santos, L.B.; Bourne, P.E.; et al. Comment: The FAIR Guiding Principles for Scientific Data Management and Stewardship. Sci. Data 2016, 3, 160018. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elliott, C.; Vijayakumar, V.; Zink, W.; Hansen, R. National Instruments LabVIEW: A Programming Environment for Laboratory Automation and Measurement. J. Assoc. Lab. Autom. 2007, 12, 17–24. [Google Scholar] [CrossRef] [Green Version]

- The Mathworks Inc. Matlab®. Available online: https://www.mathworks.com/products/matlab.html (accessed on 1 December 2022).

- Cherkasov, N.; Bai, Y.; Expósito, A.J.; Rebrov, E. V OpenFlowChem—A Platform for Quick, Robust and Flexible Automation and Self-Optimisation of Flow Chemistry. React. Chem. Eng. 2018, 3, 769–780. [Google Scholar] [CrossRef] [Green Version]

- Mateos, C.; Nieves-Remacha, M.J.; Rincón, J.A. Automated Platforms for Reaction Self-Optimization in Flow. React. Chem. Eng. 2019, 4, 1536–1544. [Google Scholar] [CrossRef]

- Kockmann, N. Digital Methods and Tools for Chemical Equipment and Plants. React. Chem. Eng. 2019, 4, 1522–1529. [Google Scholar] [CrossRef]

- O’Brien, M.; Hall, A.; Schrauwen, J.; van der Made, J. An Open-Source Approach to Automation in Organic Synthesis: The Flow Chemical Formation of Benzamides Using an Inline Liquid-Liquid Extraction System and a Homemade 3-Axis Autosampling/Product-Collection Device. Tetrahedron 2018, 74, 3152–3157. [Google Scholar] [CrossRef]

- Ingham, R.J.; Battilocchio, C.; Hawkins, J.M.; Ley, S.V. Integration of Enabling Methods for the Automated Flow Preparation of Piperazine-2-Carboxamide. Beilstein J. Org. Chem. 2014, 10, 641–652. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Steiner, S.; Wolf, J.; Glatzel, S.; Andreou, A.; Granda, J.M.; Keenan, G.; Hinkley, T.; Aragon-Camarasa, G.; Kitson, P.J.; Angelone, D.; et al. Organic Synthesis in a Modular Robotic System Driven by a Chemical Programming Language. Science 2018, 363, eaav2211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- van der Westhuizen, C.J.; du Toit, J.; Neyt, N.; Riley, D.; Panayides, J.-L. Use of Open-Source Software Platform to Develop Dashboards for Control and Automation of Flow Chemistry Equipment. Digit. Discov. 2022, 1, 596–604. [Google Scholar] [CrossRef]

- OpenJS Foundation & Contributors Node-RED. Available online: https://openjsf.org/category/node-red/ (accessed on 3 January 2023).

- Charlet, C.; Christ, T. Open Source IoT Data Pipelines; White Paper; d-fine: Frankfurt, Germany; München, Germany, 2022. [Google Scholar]

- Reichmann, F.; Millhoff, S.; Jirmann, Y.; Kockmann, N. Reaction Calorimetry for Exothermic Reactions in Plate-Type Microreactors Using Seebeck Elements. Chem. Eng. Technol. 2017, 40, 2144–2154. [Google Scholar] [CrossRef] [Green Version]

- Frede, T.A.; Greive, M.; Kockmann, N. Measuring Kinetics in Flow Using Isoperibolic Flow Calorimetry. Reactions 2022, 3, 525–536. [Google Scholar] [CrossRef]

- Ładosz, A.; Kuhnle, C.; Jensen, K.F. Characterization of Reaction Enthalpy and Kinetics in a Microscale Flow Platform. React. Chem. Eng. 2020, 5, 2115–2122. [Google Scholar] [CrossRef]

- Steinemann, F.L.; Rütti, D.P.; Moser, M.; Georg, A.G.; Meier, D.M. Simultaneous Determination of Enthalpy of Mixing and Reaction Using Milli-Scale Continuous Flow Calorimetry. J. Flow Chem. 2022, 12, 389–396. [Google Scholar] [CrossRef]

- Glotz, G.; Knoechel, D.J.; Podmore, P.; Gruber-Woelfler, H.; Kappe, C.O. Reaction Calorimetry in Microreactor Environments—Measuring Heat of Reaction by Isothermal Heat Flux Calorimetry. Org. Process Res. Dev. 2017, 21, 763–770. [Google Scholar] [CrossRef]

- Martin, H. Wärmeflusskalorimetrie Unter Präparativen Bedingungen Und Ihre Anwendung Zur Verfolgung Der Isomerisierungskinetik von Trimethylphosphit; Universität Basel: Basel, Switzerland, 1975. [Google Scholar]

- Zogg, A.; Fischer, U.; Hungerbühler, K. A New Small-Scale Reaction Calorimeter That Combines the Principles of Power Compensation and Heat Balance. Ind. Eng. Chem. Res. 2003, 42, 767–776. [Google Scholar] [CrossRef]

- Gelhausen, M.G.; Kurt, S.K.; Kockmann, N. Parametrische Empfindlichkeit Einer Stark Exothermen Reaktion Im Kapillarwendelreaktor. Chem. Ing. Tech. 2015, 87, 781–790. [Google Scholar] [CrossRef]

- Baerns, M.; Behr, A.; Brehm, A.; Gmehling, J.; Hofmamm, H.; Onken, U.; Renken, A.; Hinrichsen, K.-O.; Palkovits, R. Technische Chemie, 2nd ed; Wiley-VCH: Weinheim, Germany, 2013. [Google Scholar]

| Type | Parameter | Symbol | Unit |

|---|---|---|---|

| Process data | Inlet temperature of feed 1 | °C | |

| Process data | Inlet temperature of feed 2 | °C | |

| Process data | Volumetric flow rate of feed 1 | µL min−1 | |

| Process data | Volumetric flow rate of feed 2 | µL min−1 | |

| Process data | Concentration in feed 1 | mol L−1 | |

| Process data | Concentration in feed 2 | mol L−1 | |

| Process data | Outlet temperature of product stream | °C | |

| Process data | Ambient temperature within the closed box | °C | |

| Process data | Measured thermoelectric voltages of SEs anlong the reaction channel | V | |

| Process data | Heat loss over the top of the reactor | W | |

| Thermokinetic data | Reaction enthalpy | kJ mol−1 | |

| Thermokinetic data | Activation energy | kJ mol−1 | |

| Thermokinetic data | Pre-exponential factor | [(m3 mol−1)n−1 s−1] |

| Author | [kJ mol−1] | [kJ mol−1] |

|---|---|---|

| Martin [20] | −61 to −59 | not stated |

| Zogg, Fischer & Hungerbühler [21] | −62 to −57 | −3 to +3 |

| Ładosz, Kuhnle & Jensen [17] | −63 | +9 |

| Steinemann et al. [18] | −62 | +7 |

| Substance | Supplier | Specification | Concentration [mol L−1] |

|---|---|---|---|

| Acetic anhydride | Merck | 98.0% | 10.52 (neat) |

| Acetic acid | Merck | 99.0% | 5.54 |

| Nitric acid | Merck | 98.5% | 5.32 |

| Deionized water | TU Dortmund University | 5 × 10−4 S m−1 | 28.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frede, T.A.; Weber, C.; Brockhoff, T.; Christ, T.; Ludwig, D.; Kockmann, N. Data Management of Microscale Reaction Calorimeter Using a Modular Open-Source IoT-Platform. Processes 2023, 11, 279. https://doi.org/10.3390/pr11010279

Frede TA, Weber C, Brockhoff T, Christ T, Ludwig D, Kockmann N. Data Management of Microscale Reaction Calorimeter Using a Modular Open-Source IoT-Platform. Processes. 2023; 11(1):279. https://doi.org/10.3390/pr11010279

Chicago/Turabian StyleFrede, Timothy Aljoscha, Constantin Weber, Tobias Brockhoff, Tassilo Christ, Denis Ludwig, and Norbert Kockmann. 2023. "Data Management of Microscale Reaction Calorimeter Using a Modular Open-Source IoT-Platform" Processes 11, no. 1: 279. https://doi.org/10.3390/pr11010279

APA StyleFrede, T. A., Weber, C., Brockhoff, T., Christ, T., Ludwig, D., & Kockmann, N. (2023). Data Management of Microscale Reaction Calorimeter Using a Modular Open-Source IoT-Platform. Processes, 11(1), 279. https://doi.org/10.3390/pr11010279