Downtime Reduction with Fast Restart Function in a Beverage Production System

Abstract

:1. Introduction

- Study the production process and working principles of machines in the production of plastic bottled beverages in order to improve the efficiency of the production system.

- A fast restart function is designed to reduce the waiting time to empty the bottle from the conveyor before the machine restarts.

- The performance of the fast restart function was analysed to determine its application in the production system.

2. The Plastic Bottled-Beverage Production System

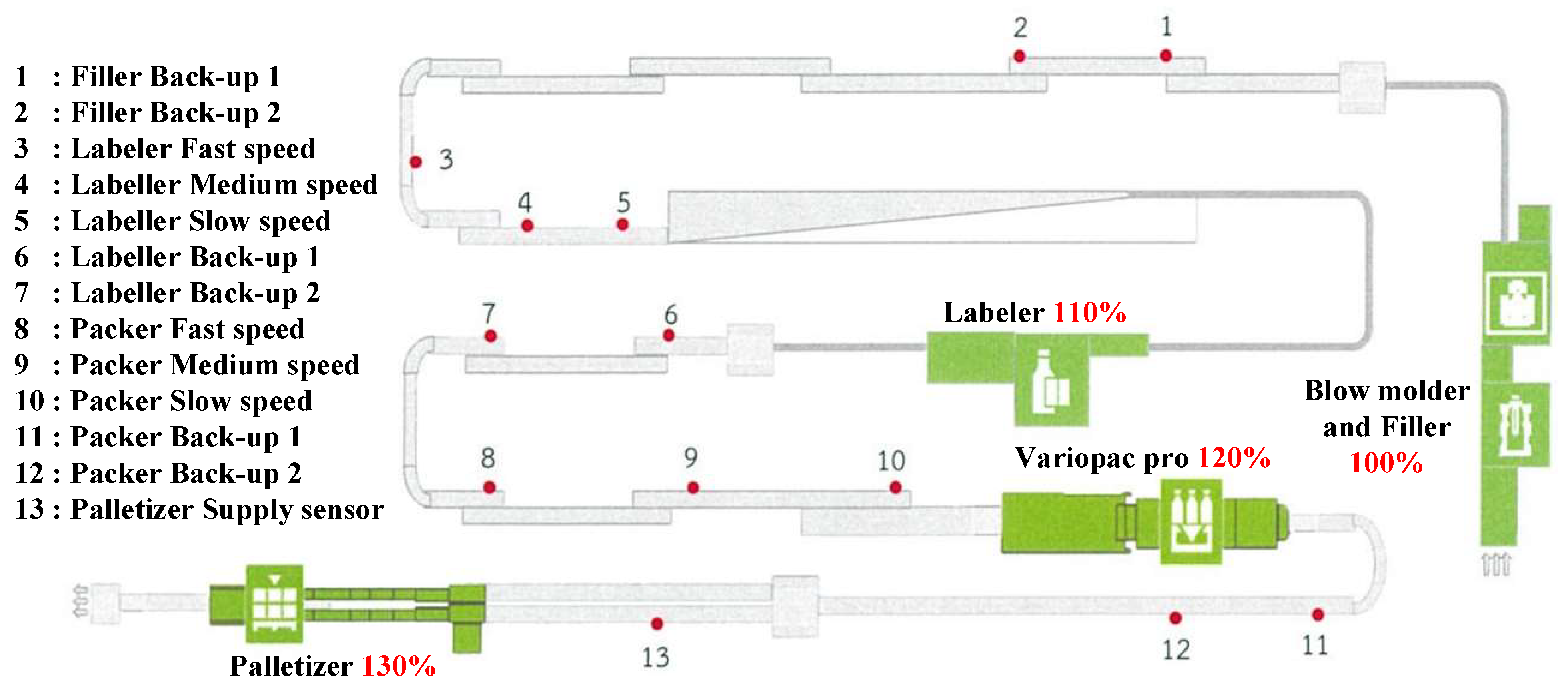

2.1. Production Machine of the Plastic Bottled-Beverage Production System

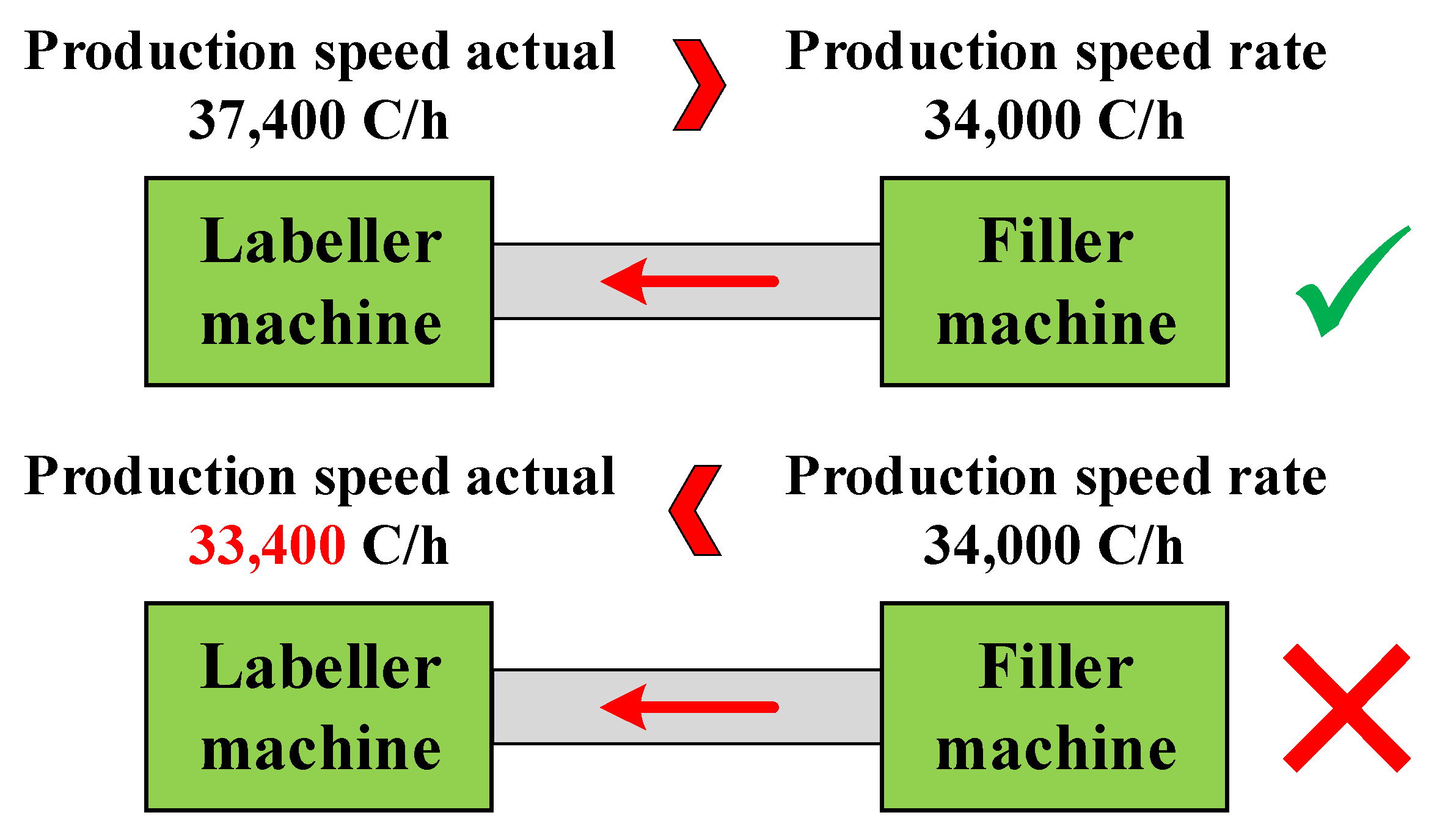

2.2. Working Speed of the Plastic Bottled-Beverage Production System

3. The Production System

3.1. Starting and Stopping Control

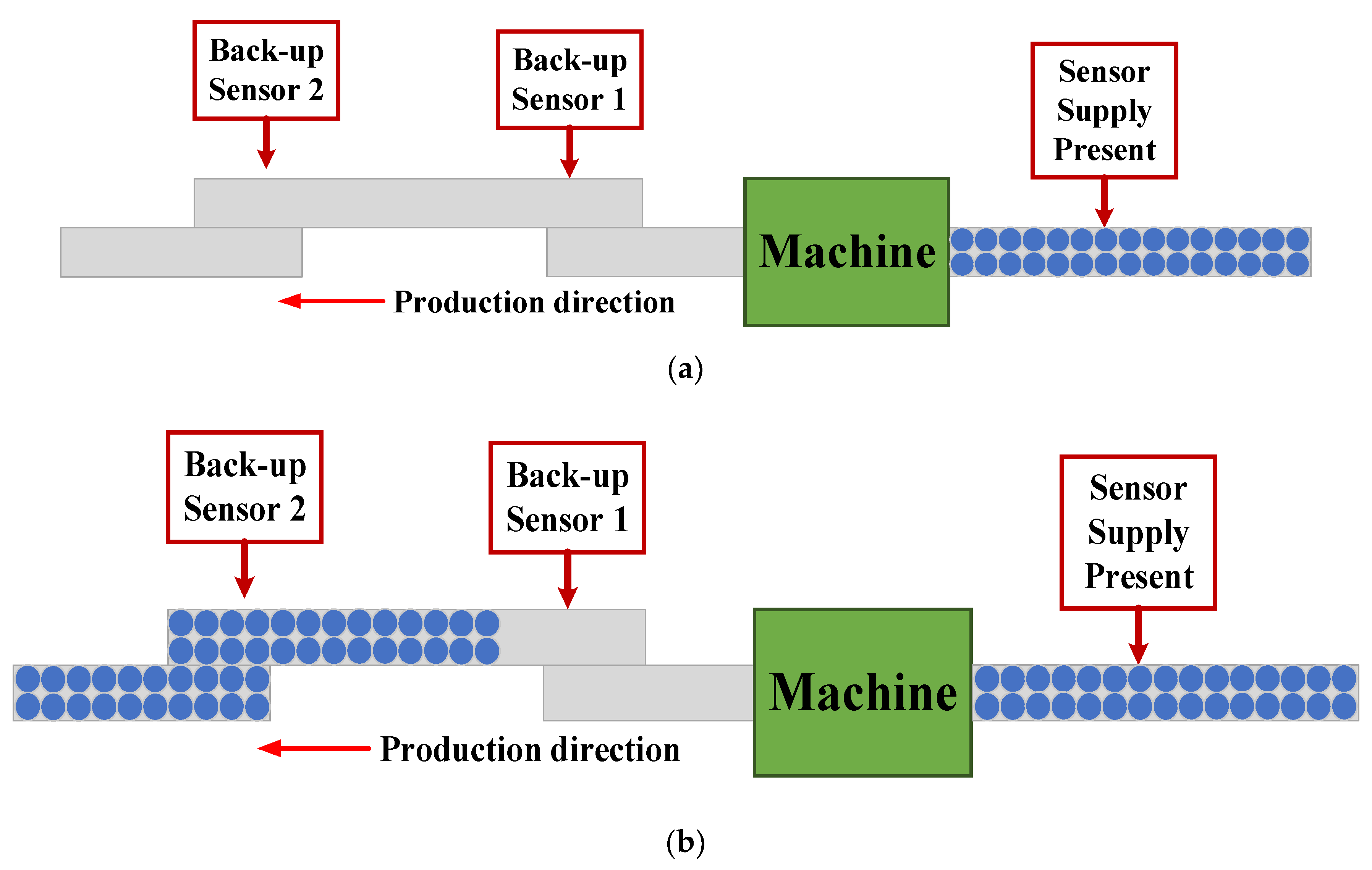

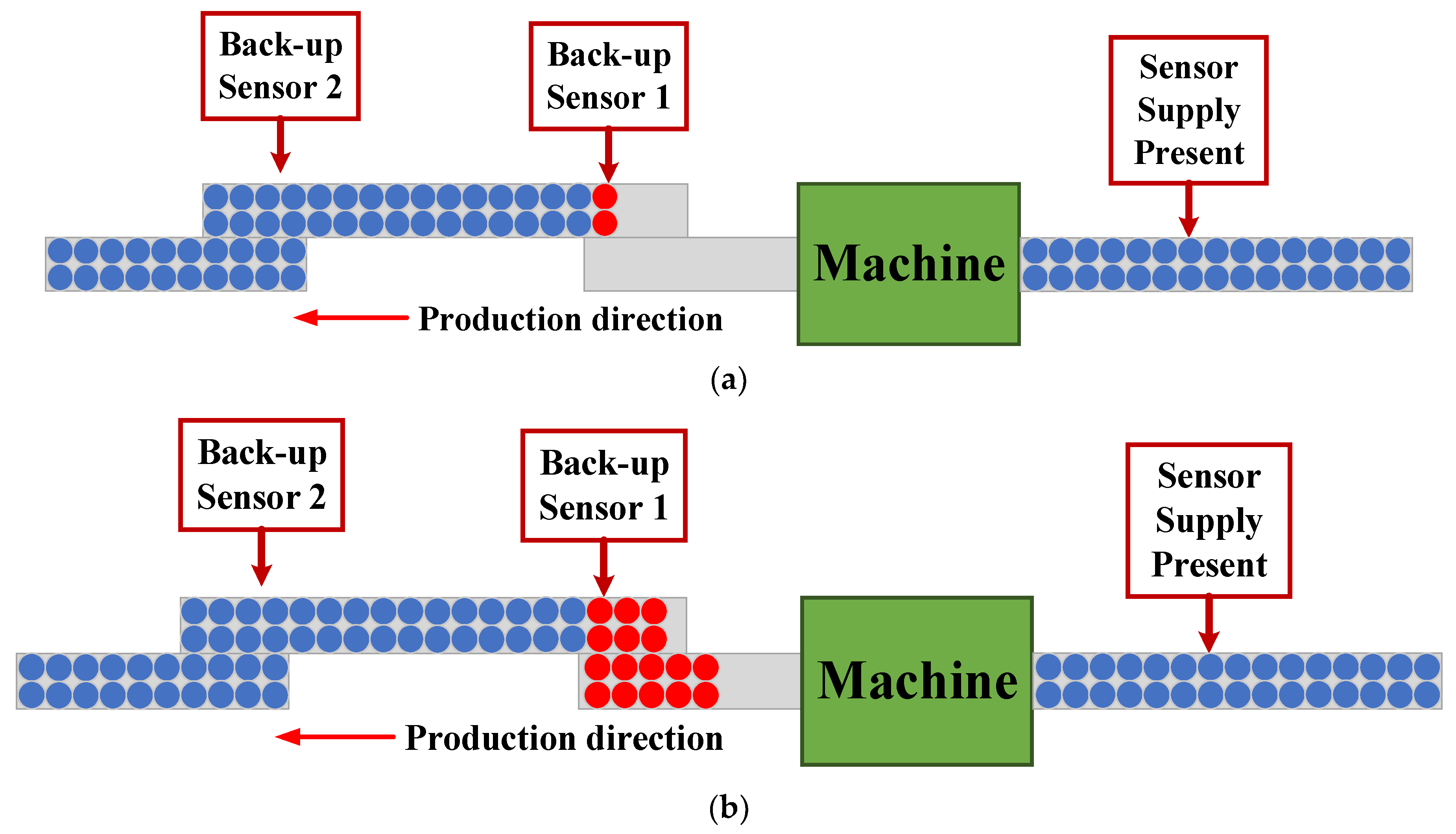

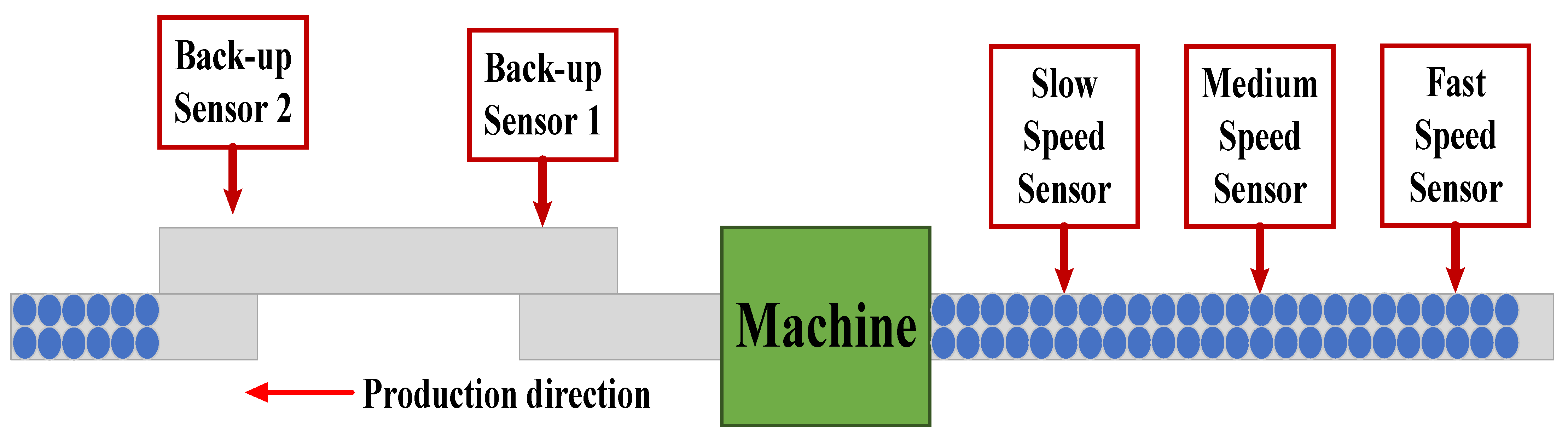

3.2. Production Speed Control

3.3. Downtime for Machine-Restart Waiting

4. Production System Improvement

4.1. Concept of ‘Fast Restart Function’

4.2. ‘Fast Restart Function’ Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wichailert, K.; Yousapornpaiboon, K. Brand Equity Affects Brand Loyalty of the Bottled Mineral Drinking Water in Thailand. J. Adm. Bus. Stud. 2017, 3, 180–191. [Google Scholar]

- Kruawal, K.; Sacher, F.; Werner, A.; Müller, J.; Knepper, T.P. Chemical water quality in Thailand and its impacts on the drinking water production in Thailand. Sci. Total Environ. 2005, 340, 57–70. [Google Scholar] [CrossRef] [PubMed]

- Padhee, S.; Nandan, D. Design of Automated Visual Inspection System for Beverage Industry Production Line. Trait. Signal 2021, 38, 461–466. [Google Scholar] [CrossRef]

- Jacob, B.; Mohamed, A.O.; Muduli, K. Effect of Preventive Maintenance on Machine Reliability in a Beverage Packaging Plant. Int. J. Syst. Dyn. Appl. 2021, 10, 50–66. [Google Scholar]

- De Mattosa, D.L.; Netob, R.A.; Díaz Merinoa, E.A.; Forcellinib, F.A. Simulating the influence of physical overload on assembly line performance: A case study in an automotive electrical component plant. Appl. Ergon. 2019, 79, 107–121. [Google Scholar] [CrossRef] [PubMed]

- Gola, A.; Nieoczym, A. Application of OEE Coefficient for Manufacturing Lines Reliability Improvement. Adv. Econ. Bus. Manag. Res. 2017, 31, 189–194. [Google Scholar]

- Li, Y.; Chang, Q.; Xiao, G.; Arinez, J. Data-Driven Analysis of Downtime Impacts in Parallel Production Systems. IEEE Trans. Autom. Sci. Eng. 2015, 12, 1541–1547. [Google Scholar] [CrossRef]

- Wolniak, R. Downtime in the Automotive Industry Production Process—Cause Analysis. Qual. Innov. Prosper. 2019, 23, 101. [Google Scholar] [CrossRef] [Green Version]

- Ashraf, S.R.B.; Rashid, M.M.; Harunur Rashid, A.R.M. Implementation of 5S Methodology in a Food & Beverage Industry: A Case Study. Int. Res. J. Eng. Technol. 2017, 4, 1791–1796. [Google Scholar]

- Rajasekar, D.; Sengupta, G. Line feeding downtime reduction by implementing lean material handling techniques in automotive manufacturing. Int. J. Manag. IT Eng. 2020, 10, 39–52. [Google Scholar]

- Kumara, P.; Tewarib, P.C. Performance analysis and optimization for CSDGB filling system of a beverage plant using particle swarm optimization. Int. J. Ind. Eng. Comput. 2017, 8, 303–314. [Google Scholar] [CrossRef]

- Zou, J.; Chang, Q.; Lei, Y.; Arinez, J. Production System Performance Identification Using Sensor Data. IEEE Trans. Syst. Man Cybern. Syst. 2018, 48, 255–264. [Google Scholar] [CrossRef]

- Petchwattana, N.; Naknaen, P.; Jakrabutr, W.; Sanetuntikul, J.; Narupai, B. Modification of Poly (Lactic Acid) by Blending with Poly (Methyl Methacrylate-Co-Ethyl Acrylate) for Extrusion Blow Molding Application. J. Eng. Sci. Technol. 2017, 12, 2766–2777. [Google Scholar]

- Biglione, J.; Béreaux, Y.; Charmeau, J.-Y.; Balcaen, J.; Chhay, S. Numerical simulation and optimization of the injection blow molding of polypropylene bottles—A single stage process. Int. J. Mater. Form. 2016, 9, 471–487. [Google Scholar] [CrossRef]

- Hsieh, Y.-C.; Doan, M.H. Research on both the radiation heating and the cooling system inside the stretch blow molding machine CPSB-LSS12. Int. J. Adv. Manuf. Technol. 2018, 98, 2357–2364. [Google Scholar] [CrossRef]

- Kalidasan, B.; Ben Ajai Raja, J.; Giri Gowtham, M.; Kadeesh, M. Automatic Bottle Filling Machine. Int. Res. J. Eng. Technol. 2018, 5, 407–408. [Google Scholar]

- Nwadinobi, C.P.; Mejeh, K.I.; Eti, P.E. Development of Network Model for Overhaul Maintenance of Meyer 78/18 Bottle Filling Machine. Int. J. Eng. Mod. Technol. 2017, 3, 8–21. [Google Scholar]

- Sawai Ben, J. Implementation of Autonomous Maintenance and its Effect on MTBF, MTTR, and Reliability of a Critical Machine in a Beer Processing Plant. Int. J. Progress. Sci. Technol. 2022, 31, 57–66. [Google Scholar]

- Ben, J.; Mohamed, A.; Muduli, K. Optimizing Bottle Washer Performance in Cleaning Returnable Glass Bottles for Reuse in Beverage Packaging. Int. J. Adv. Sci. Technol. 2020, 29, 8149–8159. [Google Scholar]

| Machine | Adjust Speed | Speed (Bottles/Hour) | Speed (Percentage) |

|---|---|---|---|

| Blow moulding machine | Constant speed | 34,000 | 100 |

| Filler machine | Constant speed | 34,000 | 100 |

| Labeller machine | Adjustable speed | 37,400 | 110 |

| Variopac machine | Adjustable speed | 40,800 | 120 |

| Palletizer machine | Adjustable speed | 44,200 | 130 |

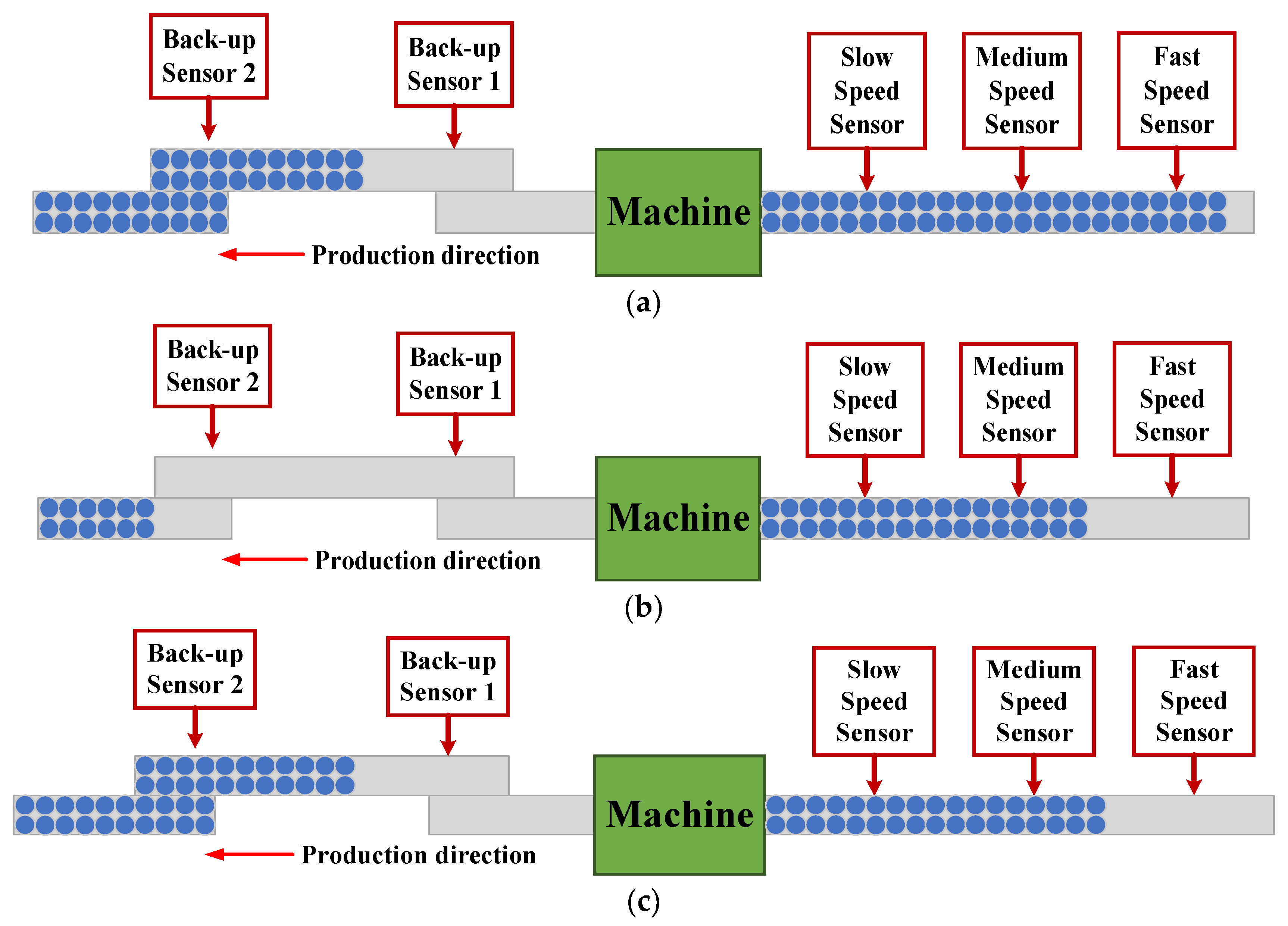

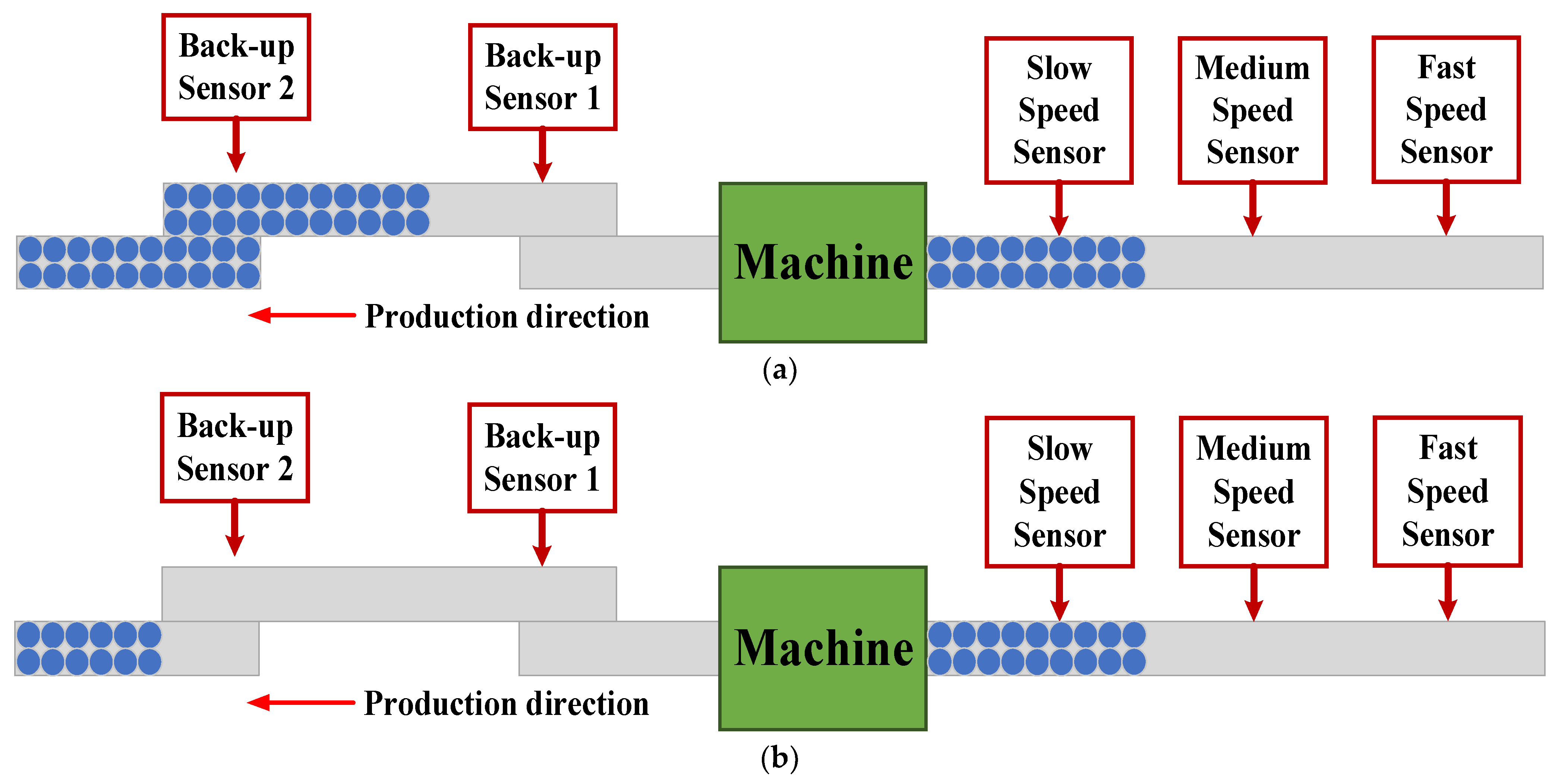

| Machine Status | Production Speed | Back-Up Sensor 2 | Back-Up Sensor 1 | Slow Speed Sensor | Medium Speed Sensor | Fast Speed Sensor | Figure Match |

|---|---|---|---|---|---|---|---|

| Run | Fast | ON | ON | OFF | OFF | OFF | 5 |

| Medium | OFF | ON | OFF | OFF | OFF | 6 (a) | |

| Medium | OFF | ON | OFF | OFF | ON | 6 (b) | |

| Medium | ON | ON | OFF | OFF | ON | 6 (c) | |

| Slow | OFF | ON | OFF | ON | ON | 7 (a) | |

| Slow | ON | ON | OFF | ON | ON | 7 (b) | |

| Stop | - | OFF | OFF | N/C | N/C | N/C | 4 |

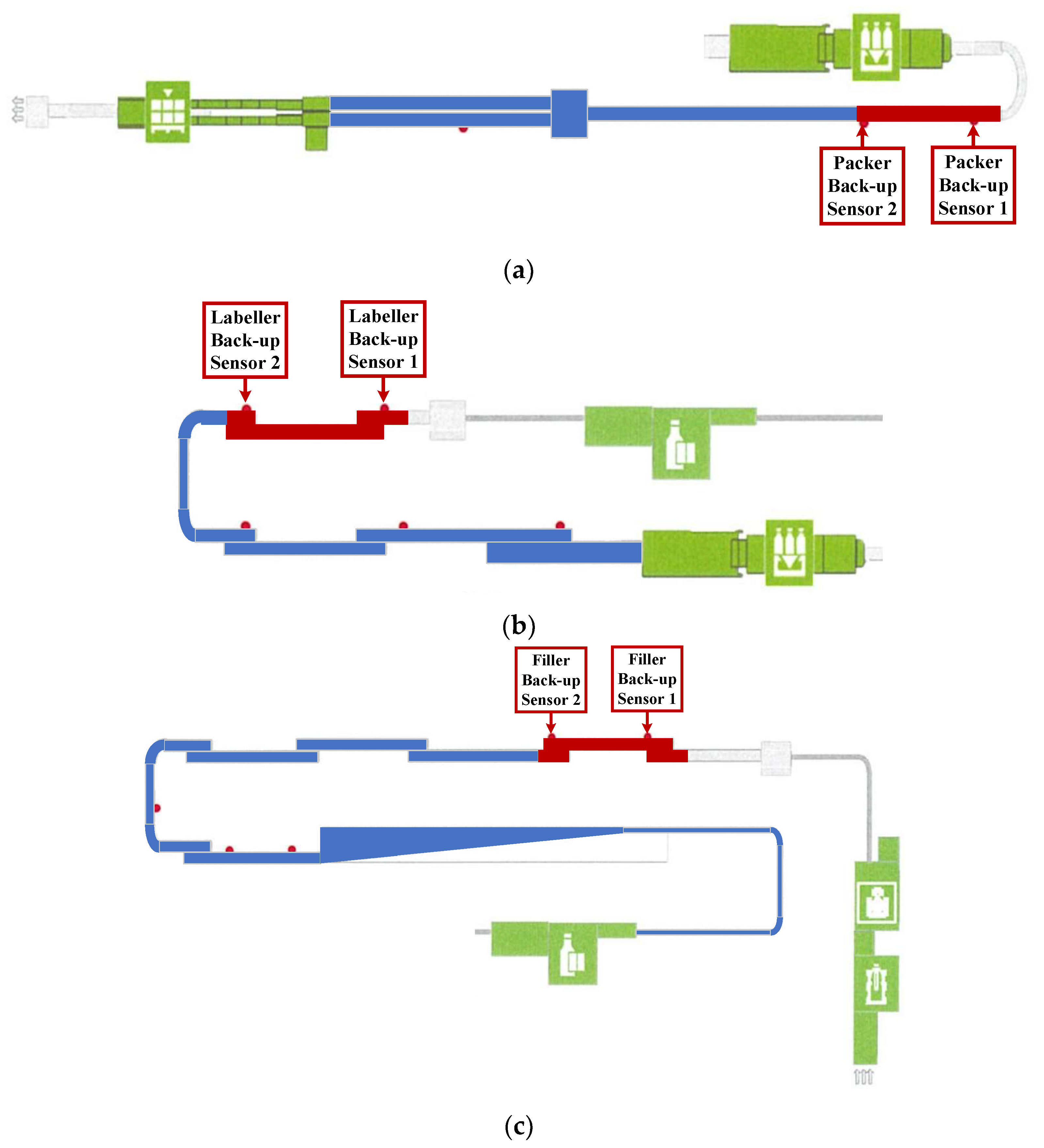

| Machine | Time (s) | Figure Match |

|---|---|---|

| Variopac machine | 22 | 8 (c) |

| Labeller machine | 40 | 8 (b) |

| Filler machine | 150 | 8 (a) |

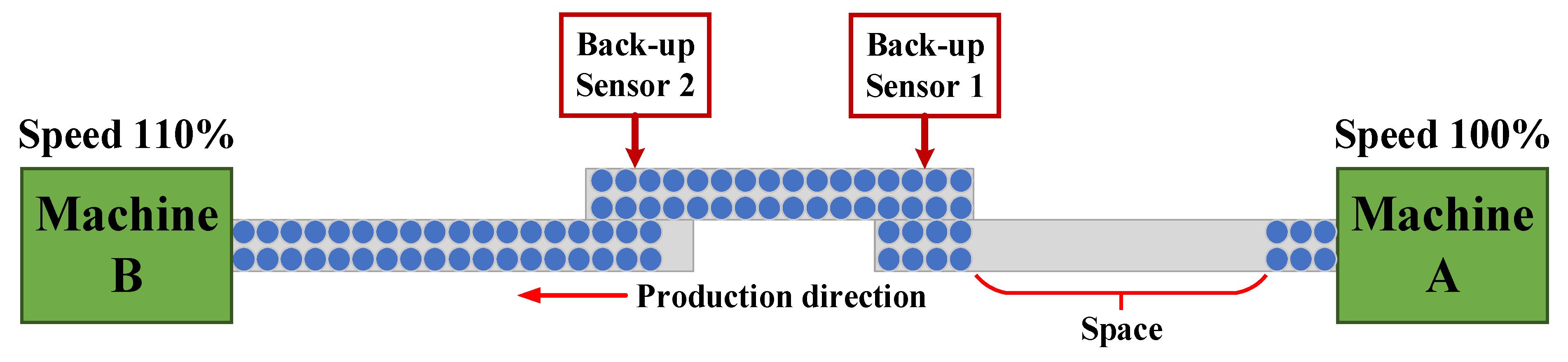

| Started Machine | Next Machine | Waiting for Start (s) | Reduced Time (s) | |

|---|---|---|---|---|

| Original | Fast Restart | |||

| Variopac machine | Palletizer machine | 22 | 6 | 16 |

| Labeller machine | Variopac machine | 40 | 6 | 34 |

| Filler machine | Labeller machine | 150 | 6 | 144 |

| Stopped Working Machine | Waiting Time (s) | Reduced Time (s) | |

|---|---|---|---|

| Original | Fast Restart | ||

| Palletizer machine | 212 | 18 | 194 |

| Variopac machine | 190 | 12 | 178 |

| Labeller machine | 150 | 6 | 144 |

| Topics | Original | Fast Restart | Unit |

|---|---|---|---|

| Average system malfunction | 20 | 20 | times/day |

| Average system fix time | 7920 | 7920 | seconds/day |

| Average starting time (per time) | 150 | 6 | seconds/time |

| Average starting time (per day) | 3000 | 120 | seconds/day |

| Total downtime | 10,920 | 8040 | seconds/day |

| Average system operating time | 71,880 | 74,760 | seconds/day |

| Average number of bottles produced | 678,547 | 705,734 | bottles/day |

| System performance | 86.81 | 90.29 | percent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jettanasen, C.; Phannil, N.; Yoomak, S.; Thongsuk, S.; Bunjongjit, S.; Ngaopitakkul, A. Downtime Reduction with Fast Restart Function in a Beverage Production System. Processes 2023, 11, 39. https://doi.org/10.3390/pr11010039

Jettanasen C, Phannil N, Yoomak S, Thongsuk S, Bunjongjit S, Ngaopitakkul A. Downtime Reduction with Fast Restart Function in a Beverage Production System. Processes. 2023; 11(1):39. https://doi.org/10.3390/pr11010039

Chicago/Turabian StyleJettanasen, Chaiyan, Natthanon Phannil, Suntiti Yoomak, Surakit Thongsuk, Sulee Bunjongjit, and Atthapol Ngaopitakkul. 2023. "Downtime Reduction with Fast Restart Function in a Beverage Production System" Processes 11, no. 1: 39. https://doi.org/10.3390/pr11010039

APA StyleJettanasen, C., Phannil, N., Yoomak, S., Thongsuk, S., Bunjongjit, S., & Ngaopitakkul, A. (2023). Downtime Reduction with Fast Restart Function in a Beverage Production System. Processes, 11(1), 39. https://doi.org/10.3390/pr11010039