Crucial Development Technologies for Volcanic Hydrocarbon Reservoirs: Lessons Learned from Asian Operations

Abstract

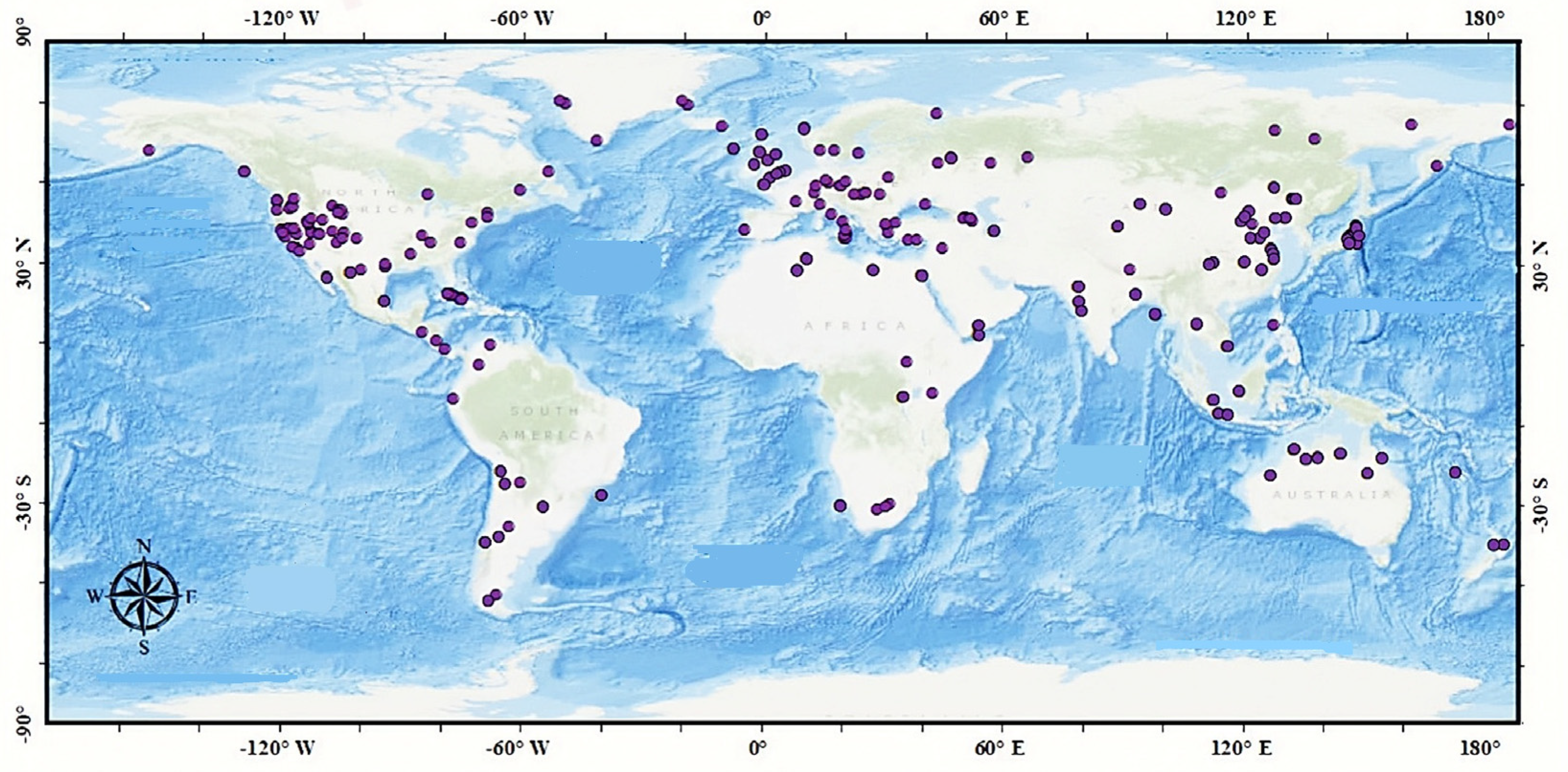

:1. Introduction

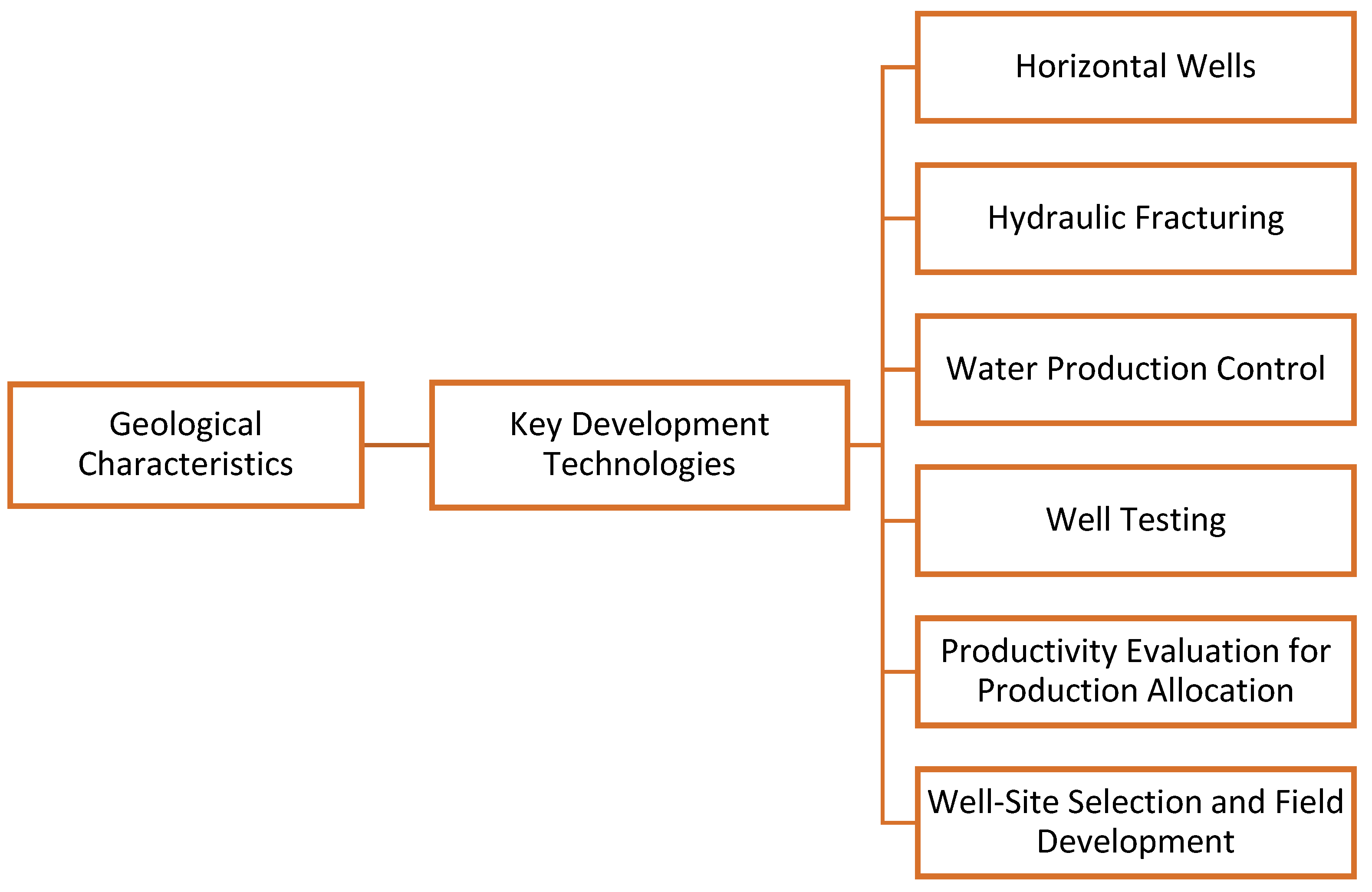

2. Geological Characteristics

2.1. Reservoir Evaluation and Characterization

2.2. Heterogeneity, Formation Mechanisms, Lithology, and Lithofacies

2.3. Porosity and Permeability

3. Key Technologies of Development

3.1. Horizontal Wells

3.2. Hydraulic Fracturing

- (1)

- Volcanic reservoirs usually bear deep burial depth, high Young’s modulus, and high in-situ and closure stress. This poses high-pressure requirement for surface pumps, makes the proppant vulnerable to crash, impairs the hydraulic fracture conductivity, restrains the fracture opening width, and causes the proppant at the fracture tip to form a bridge plug, leading to the failure of so-called “tip-screen-out”.

- In the intervals with low clay content, a second HF treatment (refracturing) can be carried out after the first proppant slugging [48]. For high clay layers with swelling/slaking/dispersion problems, higher pump rate/pressure, certain inhibitive low-leakoff fracturing fluids, and better proppant concentration can be implemented [48]. People also use smaller-size proppant (such as 40/70 and 100 mesh) for spearhead pad and larger-size proppant (such as 20/40 mesh) for tail slurry, or small/large-size alternate sand slugs, intermediate- to high-strength proppant, shorter perforation interval [44], high-viscosity frac fluid, larger tubing size, and higher wellhead pressure, and Extreme Overbalance Perforating to overcome the high in situ stress, near wellbore tortuosity, and tip-screen-out problems [49].

- (2)

- A volcanic reservoir is a type of naturally fractured, low-permeability reservoir. A large number of natural fractures, dissolved pores, and faults have a serious impact on the opening/propagation of hydraulic fractures. Although they would increase porosity and permeability and fracture network complexity, they would also dampen the fracturing effect, cause extra fluid leakoff and formation damage, change the stress distribution around a wellbore, and increase the near-wellbore fracture complexity and tortuosity, and thus increase fracturing initiation pressure, alter the extension direction of fracture and fracture mode, and even cause fracturing operation failure.

- The corresponding fluid-loss control measures should be taken to control fluid leakoff, including adding fluid-loss reducer, adjusting prepad fluid ratio, using small-sized proppant, etc. Commonly used conventional fluid-loss reducer contains silica and clay, which might permanently block some pore channels. Some specially formulated fluid-loss reducers can be selected. We may reduce the amount of the prepad fluid to minimize the fluid leakoff damage to the reservoir or increase the prepad fluid ratio to meet the high-fluid-loss situation. Proppant with mixed, smaller diameters (40/70 + 100 mesh) can be used to overcome the near-wellbore tortuosity and control leakoff and maintain fracture conductivity [50].

- (3)

- Deep volcanic reservoirs of high temperature (up to ~290 °C) render fracturing fluid and other working fluid challenges.

- Use specially formulated fluid systems to endure high temperatures [50].

- (4)

- Volcanic reservoirs bear substantial heterogeneity and complexity in all physical/chemical properties due to their complex forming mechanism: volcano eruption, several eruptions overlapping each other, structural activities, diagenesis, etc. This renders effective HF operation difficult.

- Conduct comprehensive reservoir survey and rock tests to understand reservoir and rock properties so as to better design the HF treatment [48]. This includes seismic survey, (extended) leak-off test, well logging, core analysis by X-ray diffraction (XRD) mineral analysis, scanning electron microscope (SEM) analysis, electron microprobe elemental analysis, electron microscope energy spectrum analysis, etc., as well as ISRM standard rock mechanics tests such as uniaxial and triaxial tests and differential strain curve analysis, etc. The limited-entry fracturing, pin-point hydraulic fracturing techniques can be deployed to maximize net pay coverage.

- (5)

- Rhyolite volcanic reservoirs usually have more developed fracture systems and higher permeability than tuff volcanic reservoirs, thus hydraulic fracturing will not be effective. In another case, when the fracture system of a volcanic reservoir is close to the oil–water contact, hydraulic fractures will probably extend into the aquifer below, therefore hydraulic fracturing can be risky.

3.3. Water Production Control

3.3.1. Water Source Identification

3.3.2. Water Production Patterns

3.3.3. Water Control Measures

- (1)

- Produce below the critical producing rate using the wellhead choke; thus, minimize water coning by controlling bottomhole pressure. The critical rate is a function of the perforation length. As the perforation length increases, the critical producing rate decreases. If the critical rate is less than the minimum economic rate, then operators have no choice but to produce above the critical rate or abandon the well. There are some analytical solutions and empirical correlations regarding critical producing rate calculation [53,54,55,56,57,58,59,60], although the most reliable way to study coning and critical producing rate is numerical simulation.

- (2)

- Perforate the pay zone with partial perforation or penetration. Only a limited portion of the pay thickness is perforated. The portion near bottom water contact is avoided. This approach sacrifices hydrocarbon production in the hope of avoiding coning.

- (3)

- Control hydraulic fracture height and avoid water intrusion by creating a barrier layer at fracture bottom. This barrier layer can be a low-permeability subsidence agent, such as 40/70-mesh + 100-mesh proppant slurry [61]. Also, fracture height can be controlled by injecting an appropriate amount of fracturing fluid at the optimum pumping rate.

- (4)

- Adopt horizontal wells to produce at higher rates while under higher bottomhole flowing pressure and smaller pressure differential between wells and reservoir so that the pressure differential is not large enough to induce the intrusion of water. Also, horizontal wells should keep a proper distance above the aquifer.

- (5)

- Implement complete cementing jobs to avoid channels between the casing/cement/borehole. Check and ensure the cement bond integrity after cementing. This will ensure isolation of water layers from pay layers.

3.4. Well Testing

3.5. Productivity Evaluation for Production Allocation

3.6. Well-Site Selection and Field Development

4. Conclusions

- (1)

- Geological characteristics. Volcanic oil and gas reservoirs are highly complex and heterogeneous with diverse lithofacies and lithologies, pore-fracture systems, low porosity, and low permeability. This is due to the unique origins of volcanic reservoirs. The profitable zones are usually within the flooding, explosive, and subvolcanic (intrusive) lithofacies. Lithology mainly includes basalt (38.5%), andesite (15.9%), volcaniclastic (12.1%), and rhyolite (11.5%). Porosity ranges from 0.1 to 70%, and permeability ranges from 0.0007 to 762 md. In some developed volcanic reservoirs of China, the average porosity is 7.7–13%; the average permeability is 0.41–3.4 md.

- (2)

- In engineering technology considerations, there are several crucial technologies to be emphasized.

- A.

- Horizontal well drilling: Horizontal wells may improve the production rate by approximately 4.7 times, the drainage areas about 4.3 times, and the recoverable reserves about 5.8 times in comparison with vertical wells according to Chinese experience. And longer horizontal wells are preferred, especially for thin reservoirs.

- B.

- Hydraulic fracturing (HF): Unique reservoir characteristics (such as deep burial depth, high in situ stress, high temperature, natural fractures, substantial heterogeneity, and developed fracture systems) render unique difficulties for HF, including, tip-screen-out, high fluid leakoff, formation damage, and inefficient HF operation. Special engineering solutions are suggested accordingly, e.g., small or mixed proppant size, second HF treatment after proppant slugging, high-viscosity frac fluid with high-temperature resistance, special fluid loss reducer, high pump pressure, Extreme Overbalance Perforating, limited-entry fracturing, matrix acidizing, etc.

- C.

- Water production control: Water production is common in volcanic reservoirs due to widespread fractures that connect formations with edge/bottom aquifers. This can cause oil and gas production rates to decline dramatically or even stop. The water control measures include producing below critical rates, partial perforation or penetration, controlling hydraulic fracture height, using horizontal wells, implementing complete cementing jobs, etc.

- D.

- Well testing: Well testing is critical to understand the dynamic properties of volcanic reservoirs and take actions accordingly during production. The well testing curves for volcanic reservoirs are different due to reservoir heterogeneity and water production.

- E.

- Well productivity evaluation: Well productivity evaluation is necessary to understand well performance and appropriately allocate production rates among wells. The main controlling factors of productivity are formation structure, reservoir property, edge/bottom water, and well type. The modified AOF method should be used. And many productivity prediction models have been proposed considering breakdown fracture gradient, gas slippage effect, stress sensitivity, non-Darcy effect, and interference coefficient among fractures.

- F.

- Well-site selection. For field development, well sites need to be selected based on recognizing profitable lithologies, lithofacies, high porosity and permeability, relatively developed fracture systems, thick net pay zones, etc.

- (3)

- Advantages, limitations, and outlook of future research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schutter, S.R. Hydrocarbon occurrence and exploration in and around igneous rocks. Geol. Soc. Lond. Spec. Publ. 2003, 214, 7–13. [Google Scholar] [CrossRef]

- Lopes Descovi, P.; Ade, M.; Avellar, G.; Bejarano, S.; Vieira, F. Volcanic reservoirs: Historic and current context. Pesqui. Em Geociências 2021, 48, e104451. [Google Scholar] [CrossRef]

- Zhao, W.; Zou, C.; Feng, Z.; Hu, S.; Zhang, Y.; Li, M.; Wang, Y.; Yang, T.; Yang, H. Geological features and evaluation techniques of deep-seated volcanics gas reservoirs, Songliao Basin. Pet. Explor. Dev. 2008, 35, 129–142. [Google Scholar] [CrossRef]

- Ren, K.; Zhao, J.; Liu, Q.; Zhao, J. Hydrocarbons in igneous rock of Brazil: A review. Pet. Res. 2020, 5, 265–275. [Google Scholar] [CrossRef]

- Koning, T. Oil and gas production from basement reservoirs: Examples from Indonesia, USA and Venezuela. Geol. Soc. Lond. Spec. Publ. 2003, 214, 83–93. [Google Scholar] [CrossRef]

- Niu, J.; Zhang, Y.; Yuan, X.; Wu, X. Petroleum geology study, oil and gas exploration future and problems faced in Mesozoic and Cenozoic igneous rocks in eastern China. Spec. Oil Gas Reserv. 2003, 10, 7–12. [Google Scholar]

- Li, S.; Lu, F.; Lin, C. Evolution and Geodynamic Background of Meso-Cenozoic Basins in Eastern China and Adjacent Areas; China University of Geosciences Publishing House: Wuhan, China, 1997. [Google Scholar]

- Luo, J.; Shao, H.; Zhang, C. Summary of research methods and exploration technologies for volcanic reservoirs. Acta Pet. Sin. 2003, 24, 31–38. [Google Scholar] [CrossRef]

- Yi, P.; Peng, F.; Han, Y. Characteristics and exploration methods of volcanic reservoirs abroad. SPEC Oil Gas Technol. 1998, 5, 65–70. [Google Scholar]

- Potter, J.; Konnerup-Madsen, J. A review of the occurrence and origin of abiogenic hydrocarbons in igneous rocks. Geol. Soc. Lond. Spec. Publ. 2003, 214, 151–175. [Google Scholar] [CrossRef]

- Mitsuhata, Y.; Matsuo, K.; Minegishi, M. Magnetotelluric survey for exploration of a volcanic-rock reservoir in the Yurihara oil and gas field, Japan *. Geophys. Prospect. 1999, 47, 195–218. [Google Scholar] [CrossRef]

- Jia, C.Z.; Zhao, W.Z.; Zou, C.N.; Feng, Z.Q.; Yuan, X.J.; Chi, Y.L.; Tao, S.Z.; Xue, S.H. Geological theory and exploration technology for lithostratigraphic hydrocarbon reservoirs. Pet. Explor. Dev. 2007, 34, 257–272. [Google Scholar]

- Qiang, J. Hydrocarbon generation in rift basins, eastern China: Catalysis and hydrogenation interaction between volcanic minerals and organic matter. Adv. Earth Sci. 1998, 13, 542–546. [Google Scholar]

- Luo, Q.; Liu, W.; Zheng, D. Distribution Peculiarity of deep-buried volcanic reservoirs. Xinjiang Pet. Geol. 2001, 22, 196–198. [Google Scholar]

- Guo, Z. Volcanic activity and formation and distribution of oil and gas fields. Xinjiang Pet. Geol. 2002, 23, 183–185. [Google Scholar]

- Wu, C.; Gu, L.; Ren, Z.; Chen, Z.; Zhao, M.; Qiu, J. Formation mechanism of hydrocarbon reservoirs related to igneous rocks in Mesozoic-Cenozoic basin, Eastern China. ACTA Geol. Sin. 2005, 79, 522–529. [Google Scholar]

- Lu, B.; Zhang, Y.; Wang, H.; Zhang, Y. Present and Prospect of Cenozoic /Masozoic Volcanic Rock Oil and Gas Accumulations In East of China. Offshore Pet. 2003, 23, 9–11. [Google Scholar]

- Ran, Q.; Ren, D.; Wang, Y.; Tong, M.; Sun, Y.; Yan, L.; Dong, J.; Wang, Z.; Xu, M.; Li, N.; et al. (Eds.) Flowing Mechanism and Development Performance in Volcanic Gas Reservoirs. In Development of Volcanic Gas Reservoirs; Elsevier: Berlin/Heidelberg, Germany, 2019; pp. 343–438. [Google Scholar] [CrossRef]

- Zou, C.; Zhao, W.; Jia, C.; Zhu, R.; Zhang, G.; Zhao, X.; Yuan, X. Formation and distribution of volcanic hydrocarbon reservoirs in sedimentary basins of China. Pet. Explor. Dev. 2008, 35, 257–271. [Google Scholar] [CrossRef]

- Li, B. Study on the initial production characteristics and development strategy for the Kelameili volcanic gas field. In Academic Paper of China Petroleum Association; China Petroleum Association: Beijing, China, 2017. [Google Scholar]

- Zhu, L.; Li, L.; Ma, C. Development Techniques of The Horizontal Wells in Changling Volcanic Gas Reservoir. J. Xi’an Pet. Univ. Sci. 2009, 24, 53–56. [Google Scholar]

- Wang, P. Characteristics of volcanic reservoirs and distribution rules of effective reservoirs in the Changling fault depression, Songliao Basin. Nat. Gas Ind. 2015, 35, 10–18. [Google Scholar] [CrossRef]

- Chen, H.; Hu, Y.; Ran, Q.; Yan, L.; Sun, Z. Lithofacies characteristics of volcanic gas reservoirs and their influence on reservoir physical properties: A case study of Member 1 of Cretaceous Yingcheng Formation in Xudong area of the Xushen gas field. Acta Petrol. Mineral. 2011, 30, 60–70. [Google Scholar]

- Xu, Z.; Fang, B. Xushen gas field vocanic reservoir characteristics and development strategies. Nat. Gas Ind. 2010, 30, 1–4. [Google Scholar]

- Chen, H.; Jiang, P.; Zhang, D.; Li, J. Pore structure of volcanic reservoir classified and distribution characteristics evaluated: Taking Member 1 of Yingcheng Formation in Xudong Area in Songliao Basin as an example. J. Cent. South Univ. (Sci. Technol.) 2013, 44, 1453–1463. [Google Scholar]

- Liu, S.; Zhang, S.; Dai, L.; Jiao, R.; Lu, X.; Shi, J.; Zhang, S.; Zou, N. Characteristics and main controlling factors of high quality carboniferous volcanic reservoirs in Junggar Basin. J. Lanzhou Univ. (Nat. Sci.) 2014, 50, 786–794. [Google Scholar] [CrossRef]

- Zhang, S.; Yao, W.; Xing, C.; Jia, C.; Shi, J.; Li, B. Lithofacies of volcanic rocks from Zhongguai swell to district-5 and district-8 in northwestern margin of Junggar Basin. Xinjiang Pet. Geol. 2011, 32, 7–10. [Google Scholar]

- Chen, Q.; Zhang, L. Relationship between the characteristic of lithology-lithofacies and distribution of fractures in Carboniferous reservoirs, northwest margin of Junggar Basin. Geoscience 2009, 23, 305–312. [Google Scholar]

- Huang, F. A Research on Volcanic Lithofacies and Characteristics of Volcanic Fesevoir of Carboniferous, in the Northwest Edge of Junggar Basin; China University of Geosciences: Beijing, China, 2011. [Google Scholar]

- Qiu, Z.; Zhou, Y.; Zhao, L.; Gao, Y.; Lu, Z. Volcanic-rock facies and reservoir characteristics in the northwest of Junggar Basin. J. Oil Gas Technol. 2012, 34, 34–38. [Google Scholar]

- He, X.; Liu, Y.; Xu, X.; Liu, B.; Zhang, S. Controlling factors of Carboniferous volcanic reservoirs and favorable reservoir prediction in Xiquan area, Junggar Basin. Lithol. Reserv. 2017, 29, 42–51. [Google Scholar]

- Couves, C.R. Investigating the petrophysical properties of volcanic reservoir analogues through the use of micro-focus x-ray computed tomography. Ph.D. Dissertation, Faculty of Natural and Environmental Sciences, University of Southampton, Southampton, UK, 2015; p. 317. [Google Scholar]

- Sun, X.; Bin, Y.; Yang, Z. Main development technologies of volcanic gas reservoirs in the Kelameili gas field. Nat. Gas Ind. 2010, 30, 11–15. [Google Scholar]

- Zhao, C. Formation mechanism of reservoir space and oil possibility of volcanic reservoirs. Geol. Rev. 1996, 42, 37–43. [Google Scholar]

- Yuan, S.; Ran, Q.; Xu, Z.; Hu, Y.; Pang, Y.; Tong, M. Strategy of high-efficiency development for volcanic gas reservoirs. Acta Pet. Sin. 2007, 28, 73–77. [Google Scholar]

- Chowdhury, M.; Guha, R.; Singh, S.; Verma, S.K.; Tandon, R.; Gould, T.; Taylor, A.; Goodall, I. Characterization of Volcanic Reservoir—New Integrated Approach: A Case Study from Raageshwari Deep Gas Field, Rajasthan, India. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 10–12 December 2014; Volume 24. [Google Scholar] [CrossRef]

- Wang, W.; Guo, H.; Huang, Y.; Yu, Y.; Li, D.; Li, Q.; Sui, H. A Case Study for the First Successful Refracturing on Horizontal Well in Tight Volcanic Gas Reservoir in China. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019; Volume 11. [Google Scholar] [CrossRef]

- Deng, Y.; ZHeng, B.; Li, Y.; Yue, H.; Li, B. Refracturing technology for horizontal wells in Niudong volcanic oil reservoir. Well Test. 2021, 30, 32–36. [Google Scholar] [CrossRef]

- Mansouri, M.; Ahmadi, Y.; Jafarbeigi, E. Introducing a new method of using nanocomposites for preventing asphaltene aggregation during real static and dynamic natural depletion tests. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 7499–7513. [Google Scholar] [CrossRef]

- Guo, J.; Ma, L.; Lu, C. Progress and development directions of fracturing flooding technology for tight reservoirs in China. Acta Petrolei Sinica 2022, 43, 1788–1797. [Google Scholar] [CrossRef]

- Jafarbeigi, E.; Ahmadi, Y.; Mansouri, M.; Ayatollahi, S. Experimental Core Flooding Investigation of New ZnO−γAl2O3 Nanocomposites for Enhanced Oil Recovery in Carbonate Reservoirs. ACS Omega 2022, 7, 39107–39121. [Google Scholar] [CrossRef]

- Liu, S.; Ott, W.K. Sodium silicate applications in oil, gas & geothermal well operations. J. Pet. Sci. Eng. 2020, 195, 107693. [Google Scholar] [CrossRef]

- Mishra, S.; Gupta, A.; Mathur, M.; Purusharthy, N.K.; Wenk, A.D.G. A New Dimension Added To The Hydraulic Fracture Stimulation Design Of A Volcanic Reservoir Based On Microseismic Monitoring. In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Vienna, Austria, 23–26 May 2011; Volume 9. [Google Scholar] [CrossRef]

- Vermani, S.; Gupta, A.; Purusharthy, N.K.; Stolyarov, S.M.; Arora, G.; Dean, G.D. Fracturing Deep Nonconventional Volcanic Reservoir: A Case History Raageshwari Gas Field, Onshore India. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010; Volume 17. [Google Scholar] [CrossRef]

- Liu, S.; Valkó, P.P.; McKetta, S.; Liu, X. Microseismic Closure Window Characterizes Hydraulic-Fracture Geometry Better. SPE Reserv. Eval. Eng. 2017, 20, 423–445. [Google Scholar] [CrossRef]

- Tiwari, S.; Tibbles, R.J.; Pathak, S.; Anand, S.; Agustinus, Y.; Siddharth, P.; Goyal, R.; Ranjan, V.; Shrivastava, P.; Bharadwaj, H.; et al. Cracking the Volcanic Rocks in India Substantial Benefits From Continuous Improvements Over 11 Years and 100 Fracturing Treatments. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 24–26 January 2017; Volume 32. [Google Scholar] [CrossRef]

- Pathak, S.; Tibbles, R.J.; Tiwari, S.; Anand, S.; Ranjan, V.; Siddarth, P.; Bohra, A. Advanced Fracture Diagnostics by Utilizing Over 250 Fracture Diagnostic Tests in Indian Volcanic Tight Gas Reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018; Volume 19. [Google Scholar] [CrossRef]

- Han, H.X.; Dusseault, M.B.; Wang, X.J.; Tang, P.F.; Zhang, H.; Deng, X.W. Hydraulic Fracturing of Oil Reservoirs. In Water-Sensitive Tuff, Proceedings of the 1st Canada—U.S. Rock Mechanics Symposium, Vancouver, BC, Canada, 27–31 May 2007; American Rock Mechanics Association: Vancouver, BC, Canada, 2007; p. 6. [Google Scholar]

- Weijers, L.; Griffin, L.G.; Sugiyama, H.; Shimamoto, T.; Takada, S.; Chong, K.K.; Terracina, J.M.; McDaniel, B.W.; Wright, C.A. Hydraulic Fracturing in a Deep, Naturally Fractured Volcanic Rock in Japan—Design Considerations and Execution Results. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Melbourne, Australia, 8–10 October 2002; Volume 14. [Google Scholar] [CrossRef]

- Cheng, H.; Huang, B.; Han, S.; Fu, Y. Optimal Design of Hydraulic Fracturing for Deep Volcanic Reservoir in Zhungeer Basin. MATEC Web Conf. 2017, 100, 1–9. [Google Scholar] [CrossRef]

- Sun, J.; Qin, Y.; Tan, Q. Application of the Acidification Technology in Complex Volcanic Gas Reservoirs. Liaoning Chem. Ind. 2016, 45, 979–984. [Google Scholar] [CrossRef]

- Ge, C. Application of Acid Stimulation Technology in Horizontal Wells of Songnan Volcanic Rock Gas Field. Liaoning Chem. Ind. 2018, 47, 1050–1052. [Google Scholar] [CrossRef]

- Wheatley, M.J. An Approximate Theory of Oil/Water Coning, in: SPE Annu. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 22–26 September 1985. [Google Scholar] [CrossRef]

- Sobocinski, D.P.; Cornelius, A.J. A Correlation for Predicting Water Coning Time. J. Pet. Technol. 1965, 17, 594–600. [Google Scholar] [CrossRef]

- Kuo, M.C.T. A Simplified Method for Water Coning Predictions. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Francisco, CA, USA, 5–8 October 1983. [Google Scholar] [CrossRef]

- Høyland, L.A.; Papatzacos, P.; Skjaeveland, S.M. Critical Rate for Water Coning: Correlation and Analytical Solution. SPE Reserv. Eng. 1989, 4, 495–502. [Google Scholar] [CrossRef]

- Bournazel, C.; Jeanson, B. Fast Water-Coning Evaluation Method. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, New Orleans, LA, USA, 3–6 October 1971. [Google Scholar] [CrossRef]

- Chierici, G.L.; Ciucci, G.M.; Pizzi, G. A Systematic Study of Gas and Water Coning By Potentiometric Models. J. Pet. Technol. 1964, 16, 923–929. [Google Scholar] [CrossRef]

- Meyer, H.I.; Garder, A.O. Mechanics of Two Immiscible Fluids in Porous Media. J. Appl. Phys. 1954, 25, 1400–1406. [Google Scholar] [CrossRef]

- Schols, R.S. Water coning. An empirical formula for the critical oil-production rate. Erdoel-Erdgas Z. 1972, 88, 6–11. (In Germany) [Google Scholar]

- Yi, X.; Wang, D.; Hou, Y.; Zhou, F.; Liu, X.; Li, X. A method of Determining Optimal Amount of Artificial Barrier Agent to Control Fracture Altitude. J. Oil Gas Technol. 2012, 34, 145–147. [Google Scholar]

- Tang, H.; Duan, Y.; Li, J.; Yuan, S.; Chen, Z. Yaoshen #1 Well production potential evaluation and well test analysis in Yaoyingtai gas field. Drill. Prod. Technol. 2009, 32, 38–40. [Google Scholar]

- Chaudhry, A.U. Deliverability Testing and Well Production Potential Analysis Methods. In Gas Well Testing Handbook; Chaudhry, A.U., Ed.; Elsevier: Burlington, MA, USA, 2003; pp. 140–236. [Google Scholar] [CrossRef]

- Zhu, L. Integrated Application of Steady & Unsteady Well Testing in Radial Composite Gas Reservoir. Oil Gas Well Tests 2012, 21, 11–16. [Google Scholar]

- Zhu, L. Development Strategy for Volcanic Gas Reservoirs Bearing CO2. Doctoral Dissertation, Research Institute of Petroleum Exploration and Development, Beijing, China, 2009. [Google Scholar]

| Basin/Field | Lithologies/Lithofacies | Porosity/Permeability | Main Development Technologies | Annual Gas Production Rate (×104 MMCF) |

|---|---|---|---|---|

| Junger Basin, Kelameili Field, China [20] | Lithologies: tuff breccia, syenite porphyry, rhyolitic tuff, and basalt. Lithofacies: falling and sputtering subfacies of the explosive facies; top and lower subfacies of flooding facies; out-belt and middle-belt subfacies of subvolcanic facies. | Average porosity: 12.3% Average permeability: 0.41 md | Geological evaluation and 3D modeling, profitable reserve prediction, fine reservoir characterization, reservoir engineering analysis, hydraulic fracturing (about 50% of wells), vertical and horizontal well combination, simulation, irregular well spacing, water drainage by lifting. | 4.0 |

| Songliao Basin, Changling Field, China [21,22] | Lithologies: rhyolite, rhyolite tuff lava, Anshan volcanic breccia, rhyolite tuff, rhyolite volcanic breccia; andesite, basalt, rhyolite breccia lava. Lithofacies: flooding and explosive facies. | Porosity: 3.5~22%; Permeability: 0.03~17.31 md | Geological evaluation and 3D modeling, profitable reserve prediction, fine reservoir characterization, reservoir engineering analysis and prediction, no hydraulic fracturing, vertical and horizontal wells, simulation for production. | 3.2 |

| Songliao Basin, Xushen Field, China [23,24] | Lithologies: spherulites, stomatal rhyolites, and volcanoes in volcanic lava; fused tuff and clastic tuff in clastic rocks. Lithofacies: hot debris flow subfacies in eruption facies, top subfacies in flowing facies, inner-belt subfacies in invasion facies, volcano-neck subfacies in the channel facies, etc. | Porosity: <7.75%; Permeability: <3.36 md | Geological evaluation, 3D modeling, sweet-spot and other profitable reserves identifying, well productivity assessment and effective producing techniques optimization for different reserves, horizontal wells, MWD/LWD, advanced hydraulic fracturing. | 3.34 |

| Year, Location, Company | Geology | Problems | Solutions and Results |

|---|---|---|---|

| 2001. Minami-Nagaoka Field, Japan. Teikoku Oil Company & Halliburton. [49] | Deep, hot, naturally fractured, volcanic rock. Depth = 12,500–16,000 ft, initial reservoir P = 8100 psi, temperature = 350 °F/177 °C. Repeated volcanisms of rhyolite eruptions formed a thick formation with rapid facies change: hyaloclastite, lava, and pillow breccia. Large-scale natural fractures are developed abundantly in lava and pillow breccia facies in the south but not as abundantly in the north. | The initial frac design failed for two wells. Only 20% of designed proppant placed due to premature screen-outs. Due to very narrow factures, there was a high net pressure of around 4000 psi prior to proppant pumping stage. | (1) 6 HF stages, targeting at 10 MMSCF/d. (2) Use 30/60 mesh proppant instead of 20/40, pump ~80,000 lb for each stage. (3) Select 4 target zones with maximum caliper log and kh values and high natural fracture density. (4) Decrease pad size from 50% to 25%. (5) Use CMHPG zirconate as frac fluid of 60–70 ppt; if tortuosity is excessively high, use 120 ppt high-viscosity gel pills of HPG/borate. (6) Use a short perforation interval of 6 m instead of 10 s of m to reduce fracture initiation points. (7) Test crosslink time each time on location, for it changes with pH as premixed gel ages. (8) Use a larger tubing size (4 ½ in liner instead of 3 ½ in) and higher wellhead pressure. (9) Apply Extreme Overbalance Perforating. The initial gas rate is 16 MMSCF/d, above the economic target of 10 MMSCF/d. |

| 2006. Hailaer Basin, China. Daqing Oilfield Ltd. [48] | Nonmarine extrusive sedimentary rock (basalt and tuff) and tuffaceous conglomerate. φ = 5.6–22%, k = 0.03–28 md, depth = 1655–1948 m, clay content in tuff and tuffaceous layers = 18–69%, mainly smectite–illite-type | The initial fracture design for two wells failed. Tip-screen-out after proppant concentration reached 200 kg/m3. Petrophysics and rock mechanics research found the rock is relatively strong and stiff before HF is undertaken; some tuffaceous strata are highly plastic, so the fracture width is narrower and propagation is slower, which may cause proppant slugging and tip-screen-out; alkali tuffaceous rock is sensitive to water, swelling/slaking/dispersion occurred when exposed to aqueous frac fluid, which caused proppant slugging and then tip-screen-out. | (1) In the nonalkali intervals with low clay content, a second HF treatment was performed after the first proppant slugging. (2) For high clay layers with swelling/slaking/dispersion problems, higher pump rate/pressure, inhibitive low-leakoff cross-linked polymer fracturing fluids, and better proppant concentration were implemented. A new fracturing strategy was applied to 190 separate layers in 95 wells; a 97% success rate was achieved. |

| 2009. Raageshwari deep gas field, Barmer Basin, West Rajasthan, India. Cairn India & BJ Services. [44] | Eroded volcanic formations (basalt, felsic, and subfelsic sublayers) underlying clastic Fatehgarh formations. High gamma-ray and density logs. Depth = ~3000 m. φ = 1.1–16.2%. k = 0.004–0.662 md. E = 1.45–4.73 × 106 psi. Poisson ratio ν = 0.167–0.253. Best pay lies at the top of the basalt unit. | Unsuccessful frac treatment encountered initially, wellbore tortuosity and multiple fractures were the reasons. High ISIP gradient (>overburden gradient) and high net pressure from injection tests indicate complex fracture network and small natural fractures. | They used 3.5′′ monobore slim-hole strategy to eliminate the use of a rig and a separate frac string. Two-hundred barrels of crude oil crosslinked mini frac polymer gel loading at 40 ppt. Intermediate strength proppant loadings are 100 mesh for the pad stage, 20/40 for the main stages, and 16/30 for the tail end. Liquid clay stabilizer (quaternary ammonium chloride) achieved regained gas perm of ~80%. The perforation interval was reduced from 5 m to 2.5 m. Abandoned the unsuitable intervals with sand plugs to isolate them from other perforated intervals. One-hundred-mesh sand in pad treatment proved a successful means to avoid tip-screen-out. A total of 20MMSCF/D of gas production at 1000 psi drawdown. Improved the success rate of volcanic rocks fracturing |

| 2013–2018. Raageshwari deep gas condensate reservoir, Barmer Basin, West Rajasthan, India. Cairn Oil & Gas, Vedanta Ltd., [46,47] | A poorly sorted clastic (Fatehgarh) interval on top of a stacked volcanic succession of lava flow cycles of basalt and felsic units. A total of 15–40 vertically separated pay layers. Pay depth = 2500–3500 m, low net-to-gross ratio. φ = 8–12%. k = 0.01–1 md. Sw = 50%. 80% CH4, and low CO2 and H2S. Condensate gravity = 56 API. Gas calorific value = 1070 BTU/SCF. | In 2013, commercial gas sales started, allowing extensive data acquisition and well surveillance. Thirty wells were treated with 168 hydraulic fractures. Based on data acquired and four years of production history, they conducted a comprehensive re-evaluation of the resource, improved fracture design, and prepared a revised field development plan. | Limited-entry fracture technique to maximize net pay coverage and reduce cost because conventional plug and perf technique costs much more. They conducted and analyzed fracture diagnostic tests: Diagnostic Fracture Injection Test (DFIT), Step-Up Rate Test (SRT), Step-Down Tests (SDT), Temperature Surveys, and Production Log Tests (PLT). Perforation intensity was increased from 3 clusters/fracture stage to 6. Productivity was increased by 80% and Estimated Ultimate Recovery (EUR) by 20%. Screen-out rate dropped from 33% to 5%. |

| 2016. Jinlong #2 reservoir, Junger Basin, China. PetroChina Xinjiang Oilfield Company. [50] | Depth = 3160–4400 m. Two sets of faults: three near-NS faults and seven near EW faults. φ = 10.82%. k = 0.43 md. Natural fractures mainly developed in the north, weak in the south. NF width = 0.01–0.19 mm, fracture density = 0.02–6.93 m−1, NF strike = EW, dip angle > 45°. E = 30,152 MPa, ν = 0.186, azimuth of Sv = 118°, Sv = 82 MPa, Shmin = 68 MPa. | Among 12 wells, 4 did not complete the target amount of proppant, and 6 wells were dry layers or water layers after fracturing. Efficiency at the edge and bottom of the reservoir is low; The oil test results are either dry layer or water layer. The fracturing effect of gas-bearing fault block in the high part of the structure is good. The fracturing effect in the natural fracture development zone is good. Low sand ratio (<10%) or low average proppant concentration is associated with low postfrac production. | Select the high parts of the reservoir and zones with more natural fractures to conduct HF. Using mixed proppant with different diameters to fill fractures, large proppant—20/40 mesh—for fracture bridging and small proppant—100 mesh—for fluid loss control. Tests of a new fluid-loss reducer JL-1 of 1% and 2% found the wall-building filtration coefficient is reduced by over 50%, and the time to filter out was reduced by 15 and 20+ min. Formation damage by fracturing fluid with 2% JL-1 filtrate reducers is negligible, equivalent to that without JL-1. Perforation interval length is controlled in 5–10 m. Based on simulation optimization, the average sand ratio should be 15–18% to induce optimal fracture conductivity of 20 D·cm and avoid sand screen out; pumping rate should be 3.0–4.0 m3/min considering capacity to carry 35% design sand ratio and balance between shear activation of NF and excessive fluid leakoff; Prepaid fluid volume ratio was optimized as ~40% with the presence of fluid-loss reducer. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhang, Y.; Wu, Q.; Ayers, W.B.; Wang, Y.; Ott, W.K. Crucial Development Technologies for Volcanic Hydrocarbon Reservoirs: Lessons Learned from Asian Operations. Processes 2023, 11, 3052. https://doi.org/10.3390/pr11113052

Liu S, Zhang Y, Wu Q, Ayers WB, Wang Y, Ott WK. Crucial Development Technologies for Volcanic Hydrocarbon Reservoirs: Lessons Learned from Asian Operations. Processes. 2023; 11(11):3052. https://doi.org/10.3390/pr11113052

Chicago/Turabian StyleLiu, Songxia, Yaoyuan Zhang, Qilin Wu, Walter B. Ayers, Yanquan Wang, and William K. Ott. 2023. "Crucial Development Technologies for Volcanic Hydrocarbon Reservoirs: Lessons Learned from Asian Operations" Processes 11, no. 11: 3052. https://doi.org/10.3390/pr11113052