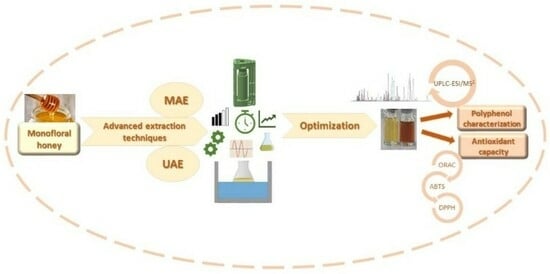

Efficiency of Microwave and Ultrasound-Assisted Extraction as a Green Tool for Polyphenolic Isolation from Monofloral Honeys

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Honey Samples

2.3. Extraction of Polyphenols

2.3.1. MAE

2.3.2. UAE

2.4. Total Phenolic Content

2.5. UPLC/ESI-MS2 Determination of Phenolic Compounds

2.6. Antioxidant Capacity Determination

2.6.1. Oxygen Radical Absorbance Capacity (ORAC) Assay

2.6.2. ABTS (2,2-Azinobis(3-ethylbenzothiazoline-6-sulfonic Acid) Assay

2.6.3. DPPH (2,2-Diphenyl-1-picrylhydrazyl Radical) Assay

2.7. Statistical Analysis

3. Results and Discussion

3.1. MAE Optimization

3.2. UAE Optimization

3.3. Polyphenolic Characterization of Different Monofloral Honey Extracts

3.4. Antioxidant Capacity of Honey Extracts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Margaoan, R.; Topal, E.; Balkanska, R.; Yucel, B.; Oravecz, T.; Cornea-Cipcigan, M.; Vodnar, D.C. Monofloral Honeys as a Potential Source of Natural Antioxidants, Minerals and Medicine. Antioxidants 2021, 10, 1023. [Google Scholar] [CrossRef] [PubMed]

- Gul, A.; Pehlivan, T. Antioxidant activities of some monofloral honey types produced across Turkey. Saudi J. Biol. Sci. 2018, 25, 1056–1065. [Google Scholar] [CrossRef] [PubMed]

- Halouzka, R.; Tarkowski, P.; Cavar Zeljkovic, S. Characterisation of Phenolics and other Quality Parameters of Different Types of Honey. Czech J. Food Sci. 2016, 34, 244–253. [Google Scholar] [CrossRef]

- Diaconeasa, Z.; Leopold, L.; Rugina, D.; Ayvaz, H.; Socaciu, C. Antiproliferative and Antioxidant Properties of Anthocyanin Rich Extracts from Blueberry and Blackcurrant Juice. Int. J. Mol. Sci. 2015, 16, 2352–2365. [Google Scholar] [CrossRef]

- Lawag, I.L.; Lim, L.Y.; Joshi, R.; Hammer, K.A.; Locher, C. A Comprehensive Survey of Phenolic Constituents Reported in Monofloral Honeys around the Globe. Foods 2022, 11, 1152. [Google Scholar] [CrossRef]

- Arya, P.; Kumar, P. Comparison of ultrasound and microwave assisted extraction of diosgenin from Trigonella foenum graceum seed. Ultrason. Sonochem. 2021, 74, 105572. [Google Scholar] [CrossRef]

- Biesaga, M.; Pyrzynska, K. Stability of bioactive polyphenols from honey during different extraction methods. Food Chem. 2013, 136, 46–54. [Google Scholar] [CrossRef]

- Dobroslavic, E.; Garofulic, I.E.; Zoric, Z.; Pedisic, S.; Dragovic-Uzelac, V. Polyphenolic Characterization and Antioxidant Capacity of Laurus nobilis L. Leaf Extracts Obtained by Green and Conventional Extraction Techniques. Processes 2021, 9, 1840. [Google Scholar] [CrossRef]

- Do, Q.D.; Angkawijaya, A.E.; Phuong, L.T.N.; Huynh, L.H.; Soetaredjo, F.E.; Ismadji, S.; Ju, Y.H. Effect of extraction solvent on total phenol content, total flavonoid content, and antioxidant activity of Limnophila aromatica. J. Food Drug Anal. 2014, 22, 296–302. [Google Scholar] [CrossRef]

- Sanches, V.L.; Cunha, T.A.; Vigano, J.; Mesquita, L.M.D.; Faccioli, L.H.; Breitkreitz, M.C.; Rostagno, M.A. Comprehensive analysis of phenolics compounds in citrus fruits peels by UPLC-PDA and UPLC-Q/TOF MS using a fused-core column. Food Chem. X 2022, 14, 100262. [Google Scholar] [CrossRef]

- Hanula, M.; Wyrwisz, J.; Moczkowska, M.; Horbanczuk, O.K.; Pogorzelska-Nowicka, E.; Wierzbicka, A. Optimization of Microwave and Ultrasound Extraction Methods of Acai Berries in Terms of Highest Content of Phenolic Compounds and Antioxidant Activity. Appl. Sci. 2020, 10, 8325. [Google Scholar] [CrossRef]

- Liang, N.J.; Kitts, D.D. Antioxidant Property of Coffee Components: Assessment of Methods that Define Mechanisms of Action. Molecules 2014, 19, 19180–19208. [Google Scholar] [CrossRef] [PubMed]

- Rumpf, J.; Burger, R.; Schulze, M. Statistical evaluation of DPPH, ABTS, FRAP, and Folin-Ciocalteu assays to assess the antioxidant capacity of lignins. Int. J. Biol. Macromol. 2023, 233, 123470. [Google Scholar] [CrossRef] [PubMed]

- Shortle, E.; O’Grady, M.N.; Gilroy, D.; Furey, A.; Quinn, N.; Kerry, J.P. Influence of extraction technique on the anti-oxidative potential of hawthorn (Crataegus monogyna) extracts in bovine muscle homogenates. Meat Sci. 2014, 98, 828–834. [Google Scholar] [CrossRef]

- Garofulic, I.E.; Zoric, Z.; Pedisic, S.; Brncic, M.; Dragovic-Uzelac, V. UPLC-MS2 Profiling of Blackthorn Flower Polyphenols Isolated by Ultrasound-Assisted Extraction. J. Food Sci. 2018, 83, 2782–2789. [Google Scholar] [CrossRef]

- Miller, N.J.; RiceEvans, C. Factor influencing the antioxidant activity determined by the ABTS•+ radical cation assay. Free Radic. Res. 1997, 26, 195–199. [Google Scholar] [CrossRef]

- Cegledi, E.; Garofulic, I.E.; Zoric, Z.; Roje, M.; Dragovic-Uzelac, V. Effect of Spray Drying Encapsulation on Nettle Leaf Extract Powder Properties, Polyphenols and Their Bioavailability. Foods 2022, 11, 2852. [Google Scholar] [CrossRef]

- Chaikham, P.; Prangthip, P. Alteration of antioxidative properties of longan flower-honey after high pressure, ultra-sonic and thermal processing. Food Biosci. 2015, 10, 1–7. [Google Scholar] [CrossRef]

- Pavlesic, T.; Poljak, S.; Ostojic, D.M.; Lucin, I.; Reynolds, C.A.; Kalafatovic, D.; Martinovic, L.S. Mint (Mentha spp.) Honey: Analysis of the Phenolic Profile and Antioxidant Activity. Food Technol. Biotechnol. 2022, 60, 509–519. [Google Scholar] [CrossRef]

- Pauliuc, D.; Dranca, F.; Oroian, M. Antioxidant Activity, Total Phenolic Content, Individual Phenolics and Physicochemical Parameters Suitability for Romanian Honey Authentication. Foods 2020, 9, 306. [Google Scholar] [CrossRef]

- Piljac-Žegarac, J.S.T.; Belščak, A. Antioxidant properties and phenolic content of different floral origin honeys. J. ApiProduct ApiMedical Sci. 2009, 1, 7. [Google Scholar] [CrossRef]

- Wesolowska, M.; Kacaniova, M.; Dzugan, M. The Antioxidant Properties and Microbiological Quality of Polish Honeys. J. Microb. Biotechnol. Food 2014, 3, 422–425. [Google Scholar]

- Albu, A.; Radu-Rusu, C.G.; Pop, I.M.; Frunza, G.; Nacu, G. Quality Assessment of Raw Honey Issued from Eastern Romania. Agriculture 2021, 11, 247. [Google Scholar] [CrossRef]

- Tomasi, I.T.; Santos, S.C.R.; Boaventura, R.A.R.; Botelho, C.M.S. Optimization of microwave-assisted extraction of phenolic compounds from chestnut processing waste using response surface methodology. J. Clean. Prod. 2023, 395, 136452. [Google Scholar] [CrossRef]

- Dobrincic, A.; Repajic, M.; Garofulic, I.E.; Tuden, L.; Dragovic-Uzelac, V.; Levaj, B. Comparison of Different Extraction Methods for the Recovery of Olive Leaves Polyphenols. Processes 2020, 8, 1008. [Google Scholar] [CrossRef]

- Wong-Paz, J.E.; Contreras-Esquivel, J.C.; Muñiz-Marquez, D.; Belmares, R.; Rodriguez, R.; Flores, P.; Aguilar, C.N. Microwave-assisted extraction of phenolic antioxidants from semiarid plants. Am. J. Agric. Biol. Sci. 2014, 9, 11. [Google Scholar] [CrossRef]

- Rodriguez-Gonzalez, I.O.-T.R.; Díaz-Moreno, A. Influence of microwave- and ultrasound-assisted extraction on bioactive compounds from pollen. Contemp. Eng. Sci. 2018, 11, 8. [Google Scholar] [CrossRef]

- Routray, W.; Orsat, V. Microwave-Assisted Extraction of Flavonoids: A Review. Food Bioprocess. Technol. 2012, 5, 409–424. [Google Scholar] [CrossRef]

- Tan Quoc, L.P. Microwave-assisted extraction of phenolic compounds from coffee (Coffea robusta L. Linden) bee pollen. Herba Pol. 2021, 67, 7. [Google Scholar] [CrossRef]

- Hajek, T. Effect of Liquefaction of Honey on the Content of Phenolic Compounds. Molecules 2023, 28, 714. [Google Scholar] [CrossRef]

- Oroian, M.; Ursachi, F.; Dranca, F. Influence of ultrasonic amplitude, temperature, time and solvent concentration on bioactive compounds extraction from propolis. Ultrason. Sonochem. 2020, 64, 105021. [Google Scholar] [CrossRef] [PubMed]

- Suhaimi, S.H.; Hasham, R.; Idris, M.K.H.; Ismail, H.F.; Ariffin, N.H.M.; Majid, F.A.A. Optimization of Ultrasound-Assisted Extraction Conditions Followed by Solid Phase Extraction Fractionation from Orthosiphon stamineus Benth (Lamiace) Leaves for Antiproliferative Effect on Prostate Cancer Cells. Molecules 2019, 24, 4183. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, P.; Lante, A. Environmentally Friendly Techniques for the Recovery of Polyphenols from Food By-Products and Their Impact on Polyphenol Oxidase: A Critical Review. Appl. Sci. 2022, 12, 1923. [Google Scholar] [CrossRef]

- Singh, Y.; Mazumder, A.; Giri, A.; Mishra, H.N. Optimization of Ultrasound-Assisted Extraction of β-Carotene from Chlorella Biomass (MCC7) and its Use in Fortification of Apple Jam. J. Food Process Eng. 2017, 40, e12321. [Google Scholar] [CrossRef]

- Pelaez-Acero, A.; Garrido-Islas, D.B.; Campos-Montiel, R.G.; Gonzalez-Montiel, L.; Medina-Perez, G.; Luna-Rodriguez, L.; Gonzalez-Lemus, U.; Cenobio-Galindo, A.D. The Application of Ultrasound in Honey: Antioxidant Activity, Inhibitory Effect on alpha-amylase and alpha-glucosidase, and In Vitro Digestibility Assessment. Molecules 2022, 27, 5825. [Google Scholar] [CrossRef]

- Borras-Enriquez, A.J.; Reyes-Ventura, E.; Villanueva-Rodriguez, S.J.; Moreno-Vilet, L. Effect of Ultrasound-Assisted Extraction Parameters on Total Polyphenols and Its Antioxidant Activity from Mango Residues (Mangifera indica L. var. Manililla). Separations 2021, 8, 94. [Google Scholar] [CrossRef]

- Leksawasdi, N.; Taesuwan, S.; Prommajak, T.; Techapun, C.; Khonchaisri, R.; Sittilop, N.; Halee, A.; Jantanasakulwong, K.; Phongthai, S.; Nunta, R.; et al. Ultrasonic Extraction of Bioactive Compounds from Green Soybean Pods and Application in Green Soybean Milk Antioxidants Fortification. Foods 2022, 11, 588. [Google Scholar] [CrossRef]

- Dent, M.; Dragovic-Uzelac, V.; Garofulic, I.E.; Bosiljkov, T.; Jezek, D.; Brncic, M. Comparison of Conventional and Ultrasound-assisted Extraction Techniques on Mass Fraction of Phenolic Compounds from Sage (Salvia officinalis L.). Chem. Biochem. Eng. Q. 2015, 29, 475–484. [Google Scholar] [CrossRef]

- Golmahit, Z.; Elhamirad, A.H. Ultrasound-Assisted Extraction of Phenolics and Antioxidants from Propolis for Stabilization of Sunflower Oil. Rev. Cienc. Agric. 2021, 38, 4–19. [Google Scholar] [CrossRef]

- Rajaei, A.; Barzegar, M.; Hamidi, Z.; Sahari, M.A. Optimization of Extraction Conditions of Phenolic Compounds from Pistachio (Pistachia vera) Green Hull through Response Surface Method. J. Agr. Sci. Technol. 2010, 12, 605–615. [Google Scholar]

- Oroian, M.; Ursachi, F.; Dranca, F. Ultrasound-Assisted Extraction of Polyphenols from Crude Pollen. Antioxidants 2020, 9, 322. [Google Scholar] [CrossRef] [PubMed]

- Peng, S.Q.; Zhu, M.F.; Li, S.S.; Ma, X.B.; Hu, F.L. Ultrasound-assisted extraction of polyphenols from Chinese propolis. Front. Sustain. Food Syst. 2023, 7, 1131959. [Google Scholar] [CrossRef]

- Gheldof, N.; Wang, X.H.; Engeseth, N.J. Identification and quantification of antioxidant components of honeys from various floral sources. J. Agric. Food Chem. 2002, 50, 5870–5877. [Google Scholar] [CrossRef] [PubMed]

- Ogo, Y.; Mori, T.; Nakabayashi, R.; Saito, K.; Takaiwa, F. Transgenic rice seed expressing flavonoid biosynthetic genes accumulate glycosylated and/or acylated flavonoids in protein bodies. J. Exp. Bot. 2016, 67, 95–106. [Google Scholar] [CrossRef]

- Iurlina, M.O.; Saiz, A.I.; Fritz, R.; Manrique, G.D. Major flavonoids of Argentinean honeys. Optimisation of the extraction method and analysis of their content in relationship to the geographical source of honeys. Food Chem. 2009, 115, 1141–1149. [Google Scholar] [CrossRef]

- Halagarda, M.; Groth, S.; Popek, S.; Rohn, S.; Pedan, V. Antioxidant Activity and Phenolic Profile of Selected Organic and Conventional Honeys from Poland. Antioxidants 2020, 9, 44. [Google Scholar] [CrossRef]

- Wen, Y.Q.; Zhang, J.Z.; Li, Y.; Chen, L.Z.; Zhao, W.; Zhou, J.H.; Jin, Y. Characterization of Chinese Unifloral Honeys Based on Proline and Phenolic Content as Markers of Botanical Origin, Using Multivariate Analysis. Molecules 2017, 22, 735. [Google Scholar] [CrossRef]

- Salonen, A.; Virjamo, V.; Tammela, P.; Fauch, L.; Julkunen-Tiitto, R. Screening bioactivity and bioactive constituents of Nordic unifloral honeys. Food Chem. 2017, 237, 214–224. [Google Scholar] [CrossRef]

- Trusheva, B.; Trunkova, D.; Bankova, V. Different extraction methods of biologically active components from propolis: A preliminary study. Chem. Cent. J. 2007, 1, 13. [Google Scholar] [CrossRef]

- Quintero-Lira, A.; Santos, A.A.; Aguirre-Alvarez, G.; Reyes-Munguia, A.; Almaraz-Buendia, I.; Campos-Montiel, R.G. Effects of liquefying crystallized honey by ultrasound on crystal size, 5-hydroxymethylfurfural, colour, phenolic compounds and antioxidant activity. Eur. Food Res. Technol. 2017, 243, 619–626. [Google Scholar] [CrossRef]

- Masuda, N.; Maruyama, A.; Eguchi, T.; Hirakawa, T.; Murakami, Y. Influence of Microbubbles on Free Radical Generation by Ultrasound in Aqueous Solution: Dependence of Ultrasound Frequency. J. Phys. Chem. B 2015, 119, 12887–12893. [Google Scholar] [CrossRef] [PubMed]

- Dzah, C.S.; Duan, Y.Q.; Zhang, H.H.; Wen, C.T.; Zhang, J.X.; Chen, G.Y.; Ma, H.L. The effects of ultrasound assisted extraction on yield, antioxidant, anticancer and antimicrobial activity of polyphenol extracts: A review. Food Biosci. 2020, 35, 100547. [Google Scholar] [CrossRef]

- Kenari, R.E.; Mohsenzadeh, F.; Amiri, Z.R. Antioxidant activity and total phenolic compounds of Dezful sesame cake extracts obtained by classical and ultrasound-assisted extraction methods. Food Sci. Nutr. 2014, 2, 426–435. [Google Scholar] [CrossRef] [PubMed]

- Yildirim, H.K. Assessment of Propolis Treated by Different Extraction Methods. Braz. Arch. Biol. Technol. 2022, 65, 2022210251. [Google Scholar] [CrossRef]

- Liazid, A.; Palma, M.; Brigui, J.; Barroso, C.G. Investigation on phenolic compounds stability during microwave-assisted extraction. J. Chromatogr. A 2007, 1140, 29–34. [Google Scholar] [CrossRef]

- Attanzio, A.; Tesoriere, L.; Allegra, M.; Livrea, M.A. Monofloral honeys by Sicilian black honeybee (Apis mellifera ssp. sicula) have high reducing power and antioxidant capacity. Heliyon 2016, 2, e00193. [Google Scholar] [CrossRef]

- Can, Z.; Yildiz, O.; Sahin, H.; Turumtay, E.A.; Silici, S.; Kolayli, S. An investigation of Turkish honeys: Their physico-chemical properties, antioxidant capacities and phenolic profiles. Food Chem. 2015, 180, 133–141. [Google Scholar] [CrossRef]

- Chua, L.S.; Rahaman, N.L.A.; Adnan, N.A.; Tan, T.T.E. Antioxidant Activity of Three Honey Samples in relation with Their Biochemical Components. J. Anal. Methods Chem. 2013, 2013, 313798. [Google Scholar] [CrossRef]

- Zivkovic, J.; Sunaric, S.; Stankovic, N.; Mihajilov-Krstev, T.; Spasic, A. Total Phenolic and Flavonoid Contents, Antioxidant and Antibacterial Activities of Selected Honeys against Human Pathogenic Bacteria. Acta Pol. Pharm. 2019, 76, 671–681. [Google Scholar] [CrossRef]

- Contreras-Martinez, C.S.; Macias-Nieves, J.P.; Garcia-Gonzalez, J.M.; Trejo-Guardado, V.I.; Carranza-Concha, J. Antioxidant Capacity and Phenolic Content of Bee Honey Produced in Zacatecas, Mexico. Rev. Fitotec. Mex. 2020, 43, 453–460. [Google Scholar] [CrossRef]

- Platzer, M.; Kiese, S.; Tybussek, T.; Herfellner, T.; Schneider, F.; Schweiggert-Weisz, U.; Eisner, P. Radical Scavenging Mechanisms of Phenolic Compounds: A Quantitative Structure-Property Relationship (QSPR) Study. Front. Nutr. 2022, 9, 882458. [Google Scholar] [CrossRef] [PubMed]

- Fuente-Ballesteros, A.; Priovolos, I.; Ares, A.M.; Samanidou, V.; Bernal, J. Green sample preparation methods for the analysis of bioactive compounds in bee products: A review. Adv. Sample Prep. 2023, 6, 100060. [Google Scholar] [CrossRef]

- Yalcin, G. Effects of Thermal Treatment, Ultrasonication, and Sunlight Exposure on Antioxidant Properties of Honey. Turk. J. Pharm. Sci. 2021, 18, 776–780. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Navajas, Y.; Viuda-Martos, M.; Fernandez-Lopez, J.; Zaldivar-Cruz, J.M.; Kuri, V.; Perez-Alvarez, J.A. Antioxidant Activity of Artisanal Honey from Tabasco, Mexico. Int. J. Food Prop. 2011, 14, 459–470. [Google Scholar] [CrossRef]

| No. | Monofloral Honey Samples | Collection Region | Collection Year |

|---|---|---|---|

| 1 | Mint (Mentha spp.) | Osekovo | 2020 |

| 2 | Mint (Mentha spp.) | Bjelovar | 2020 |

| 3 | Mint (Mentha spp.) | Popovača | 2021 |

| 4 | Mint (Mentha spp.) | Zagreb | 2021 |

| 5 | Fennel (Foeniculum vulgare) | Županja | 2021 |

| 6 | Raspberry (Rubus idaeus) | Vinkovci | 2021 |

| 7 | Lavender (Lavandula sp.) | Gorski kotar | 2021 |

| 8 | Lavender (Lavandula sp.) | Novi vinodolski | 2021 |

| 9 | Ailanthus (Ailanthus altissima) | Ičići | 2021 |

| 10 | Lovran Marron (Castanea sativa Mill.) | Lovran | 2021 |

| 11 | Sage (Salvia officinalis L.) | Omišalj | 2021 |

| 12 | Buckwheat (Fagopyrum esculentum Moench | Ludberg | 2021 |

| 13 | Marron (Castanea sativa Mill.) | Gorski kotar | 2021 |

| MAE | UAE | ||||||

|---|---|---|---|---|---|---|---|

| t (min) | T (°C) | Power (W) | TPC (mg GAE/100 g) | t (min) | T (°C) | Ultrasound Amplitude (%) | TPC (mg GAE/100 g) |

| 5 | 60 | 300 | 75.00 ± 2.09 | 10 | 35 | 30 | 55.86 ± 3.39 |

| 5 | 60 | 450 | 78.10 ± 3.79 | 10 | 35 | 60 | 71.27 ± 1.57 |

| 5 | 60 | 600 | 68.39 ± 2.27 | 10 | 35 | 90 | 61.35 ± 1.23 |

| 5 | 80 | 300 | 62.58 ± 3.07 | 10 | 60 | 30 | 63.61 ± 3.00 |

| 5 | 80 | 450 | 59.68 ± 3.40 | 10 | 60 | 60 | 62.46 ± 2.36 |

| 5 | 80 | 600 | 65.88 ± 3.05 | 10 | 60 | 90 | 74.21 ± 2.42 |

| 5 | 100 | 300 | 47.10 ± 1.97 | 10 | 90 | 30 | 71.12 ± 0.91 |

| 5 | 100 | 450 | 61.10 ± 1.81 | 10 | 90 | 60 | 74.12 ± 2.74 |

| 5 | 100 | 600 | 67.97 ± 3.18 | 10 | 90 | 90 | 58.19 ± 3.34 |

| 10 | 60 | 300 | 55.99 ± 3.56 | 20 | 35 | 30 | 61.40 ± 2.34 |

| 10 | 60 | 450 | 61.81 ± 1.50 | 20 | 35 | 60 | 74.41 ± 2.73 |

| 10 | 60 | 600 | 65.50 ± 3.54 | 20 | 35 | 90 | 76.35 ± 3.73 |

| 10 | 80 | 300 | 65.28 ± 0.78 | 20 | 60 | 30 | 70.04 ± 2.71 |

| 10 | 80 | 450 | 58.53 ± 2.41 | 20 | 60 | 60 | 72.38 ± 3.11 |

| 10 | 80 | 600 | 64.66 ± 2.65 | 20 | 60 | 90 | 59.68 ± 3.54 |

| 10 | 100 | 300 | 76.97 ± 2.42 | 20 | 90 | 30 | 61.79 ± 3.58 |

| 10 | 100 | 450 | 64.22 ± 2.11 | 20 | 90 | 60 | 68.71 ± 4.23 |

| 10 | 100 | 600 | 82.74 ± 1.81 | 30 | 90 | 90 | 88.95 ± 3.49 |

| 15 | 60 | 300 | 78.55 ± 4.15 | 30 | 35 | 30 | 65.52 ± 4.30 |

| 15 | 60 | 450 | 84.19 ± 0.57 | 30 | 35 | 60 | 69.21 ± 3.29 |

| 15 | 60 | 600 | 71.56 ± 1.53 | 30 | 35 | 90 | 67.49 ± 2.50 |

| 15 | 80 | 300 | 74.41 ± 2.74 | 30 | 60 | 30 | 70.10 ± 0.55 |

| 15 | 80 | 450 | 71.84 ± 1.44 | 30 | 60 | 60 | 67.56 ± 2.46 |

| 15 | 80 | 600 | 68.79 ± 2.92 | 30 | 60 | 90 | 63.78 ± 1.51 |

| 15 | 100 | 300 | 79.09 ± 3.21 | 30 | 90 | 30 | 66.87 ± 3.68 |

| 15 | 100 | 450 | 70.61 ± 1.27 | 30 | 90 | 60 | 76.67 ± 3.53 |

| 15 | 100 | 600 | 83.16 ± 0.96 | 30 | 90 | 90 | 87.86 ± 3.03 |

| MAE Parameters | TPC (mg GAE/100 g) |

|---|---|

| Time (min) | p < 0.01 * |

| 5 | 65.09 ± 2.14 a |

| 10 | 66.19 ± 1.99 a |

| 15 | 75.80 ± 1.35 b |

| Temperature (°C) | p = 0.17 |

| 60 | 71.01 ± 2.11 a |

| 80 | 65.74 ± 1.29 a |

| 100 | 70.33 ± 2.72 a |

| Microwave Power (W) | p = 0.55 |

| 300 | 68.33 ± 2.63 a |

| 450 | 67.79 ± 2.09 a |

| 600 | 70.96 ± 1.68 a |

| UAE Parameters | TPC (mg GAE/100 g) |

|---|---|

| Time (min) | p = 0.26 |

| 10 | 65.80 ± 1.65 a |

| 20 | 70.41 ± 2.17 a |

| 30 | 70.56 ± 1.77 a |

| Temperature (°C) | p = 0.18 |

| 35 | 66.99 ± 1.61 a |

| 50 | 67.09 ± 1.21 a |

| 65 | 72.70 ± 2.48 a |

| Ultrasound amplitude (%) | p = 0.03 * |

| 30 | 65.15 ± 1.25 a |

| 60 | 70.76 ± 1.11 b |

| 90 | 70.87 ± 2.72 b |

| Compound | Rt (min) | Precursor Ion (m/z) | Product Ion (m/z) | Collision Energy (V) | Cone (V) | Mode | Concentration Range (mg/100 g) |

|---|---|---|---|---|---|---|---|

| Kaempferol-3-glucoside ** | 1.387 | 449 | 287 | 5 | 100 | ESI (+) | 0.029–0.191 |

| Quercetin-3-glucoside ** | 1.713 | 465 | 303.1 | 5 | 100 | ESI (+) | 0.052–0.347 |

| Isorhamnetin | 2.085 | 317 | 257 | 10 | 100 | ESI (+) | 0.035–0.554 |

| Galangin ** | 2.248 | 269 | 168.9 | 24 | 170 | ESI (-) | 0.034–0.554 |

| Rutin ** | 6.811 | 611 | 303 | 15 | 120 | ESI (+) | 0.023–0.226 |

| Kaemferol | 9.600 | 287 | 165 | 10 | 100 | ESI (+) | 0.052–0.429 |

| Myricetin ** | 10.594 | 316.8 | 151 | 22 | 150 | ESI (-) | 0.016–0.912 |

| Quercetin | 12.069 | 303 | 153 | 5 | 100 | ESI (+) | 0.071–0.815 |

| TOTAL FLAVONOLS | 0.672–1.870 | ||||||

| Naringenin ** | 1.560 | 270.9 | 151 | 12 | 140 | ESI (-) | 0.015–0.078 |

| Pinocembrin ** | 11.677 | 257 | 257 | 5 | 100 | ESI (+) | 0.142–0.407 |

| TOTAL FLAVANONES | 0.176–0.422 | ||||||

| Apigenin ** | 1.577 | 271 | 153 | 30 | 80 | ESI (+) | 0.192–0.764 |

| Chrysin ** | 1.805 | 253 | 253 | 5 | 140 | ESI (-) | 0.165–0.981 |

| Apigenin-7-O-glucoside | 8.300 | 433 | 271 | 24 | 200 | ESI (+) | 0.027–0.183 |

| Luteolin ** | 10.965 | 287 | 153 | 25 | 140 | ESI (+) | 0.014–0.097 |

| TOTAL * FLAVONES | 0.653–1.787 | ||||||

| Chlorogenic acid ** | 2.517 | 353 | 191 | 10 | 80 | ESI (-) | 0.035–0.380 |

| Caffeic acid ** | 9.110 | 179 | 135 | 10 | 80 | ESI (-) | 0.110–0.250 |

| p-coumaric acid ** | 9.481 | 163 | 119 | 10 | 80 | ESI (-) | 0.212–1.991 |

| Ferulic acid ** | 9.777 | 193 | 149 | 6 | 100 | ESI (-) | 0.512–1.618 |

| TOTAL HCA | 1.108–4.009 | ||||||

| 3,4-Dihydroxybenzoic acid | 1.665 | 152.9 | 108 | 20 | 90 | ESI (-) | 0.058–0.475 |

| 2,5- Dihydroxybenzoic acid | 6.426 | 152.8 | 81.8 | 16 | 80 | ESI (-) | 0.041–0.428 |

| Vanillic acid ** | 10.152 | 166.9 | 122.9 | 6 | 90 | ESI (-) | 0.143–0.582 |

| p-hydroxybenzoic acid | 11.568 | 137 | 93 | 5 | 80 | ESI (-) | 0.018–3.102 |

| TOTAL HBA | 0.407–3.831 |

| Sample | Total Flavonols (mg/100 g) | Total Flavanones (mg/100 g) | Total Flavones (mg/100 g) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UAE | MAE | UAE | MAE | UAE | MAE | ||||

| p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | ||||

| 1 | p < 0.001 * | 1.22 ± 0.23 f,A | 1.28 ± 0.02 f,B | p = 0.001 * | 0.25 ± 0.06 d,B | 0.21 ± 0.01 c,A | p = 0.003 * | 1.20 ± 0.14 f,B | 1.18 ± 0.02 e,A |

| 2 | p = 0.002 * | 1.67 ± 0.26 k,B | 1.61 ± 0.02 k,A | p = 0.001 * | 0.18 ± 0.07 a,A | 0.27 ± 0.05 f,B | p < 0.001 * | 1.06 ± 0.11 e,A | 1.29 ± 0.03 i,B |

| 3 | p = 0.001 * | 1.35 ± 0.21 h,A | 1.42 ± 0.07 i,B | p < 0.001 * | 0.32 ± 0.04 f,A | 0.42 ± 0.04 k,B | p = 0.001 * | 1.53 ± 0.14 l,B | 1.51 ± 0.03 l,A |

| 4 | p < 0.001 * | 1.48 ± 0.08 j,A | 1.58 ± 0.03 j,B | p < 0.001 * | 0.36 ± 0.04 g,B | 0.23 ± 0.02 de,A | p < 0.001 * | 1.41 ± 0.02 i,B | 0.85 ± 0.02 c,A |

| 5 | p < 0.001 * | 0.75 ± 0.09 b,A | 1.28 ± 0.04 f,B | p = 0.001 * | 0.22 ± 0.01 c,B | 0.20 ± 0.01 b,A | p < 0.001 * | 0.80 ± 0.03 b,B | 0.52 ± 0.02 b,A |

| 6 | p < 0.001 * | 1.03 ± 0.09 d,B | 0.94 ± 0.03 c,A | p = 0.003 * | 0.33 ± 0.02 f,A | 0.34 ± 0.02 i,B | p < 0.001 * | 1.46 ± 0.06 j,B | 1.27 ± 0.04 h,A |

| 7 | p < 0.001 * | 0.83 ± 0.06 c,A | 1.13 ± 0.07 d,B | p < 0.001 * | 0.20 ± 0.04 b,A | 0.38 ± 0.06 j,B | p < 0.001 * | 1.03 ± 0.06 c,A | 1.32 ± 0.03 j,B |

| 8 | p < 0.001 * | 1.03 ± 0.16 d,A | 1.15 ± 0.09 e,B | p < 0.001 * | 0.39 ± 0.07 i,B | 0.25 ± 0.06 e,A | p < 0.001 * | 1.79 ± 0.05 m,B | 1.62 ± 0.01 m,A |

| 9 | p < 0.001 * | 1.45 ± 0.05 i,B | 1.35 ± 0.08 h,A | p < 0.001 * | 0.38 ± 0.01 h,B | 0.31 ± 0.05 h,A | p < 0.001 * | 1.38 ± 0.04 h,B | 0.30 ± 0.05 a,A |

| 10 | p = 0.028 * | 1.34 ± 0.21 g,B | 1.32 ± 0.05 g,A | p = 0.002 * | 0.30 ± 0.03 e,B | 0.28 ± 0.05 g,A | p < 0.001 * | 1.05 ± 0.10 d,B | 0.27 ± 0.03 a,A |

| 11 | p < 0.001 * | 0.67 ± 0.09 a,A | 0.79 ± 0.06 a,B | p = 0.032 * | 0.18 ± 0.04 a,A | 0.19 ± 0.04 a,B | p < 0.001 * | 1.48 ± 0.06 k,B | 1.35 ± 0.07 k,A |

| 12 | p = 0.004 * | 1.87 ± 0.07 l,B | 1.85 ± 0.04 l,A | p < 0.001 * | 0.36 ± 0.01 g,B | 0.24 ± 0.02 d,A | p = 0.002 * | 1.29 ± 0.07 g,B | 1.26 ± 0.04 g,A |

| 13 | p < 0.001 * | 1.04 ± 0.06 e,B | 0.81 ± 0.04 b,A | p < 0.001 * | 0.41 ± 0.02 j,B | 0.27 ± 0.03 f,A | p = 0.001 * | 0.65 ± 0.03 a,A | 0.67 ± 0.07 b,B |

| Mean | 1.21 | 1.27 | 0.30 | 0.28 | 1.24 | 1.03 | |||

| Sample | Total HCA (mg/100 g) | Total HBA (mg/100 g) | Total Phenols (mg/100 g) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UAE | MAE | UAE | MAE | UAE | MAE | ||||

| p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | ||||

| 1 | p < 0.001 * | 2.53 ± 0.01 g,B | 2.16 ± 0.08 e,A | p < 0.001 * | 2.60 ± 0.04 l,A | 2.85 ± 0.01 k,B | p = 0.001 * | 7.81 ± 0.47 i,B | 7.69 ± 0.03 j,A |

| 2 | p < 0.001 * | 2.99 ± 0.17 k,B | 2.58 ± 0.04 h,A | p < 0.001 * | 1.99 ± 0.02 h,B | 1.87 ± 0.04 e,A | p < 0.001 * | 7.90 ± 0.62 j,B | 7.61 ± 0.07 i,A |

| 3 | p < 0.001 * | 1.81 ± 0.03 c,A | 2.04 ± 0.08 d,B | p = 0.138 | 0.70 ± 0.06 b,A | 0.68 ± 0.05 b,A | p < 0.001 * | 5.71 ± 0.48 b,A | 6.08 ± 0.03 d,B |

| 4 | p < 0.001 * | 2.40 ± 0.10 f,A | 2.76 ± 0.07 k,B | p < 0.001 * | 1.96 ± 0.04 g,B | 1.83 ± 0.04 d,A | p < 0.001 * | 7.61 ± 0.04 h,B | 7.23 ± 0.03 h,A |

| 5 | p < 0.001 * | 2.97 ± 0.40 j,B | 2.71 ± 0.05 j,A | p < 0.001 * | 1.91 ± 0.03 f,A | 2.21 ± 0.04 i,B | p < 0.001 * | 6.65 ± 0.53 e,A | 6.92 ± 0.06 f,B |

| 6 | p < 0.001 * | 2.72 ± 0.22 h,B | 2.60 ± 0.06 i,A | p < 0.001 * | 1.82 ± 0.06 d,A | 1.90 ± 0.02 f,B | p < 0.001 * | 7.35 ± 0.02 g,B | 7.05 ± 0.09 g,A |

| 7 | p < 0.001 * | 2.90 ± 0.08 i,B | 2.48 ± 0.06 g,A | p < 0.001 * | 3.83 ± 0.20 m,B | 3.49 ± 0.04 l,A | p = 0.017 * | 8.78 ± 0.33 l,A | 8.80 ± 0.05 l,B |

| 8 | p < 0.001 * | 3.10 ± 0.03 l,B | 2.87 ± 0.04 l,A | p < 0.001 * | 0.41 ± 0.05 a,A | 0.45 ± 0.02 a,B | p < 0.001 * | 6.72 ± 0.35 f,B | 6.34 ± 0.22 e,A |

| 9 | p < 0.001 * | 1.26 ± 0.02 b,B | 1.11 ± 0.07 a,A | p < 0.001 * | 2.10 ± 0.08 i,B | 2.05 ± 0.07 g,A | p < 0.001 * | 6.57 ± 0.06 d,B | 6.01 ± 0.03 c,A |

| 10 | p < 0.001 * | 4.01 ± 0.05 m,B | 3.84 ± 0.07 m,A | p < 0.001 * | 2.15 ± 0.07 j,B | 2.05 ± 0.06 g,A | p < 0.001 * | 8.85 ± 0.46 m,B | 7.76 ± 0.07 j,A |

| 11 | p < 0.001 * | 1.94 ± 0.03 d,B | 1.70 ± 0.02 c,A | p < 0.001 * | 1.65 ± 0.02 c,A | 1.80 ± 0.05 c,B | p < 0.001 * | 5.92 ± 0.25 c,B | 5.83 ± 0.04 b,A |

| 12 | p < 0.001 * | 2.27 ± 0.03 e,A | 2.40 ± 0.04 f,B | p < 0.001 * | 2.17 ± 0.02 k,A | 2.31 ± 0.05 j,B | p < 0.001 * | 7.96 ± 0.13 k,A | 8.07 ± 0.16 k,B |

| 13 | p < 0.001 * | 1.04 ± 0.08 a,A | 1.29 ± 0.02 b,B | p < 0.001 * | 1.89 ± 0.04 e,A | 2.18 ± 0.07 h,B | p < 0.001 * | 5.04 ± 0.15 a,A | 5.22 ± 0.13 a,B |

| Mean | 2.46 | 2.35 | 1.94 | 1.97 | 7.14 | 6.97 | |||

| Sample | ORAC (µmol TE/100 g) | ABTS (µmol TE/100 g) | DPPH (µmol TE/100 g) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UAE | MAE | UAE | MAE | UAE | MAE | ||||

| p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | p < 0.001 * | ||||

| 1 | p < 0.001 * | 553.9 ± 0.1 d,A | 590.3 ± 0.9 fg,B | p < 0.001 * | 587.80 ± 0.2 a,B | 580.32 ± 0.4 a,A | p = 0.002 * | 243.99 ± 0.1 m,B | 243.26 ± 0.4 m,A |

| 2 | p = 0.903 | 575.7 ± 0.7 h,A | 578.2 ± 4.8 ef,A | p < 0.001 * | 635.39 ± 0.3 c,B | 593.39 ± 0.2 c,A | p < 0.001 * | 237.35 ± 0.6 k,A | 240..3 ± 0.3 l,B |

| 3 | p = 0.009 * | 603.4 ± 0.8 k,B | 597.4 ± 0.3 fg,A | p < 0.001 * | 642.85 ± 0.3 d,B | 606.44 ± 0.4 d,A | p < 0.001 * | 225.23 ± 0.3 i,A | 235.23 ± 0.3 j,B |

| 4 | p = 0.016 * | 597.9 ± 0.9 j,B | 592.3 ± 0.5 fg,A | p < 0.001 * | 645.64 ± 0.4 d,A | 653.11 ± 0.4 l,B | p < 0.001 * | 228.63 ± 0.2 j,A | 230.75 ± 0.5 i,B |

| 5 | p = 0.006 * | 565.1 ± 0.3 ef,B | 561.5 ± 0.3 de,A | p < 0.001 * | 631.62 ± 0.7 c,A | 636.32 ± 0.3 g,B | p < 0.001 * | 204.33 ± 0.3 e,A | 211.49 ± 0.2 e,B |

| 6 | p < 0.001 * | 473.0 ± 0.3 b,A | 510.2 ± 0.4 b,B | p < 0.001 * | 666.19 ± 0.1 e,B | 654.99 ± 0.2 m,A | p < 0.001 * | 200.41 ± 0.2 b,A | 210.23 ± 0.3 d,B |

| 7 | p < 0.001 * | 562.9 ± 0.2 e,A | 574.0 ± 0.1 def,B | p < 0.001 * | 646.58 ± 0.3 d,A | 651.25 ± 0.3 k,B | p < 0.001 * | 211.49 ± 0.1 g,A | 215.76 ± 0.4 f,B |

| 8 | p = 0.002 * | 568.2 ± 1.0 g,B | 549.8 ± 0.6 cd,A | p < 0.001 * | 643.79 ± 0.2 d,A | 645.64 ± 0.4 i,B | p < 0.001 * | 209.15 ± 0.4 f,A | 217.29 ± 1.1 g,B |

| 9 | p = 0.002 * | 581.9 ± 0.3 i,B | 575.8 ± 0.2 def,A | p < 0.001 * | 647.51 ± 0.3 d,B | 637.24 ± 0.4 h,A | p < 0.001 * | 211.66 ± 0.3 h,A | 219.70 ± 0.3 h,B |

| 10 | p < 0.001 * | 583.3 ± 0.5 i,B | 527.5 ± 0.4 bc,A | p < 0.001 * | 636.31 ± 0.3 c,A | 647.52 ± 0.3 j,B | p < 0.001 * | 203.99 ± 0.2 d,A | 206.30 ± 0.2 c,B |

| 11 | p = 0.078 | 381.8 ± 0.5 a,A | 380.1 ± 0.6 a,A | p < 0.001 * | 664.31 ± 0.4 e,B | 627.00 ± 0.1 f,A | p < 0.001 * | 190.40 ± 0.4 a,B | 186.83 ± 0.4 a,A |

| 12 | p = 0.003 * | 566.5 ± 0.5 fg,B | 558.9 ± 0.3 de,A | p < 0.001 * | 615.78 ± 0.4 d,B | 585.93 ± 0.3 b,A | p = 0.002 * | 240.94 ± 0.4 l,B | 240.05 ± 0.3 k,A |

| 13 | p < 0.001 * | 525.0 ± 0.2 c,A | 615.0 ± 0.2 g,B | p = 0.012 * | 645.46 ± 0.3 b,B | 613.92 ± 0.3 e,A | p < 0.001 * | 201.30 ± 0.3 c,A | 204.51 ± 0.3 b,B |

| Mean | 549.1 | 554.7 | 639.17 | 625.62 | 216.07 | 220.13 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedisić, S.; Čulina, P.; Pavlešić, T.; Vahčić, N.; Elez Garofulić, I.; Zorić, Z.; Dragović-Uzelac, V.; Repajić, M. Efficiency of Microwave and Ultrasound-Assisted Extraction as a Green Tool for Polyphenolic Isolation from Monofloral Honeys. Processes 2023, 11, 3141. https://doi.org/10.3390/pr11113141

Pedisić S, Čulina P, Pavlešić T, Vahčić N, Elez Garofulić I, Zorić Z, Dragović-Uzelac V, Repajić M. Efficiency of Microwave and Ultrasound-Assisted Extraction as a Green Tool for Polyphenolic Isolation from Monofloral Honeys. Processes. 2023; 11(11):3141. https://doi.org/10.3390/pr11113141

Chicago/Turabian StylePedisić, Sandra, Patricija Čulina, Tomislav Pavlešić, Nada Vahčić, Ivona Elez Garofulić, Zoran Zorić, Verica Dragović-Uzelac, and Maja Repajić. 2023. "Efficiency of Microwave and Ultrasound-Assisted Extraction as a Green Tool for Polyphenolic Isolation from Monofloral Honeys" Processes 11, no. 11: 3141. https://doi.org/10.3390/pr11113141