Bed Separation Formation Mechanism and Water Inrush Evaluation in Coal Seam Mining under a Karst Cave Landform

Abstract

:1. Introduction

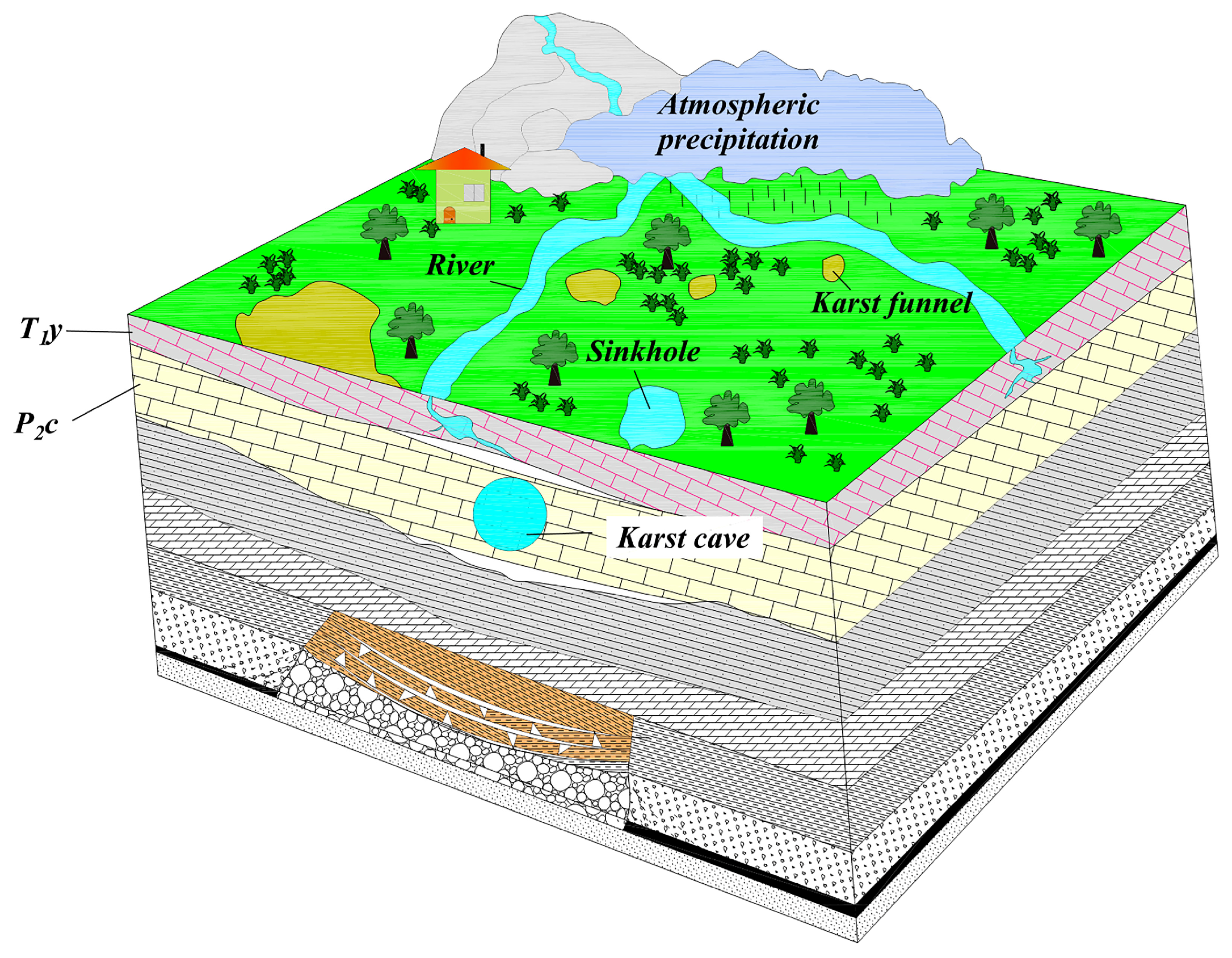

2. Engineering Background

3. The Dynamic Evolution of Bed Separation in a Karst Cave Landform

3.1. Separation Zone Formation Mechanism

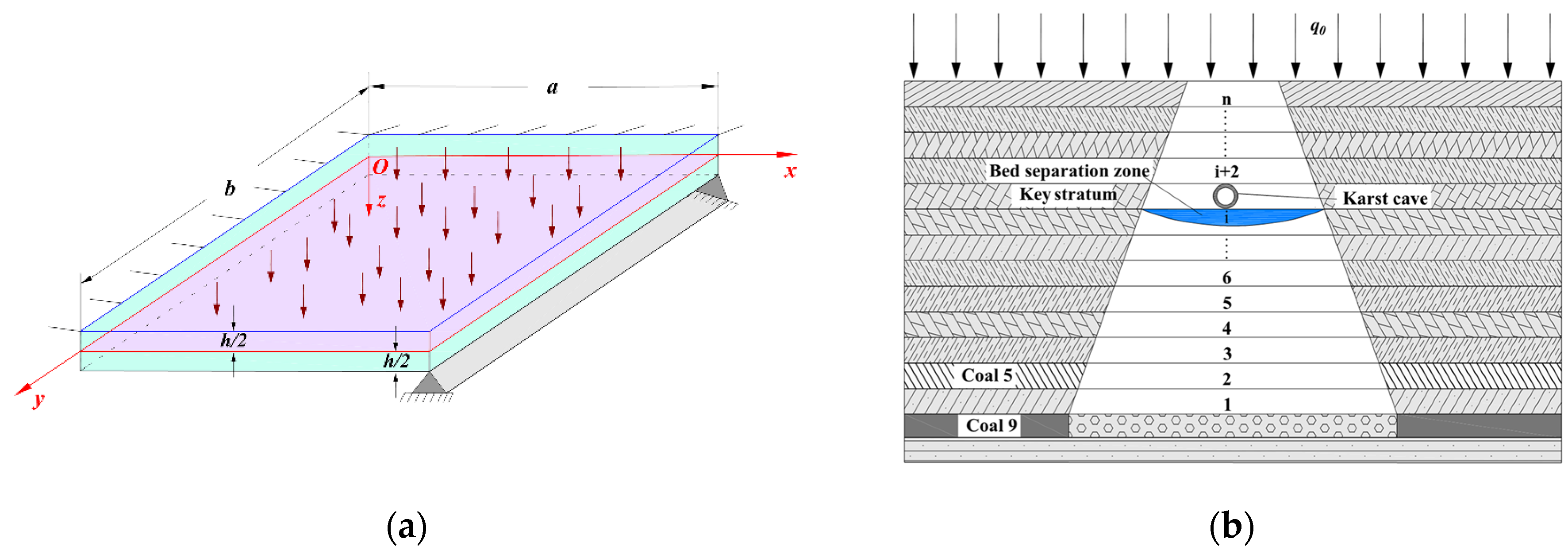

3.2. Mechanical Model of Bed Separation Space Development

- (1).

- Mechanical model of periodic separation development under uniform distribution load

- (2).

- Mechanical analysis of a circular cave

3.3. Bed Separation Location

- a.

- The hard rock formations are identified from the bottom up, as follows:

- b.

- The load of the n + 1 layer on the first layer is calculated. A bed separation is formed when the following relationship is satisfied:

- c.

- The deflections of the different rock strata are calculated using Equation (15), when the following relationship is satisfied:

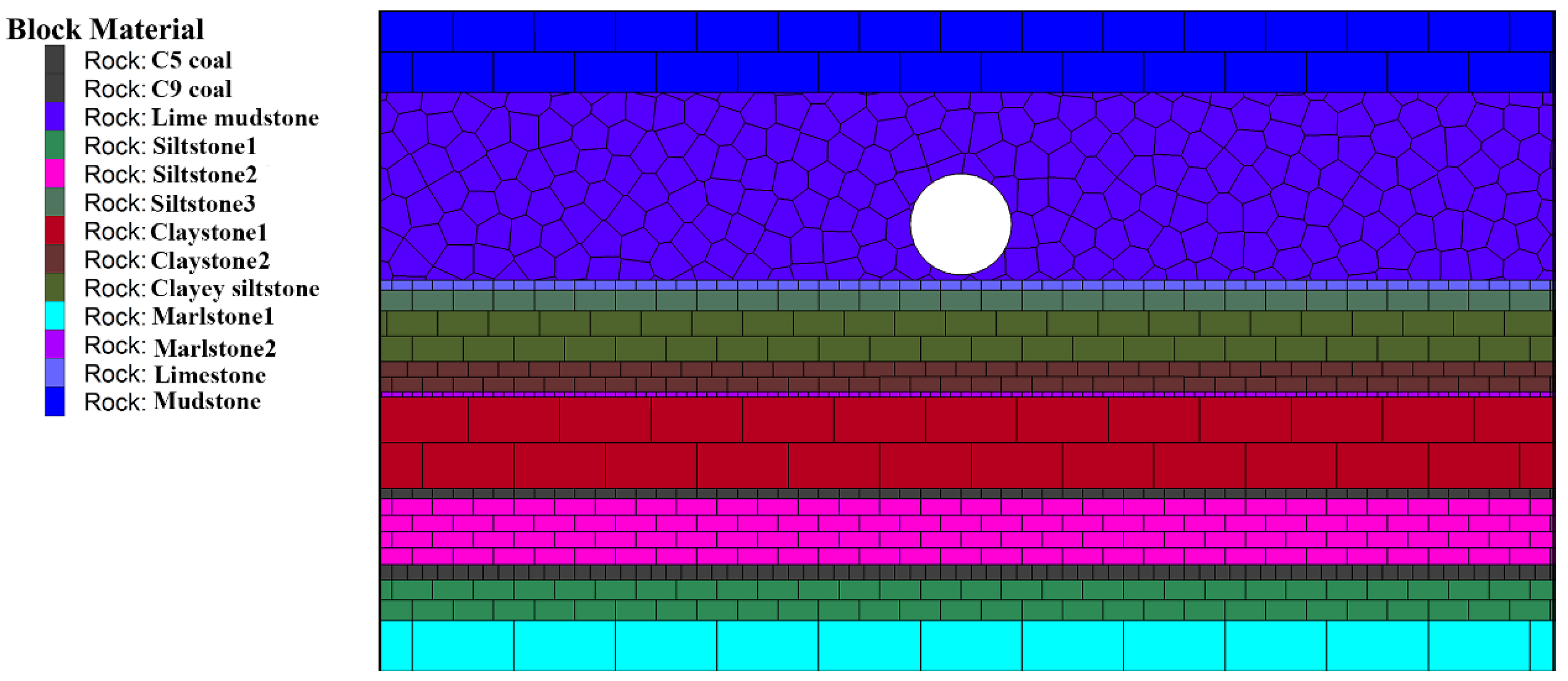

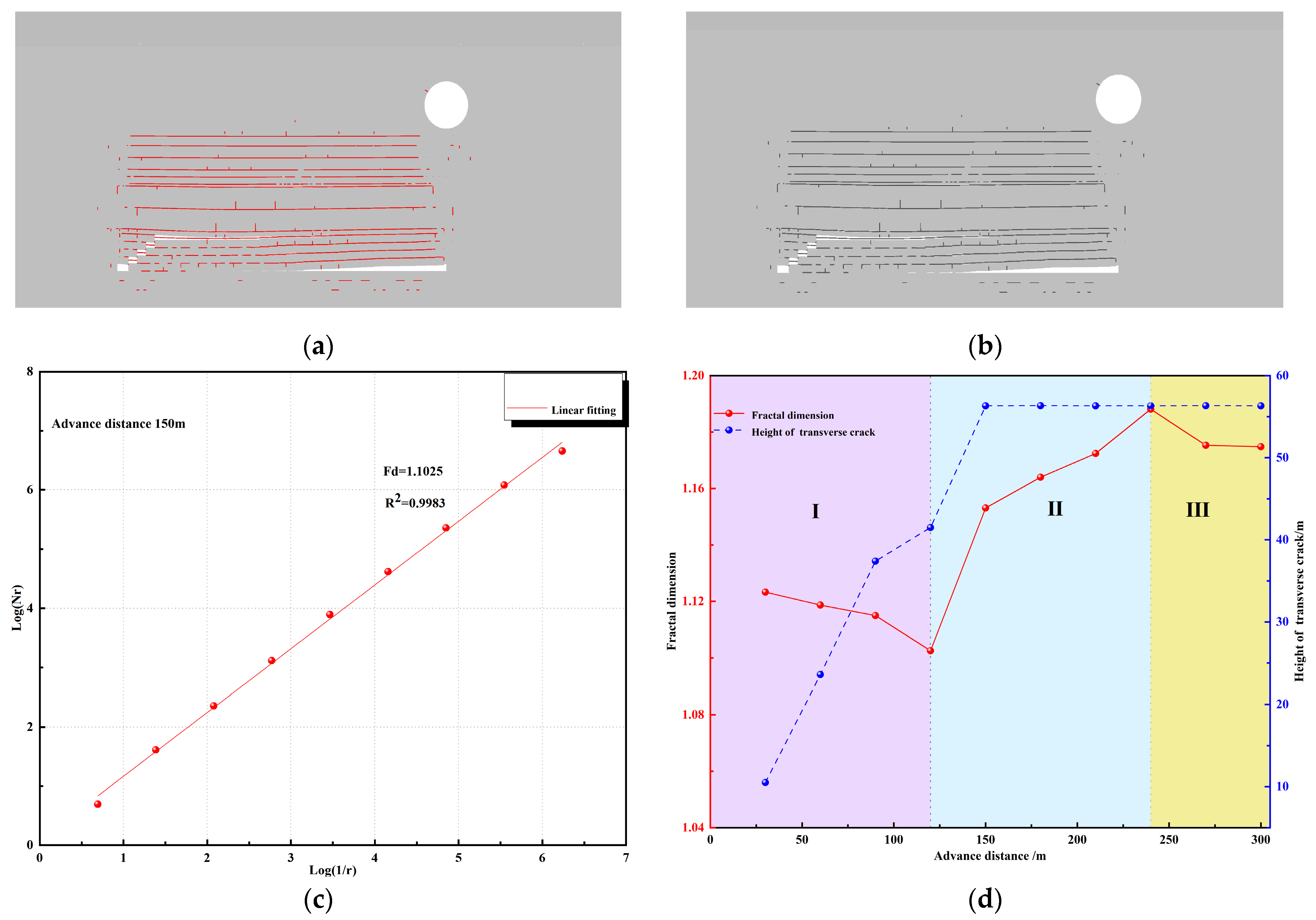

4. Evolution and Fractal Characteristics of Overburden Fracture under a Circular Cave

4.1. Numerical Model

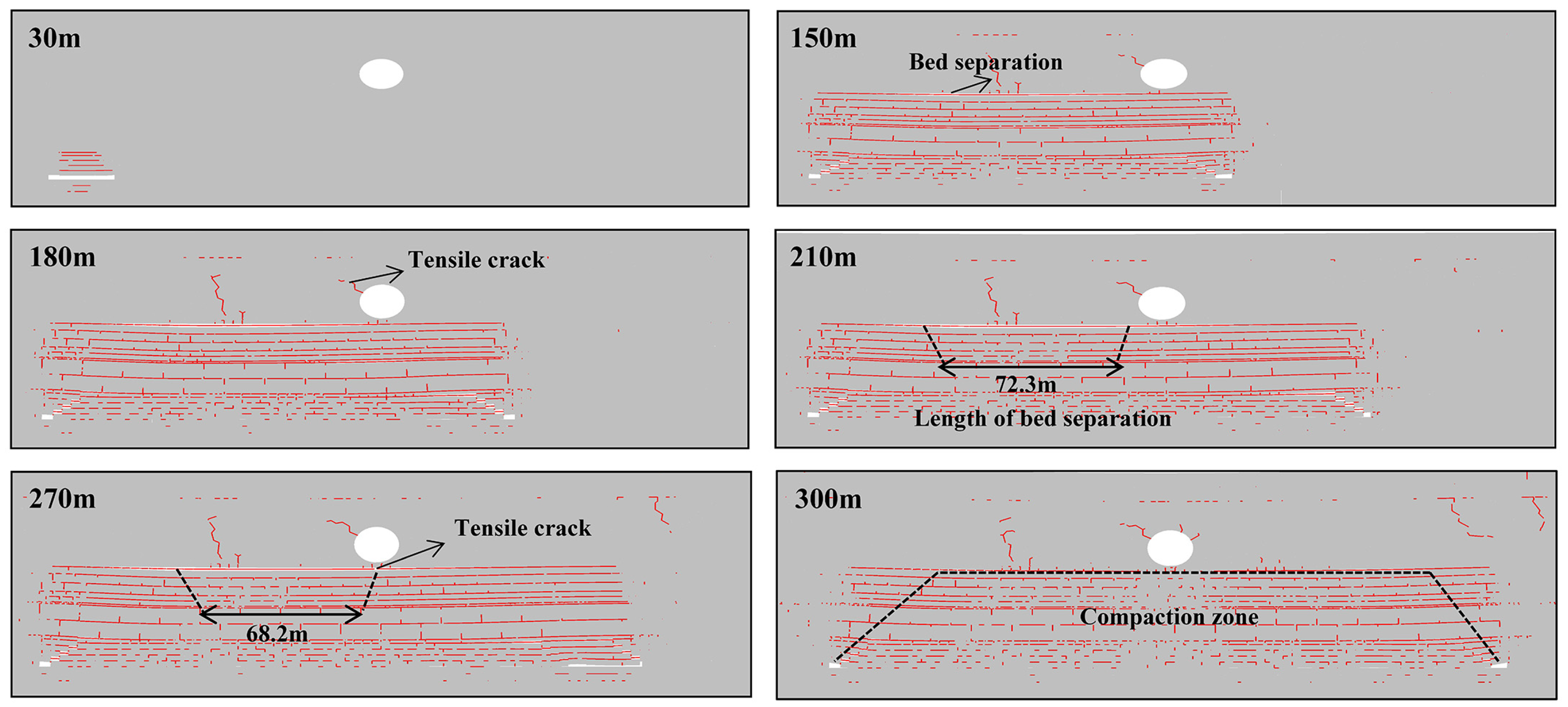

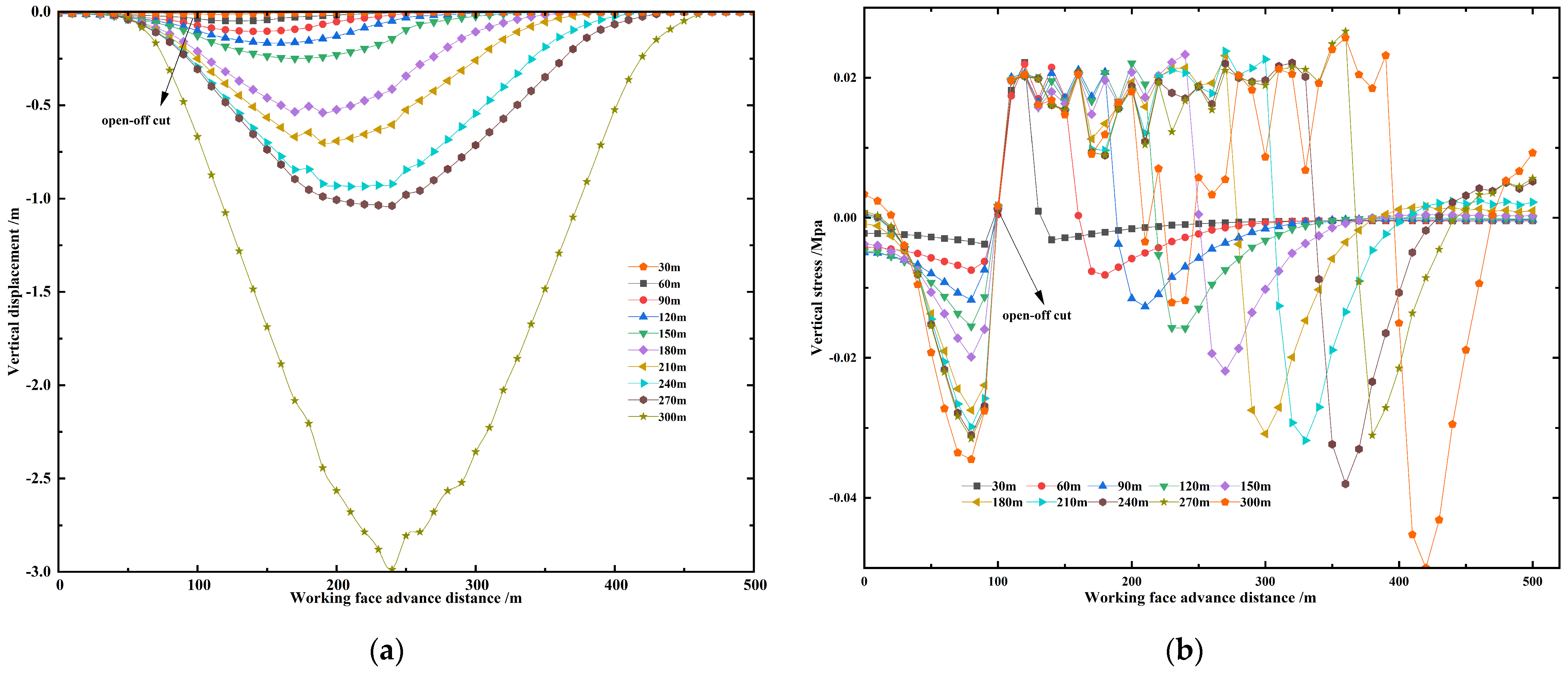

4.2. Dynamic Laws and Fractal Characteristics of Overlying Strata

- (1).

- Evolution pattern of the stratification and the movement of overburden

- (2).

- Fractal dimension calculation method and dimension features

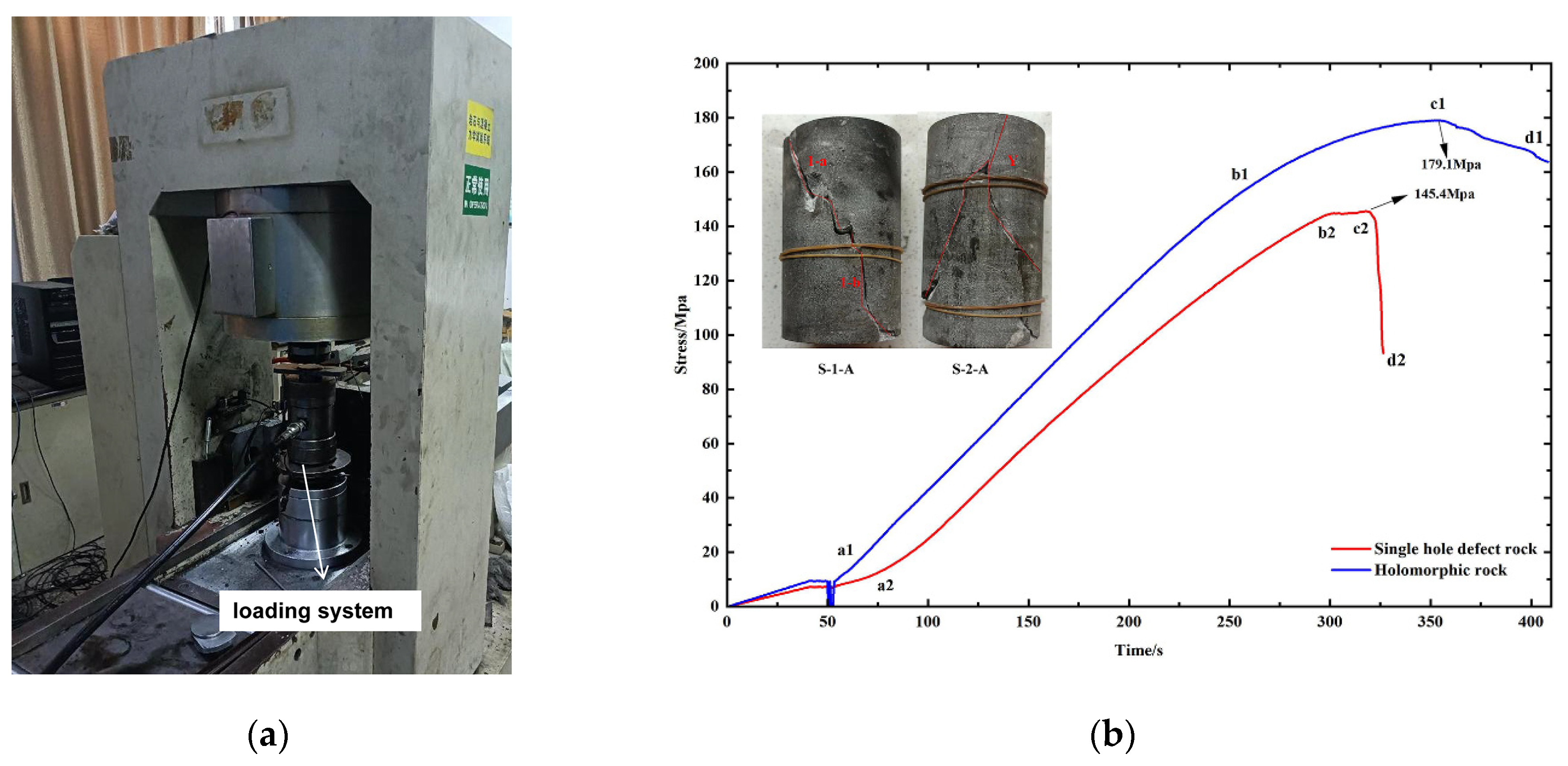

5. Rock Mechanics Test and the Overlying Strata Measurement

5.1. Rock Mechanics Test

- (1).

- Preparation of rock samples

- (2).

- Test process and results analysis

5.2. Double-Ended Water Plugging Test

5.3. Drilling Peeking Method

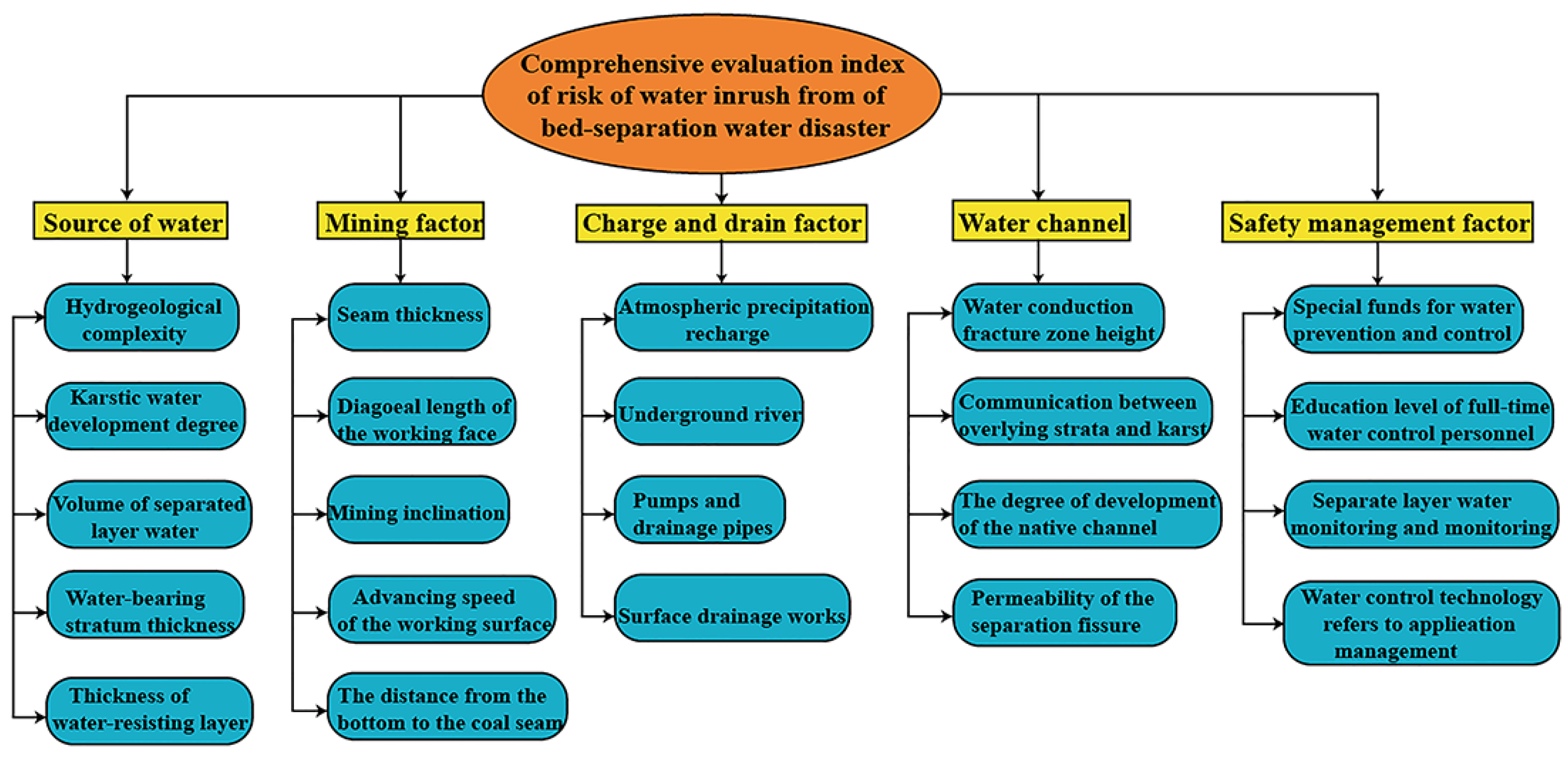

6. Evaluation Method of Water Inrush in the Bed Separation Based on the Cloud Model and Improved Fusion Weighting

6.1. Construction of a Comprehensive Indicator System for the Risk of Water Inrush from Separated Layers

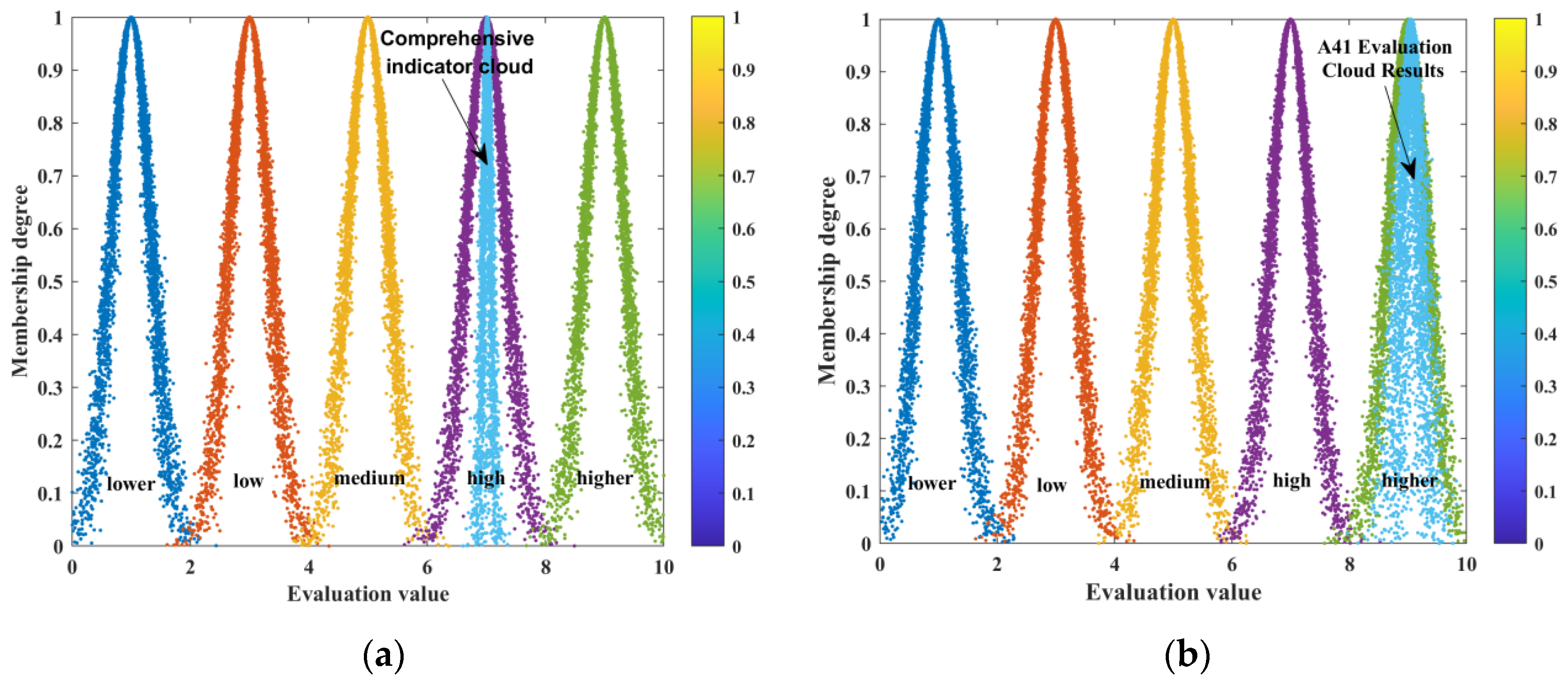

6.2. Risk Assessment of Water Inrush in the Bed Separation Based on Cloud Model

- (1).

- The risk assessment set for water inrush in the cloud model

- (2).

- Improving the determination of indicator weights in the weighted fusion method

- a.

- Improving the Analytic Hierarchy Process to determine subjective weights

- b.

- Improving the entropy weight method to determine objective weights

- c.

- To make the results more accurate, the weights W1 (j) and W2 (j) obtained by the analytic hierarchy process (AHP) and the entropy weight method should be as close as possible. Using Equation (19), Lagrangian multiplication for optimization, the weight W (j) is recalculated to obtain the weights of each secondary indicator and cloud feature parameter, as shown in Table 4.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Q.; Zhao, S.Q.; Sun, W.J. Classification of the hydrogeological type of coal mine and analysis of its characteristics in China. J. China Coal Soc. 2013, 38, 902–905. [Google Scholar]

- Cao, X.F.; Li, H.L. Typical Zone Division of Karst Development in China. Adv. Geosci. 2018, 8, 845–851. [Google Scholar] [CrossRef]

- Favara, R.; Cangemi, M.; Grassa, F. Chemical and isotopic signature of groundwater in the Santa Ninfa karst system and possible inferences on neotectonics. Ann. Geophys. 2020, 62, 1–13. [Google Scholar] [CrossRef]

- Ivanik, O.; Shevchuk, V.; Kravchenko, D. Geological and Geomorphological Factors of Natural Hazards in Ukrainian Carpathians. J. Ecol. Eng. 2019, 20, 177–186. [Google Scholar] [CrossRef] [PubMed]

- Batugin, A.; Batugin, A.S. Reactivation of major faults during strong rock bursts as realization of tectonic process. In Proceedings of the 14th ISRM Congress, Foz do Iguaçu, Brazil, 13–18 September 2019. Paper Presented at the Rock Mechanics for Natural Resources and Infrastructure. [Google Scholar]

- Gou, R.; Jiang, C.; Liu, Y.; Wang, C.; Li, Y. Study on Fractal Characteristics of Evolution of Mining-Induced Fissures in Karst Landform. Energies 2022, 15, 5372. [Google Scholar] [CrossRef]

- Luo, X.Y. Study on Mechanism and Application of Water Damage Caused by Roof Separation in Longfeng District, Guizhou Province. Master’s Thesis, Guizhou University, Guiyang, China, 2023; pp. 1–85. [Google Scholar]

- Palarski, J. The experimental and practical results of applying backfill. In Innovations in Mining Backfill Technology, Proceedings of the 4th International Symposium on Mining with Backfill Montreal, 2–5 October 1989, Montreal, QC, USA; CRC Press: Boca Raton, FL, USA, 1989. [Google Scholar]

- Lv, Q.; Li, X.; Li, W. Risk Evaluation of Bed-Separation Water Inrush: A Case Study in the Yangliu Coal Mine, China. Mine Water Environ. 2018, 37, 288–299. [Google Scholar]

- Lv, Y.G.; Qiao, W. Discussion on overburden zoning model after mining and its engineering significance. Coal Geol. Explor. 2021, 49, 147–155. [Google Scholar]

- Fei, G.; Yun, S.; Mine, L.C. Water inrush from overburden strata separation reservoir and the countermeasures in lijialou coal mine. J. North China Inst. Sci. Technol. 2017, 14, 12–16. [Google Scholar]

- Qiao, W.; Li, W.P.; Wang, Z.W. Formation mechanism, disaster-causing mechanism and prevention technology of roof bed separation water disaster in coal mines. J. China Coal Soc. 2021, 46, 507–522. [Google Scholar]

- Cheng, X.G.; Qiao, W.; Li, G.F. Risk assessment of roof water disaster due to multi-seam mining at Wulunshan Coal Mine in China. Arab. J. Geosci. 2021, 14, 1116. [Google Scholar] [CrossRef]

- Qiao, W.; Liu, M.N.; Li, L.G. Disaster mechanism induced by structure evolution of “water-inrushing separation zone” of mining rock mass and prediction method of water inrush from separation layer. J. China Coal Soc. 2023, 48, 818–832. [Google Scholar]

- Xu, J.P.; Zhou, Y.; Pu, Z.H. Calculation method of separated water accumulation in the process of separated water inrush and its forecast: Taking the water inrush at 1304 working face of Zhaoxian Coal Mine in Shaanxi Province as an example. J. China Coal Soc. 2022, 47, 3084–3090. [Google Scholar]

- Cao, H.D. Study on Disaster Mechanism and Prevention and Control Technology of Overlying Strata Separation Water Body in Coal Seam Mining. Ph.D. Thesis, Graduate School of Coal Science Research Institute, Beijing, China, 2018. [Google Scholar]

- Fan, K.; Li, W.; Wang, Q. Formation mechanism and prediction method of water inrush from separated layers within coal seam mining: A case study in the Shilawusu mining area, China. Eng. Fail. Anal. 2019, 10, 158–172. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, W.; Xu, J. High-intensity longwall mining-induced ground subsidence in Shendong coalfield, China. Int. J. Rock Mech. Min. Sci. 2021, 14, 104730. [Google Scholar] [CrossRef]

- Xu, G.S.; Luo, X.K.; Su, D.G.; Li, H.G. Research on Mechanism of Water Inrush from Separated Layers under Thick Limestone in Northern Guizhou Coalfield. Coal Technol. 2021, 40, 80–83. [Google Scholar]

- Gui, H.R.; Lin, M.; Song, X. Identification and application of roof bed separation (water) in coal mines. Mine Water Environ. 2018, 37, 376–384. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Li, X.Y.; Yang, K.; Wei, Z. The spatiotemporal characteristics of coupling effect between roof and backfill body in dense backfill mining. Geofluids 2021, 2021, 6684237. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, K.; Zhang, W. Further research on “three maps-two predictions” method for prediction on coal seam roof water-bursting risk. J. China Coal Soc. 2016, 41, 1341–1347. [Google Scholar]

- Xiao, L.L.; Li, F.; Niu, C.; Dai, G.L.; Qiao, Q.; Lin, C.S. Evaluation of Water Inrush Hazard in Coal Seam Roof Based on the AHP-CRITIC Composite Weighted Method. Energies 2022, 14, 114. [Google Scholar] [CrossRef]

- Liu, W.T.; Zheng, Q.S.; Pang, L.F.; Dou, W.M.; Meng, X.X. Study of roof water inrush forecasting based on EM-FAHP two-factor model. Math. Biosci. Eng. 2021, 18, 4987–5005. [Google Scholar] [CrossRef]

- Li, B.; Wei, T.; Liu, Z.J. Construction of evaluation index system for water abundance of karst aquifers and risk assessment of water inrush on coal seam roof in Southwest of China. J. China Coal Soc. 2022, 47, 152–159. [Google Scholar]

- Li, J.G. Evaluation of water-richness in weathering bedrock aquifer of roof. Coal Technol. 2019, 38, 105–107. [Google Scholar]

- Li, M.; Wang, H.T.; Wang, D. Risk assessment of gas explosion in coal mines based on fuzzy AHP and bayesian network. Process Saf. Environ. Prot. 2020, 135, 207–218. [Google Scholar] [CrossRef]

- Liu, J.; Yang, B.; Yuan, S.; Li, L.; Duan, L. A Fuzzy Analytic Hierarchy Process Model to Assess the Risk of Disaster Reduction Due to Grouting in Coal Mining. J. Math. 2020, 13, 227. [Google Scholar] [CrossRef]

- Wang, X.X. Risk assessment of long-span tunnel based on AHP and expert scoring method. Mod. Tunn. Technol. 2020, 57 (Suppl. S1), 233–240. [Google Scholar]

- Zhang, K. Study on the Risk Assessment of Water and Sand Inrush in Thick Unconsolidated Strata Based on Combined Objective Weighting Method. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2018; pp. 1–128. [Google Scholar]

- Ruo, X.H. The evaluation of groundwater environmental quality in bozhou based on fuzzy mathematics comprehensive evaluation. Ground Water 2018, 40, 27–30. [Google Scholar]

- Zhang, Y.Q.; He, N.; Li, Y.J. Risk Assessment of Water Environment Treatment PPP Projects Based on a Cloud Model. Discret. Dyn. Nat. Soc. 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, J.Y.; Lian, Y.P. Cloud model combined with multiple weighting methods to evaluate hydrological alteration and its contributing factors. J. Hydrol. 2022, 610, 127794. [Google Scholar] [CrossRef]

- Zhao, Z.M.; Ma, D.; Wang, P.Y. Study on Safety Risk Assessment of Hazardous Materials Transportation Enterprises Based on Combined Weighting and Cloud Model. Saf. Secur. 2023, 44, 23–29. [Google Scholar]

- Hu, B.; Li, X.J.; Dai, F.R. Dangerous rock mass risk assessment based on combination weighting and cloud model. Yangtze River. 2023, 54, 145–150. [Google Scholar]

- Wang, X.; Wu, W.; Wu, B. Grouting of bed separation spaces to control sliding of the high-located main key stratum during longwall mining. Q. J. Eng. Geol. Hydro-Geol. 2020, 53, 569–578. [Google Scholar] [CrossRef]

- Ma, H.W. Spatiotemporal Evolution of Bed Separation due to Mining and the Dynamic Hazards Identification for Groundwater Inrush. China Univ. Min. Technol. 2020, 3, 1–165. [Google Scholar]

- Ji, J.S.; Li, Z.H.; Yang, K.; Zhou, G.H.; Ma, G.J. Research on Formation Mechanism and Evolution Pattern of Bed Separation Zone during Repeated Mining in Multiple Coal Seams. Geofluids 2022, 2022, 4290063. [Google Scholar] [CrossRef]

- Zhou, Z. Study on the development law of mining fracture and karst surface collapse when mining in karst area. Hunan Univ. Sci. Technol. 2017, 7, 1–141. [Google Scholar]

- Xu, J.L.; Qian, M.G.; Jin, H.W. Study and application of bed separation distribution and development in the process of strata movement. Chin. J. Geotech. Eng. 2004, 2004, 632–636. [Google Scholar]

- Chen, Y.G.; Qian, M.G. Control of Surrounding Rocks in Coal Mines in China. China Univ. Min. Technol. Press 1994, 5, 23–54. [Google Scholar]

- Zhao, Y.; Wang, C.; Ning, L.; Zhao, H.; Bi, J. Pore and fracture development in coal under stress conditions based on nuclear magnetic resonance and fractal theory. Fuel J. Fuel Sci. 2022, 309, 58–73. [Google Scholar] [CrossRef]

- Sun, F.; Pan, R.; Zhu, X.Y.; Chen, T.L. Meso-mechanical simulation of fracture grouting under fluid-solid coupling environment and engineering applications. Appl. Mech. Mater. 2014, 477–478, 485–491. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, B.; Li, C.; Cao, C.; Sui, Q.; Zhao, G. Experimental investigation on the spatio-temporal-energy evolution pattern of limestone fracture using acoustic emission monitoring. J. Appl. Geophys. 2022, 206, 28–34. [Google Scholar] [CrossRef]

- Li, D.Y.; Du, Y. Artificial Intelligence with Uncertainty. J. Softw. 2004, 15, 1583–1594. [Google Scholar]

- Huang, S.; Chen, Y.; Feng, X.; Qiao, T.; Yu, D.; Yang, Y. Research on dynamic assessment method of earthquake scene rescue performance based on AHP and cloud model. Mathematics 2022, 10, 207. [Google Scholar] [CrossRef]

- He, Q.Y.; He, Z.Y.; Zhang, W.Y. Evaluation strategy for the operation quality of smart meters based on improved fuzzy analytic hierarchy process. Electr. Meas. Instrum. 2022, 52, 1–11. [Google Scholar]

| No. | Lithology | Total Thickness (m) | Thickness (m) | Bulk Density (KN/m3) | Elastic Modulus (Gpa) | Tensile Strength (Mpa) | Remarks |

|---|---|---|---|---|---|---|---|

| 13 | Mudstone | 120.97 | 16.09 | 21 | 13 | 1.5 | |

| 12 | Limestone | 104.88 | 36.93 | 27 | 20 | 3.2 | KS3 |

| 11 | Marlstone | 67.95 | 2.36 | 24.6 | 17 | 2.4 | |

| 10 | Siltstone | 65.59 | 3.5 | 25.5 | 22 | 4 | |

| 9 | Clayey siltstone | 62.09 | 10.2 | 24.5 | 20 | 3.4 | |

| 8 | Claystone | 51.89 | 6.48 | 24.1 | 18 | 2.6 | |

| 7 | Marlstone | 45.41 | 1.14 | 24.6 | 17 | 2.4 | |

| 6 | Claystone | 44.27 | 18.31 | 24.1 | 18 | 2.6 | KS2 |

| 5 | C5 coal | 25.96 | 1.87 | 18 | 10 | 1 | |

| 4 | Siltstone | 24.09 | 13.09 | 25.5 | 22 | 4 | KS1 |

| 3 | C9 coal | 11 | 2.5 | 18 | 10 | 1 | |

| 2 | Siltstone | 8.64 | 7.6 | 25.5 | 22 | 4 | |

| 1 | Lime mudstone | 1.04 | 1.04 | 24 | 15 | 1.8 |

| Sample Number | H/mm | D/mm | σ1/Mpa | σ3/Mpa | Notes |

|---|---|---|---|---|---|

| S-1-A | 99.69 | 49.90 | 179.1 | 10.01 | Holomorphic rock |

| S-1-B | 100.16 | 50.04 | 172.3 | 10.01 | |

| S-1-C | 100.77 | 49.71 | 158.5 | 10.00 | |

| S-2-A | 100.31 | 50.10 | 145.4 | 10.00 | Single-hole defect rock |

| S-2-B | 99.78 | 49.96 | 141.2 | 10.00 | |

| S-2-C | 100.17 | 50.08 | 126.4 | 10.00 |

| Risk Assessment Criteria | Lower | Low | Intermediate | High | Higher |

|---|---|---|---|---|---|

| Rank division | [0,2) | [2,4) | [4,6) | [6,8) | [8,10) |

| Ex | 1.0 | 3.0 | 5.0 | 7.0 | 9.0 |

| En | 0.333 | 0.333 | 0.333 | 0.333 | 0.333 |

| He | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Evaluation Index | Subjective Weight W1 | Objective Weight W2 | Combined Weight W | Index Cloud Parameter (Ex, En, He) |

|---|---|---|---|---|

| A11 Hydrogeological complexity | 0.1310 | 0.2382 | 0.1921 | (6.83, 0.1629, 0.0446) |

| A12 Karst water development degree | 0.0801 | 0.2293 | 0.1474 | (5.60, 0.1504, 0.0792) |

| A13 Volume of separated water layer | 0.4422 | 0.1575 | 0.2870 | (8.96, 0.1454, 0.0773) |

| A14 Water-bearing stratum thickness | 0.0569 | 0.1654 | 0.1055 | (5.02, 0.2156, 0.1482) |

| A15 Thickness of water-resisting layer | 0.2898 | 0.2097 | 0.2681 | (7.91, 0.1354, 0.0518) |

| A21 Seam thickness | 0.2965 | 0.2407 | 0.2881 | (6.10, 0.1504, 0.0199) |

| A22 Diagonal length of the working face | 0.0802 | 0.2236 | 0.1444 | (5.00, 0.0752, 0.0739) |

| A23 Mining inclination | 0.0520 | 0.1759 | 0.1031 | (2.10, 0.1253, 0.0487) |

| A24 Advancing speed of the working surface | 0.1484 | 0.2044 | 0.1878 | (5.98, 0.0852, 0.0583) |

| A25 The distance from bottom to coal seam | 0.4229 | 0.1555 | 0.2765 | (8.17, 0.1880, 0.0796) |

| A31 Atmospheric precipitation recharge | 0.0751 | 0.2404 | 0.1407 | (4.17, 0.0953, 0.0085) |

| A32 Underground river | 0.4472 | 0.2356 | 0.3399 | (7.01, 0.0953, 0.0725) |

| A33 Pumps and drainage pipes | 0.3198 | 0.2835 | 0.3153 | (7.07, 0.1053, 0.0118) |

| A34 Surface drainage works | 0.1579 | 0.2404 | 0.2040 | (5.11, 0.1930, 0.0264) |

| A41 Water conduction fracture zone height | 0.5181 | 0.1911 | 0.3379 | (9.05, 0.1504, 0.0826) |

| A42 Communication between overlying strata and karst | 0.2415 | 0.2937 | 0.2860 | (6.02, 0.0652, 0.0444) |

| A43 The degree of development of the native channel | 0.0860 | 0.2349 | 0.1526 | (4.95, 0.0752, 0.0256) |

| A44 Permeability of the separation fissure | 0.1544 | 0.2802 | 0.2234 | (7.97, 0.0602, 0.0306) |

| A51 Special funds for water prevention and control | 0.4486 | 0.2390 | 0.3404 | (8.00, 0.0251, 0.0399) |

| A52 Education level of full-time water control personnel | 0.0899 | 0.2433 | 0.1538 | (4.99, 0.0953, 0.0985) |

| A53 Separated layer water monitoring and monitoring | 0.2811 | 0.2678 | 0.2852 | (6.06, 0.1203, 0.0390) |

| A54 Water control technology refers to application | 0.1803 | 0.2498 | 0.2206 | (6.09, 0.1579, 0.0414) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Xu, G.; Li, H.; Su, D.; Liu, Y. Bed Separation Formation Mechanism and Water Inrush Evaluation in Coal Seam Mining under a Karst Cave Landform. Processes 2023, 11, 3413. https://doi.org/10.3390/pr11123413

Gao Z, Xu G, Li H, Su D, Liu Y. Bed Separation Formation Mechanism and Water Inrush Evaluation in Coal Seam Mining under a Karst Cave Landform. Processes. 2023; 11(12):3413. https://doi.org/10.3390/pr11123413

Chicago/Turabian StyleGao, Zhu, Guosheng Xu, Huigui Li, Deguo Su, and Yuben Liu. 2023. "Bed Separation Formation Mechanism and Water Inrush Evaluation in Coal Seam Mining under a Karst Cave Landform" Processes 11, no. 12: 3413. https://doi.org/10.3390/pr11123413

APA StyleGao, Z., Xu, G., Li, H., Su, D., & Liu, Y. (2023). Bed Separation Formation Mechanism and Water Inrush Evaluation in Coal Seam Mining under a Karst Cave Landform. Processes, 11(12), 3413. https://doi.org/10.3390/pr11123413