Abstract

Aiming at resolving the problem of low assembly accuracy and the difficulty of guaranteeing assembly quality of remanufactured parts, an optimization classification method for the assembly sequence of remanufactured parts based on different accuracy levels is proposed. By studying the characteristics of recycled parts, based on the requirement that the quality of remanufactured products not be lower than that of the assembly quality of new products, the classification selection matching constraints of remanufactured parts are determined, and the classification selection matching optimization models of remanufactured parts with different precision levels is established. An algorithm combining particle swarm optimization and a genetic algorithm is proposed to solve the model and obtain the optimal assembly sequence. Taking the remanufacturing assembling of a 1.4 TGDI engine crank and a connecting rod mechanism as an example, the comparison of quality data shows that this method can effectively improve the qualified rate of assembly, reduce the cost of after-sale claims, provide new theories and methods for remanufacturing enterprises that need hierarchical assembly, and provide effective guidance for the development of the remanufacturing industry.

1. Introduction

Remanufacturing assembly is a critical step to ensure product quality. Compared with the original new-part manufacturing and assembly, remanufacturing assembly has higher uncertainty, low production efficiency, unstable product quality, frequent abnormal production accidents, and high repair rates [1,2]. Therefore, ensuring the assembly quality of remanufactured products, improving the success rate of product matching, and optimizing the assembly sequence during the remanufacturing assembly process have become key issues that remanufacturers need to solve urgently.

At present, a large quantity of research has been carried out on the optimization of remanufacturing assembly sequences. Yang et al. [3] built a product assembly priority correlation matrix for complex mechanical products and used an improved genetic algorithm to obtain the optimal assembly sequence. Su et al. [4,5] proposed a matching-oriented remanufacturing assembly sequence optimization method and established an assembly sequence optimization model based on the lowest cost of mass loss. According to the assembly characteristics of lithium battery modules, by analyzing the failure condition of used parts, Jiang et al. [6] set up an optimization model of remanufacturing repair scheme of used parts based on failure characteristics with the objective of remanufacturing cost and time. A genetic algorithm was used to optimize the model. Geda et al. [7] studied the remanufacturing assembly combination matching method and established a matching model aiming at minimizing quality loss in product assembly. Xiao et al. [8] studied the remanufacturing assembly inventory cost, proposed an assembly sequence optimization model based on the smallest assembly cost and the highest resource utilization, and used the network flow graph and mathematical linear programming method to solve the model. Zhu et al. [9] developed a remanufacturing cost prediction model based on an improved BP neural network. This model can effectively and accurately predict the remanufacturing cost. Marcin et al. [10,11] carried out assembly sequence planning using artificial neural networks for mechanical parts based on given conditions.

In order to improve the quality of remanufactured products, these studies are mainly conducted by introducing a new classification or calibration method. However, there are few studies on the coupling law of remanufacturing product quality and the quality control of remanufacturing product assembly process in the environment. The existing research methods cannot meet the requirements for the assembly quality of remanufactured products. Based on the above research, this paper proposes an optimization classification method for the assembly sequence of remanufactured parts based on different precision levels to raise assembly accuracy and guarantee assembly quality. By studying the characteristics of recycled parts, and based on the requirement that the quality of remanufactured products not be lower than the quality of newly assembled products, the constraints of remanufactured part classification and selection are determined in the dimension chain constraints and the optimization model of remanufactured parts classification selection with different precision is established. Designing a combined algorithm to solve the target model and obtain the optimal assembly sequence serves to improve the remanufacturing assembly success rate and assembly accuracy.

2. Optimization Model of Remanufactured Part Grading Selection with Different Precision Levels

The assembly error of remanufactured parts fluctuates widely. In order to ensure the quality of remanufactured assembly, this paper establishes different precision standards for remanufactured parts and creates an optimization model for the classification and selection of remanufactured parts under different precision conditions.

2.1. Remanufactured Part Grading Matching Constraints

Assuming that the critical dimension of the original part is , which satisfies the normal distribution, the ideal value is , the tolerance distribution is , and the variance is . Then, the critical dimension of the remanufactured part is , which also satisfies the normal distribution. The ideal value is , the tolerance distribution is , and the variance is . In the actual remanufacturing process, , assuming that a certain dimension chain consists of part sizes, the calculation formula of the dimension chain accuracy of the assembly of new parts can be obtained, as shown in Formula (1):

In the formula, represents the dimensional variance of the remanufactured part in the dimension chain.

The formula for calculating the accuracy of the assembly dimension chain of remanufactured parts is shown in Formula (2):

In the formula, represents the dimension variance of the remanufactured part in the dimension chain. Obviously, . According to this model assumption, the parts are divided into two levels in order to ensure that the assembly accuracy of remanufactured parts is not lower than that of new products. That is, it is necessary to meet the tolerances of the two ; that is, , represents the dimensional variance of the remanufactured part in the dimension chain, and represents the dimension variance of the remanufactured part in the dimension chain. When the remanufactured part X of the first type is assembled in combination with the remanufactured part Y of the second type, the tolerance of the remanufactured part X of the first type can be relaxed, the selection range is enlarged, and the relaxation ratio is 1.41. According to the above formula, reasoning, and the literature [12], different accuracy standards are established, as shown in Table 1.

Table 1.

Classification criteria for different grades.

Mechanical products are assembled using a finite size chain, which is the basis for product assembly accuracy. Assuming that there are multiple size chains in the assembly process, in order to ensure that the quality of remanufactured products is not lower than the assembly quality of newly manufactured products, the product size chain constraints are as follows [13,14,15]:

In the formula, is the subtraction loop, is the number of added loops, is the total loop number, is the upper deviation of the closed loop, is the lower deviation of the closed loop, and is the tolerance of the closed loop.

2.2. Comprehensive Model of Remanufactured Part Classification and Selection

Assuming that the remanufactured parts have dimension chains, that the error coefficient of different precision classifications of the remanufactured parts is , and that the cost of mass loss is , the remanufacturing assembly cost under different precisions is shown in Formula (6):

With the restriction that the product quality of the remanufacturing assembly process of mechanical products not be lower than the assembly quality of newly manufactured products, and the goal of optimizing the remanufacturing assembly cost, a comprehensive selection model of the remanufacturing assembly process under different precision conditions is established, as shown in Formula (7):

In the formula, represents the level of the attribute of the component, represents the quality loss cost of the remanufactured component level of the dimension chain, is the variance of the dimension chain of the remanufactured component, and is the variance of the dimension chain of the original part.

3. Model Solution

Particle swarm optimization is inspired by the behavior of bird species and is used to optimize the balance of production and assembly lines. In an n-dimensional search range, each particle can be regarded as a search individual. The position of each particle is a candidate solution of the optimal value, and the motion of the particle is the process of searching for the individual. The optimal historical location of individual particles and populations can dynamically adjust the flight speed of particles. Velocity and position are two attributes in particle search, where velocity represents the speed of motion and position represents the direction of motion. The optimal solution found by each particle in motion is called the individual extreme value, and the optimal individual extreme value in the whole particle swarm is regarded as the global optimal solution. Speed and position are updated iteratively. Finally, the optimal solution must meet the termination condition.

The assembly line studied in this paper is a discrete problem. The particle swarm optimization algorithm is used to analyze the assembly line problem, and the following formula is established:

Here, X is the position of the particle in the global learning process, representing a feasible solution; V is the particle running speed, representing the global or local optimal learning process of particles; p is the historical optimal location of the current local; g is the historical optimal position of all particles in the global learning process; i is the serial number of the particle, i = 1,2… n; d is the global dimension of the particle’s position or velocity; t is the evolutionary algebra of particles; w is the inertia weight; r1 and r2 are any number between [0, 1]; c1 and c2 are acceleration factors.

The particle swarm optimization algorithm transforms the optimal search process into the solution of the regular motion of particles in space, in which the motion of particles is affected by three main aspects: the first one is the inertia of particle motion (the first item of Formula (9)); the second is the judgment of the current particle position (i.e., the second term of Formula (9)) and the selection of the historical optimal solution of the particle. c1 ∗ r1 represents the degree to which the particle judges the historical optimal solution. The third is the cognition of the particle to the global particle and the search for the global optimal solution (the third term of Formula (9)). c2 ∗ r2 represents the degree to which particles design the current global optimal solution.

Considering that the hierarchical matching model has high requirements for the optimization accuracy of the global search, if a single intelligent optimization algorithm is used, it is easy to fall into the local optimal situation [16,17,18,19,20,21]. Based on this, this paper proposes an optimization algorithm that combines particle swarm optimization and a genetic algorithm, and integrates the crossover and mutation operators in the genetic algorithm into the particle swarm optimization algorithm to improve the global optimization ability [22].

(a) Crossover operation

Assuming that the two individuals, , () at a certain time are inherited and crossed, the new individuals generated at the time after the crossover can be expressed as follows [23,24]:

(b) Mutation operation

Mutation operation is a process of simulating gene mutation in the biological world. Its main function is to increase the local search ability of the new algorithm, which can converge to the optimal solution more quickly. Finally, the position/speed update formula of the mutation operator is introduced as follows:

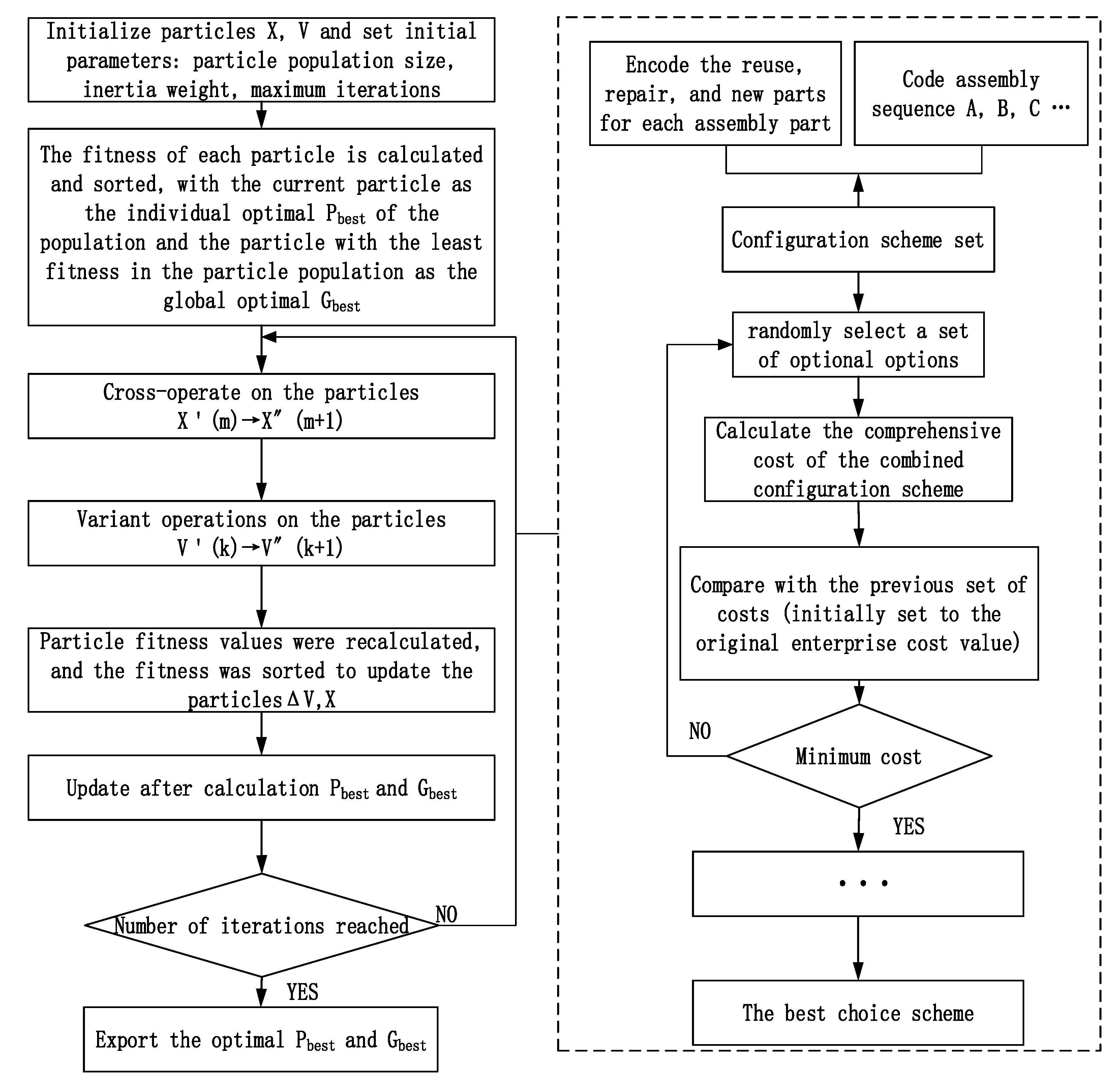

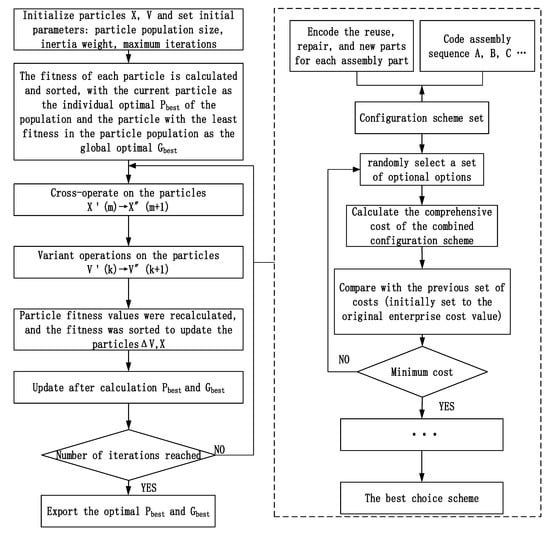

In the formulas, and are the weight of the particle tracking itself and the group optimal value, usually set to 2; and are the random number with uniform interval distribution; is the constraint factor [25,26] on the speed, which is the solution step of the algorithm as shown in Figure 1.

Figure 1.

Combined algorithm solution step.

The genetic algorithm (GA) is a typical swarm intelligence algorithm. It obtains the good properties of chromosomes through selection, crossover, and variation, and finally finds the optimal solution through convergence. The genetic algorithm has the advantages of good convergence performance and strong global search ability. Particle swarm optimization and the genetic algorithm are integrated to improve the global search ability of particles to solve some specific problems and obtain better results. This paper adopts the idea of bringing the excellent solutions selected by the genetic algorithm into the next generation. The method involves selecting the best individuals in each generation of particle population and replacing the individuals with weak adaptability in the next iteration process, so as to improve the ability of the algorithm in searching for the best individuals. The specific process is as follows:

(1) Initialize. Set the initial velocity and initial position of the particle, and set cross factor and variation factor .

(2) Calculate the fitness index of each particle using the fitness function. pbest is the best position of individual particle, and gbest is the best position within the whole world.

(3) Constantly update the velocity and position of particles in the global according to the above crossover and mutation operations.

(4) Calculate the particle adaptation value according to the respective positions of particles in the global , and replace the individual optimal position and the global optimal position in a timely manner.

(5) According to the global order of particle fitness values, particles with good fitness values replace particles with bad fitness values, leaving particles with good speed and position.

(6) If the search results meet the set conditions, stop the search and output the best global value at this time; if the stop condition is not met, the next update iteration continues.

4. Example Verification

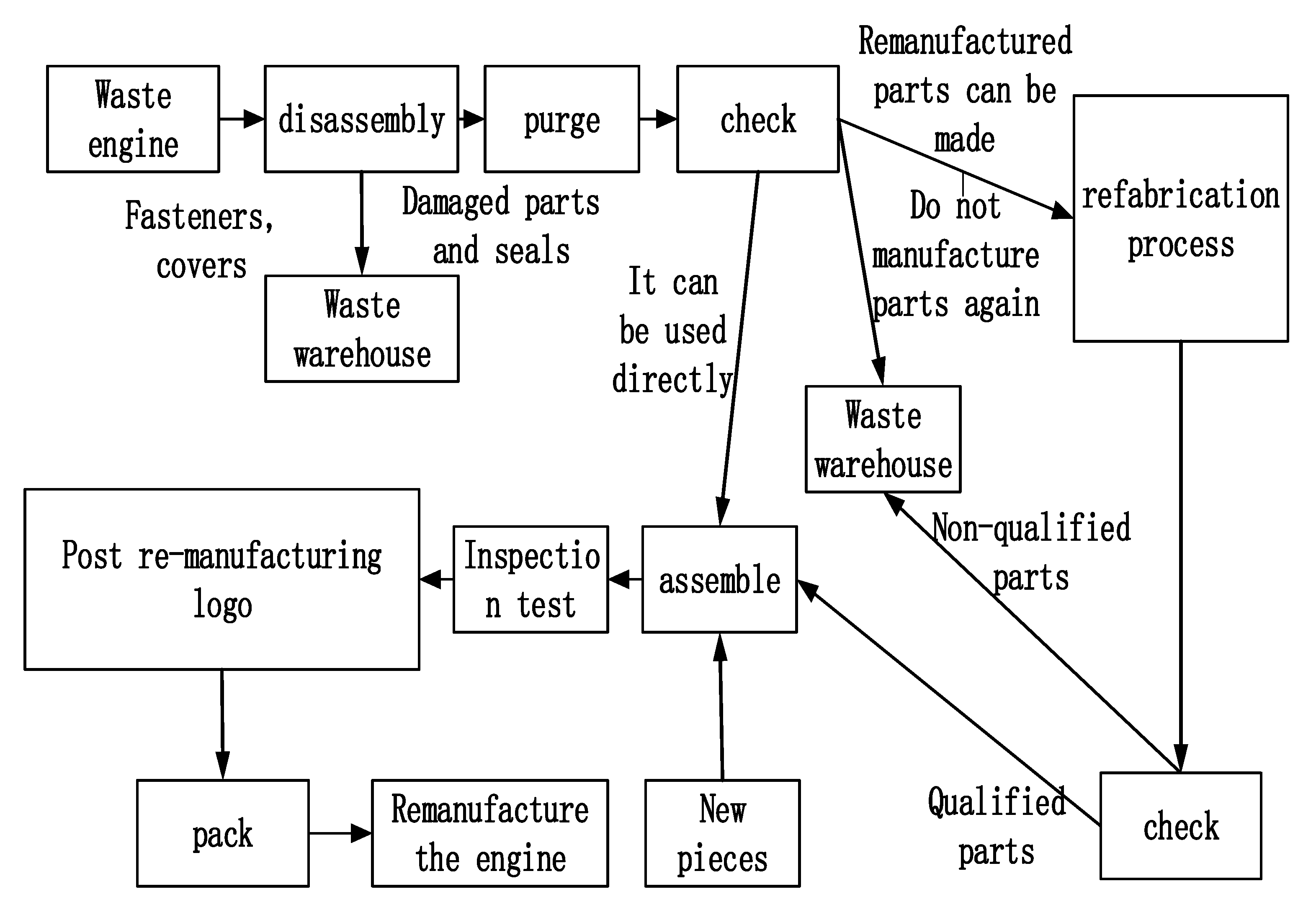

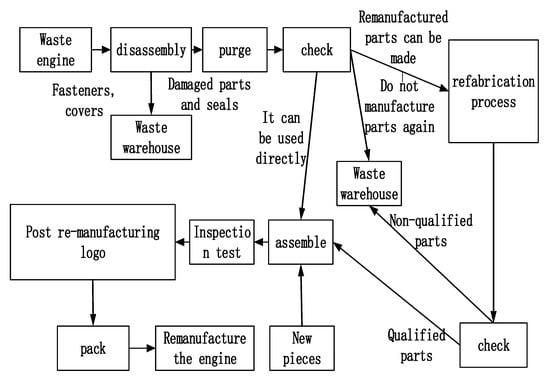

We applied the optimization model of remanufactured parts classification and selection to a domestic automobile engine remanufacturing enterprise, which has more than 100 waste engine recycling centers across the country. The recycling time and recycling location of each recycling point are different and the quality of different recycled engines is also different. A total of 80% of the remanufactured parts are used in a remanufactured engine, but the assembly success rate is only 84.41% and customer complaints are frequent. Compensation expenses were as high as CNY 9.57 million in 2019, accounting for 7.81% of sales [27,28,29,30,31,32]. Figure 2 shows the process flow chart of the company’s remanufactured engine.

Figure 2.

Process flow chart.

4.1. Method Implementation

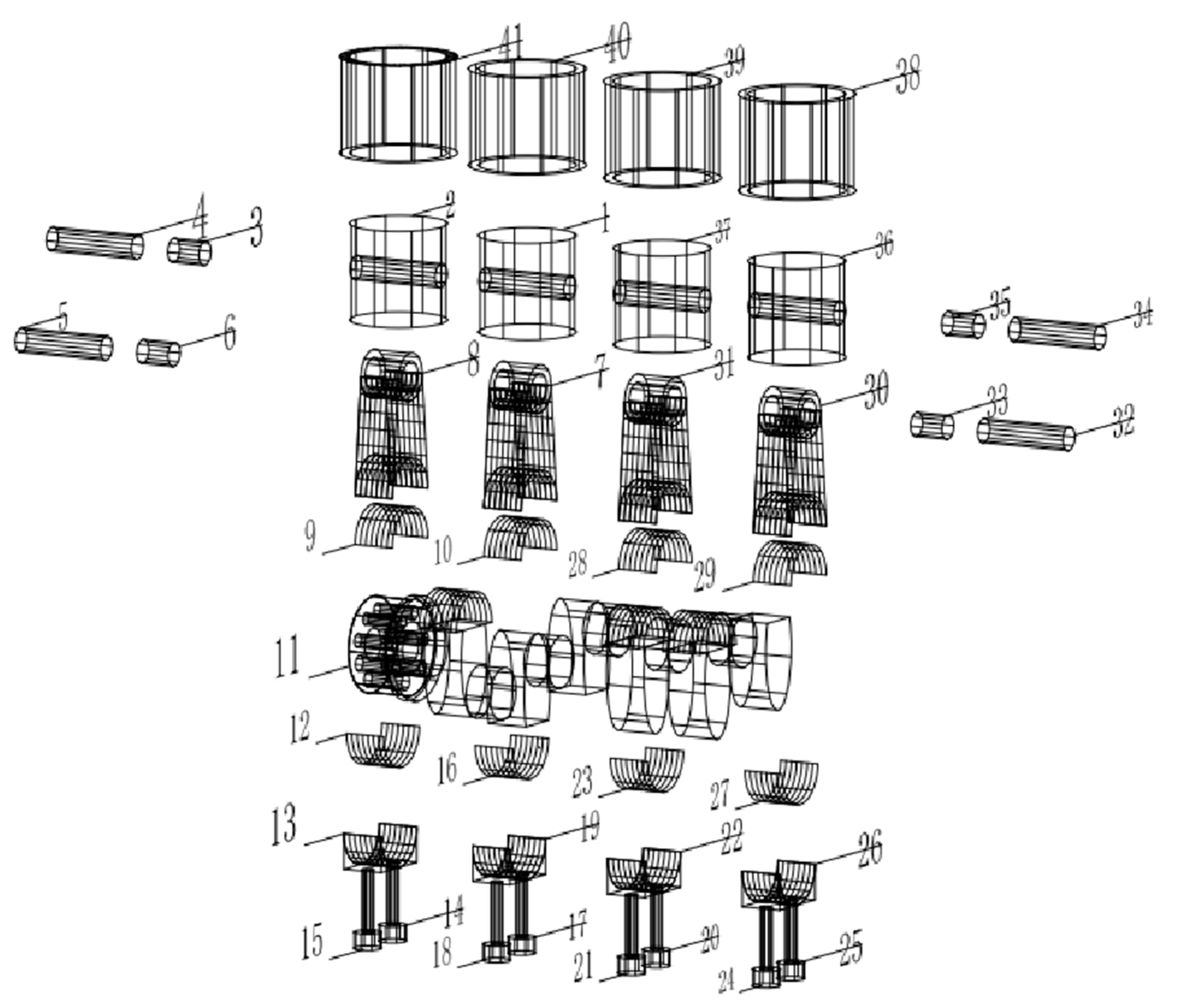

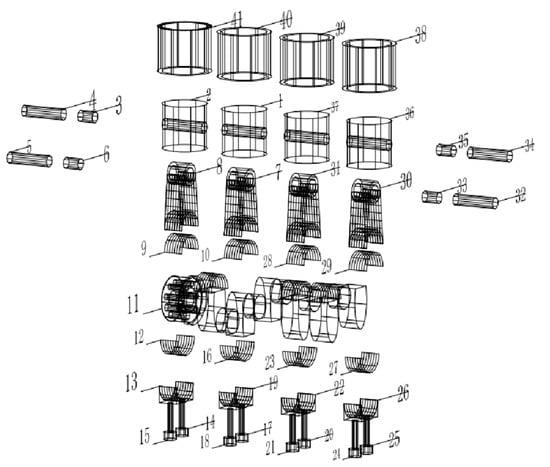

Remanufactured engine companies recycle engines from recycling stations with different quality levels. In this case, a 1.4 TGDI gasoline engine crank-connecting rod mechanism is used as an example. Figure 3 is a three-dimensional solid model of the crank-connecting rod mechanism, wherein 1, 2, 36, and 37 are pistons; 3, 6, 33, and 35 are bushings; 4, 5, 32, and 34 are piston pins; 7, 8, 30, and 31 are connecting rod bodies; 9, 10, 28, and 29 are upper half bearings; 11 are crankshafts; 12, 16, 23, and 27 are lower half bearings; 13, 19, 22, and 26 are connecting rod covers; 14, 15, 17, 18, 20, 21, 24, and 15 are connecting rod bolts; 38, 39, 40, and 41 are cylinders.

Figure 3.

Three-dimensional structural model.

The remanufactured parts are classified according to the quality grade standards set in Table 1 above. The size standard of the main bearing hole diameter of the new part of the 1.4 TGDI engine is ; the diameter of the new crankshaft main shaft is . Five sets of crank assembly parts were randomly selected, which included the dimensions of five remanufactured crankshafts and five remanufactured cylinder block parts. Table 2 and Table 3 show the main bearing hole diameter and crankshaft main journal diameter of some remanufactured cylinder blocks.

Table 2.

Main bearing bore diameter of cylinder block (mm).

Table 3.

Crankshaft main journal diameter (mm).

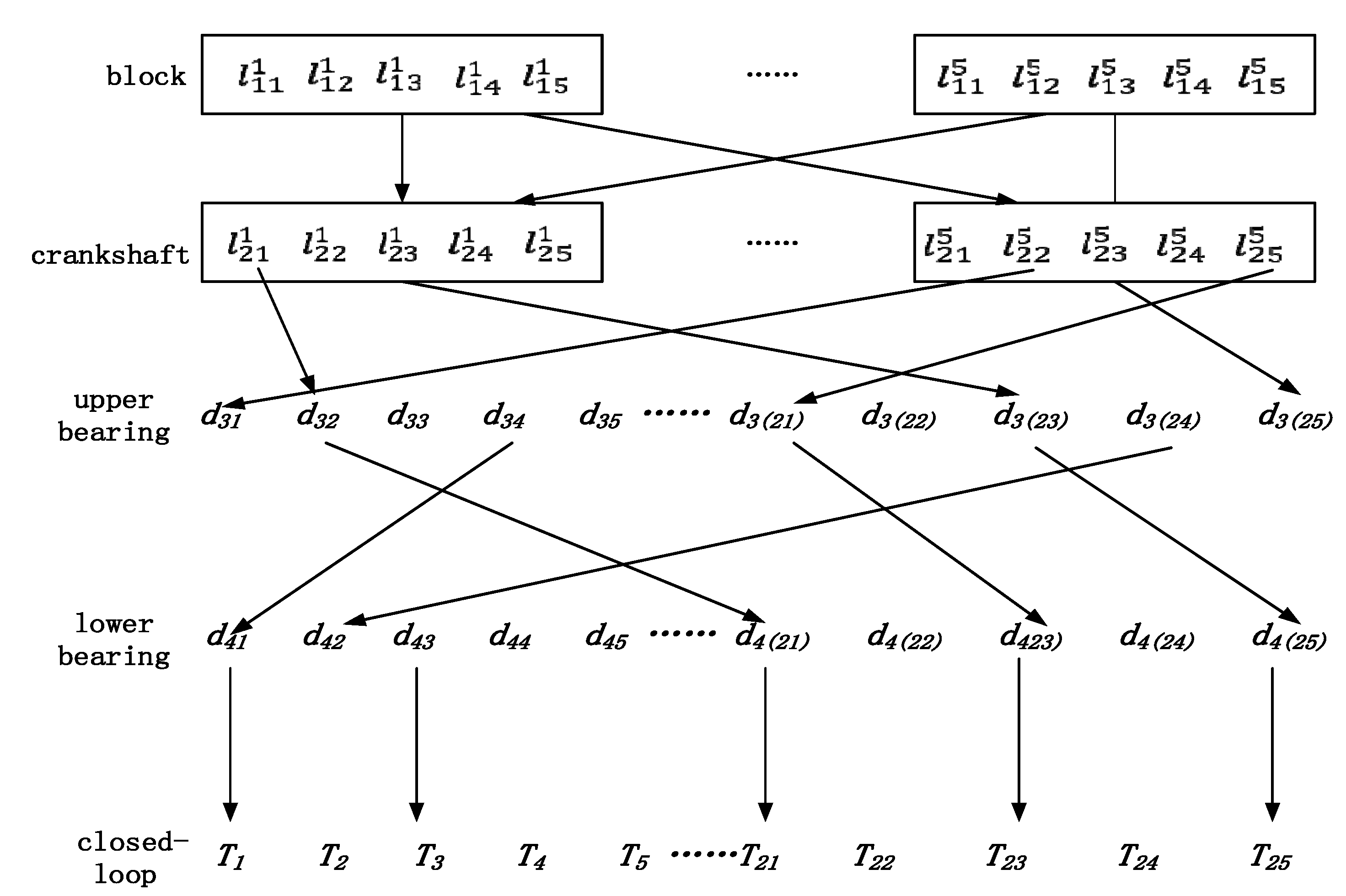

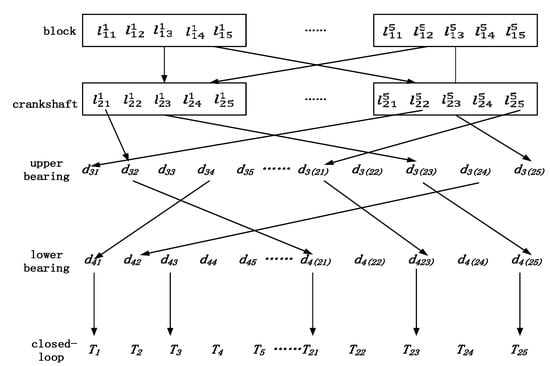

Coding the engine block and crankshaft, it can be seen in Table 2 and Table 3 that the cylinder block code 1-03 first neck, the crankshaft code 2-02 first neck, and the crankshaft code 2-03 s neck size do not meet the standard of the new part size. This can result in scrap or rework during assembly. The 1.4 TGDI remanufactured engine crank assembly closed-ring constraints are the same as new assembly constraints. The cylinder block of the engine is matched with the crankshaft during assembly; through the calculation results of arrangement and combination, a total of 120 combination schemes can be obtained. The cylinder block and the crankshaft are regarded as a whole. When selecting the upper and lower bearing shells, the commonly used greedy algorithm is used [33,34,35,36]. The bearing bush, the lower bearing bush, and 120 kinds of combinations are optimized one by one, so as to complete the optimization of an assembly scheme. The structure diagram of the matching process after optimization is shown in Figure 4.

Figure 4.

Crank assembly selection process structure.

Through the above analysis, the crankshaft matching scheme is preliminarily generated. Based on this, the assembly sequence of the crankshaft connecting rod mechanism of the remanufactured engine is optimized. The assembly attributes of the crankshaft connecting rod mechanism are shown in Table 4. The serial number, installation direction, and assembly tools used for the parts are described.

Table 4.

Assembly properties of the crank linkage.

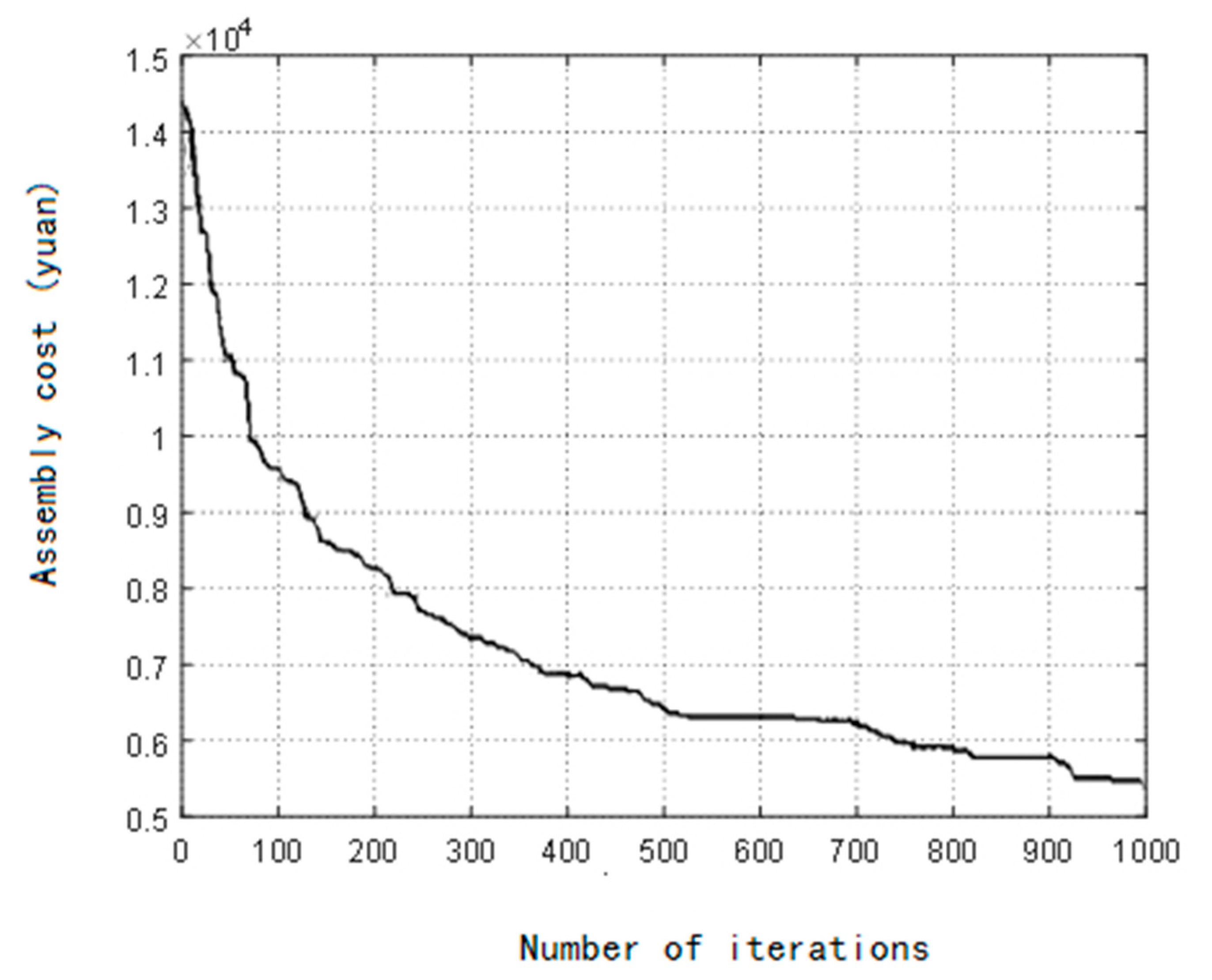

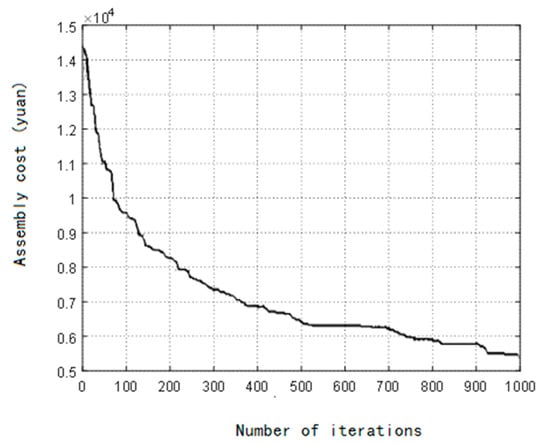

Based on the above optimized crank assembly selection scheme, the relevant programs of the remanufactured engine crank-connecting rod mechanism classification selection model are written in Matlab. The reused parts, re-repaired parts, and new parts of each assembly part were coded, and the types of parts in the assembly process were coded according to the assembly sequence. According to the assembly constraints and the classification scheme selection, the particle swarm genetic combination algorithm proposed in this study was used to optimize the model. The specific combination algorithm parameters were set as follows: the initial population size was 50; the maximum number of iterations was 1000; the cross factor was set to 0.9; the variation factor was set to 0.4; the learning factor was ; and Matlab was used to optimize the simulation. The operation results are shown in Figure 5.

Figure 5.

The calculation optimization diagram of the particle swarm genetic combination algorithm for classification selection.

The optimized assembly sequence was optimized by Matlab. The top two optimal assembly sequences are shown in Table 5.

Table 5.

Optimal assembly sequence.

4.2. Results Comparison

The company began to use the remanufactured part grading and matching method in January 2020, and compared the data for 2019 with those for 2020. According to statistics, the success rate of remanufacturing assembly increased from 84.41% to 90.17%, with an average increase of 5.76%. The company’s compensation expenses decreased by CNY 3.21 million, a decrease of 33.5% compared with 2019. The specific comparison is shown in Table 6.

Table 6.

Comparison of success rate and compensation cost data for 2019 and 2020.

4.3. Comparison with the Previous Literature

In the introduction, references [3,4,5,6,7,8,9,10,11] provide many ideas and methods for remanufacturing and assembly, effectively achieving the goal. In reference [4], an assembly sequence optimization model based on the lowest quality loss cost was established and solved by an ant colony algorithm. A single intelligent optimization algorithm easily falls into the local optimal situation. In reference [6], an assembly sequence optimization model based on the failure feature was established and solved by an ant genetic algorithm. However, few consider the different precision levels of remanufactured parts. The assembly error of remanufactured parts fluctuates widely, so this paper sets up different precision standards for remanufactured parts and establishes the optimization model of classification and selection of remanufactured parts under different precision conditions. In addition, the combination of the particle swarm optimization algorithm and genetic algorithm, which has a wider range and better accuracy, is used to solve the problem.

5. Conclusions

Because the assembly accuracy of remanufactured parts is low and it is difficult to guarantee assembly quality, an optimization classification method of the assembly sequence of remanufactured parts based on different precisions is proposed. The main conclusions are as follows:

- Remanufactured assembly control is difficult to standardize. Under the condition that the assembly accuracy of remanufactured parts not be lower than that of new products, the classification accuracy standard of remanufactured parts was calculated through mathematical formulas, the optimization model of classification selection under different accuracy conditions was established, and a combinatorial optimization algorithm to solve the model was proposed;

- This article took the remanufacturing assembly of an engine crank-connecting rod mechanism as an example. The data comparison showed that the optimal assembly sequence obtained by the hierarchical matching model proposed in this study can effectively ensure different remanufacturing assembly accuracy requirements and improve remanufacturing. The success rate guarantees an improvement in assembly quality and a reduction in after-sale claim costs. The best assembly sequence provides the best assembly quality and the lowest claim cost. The concept of optimality refers to the best assembly time and quality of remanufactured parts with different precisions. The success rate of assembly and the reduction in after-sale claim costs provided new theories and methods for remanufacturing enterprises, which should adopt hierarchical assembly.

Author Contributions

Conceptualization, Y.X., J.Z., and X.Z. ; Methodology, Y.X., and S.X.; Software, Y.X., J.Z., and S.X. ; Formal analysis, Y.X.; visualization, J.Z. and X.Z.; supervision, J.Z. and X.Z.; project administration, S.X.; review and editing, Y.X., and S.X. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for National Science Foundation, China (No. 61862051); the Natural Science Foundation of Hunan Province, China (No. 2022JJ50244); the China Education Department of Hunan Province (No. 21B0695); the project of the Hunan Social Science Achievement Evaluation Committee in 2022 (No. XSP22YBC081); the Science and Technology Foundation of Guizhou Province under Grant (No. [2019]1299); the Top-notch Talent Program of Guizhou Province under Grant (No. KY [2018]080); the program of Qiannan Normal University for Nationalities under Grant (Nos. QNSY2018JS013, QNSYRC201715).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, L.; Guo, Y.; Zhang, Z.; Xia, X. Extensive Concept, State-of-the Art Developing Trends of Remanufacturing Service. J. Mech. Eng. 2021, 57, 138–153. [Google Scholar]

- Yin, L.; Yang, F. Study on selective assembly of remanufacturing parts to be assembled based on NSGA-Ⅲ. J. Mach. Des. 2022, 39, 53–60. [Google Scholar]

- Yang, W.; Meng, C.; Cao, W.; Xie, K.; Yu, P. Assembly Sequence Optimization based on Improved Genetic Algorithm. J. Mech. Transm. 2016, 40, 67–70. [Google Scholar]

- Su, B.; Huang, X.; Ren, Y.; Wang, F.; Xiao, H.; Zheng, B. Research on Selective Assembly Method Optimization for Construction Machinery Remanufacturing Based on Ant Colony Algorithm. J. Mech. Eng. 2017, 53, 60–68. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, H.; Jiang, Z. An approach for blank dimension design considering energy consumption. Int. J. Adv. Manuf. Technol. 2016, 87, 1229–1235. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, Z.; Zhang, H.; Cheng, H. Optimization Study of Remanufacturing Reconditioning Scheme for Used Parts Based on Failure Features—Research on optimization of waste parts based on failure feature. Mach. Tool Hydraul. Press. 2016, 44, 168–172. [Google Scholar]

- Geda, M.W.; Kwong, C.K.; Jiang, H.M. Fastening method selection with simultaneous consideration of product assembly and disassembly from a remanufacturing perspective. Int. J. Adv. Manuf. Technol. 2019, 101, 1481–1493. [Google Scholar] [CrossRef]

- Xiao, Y.; Yan, W.; Wang, R. Research on Blank Optimization Design Based on Low-Carbon and Low-Cost Blank Process Route Optimization Mode. Sustainability 2021, 13, 1929. [Google Scholar] [CrossRef]

- Zhu, H.; Ding, Z.; Chen, B.; Jiang, Z. Cost Prediction of End-of-life Products Remanufacturing Based on Improved BP Neural Network. Mach. Tool Hydraul. 2020, 48, 34–38. [Google Scholar]

- Suszyński, M.; Peta, K. Assembly Sequence Planning Using Artificial Neural Networks for Mechanical Parts Based on Selected Criteria. Appl. Sci. 2021, 11, 10414. [Google Scholar] [CrossRef]

- Suszyński, M.; Peta, K.; Černohlávek, V.; Svoboda, M. Mechanical Assembly Sequence Determination Using Artificial Neural Networks Based on Selected DFA Rating Factors. Symmetry 2022, 14, 1013. [Google Scholar] [CrossRef]

- Liu, M.; Liu, C. The invention relates to an assembly size classification method for remanufactured parts. U.S. Patent CN103413024B, 8 February 2017. [Google Scholar]

- Oh, Y.; Behdad, S. Simultaneous reassembly and procurement planning in assemble-to-order remanufacturing systems. Int. J. Prod. Econ. 2017, 184, 168–178. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, X.; Liu, W.; Shi, M.; Yang, S.; Yang, G. Precision prediction and error propagation model of remanufacturing machine tool assembly process. Comput. Integr. Manuf. Syst. 2021, 27, 1300–1308. [Google Scholar]

- Yenipazarli, A. Managing new and remanufactured products to mitigate environmental damage under emissions regulation. Eur. J. Oper. Res. 2016, 249, 117–130. [Google Scholar] [CrossRef]

- Kiranyaz, S.; Pulkkinen, J.; Gabbouj, M. Particle Swarm Optimization. Expert Syst. Appl. 2014, 38, 2212–2223. [Google Scholar] [CrossRef]

- Kiani, A.T.; Nadeem, M.F.; Ahmed, A.; Khan, I.A.; Alkhammash, H.I.; Sajjad, I.A.; Hussain, B. An Improved Particle Swarm Optimization with Chaotic Inertia Weight and Acceleration Coefficients for Optimal Extraction of PV Models Parameters. Energies 2021, 14, 2980. [Google Scholar] [CrossRef]

- Xian, X.; Zhou, Z.; Huang, G.; Nong, J.; Liu, B.; Xie, L. Optimal Sensor Placement for Estimation of Center of Plantar Pressure Based on the Improved Genetic Algorithms. IEEE Sens. J. 2021, 21, 28077–28086. [Google Scholar] [CrossRef]

- Kang, M.; Li, Y.; Jiao, L.; Wang, M. Differential Analysis of ARX Block Ciphers Based on an Improved Genetic Algorithm. Chin. J. Electron. 2022, 32, 225–236. [Google Scholar]

- Vanderstar, G.; Musilek, P. Optimal Design of Distribution Overhead Powerlines using Genetic Algorithms. IEEE Trans. Power Deliv. 2021, 37, 1803–1812. [Google Scholar] [CrossRef]

- Fernandes, J.; Arsenio, A.J.; Arnaud, J. Optimization of a Horizontal Axis HTS ZFC Levitation Bearing Using Genetic Decision Algorithms Over Finite Element Results. IEEE Trans. Appl. Supercond. 2020, 30, 3601308. [Google Scholar] [CrossRef]

- Chen, J. The Research on Critical Assembly Process Quality Control Method and Supporting System for Remanufacturing Engine. Ph.D. Thesis, Hefei University of Technology, Hefei, China, 2016. [Google Scholar]

- Xiao, Y.M.; Zhang, H. Multiobjective optimization of machining center process route: Tradeoffs between energy and cost. J. Clean. Prod. 2021, 28, 21–26. [Google Scholar] [CrossRef]

- Zhang, Y. Method and Key Technology of Assembly Quality Control for Remanufactured Engine. Ph.D. Thesis, Hefei University of Technology, Hefei, China, 2017. [Google Scholar]

- Zhang, J.; Li, Y. Motor Rolling Bearing Compound Fault Diagnosis Based on Particle Swarm Optimization & Blind Source Separation. Mach. Tool Hydraul. 2019, 47, 167–172. [Google Scholar]

- Xiao, Y.; Wang, R.; Yan, W.; Ma, L. Optimum Design of Blank Dimensions Guided by a Business Compass in the Machining Process. Processes 2021, 9, 1286. [Google Scholar] [CrossRef]

- Xing, Z.; Jiang, A.L.; Xie, J.J.; Feng, Y.C. Benefit analysis and Surface Engineering Application of Automobile Engine Remanufacturing. China Surf. Eng. 2004, 9, 1–5. [Google Scholar]

- Chang, X.; Zhong, Y.; Wang, Y.; Chen, Z. Research of low-carbon policy to promote automotive parts remanufacturing in China:A case study of auto engine remanufacturing. Syst. Eng. Theory Pract. 2013, 33, 2811–2821. [Google Scholar]

- Zhang, Y.F.; Li, M.; Liu, S.C. IoT-based production process optimization method for automobile engine remanufacturing. In Proceedings of the ICRA 2014—IEEE International Conference on Robotics and Automation, Hong Kong, China, 31 May–5 June 2014. [Google Scholar]

- Shi, J.; Hu, J.; Jin, Z.; Ma, Y.; Ma, M.; Wang, H.; Ma, Q. Recycling Mode and Remanufacturing Cost Analysis of Used Automobile Engine Based on System Dynamics. J. Phys. Conf. Ser. 2021, 1986, 012041. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Liu, Y.; Yang, H.; Li, M.; Huisingh, D.; Wang, L. The ‘Internet of Things’ enabled real-time scheduling for remanufacturing of automobile engines. J. Clean. Prod. 2018, 185, 562–575. [Google Scholar] [CrossRef]

- Yu, X.; Jiang, N.; Wang, L.P. Characteristics and Approaches to the Information System of Automobile Engine Remanufacturing. J. Cent. South Univ. For. Technol. 2009, 29, 176–179. [Google Scholar]

- Ju, J.; Li, W.; Wang, Y.; Fan, M.; Liu, Y. Optimization Design of Vibration Control Parameters of Flexible Manipulators Based on Multi-Population Genetic Algorithm. Mach. Tool Hydraul. 2016, 44, 94–97. [Google Scholar]

- Liu, L. Research on assembling method of remanufacturing engine. Ph.D. Thesis, Tianjin University of Science and Technology, Tianjin, China, 2017. [Google Scholar]

- Wen, H.; Meng, X.; Zeng, A.; Guo, X.; Xu, X. Fatigue life prediction of neural network remanufactured based on second-order particle swarm optimization. Sci. Technol. Eng. 2019, 19, 21–26. [Google Scholar]

- Yuan, S.; Li, T.; Wang, B.; Liu, Q. Co-evolutionary iterated greedy algorithm for the two-stage flow shop group scheduling problem. Syst. Eng. Theory Pract. 2020, 40, 2707–2716. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).