Kiwifruit Harvesting Damage Analysis and Verification

Abstract

:1. Introduction

- The finite element method was used to simulate the viscoelastic properties of kiwifruit samples.

- Under different forces, we observed the stress–strain generated on different tissues of the sample.

- During the packing process after picking, we observed the stress–strain generated on different tissues of the specimen.

- Comparison of laboratory results with finite element simulation results.

2. Materials and Methods

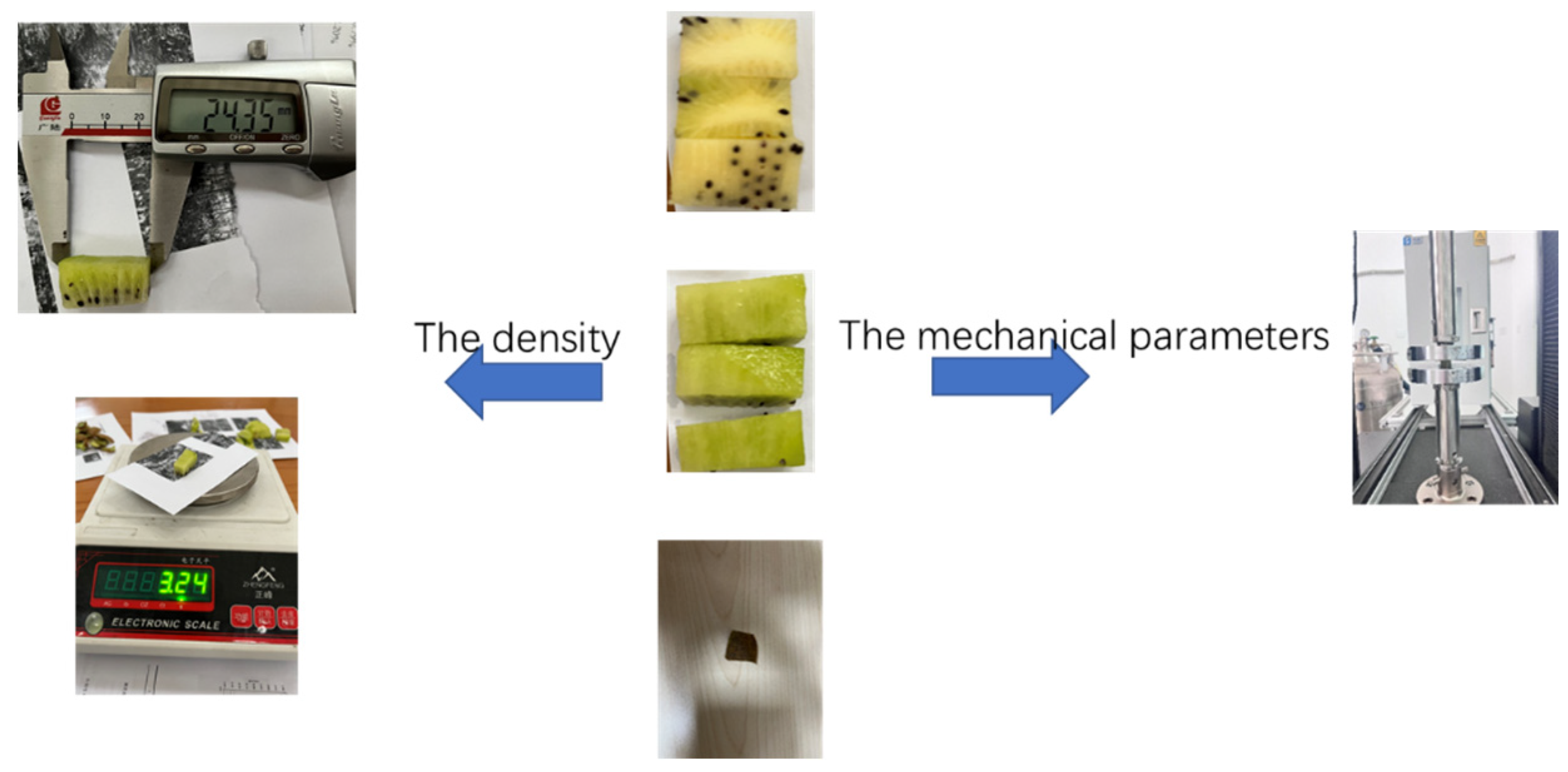

2.1. Test Materials

2.2. Experimental Designs

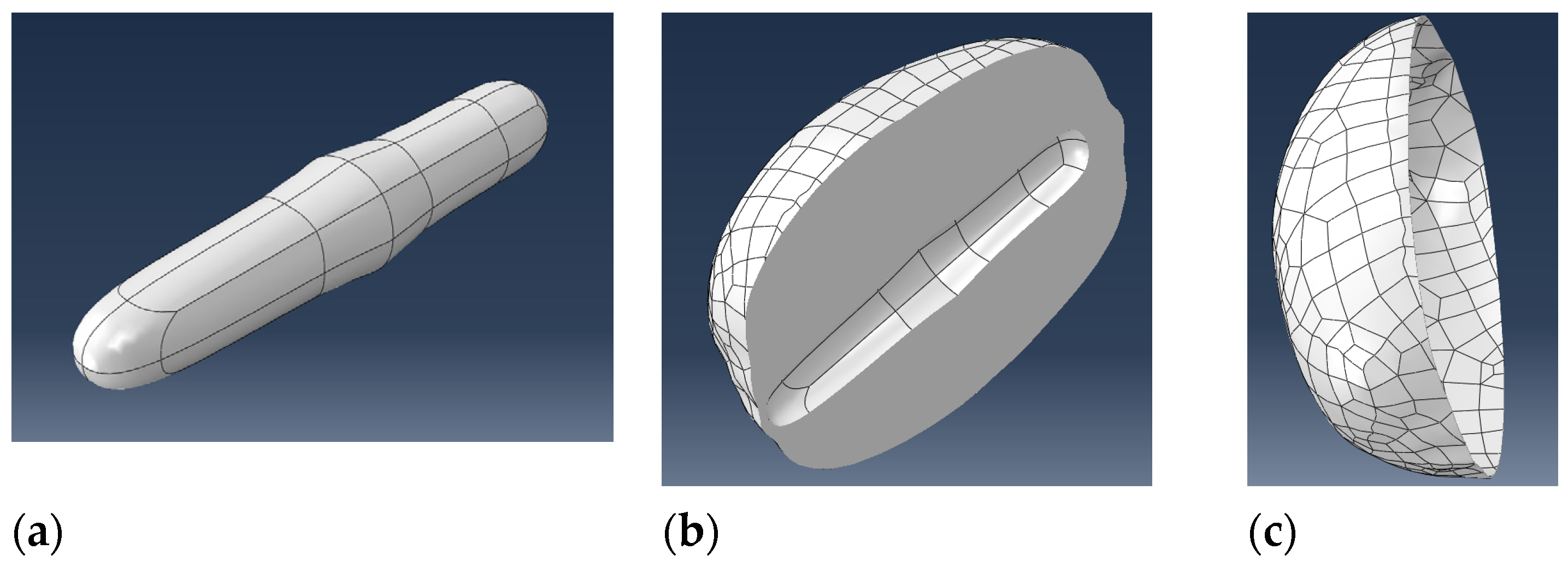

2.3. Finite Element Modeling and Simulation

2.3.1. Kiwifruit Three-Dimensional Finite Element Model Establishment

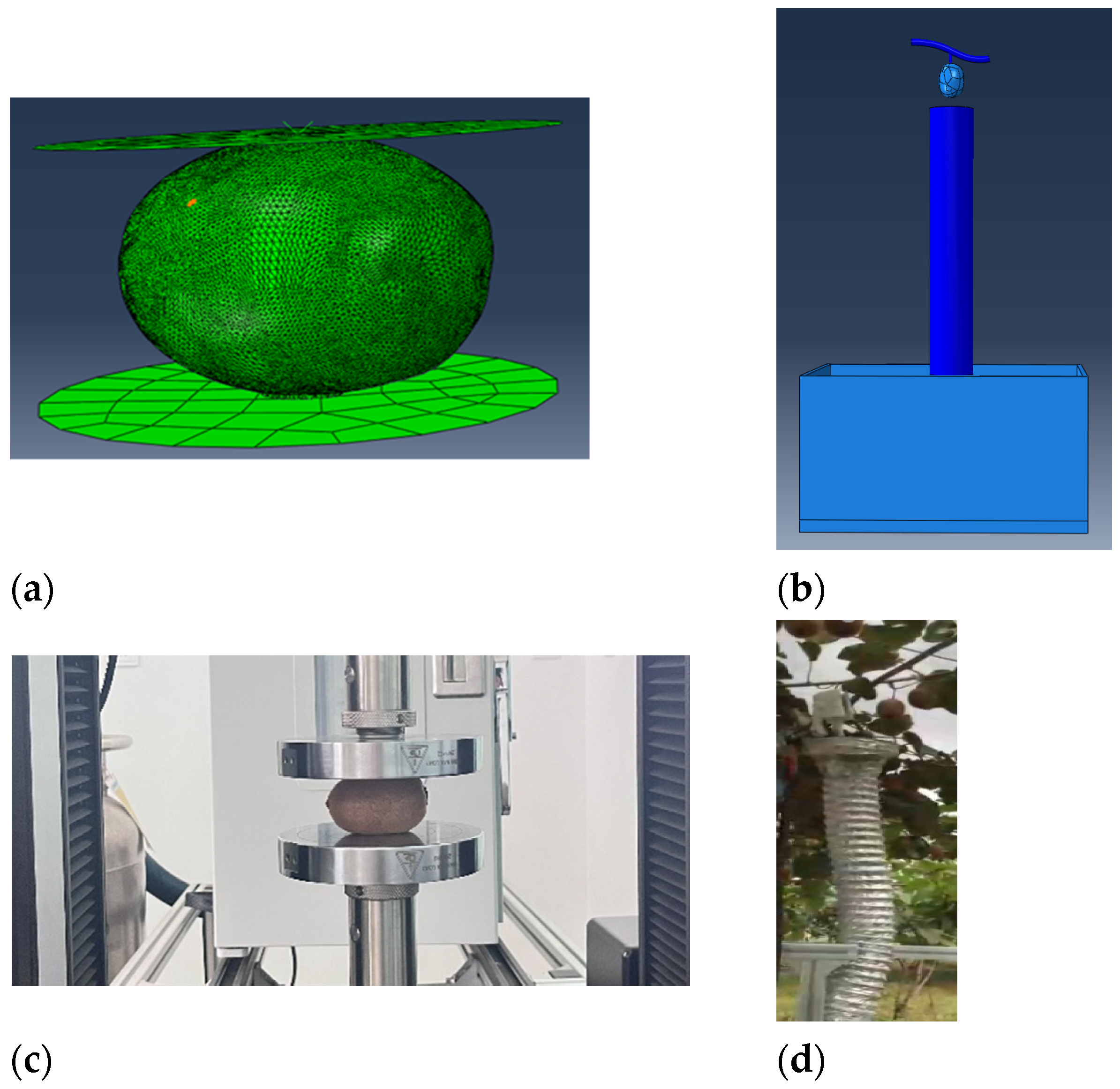

2.3.2. Kiwifruit Grabbing and Collection Simulation

2.4. Kiwifruit Test Verification

2.4.1. Kiwifruit Finite Element Model Validation Test

2.4.2. Statistical Analysis

3. Results

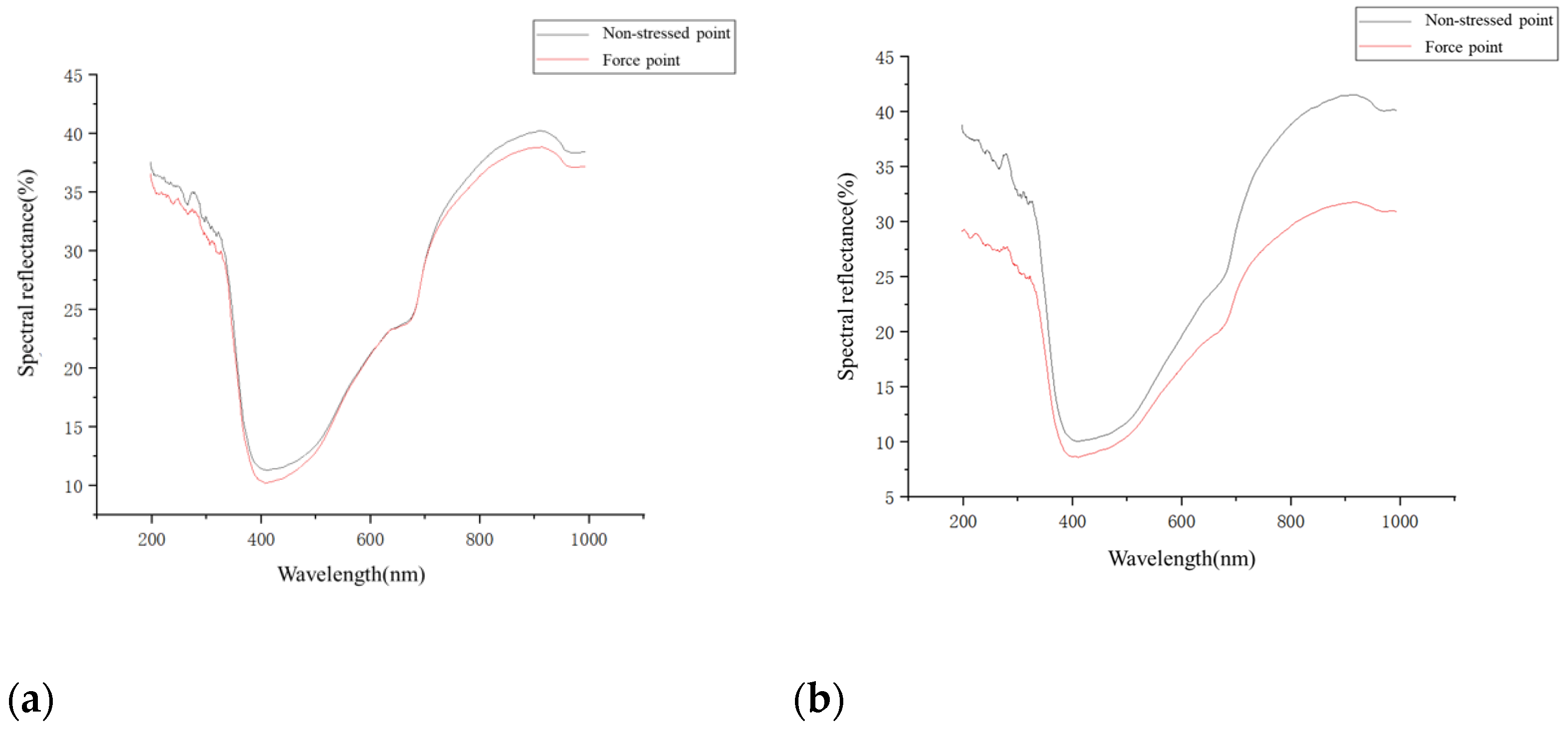

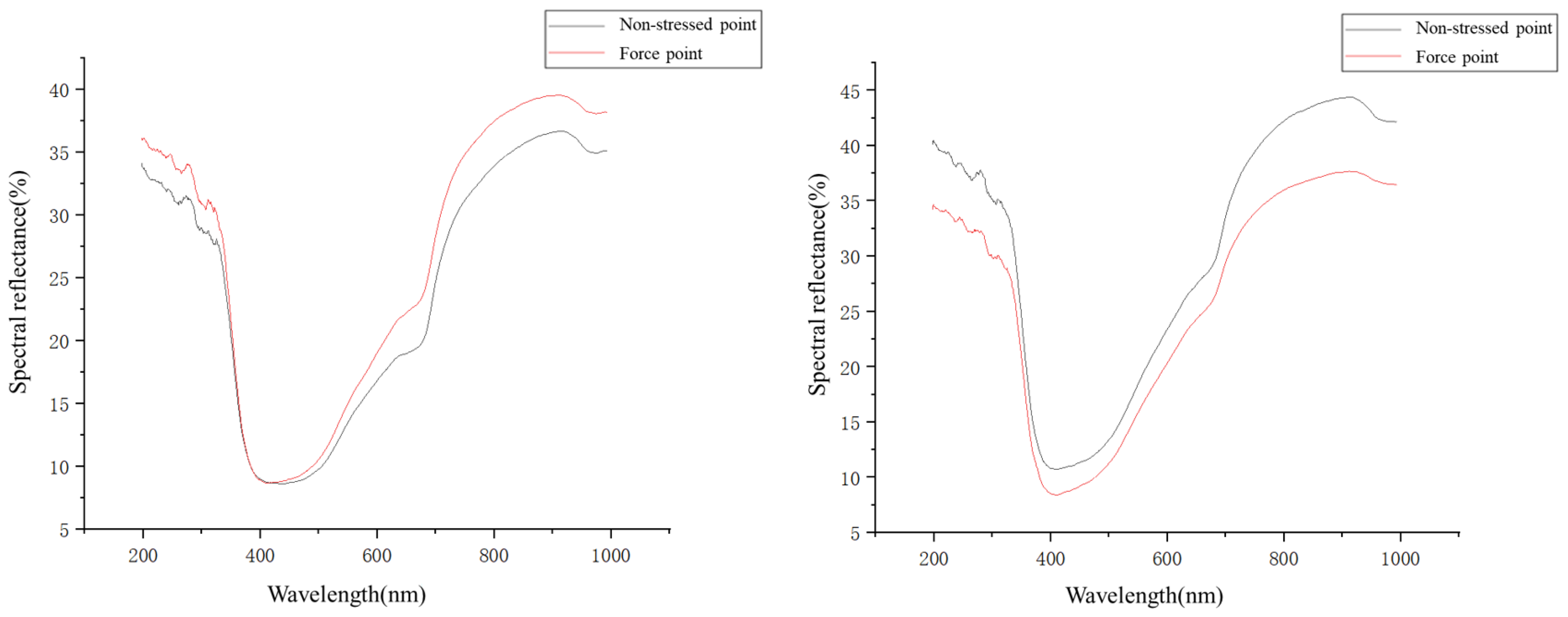

3.1. Kiwifruit Mechanical Parameters

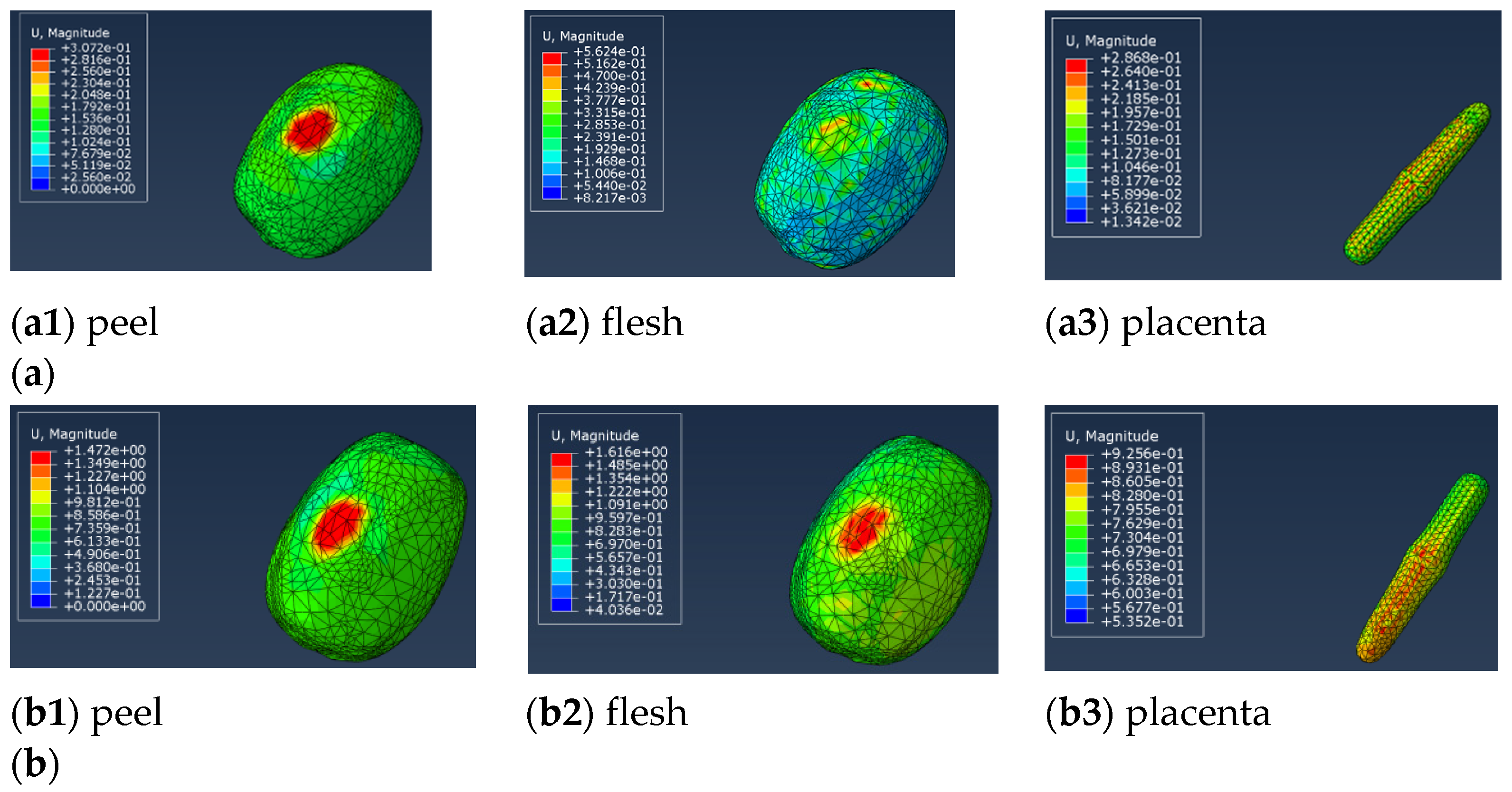

3.2. Simulation and Results Analysis

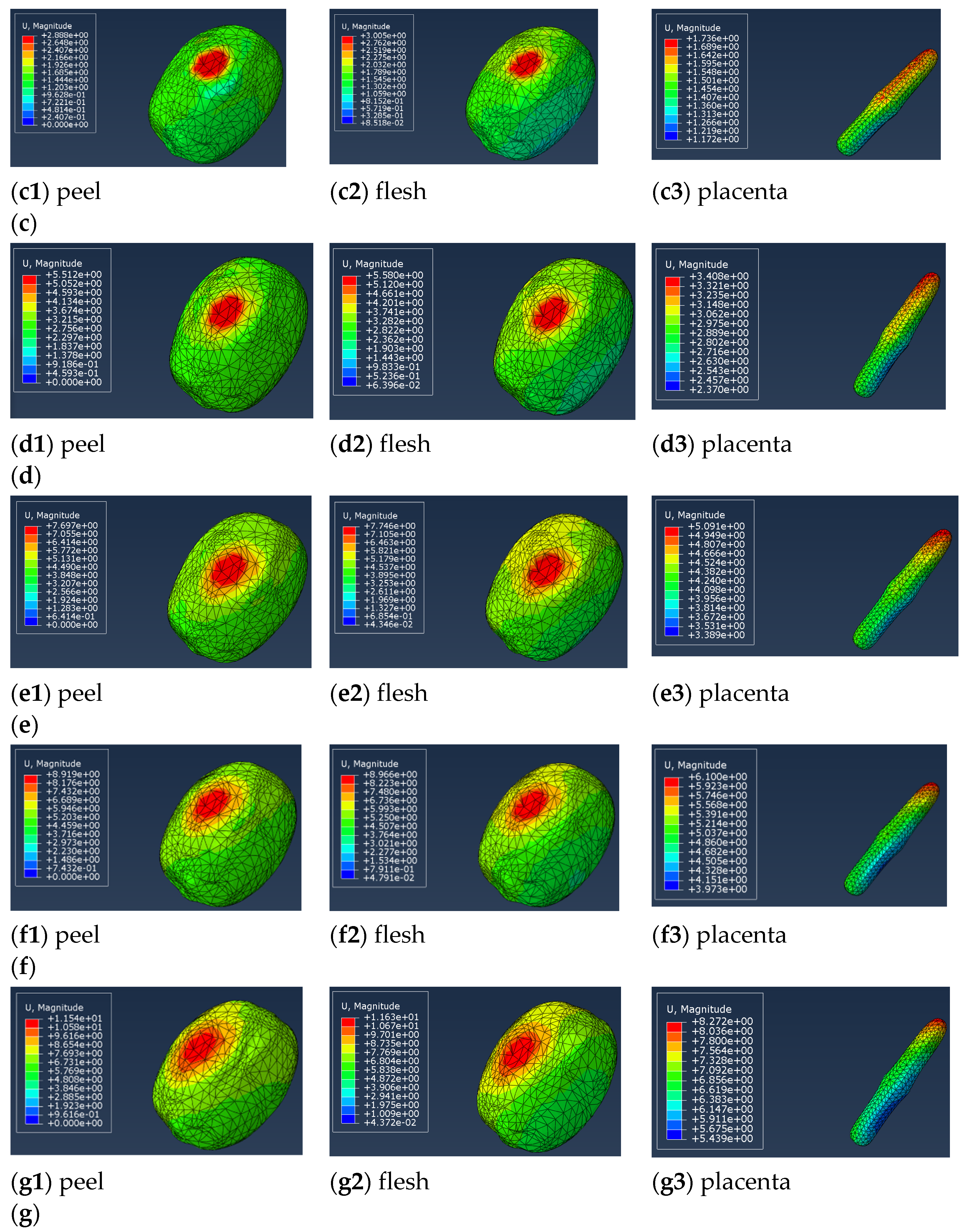

3.2.1. Analysis of Grasping Kiwifruit Results

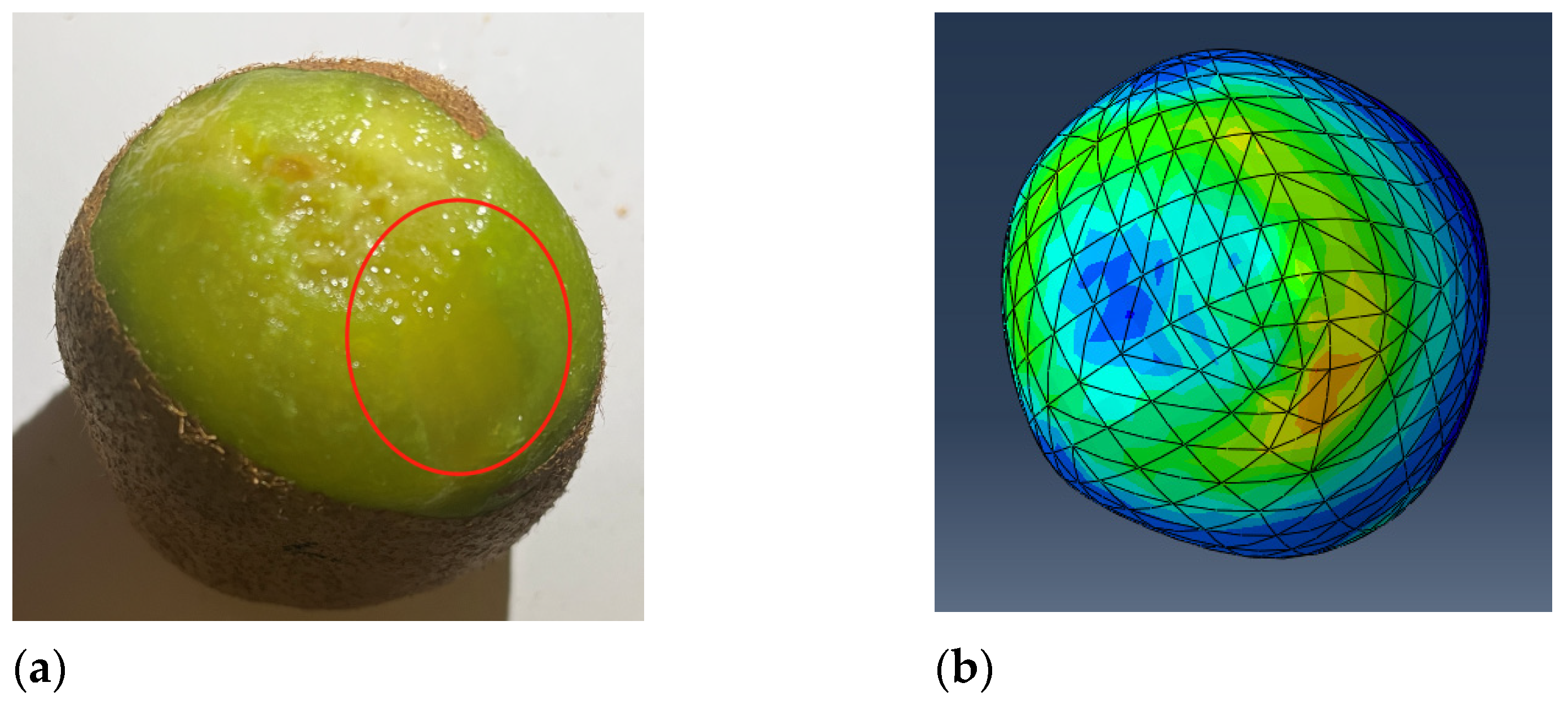

3.2.2. Analysis of Kiwifruit Picking Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN Food & Agriculture Organization. Production of Kiwi (Fruit) by Countries. 2020. Available online: https://www.un.org/en/node/96999 (accessed on 25 June 2020).

- FAO. FAOSTAT: Crops and Livestock Products. 2020. Available online: https://www.fao.org/faostat (accessed on 25 June 2020).

- Fu, L.; Wang, B.; Cui, Y.; Su, S.; Gejima, Y.; Kobayashi, T. Kiwifruit recognition at nighttime using artificial lighting based on machine vision. Int. J. Agric. Biol. Eng. 2015, 8, 52–59. [Google Scholar]

- Zhou, J.; He, L.; Karkee, M.; Zhang, Q. Effect of catching surface and tilt angle on bruise damage of sweet cherry due to mechanical impact. Comput. Electron. Agric. 2016, 121, 282–289. [Google Scholar] [CrossRef] [Green Version]

- Barnett, J.; Duke, M.; Au, C.K.; Lim, S.H. Work distribution of multiple Cartesian robot arms for kiwifruit harvesting. Comput. Electron. Agric. 2020, 169, 105202. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Satitmunnaithum, J.; Kitazawa, H.; Arofatullah, N.A.; Widiastuti, A.; Kharisma, A.D.; Yamane, K.; Tanabata, S.; Sato, T. Microbial population size and strawberry fruit firmness after drop shock−induced mechanical damage. Postharv. Biol. Technol. 2022, 192, 112008. [Google Scholar] [CrossRef]

- An, X.; Liu, H.; Fadiji, T.; Li, Z.; Dimitrovski, D. Prediction of the temperature sensitivity of strawberry drop damage using dynamic finite element method. Postharv. Biol. Technol. 2022, 190, 111939. [Google Scholar] [CrossRef]

- Fu, H.; Du, W.; Yang, J.; Wang, W.; Wu, Z.; Yang, Z. Bruise measurement of fresh market apples caused by repeated impacts using a pendulum method. Postharv. Biol. Technol. 2023, 195, 112143. [Google Scholar] [CrossRef]

- Guan, X.; Li, T.; Zhou, F. Determination of bruise susceptibility of fresh corn to impact load by means of finite element method simulation. Postharv. Biol. Technol. 2023, 198, 112227. [Google Scholar] [CrossRef]

- Lewis, R.; Yoxall, A.; Canty, L.A. Development of engineering design tools to help reduce apple bruising. J. Food Eng. 2007, 83, 356–365. [Google Scholar] [CrossRef] [Green Version]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Bruise damage susceptibility of pomegranates (Punica granatum, L.) and impact on fruit physiological response during short term storage. Sci. Hortic. 2019, 246, 664–674. [Google Scholar] [CrossRef]

- Liu, W.; Liu, T.; Zeng, T.; Ma, R.; Cheng, Y.; Zheng, Y.; Qiu, J.; Qi, L. Prediction of internal mechanical damage in pineapple compression using finite element method based on Hooke’s and Hertz’s laws. Sci. Hortic. 2023, 308, 111592. [Google Scholar] [CrossRef]

- Ji, W.; Li, J.; Yang, J.; Ding, S.; Zhao, D. Finite element analysis and verification of the grasping damage mechanism of apple picking by robotic hand. Trans. Chin. Soc. Agric. Eng. 2015, 31, 17–22. (In Chinese) [Google Scholar]

- Scheffler, O.C.; Coetzee, C.J.; Opara, U.L. A discrete element model (DEM) for predicting apple damage during handling. Biosyst. Eng. 2018, 172, 29–48. [Google Scholar] [CrossRef] [Green Version]

- Celik, H.K. Determination of bruise susceptibility of pears (Ankara variety) to impact load by means of FEM−based explicit dynamics simulation. Postharv. Biol. Technol. 2017, 128, 83–97. [Google Scholar] [CrossRef]

- Salarikia, A.; Ashtiani, S.-H.M.; Golzarian, M.R. Hamid Mohammadinezhad, Finite element analysis of the dynamic behavior of pear under impact loading. Inf. Process. Agric. 2017, 4, 64–77. [Google Scholar]

- Han, X.; Liu, Y.; Tchuenbou−Magaia, F.; Li, Z.; Khojastehpour, M.; Li, B. Analysis of the collision−damage susceptibility of sweet cherry related to environment temperature: A numerical simulating method. J. Food Eng. 2022, 333, 111140. [Google Scholar] [CrossRef]

- Liu, H.; Han, X.; Fadiji, T.; Li, Z.; Ni, J. Prediction of the cracking susceptibility of tomato pericarp: Three−point bending simulation using an extended finite element method. Postharv. Biol. Technol. 2022, 187, 111876. [Google Scholar] [CrossRef]

- Du, D.; Wang, B.; Wang, J.; Yao, F.; Hong, X. Prediction of bruise susceptibility of harvested kiwifruit (Actinidia chinensis) using finite element method. Postharv. Biol. Technol. 2019, 152, 36–44. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y. A multiscale finite element model for mechanical response of fruits. Postharv. Biol. Technol. 2016, 121, 19–26. [Google Scholar] [CrossRef]

- Otero, R.; Lagüela, S.; Cabaleiro, M.; Sousa, H.S.; Arias, P. Semi−automatic 3D frame modelling of wooden trusses using indoorpoint clouds. Structures 2023, 47, 1743–1753. [Google Scholar] [CrossRef]

- Uba, F.; Esandoh, E.O.; Zogho, D.; Anokye, E.G. Physical and mechanical properties of locally cultivated tomatoes in Sunyani, Ghana. Sci. Afr. 2020, 10, e00616. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, J.; Yi, B.; Zhang, B.; Wang, K. A flexible swallowing gripper for harvesting apples and its grasping force sensing model. Comput. Electron. Agric. 2023, 204, 107489. [Google Scholar] [CrossRef]

- Polychroniadou, C.; Michailidis, M.; Adamakis, I.-D.S.; Karagiannis, E.; Ganopoulos, I.; Tanou, G.; Bazakos, C.; Molassiotis, A. Mechanical stress elicits kiwifruit ripening changes in gene expression and metabolic status. Postharv. Biol. Technol. 2022, 194, 112102. [Google Scholar] [CrossRef]

- Li, H.; Guo, W.; Yue, R. Non−destructive testing of kiwifruit hardness, near−infrared diffuse reflectance spectroscopy. Trans. Chin. Soc. Agric. Mach. 2011, 42, 145–149. (In Chinese) [Google Scholar]

- Fu, L.; Zhang, F.; Guidang, F.; Li, Z.; Wang, B.; Cui, Y. Design and test of end effector for kiwifruit picking robot. Trans. Chin. Soc. Agric. Mach. 2015, 46, 1–8. (In Chinese) [Google Scholar]

| Density | Elastic Modulus /(MPa) | Breaking Stress /(MPa) | Poisson’s Ratio | |

|---|---|---|---|---|

| Peel | 0.551 ± 0.050 | 11.20 ± 0.50 | 1.51 ± 0.21 | 0.30 |

| Flesh | 1.122 ± 0.020 | 2.22 ± 0.30 | 0.45 ± 0.08 | 0.30 |

| Placenta | 1.063 ± 0.040 | 4.17 ± 0.20 | 1.60 ± 0.15 | 0.30 |

| Stressed | Peel/(MPa) | Flesh/(MPa) | Placenta/(MPa) | |||

|---|---|---|---|---|---|---|

| Max | Min | Max | Min | Max | Min | |

| 5 | 0.36 | 1.86 × 10−3 | 7.29 × 10−2 | 3.02 × 10−4 | 1.36 × 10−2 | 1.38 × 10−4 |

| 25 | 1.72 | 7.08 × 10−3 | 0.22 | 1.65 × 10−3 | 9.97 × 10−2 | 6.75 × 10−4 |

| 50 | 3.27 | 1.96 × 10−2 | 0.56 | 9.65 × 10−4 | 0.56 | 9.65 × 10−4 |

| 100 | 4.26 | 3.08 × 10−2 | 0.89 | 4.40 × 10−3 | 0.71 | 2.04 × 10−3 |

| 150 | 4.38 | 5.41 × 10−2 | 0.69 | 6.85 × 10−3 | 1.17 | 3.39 × 10−3 |

| 180 | 4.21 | 6.88 × 10−2 | 0.92 | 1.29 × 10−2 | 1.19 | 5.24 × 10−3 |

| 250 | 4.33 | 8.54 × 10−2 | 0.93 | 1.55 × 10−2 | 1.27 | 6.80 × 10−2 |

| Stressed | Peel/(mm) | Flesh/(mm) | Placenta/(mm) | |||

|---|---|---|---|---|---|---|

| Max | Min | Max | Min | Max | Min | |

| 5 | 0.31 | 0.00 | 0.56 | 8.22 × 10−3 | 0.29 | 1.34 × 10−2 |

| 25 | 1.47 | 0.00 | 1.62 | 4.04 × 10−2 | 0.93 | 0.54 |

| 50 | 2.89 | 0.00 | 3.01 | 8.52 × 10−2 | 1.74 | 1.17 |

| 100 | 5.51 | 0.00 | 5.58 | 6.40 × 10−2 | 3.41 | 2.37 |

| 150 | 7.70 | 0.00 | 7.75 | 4.35 × 10−2 | 5.09 | 3.39 |

| 180 | 8.92 | 0.00 | 8.97 | 4.79 × 10−2 | 6.10 | 3.97 |

| 250 | 11.54 | 0.00 | 11.63 | 4.37 × 10−2 | 8.27 | 5.44 |

| No. | Force /N | Simulate Deformation /mm | Test Deformation /mm | Error Rate /% | Correlation Coefficient r |

|---|---|---|---|---|---|

| 1 | 5.00 | 0.56 | 0.62 | 9.68% | 0.99 |

| 2 | 25.00 | 1.62 | 1.45 | −11.72% | |

| 3 | 50.00 | 3.01 | 3.46 | 13.01% | |

| 4 | 100.00 | 5.58 | 5.90 | 5.42% | |

| 5 | 150.00 | 7.75 | 7.76 | 0.13% | |

| 6 | 180.00 | 8.97 | 8.83 | −1.59% | |

| 7 | 250.00 | 11.63 | 11.25 | −3.38% |

| Force/N | 0 | 5 | 25 | 50 | 100 | 150 | 180 | 250 |

|---|---|---|---|---|---|---|---|---|

| Hardness value | 12.73 | 12.06 | 10.19 | 9.55 | 8.91 | 8.53 | 6.37 | 5.86 |

| ∆x/% | / | 1.80 | 2.18 | 3.77 | 5.48 | 9.84 | / | / |

| /nm | / | 346.301 | 424.257 | 503.746 | 916.089 | 891.24 | / | / |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Hardness value | 9.42 | 8.66 | 6.37 | 6.49 | 10.70 | 7.56 | 8.62 | 9.15 | 7.88 | 8.16 |

| ∆x/% | 4.15 | 5.21 | 6.73 | 12.11 | 3.81 | 6.33 | 6.12 | 4.57 | 6.91 | 5.88 |

| /nm | 735.59 | 913.90 | 687.42 | 909.52 | 197.72 | 691.29 | 678.35 | 712.45 | 192.81 | 921.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; He, Z.; Hao, W.; Li, K.; Ding, X.; Cui, Y. Kiwifruit Harvesting Damage Analysis and Verification. Processes 2023, 11, 598. https://doi.org/10.3390/pr11020598

Li Z, He Z, Hao W, Li K, Ding X, Cui Y. Kiwifruit Harvesting Damage Analysis and Verification. Processes. 2023; 11(2):598. https://doi.org/10.3390/pr11020598

Chicago/Turabian StyleLi, Zixu, Zhi He, Wei Hao, Kai Li, Xinting Ding, and Yongjie Cui. 2023. "Kiwifruit Harvesting Damage Analysis and Verification" Processes 11, no. 2: 598. https://doi.org/10.3390/pr11020598

APA StyleLi, Z., He, Z., Hao, W., Li, K., Ding, X., & Cui, Y. (2023). Kiwifruit Harvesting Damage Analysis and Verification. Processes, 11(2), 598. https://doi.org/10.3390/pr11020598