Textural, Rheological, and Sensory Modifications in Oaxaca Cheese Made with Ultrasonicated Raw Milk

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

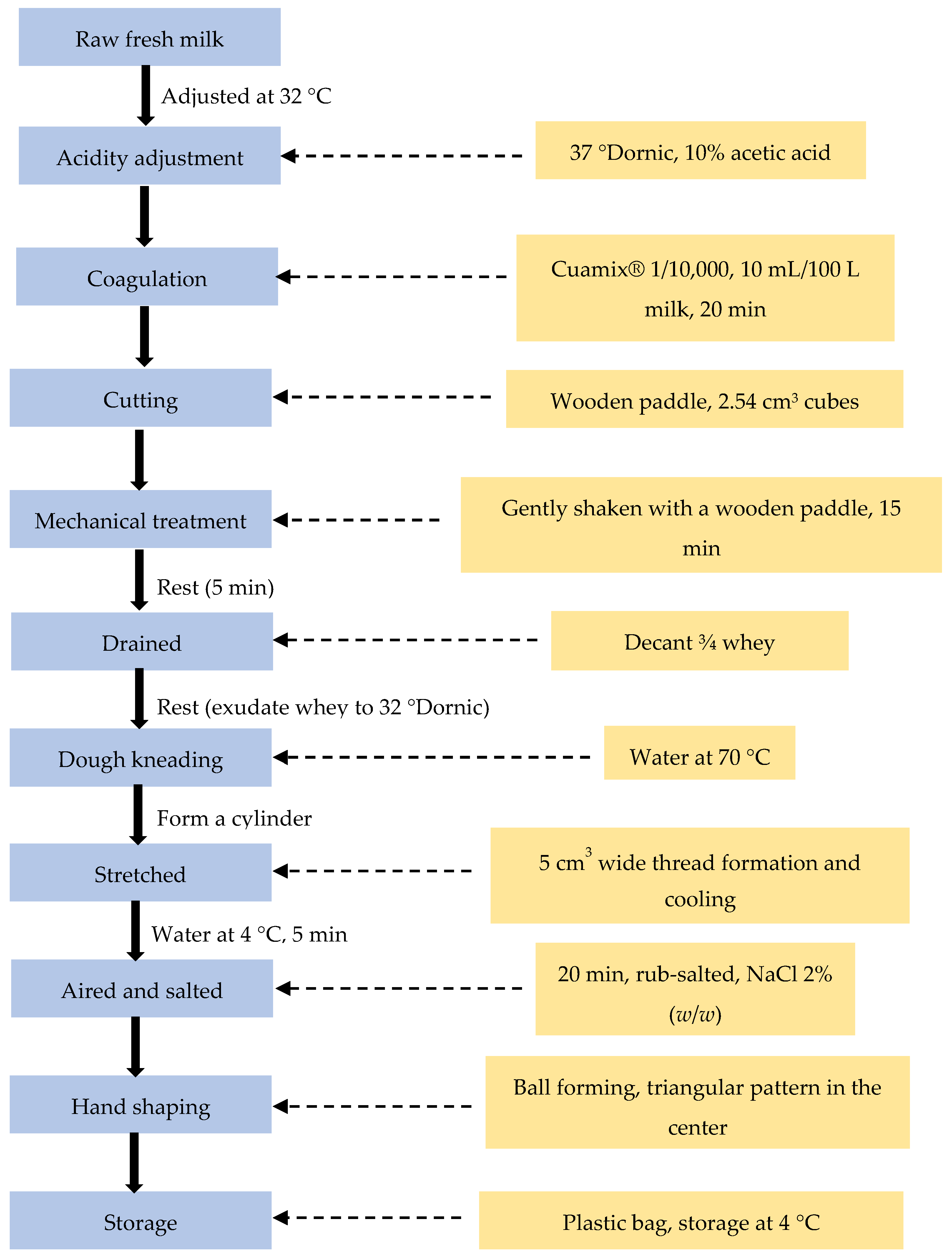

2.2. Oaxaca Cheese-Making Process

2.3. Strand and Melt Tests

2.4. Texture and Rheological Properties

2.5. Microstructural Analysis

2.6. Consumer Sensory Analysis

2.7. Statistical Analysis

3. Results and Discussion

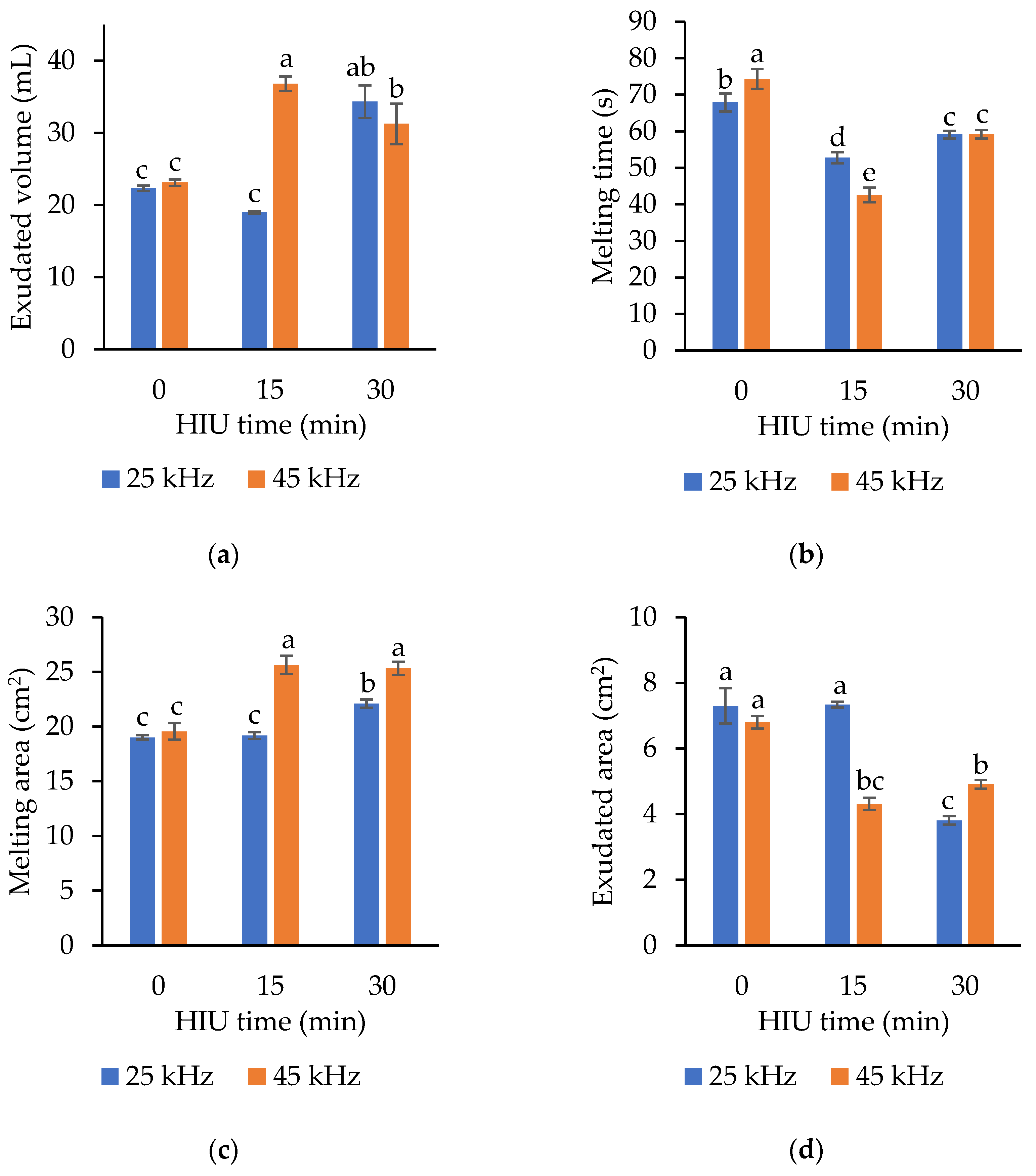

3.1. Strand and Melt Tests

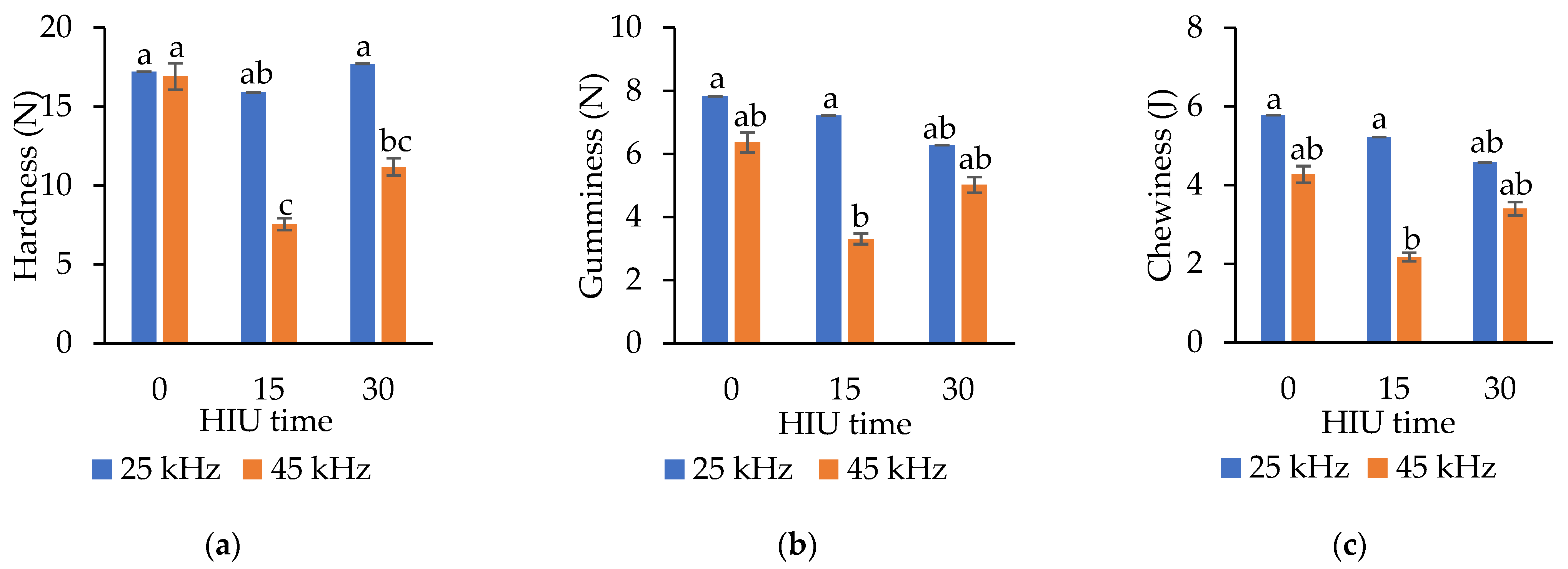

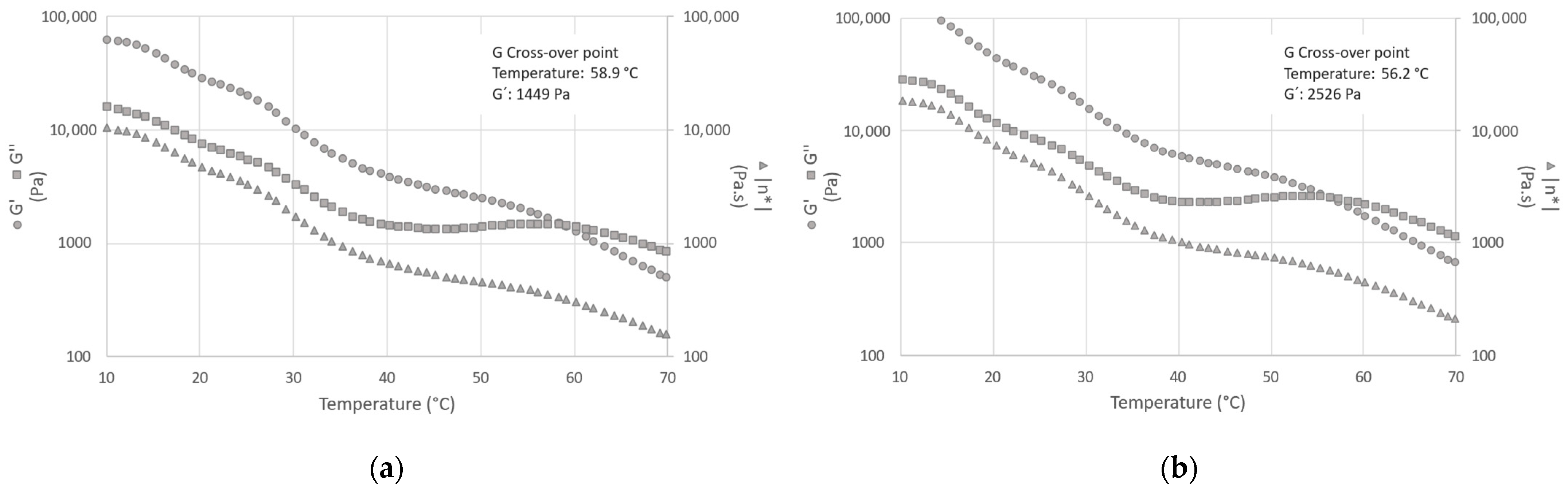

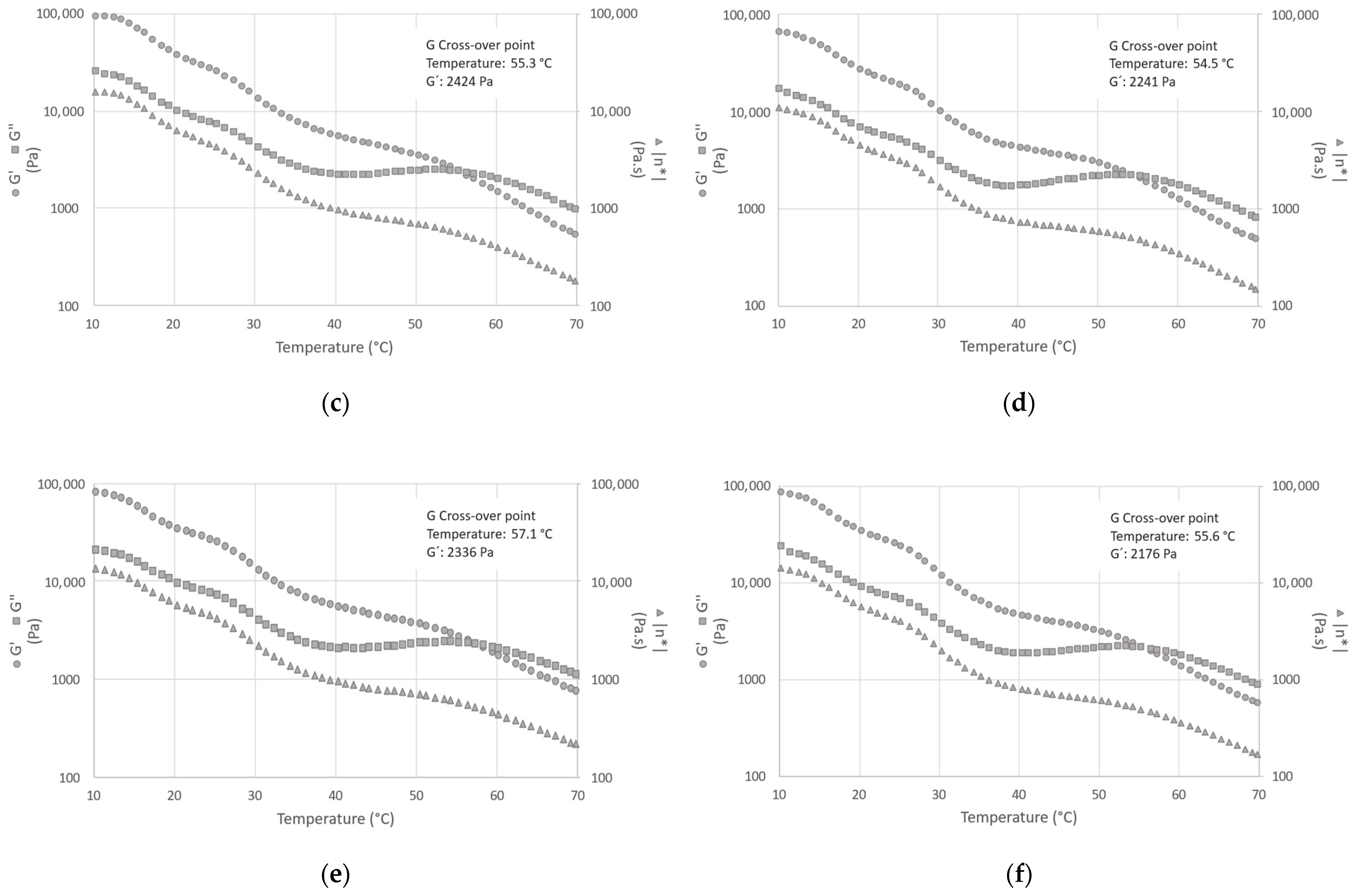

3.2. Texture Profile and Rheometry

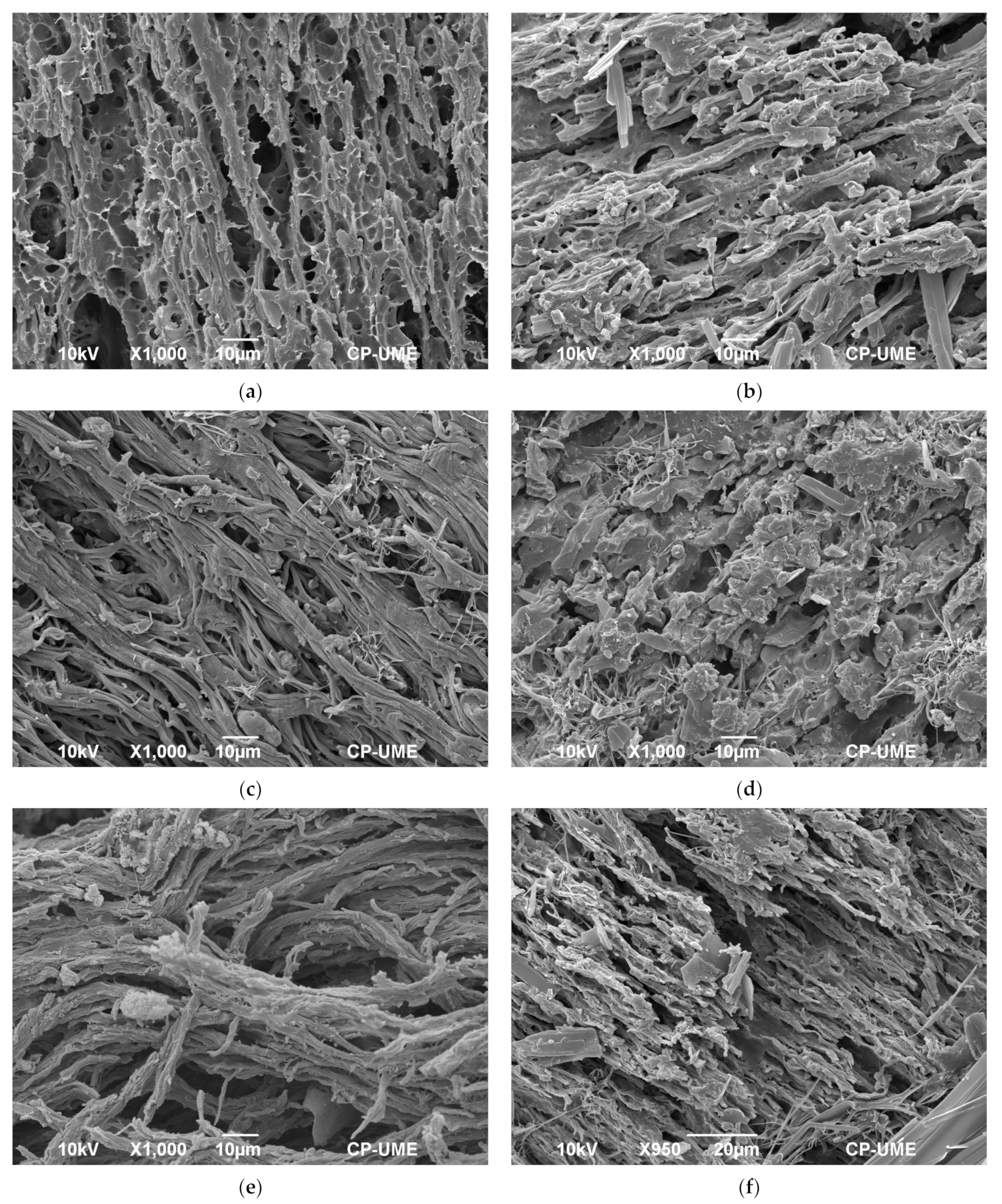

3.3. Microstructure

3.4. Consumer Sensory Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Oca-Flores, E.M.; Castelán-Ortega, O.A.; Estrada-Flores, J.G.; Espinoza-Ortega, A. Oaxaca cheese: Manufacture process and physicochemical characteristics. Int. J. Dairy Technol. 2009, 62, 535–540. [Google Scholar] [CrossRef]

- Cervantes-Escoto, F.; Villegas de Gante, A.; Cesín-Vargas, J.A.; Espinoza-Ortega, A. Los Quesos Mexicanos Genuinos. Patrimonio Cultural Que Debe Rescatarse, 1st ed.; Mundi Prensa México: México City, México, 2008; pp. 1–25. [Google Scholar]

- Aguilar-Uscanga, B.R.; Montero-Lagunes, M.; De la Cruz, J.; Solís-Pacheco, J.R.; García, H.S. Using fermented cheese whey to reduce acidification time of Oaxaca cheese. Agrociencia 2006, 40, 569–575. [Google Scholar]

- González-Córdova, A.F.; Yescas, C.; Ortiz-Estrada, A.M.; De la Rosa-Alcaraz, M.; Hernández-Mendoza, A.; Vallejo-Cordoba, B. Invited review: Artisanal Mexican cheeses. J. Dairy Sci. 2016, 99, 3250–3262. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Villanueva-Carvajal, A.; Esteban-Chávez, M.; Espinoza-Ortega, A.; Arriaga-Jordán, C.M.; Dominguez-Lopez, A. Oaxaca cheese: Flavour, texture and their interaction in a Mexican traditional pasta filata type cheese. CyTA J. Food 2012, 10, 63–70. [Google Scholar] [CrossRef] [Green Version]

- Morales-Celaya, M.F.; Lobato-Calleros, C.; Alvarez-Ramirez, J.; Vernon-Carter, E.J. Effect of milk pasteurization and acidification method on the chemical composition and microstructure of a Mexican pasta filata cheese. LWT-Food Sci. Technol. 2012, 45, 132–141. [Google Scholar] [CrossRef]

- Metzger, L.E.; Barbano, D.M.; Kindstedt, P.S.; Guo, M.R. Effect of milk preacidification on low fat Mozzarella cheese: II. Chemical and functional properties during storage. J. Dairy Sci. 2001, 84, 1348–1356. [Google Scholar] [CrossRef]

- Carrillo-Lopez, L.M.; Garcia-Galicia, I.A.; Tirado-Gallegos, J.M.; Sanchez-Vega, R.; Huerta-Jimenez, M.; Ashokkumar, M.; Alarcon-Rojo, A.D. Recent advances in the application of ultrasound in dairy products: Effect on functional, physical, chemical, microbiological and sensory properties. Ultrason. Sonochem. 2021, 73, 105467. [Google Scholar] [CrossRef]

- Liu, Z.; Juliano, P.; Williams, R.P.; Niere, J.; Augustin, M.A. Ultrasound improves the renneting properties of milk. Ultrason. Sonochem. 2014, 21, 2131–2137. [Google Scholar] [CrossRef]

- Chandrapala, J.; Martin, G.J.O.; Zisu, B.; Kentish, S.E.; Ashokkumar, M. The effect of ultrasound on casein micelle integrity. J. Dairy Sci. 2012, 95, 6882–6890. [Google Scholar] [CrossRef] [Green Version]

- Hayaloglu, A.A.; Guven, M.; Fox, P.F.; McSweeney, P.L. Influence of starters on chemical, biochemical, and sensory changes in Turkish White-brined cheese during ripening. J. Dairy Sci. 2005, 88, 3460–3474. [Google Scholar] [CrossRef] [Green Version]

- Jalilzadeh, A.; Hesari, J.; Peighambardoust, S.H.; Javidipour, I. The effect of ultrasound treatment on microbial and physicochemical properties of Iranian ultrafiltered feta-type cheese. J. Dairy Sci. 2018, 101, 5809–5820. [Google Scholar] [CrossRef]

- Huerta-Jimenez, M.; Herrera-Gomez, B.; Dominguez-Ayala, E.A.; Chavez-Martinez, A.; Juarez-Moya, J.; Felix-Portillo, M.; Alarcon-Rojo, A.D.; Carrillo-Lopez, L.M. Properties of Oaxaca Cheese Elaborated with Ultrasound-Treated Raw Milk: Physicochemical and Microbiological Parameters. Foods 2022, 11, 1735. [Google Scholar] [CrossRef]

- Villegas de Gante, A. Tecnología Quesera, 2nd ed.; Trillas: México City, México, 2012; pp. 135–218. [Google Scholar]

- Muthukumarappan, K.; Wang, Y.-C.; Gunasekaran, S. Short communication: Modified Schreiber Test for evaluation of Mozzarella cheese meltability. J. Dairy Sci. 1999, 82, 1068–1071. [Google Scholar] [CrossRef]

- Nájera-Domínguez, C.; Gutiérrez-Méndez, N.; Aguirre-Gardea, K.; Peralta-Bolivar, A.; Chavez-Garay, D.R.; Leal-Ramos, M.Y. Texture Properties of Miniature Chihuahua-Type Cheese Manufactured with Different Strains of Lactococcus Lactis Isolated from Plants and Raw Milk Cheese. J. Texture Stud. 2014, 45, 487–494. [Google Scholar] [CrossRef]

- MacFie, H.J.; Bratchell, N.; Greenhoff, K.; Vallis, L.V. Designs to balance the effect of order of presentation and first-order carry-over effects in hall tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Ceville, G.V.; Carr, B.T. Sensory Evaluation Techniques, 5th ed.; CRC Press: Boca Raton, FL, USA, 2015; 632p. [Google Scholar]

- Lawless, H.T.; Heymann, H. Preference testing. In Sensory Evaluation of Food: Principles and Practices, 1st ed.; Lawless, H.T., Heymann, H., Eds.; Springer New York: New York, NY, USA, 2010; pp. 303–324. [Google Scholar]

- Lazzaroni, C.; Gigli, S.; Gabina, D. Evaluation of Carcass and Meat Quality in Cattle and Sheep, EAAP Scientific Series 23 Volume 123, 1st ed.; Wageningen Academic Publishers: Wageningen, The Netherlands, 2007; 228p. [Google Scholar]

- Carrillo-Lopez, L.M.; Juarez-Morales, M.G.; Garcia-Galicia, I.A.; Alarcon-Rojo, A.D.; Huerta-Jimenez, M. The effect of high-intensity ultrasound on the physicochemical and microbiological properties of Mexican panela cheese. Foods 2020, 9, 313. [Google Scholar] [CrossRef] [Green Version]

- Bermúdez-Aguirre, D.; Mobbs, T.; Barbosa-Cánovas, G.V. Ultrasound Applications in Food Processing. In Ultrasound Technologies for Food and Bioprocessing, 1st ed.; Feng, H., Barbosa-Cánovas, G., Weiss, J., Eds.; Springer: New York, NY, USA, 2011; pp. 65–105. [Google Scholar]

- Zhao, L.; Zhang, S.; Uluko, H.; Liu, L.; Lu, J.; Xue, H.; Kong, F.; Lv, J. Effect of ultrasound pretreatment on rennet-induced coagulation properties of goat’s milk. Food Chem. 2014, 165, 167–174. [Google Scholar] [CrossRef]

- McMahon, D.J.; Paulsen, B.; Oberg, C.J. Influence of Calcium, pH, and Moisture on Protein Matrix Structure and Functionality in Direct-Acidified Nonfat Mozzarella Cheese. J. Dairy Sci. 2005, 88, 3754–3763. [Google Scholar] [CrossRef] [Green Version]

- Uluko, H.; Zhang, S.; Liu, L.; Tsakama, M.; Lu, J.; Lv, J. Effect of thermal, microwave, and ultrasound pretreatments on antioxidative capacity of enzymatic milk protein concentrate hydrolysates. J. Func. Foods 2015, 18, 1138–1146. [Google Scholar] [CrossRef]

- Supeno Kruus, P. Sonochemical formation of nitrate and nitrite in water. Ultrason. Sonochem. 2000, 7, 109–113. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Lelas, V.; Mason, T.J.; Krešić, G.; Badanjak, M. Physical properties of ultrasound treated soy proteins. J. Food Eng. 2009, 93, 386–393. [Google Scholar] [CrossRef]

- McMahon, D.J.; Oberg, C.J. Pasta-filata cheeses. In Cheese: Chemistry, Physics and Microbiology (Vol. 2), 4th ed.; Fox, P., McSweeney, P., Fox, P.F., Cotter, P.D., Everett, D.W., Eds.; Elsevier Academic Press: London, UK, 2017; pp. 1041–1068. [Google Scholar]

- Correia, G.M.; Cardarelli, H.R. Mozzarella cheese stretching: A minireview. Food Technol. Biotechnol. 2021, 59, 82–91. [Google Scholar] [CrossRef] [PubMed]

- Kindstedt, P.S. Low-moisture mozzarella cheese (LMMC). In Cheese problems solved, A volume in Woodhead Publishing Series in Food Science, Technology and Nutrition, 1st ed.; McSweeney, P.L.H., Ed.; Woodhead Publishing: Cambridge, UK, 2007; pp. 298–329. [Google Scholar]

- Gonçalves, M.C.; Cardarelli, H.R. Composition, microstructure and chemical interactions during the production stages of mozzarella cheese. Int. Dairy J. 2019, 88, 34–41. [Google Scholar] [CrossRef]

- Bahri, S.M.H.; Kenari, R.E. The effects of ultrasound waves on yield, texture and some qualitative characteristics of cheese. Iran. Food Sci. Technol Res. J 2018, 14, 41–51. [Google Scholar] [CrossRef]

- Koca, N.; Metin, M. Textural, melting and sensory properties of low-fat fresh kashar cheeses produced by using fat replacers. Int. Dairy J. 2004, 14, 365–373. [Google Scholar] [CrossRef]

- Tunick, M.H.; Mackey, K.L.; Smith, P.W.; Holsinger, V.H. Effects of composition and storage on the texture of Mozzarella cheese. Neth. Milk Dairy J. 1991, 45, 117–125. [Google Scholar]

- Gaya, P.; Sánchez, C.; Nuñez, M.; Fernández-García, E. Proteolysis during ripening of Manchego cheese made from raw or pasteurized ewes’ milk. Seasonal variation. J. Dairy Res. 2005, 72, 287–295. [Google Scholar] [CrossRef]

- Sánchez, E.; Simal, S.; Femenia, A.; Llull, P.; Rosselló, C. Proteolysis of Mahon cheese as affected by acoustic-assisted brining. Eur. Food Res. Technol. 2001, 212, 147–152. [Google Scholar] [CrossRef]

- Pastorino, A.J.; Hansen, C.L.; McMahon, D.J. Effect of pH on the chemical composition and structure-function relationships of cheddar cheese. J. Dairy Sci. 2003, 86, 2751–2760. [Google Scholar] [CrossRef] [Green Version]

- Eroglu, A.; Toker, O.S.; Dogan, M. Changes in the texture, physicochemical properties and volatile compound profiles of fresh Kashar cheese (<90 days) during ripening. Int. J. Dairy Technol. 2016, 69, 243–253. [Google Scholar]

- Al-Hilphy, R.S.; Niamah, A.K.; Al-Temimi, A.B. Effect of ultrasonic treatment on buffalo milk homogenization and numbers of bacteria. Int. J. Food Sci. Nutr. Eng. 2012, 2, 113–118. [Google Scholar] [CrossRef] [Green Version]

- Fröhlich-Wyder, M.T.; Guggisberg, D.; Wechsler, D. Influence of low calcium and low pH on melting characteristics of model Raclette cheese. Dairy Sci. Technol. 2009, 89, 463–483. [Google Scholar] [CrossRef]

- Zeke, I.C.; Juhász, R.; Schüller, R.B.; Rukke, E.O. Rheological Properties of a Selection of Common Norwegian Food Products. Annu. Trans. Nord. Rheol. Soc. 2010, 18, 123–127. [Google Scholar]

- Almanza-Rubio, J.L.; Gutiérrez-Méndez, N.; Leal-Ramos, M.Y.; Sepulveda, D.; Salmeron, I. Modification of the textural and rheological properties of cream cheese using thermosonicated milk. J. Food Eng. 2016, 168, 223–230. [Google Scholar] [CrossRef]

- Everett, D.W.; Auty, M.A. Cheese structure and current methods of analysis. Int. Dairy J. 2008, 18, 759–773. [Google Scholar] [CrossRef]

- Schenkel, P.; Samudrala, R.; Hinrichs, J. Thermo-physical properties of semi-hard cheese made with different fat fractions: Influence of melting point and fat globule size. Int. Dairy J. 2013, 30, 79–87. [Google Scholar] [CrossRef]

- Kindstedt, P.; Carić, M.; Milanović, S. Pasta-filata cheeses. In Cheese: Chemistry, Physics and Microbiology (Vol. 2), 3rd ed.; Fox, P., McSweeney, P., Cogan, T., Guinee, T., Eds.; Elsevier Academic Press: London, UK, 2004; pp. 251–277. [Google Scholar]

- Oberg, C.J.; McManus, W.R.; McMahon, D.J. Microstructure of mozzarella cheese during manufacture. Food Struct. 1993, 12, 251–258. [Google Scholar]

- Feeney, E.P.; Guinee, T.P.; Fox, P.F. Effect of pH and calcium concentration on proteolysis in Mozzarella cheese. J. Dairy Sci. 2002, 85, 1646–1654. [Google Scholar] [CrossRef]

- Zisu, B.; Shah, N.P. Textural and functional changes in low fat Mozzarella cheese in relation to proteolysis and microstructure as influenced by the use of fat replacers, pre-acidification and EPS starter. Int. Dairy J. 2005, 15, 957–972. [Google Scholar] [CrossRef]

- Fox, P.F. Proteolysis during cheese manufacture and ripening. J. Dairy Sci. 1989, 72, 1379–1400. [Google Scholar] [CrossRef]

- Joshi, N.S.; Muthukumarappan, K.; Dave, R.I. Understanding the role of calcium in functionality of part-skim mozzarella cheese. J. Dairy Sci. 2003, 86, 1918–1926. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lindsay, R.M.; Saldaña, E. Consumer attitudes towards ultrasound processing and product price: Guava juice as a case study. Sci. Agropecu. 2021, 12, 193–202. [Google Scholar] [CrossRef]

- Monteiro, M.L.G.; Deliza, R.; Mársico, E.T.; de Alcantara, M.; de Castro, I.P.L.; Conte-Junior, C.A. What Do Consumers Think About Foods Processed by Ultraviolet Radiation and Ultrasound? Foods 2022, 11, 434. [Google Scholar] [CrossRef] [PubMed]

- O’Mahony, M. Sensory adaptation. J. Sens. Stud. 1986, 1, 237–258. [Google Scholar] [CrossRef]

- Villamiel, M.; van Hamersveld, E.H.; de Jong, P. Review: Effect of ultrasound processing on the quality of dairy products. Milchwissenschaft 1999, 54, 69–73. [Google Scholar]

- Yeung, C.; Huang, S. Effects of Ultrasound Pretreatment and Ageing Processing on Quality and Tenderness of Pork Loin. J. Food Nutr. Res. 2017, 5, 809–816. [Google Scholar] [CrossRef]

- Barretto, T.L.; Rodrigues, P.M.A.; Telis-Romero, J.; da Silva, B.A.C. Improving sensory acceptance and physicochemical properties by ultrasound application to restructured cooked ham with salt (NaCl) reduction. Meat Sci. 2018, 145, 55–62. [Google Scholar] [CrossRef] [Green Version]

| Block | Titratable Acidity (°Dornic)/pH | Fat (%) | Protein (%) | Lactose (%) | Non-Fat Solids (%) |

|---|---|---|---|---|---|

| 1 | 17/6.56 | 3.64 | 3.19 | 4.91 | 8.81 |

| 2 | 17/6.57 | 3.57 | 3.22 | 4.95 | 8.88 |

| 3 | 17/6.57 | 3.59 | 3.18 | 4.89 | 8.78 |

| Factor | Exudate * | Melting ** | ||

|---|---|---|---|---|

| Block | Volume (mL) | Time (s) | Cheese Area (cm2) | Exudate Area (cm2) |

| 1 | 27.1 ± 6.8 a | 59.7 ± 12.5 a | 22.0 ± 3.3 a | 5.84 ± 1.7 a |

| 2 | 28.6 ± 8.2 a | 59.1 ± 11.8 a | 21.9 ± 2.9 a | 5.67 ± 1.5 a |

| 3 | 27.7 ± 7.1 a | 59.2 ± 9.2 a | 21.6 ± 3.1 a | 5.73 ± 1.6 a |

| HIU Frequency (kHz) | Volume (mL) | Time (s) | Cheese Area (cm2) | Exudate Area (cm2) |

| 25 | 25.2 ± 7.1 b | 59.9 ± 6.8 a | 20.1 ± 1.5 b | 6.15 ± 1.8 a |

| 45 | 30.4 ± 1.1 a | 58.7 ± 13.9 a | 23.5 ± 3.0 a | 5.34 ± 1.1 b |

| HIU Time (min) | Volume (mL) | Time (s) | Cheese Area (cm2) | Exudate Area (cm2) |

| 0 | 22.8 ± 0.6 c | 71.1 ± 4.2 a | 19.3 ± 0.6 c | 7.05 ± 0.5 a |

| 15 | 27.9 ± 9.8 b | 47.7 ± 5.8 c | 22.4 ± 3.6 b | 5.82 ± 1.7 b |

| 30 | 32.8 ± 2.8 a | 59.1 ± 1.0 b | 23.7 ± 1.8 a | 4.36 ± 0.6 c |

| Treatment | Texture Profile Analysis * | ||||||

|---|---|---|---|---|---|---|---|

| Block | H (N) | S (mm) | C (%) | G (N) | Ch (J) | R | A (N*s) |

| 1 | 14.2 ± 4.7 a | 0.68 ± 0.0 a | 0.40 ± 0.0 a | 5.61 ± 1.9 a | 3.9 ± 1.5 a | 0.20 ± 0.0 a | −0.13 ± 0.0 a |

| 2 | 14.4 ± 4.8 a | 0.69 ± 0.1 a | 0.45 ± 0.1 a | 6.38 ± 2.0 a | 4.47 ± 1.7 a | 0.23 ± 0.0 a | −0.18 ± 0.0 a |

| 3 | 14.6 ± 3.4 a | 0.72 ± 0.0 a | 0.42 ± 0.1 a | 6.02 ± 1.7 a | 4.34 ± 1.3 a | 0.23 ± 0.0 a | −0.2 ± 0.0 a |

| HIU Frequency (kHz) | H (N) | S (mm) | C (%) | G (N) | Ch. (J) | R. | A (N*s) |

| 25 | 17.0 ± 1.2 a | 0.73 ± 0.0 a | 0.42 ± 0.1 a | 7.11 ± 1.2 a | 5.19 ± 0.9 a | 0.23 ± 0.0 a | −0.16 ± 0.0 a |

| 45 | 11.9 ± 4.5 b | 0.66 ± 0.0 a | 0.44 ± 0.1 a | 4.9 ± 1.6 b | 3.28 ± 1.2 b | 0.20 ± 0.0 a | −0.18 ± 0.0 a |

| HIU Time (min) | H (N) | S (mm) | C (%) | G (N) | Ch. (J) | R. | A (N*s) |

| 0 | 17.1 ± 0.6 a | 0.70 ± 0.0 a | 0.41 ± 0.0 a | 7.09 ± 0.8 a | 5.02 ± 0.9 a | 0.21 ± 0.0 a | −0.19 ± 0.0 a |

| 15 | 11.7 ± 4.8 b | 0.69 ± 0.1 a | 0.45 ± 0.1 a | 5.27 ± 2.4 b | 3.69 ± 1.8 a | 0.23 ± 0.0 a | −0.13 ± 0.0 a |

| 30 | 14.5 ± 4.2 a,b | 0.70 ± 0.1 a | 0.40 ± 0.1 a | 5.65 ± 1.5 a,b | 3.99 ± 1.2 a | 0.22 ± 0.0 a | −0.19 ± 0.0 a |

| Preference | Treatment Group 1 * | Treatment Group 2 * | ||||

|---|---|---|---|---|---|---|

| 25 kHz, 0 min | 25 kHz, 15 min | 25 kHz, 30 min | 45 kHz, 0 min | 45 kHz, 15 min | 45 kHz, 30 min | |

| Rank sum ** | 108 a | 106 a | 86 b | 112 a | 87 b | 101 a,b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrillo-López, L.M.; Huerta-Jiménez, M.; Morales-Rodríguez, S.; Gámez-Piñón, J.R.; Carballo-Carballo, D.E.; Gutiérrez-Méndez, N.; Alarcón-Rojo, A.D. Textural, Rheological, and Sensory Modifications in Oaxaca Cheese Made with Ultrasonicated Raw Milk. Processes 2023, 11, 1122. https://doi.org/10.3390/pr11041122

Carrillo-López LM, Huerta-Jiménez M, Morales-Rodríguez S, Gámez-Piñón JR, Carballo-Carballo DE, Gutiérrez-Méndez N, Alarcón-Rojo AD. Textural, Rheological, and Sensory Modifications in Oaxaca Cheese Made with Ultrasonicated Raw Milk. Processes. 2023; 11(4):1122. https://doi.org/10.3390/pr11041122

Chicago/Turabian StyleCarrillo-López, Luis M., Mariana Huerta-Jiménez, Simón Morales-Rodríguez, Jesús R. Gámez-Piñón, Diego E. Carballo-Carballo, Néstor Gutiérrez-Méndez, and Alma D. Alarcón-Rojo. 2023. "Textural, Rheological, and Sensory Modifications in Oaxaca Cheese Made with Ultrasonicated Raw Milk" Processes 11, no. 4: 1122. https://doi.org/10.3390/pr11041122

APA StyleCarrillo-López, L. M., Huerta-Jiménez, M., Morales-Rodríguez, S., Gámez-Piñón, J. R., Carballo-Carballo, D. E., Gutiérrez-Méndez, N., & Alarcón-Rojo, A. D. (2023). Textural, Rheological, and Sensory Modifications in Oaxaca Cheese Made with Ultrasonicated Raw Milk. Processes, 11(4), 1122. https://doi.org/10.3390/pr11041122