Abstract

Mobile robot is an automatic vehicle with wheels that can be moved automatically from one place to another. A motor is built in its wheels for mobility purposes, which is controlled using a controller. DC motor speed is controlled by the proportional integral derivative (PID) controller. Kinematic modeling is used in our work to understand the mechanical behavior of robots for designing the appropriate mobile robots. Right and left wheel velocity and direction are calculated by using the kinematic modeling, and the kinematic modeling is given to the PID controller to gain the output. Motor speed is controlled by the PID low-level controller for the robot mobility; the speed controlling is done using the constant values Kd, Kp, and Ki which depend on the past, future, and present errors. For better control performance, the integral gain, differential gain, and proportional gain are adjusted by the PID controller. Robot speed may vary by changing the direction of the vehicle, so to avoid this the Social Spider Optimization (SSO) algorithm is used in PID controllers. PID controller parameter tuning is hard by using separate algorithms, so the parameters are tuned by the SSO algorithm which is a novel nature-inspired algorithm. The main goal of this paper is to demonstrate the effectiveness of the proposed approach in achieving precise speed control of the robot, particularly in the presence of disturbances and uncertainties.

1. Introduction

Robotics is one of the engineering branches that deal with modeling, controlling, and utilization of robots. Robotics manipulators comprise two billion industries [1,2,3,4]. Although they have a lot of advantages; they suffer from disadvantages such as lack of mobility. The first challenge in robotics is locomotion itself, i.e., how a robot moves and what effective locomotion method can be used as an alternative locomotion mechanism [5]. RPA is a robotic process automation to allow the company employees to arrange the robot to know about the other application for handling a triggering response, manipulating data, computer software, and communicating with another digital system [6,7,8]. The robot benefits from improved flexibility and is able to perform different applications and tasks, which are more accurate than manual work. Those artificial machines can be employed in any dangerous work that is likely to result in injuries. This, in addition, makes the working environment safer [9,10,11].

Meanwhile, the WMRs (wheeled mobile robots have great energy proficiency which leads to their simple mechanical design, and their dynamics are also simpler compared to the legged robots as they have to make contact with the ground for mobility purposes. Compared to wheeled robots, the double-wheel robot has many benefits [12]. Compared to stable wheeled robots, they are hard to control; however, compared to legged robots they are simple to control [13,14,15,16]. It also computes the orientation and position of the robot manipulator’s end effector which is related to the manipulator base as a function of joint variable [17]. The basic function of the robot is to give the direction from starting to the destination of the robot using a collision-free motor [18]. The acceleration and deceleration of the robot are important in path planning, the path can be generated using the Cartesian coordinate system [19]. The synchronous robot path is tracked by using the PI controller with the help of a feed-forward compensator. From the above observation, this research inspired develop of the speed regulator for the direct current motor speed control, which is connected to the wheels of a mobile robot [20].

The use of various optimization strategies to fine-tune the proportional integral derivative control’s parameters is investigated. The DC motor, which is widely used in numerous technical applications, is the system under investigation. According to the simulation’s results, the control’s overshoot and rising and settling times were performed satisfactorily [21]. To fine-tune the gains in the feedback controller, a novel fitness function with multiple objectives is developed for advanced particle swarm optimization. The nonlinear Euler–Lagrange model is used to validate the state-space model. The APSO technique uses the traditional Lyapunov approach [22]. Using the Gauss pseudo-spectral approach, parking trajectory planning is represented as an optimum control issue that is then converted into a nonlinear programming problem. For parking trajectory tracking, the velocity and front-wheel swing angle are collected as control signals. To confirm the efficiency of the suggested hierarchical control approach, actual vehicle testing is conducted [23].

1.1. Background

The flexibility and simplicity of nature-inspired optimization algorithms, such as swarm-based algorithms, enable them to be applied without structural modifications to scientific and engineering problems. An original nature-roused metaheuristic improvement calculation, called Sail Fish Optimizer, which is propelled by a gathering of chasing sailfish has been proposed. In Ref. [24], the authors show promising outcomes on five certifiable optimization issues demonstrating that the SFO is relevant for issue resolution with compelled and obscure search spaces. The authors [25] introduced a self-tuning mechanism for the improvement of the performance of the implemented PID-fuzzy method. By utilizing the PSO algorithm, the variables tuning issue of the PID-type FLC framework is fixed and methodically solved. The superiority and efficiency of implemented PSO optimized FLC method using DC drive have been illustrated.

1.2. Inspiration

In the previous twenty years, swarm knowledge and another sort of developmental figuring strategy have drawn much examination interest. Swarm knowledge is mostly worried about the philosophy to demonstrate the conduct of social creatures and creepy crawlies for issue fixing. Analysts contrived improvement calculations by imitating the conduct of insects, honey bees, fireflies, microorganisms, and different living beings.

1.3. Motivation

Spiders have been a significant research topic among generally seen creatures in bionic design for a long time. Most research identified with spiders is centered on the emulation of their strolling pattern for robot design. A potential justification is that a greater part of the spiders noticed are singular, which implies that they spend the vast majority of their lives without communicating with others of their species. Nevertheless, of the 35,000 species of spider noticed and portrayed by researchers, a few spiders are social. In light of the social spiders, another global optimization technique has been described for advancement issues. This is the special attribute that separates the social spiders from different organic entities as they normally trade data effectively, which minimizes the data loss somewhat but expands the energy utilized per correspondence activity.

1.4. Literature Review

The authors [26] proposed a metaheuristic algorithm for global optimization, encouraged by the extroverted habits of the social spiders, particularly their foraging behavior: the Social Spider Algorithm (SSA). The Social Spider Optimization (SSO) algorithm has been suggested and based on the participating habits of social spiders [27,28]. Individuals imitate a team of spiders in the SSO algorithm that communicate the organic regulations of a participating colony with two different spiders, one is female and another is male. SSO algorithm designs every spider on a gender basis, which is a distinct feature from the majority of swarm intelligence algorithms. Hence, the algorithm reasonably imitates the participating action of the swarms and integrates computational mechanisms to prevent crucial imperfections usually found in other algorithms. In Ref. [29], the authors utilized the SSO method to educate artificial neural networks to tune the vector machine’s specifications.

The controlling range of the automated device depends on the purpose of the device. Li et al. In Ref. [30], the wheeled robot is developed to a requested position by the proposed adaptive visual serving method, whereas the unknown depth data is simultaneously recognized. Using the experimental and simulation outcome, the proposed method is verified. The major disadvantage of the established method is that it is impossible to implement the visual serving task with the progress of depth identification without desired images. Yoo et al. [31] developed a distributed connectivity that preserves synchronized tracking problems for a variety of diffident non-holonomic robots which occurs within a limited communication range. New distributed error surface is this paper’s main objective; it deals with initial connectivity pattern preservation and synchronized tracking.

A new conflict resolution method is introduced by Shahriari et al. [32] for the many mobile robots while providing their motion liveness. The method is minimizing the robot’s overall time of travel using optimization methods by the mathematical formulation to solve the conflicts in their motion. Algorithms are used for cluttering the environment to overcome the executing computational cost, and a creative approach is developed over the atmosphere clustering into separate sub-problems that can be fixed by programming in parallel method. Simulations were conducted and the experimental outcomes confirmed that the proposed method is suitable for real-time uses. Chouhan et al. [33] presented comprehensive research on the stability and control of the mobile robot with a double wheel by the Sugano fuzzy logic method. The major disadvantage of the proposed approach is that the results obtained are not precise.

Shen et al. [34] proposed a method of adaptive control system for differently operated WMR with skidding and slipping dynamics and mass center of unknown and uncertain. Simultaneously challenging issues can be addressed in this paper. First, by the uncertain load impact, the WMR is established along with the uncertain mass concern. Second, to avoid the output constraints difficulty, an intermediate variable is introduced to change the problem of underlying constraint into without constraint. Third, by the skill of norm bounding, a WMR model, without the precise information, is developed with the user-friendly control method, which ultimately achieves bounded tracking of uniformity, and the Lyapunov method has proved this theoretically and numerically by experimental and simulation results. However, the impact of tracking control performance was not discussed in this paper.

Zhai et al. [6] discussed the tracking of path navigation issues of adaptive-sliding mode for WMR in the inertia uncertainties and external disturbances are presented. Multiple wheeled robots distributed tracking problem is going to be investigated. Maintaining multiple robots to move in a desired formation geometry is important and it is done by the formation control, it is one of the finest topics in the control and robotics field for many decades. Liang et al. [35] proposed new leader-following creation path navigation control systems for non-holonomic mobile robots with onboard cameras, except the use of velocity and position measurements.

Zafer et al. [36] uses the Cuckoo Search (CS) method and a novel time domain analysis method, a new tuning method of the PID controller. The performance of the PID controller utilizing cuckoo search has been compared to that of PID controllers modified using various algorithms and objective functions. Furthermore, the adjusted controller’s disturbance rejection and robustness performance against parametric uncertainties were measured individually. The proposed controller and PID controllers, adjusted using the PSO and ABC algorithms, consumed a lot of energy. The proposed method vastly enhances the PID-tuning optimization technique.

Mamizadeh et al. [37] modeled and simulated the boost converter’s COA-based optimization under varying loads in the MATLAB/Simulink environment. Qibing et al. [38] proposed an algorithm used to create PID controllers. The controllers supplied by the proposed SSO algorithm show the superiority over typical Ziegler–Nichols PID (ZN PID). The suggested approach has a higher convergence rate and accuracy than PSO and the conventional Cuckoo Search. Singh et al. [39] used the most recent metaheuristic algorithms which enhance the response of the PID controller. As a result, a PID tuning tool is created to tune the PID controller for diverse engineering applications utilizing versions of the Cuckoo Search algorithm. Sheshnarayan et al. [40] propose a new way of designing a PID-PSS for damping low-frequency oscillations. The CSO algorithm has been utilized to optimize the PID-PSS controller for damping out low-frequency oscillation (LFO) by reducing the weighted sum of the IAE and ITAE. The performance of the system using this suggested CS-PID-PSS is compared to that of conventional all methods.

Yaacob et al. [41] presents an optimization approach for tweaking the parameters of a PID controller to get the best output. Finding appropriate PID controller parameters is a difficult task, and the best-offered methods or procedures may result in improved performance. The artificial intelligence optimization strategy is seen as a complement to traditional methods for improving the performance of PID controllers. As a result, PID controller design approach is designed so it can handle engineering challenges with Social Spider Optimization (SSO).

Wahab et al. [42] ststudyhe four requirements for objective functions which are compared to suitable alternatives, and the best one is chosen based on design optimization. The PID controller’s parameters, Kp, Ki, and Kd, must be carefully chosen because they affect the system’s transient response. Nonlinearities, which are common in industrial plants, can be reduced by using the optimal combination of parameters. Sabir et al. [43] considered the task of developing an optimal PID controller for solar tracker-system DC motors. Because of its faster convergence rate, minimal variation, and standard deviation of design parameters obtained, CSA outperforms PSO and FFA, according to the study. In terms of performance, FFA and CSA outperform PSO for the problem domain under investigation.

To improve the AVR control system’s transient responsiveness and acquire the best controller gain values, a new goal function is presented. PSO and CS techniques are introduced in this study for tuning the settings of a PID controller for AVR system control. The suggested method’s simulation results are capable and demonstrate its usefulness. Shi et al. [44] proposed a Social Spider Optimization that is competitive. The spiders are regrouped and the population variety is raised in CSSO to improve the performance of SSO. The competitive mating mechanism is presented, and a learning technique is applied for the newborn spider, which is inspired by spiders’ competitive mating behavior. The CSSO is used to improve the PID controller’s settings, and the simulation results suggest that CSSO’s performance in PID controller optimization is promising.

The objective of this paper is to control the speed of a wheeled mobile robot and for the tracking of the wheeled mobile robot. First of all, the speed has been controlled by utilizing the PID controller. Then, Social Spider Optimization-based and Cuckoo Search Optimization-based PID controllers have been utilized to control the speed of the wheeled mobile robot and then, tracking of wheeled mobile robots has been done.

2. Proposed Methodology

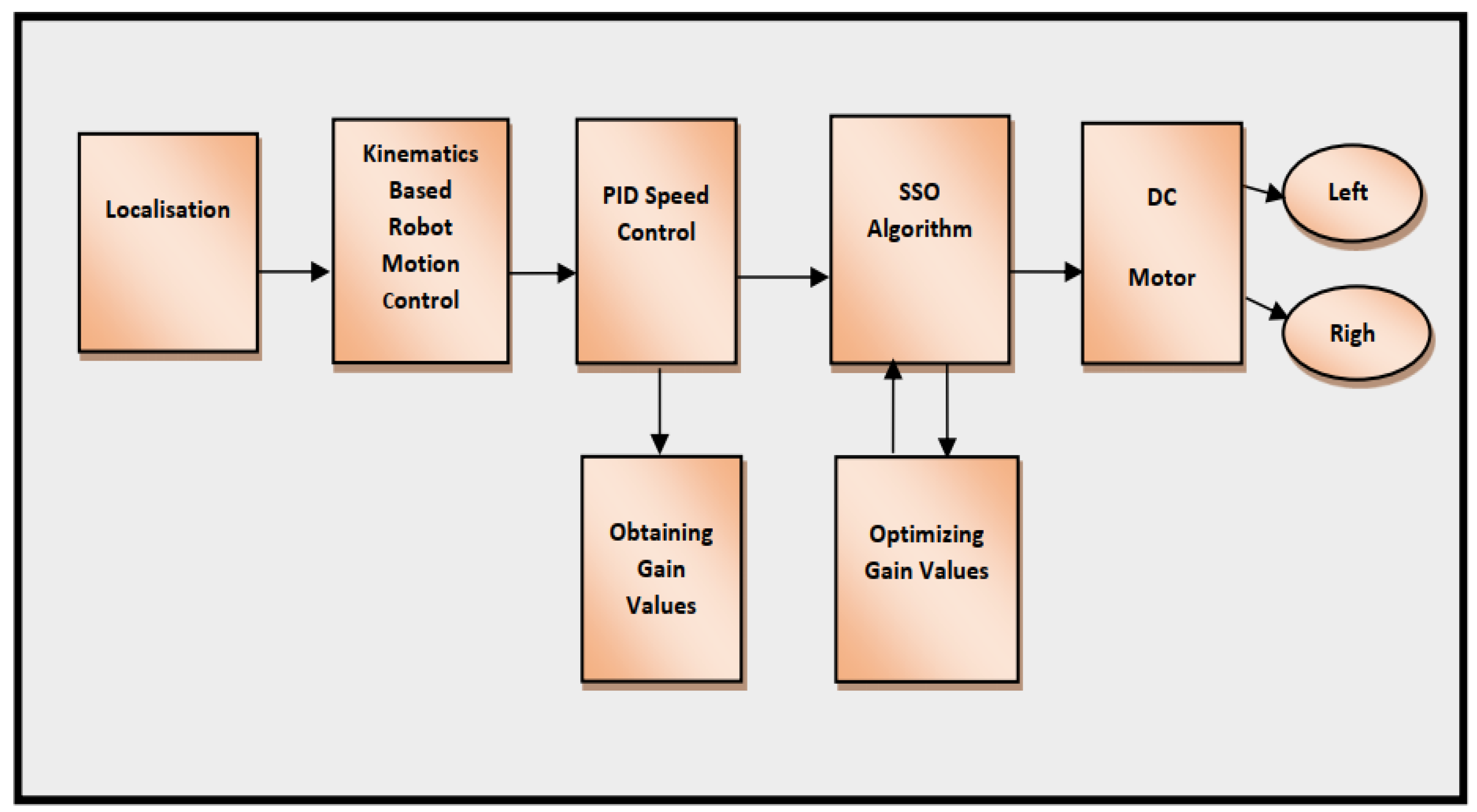

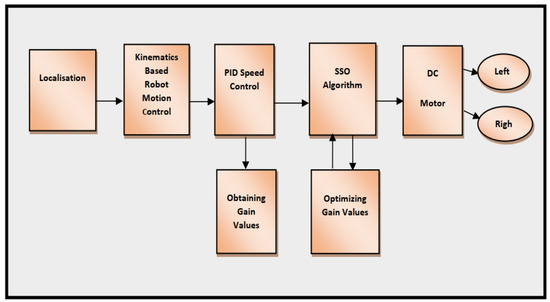

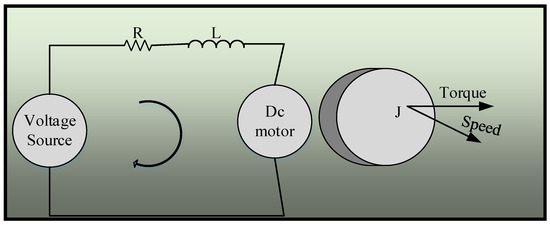

The robots can move from one place to another automatically, they may be classified as mobile robots and industrial robots. In the case of the mobile robots, they can freely move on the workspace, but the industrial robots are moved around the particular workspace in the field. The design procedures include the designing of robot platforms. A DC motor is designed and it is placed in the wheels of the robot for robotic mobility. The drive structure consists of wheels, the wheels are fixed on the right and left sides of the robots. The DC motor is used to control the motion of the robots and the modeling is shown in Figure 1 [45,46,47,48]. The speed characteristics may vary while moving the vehicles in forward, backward, and in a circle. So, this can be controlled through the Social Spider algorithm of the PID controller, the gain parameters are tuned through the corresponding algorithm.

Figure 1.

Proposed methodology.

2.1. Contribution of This Work

- Kinematic modeling of mobile robot

- Modeling of DC motor

- Designing of Social Spider-based PID controller for controlling speed

- Tracking of wheeled mobile robot

2.2. Mathematical Modeling of Mobile Kinematics

In the robot system, mobile kinematics mathematical modeling is a major role in the control method. Robot velocity is taken by the kinematic modeling and it is changed into a coordinate vector generalized by below Equations (1)–(3).

From the velocity of each wheel, the robot velocity is taken by below Equations (4) and (5):

The first step is to take the wheel velocity from the mobile robot parameters, L is the robot wheel axial distance and r is the wheel radius. After describing mobile robot velocity, it will be obtained from the velocity of the wheel. These all depend on the robot base. The base of the robot is discrimination drive in this research. To control the robot’s weight, a plastic chassis is used as the torque of the motor can be affected by the robot’s weight [38]. For driving the mobile robot using dual DC motors [49,50,51,52], a directly fixed the motor with an optical encoder is used for the motor shaft velocity control with the PID controller. Based on kinematic modeling, the mobile robot parameters are given as follows.

2.3. Motion Model

Robot and inertial coordinate systems describe the position of a differentially derived mobile robot. Let the inertial frame be denoted as (XI, YI) and the robot frame be (XR, YR). The inertia-frame Cartesian coordinate method is used for the position of the robot. The robot similarity can be represented using the basic transformation matrix as follows in Equations (6)–(8).

The differential drive two-wheeled robot is independently driven. The robot moves forward when the motor wheels are operating at the same direction and speed. A robot right turn is obtained by driving the right wheel at a lower rate and the left wheel at a high rate and a left turn is obtained by turning the right wheel at a lower rate and the left wheel at a high rate. It assumed the wheel of the robot would not slide. Non-holonomic constraint is used to express this Equation (9).

Normally, the motion of the robot motor is controlling the angular velocities ωL and ω of the left and right wheel, respectively.

2.4. Kinematic Modeling of Robot Mobility

Without considering mass and force, object motion is described by the kinematics which is a division of mechanics [4]. The input needed for the robot mobility are the orientation θ and V linear velocity. The robot rate of change in X direction is x and in Y direction is y, which is written by the Equations (10) and (11).

Robot angular velocity is given by the Equation (12).

In the below Equation (13)

- —right wheel velocity

- —left wheel velocity

Substitute Equation (13) in Equations (10) and (11).

Fixed coordination of robot velocity V is given by Equation (16).

From Equations (14) and (15)

Equations (10)–(12) used for the right and left wheel velocities are used to create X′, Y′ and output [53]. The actual orientation is used to compute the error to create the system as a closed loop.

The robot’s direction can be decided using four cases, which explains the relationship between the direction and velocity they are,

- I.

- When, Vr = VL the robot will remain ideal. ω is zero and infinity is R.

- II.

- When, Vr = −VL the robot moves through a straight line so the value of R is zero.

- III.

- When, VL = 0, the robot left wheel is turned about R = 1/2 radius

- IV.

- When, Vr = 0, the robot right wheel is turned about R = 1/2 radius

2.5. DC Motor Modeling

SEM and XRD analytical approaches are often employed for the classification of different nano additives. DC machines are considered for their flexibility. By the combinations of separately excited and shunt-series field windings, they are considered to show a wide range of characteristics for both steady state and dynamics [54]. DC motors are used where there is a need for accurate output motor control and a wide range of motor speed.

The normal DC motor and permanent magnet DC motor are the same in their basic formation. The working principle of permanent magnet DC motor is also similar to that of the DC motor, i.e., force is created by placing a conductor in the magnetic field.

The DC motor speed can be increased to any extent to deliver high performance and easy control. The direct current engine speed can be regulated by several conventional and numeric controllers.

Figure 2.

Model of DC motor.

Figure 2.

Model of DC motor.

The model of DC motor is shown in Figure 2. The DC motor transfer function of open loop and dynamic equation is

where,

- J = rotor moment inertia

- b = Constant viscous friction of the motor

- Ke = Electromotive force at constant

- Kt = Motor torque at constant

- R = Resistance

- L = Inductance

- V = Motor terminal voltage

- I = Circuit current flow

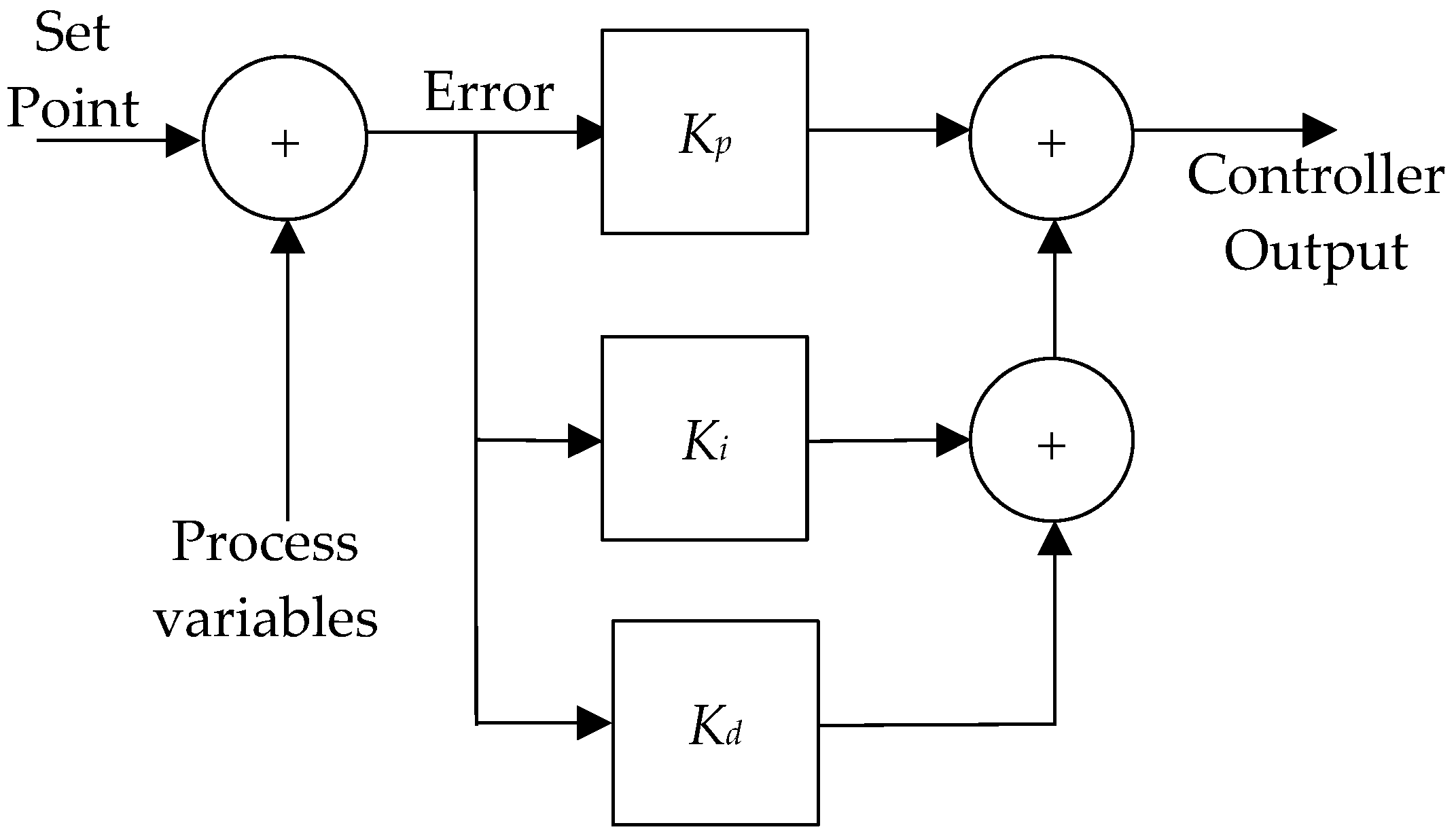

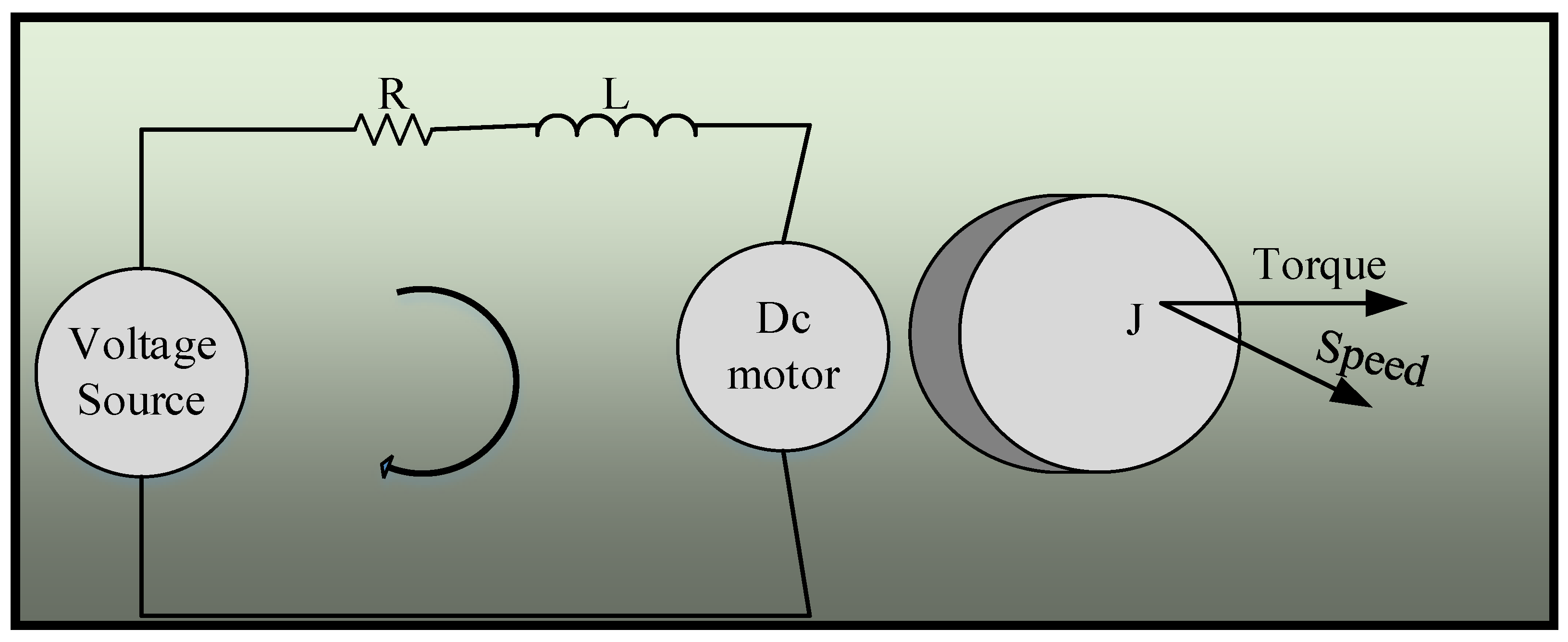

2.6. PID Controller

PID controller is used for the control system of the industry; it has a control loop feedback system and the PID stands for proportional integral derivative controller. The error value is continuously calculated by the PID controller; it is measured by the variation between the desired and measured values. The controller is used to control errors by adjusting the control variables such as controlling the power supplied to the heating element, varying the position of a control valve. Kp, Ki, and Kd are the proportional coefficient, derivative, and integral controller [55].

In the above Equation (24)

- U(t) = Control signal

- E(t) = Error signal

- Kp = Proportional gain

- Ki = Integral gain

- Kd = Derivative gain

Figure 3 represents the PID controller for DC Motor Speed Control.

Figure 3.

PID block diagram.

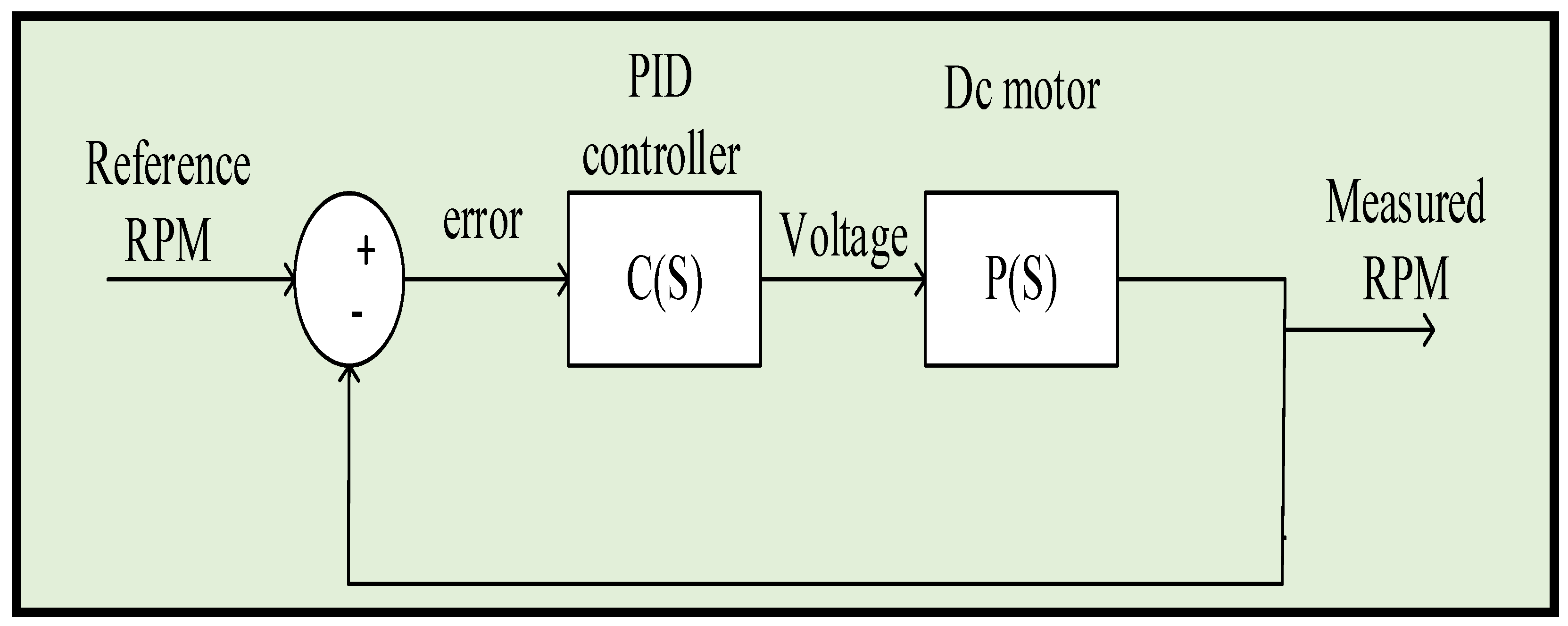

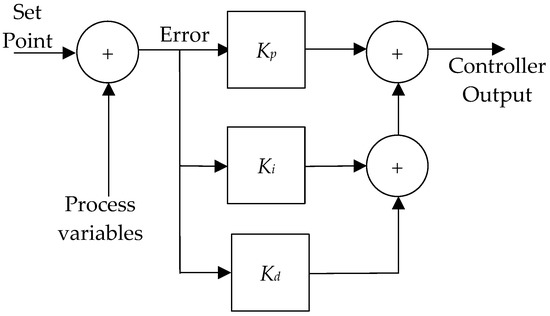

2.7. PID for DC Motor Speed Control

Many modern controlling methods such as variable structure control, optimal control, nonlinear control, etc., are available there for DC motor speed control; however, these methods have difficult theories and implementation. Therefore, the PID algorithm is used here for the direct current motor speed control. Error present is P, I is the past error, and the term D is the predicted future error. Figure 3 shows the block diagram of PID Controller. The PID controller with its three parameters performs both steady state and transient response which provides simple and efficient solutions for many controlling problems. By the PID parameters, the motor rotational speed can be controlled [56,57,58,59,60,61]. The PID controller is tuned by Kp, Ki, and Kd based on the DC motor transfer function and its individual parameters.

The PID controller design should be merged into the system. Figure 4 represents the speed control of DC motor using PID controller. The transfer function of PID controller is:

Figure 4.

DC motor speed control using PID controller.

2.8. SSO Algorithm-Based Optimization of PID Controller

2.8.1. Problem of PID Controller

Presently, many industries are using PID controllers because their structure is simple and their principles are easily understandable compared to other controllers. As explained above, the PID controllers are determined by their parameters [62,63,64,65,66]. Meanwhile, it also has its own problem, because of its robustness and simplicity, problems in tuning its parameters occur.

2.8.2. Social Spider Algorithm

Spiders are known for their vibratory and sensitive stimulation. They capture prey as per the vibration which occurs on the web. The vibration source is easily attacked if the vibration is in the range of defined frequency. The prey-produced vibrations are differentiated by the social spider web from the other spider vibrations [67,68,69]. All the spiders on the web can receive the vibrations. This unique character differentiates the social spiders from the other spiders, which reduces the loss of evidence to certain degrees rather than raising the energy used for communication action.

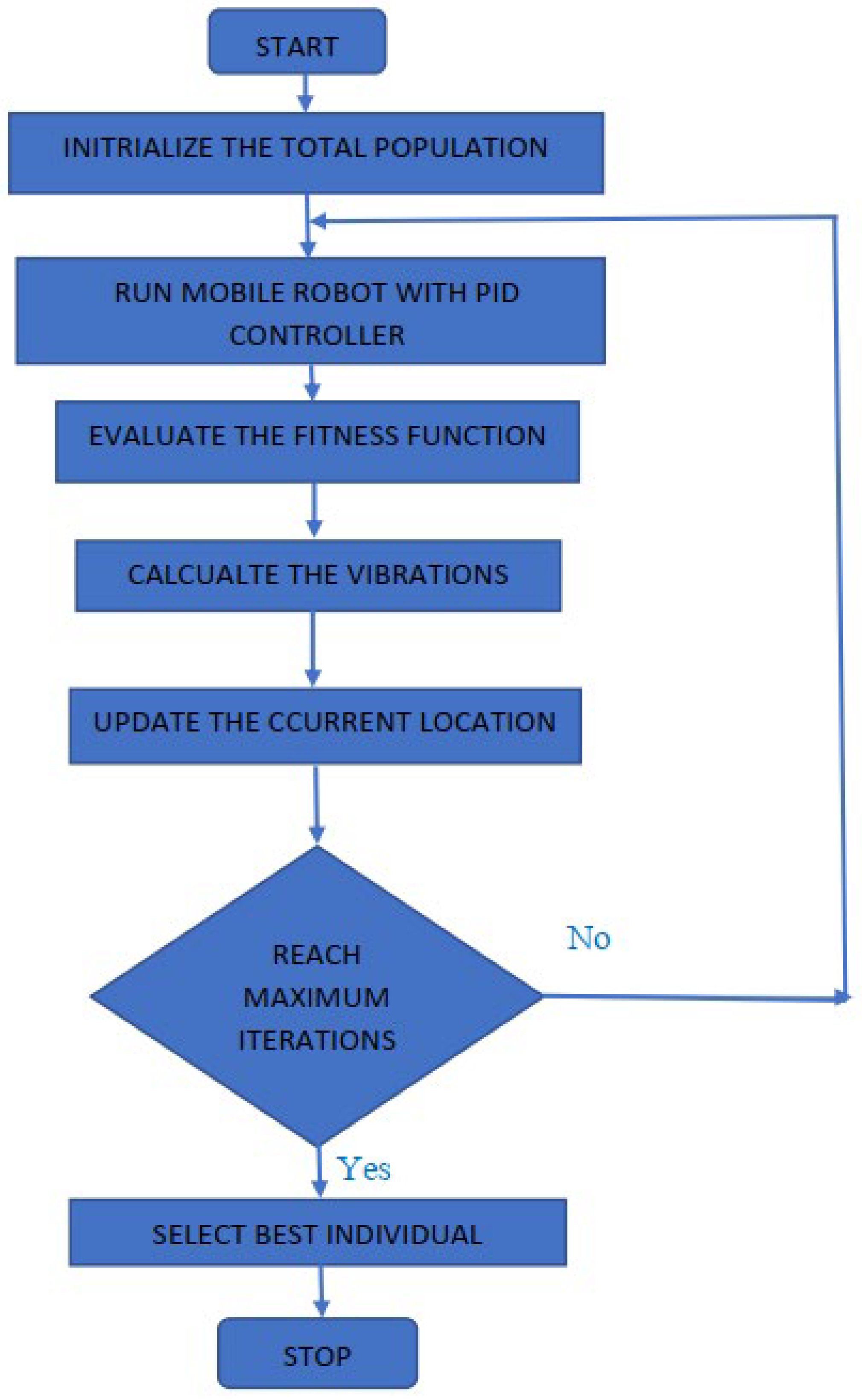

Unique forging behavior of social spiders is the motive of this paper. The foraging behavior of social spiders describes the spiders’ cooperative movement against the position of food source. The spiders find the direction of the food source by making the vibrations on the web. The Social Spider algorithm contains the natural behavior of a spider.

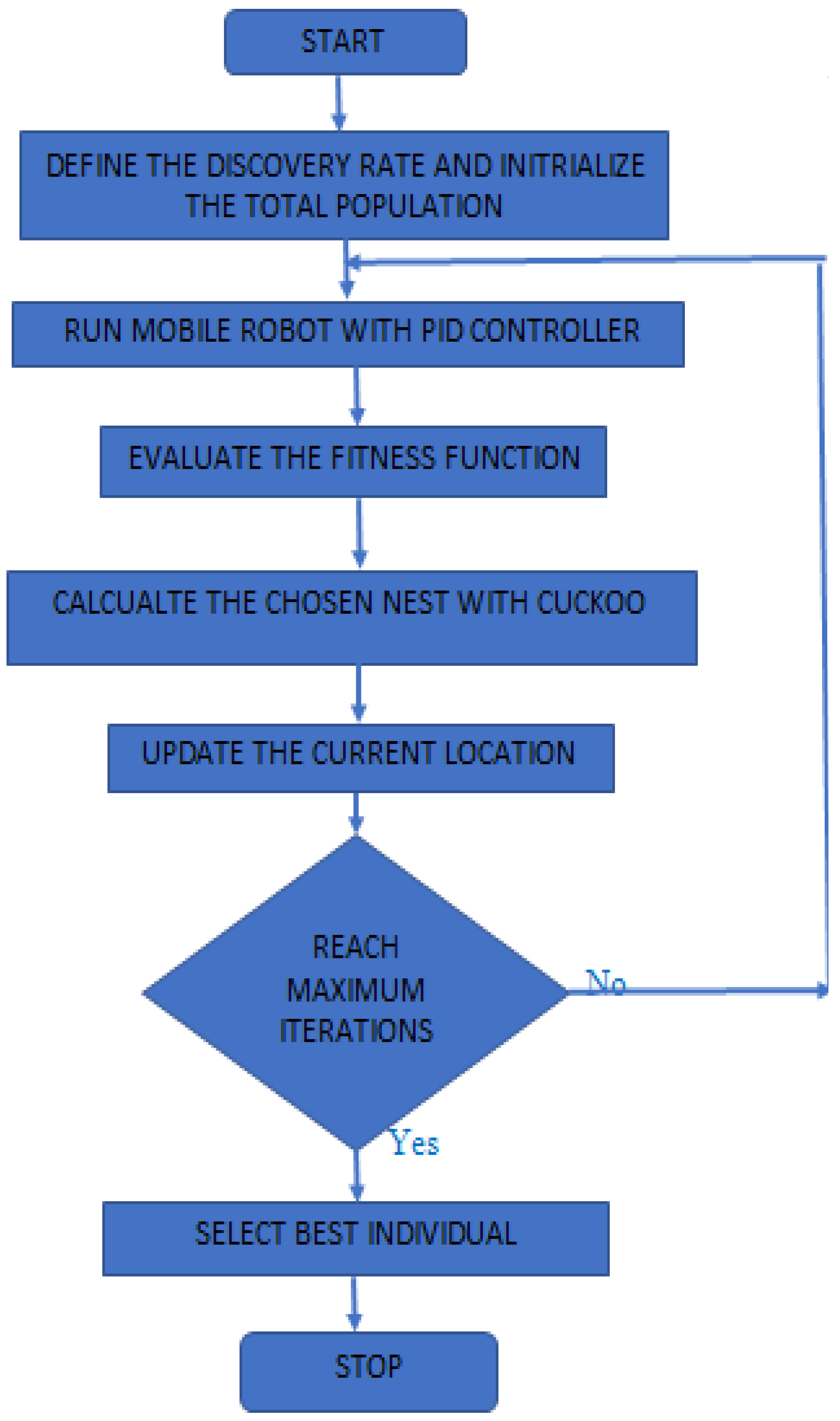

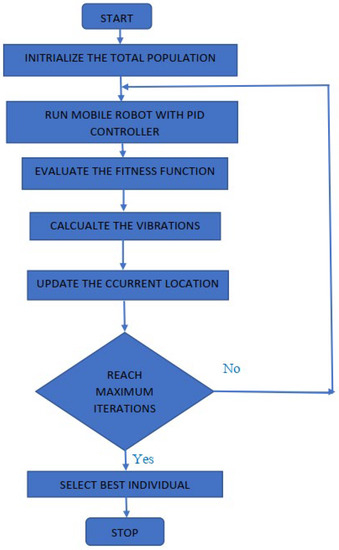

The problem of search space optimization is the spider web in SSA. The web position has appropriate results for the problem of optimization and each result defines the appropriate position on the web. The web acts as the medium of transmitting information for the vibration produced by spiders [26]. Each spider has its own position. The solution quality is depending on the objective function described by the food source finding ability at the position. On the web, the spiders freely move anywhere but they are not supposed to leave the web as, if the position is changed, it may cause unfeasible solutions, causing optimization problems. If a spider changes its position, it produces a new vibration, and that new vibration is propagated throughout the web and the nearest spider receives the data based on the vibrations received. Figure 5 represents the flow chart of social spider optimization algorithm.

Figure 5.

Flow chart of SSO algorithm.

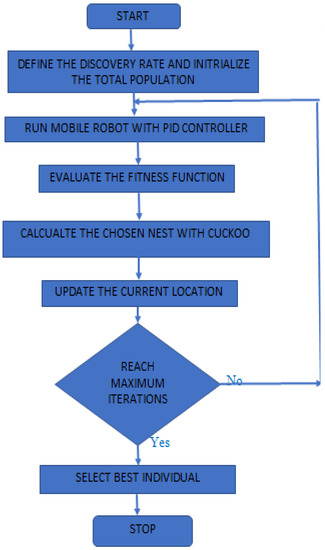

2.9. CSO Algorithm-Based Optimization of PID Controller

This algorithm is developed with the help of cuckoo bird reproduction and it is mentioned as nature inspired metaheuristic algorithm. In CS algorithms, the possible solutions are considered as an important thing [70,71,72]. Usually, cuckoos lay their enriched eggs in other cuckoo’s nests with the confidence of their offspring being raised by proxy parents. Sometimes, the cuckoos find eggs in their nests which are unfit for them. Figure 6 represents the flow chart of cuckoo search optimization algorithm.

Figure 6.

Flow Chart of CSO algorithm.

3. Results and Discussion

The parameters of motor considered for the robot in the present work are tabulated as below in Table 1.

Table 1.

12 V DC MOTOR PARAMETER.

The desired voltage is 12 V. The PID controller is then used to control the desired robot speed. It is done by testing the DC motor simulation with the wheel for = 3.88, = 3.5 and = 0.77. This simulation result shows that the robot’s linear speed is equal to 1.734 m/s. This indicates that the PID controller is successfully regulating the DC motor simulation to achieve the desired robot speed.

The Cuckoo Search Optimization-based PID controller is then used to control the robot’s linear speed. It is done by testing the DC motor simulation with the wheel for = 3.88, = 3.5, and = 0.77. In this particular case, the CSO algorithm found the values of Kp, Ki, and Kd to be the optimal values for the PID controller. These values were then used to simulate the DC motor with the wheel and the performance of the controller was evaluated. If the performance is satisfactory, these values can be implemented in the actual robot control system to achieve the desired linear speed control.

The Social Spider Optimization-based PID controller is then used to control the desired robot linear speed. It is done by testing the DC motor simulation with the wheel for = 3.88, = 3.5, and = 0.77. The result of this study shows that the designed controller provides good control of the desired robot’s linear speed.

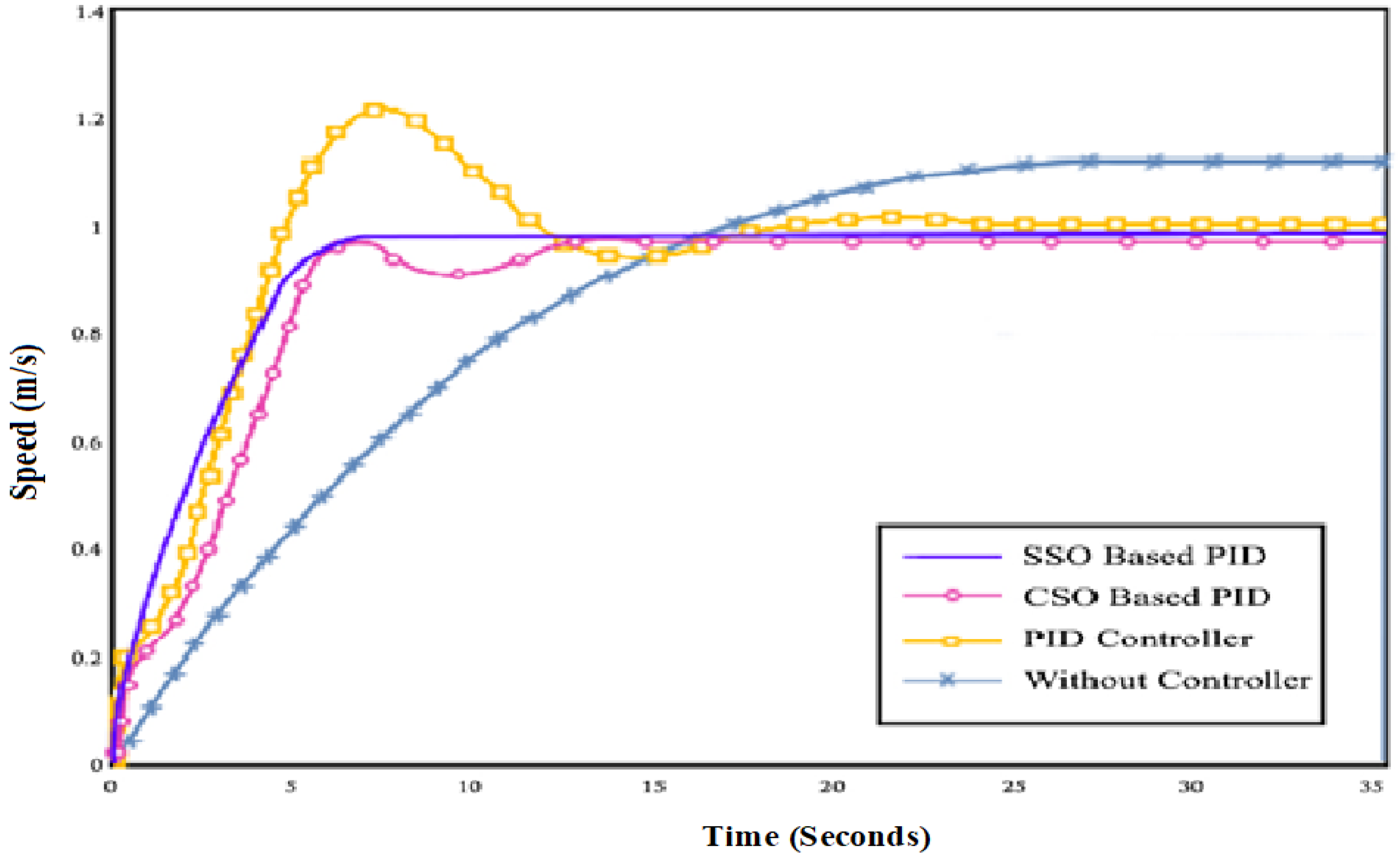

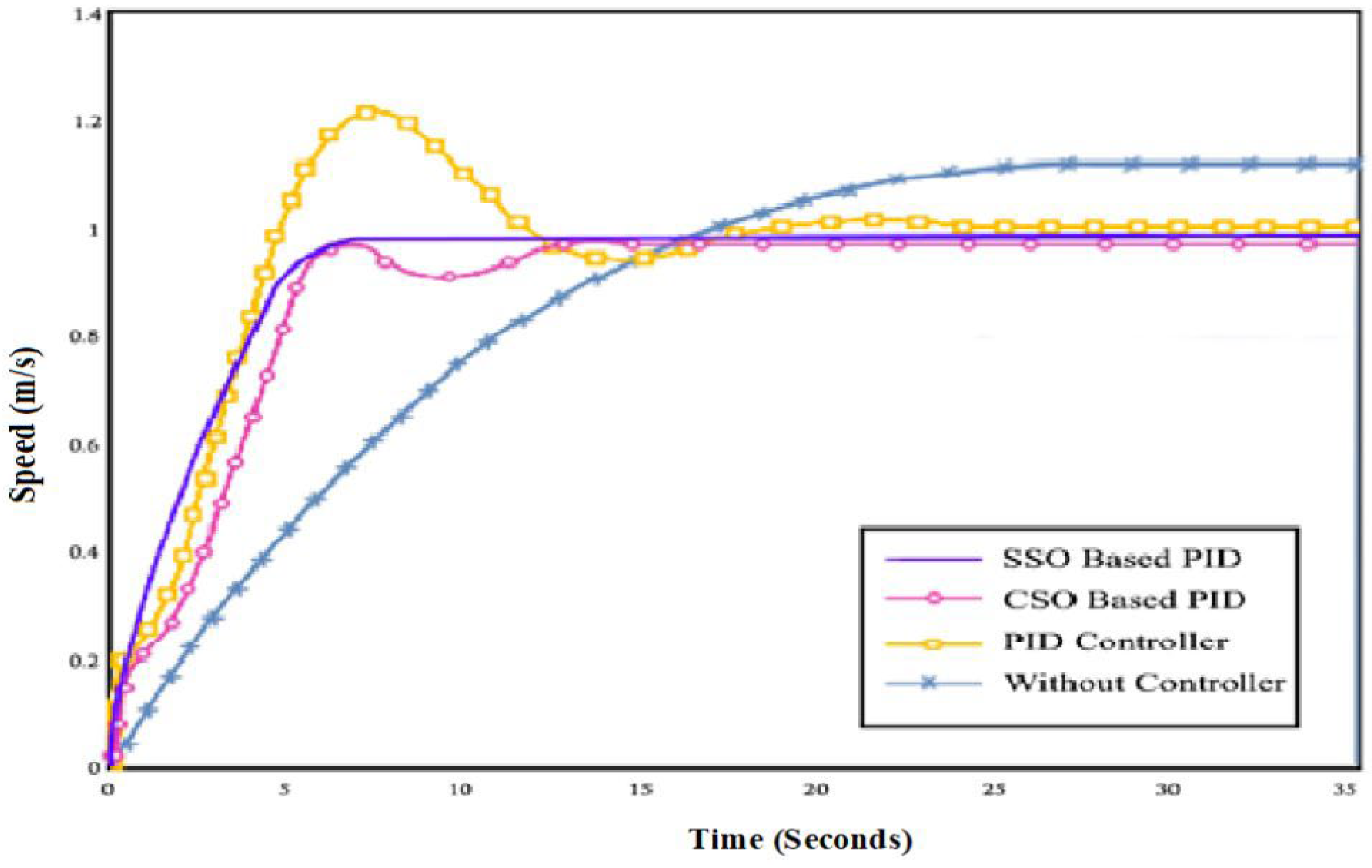

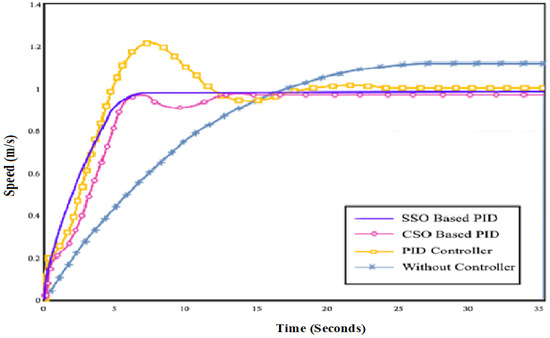

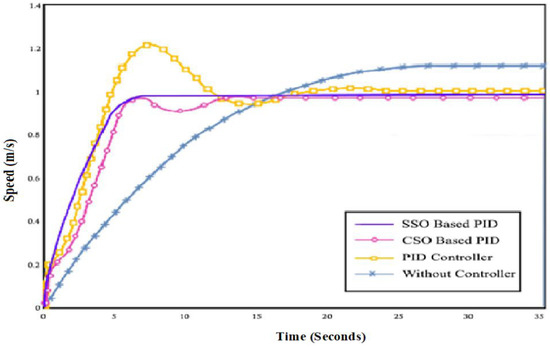

The comparison of closed-loop response of DC motor-1 with the SSO-based PID controller, CSO-based PID controller, PID controller, as well as motor response without controller is shown below in Figure 7, which shows that the SSO-based PID controller outperforms the other controllers in terms of fast settling time and almost no overshoots. The comparison of closed-loop response of DC motor 2 with SSO-based PID controller, CSO-based PID controller, PID controller, and without controller is shown below in Figure 8, which also shows the superiority of SSO-based controller design in all design specifications.

Figure 7.

Comparison of closed-loop response of DC motor 1 in SSO, CSO, PID controller, and without controller.

Figure 8.

Comparison of closed-loop response of DC motor 2 in SSO, CSO, PID controller, and without controller.

Once or if the desired robot speed is reached then we can test the Simulink model for the entire robot system using four possible options for robot motion, these are:

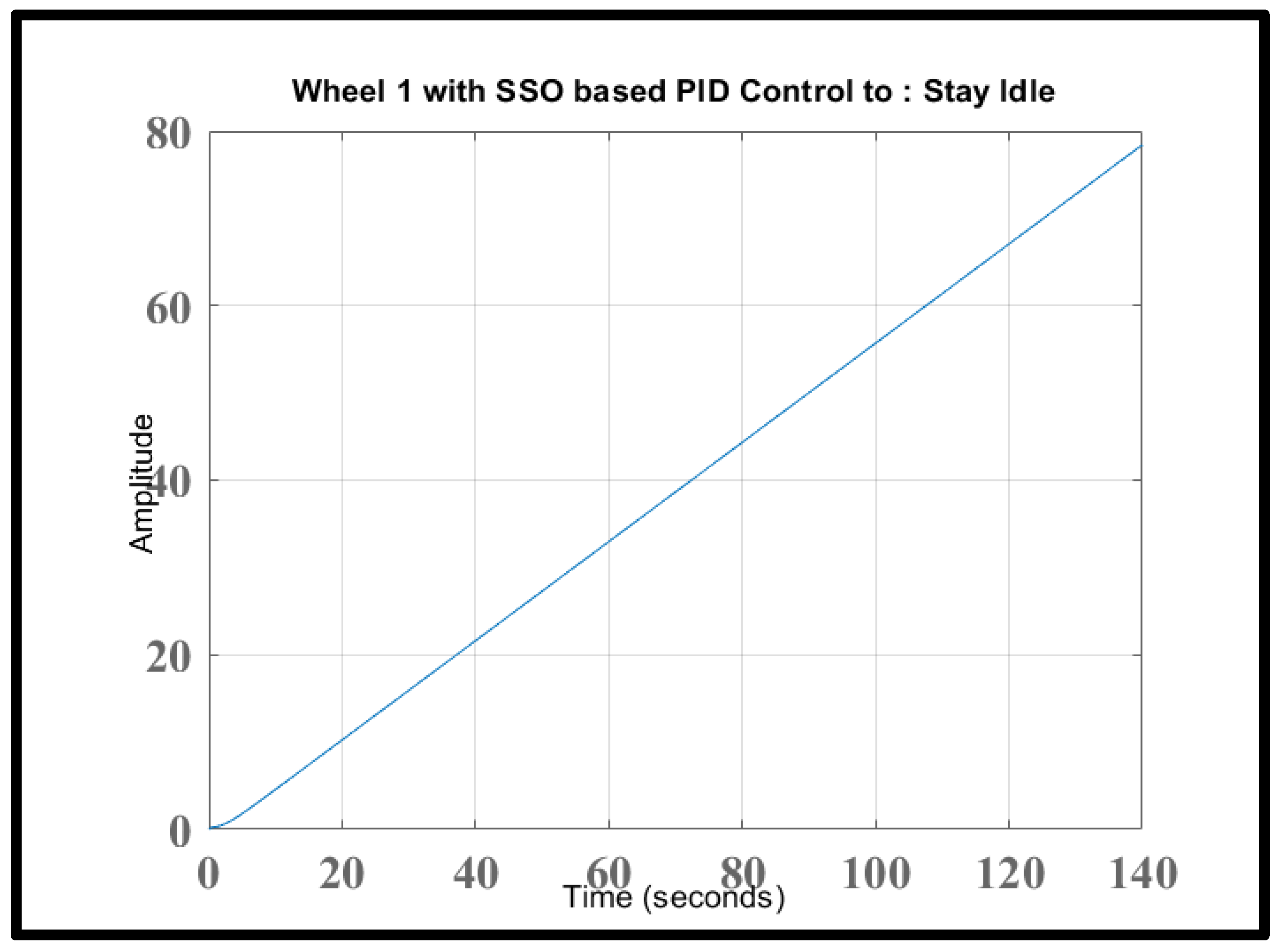

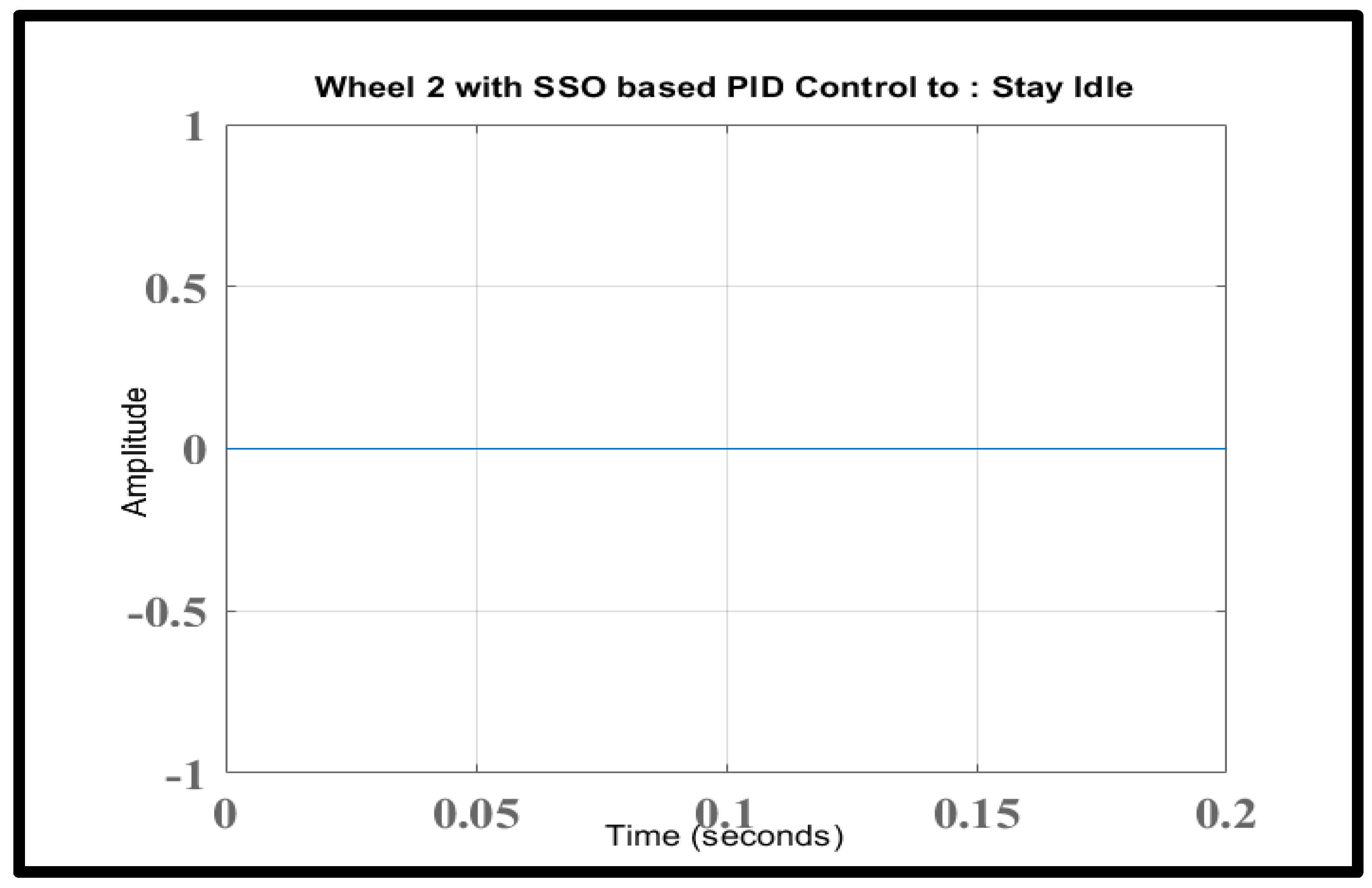

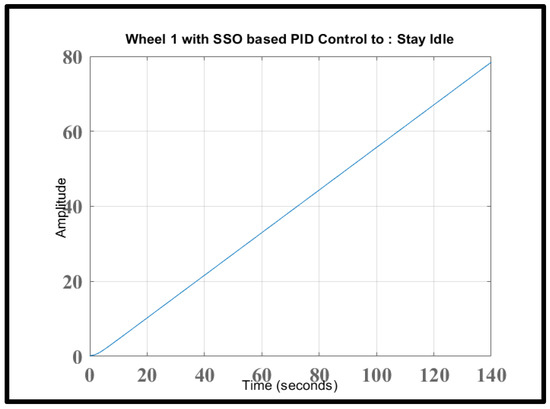

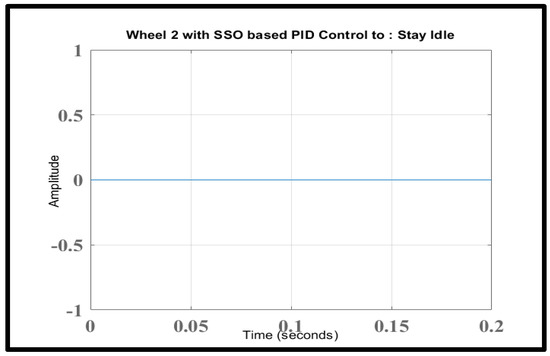

Case 1: If the wheels rotate at the same speed, then the robot remains idle (Vr = VL) as shown in Figure 9 and Figure 10. If the right and left wheel velocity are equal, then the robot motion will be ideal.

Figure 9.

Simulation of wheel 1 when VL = Vr.

Figure 10.

Simulation of wheel 2 when Vr = VL.

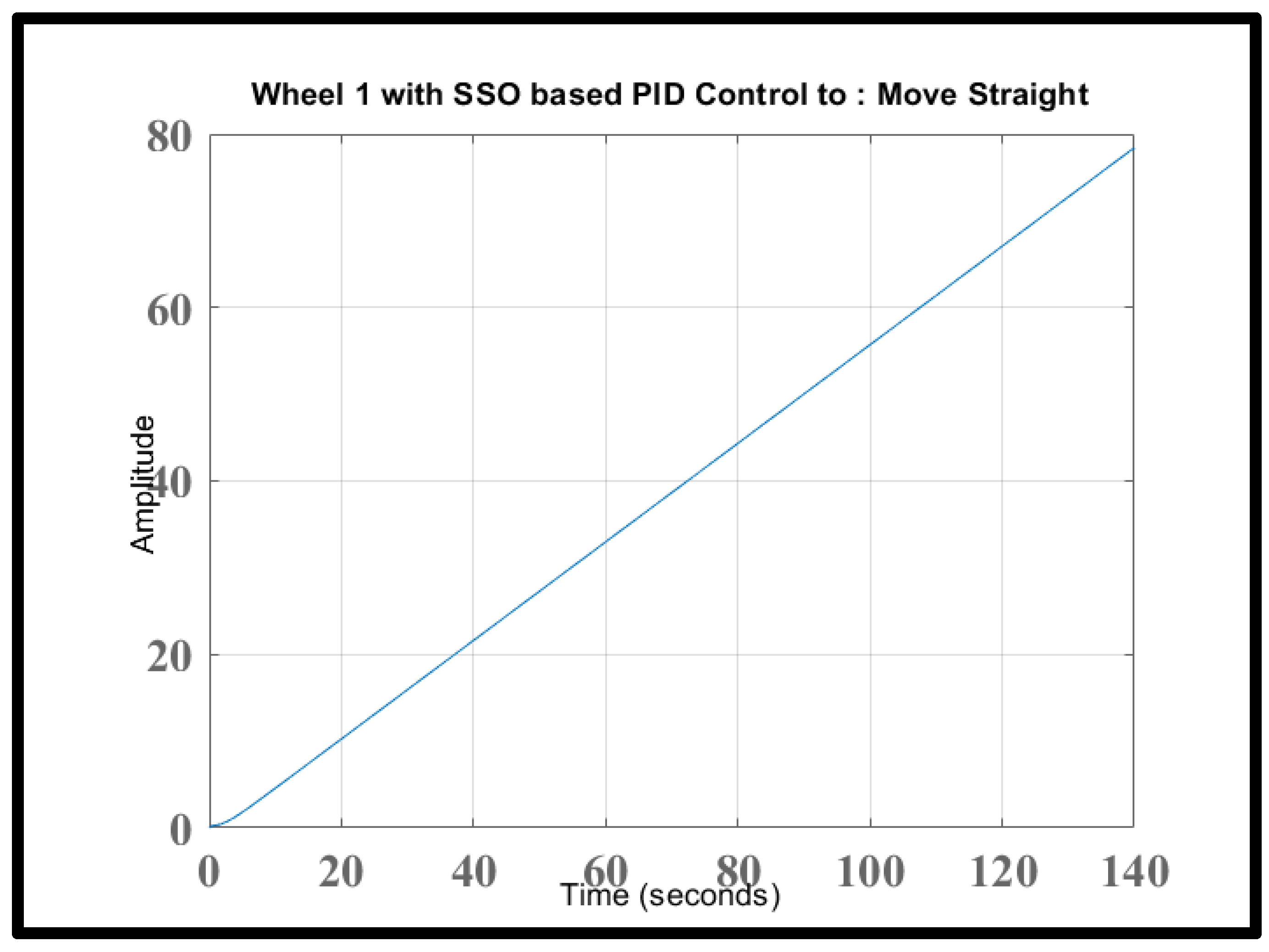

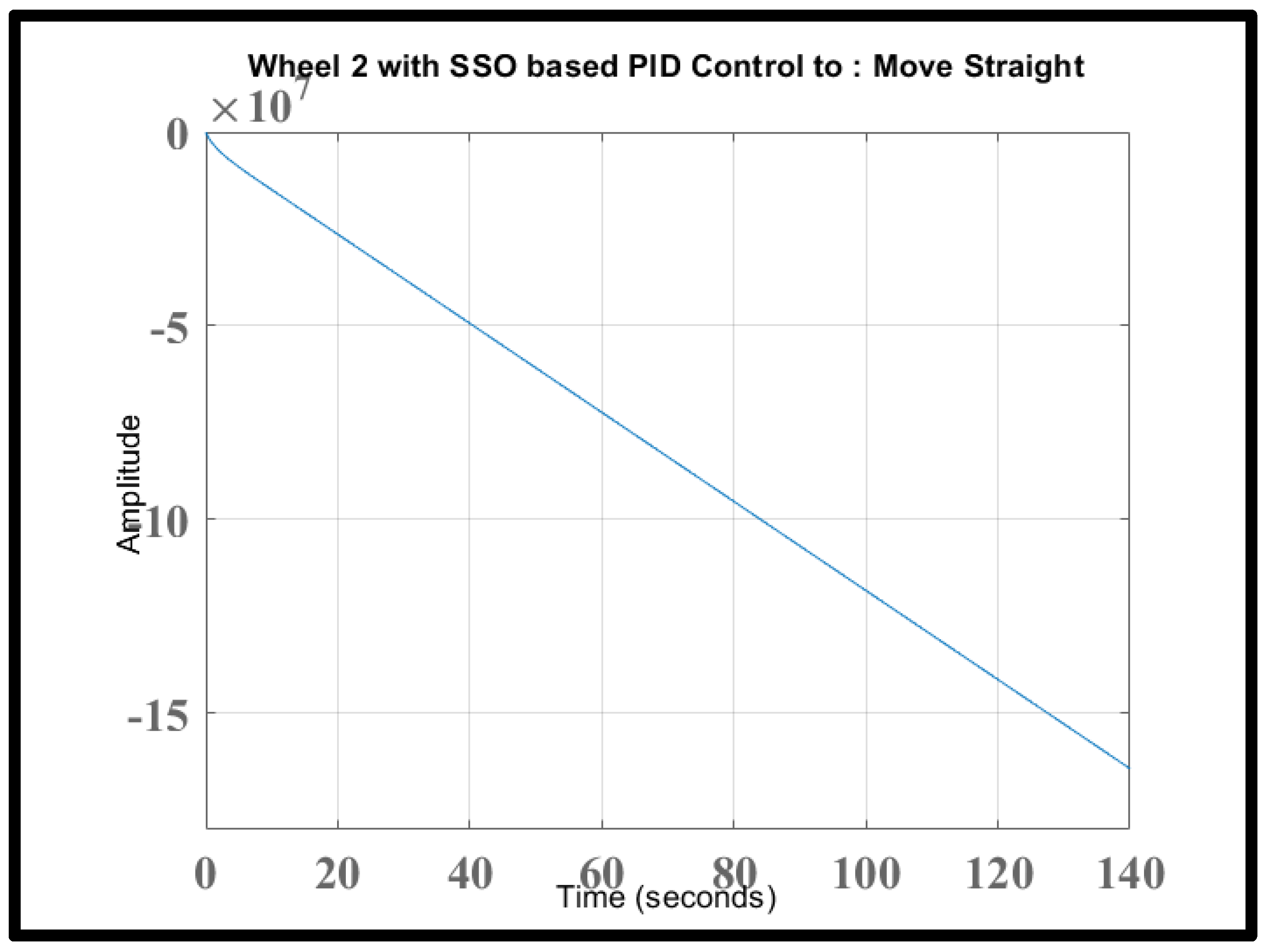

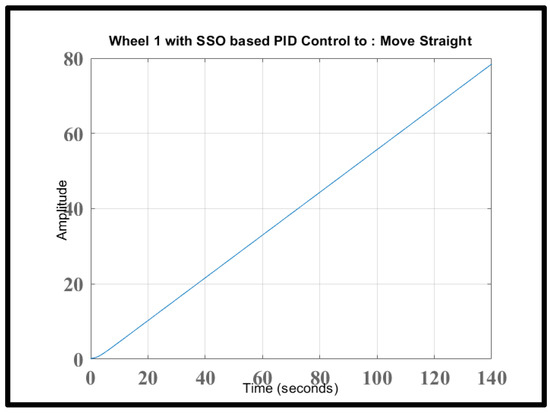

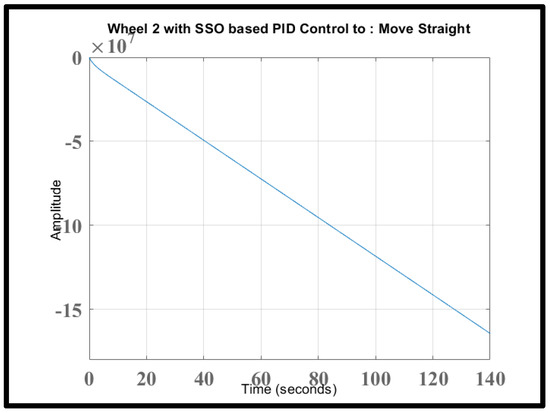

Case 2: When the wheels rotate at the same speed and opposite in direction, the robot moves forward (Vr = −VL). Below Figure 11 and Figure 12 show the simulation of the robot moving forward. While moving straight the robot’s velocity will be 4.0323 m/s.

Figure 11.

Simulation of wheel 1 moving forward when Vr = −VL.

Figure 12.

Simulation of wheel 2 moving forward when Vr = −VL.

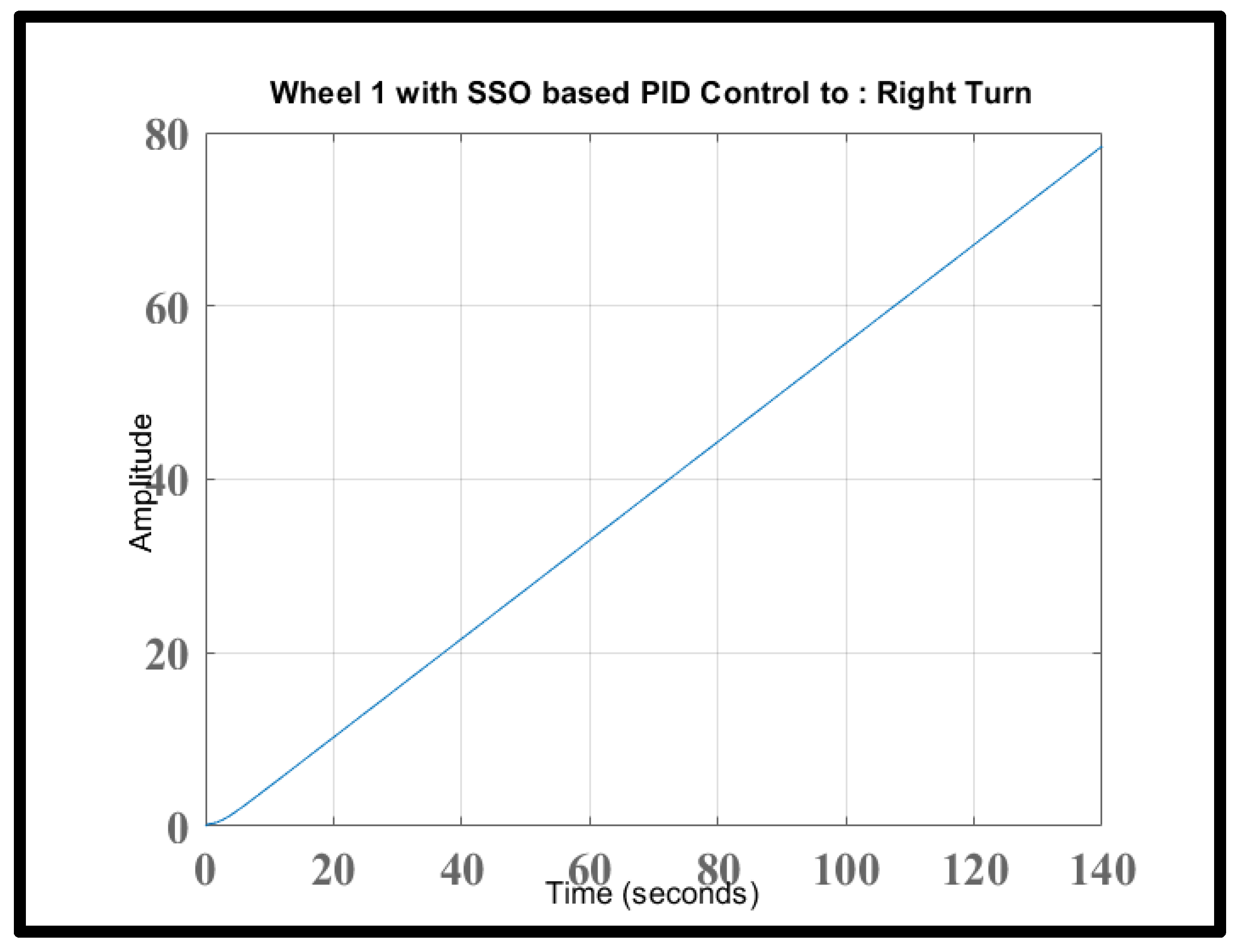

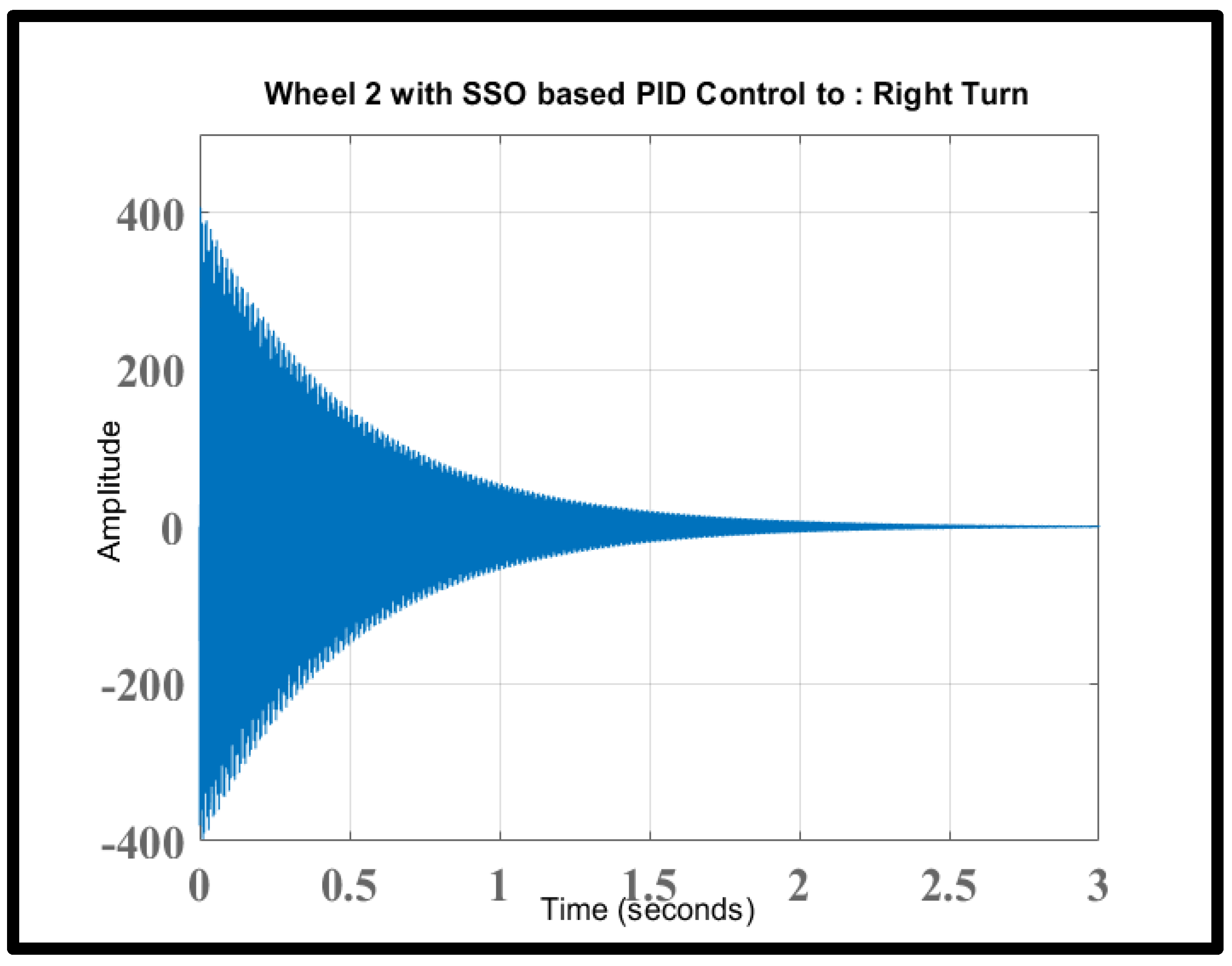

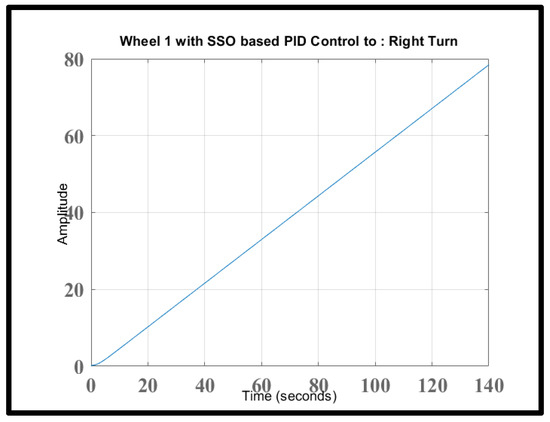

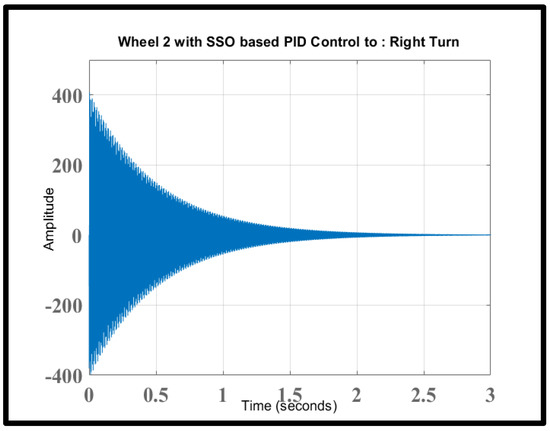

Case 3: The robot turns towards right when Vr > VL.

If the velocity of the right wheel is greater than the left wheel then the robot turns right. Below Figure 13 and Figure 14 show the simulation of the robot turning right. While turning right the robot velocity will be 2.016 m/s and the angular velocity will be 80.64 m/s.

Figure 13.

Simulation of wheel 1 turning right when Vr > VL.

Figure 14.

Simulation of wheel 2 turning right when Vr > VL.

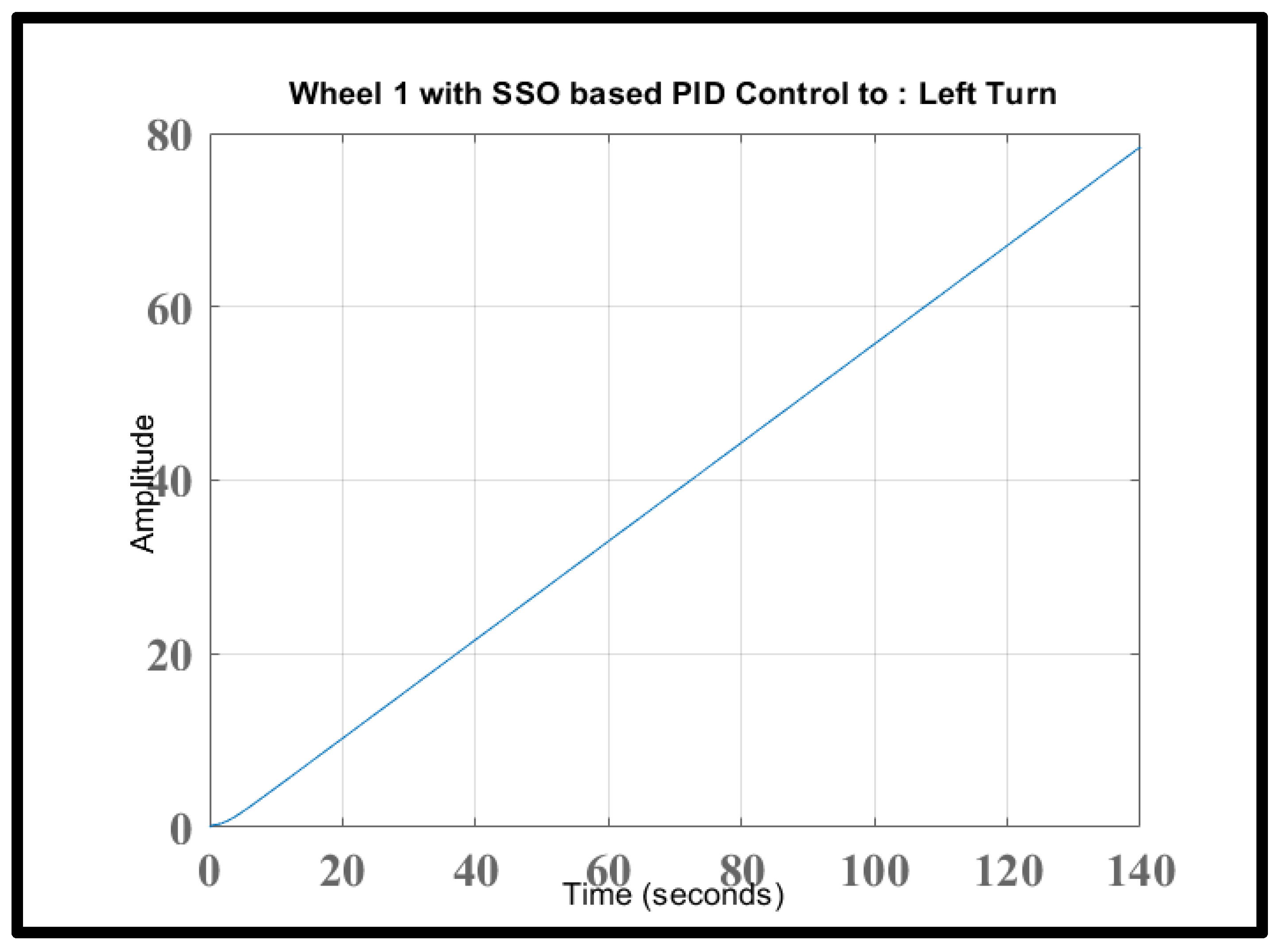

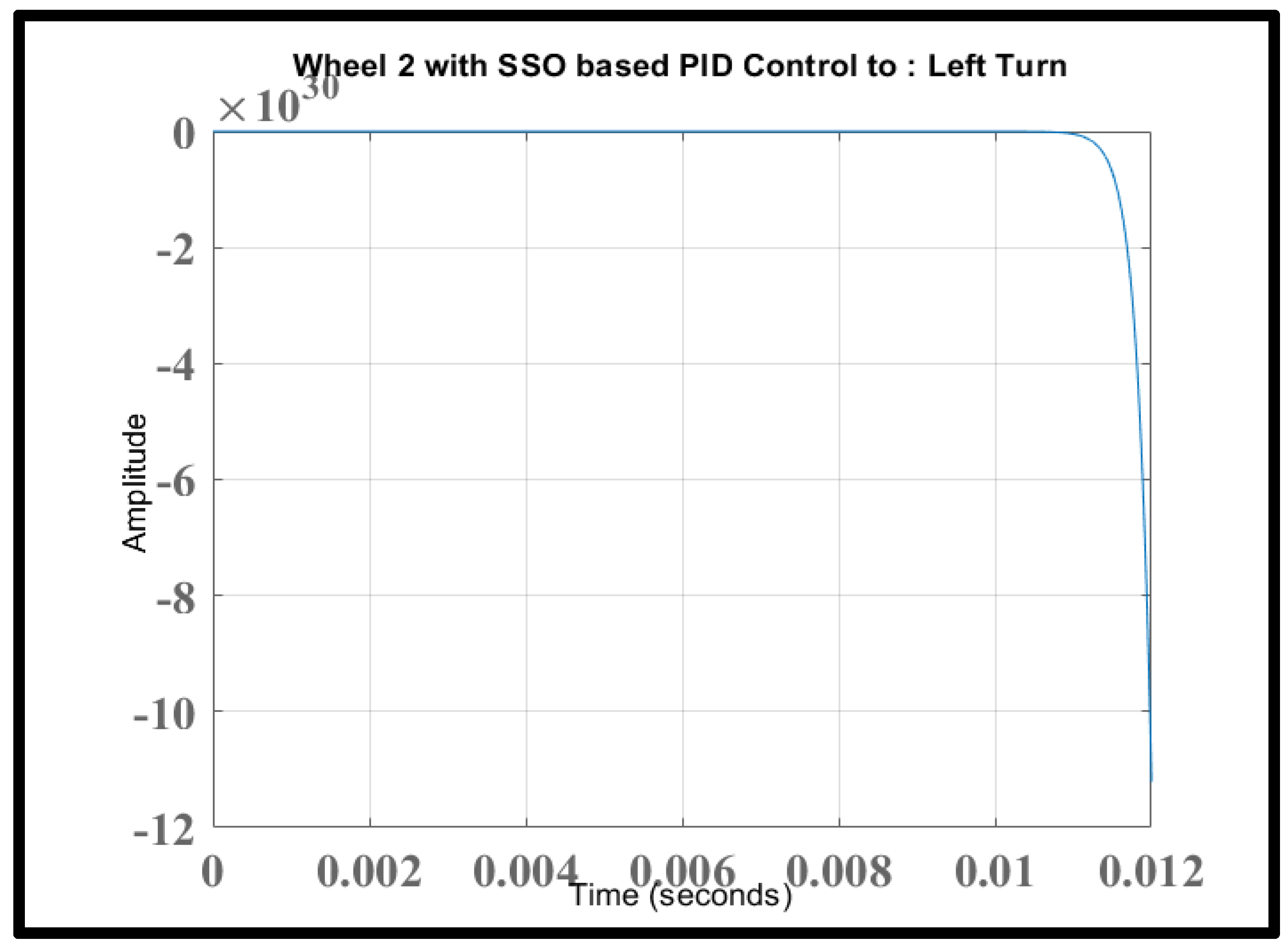

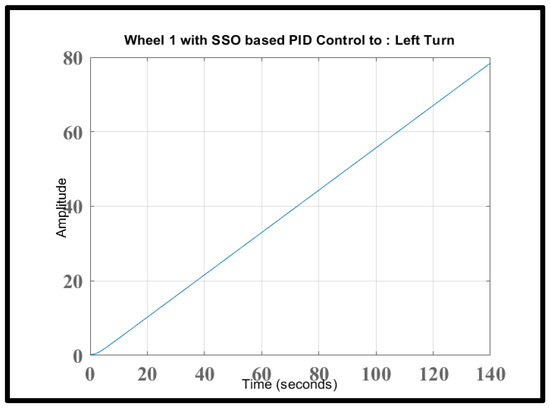

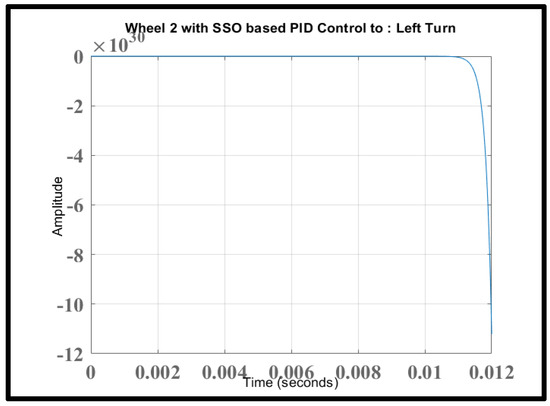

Case 4: Robot turns left when Vr < VL.

If the velocity of the left wheel is greater than the right wheel, then the robot turns left. Simulation of wheels turning left is shown in below Figure 15 and Figure 16. Velocity and angular velocity of the robot while turning left will be 2.016 m/s and 80.64 m/s, respectively.

Figure 15.

Simulation of wheel 1 turning left when Vr < VL.

Figure 16.

Simulation of wheel-2 turning left when Vr < VL.

4. Conclusions

This research work presents a novel approach to control the speed of a two-wheeled mobile robot using a PID controller optimized by the Social Spider Optimization (SSO) algorithm. The proposed system employs a DC motor for the mobility of the robot and uses the PID controller to regulate the motor speed. The SSO algorithm is employed to optimize the PID controller gain values for better performance compared to previous works. The four cases discussed in this study demonstrate the versatility of the proposed system in controlling the direction of the mobile robot. The simulation results obtained in MATLAB show that the proposed system can effectively control the speed of the mobile robot with improved settling time compared to traditional PID controllers and CSO-based PID controllers. The proposed SSO-based PID controller provides a promising solution for the control of mobile robots, and the results of this study demonstrate its effectiveness in controlling the speed of a two-wheel mobile robot. Table 2 represents the comparison of settling time of speed response of all the controllers.

Table 2.

Comparison of Settling Time of Speed Response of All The Controllers.

In this paper, SSO-based PID controller is showing the best results as it has been settled at 6 ms whereas CSO-based PID response has been settled at 14 ms and PID controller response has been settled at 23 ms. Therefore, we can conclude that the existing method such as CSO algorithms is not perfect for our PID-based mobile robot speed control. However, our proposed SSO algorithm is showing the best response and settled the speed of the motor as the fastest of all the controllers. In the future, this work can be implemented to control the speed of WMR in a real-time environment by using both optimization technique-based PID controllers. Moreover, the study suggests that other optimization techniques such as Red Deer Optimization (RDO) can also be employed for PID controller design and compared with the proposed SSO-optimized PID controller. This can provide a better understanding of the performance of different optimization techniques for PID controller design in mobile. Overall, the findings of this study highlight the importance of optimization techniques in PID controller design for mobile robot control and pave the way for further research in this field.

Author Contributions

Conceptualization, H.K., S.K., P.G., M.A., C.A.S. and S.A.K.; methodology, H.K.; validation, H.K., S.K., P.G., M.A., C.A.S. and S.A.K.; software, H.K.; validation, H.K., S.K., P.G., M.A., C.A.S. and S.A.K.; formal analysis, H.K., S.K., P.G., M.A, C.A.S., S.A.K.; investigation, H.K., S.K., P.G., M.A., C.A.S. and S.A.K.; resources, H.K.; data curation, H.K.; writing—original draft preparation, H.K.; writing—review and editing, H.K.; visualization, H.K., S.K., P.G., M.A., C.A.S. and S.A.K.; supervision, S.K. and P.G.; project administration, M.A.; funding acquisition, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University (KKU) for funding this work through the Research Group Program Under the Grant Number: (R.G.P.2/382/44).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Abbreviations | Explanation |

| WMR | Wheeled Mobile Robot |

| DC | Direct Current |

| PID | Proportional integral derivative controller |

| FLC | Fuzzy Logic Controller |

| ANFIS | Adaptive Neuro-Fuzzy Interference System |

| MPC | Model predictive controller |

| DOF | Degree Of Freedom |

| SSO | Social Spider Optimization |

| CSO | Cuckoo Search Optimization |

| PSO | Particle Swarm Optimization |

| ABC | Ant Bee Colony |

| UAV | Unmanned Aerial Vehicle |

| IAE | Integral Absolute Error |

| ITAE | Integral Time Absolute Error |

| LFO | Low-Frequency Oscillator |

| PSS | Power System stabilizer |

| ZN | Ziegler–Nicol’s |

| FFA | Fire Fly Algorithm |

| Kp | Constant of Proportionality |

| Ki | Integral Constant |

| Kd | Derivative Constant |

| AVR | Automatic Voltage Regulator |

| CS | Cuckoo Search |

References

- Parhi, D.R.; Mohanty, P.K. IWO-based adaptive neuro-fuzzy controller for mobile robot navigation in cluttered environments. Int. J. Adv. Manuf. Technol. 2016, 83, 1607–1625. [Google Scholar] [CrossRef]

- Kim, H.; Kim, B.K. Minimum-energy cornering trajectory planning with self-rotation for three-wheeled omni-directional mobile robots. Int. J. Control. Autom. Syst. 2017, 15, 1857–1866. [Google Scholar] [CrossRef]

- Pandey, A.; Parhi, D.R. Autonomous mobile robot navigation in cluttered environment using hybrid Takagi-Sugeno fuzzy model and simulated annealing algorithm controller. World J. Eng. 2016, 13, 431–440. [Google Scholar] [CrossRef]

- Huang, J.; Ri, M.H.; Wu, D.; Ri, S. Interval type-2 fuzzy logic modelling and control of a mobile two-wheeled inverted pendulum. IEEE Trans. Fuzzy Syst. 2017, 26, 2030–2038. [Google Scholar] [CrossRef]

- Bayar, G.; Bergermanand, M.; Koku, A.B. Improving the trajectory tracking performance of autonomous orchard vehicles using wheel slip compensation. Biosyst. Eng. 2016, 146, 149–164. [Google Scholar] [CrossRef]

- Zhai, J.; Song, Z. Adaptive sliding mode trajectory tracking control for wheeled mobile robots. Int. J. Control 2018, 92, 2255–2262. [Google Scholar] [CrossRef]

- Rossomando, F.G. Sliding mode control for trajectory tracking of a non-holonomic mobile robot using adaptive neural networks. J. Control Eng. Appl. Inform. 2014, 16, 12–21. [Google Scholar]

- Zadarnowska, K. Switched modelling and task–priority motion planning of wheeled mobile robots subject to slipping. J. Intell. Robot. Syst. 2017, 85, 449–469. [Google Scholar] [CrossRef]

- Güzey, H.M.; Dierks, T.; Jagannathan, S.; Acar, L. Hybrid consensus-based control of nonholonomic mobile robot formation. J. Intell. Robot. Syst. 2017, 88, 181–200. [Google Scholar] [CrossRef]

- Xiao, H.; Li, Z.; Yang, C.; Zhang, L.; Yuan, P.; Ding, L.; Wang, T. Robust stabilization of a wheeled mobile robot using model predictive control based on neurodynamic optimization. IEEE Trans. Ind. Electron. 2016, 64, 505–516. [Google Scholar] [CrossRef]

- Poonawala, H.; Satici, A.C.; Gans, N.; Spong, M.W. Formation control of wheeled robots with vision-based position measurement. In Proceedings of the 2012 American Control Conference (ACC), Montreal, QC, Canada, 27–29 June 2012; pp. 3173–3178. [Google Scholar]

- Raja, R.; Dutta, A.; Venkatesh, K.S. New potential field method for rough terrain path planning using genetic algorithm for a 6-wheel rover. Robot. Auton. Syst. 2015, 72, 295–306. [Google Scholar] [CrossRef]

- Sentis, L.; Petersen, J.; Philippsen, R. Experiments with balancing on irregular terrains using the dreamer mobile humanoid robot. In Robotics: Science and Systems (RSS); University of Sydney: Sydney, NSW, Australia; MIT Press: Cambridge, MA, USA, 2012; Volume 8, pp. 393–400. [Google Scholar]

- Sanders, D.A. Non-model-based control of a wheeled vehicle pulling two trailers to provide early powered mobility and driving experiences. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 26, 96–104. [Google Scholar] [CrossRef] [PubMed]

- Pei, Y.; Zhang, K.; Pan, J.; Shi, Y. Nonlinear model predictive tracking control of nonholonomic wheeled mobile robot using modified C/GMRES algorithm. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October 2017; pp. 6298–6303. [Google Scholar]

- Wang, C.; Liu, X.; Yang, X.; Hu, F.; Jiang, A.; Yang, C. Trajectory tracking of an omni-directional wheeled mobile robot using a model predictive control strategy. Appl. Sci. 2018, 8, 231. [Google Scholar] [CrossRef]

- Mobayen, S. An adaptive fast terminal sliding mode control combined with global sliding mode scheme for tracking control of uncertain nonlinear third-order systems. Nonlinear Dyn. 2015, 82, 599–610. [Google Scholar] [CrossRef]

- Kang, H.S.; Hyun, C.H.; Kim, S. Robust tracking control using fuzzy disturbance observer for wheeled mobile robots with skidding and slipping. Int. J. Adv. Robot. Syst. 2014, 11, 75. [Google Scholar] [CrossRef]

- Li, S.; Ding, L.; Gao, H.; Chen, C.; Liu, Z.; Deng, Z. Adaptive neural network tracking control-based reinforcement learning for wheeled mobile robots with skidding and slipping. Neurocomputing 2018, 283, 20–30. [Google Scholar] [CrossRef]

- Tan, L.N. Omnidirectional-vision-based distributed optimal tracking control for mobile multirobot systems with kinematic and dynamic disturbance rejection. IEEE Trans. Ind. Electron. 2017, 65, 5693–5703. [Google Scholar] [CrossRef]

- Shouran, M.; Habil, M. Tuning of PID Controller Using Different Optimization Algorithms for Industrial DC Motor. In Proceedings of the International Conference on Advance Computing and Innovative Technologies in Engineering (ICACITE), Greater Noida, India, 4–5 March 2021; pp. 756–759. [Google Scholar]

- Zhao, H.; Sun, Y.; Chen, Z.; Liu, M.; Liang, B. Advanced Particle Swarm Algorithm for Bicycle Robot Balancing Optimization Control Under Constant Speed. In Proceedings of the 36th Youth Academic Annual Conference of Chinese Association of Automation (YAC), Nanchang, China, 28–30 May 2021; pp. 203–209. [Google Scholar]

- Qiu, D.; Qiu, D.; Wu, B.; Gu, M.; Zhu, M. Hierarchical Control of Trajectory Planning and Trajectory Tracking for Autonomous Parallel Parking. IEEE Access 2021, 9, 94845–94861. [Google Scholar] [CrossRef]

- Shadravan, S.; Naji, H.R.; Bardsiri, V.K. The Sailfish Optimizer: A novel nature-inspired metaheuristic algorithm for solving constrained engineering optimization problems. Eng. Appl. Artif. Intell. 2019, 80, 20–34. [Google Scholar] [CrossRef]

- Bouallègue, S.; Haggège, J.; Ayadi, M.; Benrejeb, M. PID-type fuzzy logic controller tuning based on particle swarm optimization. Eng. Appl. Artif. Intell. 2012, 25, 484–493. [Google Scholar] [CrossRef]

- James, J.Q.; Li, V.O.K. A social spider algorithm for global optimization. Appl. Soft Comput. 2015, 30, 614–627. [Google Scholar]

- Cuevas, E.; Cienfuegos, M. A new algorithm inspired in the behavior of the social-spider for constrained optimization. Expert Syst. Appl. 2014, 41, 412–425. [Google Scholar] [CrossRef]

- Cuevas, E.; Cienfuegos, M.; Zaldívar, D.; Pérez-Cisneros, M. A swarm optimization algorithm inspired in the behavior of the social-spider. Expert Syst. Appl. 2013, 40, 6374–6384. [Google Scholar] [CrossRef]

- Pereira, L.A.M.; Rodrigues, D.; Ribeiro, P.B.; Papa, J.P.; Weber, S.A.T. Social-spider optimization-based artificial neural networks training and its applications for Parkinson’s Disease identification. In Proceedings of the 2014 IEEE 27th International Symposium on Computer-Based Medical Systems, New York, NY, USA, 27–29 May 2014; pp. 14–17. [Google Scholar] [CrossRef]

- Li, B.; Zhang, X.; Fang, Y.; Shi, W. Visual servo regulation of wheeled mobile robots with simultaneous depth identification. IEEE Trans. Ind. Electron. 2018, 65, 460–469. [Google Scholar] [CrossRef]

- Yoo, S.J.; Park, B.S. Connectivity-preserving approach for distributed adaptive synchronized tracking of networked uncertain nonholonomic mobile robots. IEEE Trans. Cybern. 2018, 48, 2598–2608. [Google Scholar] [CrossRef] [PubMed]

- Shahriari, M.; Biglarbegian, M. A new conflict resolution method for multiple mobile robots in cluttered environments with motion-liveness. IEEE Trans. Cybern. 2018, 48, 300–311. [Google Scholar] [CrossRef] [PubMed]

- Chouhan, A.S.; Parhi, D.R.; Chhotray, A. Control and Balancing of Two-Wheeled Mobile Robots using Sugeno Fuzzy Logic in the domain of AI Techniques. In Emerging Trends in Engineering, Science and Manufacturing, (ETESM-2018); IGIT: Sarang, India, 2018. [Google Scholar]

- Shen, Z.; Ma, Y.; Song, Y. Robust adaptive fault-tolerant control of mobile robots with varying centre of mass. IEEE Trans. Ind. Electron. 2018, 65, 2419–2428. [Google Scholar] [CrossRef]

- Liang, X.; Wang, H.; Liu, Y.H.; Chen, W.; Liu, T. Formation control of nonholonomic mobile robots without position and velocity measurements. IEEE Trans. Robot. 2018, 34, 434–446. [Google Scholar] [CrossRef]

- Mamizadeh, A.; Genc, N.; Rajabioun, R. Optimal Tuning of PI Controller for Boost DC-DC Converters Based on Cuckoo Optimization Algorithm. In Proceedings of the 2018 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018; pp. 677–680. [Google Scholar] [CrossRef]

- Jin, Q.; Qi, L.; Jiang, B.; Wang, Q. Novel improved cuckoo search for PID controller design. Trans. Inst. Meas. Control. 2015, 37, 721–731. [Google Scholar] [CrossRef]

- Singh, K.S.M.J.; Elamvazuthi, I.; Shaari, K.Z.K.; Perumal, N. Development of PID controller tuning tool based on cuckoo search algorithms. In Proceedings of the 2017 IEEE 3rd International Symposium in Robotics and Manufacturing Automation (ROMA), Kuala Lumpur, Malaysia, 19–21 September 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Sheshnarayan; Verma, B.; Padhy, P.K. Design PID Controller based PSS using Cuckoo Search Optimization Technique. In Proceedings of the 2019 4th International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bengaluru, India, 17–18 May 2019; pp. 459–463. [Google Scholar] [CrossRef]

- Yaacob, N.D.; Othman, W.A.F.W.; Wahab, A.A.A.; Alhady, S.S.N. Social Spider Optimization (SSO) for Tuning PID Controller on DC Motors; Alhady School of Electrical & Electronic Engineering, Universiti Sains Malaysia: Penang, Malaysia, 2018; Volume 5. [Google Scholar]

- Wahab, A.A.A.; Alhady, S.S.N.; Sofik, N.H.B.; Othman, W.A.F.W. Optimization of PID Controller Using Crow Search Algorithm and Bat Algorithm; Othman School of Electric and Electronic Engineering, Universiti Sains Malaysia (USM): Penang, Malaysia, 2018. [Google Scholar]

- Sabir, M.M.; Ali, T. Optimal PID controller design through swarm intelligence algorithms for sun tracking system. Appl. Math. Comput. 2016, 274, 690–699. [Google Scholar] [CrossRef]

- Govindan, P. Evolutionary algorithms-based tuning of PID controller for an AVR system. Int. J. Electr. Comput. Eng. (IJECE) 2020, 10, 3047–3056. [Google Scholar] [CrossRef]

- Yuhui, S.; Chen, T.K.; Mengjie, Z.; Ke, T.; Xiaodong, L.; Qingfu, Z.; Ying, T.; Martin, M.; Yaochu, J. A Competitive Social Spider Optimization with Learning Strategy for PID Controller Optimization. In Simulated Evolution and Learning, Proceedings of the 11th International Conference, SEAL 2017, Shenzhen, China, 10–13 November 2017; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2017; Volume 1059310, pp. 1026–1038. [Google Scholar] [CrossRef]

- Khan, T.M.Y.; Soudagar, M.E.M.; Kanchan, M.; Afzal, A.; Banapurmath, N.R.; Akram, N.; Mane, S.D.; Shahapurkar, K. Optimum location and influence of tilt angle on performance of solar PV panels. J. Therm. Anal. Calorim. 2019, 141, 511–532. [Google Scholar] [CrossRef]

- Samylingam, L.; Aslfattahi, N.; Saidur, R.; Mohd, S.; Afzal, A. Solar Energy Materials and Solar Cells Thermal and energy performance improvement of hybrid PV / T system by using olein palm oil with MXene as a new class of heat transfer fluid. Sol. Energy Mater. Sol. Cells 2020, 218, 110754. [Google Scholar] [CrossRef]

- Attia, M.E.H.; Driss, Z.; Kabeel, A.E.; Afzal, A.; Manokar, A.M.; Sathyamurthy, R. Phosphate bed as energy storage materials for augmentation of conventional solar still productivity. Environ. Prog. Sustain. Energy 2021, 2020, e13581. [Google Scholar] [CrossRef]

- Prasad, A.R.; Attia, M.E.H.; Al-Kouz, W.; Afzal, A.; Athikesavan, M.M.; Sathyamurthy, R. Energy and exergy efficiency analysis of solar still incorporated with copper plate and phosphate pellets as energy storage material. Environ. Sci. Pollut. Res. 2021, 28, 48628–48636. [Google Scholar] [CrossRef]

- Kumar, R.; Gaurav; Kumar, S.; Afzal, A.; Manokar, A.M.; Sharifpur, M.; Issakhov, A. Experimental investigation of impact of the energy storage medium on the thermal performance of double pass solar air heater. Sustain. Energy Technol. Assess. 2021, 48, 101673. [Google Scholar] [CrossRef]

- Kumar, P.S.; Naveenkumar, R.; Sharifpur, M.; Issakhov, A.; Ravichandran, M.; Mohanavel, V.; Aslfattahi, N.; Afzal, A. Experimental investigations to improve the electrical efficiency of photovoltaic modules using different convection model. Sustain. Energy Technol. Assess. 2021, 48, 101582. [Google Scholar] [CrossRef]

- Kumar, R.; Nadda, R.; Kumar, S.; Kumar, K.; Afzal, A.; Razak, R.A.; Sharifpur, M. Heat transfer and friction factor correlations for an impinging air jets solar thermal collector with arc ribs on an absorber plate. Sustain. Energy Technol. Assess. 2021, 47, 101523. [Google Scholar] [CrossRef]

- Benoudina, B.; Attia, M.E.H.; Driss, Z.; Afzal, A.; Manokar, A.M.; Sathyamurthy, R. Enhancing the solar still output using micro/nano-particles of aluminum oxide at different concentrations: An experimental study, energy, exergy and economic analysis. Sustain. Mater. Technol. 2021, 29, e00291. [Google Scholar] [CrossRef]

- Kothandaraman, K. Motion Planning and Control of Differential Drive Robot; Wright State University: Dayton, OH, USA, 2016. [Google Scholar]

- Allaoua, B.; Gasbaoui, B.; Mebarki, B. Setting up PID DC motor speed control alteration parameters using particle swarm optimization strategy. Leonardo Electron. J. Pract. Technol. 2009, 1, 19–32. [Google Scholar]

- Bingul, Z.; Karahan, O. A novel performance criterion approach to optimum design of PID controller using cuckoo search algorithm for AVR system. J. Frankl. Inst. 2018, 355, 5534–5559. [Google Scholar] [CrossRef]

- Afzal, A.; Khan, S.A.; Islam, T.; Jilte, R.D.; Khan, A.; Soudagar, M.E.M. Investigation and Back-Propagation Modeling of Base Pressure at Sonic and Supersonic Mach Numbers. Phys. Fluids 2020, 32, 096109. [Google Scholar] [CrossRef]

- David, O.; Okwu, M.O.; Oyejide, O.J.; Taghinezhad, E.; Asif, A.; Kaveh, M. Optimizing Biodiesel Production from Abundant Waste Oils through Empirical Method and Grey Wolf Optimizer. Fuel 2020, 281, 118701. [Google Scholar] [CrossRef]

- Afzal, A.; Saleel, C.A.; Badruddin, I.A.; Khan, T.M.Y.; Kamangar, S.; Mallick, Z.; Samuel, O.D.; Soudagar, M.E.M. Human Thermal Comfort in Passenger Vehicles Using an Organic Phase Change Material–An Experimental Investigation, Neural Network Modelling, and Optimization. Build. Environ. 2020, 180, 107012. [Google Scholar] [CrossRef]

- Afzal, A.; Alshahrani, S.; Alrobaian, A.; Buradi, A.; Khan, S.A. Power Plant Energy Predictions Based on Thermal Factors Using Ridge and Support Vector Regressor Algorithms. Energies 2021, 14, 7254. [Google Scholar] [CrossRef]

- Afzal, A. Optimization of Thermal Management in Modern Electric Vehicle Battery Cells Employing Genetic Algorithm. J. Heat Transf. 2021, 143, 112902. [Google Scholar] [CrossRef]

- Afzal, A.; Navid, K.M.Y.; Saidur, R.; Razak, R.K.A.; Subbiah, R. Back Propagation Modeling of Shear Stress and Viscosity of Aqueous Ionic—MXene Nanofluids. J. Therm. Anal. Calorim. 2021, 145, 2129–2149. [Google Scholar] [CrossRef]

- Mokashi, I.; Afzal, A.; Khan, S.A.; Abdullah, N.A.; Bin Azami, M.H.; Jilte, R.D.; Samuel, O.D. Nusselt Number Analysis from a Battery Pack Cooled by Different Fluids and Multiple Back-Propagation Modelling Using Feed-Forward Networks. Int. J. Therm. Sci. 2021, 161, 106738. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Krishna Moorthy, R.; Parthasarathy, M.; Samuel, O.D.; Owamah, H.I.; Saleel, C.A.; Enweremadu, C.C.; Sreenivasa Reddy, M.; Afzal, A. Artificial Neural Networks Model for Predicting the Behavior of Different Injection Pressure Characteristics Powered by Blend of Biofuel-Nano Emulsion. Energy Sci. Eng. 2022, 10, 2367–2396. [Google Scholar] [CrossRef]

- Veza, I.; Afzal, A.; Mujtaba, M.A.; Tuan Hoang, A.; Balasubramanian, D.; Sekar, M.; Fattah, I.M.R.; Soudagar, M.E.M.; EL-Seesy, A.I.; Djamari, D.W.; et al. Review of Artificial Neural Networks for Gasoline, Diesel and Homogeneous Charge Compression Ignition Engine: Review of ANN for Gasoline, Diesel and HCCI Engine. Alex. Eng. J. 2022, 61, 8363–8391. [Google Scholar] [CrossRef]

- Bakır, H.; Ağbulut, Ü.; Gürel, A.E.; Yıldız, G.; Güvenç, U.; Soudagar, M.E.M.; Hoang, A.T.; Deepanraj, B.; Saini, G.; Afzal, A. Forecasting of Future Greenhouse Gas Emission Trajectory for India Using Energy and Economic Indexes with Various Metaheuristic Algorithms. J. Clean. Prod. 2022, 360, 131946. [Google Scholar] [CrossRef]

- Sharma, P.; Said, Z.; Kumar, A.; Nižetić, S.; Pandey, A.; Hoang, A.T.; Huang, Z.; Afzal, A.; Li, C.; Le, A.T.; et al. Recent Advances in Machine Learning Research for Nanofluid-Based Heat Transfer in Renewable Energy System. Energy Fuels 2022, 36, 6626–6658. [Google Scholar] [CrossRef]

- Sharma, J.; Soni, S.; Paliwal, P.; Saboor, S.; Chaurasiya, P.K.; Sharifpur, M.; Khalilpoor, N.; Afzal, A. A Novel Long Term Solar Photovoltaic Power Forecasting Approach Using LSTM with Nadam Optimizer: A Case Study of India. Energy Sci. Eng. 2022, 10, 2909–2929. [Google Scholar] [CrossRef]

- Ziaee, O.; Zolfaghari, N.; Baghani, M.; Baniassadi, M.; Wang, K. A modified cellular automaton model for simulating ion dynamics in a Li-ion battery electrode. Energy Equip. Syst. 2022, 10, 41–49. [Google Scholar]

- Taslimi, M.S.; Maleki Dastjerdi, S.; Bashiri Mousavi, S.; Ahmadi, P.; Ashjaee, M. Assessment and multi-objective optimization of an off-grid solar based energy system for a Conex. Energy Equip. Syst. 2021, 9, 127–143. [Google Scholar]

- Sharifi, M.; Amidpour, M.; Mollaei, S. Investigating carbon emission abatement long-term plan with the aim of energy system modeling; case study of Iran. Energy Equip. Syst. 2018, 6, 337–349. [Google Scholar]

- Zare, S.; Ayati, M.; Ha’iri Yazdi, M.R.; Kabir, A.A. Convolutional neural networks for wind turbine gearbox health monitoring. Energy Equip. Syst. 2022, 10, 73–82. [Google Scholar]

- Sabzi, S.; Asadi, M.; Moghbelli, H. Review, analysis and simulation of different structures for hybrid electrical energy storages. Energy Equip. Syst. 2017, 5, 115–129. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).