Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material and Reagents

2.2. Dryers Used in Experiments

2.3. Drying Procedure

2.4. Color Measurement

2.5. Texture Analysis

2.6. Extraction and Total Phenolic Content (TPC) Quantification

2.7. Antioxidant Capacity by DPPH and ABTS Assays

2.8. Phenolic Compounds Identification by UPLC-PDA-ESI-MS/MS

2.9. Statistical Analysis

3. Results and Discussion

3.1. Drying Kinetics

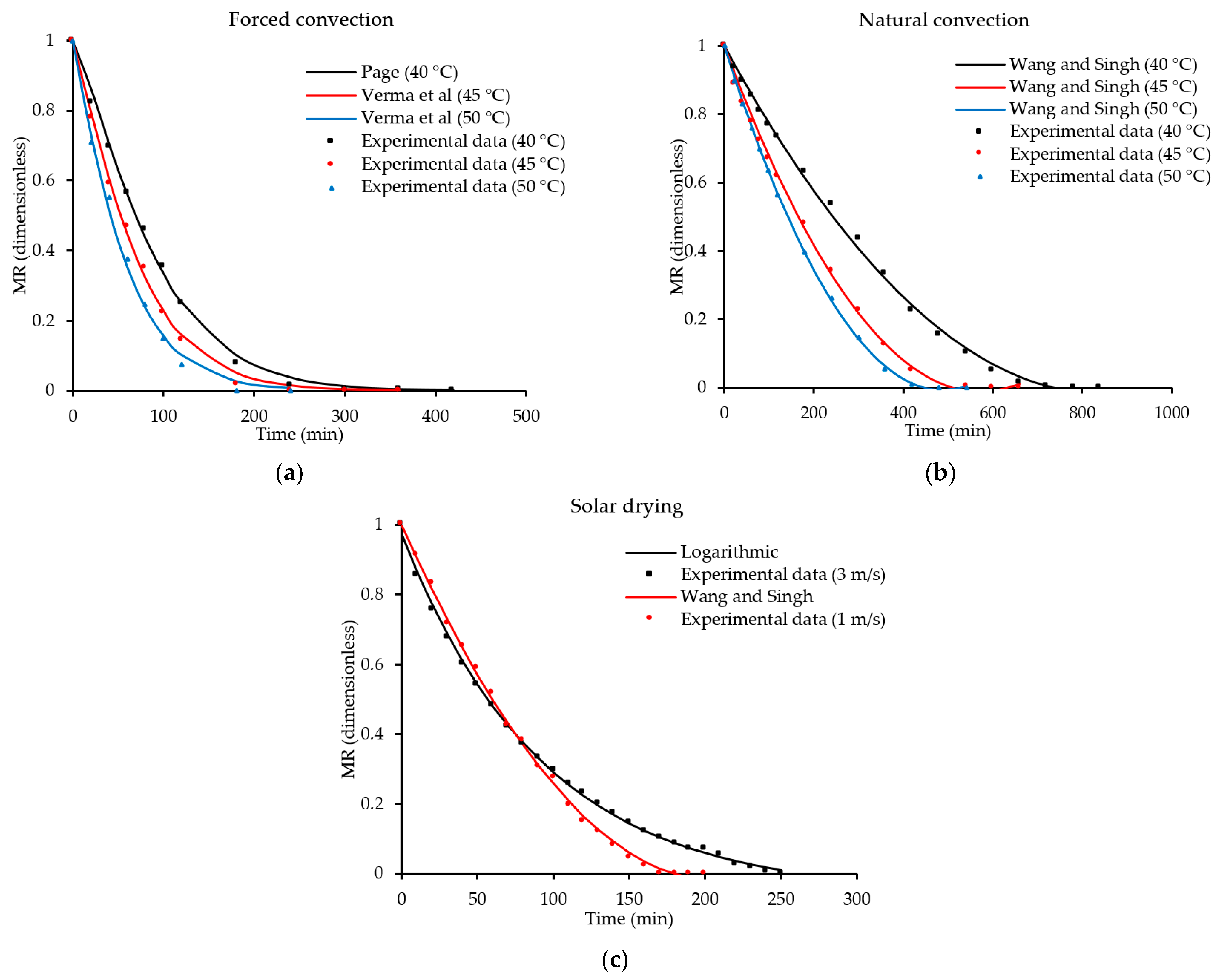

3.2. Analysis of Thin Layer Models

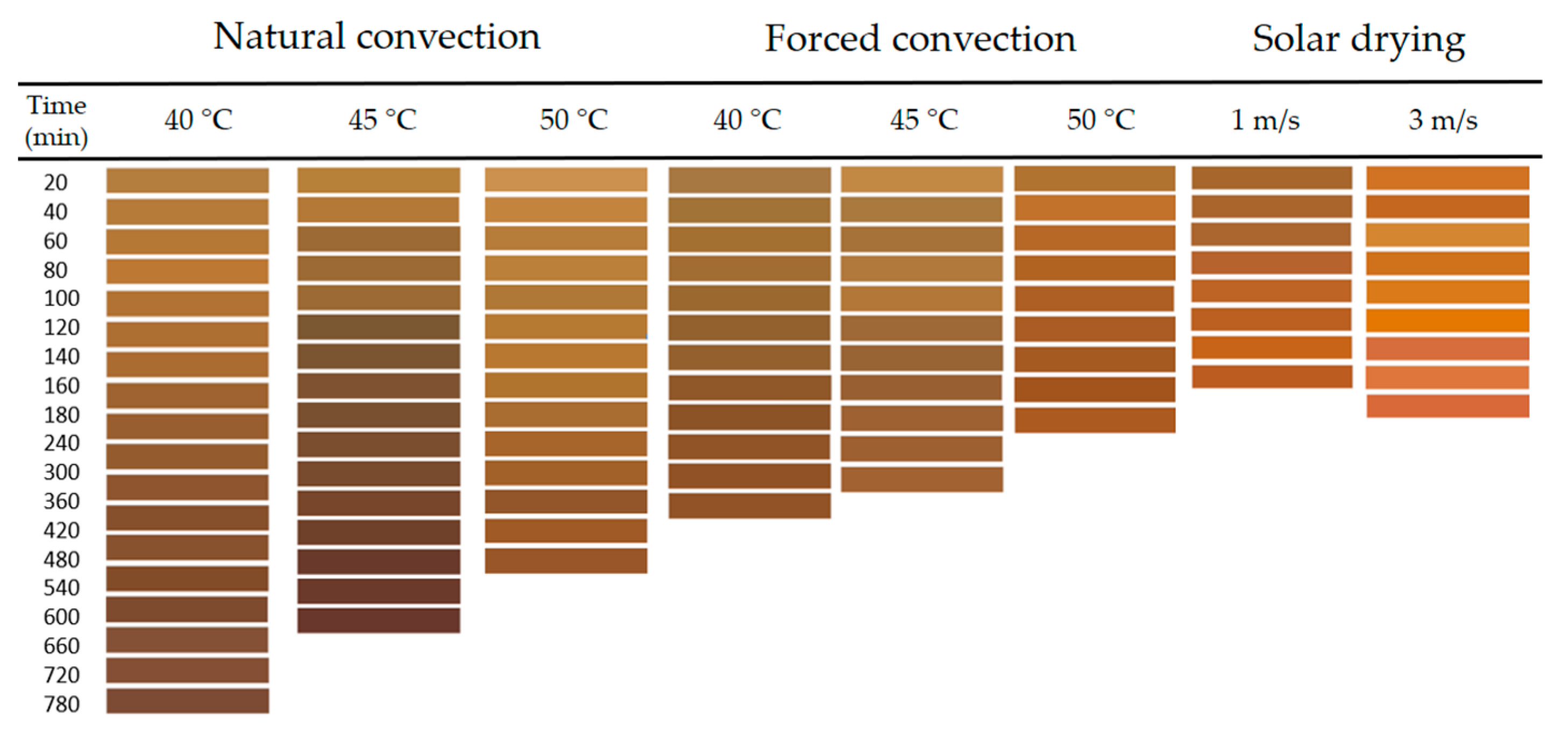

3.3. Color Analysis

3.4. Hardness

3.5. Total Phenolic Content and Antioxidant Activity

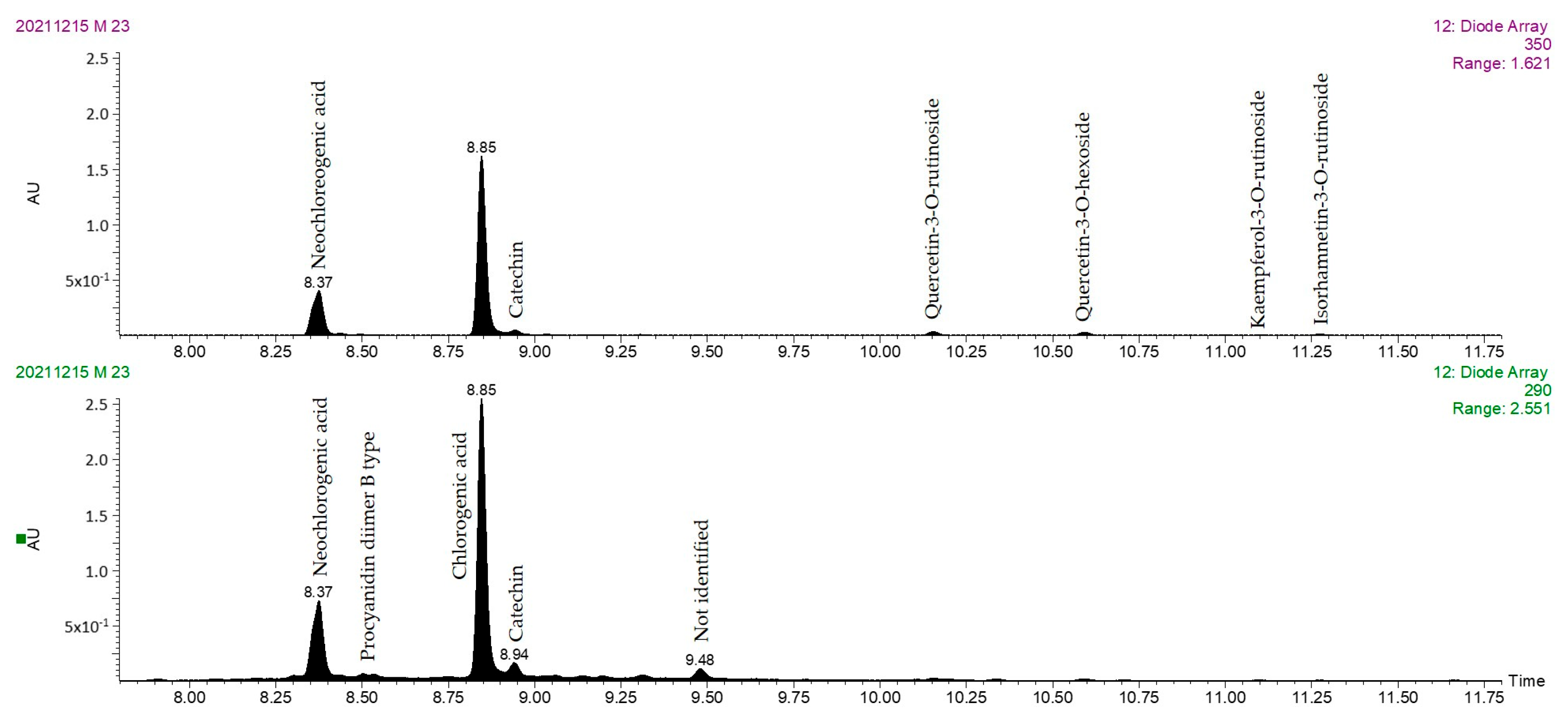

3.6. Phenolic Compounds Identification and Profile

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Farcuh, M.; Hopfer, H. Aroma volatiles as predictors of chilling injury development during peach (Prunus persica (L.) Batsch) cold storage and subsequent shelf-life. Postharvest Biol. Technol. 2023, 195, 112137. [Google Scholar] [CrossRef]

- Zhao, X.; Zeng, L.; Wang, J.; Shi, Y.; Zhang, B. Quantitative N-Glycomic and N-Glycoproteomic Profiling of Peach [Prunus persica (L.) Batsch] during Fruit Ripening. J. Proteome Res. 2022, 22, 885–895. [Google Scholar] [CrossRef] [PubMed]

- Coyotl-Pérez, W.A.; Pacheco-Hernández, Y.; Velázquez-Herrera, F.D.; Fetter, G.; Hidalgo-Martínez, D.; Villa-Ruano, N.; Becerra-Martínez, E. Metabolomics profiling of Prunus persica cv. diamante showing symptoms of Rhizopus rot: A new hydrotalcite/shilovite composite to improve fruit quality. Postharvest Biol. Technol. 2022, 188, 111897. [Google Scholar] [CrossRef]

- Doymaz, I.; Bilici, B. Influence of Citric Acid Pretreatment on Drying of Peach Slices. Int. J. Food Eng. 2014, 10, 829–837. [Google Scholar] [CrossRef]

- Polat, A.; Taskin, O.; Izli, N. Application of Different Drying Techniques on Peach Puree. J. Agric. Sci. 2021, 27, 211–218. [Google Scholar]

- Sun, Y.; Zhang, M.; Mujumdar, A. Berry drying: Mechanism, pretreatment, drying technology, nutrient preservation, and mathematical models. Food Eng. Rev. 2019, 11, 61–71. [Google Scholar] [CrossRef]

- Seerangurayar, T.; Al-Ismaili, A.M.; Jeewantha, L.H.J.; Al-Habsi, N.A. Effect of solar drying methods on color kinetics and texture of dates. Food Bioprod. Process. 2019, 116, 227–239. [Google Scholar]

- González-Cavieres, L.; Pérez-Won, M.; Tabilo-Munizaga, G.; Jara-Quijada, E.; Díaz-Álvarez, R.; Lemus-Mondaca, R. Advances in vacuum microwave drying (VMD) systems for food products. Trends Food Sci. Technol. 2021, 116, 626–638. [Google Scholar] [CrossRef]

- Feng, L.; Xu, Y.; Xiao, Y.; Song, J.; Li, D.; Zhang, Z.; Liu, C.; Liu, C.; Jiang, N.; Zhang, M.; et al. Effects of pre-drying treatments combined with explosion puffing drying on the physicochemical properties, antioxidant activities and flavor characteristics of apples. Food Chem. 2021, 338, 128015. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Han, X.; Ni, Y.; Zhao, D.; Hao, J. Quality evaluation and drying kinetics of shitake mushrooms dried by hot air, infrared and intermittent microwave–assisted drying methods. LWT 2019, 107, 236–242. [Google Scholar] [CrossRef]

- Johnson, A.C.; Al Mukhaini, E.M.A. Drying studies on peach and strawberry slices. Cogent Food Agric. 2016, 2, 1141654. [Google Scholar] [CrossRef]

- Liu, J.; Jiao, Z.; Zhang, C.; Yang, W.; Liu, H.; Lv, Z. Effects of different drying methods on phenolic contents, antioxidant, and tyrosinase inhibitory activity of peach blossoms. J. Food Meas. Charact. 2018, 12, 2339–2348. [Google Scholar] [CrossRef]

- Kingsly, R.P.; Goyal, R.K.; Manikantan, M.R.; Ilyas, S.M. Effects of pretreatments and drying air temperature on drying behaviour of peach slice. Int. J. Food Sci. Technol. 2007, 42, 65–69. [Google Scholar] [CrossRef]

- Lopez-Vidaña, E.C.; Munguía, A.L.C.; Valladares, O.G.; Figueroa, I.P.; Orosco, R.B. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum). Renew. Energy 2020, 147, 845–855. [Google Scholar]

- Amantéa, R.P.; Fortes, M.; Ferreira, W.R.; Santos, G.T. Energy and exergy efficiencies as design criteria for grain dryers. Dry. Technol. 2018, 36, 491–507. [Google Scholar] [CrossRef]

- Patrón-Vázquez, J.; Baas-Dzul, L.; Medina-Torres, N.; Ayora-Talavera, T.; Sánchez-Contreras, Á.; García-Cruz, U.; Pacheco, N. The Effect of Drying Temperature on the Phenolic Content and Functional Behavior of Flours Obtained from Lemon Wastes. Agronomy 2019, 9, 474. [Google Scholar] [CrossRef][Green Version]

- Medina-Torres, N.; Ayora-Talavera, T.; Espinosa-Andrews, H.; Sánchez-Contreras, A.; Pacheco, N. Ultrasound Assisted Ex-traction for the Recovery of Phenolic Compounds from Vegetable Sources. Agronomy 2017, 7, 47. [Google Scholar] [CrossRef]

- Moussaoui, H.; Bahammou, Y.; Tagnamas, Z.; Kouhila, M.; Lamharrar, A.; Idlimam, A. Application of solar drying on the apple peels using an indirect hybrid solar-electrical. Renew. Energy 2021, 168, 131–140. [Google Scholar] [CrossRef]

- Sallam, Y.; Aly, M.; Nassar, A.; Mohamed, E. Solar drying of whole mint plant under natural and forced convection. J. Adv. Res. 2015, 6, 171–178. [Google Scholar] [CrossRef][Green Version]

- Zhu, A.; Shen, X. The model and mass transfer characteristics of convection drying of peach slices. Int. J. Heat Mass Transf. 2014, 72, 345–351. [Google Scholar] [CrossRef]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 1949. [Google Scholar]

- To, H. Simple modeling of infrared drying of fresh apple slices. J. Food Eng. 2005, 71, 311–323. [Google Scholar]

- Sharaf-Eldeen, Y.I.; Blaisdell, J.L.; Hamdy, M.Y. A Model for Ear Corn Drying. Trans. ASAE 1980, 23, 1261–1271. [Google Scholar] [CrossRef]

- Wang, C.Y.; Singh, R.P. A single layer drying equation for rough rice. Am. Soc. Agric. Eng. 1978, 78, 3001. [Google Scholar]

- Verma, L.R.; Bucklin, R.A.; Endan, J.B.; Wratten, F.T. Effects of Drying Air Parameters on Rice Drying Models. Trans. Am. Soc. Agric. Eng. 1985, 28, 296–301. [Google Scholar] [CrossRef]

- Pacheco, N.; Méndez-Campos, G.K.; Herrera-Pool, I.E.; Alvarado-López, C.J.; Ramos-Díaz, A.; Ayora-Talavera, T.; Talcott, S.U.; Cuevas-Bernardino, J.C. Physicochemical composition, phytochemical analysis and biological activity of ciricote (Cordia dodecandra A. D.C.) fruit from Yucatán. Yucatán Nat. Prod. Res. 2022, 36, 440–444. [Google Scholar] [CrossRef]

- Herrera-Pool, E.; Ramos-Díaz, A.L.; Lizardi-Jiménez, M.A.; Pech-Cohuo, S.; Ayora-Talavera, T.; Cuevas-Bernardino, J.C.; García-Cruz, U.; Pacheco, N. Effect of solvent polarity on the Ultrasound Assisted extraction and antioxidant activity of phenolic compounds from habanero pepper leaves (Capsicum chinense) and its identification by UPLC-PDA-ESI-MS/MS. Ultrason. Sonochem. 2021, 76, 105658. [Google Scholar] [CrossRef]

- Park, Y.; Bell, L. Determination of Moisture and Ash Contents of Foods. In Handbook of Food Analysis; CRC Press: Boca Raton, FL, USA, 2004; pp. 55–82. [Google Scholar] [CrossRef]

- Aral, S.; Bese, A.V. Convective drying of hawthorn fruit (Crataegus spp.): Effect of experimental parameters on drying kinetics, color, shrinkage, and rehydration capacity. Food Chem. 2016, 210, 577–584. [Google Scholar] [CrossRef]

- Brar, A.S.; Kaur, P.; Kaur, G.; Subramanian, J.; Kumar, D.; Singh, A. Optimization of Process Parameters for Foam-Mat Drying of Peaches. Int. J. Fruit Sci. 2020, 20, S1495–S1518. [Google Scholar] [CrossRef]

- Dandamrongrak, R.; Mason, R.; Young, G. The effect of pretreatments on the drying rate and quality of dried bananas. Int. J. Food Sci. Technol. 2003, 38, 877–882. [Google Scholar] [CrossRef]

- Azam, S.M.R.; Zhang, M.; Law, C.L.; Mujumdar, A.S. Effects of drying methods on quality attributes of peach (Prunus persica) leather. Dry. Technol. 2019, 37, 341–351. [Google Scholar] [CrossRef]

- Tan, S.; Miao, Y.; Zhou, C.; Luo, Y.; Lin, Z.; Xie, R.; Li, W. Effects of Hot Air Drying on Drying Kinetics and Anthocyanin Degradation of Blood-Flesh Peach. Foods 2022, 11, 1596. [Google Scholar] [CrossRef]

- Ertekin, C.; Yaldiz, O. Drying of eggplant and selection of a suitable thin layer drying model. J. Food Eng. 2004, 63, 349–359. [Google Scholar] [CrossRef]

- Matiacevich, S.B. Caracterización Y Fotoestabilidad De Compuestos Fluorescentes Y Pardos Generados En Reacciones Enzimáticas Y No Enzimáticas. Implicancias En La Conservación De Materiales Orgánicos. Ph.D. Thesis, Facultad de Ciencias Exactas y Naturales, Universidad de Buenos Aires, Buenos Aires, Argentina, 2008. [Google Scholar]

- Nasri, F. Solar thermal drying performance analysis of banana and peach in the region of Gafsa (Tunisia). Case Stud. Therm. Eng. 2020, 22, 100771. [Google Scholar] [CrossRef]

- Udomkun, P.; Nagle, M.; Mahayothee, B.; Nohr, D.; Koza, A.; Müller, J. Influence of air drying properties on non-enzymatic browning, major bio-active compounds and antioxidant capacity of osmotically pretreated papaya. LWT 2015, 60, 914–922. [Google Scholar] [CrossRef]

- Wang, F.; Lyu, J.; Xie, J.; Bi, J. Texture formation of dehydrated yellow peach slices pretreated by osmotic dehydration with different sugars via cell wall pectin polymers modification. Food Hydrocoll. 2023, 134, 108080. [Google Scholar] [CrossRef]

- Çetin, N.; Sağlam, C. Effects of ultrasound pretreatment assisted drying methods on drying characteristics, physical and bioactive properties of windfall apples. J. Sci. Food Agric. 2023, 103, 534–547. [Google Scholar] [CrossRef]

- Sultana, B.; Anwar, F.; Ashraf, M.; Saari, N. Effect of drying techniques on the total phenolic contents and antioxidant activity of selected fruits. J. Med. Plants Res. 2012, 6, 161–167. [Google Scholar]

- Rodríguez-Ramírez, J.; Méndez-Lagunas, L.L.; Lopez-Ortiz, A.; Muniz-Becer, S.; Nair, K. Solar drying of strawberry using polycarbonate with UV protection and polyethylene covers: Influence on anthocyanin and total phenolic content. Sol. Energy 2021, 221, 120–130. [Google Scholar] [CrossRef]

- Siriwoharn, T.; Wrolstad, R.E.; Finn, C.E.; Pereira, C.B. Influence of cultivar, maturity, and sampling on blackberry (Rubus L. Hybrids) anthocyanins, polyphenolics, and antioxidant properties. J. Agric. Food Chem. 2004, 52, 8021–8030. [Google Scholar] [CrossRef]

| Equation | Name | References |

|---|---|---|

| Page | [21] | |

| Logarithmic | [22] | |

| Two-term exponential | [23] | |

| Wang and Singh | [24] | |

| Verma et al. | [25] |

| Models and Parameters | Natural Convection | Forced Convection | Solar Drying | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Temperatures | Air Velocity | ||||||||

| 40 °C | 45 °C | 50 °C | 40 °C | 45 °C | 50 °C | 1 m/s | 3 m/s | ||

| Page [21] | k | 0.000 | 0.001 | 0.001 | 0.003 | 0.006 | 0.009 | 0.001 | 0.006 |

| n | 1.332 | 1.244 | 1.278 | 1.248 | 1.190 | 1.165 | 1.417 | 1.064 | |

| r2 | 0.991 | 0.991 | 0.994 | 0.996 | 0.996 | 0.995 | 0.993 | 0.997 | |

| RMSE | 0.034 | 0.032 | 0.027 | 0.019 | 0.019 | 0.021 | 2.85 × 10−2 | 2.07 × 10−2 | |

| χ2 | 0.001 | 0.001 | 0.001 | 4.13 × 10−4 | 4.20 × 10−4 | 5.81 × 10−4 | 9.01 × 10−4 | 5.06 × 10−4 | |

| Logarithmic [22] | a | 1.276 | 1.159 | 1.187 | 1.072 | 1.055 | 1.062 | 1.302 | 1.049 |

| c | −0.265 | −0.156 | −0.174 | −0.047 | −0.036 | −0.055 | −0.257 | −0.065 | |

| k | 0.002 | 0.004 | 0.004 | 0.010 | 0.013 | 0.016 | 0.005 | 0.007 | |

| r2 | 0.994 | 0.994 | 0.995 | 0.994 | 0.994 | 0.995 | 0.996 | 0.999 | |

| RMSE | 0.026 | 0.027 | 0.023 | 0.011 | 0.008 | 0.006 | 2.24 × 10−2 | 0.012 | |

| χ2 | 8.09 × 10−4 | 8.96 × 10−4 | 6.68 × 10−4 | 1.33 × 10−4 | 7.92 × 10−5 | 4.69 × 10−5 | 5.88 × 10−4 | 1.12 × 10−4 | |

| Two-terms exponential [23] | a | 1.828 | 1.757 | 1.799 | 1.768 | 1.704 | 1.000 | 1.915 | 1.500 |

| k | 0.005 | 0.007 | 0.008 | 0.015 | 0.019 | 0.017 | 0.012 | 0.009 | |

| r2 | 0.989 | 0.991 | 0.993 | 0.996 | 0.996 | 0.991 | 0.988 | 0.997 | |

| RMSE | 0.037 | 0.033 | 0.028 | 0.017 | 0.016 | 0.024 | 3.49 × 10−2 | 1.96 × 10−2 | |

| χ2 | 0.002 | 0.001 | 0.001 | 4.56 × 10−4 | 4.32 × 10−4 | 1.2 × 10−3 | 1.35 × 10−3 | 4.29 × 10−4 | |

| Wang and Singh [24] | a | −0.002 | −0.004 | −0.004 | −0.007 | −0.009 | −0.012 | −0.006 | −0.006 |

| k | 1.42 × 10−6 | 3.08 × 10−6 | 4.20 × 10−6 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| r2 | 0.998 | 0.998 | 0.999 | 0.958 | 0.958 | 0.983 | 0.998 | 0.983 | |

| RMSE | 0.015 | 0.016 | 0.008 | 0.052 | 0.068 | 0.040 | 1.31 × 10−2 | 4.47 × 10−2 | |

| χ2 | 2.62 × 10−4 | 2.85 × 10−4 | 7.86 × 10−5 | 0.003 | 0.006 | 0.002 | 1.92 × 10−4 | 2.22 × 10−3 | |

| Verma et al. [25] | a | 14.685 | 1.000 | −210.081 | 277.454 | −12.286 | 18.146 | 237.569 | 0.618 |

| g | 0.006 | 0.002 | 0.002 | 0.006 | 0.023 | 0.028 | 0.003 | 0.008 | |

| k | 0.006 | 0.002 | 0.002 | 0.006 | 0.024 | 0.027 | 0.003 | 0.008 | |

| r2 | 0.990 | 0.691 | 0.996 | 0.997 | 0.997 | 0.996 | 0.995 | 0.995 | |

| RMSE | 0.035 | 0.197 | 0.021 | 0.025 | 0.018 | 0.020 | 3.21 × 10−2 | 1.52 × 10−2 | |

| χ2 | 0.001 | 0.048 | 0.001 | 8.12 × 10−4 | 4.34 × 10−4 | 6.01 × 10−4 | 1.2 × 10−3 | 2.72 × 10−4 | |

| Treatment | Hardness (N) | ABTS (µmol Eq Trolox/g d.w.) | DPPH (µmol Eq Trolox/g d.w.) | TPC 1 (mg EAG/g d.w.) | |

|---|---|---|---|---|---|

| Natural convection | 40 °C | 9.63 ± 1.97 d | 99.79 ± 9.02 b | 83.23 ± 9.38 c | 54.50 ± 3.08 cd |

| 45 °C | 4.83 ± 1.28 a | 81.28 ± 5.63 ab | 101.61 ± 12.15 d | 52.14 ± 5.43 cd | |

| 50 °C | 9.78 ± 2.23 d | 99.59 ± 14.97 b | 91.12 ± 2.07 cd | 53.79 ± 0.47 cd | |

| Forced convection | 40 °C | 9.52 ± 0.58 cd | 78.69 ± 9.11 ab | 63.18 ± 2.32 b | 40.32 ± 1.21 ab |

| 45 °C | 8.22 ± 1.12 bc | 94.22 ± 2.07 b | 99.49 ± 3.58 d | 58.52 ± 9.75 d | |

| 50 °C | 7.77 ± 1.10 b | 104.64 ± 27.07 b | 75.59 ± 8.85 bc | 45.27 ± 1.08 bc | |

| Solar drying | 1 m/s | 11.35 ± 1.53 e | 59.16 ± 4.96 a | 42.39 ± 6.35 a | 35.03 ± 0.33 a |

| 3 m/s | 10.85 ± 1.08 de | 77.17 ± 0.39 ab | 63.63 ± 1.98 b | 39.84 ± 0.22 ab | |

| Treatment | Chlorogenic Acid (µmol/L) | Neochlorogenic Acid (µmol/L) | |

|---|---|---|---|

| Natural convection | 40 °C | 822.41 ± 66.98 d | 585.01 ± 71.27 c |

| 45 °C | 653.73 ± 65.06 bc | 354.41 ± 2.44 a | |

| 50 °C | 938.67 ± 34.03 e | 558.92 ± 9.67 bc | |

| Forced convection | 40 °C | 678.48 ± 30.89 c | 390.37 ± 50.01 a |

| 45 °C | 741.84 ± 18.84 cd | 391.74 ± 9.31 a | |

| 50 °C | 813.04 ± 12.73 d | 501.09 ± 1.94 b | |

| Solar drying | 1 m/s | 522.13 ± 7.89 a | 334.73 ± 20.97 a |

| 3 m/s | 567.54 ± 33.14 ab | 319.54 ± 13.07 a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Moreira, D.P.; Hernández-Guzmán, H.; Pacheco, N.; Cuevas-Bernardino, J.C.; Herrera-Pool, E.; Moreno, I.; López-Vidaña, E.C. Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices. Processes 2023, 11, 1280. https://doi.org/10.3390/pr11041280

García-Moreira DP, Hernández-Guzmán H, Pacheco N, Cuevas-Bernardino JC, Herrera-Pool E, Moreno I, López-Vidaña EC. Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices. Processes. 2023; 11(4):1280. https://doi.org/10.3390/pr11041280

Chicago/Turabian StyleGarcía-Moreira, Diana Paola, Harumi Hernández-Guzmán, Neith Pacheco, Juan Carlos Cuevas-Bernardino, Emanuel Herrera-Pool, Ivan Moreno, and Erick César López-Vidaña. 2023. "Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices" Processes 11, no. 4: 1280. https://doi.org/10.3390/pr11041280

APA StyleGarcía-Moreira, D. P., Hernández-Guzmán, H., Pacheco, N., Cuevas-Bernardino, J. C., Herrera-Pool, E., Moreno, I., & López-Vidaña, E. C. (2023). Solar and Convective Drying: Modeling, Color, Texture, Total Phenolic Content, and Antioxidant Activity of Peach (Prunus persica (L.) Batsch) Slices. Processes, 11(4), 1280. https://doi.org/10.3390/pr11041280