Application of New High-Energy Expansion Agent in Coal Mine Roadway Excavation

Abstract

:1. Introduction

2. Experimental Research

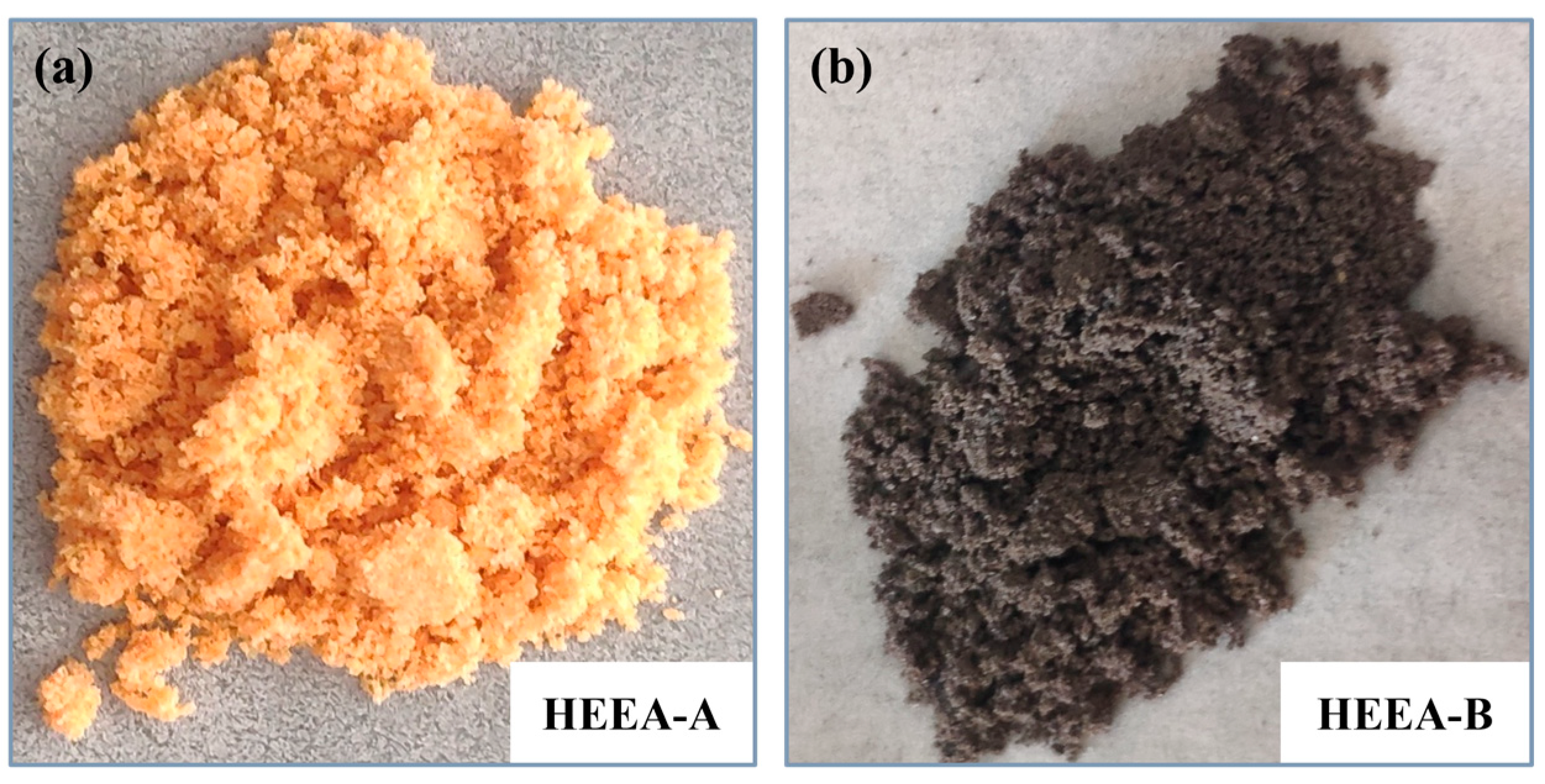

2.1. Materials

2.2. Security Testing

2.2.1. Mechanical Sensitivity

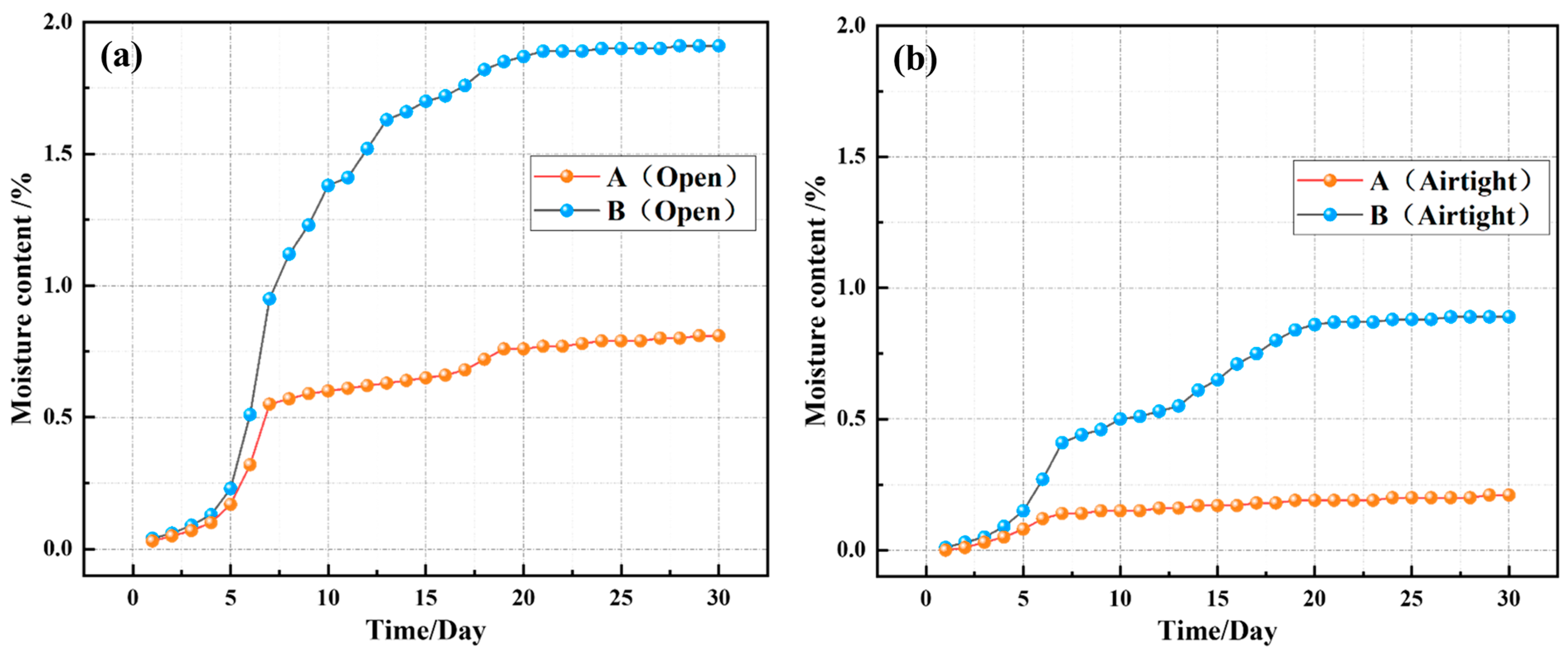

2.2.2. Moisture Content and Hygroscopicity

- (1)

- Dry the HEEA sample for 2 h at 80 °C. Cool for 1 h after drying, weigh the sample and record it. Repeat the above operation. If the mass difference after two drying periods is less than 0.002 g, the HEEA sample is considered to be completely dry.

- (2)

- Number and weigh the beaker and record it as the beaker mass, M1. Then, weigh about 10 g of dried HEEA sample into the numbered beaker and record its total mass, M2.

- (3)

- Number and weigh the sealed bag and record it as the mass, M1, of the sealed bag. Weigh about 10 g of dry HEEA into the sealed bag and record its total mass, M2.

- (4)

- Put the container containing the HEEA samples above in a safe place in the laboratory, and record the total mass M3 of the container and samples at the same time every day for 30 days.

3. High-Energy Expansion Agent Technology

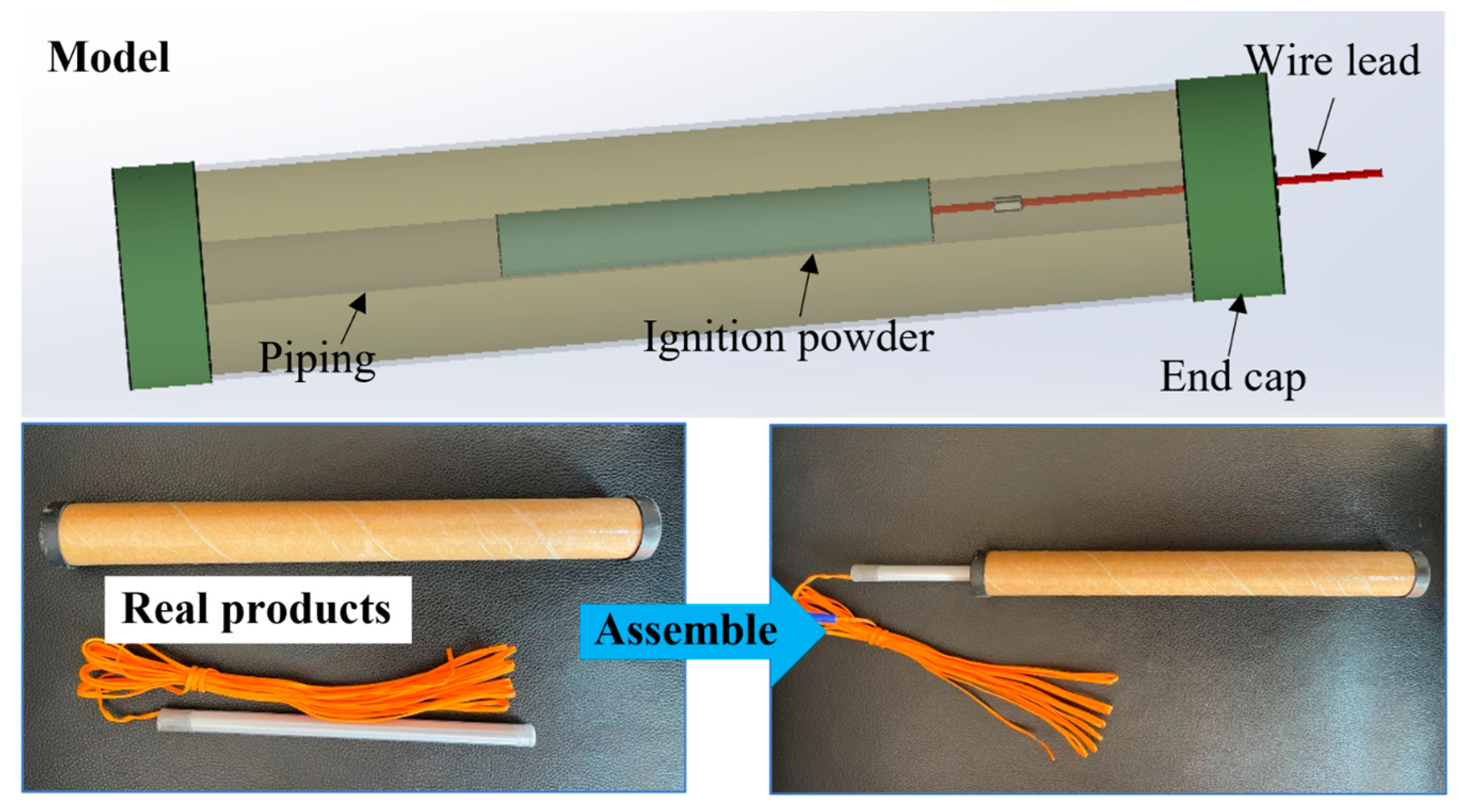

3.1. High-Energy Expansion Agent Device Structure

3.2. Ignition Powder

4. Engineering Validation

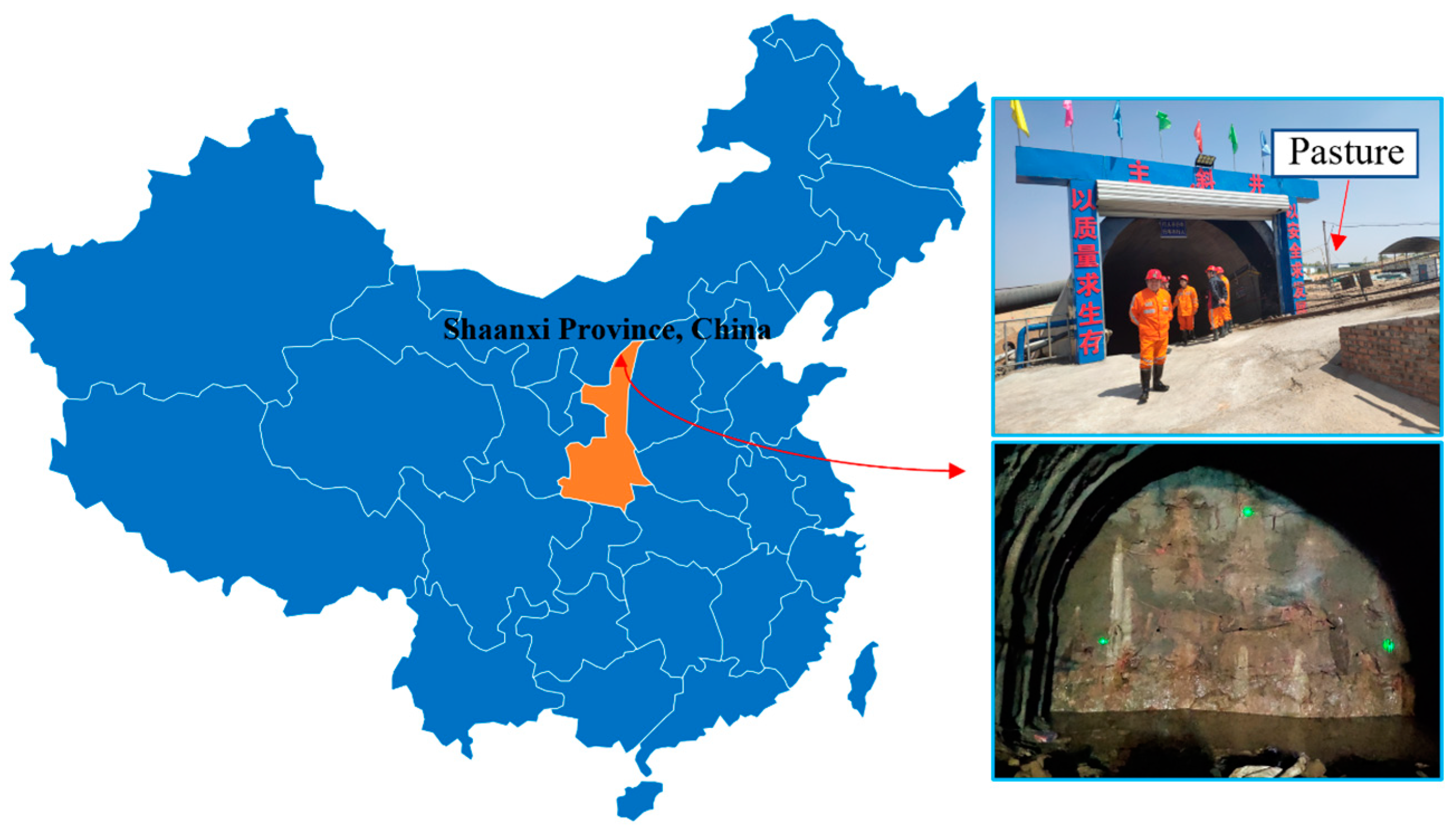

4.1. Project Overview

4.2. Test Program

4.3. Rock Breaking Effect

4.4. Advantages and Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, X.; Han, Y.; Li, D.; Tu, Y.; Deng, Z.; Yu, C.; Wu, X. Anti-pull mechanisms and weak interlayer parameter sensitivity analysis of tunnel-type anchorages in soft rock with underlying weak interlayers. Eng. Geol. 2019, 253, 123–136. [Google Scholar] [CrossRef]

- Hou, P.; Gao, F.; Ju, Y.; Yang, Y.; Gao, Y.; Liu, J. Effect of water and nitrogen fracturing fluids on initiation and extension of fracture in hydraulic fracturing of porous rock. J. Nat. Gas Sci. Eng. 2017, 45, 38–52. [Google Scholar] [CrossRef]

- Zhang, F.; Damjanac, B.; Maxwell, S. Investigating Hydraulic Fracturing Complexity in Naturally Fractured Rock Masses Using Fully Coupled Multiscale Numerical Modeling. Rock Mech. Rock Eng. 2019, 52, 5137–5160. [Google Scholar] [CrossRef]

- Rajput, A.; Kaushik, A.; Iqbal, M.A.; Gupta, N.K. International Journal of Impact Engineering Non-linear FE investigation of subsurface tunnel with gfrp protection against internal blast. Int. J. Impact Eng. 2023, 172, 104423. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Hou, D.F.; Guo, Z.; He, Z.; Zhang, Q. Experimental study of surface constraint effect on rock fragmentation by blasting. Int. J. Rock Mech. Min. Sci. 2020, 128, 104278. [Google Scholar] [CrossRef]

- He, C.; Yang, J.; Yu, Q. Laboratory study on the dynamic response of rock under blast loading with active confining pressure. Int. J. Rock Mech. Min. Sci. 2018, 102, 101–108. [Google Scholar] [CrossRef]

- Yuan, W.; Wang, W.; Su, X.; Li, J.; Li, Z.; Wen, L.; Chang, J. Numerical study of the impact mechanism of decoupling charge on blasting-enhanced permeability in low-permeability sandstones. Int. J. Rock Mech. Min. Sci. 2018, 106, 300–310. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Z.; Wang, M.; Shu, Y.; Deng, S.; Xiao, D. Influence of blasting load directions on tunnel stability in fractured rock mass. J. Rock Mech. Geotech. Eng. 2022, 14, 346–365. [Google Scholar] [CrossRef]

- Liu, D.; Lu, W.; Yang, J.; Gao, J.; Yan, P.; Hu, S.; Yao, C. International Journal of Rock Mechanics and Mining Sciences Relationship between cracked-zone radius and dominant frequency of vibration in tunnel blasting. Int. J. Rock Mech. Min. Sci. 2022, 160, 105249. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Zhao, X.; Liang, Y. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2022, 123, 104416. [Google Scholar] [CrossRef]

- Feng, X.; Jiang, Z.; Zhang, G.; Luo, X.; Zeng, F. Study on CO diffusion law and concentration distribution function under ventilation after blasting in high-altitude tunnel. J. Wind Eng. Ind. Aerodyn. 2022, 220, 104871. [Google Scholar] [CrossRef]

- Pu, J.; Yang, Y.; Pu, C.; Zou, H. On some studies about the dynamic mechanisms of carbon monoxide flow and diffusion during high energy gas fracturing. Saf. Sci. 2012, 50, 903–908. [Google Scholar] [CrossRef]

- Iwano, K.; Hashiba, K.; Nagae, J.; Fukui, K. Reduction of tunnel blasting induced ground vibrations using advanced electronic detonators. Tunn. Undergr. Space Technol. 2020, 105, 103556. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Z.; Wang, M.; Wan, D.; Zhou, L.; Liu, R. Numerical study on the behavior of blasting in deep rock masses. Tunn. Undergr. Space Technol. 2021, 113, 103968. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, H.; Ke, B.; Gao, F. Research on the Explosion Effects and Fracturing Mechanism of Liquid Carbon Dioxide Blasting. Min. Metall. Explor. 2022, 39, 521–530. [Google Scholar] [CrossRef]

- Li, Q.Y.; Chen, G.; Luo, D.Y.; Ma, H.P.; Liu, Y. An experimental study of a novel liquid carbon dioxide rock-breaking technology. Int. J. Rock Mech. Min. Sci. 2020, 128, 104244. [Google Scholar] [CrossRef]

- Guo, P.; Li, X.; Yang, W.; Mao, T. Experimental study on hydrofracture propagation through perforated wellbore in naturally fractured Guanyinqiao calcareous mudstone under true triaxial stress. J. Nat. Gas Sci. Eng. 2022, 99, 104415. [Google Scholar] [CrossRef]

- Kuznetsova, N.; Zhgun, D.; Golovanevskiy, V. Plasma blasting of rocks and rocks-like materials: An analytical model. Int. J. Rock Mech. Min. Sci. 2022, 150, 104986. [Google Scholar] [CrossRef]

- Zhai, C.; Xu, J.; Liu, S.; Qin, L. Fracturing mechanism of coal-like rock specimens under the effect of non-explosive expansion. Int. J. Rock Mech. Min. Sci. 2018, 103, 145–154. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, L.; Shi, J.; Wei, X. Study on Physicochemical Properties and Rock-Cracking Mechanism of High-Energy Expansion Agent. Energies 2022, 15, 7156. [Google Scholar] [CrossRef]

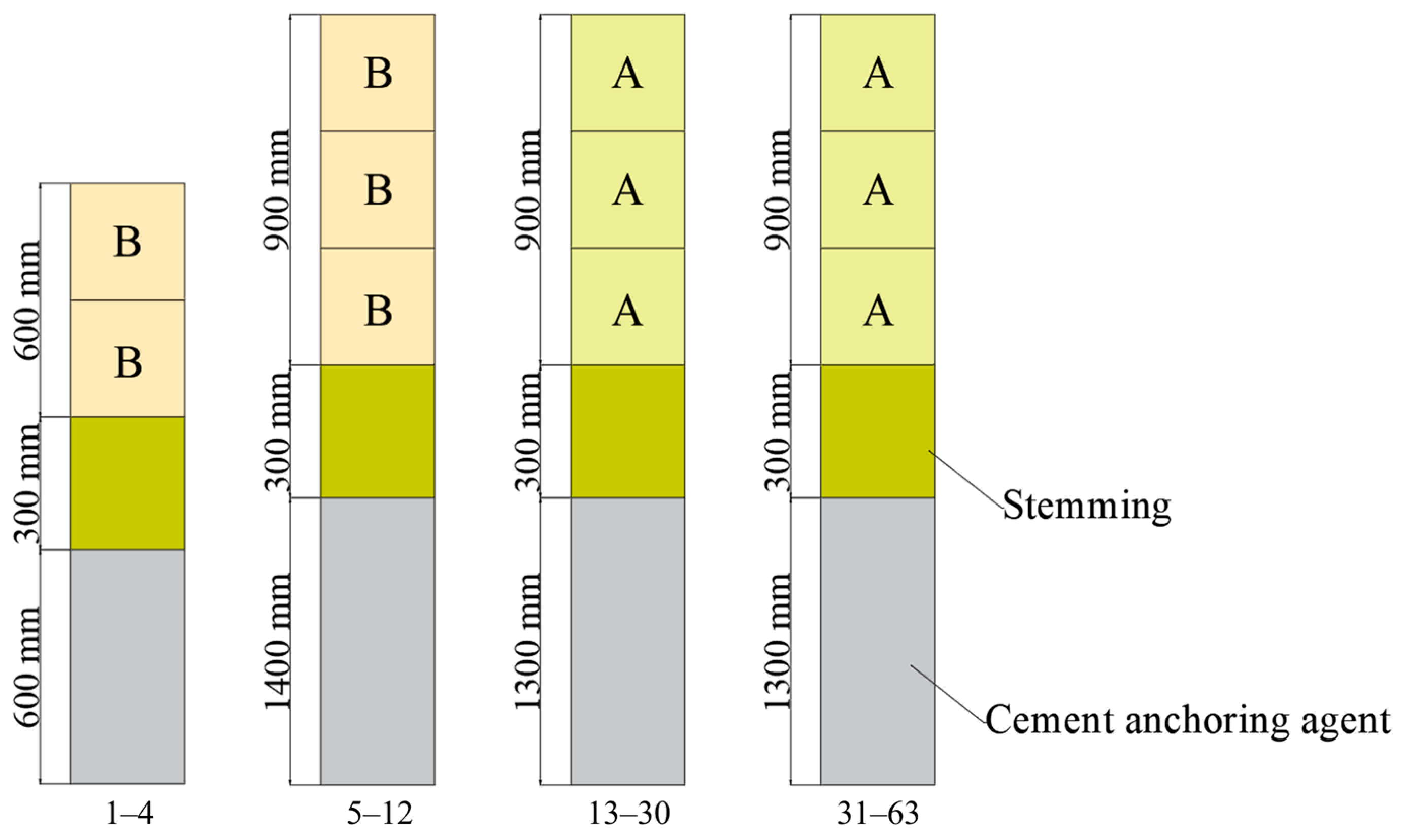

| Hole Site | Number of Boreholes | Charging Structure | Size | Weight of Charge | Number of Pieces of Ignition Powder |

|---|---|---|---|---|---|

| First-level cutting | 1~4 | 2B | 30 × 300 mm | 2.64 kg | 8 |

| Secondary cutting | 5~12 | 3B | 7.92 kg | 16 | |

| Satellite hole | 13~30 | 3A | 16.2 kg | 36 | |

| Periphery hole | 31~63 | 3A | 29.7 kg | 33 | |

| Total | 63 | 56.46 kg | 93 |

| Rock Size Distribution/cm | Average Percentage of Each Block in Different Rock Breaking Techniques/% | |

|---|---|---|

| HEEA | Emulsified Explosive | |

| 0~10 | 32 | 30 |

| 10~15 | 18 | 38 |

| 15~20 | 14 | 14 |

| 20~25 | 16 | 8 |

| 25~30 | 15 | 4 |

| 30~35 | 4 | 4 |

| >35 | 1 | 2 |

| Average size/cm | 12.63 | 13.65 |

| Maximum size/cm | 35.42 | 36.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, W.; Mu, P.; Zhang, Y.; Wei, X.; Shi, J.; Zhang, Y. Application of New High-Energy Expansion Agent in Coal Mine Roadway Excavation. Processes 2023, 11, 1356. https://doi.org/10.3390/pr11051356

Dai W, Mu P, Zhang Y, Wei X, Shi J, Zhang Y. Application of New High-Energy Expansion Agent in Coal Mine Roadway Excavation. Processes. 2023; 11(5):1356. https://doi.org/10.3390/pr11051356

Chicago/Turabian StyleDai, Wenjin, Ping Mu, Yansong Zhang, Xiangrui Wei, Jing Shi, and Yunkuan Zhang. 2023. "Application of New High-Energy Expansion Agent in Coal Mine Roadway Excavation" Processes 11, no. 5: 1356. https://doi.org/10.3390/pr11051356

APA StyleDai, W., Mu, P., Zhang, Y., Wei, X., Shi, J., & Zhang, Y. (2023). Application of New High-Energy Expansion Agent in Coal Mine Roadway Excavation. Processes, 11(5), 1356. https://doi.org/10.3390/pr11051356