An Optimization-Based Model for A Hybrid Photovoltaic-Hydrogen Storage System for Agricultural Operations in Saudi Arabia

Abstract

:1. Introduction

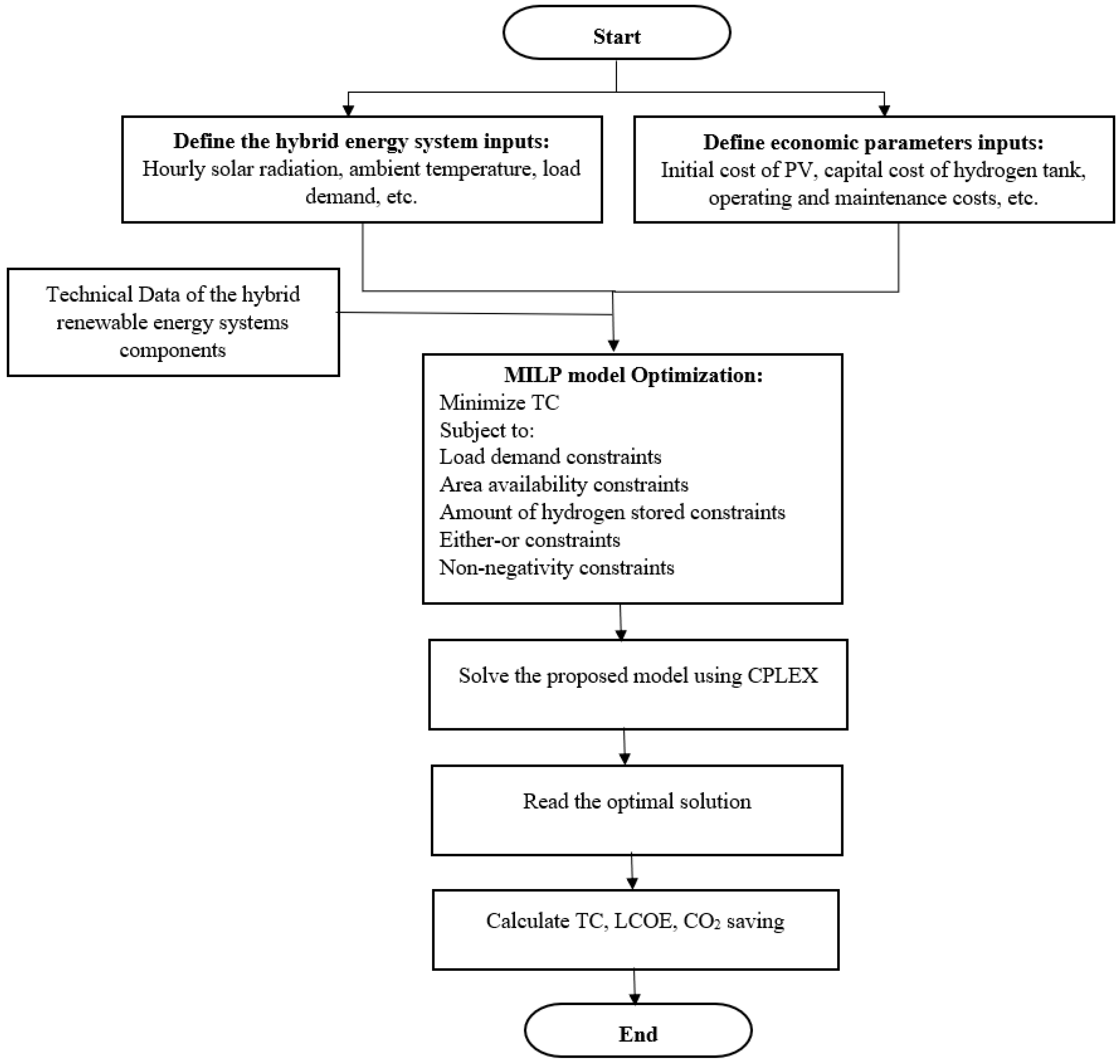

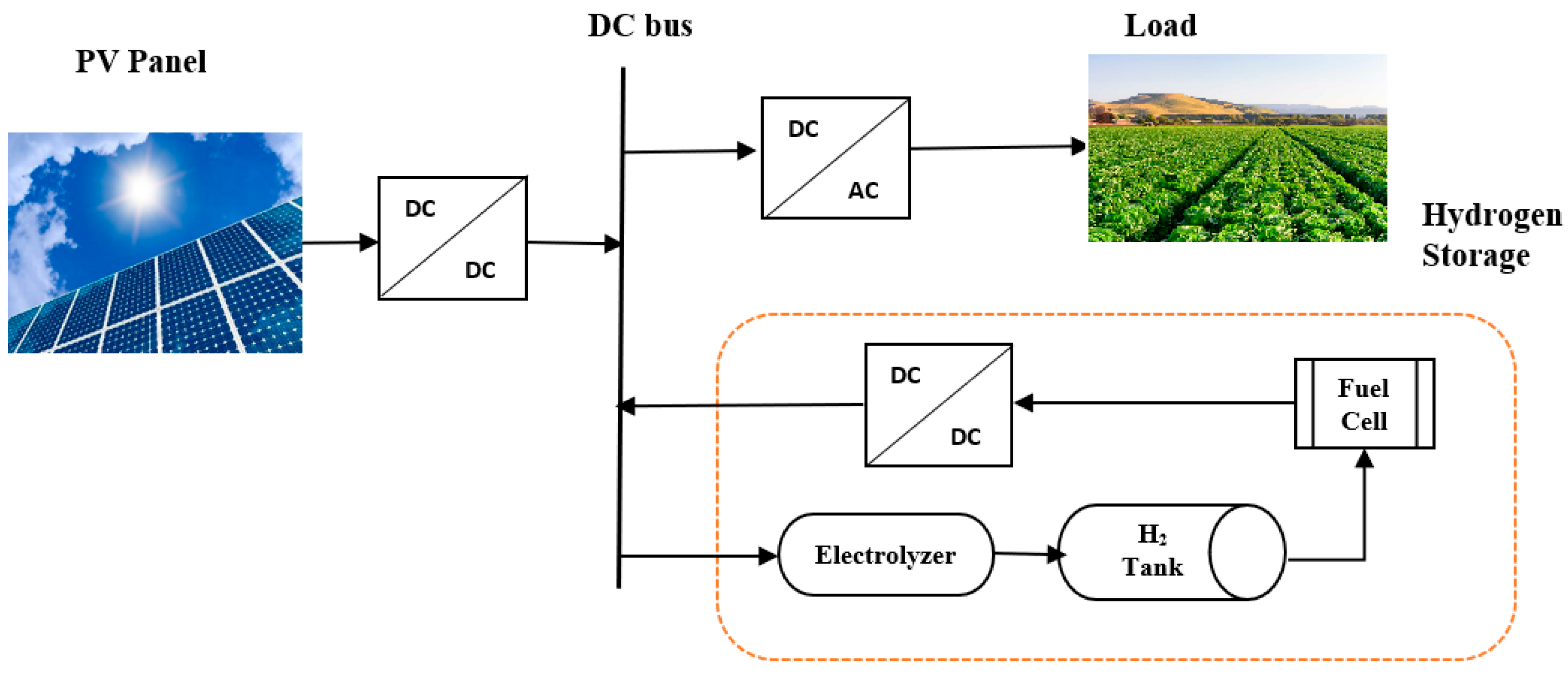

2. Materials and Methods

2.1. Mathematical Model

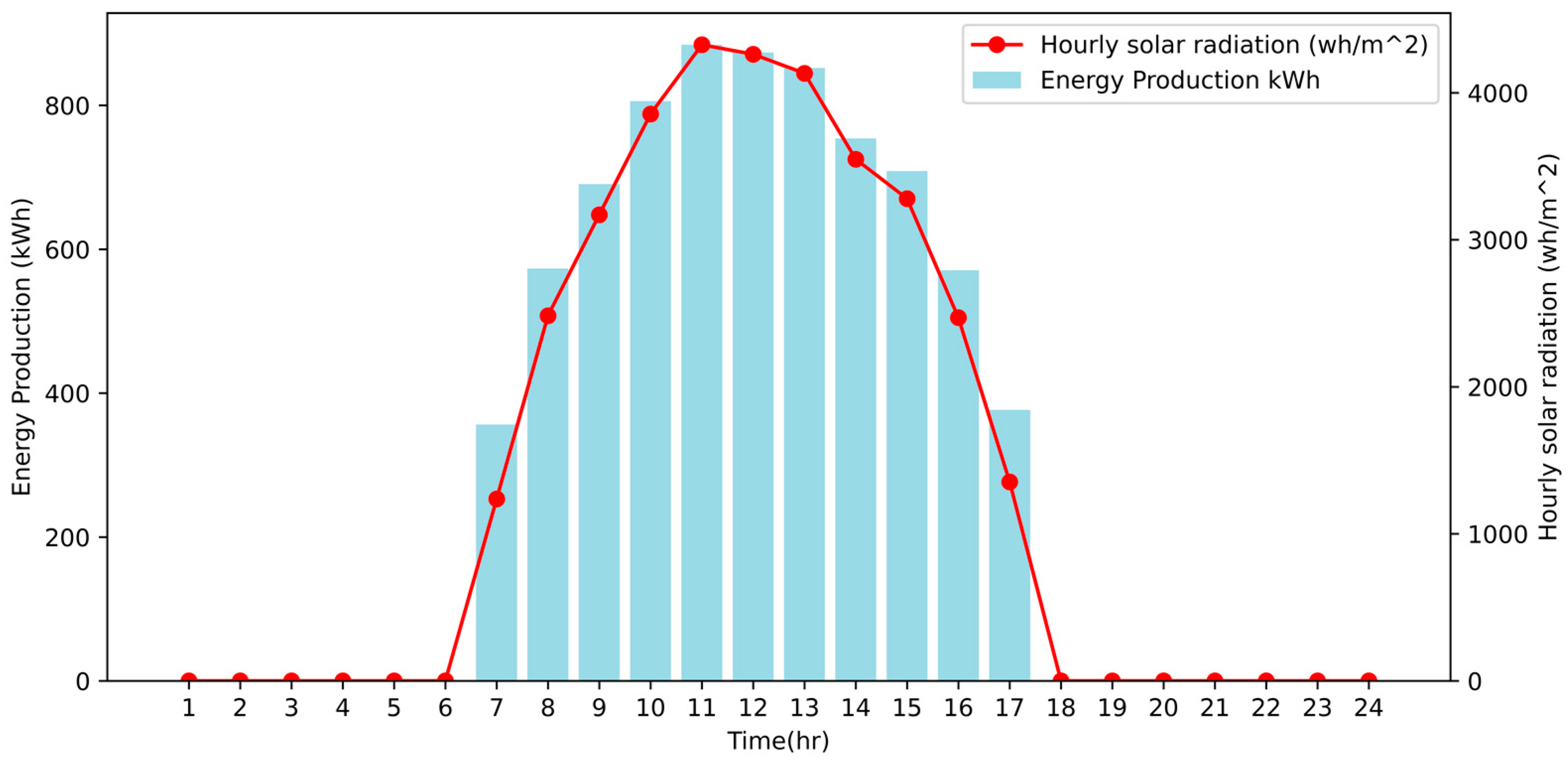

2.1.1. PV Array Electrical Power

2.1.2. Hydrogen Storage

3. Model Description

3.1. Objective Function

3.2. Constraints

3.3. Decision Variables

3.4. Carbon Dioxide Saving Calculation

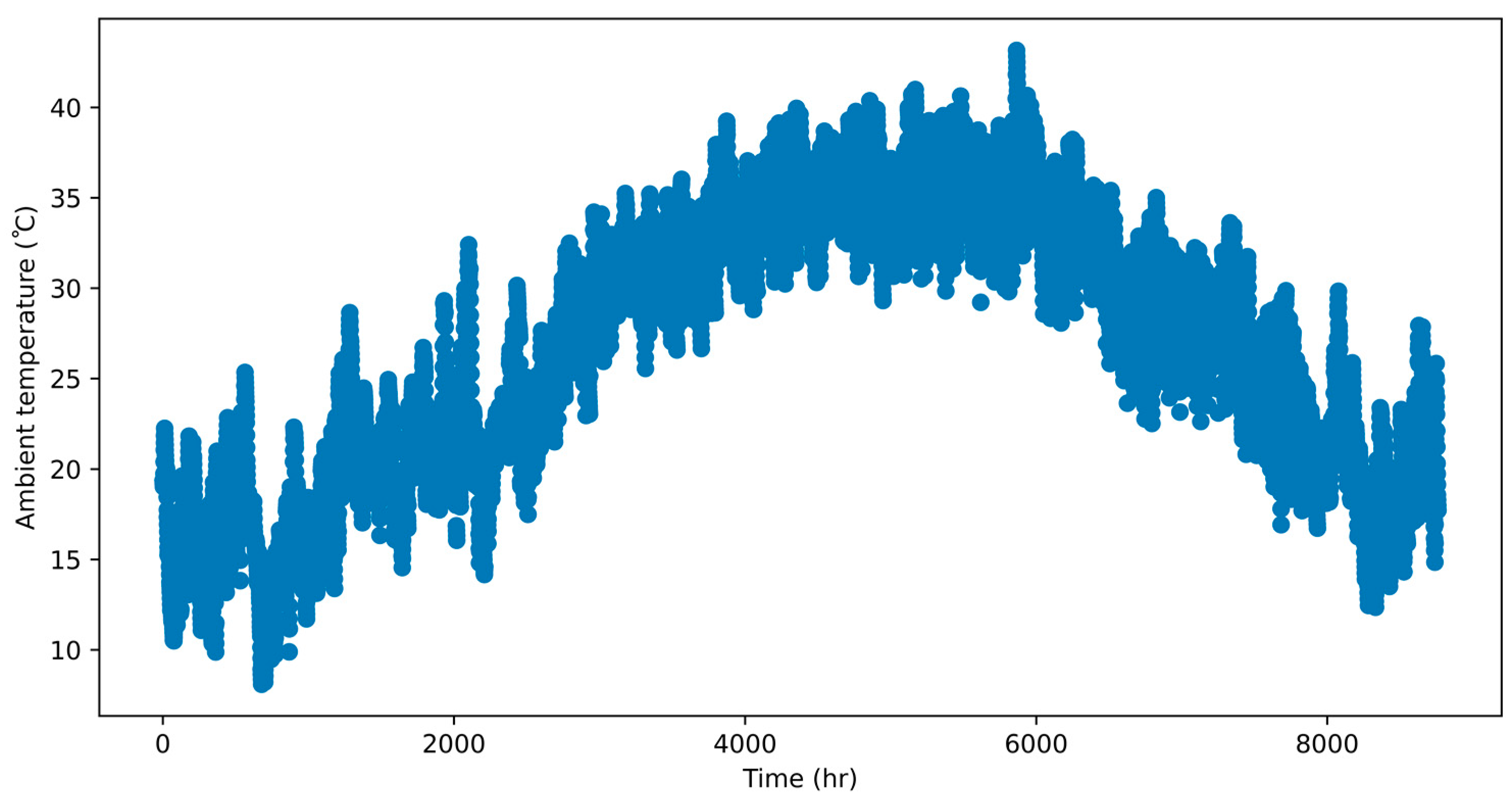

4. Case Study

5. Results and Discussion

5.1. Grid

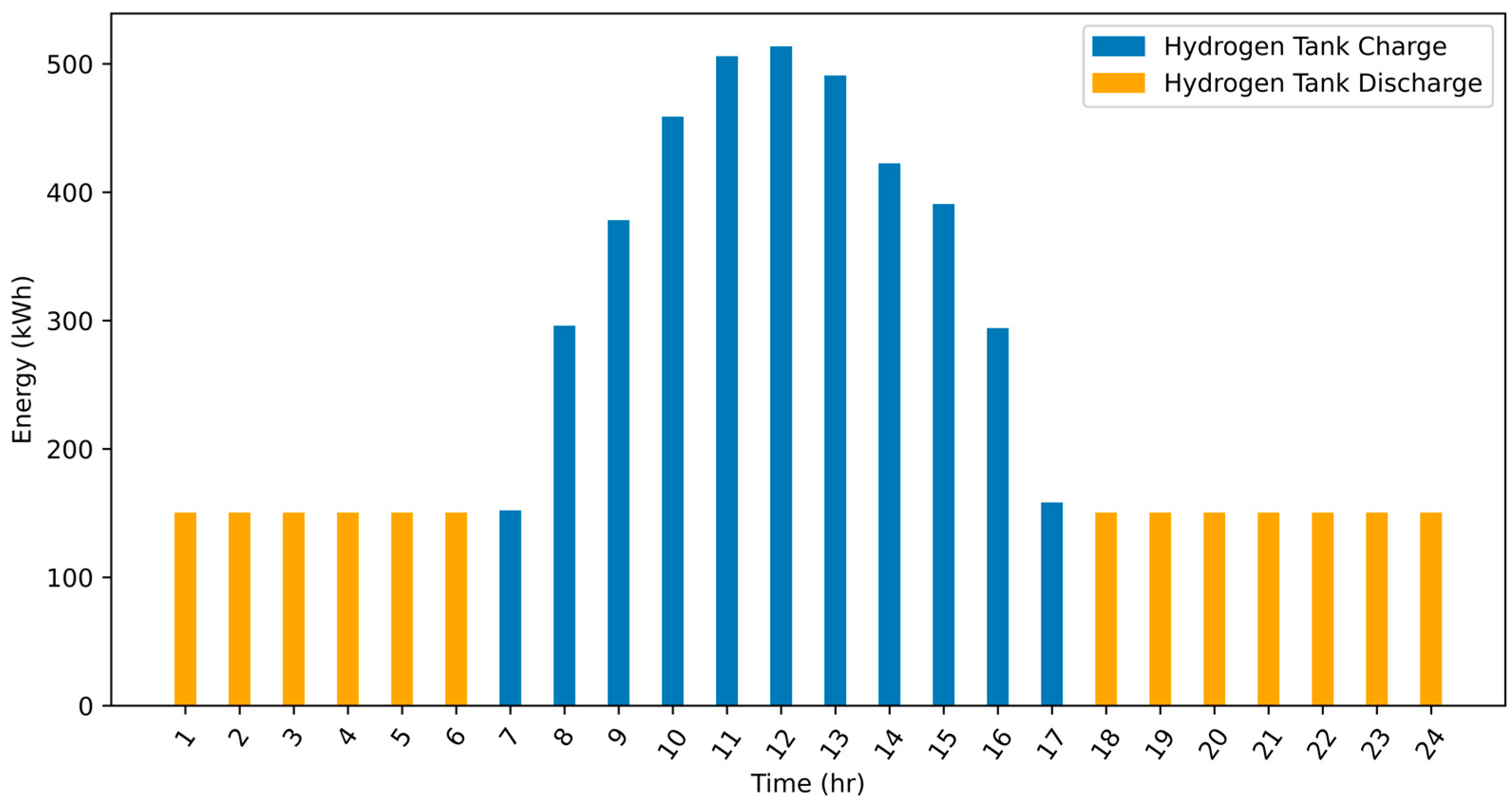

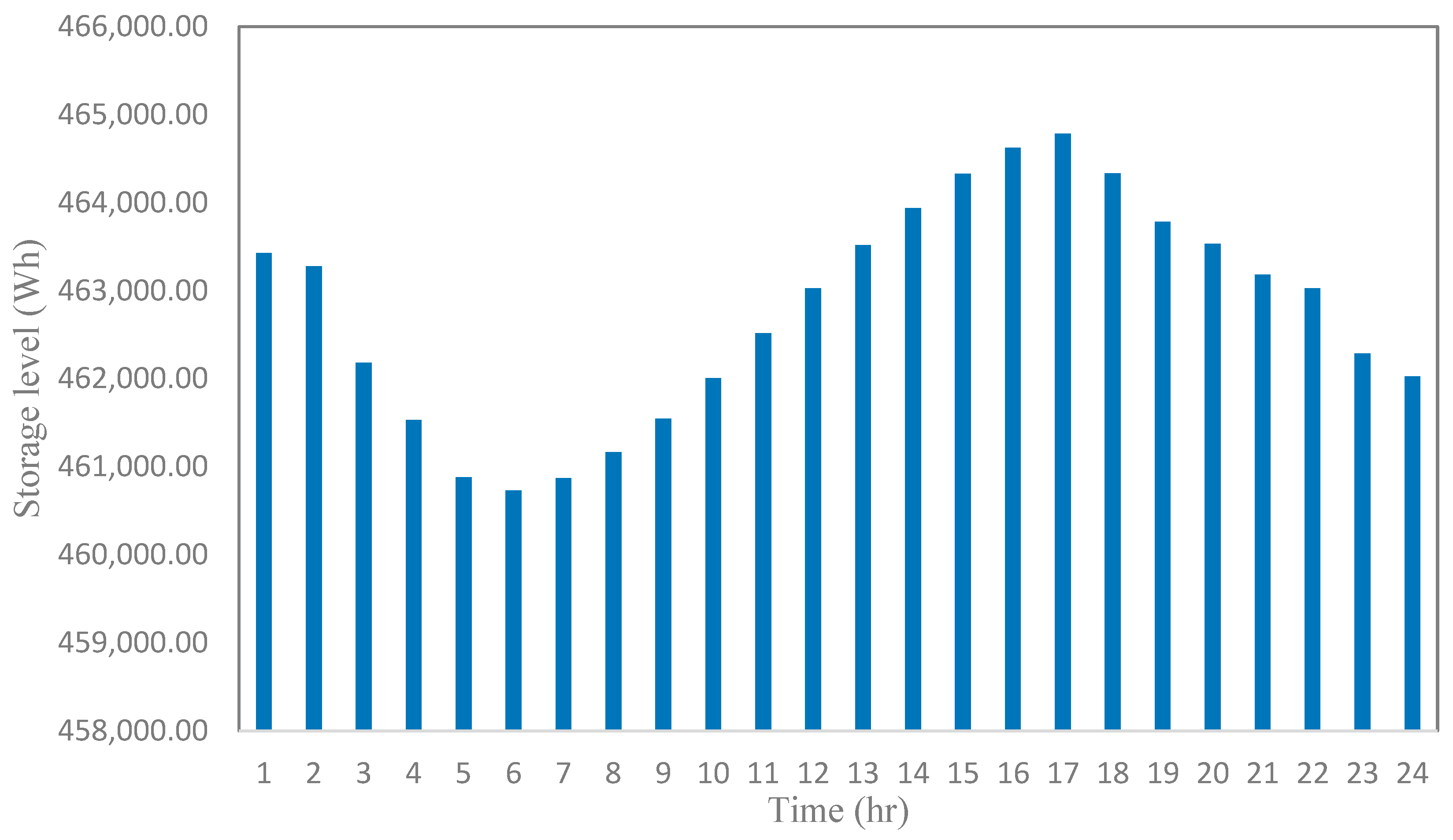

5.2. The Proposed System

5.3. Discussion

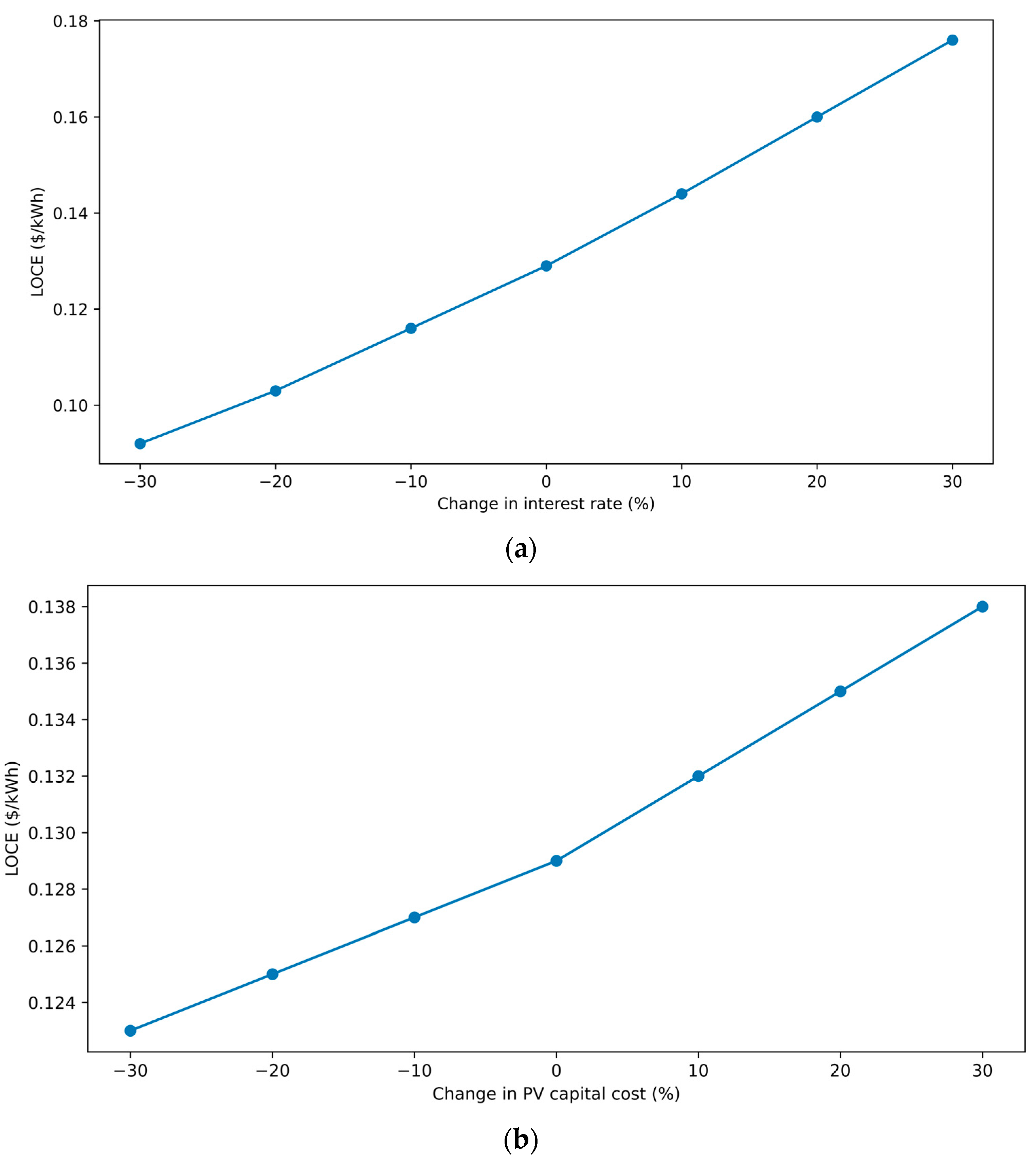

5.4. Sensitivity Analysis

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Available online: https://ourworldindata.org/co2/country/saudi-arabia (accessed on 11 March 2022).

- Alawaji, S.H. Evaluation of solar energy research and its applications in Saudi Arabia—20 years of experience. Renew. Sustain. Energy Rev. 2001, 5, 59–77. [Google Scholar] [CrossRef]

- Joe, L. Saudi Arabia Aims for 50% Renewable Energy by 2030. Climate Home. 2021. Available online: https://www.climatechangenews.com/2021/03/31/saudi-arabia-aims-50-renewable-energy-2030-backs-huge-tree-planting-initiative/ (accessed on 3 May 2022).

- Ramadan, M. A review on coupling Green sources to Green storage (G2G): Case study on solar-hydrogen coupling. Int. J. Hydrogen Energy 2021, 46, 30547–30558. [Google Scholar] [CrossRef]

- Ghaithan, A.M.; Al-Hanbali, A.; Mohammed, A.; Attia, A.M.; Saleh, H.; Alsawafy, O. Optimization of a solar-wind- grid powered desalination system in Saudi Arabia. Renew. Energy 2021, 178, 295–306. [Google Scholar] [CrossRef]

- Marocco, P.; Ferrero, D.; Martelli, E.; Santarelli, M.; Lanzini, A. An MILP approach for the optimal design of renewable battery-hydrogen energy systems for off-grid insular communities. Energy Convers. Manag. 2021, 245, 114564. [Google Scholar] [CrossRef]

- García-Triviño, P.; Fernández-Ramírez, L.M.; Gil-Mena, A.J.; Llorens-Iborra, F.; García-Vázquez, C.A.; Jurado, F. Optimized operation combining costs, efficiency and lifetime of a hybrid renewable energy system with energy storage by battery and hydrogen in grid-connected applications. Int. J. Hydrogen Energy 2016, 41, 23132–23144. [Google Scholar] [CrossRef]

- Anarbaev, A.; Tursunov, O.; Kodirov, D.; Muzafarov, S.; Babayev, A.; Sanbetova, A.; Batirova, L.; Mirzaev, B. Reduction of greenhouse gas emissions from renewable energy technologies in agricultural sectors of Uzbekistan. E3S Web Conf. 2019, 135, 01035. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Decision-making between a grid extension and a rural renewable off-grid system with hydrogen generation. Int. J. Hydrogen Energy 2018, 43, 9535–9548. [Google Scholar] [CrossRef]

- Rezk, H.; Kanagaraj, N.; Al-Dhaifallah, M. Design and Sensitivity Analysis of Hybrid Photovoltaic-Fuel-Cell-Battery System to Supply a Small Community at Saudi NEOM City. Sustainability 2020, 12, 3341. [Google Scholar] [CrossRef]

- Rezk, H.; Dousoky, G.M. Technical and economic analysis of different configurations of stand-alone hybrid renewable power systems—A case study. Renew. Sustain. Energy Rev. 2016, 62, 941–953. [Google Scholar] [CrossRef]

- Rezk, H.; Sayed, E.T.; Al-Dhaifallah, M.; Obaid, M.; El-Sayed, A.H.M.; Abdelkareem, M.A.; Olabi, A. Fuel cell as an effective energy storage in reverse osmosis desalination plant powered by photovoltaic system. Energy 2019, 175, 423–433. [Google Scholar] [CrossRef]

- Ahmadi, S.; Abdi, S. Application of the Hybrid Big Bang–Big Crunch algorithm for optimal sizing of a stand-alone hybrid PV/wind/battery system. Sol. Energy 2016, 134, 366–374. [Google Scholar] [CrossRef]

- Zhang, W.; Han, D.; Sun, W.; Li, H.; Tan, Y.; Yan, Z.; Dong, X. Optimal operation of wind-solar-hydrogen storage system based on energy hub. In Proceedings of the 2017 IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 26–28 November 2017; pp. 1–5. [Google Scholar]

- Ghorbani, N.; Kasaeian, A.; Toopshekan, A.; Bahrami, L.; Maghami, A. Optimizing a hybrid wind-PV-battery system using GA-PSO and MOPSO for reducing cost and increasing reliability. Energy 2018, 154, 581–591. [Google Scholar] [CrossRef]

- Mehrjerdi, H. Off-grid solar powered charging station for electric and hydrogen vehicles including fuel cell and hydrogen storage. Int. J. Hydrogen Energy 2019, 44, 11574–11583. [Google Scholar] [CrossRef]

- Moghaddam, M.J.H.; Kalam, A.; Nowdeh, S.A.; Ahmadi, A.; Babanezhad, M.; Saha, S. Optimal sizing and energy management of stand-alone hybrid photovoltaic/wind system based on hydrogen storage considering LOEE and LOLE reliability indices using flower pollination algorithm. Renew. Energy 2019, 135, 1412–1434. [Google Scholar] [CrossRef]

- Ma, T.; Javed, M.S. Integrated sizing of hybrid PV-wind-battery system for remote island considering the saturation of each renewable energy resource. Energy Convers. Manag. 2019, 182, 178–190. [Google Scholar] [CrossRef]

- Hemmati, R.; Mehrjerdi, H.; Bornapour, M. Hybrid hydrogen-battery storage to smooth solar energy volatility and energy arbitrage considering uncertain electrical-thermal loads. Renew. Energy 2020, 154, 1180–1187. [Google Scholar] [CrossRef]

- Gutiérrez-Martín, F.; Calcerrada, A.B.; de Lucas-Consuegra, A.; Dorado, F. Hydrogen storage for off-grid power supply based on solar PV and electrochemical reforming of ethanol-water solutions. Renew. Energy 2020, 147, 639–649. [Google Scholar] [CrossRef]

- Alturki, F.; MHFarh, H.; AAl-Shamma’a, A.; AlSharabi, K. Techno-economic optimization of small-scale hybrid energy systems using manta ray foraging optimizer. Electronics 2020, 9, 2045. [Google Scholar] [CrossRef]

- Alturki, F.A.; Al-Shamma’A, A.A.; Farh, H.M.H.; AlSharabi, K. Optimal sizing of autonomous hybrid energy system using supply-demand-based optimization algorithm. Int. J. Energy Res. 2021, 45, 605–625. [Google Scholar] [CrossRef]

- Al-Shamma’a, A.A.; Alturki, F.A.; Farh, H.M.H. Techno-economic assessment for energy transition from diesel-based to hybrid energy system-based off-grids in Saudi Arabia. Energy Transitions 2020, 4, 31–43. [Google Scholar] [CrossRef]

- Zhang, G.; Shi, Y.; Maleki, A.; Rosen, M.A. Optimal location and size of a grid-independent solar/hydrogen system for rural areas using an efficient heuristic approach. Renew. Energy 2020, 156, 1203–1214. [Google Scholar] [CrossRef]

- Lambert, H.; Roche, R.; Jemeï, S.; Ortega, P.; Hissel, D. Combined Cooling and Power Management Strategy for a Standalone House Using Hydrogen and Solar Energy. Hydrogen 2021, 2, 207–224. [Google Scholar] [CrossRef]

- K/Bidi, F.; Damour, C.; Grondin, D.; Hilairet, M.; Benne, M. Power Management of a Hybrid Micro-Grid with Photovoltaic Production and Hydrogen Storage. Energies 2021, 14, 1628. [Google Scholar] [CrossRef]

- Xiang, Y.; Cai, H.; Liu, J.; Zhang, X. Techno-economic design of energy systems for airport electrification: A hydrogen-solar-storage integrated microgrid solution. Appl. Energy 2021, 283, 116374. [Google Scholar] [CrossRef]

- Coppitters, D.; De Paepe, W.; Contino, F. Robust design optimization and stochastic performance analysis of a grid-connected photovoltaic system with battery storage and hydrogen storage. Energy 2020, 213, 118798. [Google Scholar] [CrossRef]

- Okundamiya, M. Size optimization of a hybrid photovoltaic/fuel cell grid connected power system including hydrogen storage. Int. J. Hydrogen Energy 2021, 46, 30539–30546. [Google Scholar] [CrossRef]

- Sinha, S.; Chandel, S. Review of recent trends in optimization techniques for solar photovoltaic–wind based hybrid energy systems. Renew. Sustain. Energy Rev. 2015, 50, 755–769. [Google Scholar] [CrossRef]

- Zhang, W.; Maleki, A.; Rosen, M.A.; Liu, J. Optimization with a simulated annealing algorithm of a hybrid system for renewable energy including battery and hydrogen storage. Energy 2018, 163, 191–207. [Google Scholar] [CrossRef]

- Mohammed, A.M.; Duffuaa, S.O. A tabu search based algorithm for the optimal design of multi-objective multi-product supply chain networks. Expert Syst. Appl. 2020, 140, 112808. [Google Scholar] [CrossRef]

- Ghaithan, A.M.; Mohammed, A. An optimization model for sizing a hybrid photovoltaic-wind-grid-connected system in Saudi Arabia. Process Integr. Optim. Sustain. 2022, 1–16. [Google Scholar] [CrossRef]

- Emissions Factors 2021—Data Product—IEA. Available online: https://www.iea.org/data-and-statistics/data-product/emissions-factors-2021 (accessed on 11 September 2022).

- Kyoto Protocol—Targets for the First Commitment Period|UNFCCC. Available online: https://unfccc.int/process-and-meetings/the-kyoto-protocol/what-is-the-kyoto-protocol/kyoto-protocol-targets-for-the-first-commitment-period (accessed on 7 April 2023).

- Renewable Resource Atlas. Available online: https://Rratlas.Energy.Gov.Sa/RRMMPublicPortal/ (accessed on 10 June 2022).

- Ghaithan, A.M.; Mohammed, A.; Al-Hanbali, A.; Attia, A.M.; Saleh, H. Multi-objective optimization of a photovoltaic-wind- grid connected system to power reverse osmosis desalination plant. Energy 2022, 251, 123888. [Google Scholar] [CrossRef]

- Mohammed, A.; Ghaithan, A.M.; Al-Hanbali, A.; Attia, A.M. A multi-objective optimization model based on mixed integer linear programming for sizing a hybrid PV-hydrogen storage system. Int. J. Hydrog. Energy 2023, 48, 9748–9761. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Available online: www.ausaid.gov.au (accessed on 11 September 2022).

- How Much CO2 Does a Tree Absorb? Available online: https://climate.selectra.com/en/news/co2-tree (accessed on 11 September 2022).

- Gahleitner, G. Hydrogen from renewable electricity: An international review of power-to-gas pilot plants for stationary applications. Int. J. Hydrogen Energy 2013, 38, 2039–2061. [Google Scholar] [CrossRef]

- González, E.L.; Llerena, F.I.; Pérez, M.S.; Iglesias, F.R.; Macho, J.G. Energy evaluation of a solar hydrogen storage facility: Comparison with other electrical energy storage technologies. Int. J. Hydrogen Energy 2015, 40, 5518–5525. [Google Scholar] [CrossRef]

- Abe, J.O.; Popoola, A.P.I.; Ajenifuja, E.; Popoola, O.M. Hydrogen energy, economy and storage: Review and recommendation. Int. J. Hydrog. Energy 2019, 44, 15072–15086. [Google Scholar] [CrossRef]

- Younes, Y.A.; Kospa, D.A.; Salama, R.S.; Ahmed, A.I.; Ibrahim, A.A. Hydrophilic candle wastes microcapsules as a thermal energy storage material for all-day steam and electricity cogeneration. Desalination 2023, 550, 116377. [Google Scholar] [CrossRef]

- Ibrahim, A.A.; Salama, R.S.; El-Hakam, S.A.; Khder, A.S.; Ahmed, A.I. Synthesis of 12-tungestophosphoric acid supported on Zr/MCM-41 composite with excellent heterogeneous catalyst and promising adsorbent of methylene blue. Colloids Surfaces A: Physicochem. Eng. Asp. 2021, 631, 127753. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| PV | |

| Installation cost per panel ($) | 1500 |

| Maximum Power Current (A) | 8.11 |

| Short Circuit Current (A) | 8.56 |

| Maximum Power Voltage (V) | 18.5 |

| Maximum Power (W) | 150 |

| Maintenance cost per panel per year ($) | 20 |

| Coefficient of temperature for the cell efficiency | 0.004–00.5 |

| Standard radiation from the sun (kW/m2) | 1 |

| Open Circuit Voltage (V) | 22.5 |

| Ambient Temperature °C | (8.1–43.15) |

| PV module lifetime (years), N | 25 |

| PV efficiency (%) | 15.8 |

| PV module type | Ultra-efficient polycrystalline |

| Hydrogen tank | |

| Capital cost ($) | 600 |

| Maintenance cost ($/year) | 5 |

| Nominal capacity of hydrogen tank (kWh) | 0.3 |

| Hydrogen tank lifetime (years) | 25 |

| Electrolyzer | |

| Efficiency (%) | 75 |

| Lifetime | 5 |

| Replacement cost | 700 |

| Nominal electrolyzer power (kW) | 3 |

| Capital cost ($) | 4500 |

| Model name | Bipolar, alkaline type |

| Fuel cell | |

| Efficiency (%) | 75 |

| Lifetime | 5 |

| Replacement cost ($) | 700 |

| Nominal fuel cell power (kW) | 3 |

| Capital cost ($) | 6000 |

| Single Equations | 78,850 |

| Discrete variables | 2 |

| Binary Variables | 8760 |

| Non-Zero Elements | 227,332 |

| Single Variables | 35,046 |

| Parameter | Value |

|---|---|

| Annual total cost | 228,234 |

| Number of Hydrogen tanks () | 1554 |

| Number of PV modules () | 1094 |

| LCOE ($/kWh) | 0.12 |

| Annual energy Production (kWh) | 1,763,100 |

| CO2 saving (kg of CO2) | 881,550 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, A. An Optimization-Based Model for A Hybrid Photovoltaic-Hydrogen Storage System for Agricultural Operations in Saudi Arabia. Processes 2023, 11, 1371. https://doi.org/10.3390/pr11051371

Mohammed A. An Optimization-Based Model for A Hybrid Photovoltaic-Hydrogen Storage System for Agricultural Operations in Saudi Arabia. Processes. 2023; 11(5):1371. https://doi.org/10.3390/pr11051371

Chicago/Turabian StyleMohammed, Awsan. 2023. "An Optimization-Based Model for A Hybrid Photovoltaic-Hydrogen Storage System for Agricultural Operations in Saudi Arabia" Processes 11, no. 5: 1371. https://doi.org/10.3390/pr11051371