Assessment of Physical and Sensory Attributes of Date-Based Energy Drink Treated with Ultrasonication: Modelling Changes during Storage and Predicting Shelf Life

Abstract

:1. Introduction

2. Material and Methods

2.1. Preparation of the Energy Drink from Dates

2.2. Ultrasonication Process

2.3. Thermal Treatment

2.4. Storage Study

2.5. Evaluation of Quality Properties

2.5.1. Measuring Total Soluble Solids (TSS), Electrical Conductivity (EC), and pH

2.5.2. Determination of Colour

2.5.3. Sensory Analysis Protocol

2.6. Kinetics Modelling of the Quality Changes through the Storage Period

2.7. Prediction of Shelf Life of the Drink

2.8. Data Analysis Protocol

3. Results and Discussion

3.1. Changes in EC, TSS, and Acidity of the Energy Drink and Their Kinetic Modelling

3.2. Changes in Colour Attributes of the Drink and Their Kinetic Modelling

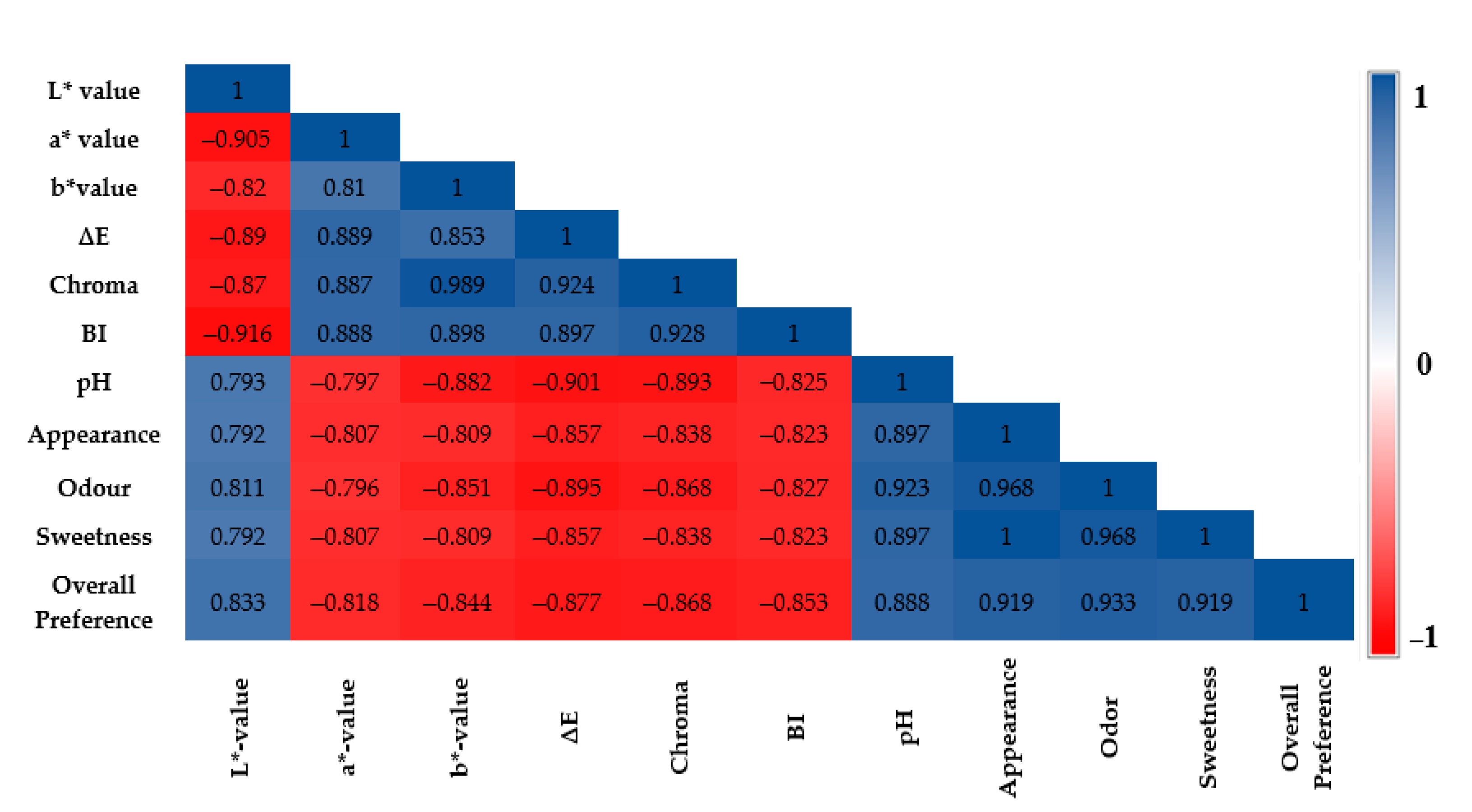

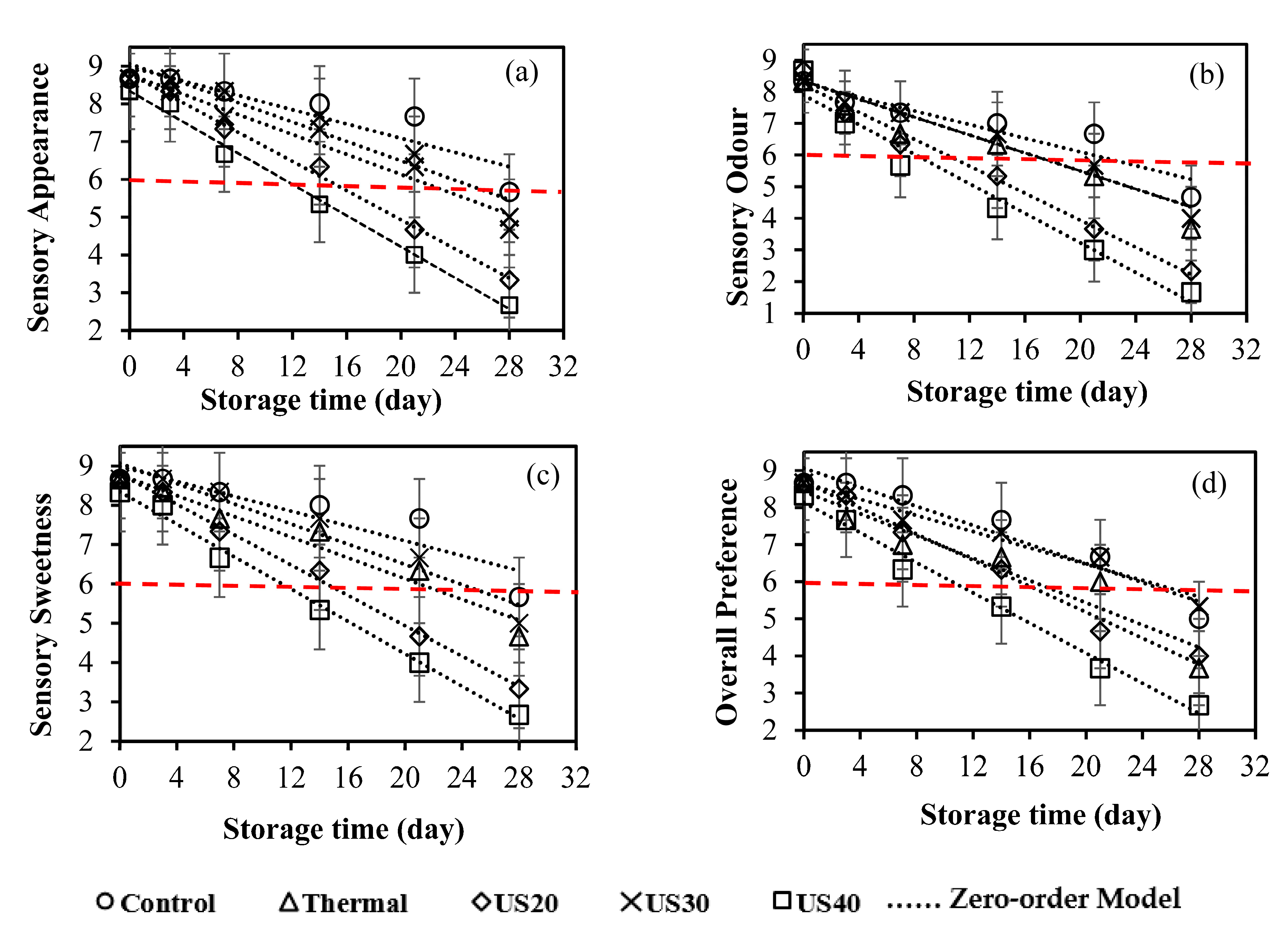

3.3. Changes in Sensory Properties of the Drink and Their Kinetic Modelling

3.4. Prediction of Shelf Life of the Energy Drink from Dates

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Data Base. Available online: http://www.faostat.fao.org (accessed on 15 December 2022).

- Hasnaoui, A.; Elhoumaizi, M.A.; Borchani, C.; Att, H. Physicochemical Characterization and Associated Antioxidant Capacity of Fiber Concentrates from Moroccan Date Flesh. Int. J. Latest Trends Agric. Food Sci. 2012, 2, 94–101. [Google Scholar]

- Chandrasekaran, M.; Bahkali, A.H. Valorization of date palm (Phoenix dactylifera) fruit processing by-products and wastes using bioprocess technology—Review. Saudi J. Biol. Sci. 2013, 20, 105–120. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, S.G.; Vijayanand, P.; Shubha, L. Effect of processing of dates into date juice concentrate and appraisal of its quality characteristics. J. Food Sci. Technol. 2010, 47, 157–161. [Google Scholar] [CrossRef] [PubMed]

- Mtaoua, H.; Elfalleh, W.; Hannachi, H.; Lachiheb, B.; Yahia, L.; Ferchichi, A. Evaluation of nutritional quality and antioxidant activity of Tunisian date juices (Phoenix dactylifera L.). J. New Sci. 2016, 27, 10. [Google Scholar]

- Abbès, F.; Kchaou, W.; Blecker, C.; Ongena, M.; Lognay, G.; Attia, H.; Besbes, S. Effect of processing conditions on phenolic compounds and antioxidant properties of date syrup. Ind. Crops Prod. 2013, 44, 634–642. [Google Scholar] [CrossRef]

- Dotto, M.C.; Pombo, M.A.; Martínez, G.A.; Civello, P.M. Heat treatments and expansin gene expression in strawberry fruit. Sci. Hortic. 2011, 130, 775–780. [Google Scholar] [CrossRef]

- Aday, M.S.; Temizkan, R.; Büyükcan, M.B.; Caner, C. An innovative technique for extending shelf life of strawberry: Ultrasound. LWT-Food Sci. Technol. 2013, 52, 93–101. [Google Scholar] [CrossRef]

- Tomadoni, B.; Cassani, L.; Viacava, G.; Moreira, M.D.R.; Ponce, A. Effect of ultrasound and storage time on quality attributes of strawberry juice. J. Food Process Eng. 2017, 40. [Google Scholar] [CrossRef]

- Entezari, M.H.; Nazary, S.H.; Khodaparast, M.H. The direct effect of ultrasound on the extraction of date syrup and its micro-organisms. Ultrason. Sonochemistry 2004, 11, 379–384. [Google Scholar] [CrossRef]

- Mtaoua, H.; Sánchez-Vega, R.; Ferchichi, A.; Martín-Belloso, O. Impact of high-intensity pulsed electric fields or thermal treatment on the quality attributes of date juice through storage. J. Food Process. Preserv. 2017, 41, e13052. [Google Scholar] [CrossRef]

- Siddeeg, A.; Zeng, X.-A.; Rahaman, A.; Manzoor, M.F.; Ahmed, Z.; Ammar, A.-F. Quality characteristics of the processed dates vinegar under influence of ultrasound and pulsed electric field treatments. J. Food Sci. Technol. 2019, 56, 4380–4389. [Google Scholar] [CrossRef] [PubMed]

- Starek, A.; Kobus, Z.; Sagan, A.; Chudzik, B.; Pawłat, J.; Kwiatkowski, M.; Terebun, P.; Andrejko, D. Influence of ultrasound on selected microorganisms, chemical and structural changes in fresh tomato juice. Sci. Rep. 2021, 11, 3488. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, B.K.; O’ Donnell, C.P.; Muthukumarappan, K.; Cullen, P.J. Ascorbic acid degradation kinetics of sonicated orange juice during storage and comparison with thermally pasteurised juice. LWT-Food Sci. Technol. 2009, 42, 700–704. [Google Scholar] [CrossRef]

- Cassani, L.; Tomadonib, B.; Moreira, M.d.R. Green ultrasound-assisted processing for extending the shelf-life of prebiotic-rich strawberry juices. J. Sci. Food Agric. 2020, 100, 5518–5526. [Google Scholar] [CrossRef] [PubMed]

- Aadil, R.M.; Zeng, X.-A.; Wang, M.-S.; Liu, Z.-W.; Han, Z.; Zhang, Z.-H.; Hong, J.; Jabbar, S. A potential of ultrasound on minerals, micro-organisms, phenolic compounds and colouring pigments of grapefruit juice. Int. J. Food Sci. Technol. 2015, 50, 1144–1150. [Google Scholar] [CrossRef]

- Labuza, T.; Altunakar, B. Water Activity in Foods: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Jena, S.; Das, H. Shelf life prediction of aluminum foil laminated polyethylene packed vacuum dried coconut milk powder. J. Food Eng. 2012, 108, 135–142. [Google Scholar] [CrossRef]

- Young, N.; O’sullivan, G. The influence of ingredients on product stability and shelf life. In Food and Beverage Stability and Shelf Life; Elsevier: Amsterdam, The Netherlands, 2011; pp. 132–183. [Google Scholar]

- Achour, M. A new method to assess the quality degradation of food products during storage. J. Food Eng. 2006, 75, 560–564. [Google Scholar] [CrossRef]

- Fikry, M.; Yusof, Y.A.; Al-Awaadh, A.M.; Rahman, R.A.; Chin, N.L. Prediction of the shelf-life of date seeds brew by integration of acceptability and quality indices. J. Food Meas. Charact. 2020, 14, 1158–1171. [Google Scholar] [CrossRef]

- Fikry, M.; Yusof, Y.A.; Al-Awaadh, A.M.; Rahman, R.A.; Chin, N.L.; Mousa, E.; Chang, L.S. Kinetics modelling of the colour, hardness, grinding energy consumption and oil yield changes during the conventional roasting of palm date seeds. Food Sci. Technol. Res. 2019, 25, 351–362. [Google Scholar] [CrossRef]

- Manzocco, L.; Lagazio, C. Coffee brew shelf life modelling by integration of acceptability and quality data. Food Qual. Prefer. 2009, 20, 24–29. [Google Scholar] [CrossRef]

- Rustom, I.Y.; Lopez-Leiva, M.; Nair, B.M. UHT-sterilized peanut beverages: Kinetics of physicochemical changes during storage and shelf-life prediction modeling. J. Food Sci. 1996, 61, 198–203. [Google Scholar] [CrossRef]

- Shanta, F.H.; Rahut, B.K.; Islam, M.J.; Azad, M.O.K.; Sohel, M.A.T.; Rajib, M.R.R.; Shams-Ud-Din, M.; Adnan, M. Development of value added drinks from date palm juice (Phoenix sylvestris). Heliyon 2021, 7, e08322. [Google Scholar] [CrossRef] [PubMed]

- Abou-Zaid, F.O. Using of Siwi Date in Production of Some New Juices. Alex. Sci. Exch. J. 2021, 42. [Google Scholar] [CrossRef]

- Vollmer, K.; Chakraborty, S.; Bhalerao, P.P.; Carle1, R.; Frank, J.; Steingass, C.B. Effect of Pulsed Light Treatment on Natural Microbiota, Enzyme Activity, and Phytochemical Composition of Pineapple (Ananas comosus [L.] Merr.) juice. Food Bioprocess Technol. 2020, 13, 1095–1109. [Google Scholar] [CrossRef]

- Manzoor, S.; Yusof, Y.A.; Chin, N.L.; Tawakkal, A.; Mohamed, I.S.; Fikry, M.; Chang, L.S. Quality Characteristics and Sensory Profile of Stirred Yogurt Enriched with Papaya Peel Powder. Pertanika J. Trop. Agric. Sci. 2019, 42, 519–533. [Google Scholar]

- Fikry, M.; Sami, R.; Al-Mushhin, A.A.; Aljahani, A.H.; Almasoudi, A.; Alharthi, S.; Ismail, K.A.; Dabbour, M. Development of Mathematical Models for Predicting Mass Transfer and Changes in Quality Properties of Falafel Prepared from Faba Bean (Vicia faba L.) by Air Frying Technique. J. Biobased Mater. Bioenergy 2022, 16, 150–158. [Google Scholar] [CrossRef]

- Fikry, M.; Al-Awaadah, A.; Rahman, R. Production and characterization of palm date powder rich in dietary fiber. J. Food Meas. Charact. 2021, 15, 2285–2296. [Google Scholar] [CrossRef]

- McSweeney, P.L.H.; Fox, P.F. Advanced Dairy Chemistry, 3rd ed.; Springer Science+Business Media, LLC: New York, NY, USA, 2009; Volume 3. [Google Scholar]

- Mosqueda-Melgar, J.; Raybaudi-Massilia, R.M.; Martín-Belloso, O. Microbiological shelf life and sensory evaluation of fruit juices treated by high-intensity pulsed electric fields and antimicrobials. Food Bioprod. Process. 2012, 90, 205–214. [Google Scholar] [CrossRef]

- Yildiz, S.; Pokhrel, P.R.; Unluturk, S.; Barbosa-Cánovas, G.V. Changes in quality characteristics of strawberry juice after equivalent high pressure, ultrasound, and pulsed electric fields processes. Food Eng. Rev. 2021, 13, 601–612. [Google Scholar] [CrossRef]

- Odriozola-Serrano, I.; Soliva-Fortuny, R.; Martín-Belloso, O. Phenolic acids, flavonoids, vitamin C and antioxidant capacity of strawberry juices processed by high-intensity pulsed electric fields or heat treatments. Eur. Food Res. Technol. 2008, 228, 239–248. [Google Scholar] [CrossRef]

- Yousif, A.K.; Alghzawi, H. Processing and characterization of carob powder. Food Chem. 2000, 69, 283–287. [Google Scholar] [CrossRef]

- Davidek, T.; Robert, F.; Devaud, S.; Vera, F.A.; Blank, I. Sugar fragmentation in the Maillard reaction cascade: Formation of short-chain carboxylic acids by a new oxidative α-dicarbonyl cleavage pathway. J. Agric. Food Chem. 2006, 54, 6677–6684. [Google Scholar] [CrossRef] [PubMed]

- Barron, F.H.; Fraser, A.M.; Innocenzo, M. Acidified foods: Food safety considerations for food processors. Food Ind. 2012, 231–239. [Google Scholar] [CrossRef]

- Pua, C.; Hamid, N.S.A.; Tan, C.; Mirhosseini, H.; Rahman, R.A.; Rusul, G. Storage stability of jackfruit (Artocarpus heterophyllus) powder packaged in aluminium laminated polyethylene and metallized co-extruded biaxially oriented polypropylene during storage. J. Food Eng. 2008, 89, 419–428. [Google Scholar] [CrossRef]

- Muralikrishna, M.; Nanjundaswamy, A.; Siddappa, G. Guava powder-preparation, packaging and storage studies. J. Food Sci. Technol. 1969, 6, 93–98. [Google Scholar]

- Muñoz, A.M.; Civille, V.G.; Carr, B.T. Sensory Evaluation in Quality Control; Van Nostrand Reinhold Company: New York, NY, USA, 1992. [Google Scholar]

- Mendes, L.C.; de Menezes, H.C.; Aparecida, M.; Da Silva, A. Optimization of the roasting of robusta coffee (C. canephora conillon) using acceptability tests and RSM. Food Qual. Prefer. 2001, 12, 153–162. [Google Scholar] [CrossRef]

- Kahyaoglu, T. Optimization of the pistachio nut roasting process using response surface methodology and gene expression programming. LWT-Food Sci. Technol. 2008, 41, 26–33. [Google Scholar] [CrossRef]

- Özdemir, M.; Devres, O. Analysis of color development during roasting of hazelnuts using response surface methodology. J. Food Eng. 2000, 45, 17–24. [Google Scholar] [CrossRef]

- Bicho, N.C.; Leitão, A.E.; Ramalho, J.C.; de Alvarenga, N.B.; Lidon, F.C. Impact of roasting time on the sensory profile of Arabica and Robusta coffee. Ecol. Food Nutr. 2013, 52, 163–177. [Google Scholar] [CrossRef]

| Treatment | Storage Time (day) | TSS (Mean ± SD) °Brix | EC (Mean ± SD) (mS/cm) |

|---|---|---|---|

| Control | 0 | 16.60 ± 0.26 a | 4.15 ± 0.006 a |

| 3 | 16.57 ± 0.06 a | 4.16 ± 0.005 a | |

| 7 | 16.77 ± 0.12 a | 4.2 ± 0.0051 a | |

| 14 | 16.67 ± 0.21 a | 4.15 ± 0.0057 a | |

| 21 | 16.67 ± 0.21 a | 4.18 ± 0.0051 a | |

| 28 | 16.67 ± 0.20 a | 4.17 ± 0.0052a | |

| Thermal | 0 | 16.37 ± 0.31 a | 4.26 ± 0.0051 a |

| 3 | 16.73 ± 0.06 a | 4.26 ± 0.0053 a | |

| 7 | 16.60 ± 0.10 a | 4.28 ± 0.0056 a | |

| 14 | 16.63 ± 0.12 a | 4.23 ± 0.0052 a | |

| 21 | 16.63 ± 0.12 a | 4.25 ± 0.0057 a | |

| 28 | 16.63 ± 0.12 a | 4.24 ± 0.0058 a | |

| US20 * | 0 | 16.37 ± 0.31 a | 4.16 ± 0.0052 a |

| 3 | 16.77 ± 0.06 a | 4.17 ± 0.0056 a | |

| 7 | 16.8 ± 0.10 a | 4.16 ± 0.0058 a | |

| 14 | 16.83 ± 0.06 a | 4.19 ± 0.0056 a | |

| 21 | 16.77 ± 0.06 a | 4.23 ± 0.0053 a | |

| 28 | 16.80 ± 0.10 a | 4.20 ± 0.0055 a | |

| US30 * | 0 | 17.30 ± 0.10 a | 4.29 ± 0.0053 a |

| 3 | 17.37 ± 0.06 a | 4.26 ± 0.0052 a | |

| 7 | 17.27 ± 0.21 a | 4.26 ± 0.0054 a | |

| 14 | 17.4 ± 0.10 a | 4.23 ± 0.0054 a | |

| 21 | 17.23 ± 0.15 a | 4.19 ± 0.0055 a | |

| 28 | 17.27 ± 0.21 a | 4.21 ± 0.0053 a | |

| US40 * | 0 | 16.37 ± 0.31 a | 4.16 ± 0.0057 a |

| 3 | 16.4 ± 0.10 a | 4.17 ± 0.0058 a | |

| 7 | 16.3 ± 0.10 a | 4.16 ± 0.0053 a | |

| 14 | 16.4 ± 0.10 a | 4.15 ± 0.0054 a | |

| 21 | 16.27 ± 0.06 a | 4.18 ± 0.0053 a | |

| 28 | 16.3 ± 0.10 a | 4.16 ± 0.0054 a |

| Treatment | Statistical Parameters | L* Value | a* Value | b* Value | ΔE | Chroma | BI | pH | Appearance | Odour | Sweetness | Overall Preference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | a | 47.67 | 12.27 | 29.97 | 3.24 | 32.39 | 279.19 | 5.53 | 8.34 | 7.90 | 8.342 | 8.14 |

| b | −0.58 | 0.23 | 0.40 | 0.75 | 0.46 | 9.04 | −0.02 | −0.21 | −0.23 | −0.206 | −0.20 | |

| R2 | 0.942 | 0.954 | 0.974 | 0.957 | 0.981 | 0.980 | 0.972 | 0.956 | 0.951 | 0.956 | 0.968 | |

| RMSE | 1.68 | 0.18 | 0.81 | 1.95 | 0.77 | 5.03 | 0.05 | 0.16 | 0.44 | 0.16 | 0.22 | |

| PE (%) | 3.82 | 1.03 | 2.00 | 9.50 | 1.73 | 0.93 | 0.86 | 2.22 | 7.99 | 2.22 | 4.11 | |

| Thermal | a | 47.17 | 12.52 | 30.70 | 3.74 | 33.16 | 293.03 | 5.50 | 8.78 | 8.05 | 8.78 | 8.44 |

| b | −0.390 | 0.175 | 0.294 | 0.51 | 0.339 | 5.154 | −0.011 | −0.132 | −0.146 | −0.132 | −0.150 | |

| R2 | 0.862 | 0.894 | 0.951 | 0.901 | 0.953 | 0.932 | 0.844 | 0.922 | 0.931 | 0.980 | 0.890 | |

| RMSE | 1.92 | 0.39 | 0.48 | 2.04 | 0.58 | 9.34 | 9.34 | 0.29 | 0.32 | 0.29 | 0.46 | |

| PE (%) | 3.47 | 2.14 | 1.24 | 11.20 | 1.31 | 2.60 | 2.60 | 3.96 | 5.40 | 3.96 | 7.46 | |

| US20 | a | 51.90 | 11.75 | 30.44 | 4.05 | 32.64 | 279.59 | 5.47 | 8.79 | 8.21 | 8.79 | 8.79 |

| b | −0.46 | 0.18 | 0.22 | 0.54 | 0.27 | 3.63 | −0.01 | −0.19 | −0.21 | −0.19 | −0.19 | |

| R2 | 0.858 | 0.890 | 0.938 | 0.869 | 0.947 | 0.974 | 0.801 | 0.985 | 0.958 | 0.955 | 0.949 | |

| RMSE | 2.57 | 0.38 | 0.37 | 2.54 | 0.32 | 6.68 | 0.10 | 0.13 | 0.27 | 0.13 | 0.28 | |

| PE (%) | 4.24 | 2.48 | 0.80 | 10.09 | 0.64 | 1.59 | 1.63 | 1.89 | 7.28 | 1.89 | 4.18 | |

| US30 | a | 54.59 | 10.98 | 30.49 | 0.79 | 32.40 | 271.03 | 5.53 | 9.06 | 8.34 | 9.06 | 8.66 |

| b | −0.45 | 0.18 | 0.19 | 0.50 | 0.25 | 3.00 | −0.01 | −0.13 | −0.14 | −0.13 | −0.11 | |

| R2 | 0.934 | 0.860 | 0.853 | 0.966 | 0.908 | 0.946 | 0.843 | 0.894 | 0.920 | 0.894 | 0.904 | |

| RMSE | 0.52 | 0.46 | 0.81 | 0.64 | 0.60 | 2.60 | 0.48 | 0.33 | 0.25 | 0.33 | 0.21 | |

| PE (%) | 0.95 | 3.38 | 2.25 | 6.21 | 1.55 | 0.70 | 7.80 | 4.30 | 3.79 | 4.30 | 2.56 | |

| US40 | a | 52.68 | 10.45 | 30.83 | 2.26 | 32.57 | 279.17 | 5.61 | 8.98 | 8.26 | 8.98 | 9.05 |

| b | −0.163 | 0.083 | 0.150 | 0.23 | 0.169 | 1.299 | −0.016 | −0.094 | −0.108 | −0.094 | −0.113 | |

| R2 | 0.833 | 0.740 | 0.824 | 0.834 | 0.870 | 0.910 | 0.985 | 0.804 | 0.847 | 0.804 | 0.819 | |

| RMSE | 0.72 | 1.99 | 0.90 | 1.22 | 0.77 | 4.83 | 0.03 | 0.43 | 0.40 | 0.43 | 0.40 | |

| PE (%) | 1.04 | 14.43 | 2.35 | 11.57 | 1.89 | 1.32 | 0.39 | 4.83 | 5.43 | 4.83 | 4.34 |

| Properties | Shelf Life (Day) | ||||

|---|---|---|---|---|---|

| Control | Thermal | US20 | US30 | US40 | |

| Colour change (ΔE) | 13.6 | 26.7 | 23.9 | 23.3 | 30.4 |

| pH | 12.2 | 19.5 | 20.8 | 20.4 | 20.4 |

| Overall appearance | 9.8 | 17.8 | 13.3 | 18.3 | 15.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fikry, M.; Yusof, Y.A.; Al-Awaadh, A.M.; Baroyi, S.A.H.M.; Ghazali, N.S.M.; Kadota, K.; Mustafa, S.; Abu Saad, H.; Shah, N.N.A.K.; Al-Ghamdi, S. Assessment of Physical and Sensory Attributes of Date-Based Energy Drink Treated with Ultrasonication: Modelling Changes during Storage and Predicting Shelf Life. Processes 2023, 11, 1399. https://doi.org/10.3390/pr11051399

Fikry M, Yusof YA, Al-Awaadh AM, Baroyi SAHM, Ghazali NSM, Kadota K, Mustafa S, Abu Saad H, Shah NNAK, Al-Ghamdi S. Assessment of Physical and Sensory Attributes of Date-Based Energy Drink Treated with Ultrasonication: Modelling Changes during Storage and Predicting Shelf Life. Processes. 2023; 11(5):1399. https://doi.org/10.3390/pr11051399

Chicago/Turabian StyleFikry, Mohammad, Yus Aniza Yusof, Alhussein M. Al-Awaadh, Syahrul Anis Hazwani Mohd Baroyi, Nashratul Shera Mohamad Ghazali, Kazunori Kadota, Shuhaimi Mustafa, Hazizi Abu Saad, Nor Nadiah Abdul Karim Shah, and Saleh Al-Ghamdi. 2023. "Assessment of Physical and Sensory Attributes of Date-Based Energy Drink Treated with Ultrasonication: Modelling Changes during Storage and Predicting Shelf Life" Processes 11, no. 5: 1399. https://doi.org/10.3390/pr11051399